Abstract

In response to rising power demands and cooling loads in thermal systems, new technologies have been adopted to enhance heat transfer characteristics. A suspended nanosized particle that has high thermal conductivity in conventional heat transfer fluids is called a nanofluid. Several studies have investigated the effects of graphene-based nanofluids on thermophysical parameters such as thermal conductivity and viscosity. The paper also highlighted potential benefits of nanofluid in terms of energy conservation, reduction of material consumption and sustainability in the preparation of high thermal conductivity fluid. Also, many numerical and experimental studies have been done for heat transfer characteristics using different graphene-based nanofluids. This review examines the preparation, thermophysical properties, and heat transfer characteristics of graphene-based nanofluids, including graphene nanoplatelets, graphene oxide, and graphene composites, across various thermal systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

New technological developments tend to increase thermal loads due to high power output, which demands improvements in heat transfer equipment to make it more energy efficient in many thermal applications like automobiles, manufacturing, electronic devices, and energy storage systems. Improved performance of a thermal system requires a good heat exchanger design. In order to improve the heat transfer performance of heat exchangers, several different approaches can be taken. Heat transfer enhancement can be achieved by mechanical aids, surface vibration, fluid vibration, electrostatic fields, injection, suction, jet impingement, etc., but it required external power to maintain the enhancement in the heat transfer. These techniques does not show much potential due to complexity in the thermal system design. Also, in several applications, it is not easy to provide external power. Heat transfer enhancement can be done by using surface treatment, displaced enhancement devices, swirl flow devices, coiled tubes, surface tension devices, additives for liquids, extended surfaces, and nanofluids. Researchers are more interested in techniques that do not require external sources of power. For heat transfer processes, nanofluids have better heat transfer characteristics than conventional fluids [1, 2]. When the efficiency of heat exchangers improves, it results in a more cost-effective configuration of the heat exchange process, leading to savings in energy, materials, and overall costs. The imperative to enhance the thermal efficiency of heat exchangers and thereby achieve energy, cost, and material savings has driven the innovation and adoption of various methods known as heat transfer augmentation [3, 4]. These methods, also known as heat transfer enhancement, work by boosting convective heat transfer through the reduction of thermal resistance within the heat exchanger [5, 6]. The application of augmentation techniques aims to enhance the heat transfer coefficient, which consequently raises the pressure drop as well. Consequently, when designing a heat exchanger using any of these approaches, a comprehensive analysis of both heat transfer rate and pressure drop becomes necessary. Furthermore, factors such as the long-term performance and intricate economic evaluation of the heat exchanger also require careful consideration.

Nanofluids are suspended fluids obtained by dispersing various nanoparticles in conventional fluids, which have higher thermal conductivities than conventional fluids [7]. Since then, the theoretical and experimental study of nanofluids has gained considerable momentum because of their high effective thermal conductivity. Nanofluids enhance thermal conductivity, stability, and heat transfer efficiency while decreasing power consumption and overall expenses. This increases the fluid’s thermal conductivity, thereby increasing its heat transfer coefficient (HTC). This has the potential to make heat exchangers more compact and efficient by reducing their size and weight.

This review paper studies graphene-based nanoparticle preparation methods, characterization, thermophysical properties, and application in the field of heat transfer. Measurement of density and specific heat will be achieved through correlation, but experimentation will be conducted to determine thermal conductivity, viscosity, heat transfer coefficient, and pressure drop. This study involves varying concentrations of graphene-based composite nanofluids including graphene nanoplatelets and graphene oxide. There were identified and discussed challenges and opportunities with the application of graphene nanofluids. On the basis of a review of these aspects of nanofluids, we will identify some challenges for future research. It may be a future research topic to extend this review study to graphene and graphene derivatives, as well as composites with other nanomaterials.

2 Synthesis techniques for nanoparticle and nanofluid

Nanoparticles can be composed of different elements and compounds. The only requirement for something to be considered a nanoparticle is its particle size. Nanoparticles typically range in diameter from 1 to 100 nm. There are two methods wisely used to prepare nanoparticles: the bottom-up approach and the top-down approach. Further, we divide these approaches into various subcategories based on the different conditions and applications, as shown in Fig. 1 [8, 9].

Synthesis methods for Nanoparticles [9]

2.1 Top-down syntheses

Using this method, larger molecules are broken down into smaller units by destructive means. This method involves grinding and milling, chemical vapor deposition (CVD), physical vapor deposition (PVD), and other decomposition techniques that convert these units into appropriate nanoparticles (NPs) [10]. To create nanoparticles from coconut shell (CS), a milling method was used. Raw CS powders were finely ground using ceramic balls and a planetary mill at varying time intervals. Various characterization techniques were used to examine how milling time affects NP size. As milling time increased, NP crystallite size decreased. Furthermore, it was observed that the NPs’ brownish color faded with each additional hour of milling due to the reduction in size. SEM results were consistent with X-ray patterns, both indicating a decrease in particle size over time [11, 12].

2.2 Bottom-up syntheses

A similar procedure employs sedimentation and reduction methods to create NPs by transforming simpler substances into NPs in reverse. This is therefore known as the “building up” method. This category encompasses techniques like sol–gel, green synthesis, spinning, and biochemical synthesis [8, 13]. Mogilevsky and colleagues utilized this strategy to synthesize TiO2 anatase NPs combined with graphene domains. They employed alizarin and titanium isopropoxide precursors in creating a photosensitive composite for breaking down methylene blue in photocatalytic reactions. Alizarin was chosen due to its robust binding capability with TiO2, facilitated by their terminal hydroxyl groups. The anatase structure was validated through XRD analysis [14].

2.3 Nanofluid preparation

There are two methods for synthesizing nanofluids: (1) a single-step method and (2) a two-step method. In order to maintain the increased thermal properties of nanofluid, additional precautions must be taken to prevent particle agglomeration and ensure a stable nanofluid. Nanofluid stability is determined by how long the nanofluids remain fully dispersed [15,16,17,18].

The synthesis and dispersion of nanoparticles take place simultaneously in a one-step method. The drying, storing, transporting, and separate dispersing processes are not required in a one-step method and can avoid problems associated with this process. By making nanofluid through this process, more stability can be achieved by reducing the agglomeration problem [19,20,21]. Nanoparticles can be uniformly dispersed through various techniques like direct condensation and evaporation, laser ablation, SANSS (submerged-arc nanoparticle synthesis system), and the chemical solution method (CSM). This leads to enhanced stability in base fluids and lower production expenses for the resulting nanofluid. The nanofluid created using CSM exhibits better thermal conductivity and stability. Nonetheless, producing nanofluid on a large scale through a one-step method remains challenging.

The two-step method involves producing nanoparticles through a range of methods like milling, grinding, sol–gel, and vapor phase. These are subsequently blended with base fluids like water, ethylene glycol, and oil using ultrasonic vibrators, magnetic force agitation, high-shear mixing, homogenizing, and other techniques [18, 22,23,24]. This approach offers benefits such as increased production capacity and reduced expenses. The most efficient means of improving the stability of nanofluids involve employing surfactants. Surfactants can improve the stability of nanofluids and reduce expenses, but challenges exist related to drying, storage, and transportation.

3 Graphene and derivatives

3.1 Graphene: an overview

It is a thin, one-atom planar sheet of carbon atoms that is densely arranged in a honeycomb crystal lattice, as shown in Fig. 2 [25,26,27,28]. The most widely used methods of synthesizing graphene include chemical vapor deposition (CVD) and mechanical exfoliation [29]. Typically, methane or ethylene is introduced into a high-temperature furnace with copper or nickel catalyst to produce a carbon-containing precursor. Under controlled conditions, carbon atoms assemble into a single layer of graphene on the catalyst surface [30,31,32,33,34]. This method allows for the large-scale production of high-quality graphene sheets. On the other hand, mechanical exfoliation starts with a bulk graphite source. A piece of adhesive tape is repeatedly applied and peeled off the graphite, causing layers of graphene to be extracted one by one. While this technique produces exceptionally pure graphene, it is labor-intensive and not suitable for mass production. Various other approaches, including liquid-phase exfoliation, chemical reduction of graphene oxide, electrochemically exfoliated graphene, and chemical synthesis from organic precursors, offer alternatives tailored to specific applications and scalability requirements [35,36,37,38,39,40,41]. It is crucial to choose the appropriate technique based on the intended use of the graphene material [42,43,44]. This two-dimensional form of carbon structure has been claimed to have features and uses that have created new possibilities for future technologies and systems. [45] Graphene’s consistent light absorption throughout the visible and near-infrared regions of the spectrum (πα ≈ 2.3%), as well as its possible application in spin transport, are other noteworthy characteristics [46].

Graphene sheet with alternate double bonds [28]

Because of their exceptional mechanical, thermal, and electrical properties, graphene materials are the most promising alternative for several applications in many sectors of materials science [47,48,49]. For these applications to be realized, massive amounts of inexpensive graphene materials must be readily available [50, 51].

