Abstract

The present study explores the application of rapid prototyping (RP) for manufacturing tool electrodes in electro-discharge machining process. The performance of a metallic electrode built via selective laser sintering is compared to solid copper and brass tools during machining of D2 tool steel. In order to efficiently evaluate the influence of several parameters, Taguchi’s L18 design is adopted to plan the experimental layout. The machining parameters considered in this study are tool type, a categorical parameter and three quantitative parameters such as duty cycle, pulse-on-time and peak current. Multiple performance measures such as material removal rate, tool wear rate, surface roughness and radial over cut of the machined cavity are considered. The multiple performance responses are converted into an equivalent single response known as grey relational grade using grey relational analysis. A nonlinear regression model is developed to relate grey relational grade with process parameters with a coefficient of determination of 0.97. In order to obtain optimal parameter settings satisfying the performance measures, three meta-heuristic algorithms are used due to their computational elegance. The comparative study indicates that particle swarm optimization and simple optimization are effective in delivering the optimized results in substantially less time compared to teaching-learning-based optimization algorithms. It is found that RP tool can perform in a superior manner for simultaneous optimization of multiple responses when compared to copper and brass tools.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Electro-discharge machining (EDM), a widely used nonconventional machining process, works on the principle of converting electrical energy into thermal energy to machine electrically conductive materials regardless of their hardness. One of the important features of EDM is that no contact between the tool and work piece occurs during machining, which causes the elimination of mechanical stresses, chatter and vibration [1]. EDM finds widespread applications in aerospace, automotive, biomedical and die and mould making industries. In this machining process, exact replicas of the tool can be reproduced on the work piece, but the cost for producing the tools themselves can be very high in both time and resources. In order to manufacture complex parts by EDM, a similar complex shaped tool is required; the more complex the needed part, the higher the cost of manufacturing. Technological advancement in the field of rapid prototyping (RP) processes can be effectively exploited to reduce the manufacturing lead time and production cost of the tools [2].

Attempts have been made to develop EDM tooling using stereo-lithography (SL) parts and fused deposition modelling (FDM) [2,3,4,5,6]. However, the tools produced by such processes are made of polymeric material that needs further processing to make the tool conductive providing a metallic layer or thick coating. Unfortunately, this coating or thin metal layer may be unreliable during EDM given the electrical load involved. Therefore, EDM tool manufactured by selective laser sintering (SLS) method from metal powder offers interesting opportunities in this area due to reduced tool wear and increased performance [7,8,9]. Similarly, researchers have investigated performance of different composite tools during EDM process [10,11,12,13]. Likewise, researchers have investigated on applications of RP tool in EDM process, where, RP tools have been fabricated by using nonconductive plastics and polymer materials with conductive coating of copper [2, 4,5,6, 14,15,16]. In this study, the performance of a tool made of AlSi10Mg manufactured by SLS is examined and compared to solid copper and brass tools.

Many different (often very hard and tough) materials are commonly processed using EDM. AISI 1040 stainless steel [1, 17, 18], nickel–chromium alloy steel (304 stainless steel) [19,20,21] and high carbon high chromium (HCHCr) steel like D2 tool steel and D3 tool steel [22,23,24,25] are commonly used materials during the EDM process. D2 tool steel is widely used for mould making, tooling applications, blanking and forming dies, wear resistance applications, etc. Hence, in this work D2 tool steel is an excellent choice as work piece material in the present study to investigate the performance of newly developed tool by RP process.

For effective utilization of resources, machining parameters need to be optimized through application of different optimization techniques. Metaheuristic algorithms for solving optimization problems are becoming popular because these algorithms are effective in solving complex constrained nonlinear optimization problems. Unlike traditional methods, these algorithms do not require that optimization problems should be continuous; this is especially useful when dealing with manufacturing problems as they are often discrete. The only drawback with these algorithms is that they do not guarantee an optimum solution for each application. Therefore, it is advised to use metaheuristic algorithm if traditional method of optimization fails to solve a problem. Researchers have used different optimization techniques like genetic algorithm, particle swarm optimization, simulated annealing algorithms, etc. in different manufacturing processes [26,27,28,29]. The simple optimization algorithm is one such metaheuristic algorithm, which is very simple to implement and fast convergence capability. The algorithm has been effectively applied to solve some design and manufacturing optimization problems, as shown in Refs [30,31,32].

In EDM process, multiple output responses such as rate of material removal, rate of tool wear, roughness of machined surface and radial over cut of the machined cavity are encountered simultaneously. The optimum performance of EDM process requires maximized material removal rate and minimized tool wear rate, surface roughness and radial over cut. To achieve optimum performance, it is necessary to get optimal selection of machining variables with suitable utilization of tool material. In this work, optimum parameter values of an EDM process are obtained using grey relational analysis (GRA)-based simple optimization (SOPT) algorithm. It is a hybrid optimization method in which grey relational analysis is performed to convert the multiple output responses into an equivalent single response known as a grey relational grade (GRG). Finally, the grey relational grade is optimized using SOPT algorithm to get the optimum parametric setting.

2 Materials and methods

The tools used for the experiments on EDM are an AlSi10Mg RP tool prepared by a rapid prototyping process, copper and brass. The work piece material considered for the experiment is D2 tool steel. The dimension of the work piece is 120 × 60 × 10 mm3. For preparing AlSi10Mg RP tool, a rapid prototyping machine (EOSINT M 280, Germany) is used. In this process, powdered particles of Al10SiMg is melted and combined using a high power laser beam to form the 3D tool. By applying turning operation to solid circular rod of copper and brass, copper and brass tools of 12 mm diameter obtained. The experiments are performed on a die sinking EDM machine model Name