3.2 Graphene oxide

Graphene oxide is graphene that has undergone oxidation. Graphene oxide (GO), a functionalized form of graphene, has garnered significant attention in recent times because of its exceptional characteristics, including its large surface area, mechanical stability, and electrical and optical properties. Graphene oxide can be conceptualized structurally as a graphene sheet with groups that contain oxygen adorning its basal plane [52,53,54,55]. It is also thought to be simple to process. The majority of the qualities of pure graphene can be restored by treating graphene oxide with light, heat, or chemical reduction, despite the fact that it is not a good conductor. It is frequently offered for sale as a coating on surfaces, in powder form, or dispersed. Actually, under a variety of reducing circumstances, graphene oxide may be reduced both in solution and as a thin film, and this process results in the transformation of the graphene oxide into a material with significantly improved electrical conductivity. It is simple to combine graphene oxide with other polymers and other materials to improve the conductivity, elasticity, and other features of composite materials. GO is derived from an extensively oxidized version of a graphene molecule using potent oxidizing agents. Specifically, GO can be chemically separated from other graphene derivatives due to its exceptional surface functionality, amphiphilicity, aqueous nature, fluorescence quenching capability, and surface-enhanced Raman scattering property [56]. These remarkable attributes stem from its distinct chemical structure, characterized by small sp2 carbon domains encircled by sp3 domains and oxygen-containing hydrophilic functional groups. A prevalent technique for GO synthesis is Hummer’s method, involving the oxidation of graphite through a mixture of graphite solution, potassium permanganate, and sulfuric acid. This process generates graphite salts that serve as GO precursors [52, 57,58,59,60]. Through solvent exfoliation with sonication, these salts are transformed into GO. A subsequent thermal and chemical reduction process can convert GO into a graphene analog [61]. This material finds extensive utility in filtration due to its ability to permit water flow while filtering out harmful gases. GO is a solid mass formed by oxidizing graphite using various chemical methods, leading to increased interlayer spacing and base planes [62].

3.3 Reduced graphene oxide

As illustrated in Fig. 3, reduced graphene oxide (rGO) is produced from graphene oxide (GO) by reducing its oxygen amount using thermal (photothermal), chemical (photochemical), microwave, or other bacterial as well as microbial techniques [28, 59, 63,64,65]. It is frequently utilized in the electronics industry for the construction of electrical devices and the creation of conductive ink circuits [66]. A modest number (2–10) of two-dimensional, sheet-like graphene oxides (GO) are stacked to create layered graphene, but each scrap should retain its high aspect ratio [67, 68].

Conversion of graphene into GO and rGO [28]

4 Characterization of graphene

Interfaces, crystals, polymorphism, nanostructures, many phases, and the distribution of nanoparticles make up the structure of nanocomposites. The primary goals of structural investigations include nano-particle interactions with the polymer matrix, morphologies, and numerous phases; these elements are intimately linked to the characteristics of the nanocomposite [69]. To develop comprehension and control over the manufacturing and use of nanoparticles, nanoparticle characterization is required [70,71,72].

4.1 Atomic structure and chemical composition

X-ray diffraction: X-ray diffraction (XRD) is a pivotal characterization technique employed in the comprehensive analysis of graphene nanomaterials. XRD facilitates the investigation of the crystalline structure of graphene by directing X-rays onto the sample, causing diffraction patterns that reveal information about the material’s lattice arrangement and interatomic distances [73, 74]. X-ray diffraction spectrum of GO can be seen in Fig. 4. In XRD patterns of graphene, the characteristic diffraction peaks correspond to the hexagonal lattice arrangement, and the intensity and position of these peaks provide insights into factors such as layer stacking, lattice distortion, and domain size. Advanced XRD techniques, such as grazing incidence XRD (GI-XRD) and synchrotron-based XRD, enhance the precision and depth of analysis [74]. The combination of XRD with other techniques like Raman spectroscopy contributes to a more comprehensive understanding of graphene’s structural properties.

X-ray diffraction spectrum of GO [73]

Ultraviolet–visible spectroscopy: UV–vis spectroscopy involves the interaction of graphene with ultraviolet and visible light, resulting in the absorption or reflection of specific wavelengths. By measuring the absorbance or reflectance spectra, valuable information about the electronic transitions, band structure, and optical properties of graphene can be obtained [75, 76]. The π plasmon resonance, arising from the collective oscillation of π electrons in graphene, is a prominent feature in UV–Vis spectra, providing insights into the number of layers and quality of graphene samples [77, 78]. Graphene–water nanofluid spectra with initial concentrations of 0.005% and 0.02% can be seen in Fig. 5 before and after the experiments, which typically last 1 week [79].

UV–Vis spectra of the graphene–water nanofluids [79]

4.2 Raman spectroscopy

Raman spectroscopy provides insights into the vibrational modes of graphene, enabling the identification of its structural integrity, number of layers, and defects [80]. There are two prominent Raman bands in graphene’s spectra: the G and 2D bands. These bands correspond to the E2g phonon mode and the second-order overtone of the D band [81, 82]. The G band reflects the in-plane vibrations of sp2-hybridized carbon atoms, while the 2D band is sensitive to the number of graphene layers and stacking arrangements. Additionally, the D band signifies disorder or defects in the lattice [83, 84]. Figure 6 illustrates the Raman spectra of two-layer EGs grown on SiC, SiC substrate, MCG, and bulk graphite. The intensity ratio of the D and G bands (I_D/I_G) serves as a valuable metric for assessing the quality of graphene samples. Further advancements, such as resonance Raman spectroscopy, have enhanced the sensitivity and precision of graphene characterization [85].

Raman spectra of single- and two-layer EGs grown on SiC, SiC substrate, MCG, and bulk graphite [84]

4.3 Determination of size, shape and surface area

4.3.1 Scanning electron microscopy

SEM facilitates high-resolution imaging of graphene’s surface morphology, allowing researchers to investigate the quality, structure, and defects present in the material [86,87,88]. By utilizing a focused electron beam, SEM captures detailed topographical information at nanoscale resolutions, enabling the visualization of graphene’s unique two-dimensional lattice structure and the detection of any irregularities, such as wrinkles, folds, or edges. The technique provides insights into the number of graphene layers as well as the arrangement and distribution of nanoparticles or functional groups on its surface [89]. Moreover, SEM can be coupled with energy-dispersive X-ray spectroscopy (EDS) to perform elemental analysis, thereby enabling the identification of chemical composition in localized regions. Such detailed information is instrumental in tailoring graphene nanomaterials for specific applications, including electronics, energy storage, and composites. The SEM image of the graphene particle can be seen in Fig. 7 [90].

SEM visualization of GnP [90]

4.3.2 Transmission electron microscopy (TEM)

It is a crucial analytical tool for the comprehensive investigation of graphene nanomaterials, offering high-resolution imaging and structural characterization at the nanoscale. TEM characteristics with exceptional precision by providing real-space images of individual graphene sheets, enabling the observation of defects, edges, and layer stacking arrangements [91, 92]. Furthermore, TEM aids in determining the quality of graphene through the assessment of defects and the identification of layer thickness variations [93]. The use of selected area electron diffraction (SAED) patterns in TEM allows for crystallographic analysis, helping to verify the integrity of graphene’s lattice structure [92]. Advanced TEM techniques like high-resolution TEM (HRTEM), shown in Fig. 8, and electron energy loss spectroscopy (EELS) contribute to investigating the atomic structure and electronic properties of graphene materials [94].

HRTEM picture of PMMA-derived graphene grown on a Ni film [94]

4.3.3 Atomic force microscopy (AFM)

AFM offers high-resolution imaging and precise topographical information at the nanoscale level, enabling the examination of graphene’s surface morphology, thickness, and structural features. By employing a sharp probe tip that interacts with the material’s surface, AFM produces topographic images with exceptional spatial resolution, as shown in Fig. 9 [95, 96]. This technique not only facilitates the visualization of individual graphene layers but also aids in identifying defects, wrinkles, and other structural variations. AFM’s capability to operate in various environments, including ambient conditions and liquids, further expands its utility in graphene studies [97]. The combination of AFM with complementary techniques contributes to a comprehensive understanding of graphene’s behavior and its potential applications in nanoelectronics, nanocomposites, and other emerging fields [98].

AFM image of the GO films where mono-, bi-, and tri layers of GO films can be identified [95]

4.3.4 Thermal properties of graphene-based nanofluid

In heat transfer applications, fluids are evaluated based on their thermophysical properties. Density, specific heat, thermal conductivity, and viscosity are the four most important thermal properties. As a result of adding nanoparticles to the convectional fluid, its thermophysical properties changed, resulting in a change in heat transfer rate compared to the base fluid [99]. The density and specific heat value of nanofluid can be found by the available co-relation, but there is no accurate relation made for calculating the thermal conductivity and viscosity of nanofluid. Nanoparticle Brownian motion, molecular layering at the liquid/particle interface, nanoparticle clustering, and different modes of heat transfer in nanoparticles all impact thermal characteristics.

Several performance parameters, such as the Nusselt and Prandtl number of heat exchanger systems, are dependent on thermal conductivity. In order to measure the thermal conductivity of nanofluids, several techniques can be used, including transient hot wire, steady-state, cylindrical cell, temperature oscillation, and 3-omega. Nonetheless, the most often used measurement technique is the transient hot-wire method [100,101,102]. Viscosity is a property that characterizes how resistant a fluid is to flowing when an external force or shear stress is applied to it. It serves as a measure of a fluid’s internal friction, reflecting the ease with which it moves. The thermal conductivity and viscosity of nanofluids, which are fluids containing nanoparticles, are influenced by factors such as the type and concentration of nanoparticles, temperature, base fluid properties, nanoparticle size and shape, shear rate, and surface treatment [103,104,105,106]. These factors collectively determine how the nanofluid’s viscosity behaves under specific conditions. The viscosity of nanofluids can vary with temperature and shear rate, making it important for various applications like heat transfer and lubrication. Researchers use experimental studies and computational modeling to understand and optimize the viscosity of nanofluids for specific purposes [107,108,109,110]. Viscosity can be measured using various methods and instruments, depending on the type of fluid and desired precision. Common methods include capillary viscometers for Newtonian fluids, rotational viscometers for a wide range of fluids, vibrating viscometers, falling sphere viscometers for very viscous fluids, and cone and plate viscometers for non-Newtonian fluids. Rheometers provide comprehensive rheological data, while dynamic light scattering measures viscosity in dilute solutions. Selecting the right method depends on the fluid’s characteristics and the required accuracy, with calibration and standardization being crucial for accuracy [111, 112]. Different researchers experimentally measured thermal conductivity and viscosity using different methods using graphene-based nanofluid, and their results are shown in Table 1.

Mohammad Mehrali et al. [113] studied graphene nanoplatelet nanofluid with varying concentrations, revealing a 27.64% increase in thermal conductivity and a 44% improvement in viscosity. This was due to increased nanoparticle concentration, agglomeration, and shear stress. Sidhartha Das et al. [114] worked on graphene nanofluid’s heat transfer enhancement in thermosyphon heat pipes, finding it 29% higher in thermal conductivity and 175% higher in viscosity compared to deionized water which can be seen in Fig. 10. Also observed that thermal conductivity was further increased at higher temperature application. Ali Rashidi et al. [115] studied graphene oxide in water, revealing its excellent thermal properties due to its high aspect ratio, two-dimensional geometry, stiffness, and low thermal interface resistance.

Thermal conductivity and viscosity measurement with temperature [114]

Syam et al. [116] prepared and studied the thermal properties of GO/Co3O4 hybrid nanoparticles. They found that nanofluids with water or ethylene glycol increased thermal conductivity by 19.14% and 11.85% at 60 °C and 0.2% volume concentration, respectively. The enhanced thermal conductivity may be due to Brownian motion. Javier et al. [117] worked on the rheological behavior of functionalized graphene nanoplatelet dispersions in water, propylene glycol, and water mixtures. They found that viscosity increased to a maximum of up to 38% for water-based nanofluid.

Wail et al. [118] synthesized graphene nanoplatelet nanofluid using four surfactants, finding (sodium dodecyl benzene sulfonate) SDBS-GNPs as the most effective combination for better thermal conductivity (8.36%) and lowest viscosity (7.4%). Hooman et al. [119] found a 17.77% enhancement in thermal conductivity of functionalized GNP-Pt nanocomposite in distilled water nanofluids. Sedaghat et al. [120] studied the effect of graphene quantum dots (GQDs) nanoparticles on thermal conductivity and dynamic viscosity in base fluids. They found that nanofluids containing 0.5% GQDs showed increased thermal conductivity and dynamic viscosity, with the effect of inter-molecular and inter-particle adhesion forces and volume fraction of nanofluids. Selvam et al. [121] found that ethylene glycol and water can enhance thermal conductivity by 21% and 16%, respectively, using graphene nanoplatelets with Sodium deoxycholate as a surfactant, but interfacial thermal resistance restricts this enhancement. Brownian motion and micro-convection effects are not significant. Ahmad Amiri et al. [122] developed a new generation of heat transfer fluid using graphene quantum dot and water-based suspensions, achieving a maximum increase in thermal conductivity ratio by 18.6%. Amir Akbari et al. [123] evaluated thermal properties of PEG-functionalized graphene nanoplatelets and gum Arabic-treated GNPs in deionized water, finding higher improvement and lower viscosity ratios for functionalized nanofluids. Yi Wang et al. [124] investigated thermal conductivity enhancement by 14.2% for 1 wt% graphene-based nanofluids at 25 °C, with a viscosity increment ratio of 1.24–2.35. They proposed a correlation for estimating apparent viscosity as given in Eq. 1.

Mahmudul Haque et al. [125] found thermal conductivity in graphene and MWCNT-based nanofluids using SDBS and SDS surfactants. They found that graphene nanoplatelet with SDS nanofluid increased maximum conductivity by 5.546%. Baby et al. [126] observed the thermal conductivity of hydrogen exfoliated graphene (HEG) and dispersed deionized water and ethylene glycol in nanofluid. They found an 16% and 75% increase at 25 °C and 50 °C, respectively, and found low enhancement in EG-based nanofluid due to high viscosity. Ahmad Amiri et al. [127, 128] developed single layer graphene (SGr) and highly crumpled few layers graphene (HCFLG) nanofluids with high specific surface area, enhancing thermal conductivity by 26% and 43% at 50 °C. S.S.

Park [129] experimentally studied on thermal conductivity of graphene nanoparticles with different sizes and revealed that small diameter nanoparticles enhance thermal conductivity bigger and also indicate higher rate of improvement using graphene oxide. Madhusree Kole et al. [130] synthesized hydrogen exfoliated graphene nano-sheets using acid and ethylene glycol, enhancing thermal conductivity by 15% at 30 °C, with linear temperature-dependent increase. Ahmad Ghozatloo [131] prepared functionalized graphene showed a 14.1% increase in thermal conductivity with 0.05 wt% Alkaline-based FG nanofluid compared to water at 25 °C and 17% at 50 °C, with the effective conductivity decreasing over time due to graphene agglomeration.

Wenshi et al. [132] synthesized functionalized graphene oil nanofluids using 3-glycidoxypropyltrimethoxysilane, enhancing thermal conductivity by 5.74% at 20 °C and viscosity by 49.95% and 48.11% at higher temperatures. Baby et al. [133, 134] developed functionalized hydrogen induced exfoliated graphene with silver and copper oxide nanoparticles and found enhanced thermal conductivity 86% and 90% enhancement at 50 °C temperatures, respectively, using deionized water. Wei et al. [135] studied about graphene oxide nanosheets (GO-EG nanofluid) have a higher thermal conductivity than base fluid and a 61% larger enhancement ratio at 5.0 vol%.

4.4 Application of graphene and its derivatives for heat exchange process

In numerous industrial applications, convective heat transfer plays a vital role, and graphene-based nanoparticle nanofluids offer a promising strategy for improving thermal performance. As a result of nanofluids’ exceptional heat transfer properties, they can be used both in laminar and turbulent flow regimes. Nanofluids provide efficient heat transfer by enhancing molecular interactions between nanoparticles and base fluids due to their increased thermal conductivity. This results in augmented convective heat transfer coefficients, leading to improved thermal efficiency. By optimizing convective heat transfer in turbulent flows, the dynamic interactions between nanoparticles and fluids become even more pronounced. Due to intensified mixing and enhanced convective heat transfer coefficients, turbulent regimes exhibit higher heat transfer rates. Due to their unique properties, nanofluids are a valuable method for cooling electronics, automobiles, and advanced heat exchangers that require heat transfer enhancement. Both laminar and turbulent flow regimes have been studied by several researchers to understand the heat transfer properties of graphene-based nanofluids. Table 2 summarizes all the research done on graphene-based nanofluids.

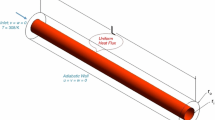

The convective heat transfer coefficient of graphene water nanofluid was investigated by Akabavan-Zanjani et al. [136], which found a 14.2% improvement at 0.02% concentration. Almost isotropic thermal conductivity was used to calculate the Nusselt number. As shown in Figs. 11 and 12, heat transfer coefficient and Nusselt number were compared with Shah’s equation and compared at different concentrations.

Experimental data compared with Shah equation [136]

In a stainless steel tube, Sadeghinezhad et al. [137] studied the turbulent heat transfer of graphene nanoplatelets nanofluids and found the Nusselt number increased by 3–83%. Ranjbarzadeh et al. [138] experimental investigated on water/graphene oxide nanofluid improved heat transfer coefficient, with an average increase of 51.4% in Nusselt number and also increase friction factor. Ghozatloo et al. [139] studied graphene nanofluids’ convective heat transfer behavior, finding that concentration increases thermal conductivity and heat transfer coefficient, with a 23.9% enhancement in water at higher temperatures. Yarmand et al. [140] found that GNP-Pt hybrid nanofluids effectively transport heat, with a 30% improvement in forced convection heat transfer capabilities at the highest weight concentration and Reynolds number. Selvam et al. [90] measured the CTHC and pressure drop of GnP/H2O-EG nanofluid for different loadings of graphene nanoplatelets. They found that high aspect ratio improves thermal conductivity and diffusivity, while convective heat transfer coefficient increases by 170%. Ranjbarzadeh et al. [141] investigated water/graphene oxide nanofluid significantly improved heat transfer and friction coefficient in a circular copper tube, resulting in a 16% increase in pressure loss but thermal performance coefficient increased by 1.148. The result can be seen in Fig. 13a, b.

Selvam et al. [142] studied thermal characteristics for automobile radiator with GnP/H2O-EG nanofluid and found that a graphene nanoplatelet with a high aspect ratio improved heat transfer by 29% at 0.5 vol%, with the increased of pressure drop and friction factor. Figures 14 and 15 show the pressure drop and friction factor at 35 °C and 45 °C with different concentrations.

a and b Pressure drop at different Reynolds number [142]

a and b Friction factor at different Reynolds number [142]

Arzani et al. [143] analyzed a new coolant with GNP-SDBS and GNP-COOH nanofluids, finding that suspended nanoparticles improved heat transfer capabilities by 22% at higher Reynolds numbers. Wang et al. found that using graphene nanoplatelets nanofluids (GnP-EGW) in a small plate heat exchanger (MPHE) lower pressure drop penalty and improves heat transfer performance. Ranjbarzadeh et al. [145] worked on water/graphene oxide nanofluid effect in twisted tape inserts, determining optimal geometry. They found that increasing Re and insert width increases heat transfer and pressure drop, making it a viable heat exchanger.

According to Yarmand et al. [146] comparison with corresponding water data, thermal conductivity and overall heat transfer coefficient enhanced. The experimental Nusselt number valve compared with standard correlation developed by Petukhov and Dittus which can be seen in Fig. 16. In comparison with base fluid, the Nusselt number improved and friction factor also increased for a weight concentration of 0.1% at a higher Reynolds number as given in Fig. 17a and b.

Comparison of measured Nusselt number with the correlations of Dittus–Boelter and Petukhov [146]

a, b Nusselt number and Friction factor of f-GNP nanofluids [146]

Agarwal et al. [147] conducted experimental research on the thermal performance of graphene nanoplatelet-kerosene-based nanofluid for regenerative cooling in a semi-cryogenic rocket thrust chamber, revealing a 49% improvement in heat transfer. Esfahani et al. [148] found that graphene oxide nanofluids with a 0.01 weight percent higher convective heat transfer coefficient had minimal relationship with Nusselt number and heat flux and velocity. Arshad et al. [149] studied the thermal and hydrodynamic performance of graphene nanoplatelets nanofluids with distilled water on integral fin heat sinks, finding that the lowest base temperature and highest convective heat transfer enhancement occur at 47.96 KW/m2. Mirzaei et al. [150] observed that adding 0.12% graphene oxide to water significantly increases the convective heat transfer coefficient by 77%, indicating that graphene oxide/water can enhance heat transfer efficiency. Akhavan-Zanjani et al. [79] worked on graphene nanosheet under turbulent condition with different concentration and observed that enhancement of heat transfer coefficient of graphene–water nanofluids by 6.04%. Selvam et al. [151] reported that using graphene nanoplatelets as a coolant enhanced the overall heat transfer coefficient of an automobile radiator by 104% at 0.5 vol%.

Yarmand et al. [152] investigated GNP-Ag/water nanofluids for heat transfer performance, friction factor, and improved empirical correlations given in Eq. 2,3.

Sadri et al. [153] proposed clove-treated GNP-water nanocoolants have superior thermo-physical properties, including increased thermal conductivity, dynamic viscosity, density, Nusselt number, convective heat transfer coefficient, and low friction factor, with a performance index greater than 1. Mehrali et al. [154] studied the convective heat transfer coefficient of GNP nanofluid with various specific surface areas and observed that valve increased by 83–200% higher than the base fluid. Baby et al. [126] developed and found increased thermal conductivity and a 141% improvement in Nusselt’s number when hydrogen exfoliated graphene (HEG), deionized water, and ethylene glycol-based nanofluids were studied. Ahammed et al. [155] investigated and found that using pure graphene–water nanofluid improved cooling capacity and performance by 17.32% and convective heat transfer coefficient by 88.62% compared to other combinations of nanofluids. Hussien et al. [156] conducted experimental research on hybrid nanofluids showed a 43.4% increase in heat transfer coefficient and 11% pressure drop at Re = 200, influenced by nanoparticle concentrations. An experiment performed by Jefferson et al. [157] showed a 56% enhancement and 28.7% pressure drop in a circular stainless steel tube with 0.6 volume percent.

Zubir et al. [158] found that Reduced Graphene Oxide (RGO) and its hybrid complexes improved convective heat transfer performance in closed conduit designs, particularly at heating section entry and high Reynolds numbers. RGO and its hybrid mixtures reduced pressure loss and friction factor, enhancing Nu by up to 144%. Sadeghinezhad et al. [159] studied the impact of a magnetic field on the heat transfer properties of hybrid reduced graphene–magnetite nanofluids, revealing a maximum enhancement of 82%. Aravind et al. [160, 161] synthesized graphene-MWNT composite nanofluids using a solution-free green method. The nanofluids improved heat transfer coefficient by 193% at 25 °C, maintaining high graphene thermal characteristics at 2000 Reynolds number. Mehrali et al. [162] examined heat transfer properties and entropy generation in a stainless steel tube using graphene nanoplatelet nanofluid. They found that adding 0.1 weight percent of GNP nanofluid can increase thermal performance by up to 1.15. Agromayor et al. [163] investigated on graphene nanoplatelets functionalized with sulfonic acid showed significant improvements in thermal conductivity and convection heat transfer coefficient. The Nusselt number of this type of nanofluid was predicted using new correlations as can see in Eq. 4.

Askari et al. [164] developed a Fe3O4/Graphene hybrid for nanofluid applications, revealing a 14.5% enhancement in convective heat transfer coefficient across a 2000–5000 Reynolds number range. Askari et al. [165] synthesized Fe3O4-decorated graphene nanoparticles for heat transfer enhancement in kerosene-based nanofluids, improving convective heat transfer coefficient by 66% at 4553 Reynolds number. Sadri et al. [166] using highly dispersed functionalized graphene nanoplatelets (GNPs), a cost-effective, environmentally friendly method was developed for synthesizing highly dispersed functionalized graphene nanofluids. The overall performance index was also higher than 1, which resulted in improved convective heat transfer coefficients and Nusselt numbers. It was reported by Baby et al. [167] that MWNTs, HEGs, and silver nanoparticles were combined to form a hybrid nanostructure with a 190% heat transfer enhancement. Salem et al. [168] showed that graphene oxide nanofluids in a heated tube significantly improved the heat transfer coefficient by 0.2 vol%.

5 Conclusions and future prospectives

This review focuses on the use of graphene-based nanofluids to enhance heat transfer and provides an extensive overview of studies conducted on graphene, graphene oxide, and graphene-based nanofluids. These studies cover synthesis methods, nanofluid preparation methods and characterization techniques and include analysis of properties such as thermal conductivity and viscosity. A graphene-based nanofluid has been investigated for its application in convection, including laminar and turbulent flows, with promising results. A number of parameters are examined in relation to heat exchange characteristics, pressure drop, and pumping power, including nanofluid concentration, Reynolds number, flow rate, and fluid temperature. Nanofluid properties are influenced by factors such as nanoparticle size, shape, surface area, and functionalization. We observed that thermal conductivity of nanofluids increases significantly as both concentration and temperature increase while using any type of nanofluid for enhanced thermal conductivity. Nanofluid viscosity generally increases with higher concentration but decreases with elevated temperature, suggesting the potential benefits of using graphene-based nanofluids at higher temperatures.

Graphene nanoparticles properties are very sensitive to their shape. In order to improve the production of nanofluids and increase thermal performance, it is imperative to investigate the effect of morphological, fluid, and thermal properties, as well as the use of different base fluids.

The paper highlights experimental and numerical heat transfer studies, which demonstrate enhanced convective heat transfer coefficients and Nusselt numbers when using graphene-based nanofluids. Importantly, the pressure losses associated with graphene-based nanofluids are typically minimal, making them an efficient choice for heat transfer applications.

5.1 Future scope of work

Ensuring long-term stability of nanofluids remains a significant challenge for industrial applications and commercialization. Limited information is available on the corrosive, fouling formation and erosive effects of graphene nanofluids in heat exchanger tubes or surfaces. Comprehensive experimental studies are needed to validate the heat transfer capabilities using graphene-based nanofluids. Despite numerous publications on the subject, the paper suggests that there is room for further research to identify the optimal properties that graphene-based nanofluids should possess and to explore more efficient synthesis processes for these nanomaterials.

References

Xuan Y, Li Q Heat transfer enhancement of nanofluids [Online]. Available: www.elsevier.com/locate/ijh

Choi SUS (1995) Enhancing thermal conductivity of fluids with nanoparticles. American Society of Mechanical Engineers, Fluids Engineering Division (Publication) FED

Ligrani PM, Oliveira MM, Blaskovich T (2003) Comparison of heat transfer augmentation techniques. AIAA J 41(3):337–362. https://doi.org/10.2514/2.1964

Bergles AE (1988) Heat Transfer Augmentation. Two-Phase Flow Heat Exchangers, vol. 143. ISBN:978-94-010-7755-2

Guot ZY, Li DY, Wang BX (1998) ‘A novel concept for convective heat transfer enhancement. Int J Heat Mass Transf 41(14):2221–2225

Dewan A, Mahanta P, Raju KS, Suresh Kumar P (2004) Review of passive heat transfer augmentation techniques. Proc Inst Mech Eng Part A J Power Energy 218(7):509–527. https://doi.org/10.1243/0957650042456953

Wang XQ, Mujumdar AS (2007) Heat transfer characteristics of nanofluids: a review. Int J Therm Sci 46(1):1–19. https://doi.org/10.1016/j.ijthermalsci.2006.06.010

Iravani S (2011) Green synthesis of metal nanoparticles using plants. Green Chem 13(10):2638–2650. https://doi.org/10.1039/c1gc15386b

Khan I, Saeed K, Khan I (2019) Nanoparticles: properties, applications and toxicities. Arab J Chem 12(7):908–931. https://doi.org/10.1016/j.arabjc.2017.05.011

Seekaew Y, Phokharatkul D, Wisitsoraat A, Wongchoosuk C (2017) Highly sensitive and selective room-temperature NO2 gas sensor based on bilayer transferred chemical vapor deposited graphene. Appl Surf Sci 404:357–363. https://doi.org/10.1016/j.apsusc.2017.01.286

Bello SA, Agunsoye JO, Hassan SB (2015) Synthesis of coconut shell nanoparticles via a top down approach: assessment of milling duration on the particle sizes and morphologies of coconut shell nanoparticles. Mater Lett 159:514–519. https://doi.org/10.1016/j.matlet.2015.07.063

Zhang X et al (2015) A facile and universal top-down method for preparation of monodisperse transition-metal dichalcogenide nanodots. Angewandte Chemie Int Ed 54(18):5425–5428. https://doi.org/10.1002/anie.201501071

Mogilevsky G et al (2014) Bottom-up synthesis of anatase nanoparticles with graphene domains [Online]. Available: http://pubs.acs.org

Wang Y, Xia Y (2004) Bottom-up and top-down approaches to the synthesis of monodispersed spherical colloids of low melting-point metals. Nano Lett 4(10):2047–2050. https://doi.org/10.1021/nl048689j

Aberoumand S, Jafarimoghaddam A (2018) Tungsten (III) oxide (WO3)—silver/transformer oil hybrid nanofluid: preparation, stability, thermal conductivity and dielectric strength. Alex Eng J. https://doi.org/10.1016/j.aej.2016.11.003

Pawar JB, Tungikar VB (2022) Alumina–di water-based nanofluid process parameter optimization for stability. J Braz Soc Mech Sci Eng. https://doi.org/10.1007/s40430-022-03541-8

Bin-Abdun NA et al (2020) Heat transfer improvement in simulated small battery compartment using metal oxide (CuO)/deionized water nanofluid. Heat Mass Transf Waerme- und Stoffuebertragung 56(2):399–406. https://doi.org/10.1007/s00231-019-02719-6

Masoud Parsa S et al (2022) A critical analysis on the energy and exergy performance of photovoltaic/thermal (PV/T) system: the role of nanofluids stability and synthesizing method. Sustain Energy Technol Assess. https://doi.org/10.1016/j.seta.2021.101887

Salehi JM, Heyhat MM, Rajabpour A (2013) Enhancement of thermal conductivity of silver nanofluid synthesized by a one-step method with the effect of polyvinylpyrrolidone on thermal behavior. Appl Phys Lett. https://doi.org/10.1063/1.4809998

Kumar SA, Meenakshi KS, Narashimhan BRV, Srikanth S, Arthanareeswaran G (2009) Synthesis and characterization of copper nanofluid by a novel one-step method. Mater Chem Phys. https://doi.org/10.1016/j.matchemphys.2008.07.027

Sonage BK, Mohanan P (2014) Characterization of zinc oxide nanoparticles used for preparation of nanofluids. Proc Mater Sci. https://doi.org/10.1016/j.mspro.2014.07.412

Soltani F, Toghraie D, Karimipour A (2020) Experimental measurements of thermal conductivity of engine oil-based hybrid and mono nanofluids with tungsten oxide (WO3) and MWCNTs inclusions. Powder Technol. https://doi.org/10.1016/j.powtec.2020.05.059

Subramaniyan AL, Kumar A, Sethupathi S, Kumar TS, Ilangovan R (2015) Preparation and stability characterization of copper oxide nanofluid by two step method. Mater Sci Forum. https://doi.org/10.4028/www.scientific.net/MSF.832.139

Chen Z, Shahsavar A, Al-Rashed AAAA, Afrand M (2020) The impact of sonication and stirring durations on the thermal conductivity of alumina-liquid paraffin nanofluid: an experimental assessment. Powder Technol. https://doi.org/10.1016/j.powtec.2019.11.036

Li D, Kaner RB (2008) Materials science: graphene-based materials. Science 320(5880):1170–1171. https://doi.org/10.1126/science.1158180

Allen MJ, Tung VC, Kaner RB (2010) Honeycomb carbon: a review of graphene. Chem Rev 110(1):132–145. https://doi.org/10.1021/cr900070d

Huang X, Qi X, Boey F, Zhang H (2012) Graphene-based composites. Chem Soc Rev 41(2):666–686. https://doi.org/10.1039/c1cs15078b

Priyadarsini S, Mohanty S, Mukherjee S, Basu S, Mishra M (2018) Graphene and graphene oxide as nanomaterials for medicine and biology application. J Nanostruct Chem 8(2):123–137. https://doi.org/10.1007/s40097-018-0265-6

Geim AK, Novoselov KS The rise of graphene [Online]. Available: www.nature.com/naturematerials

Ghaemi F, Abdullah LC, Tahir PM, Yunus R (2016) Synthesis of different layers of graphene on stainless steel using the CVD method. Nanoscale Res Lett. https://doi.org/10.1186/s11671-016-1709-x

An H, Lee WJ, Jung J (2011) Graphene synthesis on Fe foil using thermal CVD. Curr Appl Phys. https://doi.org/10.1016/j.cap.2011.03.077

Cheng L et al (2015) Low temperature synthesis of graphite on Ni films using inductively coupled plasma enhanced CVD. J Mater Chem C Mater 3(20):5192–5198. https://doi.org/10.1039/c5tc00635j

Terasawa TO, Saiki K (2012) Growth of graphene on Cu by plasma enhanced chemical vapor deposition. Carbon N Y 50(3):869–874. https://doi.org/10.1016/j.carbon.2011.09.047

Woehrl N, Ochedowski O, Gottlieb S, Shibasaki K, Schulz S (2014) Plasma-enhanced chemical vapor deposition of graphene on copper substrates. AIP Adv. https://doi.org/10.1063/1.4873157

Sadri R et al (2017) A novel, eco-friendly technique for covalent functionalization of graphene nanoplatelets and the potential of their nanofluids for heat transfer applications. Chem Phys Lett 675:92–97. https://doi.org/10.1016/j.cplett.2017.02.077

Sridhar V, Jeon JH, Oh IK (2010) Synthesis of graphene nano-sheets using eco-friendly chemicals and microwave radiation. Carbon N Y 48(10):2953–2957. https://doi.org/10.1016/j.carbon.2010.04.034

Parvez K et al (2013) Electrochemically exfoliated graphene as solution-processable, highly conductive electrodes for organic electronics. ACS Nano 7(4):3598–3606. https://doi.org/10.1021/nn400576v

Hernandez Y et al (2008) High-yield production of graphene by liquid-phase exfoliation of graphite. Nat Nanotechnol 3(9):563–568. https://doi.org/10.1038/nnano.2008.215

Bhuyan MSA, Uddin MN, Islam MM, Bipasha FA, Hossain SS (2016) Synthesis of graphene. Int Nano Lett 6(2):65–83. https://doi.org/10.1007/s40089-015-0176-1

Yu P, Lowe SE, Simon GP, Zhong YL (2015) Electrochemical exfoliation of graphite and production of functional graphene. Curr Opin Colloid Interface Sci 20(56):329–338. https://doi.org/10.1016/j.cocis.2015.10.007

Zhou M, Tang J, Cheng Q, Xu G, Cui P, Qin LC (2013) Few-layer graphene obtained by electrochemical exfoliation of graphite cathode. Chem Phys Lett 572:61–65. https://doi.org/10.1016/j.cplett.2013.04.013

Chang H, Wu H (2013) Graphene-based nanomaterials: synthesis, properties, and optical and optoelectronic applications. Adv Funct Mater 23(16):1984–1997. https://doi.org/10.1002/adfm.201202460

Hou ZL et al (2014) Flexible graphene-graphene composites of superior thermal and electrical transport properties. ACS Appl Mater Interfaces 6(17):15026–15032. https://doi.org/10.1021/am502986j

Soldano C, Mahmood A, Dujardin E (2010) Production, properties and potential of graphene. Carbon 48(8):2127–2150. https://doi.org/10.1016/j.carbon.2010.01.058

Jariwala D, Sangwan VK, Lauhon LJ, Marks TJ, Hersam MC (2013) Carbon nanomaterials for electronics, optoelectronics, photovoltaics, and sensing. Chem Soc Rev 42(7):2824–2860. https://doi.org/10.1039/c2cs35335k

Choi W, Lahiri I, Seelaboyina R, Kang YS (2010) Synthesis of graphene and its applications: a review. Crit Rev Solid State Mater Sci 35(1):52–71. https://doi.org/10.1080/10408430903505036

Gong X, Liu G, Li Y, Yu DYW, Teoh WY (2016) Functionalized-graphene composites: fabrication and applications in sustainable energy and environment. Chem Mater 28(22):8082–8118. https://doi.org/10.1021/acs.chemmater.6b01447

Sadeghinezhad E et al (2016) A comprehensive review on graphene nanofluids: recent research, development and applications. Energy Convers Manag 111:466–487. https://doi.org/10.1016/j.enconman.2016.01.004

Kuila T, Bose S, Mishra AK, Khanra P, Kim NH, Lee JH (2012) Chemical functionalization of graphene and its applications. Prog Mater Sci 57(7):1061–1105. https://doi.org/10.1016/j.pmatsci.2012.03.002

Huang X et al (2011) Graphene-based materials: synthesis, characterization, properties, and applications. Small 7(14):1876–1902. https://doi.org/10.1002/smll.201002009

Biró LP, Nemes-Incze P, Lambin P (2012) Graphene: nanoscale processing and recent applications. Nanoscale 4(6):1824–1839. https://doi.org/10.1039/c1nr11067e

Dreyer DR, Park S, Bielawski CW, Ruoff RS (2010) The chemistry of graphene oxide. Chem Soc Rev 39(1):228–240. https://doi.org/10.1039/b917103g

Dimiev AM, Eigler S (2017) Graphene oxide fundamentals and applications edited by, [Online]. Available: www.wiley.com

Suvarnaphaet P, Pechprasarn S (2017) Graphene-based materials for biosensors: a review. Sensors (Switzerland). https://doi.org/10.3390/s17102161

Marcano DC et al (2010) Improved synthesis of graphene oxide. ACS Nano 4(8):4806–4814. https://doi.org/10.1021/nn1006368

Chung C, Kim YK, Shin D, Ryoo SR, Hong BH, Min DH (2013) Biomedical applications of graphene and graphene oxide. Acc Chem Res 46(10):2211–2224. https://doi.org/10.1021/ar300159f

Yu H, Zhang B, Bulin C, Li R, Xing R (2016) High-efficient synthesis of graphene oxide based on improved hummers method. Sci Rep. https://doi.org/10.1038/srep36143

Poh HL, Šaněk F, Ambrosi A, Zhao G, Sofer Z, Pumera M (2012) Graphenes prepared by Staudenmaier, Hofmann and Hummers methods with consequent thermal exfoliation exhibit very different electrochemical properties. Nanoscale 4(11):3515–3522. https://doi.org/10.1039/c2nr30490b

Alam SN, Sharma N, Kumar L (2017) Synthesis of graphene oxide (GO) by modified Hummers method and its thermal reduction to obtain reduced graphene oxide (rGO)*. Graphene 06(01):1–18. https://doi.org/10.4236/graphene.2017.61001

Hummers WS, Offeman RE, 339 PREPARATION OF GRAPHITIC OXIDE Preparation of Graphitic Oxide

Park S, Ruoff RS (2009) Chemical methods for the production of graphenes. Nat Nanotechnol 4(4):217–224. https://doi.org/10.1038/nnano.2009.58

Compton OC, Nguyen ST (2010) Graphene oxide, highly reduced graphene oxide, and graphene: versatile building blocks for carbon-based materials. Small 6(6):711–723. https://doi.org/10.1002/smll.200901934

Thangavel S, Elayaperumal M, Venugopal G (2012) Synthesis and properties of tungsten oxide and reduced graphene oxide nanocomposites. Mater Express 2(4):327–334. https://doi.org/10.1166/mex.2012.1087

Aldawsari Y, Mussa Y, Ahmed F, Arsalan M, Alsharaeh E (2019) Novel synthesis of Holey Reduced Graphene Oxide/Polystyrene (HRGO/PS) nanocomposites by microwave irradiation as anodes for high-temperature lithium-ion batteries. https://doi.org/10.3390/ma12142248

Umrao S et al (2015) Microwave-assisted synthesis of boron and nitrogen co-doped reduced graphene oxide for the protection of electromagnetic radiation in Ku-band. ACS Appl Mater Interfaces 7(35):19831–19842. https://doi.org/10.1021/acsami.5b05890

Li B et al (2010) All-carbon electronic devices fabricated by directly grown single-walled carbon nanotubes on reduced graphene oxide electrodes. Adv Mater 22(28):3058–3061. https://doi.org/10.1002/adma.201000736

Shen J et al (2009) Fast and facile preparation of graphene oxide and reduced graphene oxide nanoplatelets. Chem Mater 21(15):3514–3520. https://doi.org/10.1021/cm901247t

Acik M et al (2010) The role of intercalated water in multilayered graphene oxide. ACS Nano 4(10):5861–5868. https://doi.org/10.1021/nn101844t

Zhong Y, Zhen Z, Zhu H (2017) Graphene: fundamental research and potential applications. FlatChem 4:20–32. https://doi.org/10.1016/j.flatc.2017.06.008

Liu WW, Chai SP, Mohamed AR, Hashim U (2014) Synthesis and characterization of graphene and carbon nanotubes: a review on the past and recent developments. J Ind Eng Chem 20(4):1171–1185. https://doi.org/10.1016/j.jiec.2013.08.028

Chen L, Yu H, Zhong J, Song L, Wu J, Su W (2017) Graphene field emitters: a review of fabrication, characterization and properties. Mater Sci Eng B Solid State Mater Adv Technol 220:44–58. https://doi.org/10.1016/j.mseb.2017.03.007

Brennan B et al (2017) Structural, chemical and electrical characterisation of conductive graphene-polymer composite films. Appl Surf Sci 403:403–412. https://doi.org/10.1016/j.apsusc.2017.01.132

Surekha G, Krishnaiah KV, Ravi N, Padma Suvarna R (2020) FTIR, Raman and XRD analysis of graphene oxide films prepared by modified Hummers method. J Phys Conf Series. https://doi.org/10.1088/1742-6596/1495/1/012012

Andonovic B, Grozdanov A, Paunović P, Dimitrov AT (2015) X-ray diffraction analysis on layers in graphene samples obtained by electrolysis in molten salts: a new perspective. Micro Nano Lett 10(12):683–685. https://doi.org/10.1049/mnl.2015.0325

Nair RR et al (2008) Fine structure constant defines visual transparency of graphene. Science (1979) 320(5881):1308. https://doi.org/10.1126/science.1156965

Paredes JI, Villar-Rodil S, Solís-Fernández P, Martínez-Alonso A, Tascón JMD (2009) Atomic force and scanning tunneling microscopy imaging of graphene nanosheets derived from graphite oxide. Langmuir 25(10):5957–5968. https://doi.org/10.1021/la804216z

Wang F et al Gate-variable optical transitions in graphene [Online]. Available: www.sciencemag.org

Li X et al (2009) Transfer of large-area graphene films for high-performance transparent conductive electrodes. Nano Lett 9(12):4359–4363. https://doi.org/10.1021/nl902623y

Akhavan-Zanjani H, Saffar-Avval M, Mansourkiaei M, Ahadi M, Sharif F (2014) Turbulent convective heat transfer and pressure drop of graphene–water nanofluid flowing inside a horizontal circular tube. J Dispers Sci Technol 35(9):1230–1240. https://doi.org/10.1080/01932691.2013.834423

Malard LM, Pimenta MA, Dresselhaus G, Dresselhaus MS (2009) Raman spectroscopy in graphene. Phys Rep 473(5–6):51–87. https://doi.org/10.1016/j.physrep.2009.02.003

Casiraghi C et al (2009) Raman spectroscopy of graphene edges. Nano Lett 9(4):1433–1441. https://doi.org/10.1021/nl8032697

Ferrari AC et al (2006) Raman spectrum of graphene and graphene layers. Phys Rev Lett 97(18). https://doi.org/10.1103/PhysRevLett.97.187401

Wang YY et al (2008) Raman studies of monolayer graphene: the substrate effect. J Phys Chem C 112(29):10637–10640. https://doi.org/10.1021/jp8008404

Ni ZH et al (2008) Raman spectroscopy of epitaxial graphene on a SiC substrate. Phys Rev B Condens Matter Mater Phys 77(11):115416. https://doi.org/10.1103/PhysRevB.77.115416

Das A et al (2008) Monitoring dopants by Raman scattering in an electrochemically top-gated graphene transistor. Nat Nanotechnol 3(4):210–215. https://doi.org/10.1038/nnano.2008.67

Lee J, Zheng X, Roberts RC, Feng PXL (2015) Scanning electron microscopy characterization of structural features in suspended and non-suspended graphene by customized CVD growth. Diam Relat Mater 54(1):64–73. https://doi.org/10.1016/j.diamond.2014.11.012

Li X et al (2009) Synthesis, Characterization, and Properties of Large-area Few-layer Graphene Films with Tunable Thickness

Shukla S, Saxena S (2011) Spectroscopic investigation of confinement effects on optical properties of graphene oxide. Appl Phys Lett. https://doi.org/10.1063/1.3555438

Balandin AA (2011) Thermal properties of graphene and nanostructured carbon materials. Nat Mater 10(8):569–581. https://doi.org/10.1038/nmat3064

Selvam C, Balaji T, Mohan Lal D, Harish S (2017) Convective heat transfer coefficient and pressure drop of water–ethylene glycol mixture with graphene nanoplatelets. Exp Therm Fluid Sci 80:67–76. https://doi.org/10.1016/j.expthermflusci.2016.08.013

Meyer JC, Geim AK, Katsnelson MI, Novoselov KS, Booth TJ, Roth S (2007) The structure of suspended graphene sheets. Nature 446(7131):60–63. https://doi.org/10.1038/nature05545

Wilson NR et al (2009) Graphene oxide: structural analysis and application as a highly transparent support for electron microscopy. ACS Nano 3(9):2547–2556. https://doi.org/10.1021/nn900694t

Gómez-Navarro C et al (2010) Atomic structure of reduced graphene oxide. Nano Lett 10(4):1144–1148. https://doi.org/10.1021/nl9031617

Sun Z, Yan Z, Yao J, Beitler E, Zhu Y, Tour JM (2010) Growth of graphene from solid carbon sources. Nature 468(7323):549–552. https://doi.org/10.1038/nature09579

Mkhoyan KA et al (2009) Atomic and electronic structure of graphene-oxide. Nano Lett 9(3):1058–1063. https://doi.org/10.1021/nl8034256

Eigler S, Hof F, Enzelberger-Heim M, Grimm S, Müller P, Hirsch A (2014) Statistical Raman microscopy and atomic force microscopy on heterogeneous graphene obtained after reduction of graphene oxide. J Phys Chem C 118(14):7698–7704. https://doi.org/10.1021/jp500580g

De Silva KKH, Huang HH, Viswanath P, Joshi R, Yoshimura M (2022) Nanoscale electrical characterization of graphene-based materials by atomic force microscopy. J Mater Res 37(20):3319–3339. https://doi.org/10.1557/s43578-022-00758-0

Zhang H et al (2018) Atomic force microscopy for two-dimensional materials: a tutorial review. Opt Commun 406:3–17. https://doi.org/10.1016/j.optcom.2017.05.015

Balandin AA et al (2008) Superior thermal conductivity of single-layer graphene. Nano Lett 8(3):902–907. https://doi.org/10.1021/nl0731872

Frank M, Drikakis D, Asproulis N (2015) Thermal conductivity of nanofluid in nanochannels. Microfl Nanofl 19:1011–1017. https://doi.org/10.1007/s10404-015-1591-3

Simpson S, Schelfhout A, Golden C, Vafaei S(2019) Nanofluid thermal conductivity and effective parameters. Appl Sci. 9(1):87. https://doi.org/10.3390/app9010087

Kang HU, Kim SH, Oh JM (2006) Estimation of thermal conductivity of nanofluid using experimental effective particle volume. Exp Heat Transf 19(3):181–191. https://doi.org/10.1080/08916150600619281

Chopkar M, Sudarshan S, Das P et al (2008) Effect of particle size on thermal conductivity of nanofluid. Metall Mater Trans A 39:1535–1542. https://doi.org/10.1007/s11661-007-9444-7

Ahammed N, Asirvatham LG, Titus J, Bose JR, Wongwises S (2016) Measurement of thermal conductivity of graphene-water nanofluid at below and above ambient temperatures. Int Commun Heat Mass Transf. https://doi.org/10.1016/j.icheatmasstransfer.2015.11.002

Li X, Chen Y, Mo S, Jia L, Shao X (2014) Effect of surface modification on the stability and thermal conductivity of water-based SiO2-coated graphene nanofluid. Thermochim Acta 595:6–10. https://doi.org/10.1016/j.tca.2014.09.006

Hong WX, Sidik NAC, Saidur R (2020) Effect of surfactants on thermal conductivity of graphene based hybrid nanofluid. IOP Conf Series Earth Environ Sci. https://doi.org/10.1088/1755-1315/463/1/012122

Ahammed N, Asirvatham LG, Wongwises S (2016) Effect of volume concentration and temperature on viscosity and surface tension of graphene-water nanofluid for heat transfer applications. J Therm Anal Calorim. https://doi.org/10.1007/s10973-015-5034-x

Zheng Y, Zhang X, Shahsavar A, Nguyen Q, Rostami S (2020) Experimental evaluating the rheological behavior of ethylene glycol under graphene nanosheets loading. Powder Technol. https://doi.org/10.1016/j.powtec.2020.04.039

Dong F, Wan J, Feng Y, Wang Z, Ni J (2021) Experimental study on thermophysical properties of propylene glycol-based graphene nanofluids. Int J Thermophys. https://doi.org/10.1007/s10765-021-02798-w

Abdulla NN, Ibrahim HA (2017) Experimental measurements of viscosity and thermal conductivity of single layer graphene based DI-water nanofluid. Eng J 23(4):142–161

Moghaddam MB, Goharshadi EK, Entezari MH, Nancarrow P (2013) Preparation, characterization, and rheological properties of graphene-glycerol nanofluids. Chem Eng J 231:365–372. https://doi.org/10.1016/j.cej.2013.07.006

Bakak A, Lotfi M, Heyd R, Ammar A, Koumina A (2021) Viscosity and rheological properties of graphene nanopowders nanofluids. Entropy. https://doi.org/10.3390/e23080979

Mehrali M et al (2014) Investigation of thermal conductivity and rheological properties of nanofluids containing graphene nanoplatelets [Online]. Available: http://www.nanoscalereslett.com/content/9/1/15

Das S, Giri A, Samanta S, Kanagaraj S (2019) Role of graphene nanofluids on heat transfer enhancement in thermosyphon. J Sci Adv Mater Devices 4(1):163–169. https://doi.org/10.1016/j.jsamd.2019.01.005

Hajjar Z, morad Rashidi A, Ghozatloo A (2014) Enhanced thermal conductivities of graphene oxide nanofluids. Int Commun Heat Mass Transf 57:128–131. https://doi.org/10.1016/j.icheatmasstransfer.2014.07.018

Syam Sundar L, Singh MK, Ferro MC, Sousa ACM (2017) Experimental investigation of the thermal transport properties of graphene oxide/Co3O4 hybrid nanofluids. Int Commun Heat Mass Transf 84:1–10. https://doi.org/10.1016/j.icheatmasstransfer.2017.03.001

Vallejo JP, Żyła G, Fernández-Seara J, Lugo L (2018) Rheological behaviour of functionalized graphene nanoplatelet nanofluids based on water and propylene glycol:water mixtures. Int Commun Heat Mass Transf 99:43–53. https://doi.org/10.1016/j.icheatmasstransfer.2018.10.001

Sarsam WS, Amiri A, Kazi SN, Badarudin A (2016) Stability and thermophysical properties of non-covalently functionalized graphene nanoplatelets nanofluids. Energy Convers Manag 116:101–111. https://doi.org/10.1016/j.enconman.2016.02.082

Yarmand H et al (2016) Study of synthesis, stability and thermo-physical properties of graphene nanoplatelet/platinum hybrid nanofluid. Int Commun Heat Mass Transf 77:15–21. https://doi.org/10.1016/j.icheatmasstransfer.2016.07.010

Sedaghat F, Yousefi F (2019) Synthesizes, characterization, measurements and modeling thermal conductivity and viscosity of graphene quantum dots nanofluids. J Mol Liq 278:299–308. https://doi.org/10.1016/j.molliq.2019.01.073

Selvam C, Lal DM, Harish S (2016) Thermal conductivity enhancement of ethylene glycol and water with graphene nanoplatelets. Thermochim Acta 642:32–38. https://doi.org/10.1016/j.tca.2016.09.002

Amiri A, Shanbedi M, Dashti H (2017) Thermophysical and rheological properties of water-based graphene quantum dots nanofluids. J Taiwan Inst Chem Eng 76:132–140. https://doi.org/10.1016/j.jtice.2017.04.005

Akbari A, Alavi Fazel SA, Maghsoodi S, Shahbazi Kootenaei A (2019) Thermo-physical and stability properties of raw and functionalization of graphene nanoplatelets-based aqueous nanofluids. J Dispers Sci Technol 40(1):17–24. https://doi.org/10.1080/01932691.2018.1462713

Wang Y, Al-Saaidi HAI, Kong M, Alvarado JL (2018) Thermophysical performance of graphene based aqueous nanofluids. Int J Heat Mass Transf 119:408–417. https://doi.org/10.1016/j.ijheatmasstransfer.2017.11.019

Mahmudul Haque AKM et al (2015) An experimental study on thermal characteristics of nanofluid with graphene and multi-wall carbon nanotubes. J Cent South Univ 22(8):3202–3210. https://doi.org/10.1007/s11771-015-2857-3

Baby TT, Ramaprabhu S (2011) Enhanced convective heat transfer using graphene dispersed nanofluids. Nanoscale Res Lett 6:1. https://doi.org/10.1186/1556-276X-6-289

Amiri A et al (2017) Functionalization and exfoliation of graphite into mono layer graphene for improved heat dissipation. J Taiwan Inst Chem Eng 71:480–493. https://doi.org/10.1016/j.jtice.2016.12.009

Amiri A et al (2016) Heat transfer enhancement of water-based highly crumpled few-layer graphene nanofluids. RSC Adv 6(107):105508–105527. https://doi.org/10.1039/c6ra22365f

Park SS, Kim NJ (2014) Influence of the oxidation treatment and the average particle diameter of graphene for thermal conductivity enhancement. J Ind Eng Chem 20(4):1911–1915. https://doi.org/10.1016/j.jiec.2013.09.011

Kole M, Dey TK (2013) Investigation of thermal conductivity, viscosity, and electrical conductivity of graphene based nanofluids. J Appl Phys. https://doi.org/10.1063/1.4793581

Ghozatloo A, Shariaty-Niasar M, Rashidi AM (2013) Preparation of nanofluids from functionalized graphene by new alkaline method and study on the thermal conductivity and stability. Int Commun Heat Mass Transf 42:89–94. https://doi.org/10.1016/j.icheatmasstransfer.2012.12.007

Ma W, Yang F, Shi J, Wang F, Zhang Z, Wang S (2013) Silicone based nanofluids containing functionalized graphene nanosheets. Colloids Surf A Physicochem Eng Asp 431:120–126. https://doi.org/10.1016/j.colsurfa.2013.04.031

Baby TT, Ramaprabhu S (2011) Synthesis and nanofluid application of silver nanoparticles decorated graphene. J Mater Chem 21(26):9702–9709. https://doi.org/10.1039/c0jm04106h

Baby TT, Sundara R (2011) Synthesis and transport properties of metal oxide decorated graphene dispersed nanofluids. J Phys Chem C 115(17):8527–8533. https://doi.org/10.1021/jp200273g

Yu W, Xie H, Chen L, Li Y, Li D (2010) IHTC14–22055 The Preparation And Thermal Conductivities Enhacement Of Nanofluids Containing Graphene Oxide Nanosheets IHTC14–22055 [Online]. Available: http://asme.org/terms

Akhavan-Zanjani H, Saffar-Avval M, Mansourkiaei M, Sharif F, Ahadi M (2016) Experimental investigation of laminar forced convective heat transfer of graphene–water nanofluid inside a circular tube. Int J Therm Sci 100:316–323. https://doi.org/10.1016/j.ijthermalsci.2015.10.003

Sadeghinezhad E et al (2015) An experimental and numerical investigation of heat transfer enhancement for graphene nanoplatelets nanofluids in turbulent flow conditions. Int J Heat Mass Transf 81:41–51. https://doi.org/10.1016/j.ijheatmasstransfer.2014.10.006

Ranjbarzadeh R, Meghdadi Isfahani AH, Afrand M, Karimipour A, Hojaji M (2017) An experimental study on heat transfer and pressure drop of water/graphene oxide nanofluid in a copper tube under air cross-flow: applicable as a heat exchanger. Appl Therm Eng 125:69–79. https://doi.org/10.1016/j.applthermaleng.2017.06.110

Ghozatloo A, Rashidi A, Shariaty-Niassar M (2014) Convective heat transfer enhancement of graphene nanofluids in shell and tube heat exchanger. Exp Therm Fluid Sci 53:136–141. https://doi.org/10.1016/j.expthermflusci.2013.11.018

Yarmand H et al (2017) Convective heat transfer enhancement with graphene nanoplatelet/platinum hybrid nanofluid. Int Commun Heat Mass Transfer 88:120–125. https://doi.org/10.1016/j.icheatmasstransfer.2017.08.010

Ranjbarzadeh R, Karimipour A, Afrand M, Isfahani AHM, Shirneshan A (2017) Empirical analysis of heat transfer and friction factor of water/graphene oxide nanofluid flow in turbulent regime through an isothermal pipe. Appl Therm Eng 126:538–547. https://doi.org/10.1016/j.applthermaleng.2017.07.189

Selvam C, Mohan Lal D, Harish S (2017) Enhanced heat transfer performance of an automobile radiator with graphene based suspensions. Appl Therm Eng 123:50–60. https://doi.org/10.1016/j.applthermaleng.2017.05.076

Arzani HK, Amiri A, Kazi SN, Chew BT, Badarudin A (2015) Experimental and numerical investigation of thermophysical properties, heat transfer and pressure drop of covalent and noncovalent functionalized graphene nanoplatelet-based water nanofluids in an annular heat exchanger. Int Commun Heat Mass Transf 68:267–275. https://doi.org/10.1016/j.icheatmasstransfer.2015.09.007

Wang Z, Wu Z, Han F, Wadsö L, Sundén B (2018) Experimental comparative evaluation of a graphene nanofluid coolant in miniature plate heat exchanger. Int J Therm Sci 130:148–156. https://doi.org/10.1016/j.ijthermalsci.2018.04.021

Ranjbarzadeh R, Meghdadi Isfahani AH, Hojaji M (2018) Experimental investigation of heat transfer and friction coefficient of the water/graphene oxide nanofluid in a pipe containing twisted tape inserts under air cross-flow. Exp Heat Transf 31(5):373–390. https://doi.org/10.1080/08916152.2018.1431736

Yarmand H et al (2016) Experimental investigation of thermo-physical properties, convective heat transfer and pressure drop of functionalized graphene nanoplatelets aqueous nanofluid in a square heated pipe. Energy Convers Manag 114:38–49. https://doi.org/10.1016/j.enconman.2016.02.008

Agarwal DK, Vaidyanathan A, Sunil Kumar S (2016) Experimental investigation on thermal performance of kerosene–graphene nanofluid. Exp Therm Fluid Sci 71:126–137. https://doi.org/10.1016/j.expthermflusci.2015.10.028

Esfahani MR, Nunna MR, Languri EM, Nawaz K, Cunningham G (2019) Experimental study on heat transfer and pressure drop of in-house synthesized graphene oxide nanofluids. Heat Transf Eng 40(20):1722–1735. https://doi.org/10.1080/01457632.2018.1497001

Arshad W, Ali HM (2017) Graphene nanoplatelets nanofluids thermal and hydrodynamic performance on integral fin heat sink. Int J Heat Mass Transf 107:995–1001. https://doi.org/10.1016/j.ijheatmasstransfer.2016.10.127

Mirzaei M, Azimi A (2016) Heat transfer and pressure drop characteristics of graphene oxide/water nanofluid in a circular tube fitted with wire coil insert. Exp Heat Transf 29(2):173–187. https://doi.org/10.1080/08916152.2014.973975

Selvam C, Solaimalai Raja R, Mohan Lal D, Harish S (2017) Overall heat transfer coefficient improvement of an automobile radiator with graphene based suspensions. Int J Heat Mass Transf 115:580–588. https://doi.org/10.1016/j.ijheatmasstransfer.2017.08.071

Yarmand H et al (2015) Graphene nanoplatelets-silver hybrid nanofluids for enhanced heat transfer. Energy Convers Manag 100:419–428. https://doi.org/10.1016/j.enconman.2015.05.023

Sadri R et al (2018) A facile, bio-based, novel approach for synthesis of covalently functionalized graphene nanoplatelet nano-coolants toward improved thermo-physical and heat transfer properties. J Colloid Interface Sci 509:140–152. https://doi.org/10.1016/j.jcis.2017.07.052

Sadeghinezhad E et al (2016) Experimental investigation of the effect of graphene nanofluids on heat pipe thermal performance. Appl Therm Eng 100:775–787. https://doi.org/10.1016/j.applthermaleng.2016.02.071

Ahammed N, Asirvatham LG, Wongwises S (2016) Entropy generation analysis of graphene–alumina hybrid nanofluid in multiport minichannel heat exchanger coupled with thermoelectric cooler. Int J Heat Mass Transf 103:1084–1097. https://doi.org/10.1016/j.ijheatmasstransfer.2016.07.070

Hussien AA, Abdullah MZ, Yusop NM, Al-Nimr MA, Atieh MA, Mehrali M (2017) Experiment on forced convective heat transfer enhancement using MWCNTs/GNPs hybrid nanofluid and mini-tube. Int J Heat Mass Transf 115:1121–1131. https://doi.org/10.1016/j.ijheatmasstransfer.2017.08.120

Jefferson Raja Bose B, Asirvatham LG, Kumar MN (2017) Experimental convective heat transfer studies on graphene nanofluid for the cooling of next generation electronic components [Online]. Available: http://www.ripublication.com

Zubir MNM et al (2015) Experimental investigation on the use of reduced graphene oxide and its hybrid complexes in improving closed conduit turbulent forced convective heat transfer. Exp Therm Fluid Sci 66:290–303. https://doi.org/10.1016/j.expthermflusci.2015.03.022

Mehrali M et al (2017) Heat transfer and entropy generation analysis of hybrid graphene/Fe3O4 ferro-nanofluid flow under the influence of a magnetic field. Powder Technol 308:149–157. https://doi.org/10.1016/j.powtec.2016.12.024

Jyothirmayee Aravind SS, Ramaprabhu S (2012) Graphene wrapped multiwalled carbon nanotubes dispersed nanofluids for heat transfer applications. J Appl Phys. https://doi.org/10.1063/1.4769353

Aravind SSJ, Ramaprabhu S (2013) Graphene-multiwalled carbon nanotube-based nanofluids for improved heat dissipation. RSC Adv 3(13):4199–4206. https://doi.org/10.1039/c3ra22653k

Mehrali M et al (2015) Effect of specific surface area on convective heat transfer of graphene nanoplatelet aqueous nanofluids. Exp Therm Fluid Sci 68:100–108. https://doi.org/10.1016/j.expthermflusci.2015.03.012

Agromayor R, Cabaleiro D, Pardinas AA, Vallejo JP, Fernandez-Seara J, Lugo L (2016) Heat transfer performance of functionalized graphene nanoplatelet aqueous nanofluids. Materials. https://doi.org/10.3390/ma9060455

Askari S, Koolivand H, Pourkhalil M, Lotfi R, Rashidi A (2017) Investigation of Fe3O4/Graphene nanohybrid heat transfer properties: experimental approach. Int Commun Heat Mass Transf 87:30–39. https://doi.org/10.1016/j.icheatmasstransfer.2017.06.012

Askari S, Lotfi R, Rashidi AM, Koolivand H, Koolivand-Salooki M (2016) Rheological and thermophysical properties of ultra-stable kerosene-based Fe3O4/Graphene nanofluids for energy conservation. Energy Convers Manag 128:134–144. https://doi.org/10.1016/j.enconman.2016.09.037

Sadri R et al (2017) Study of environmentally friendly and facile functionalization of graphene nanoplatelet and its application in convective heat transfer. Energy Convers Manag 150:26–36. https://doi.org/10.1016/j.enconman.2017.07.036

Baby TT, Sundara R (2013) Synthesis of silver nanoparticle decorated multiwalled carbon nanotubes-graphene mixture and its heat transfer studies in nanofluid. AIP Adv. https://doi.org/10.1063/1.4789404

Salem M, Meakhail T, Bassily M, Torii S (2016) Thermal transport phenomena of graphene oxide nanofluids in turbulent pipe flow. Adv Exp Mech 1:30–35. https://doi.org/10.11395/aem.1.0_30

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there is no conflict of interest to declare for this publication.

Additional information

Technical Editor: Ahmad Arabkoohsar.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gupta, R.M., Mohite, A. & Patel, B. Potential application of graphene-based nanofluid for improving heat transfer characteristics: a review. J Braz. Soc. Mech. Sci. Eng. 46, 464 (2024). https://doi.org/10.1007/s40430-024-05036-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-024-05036-0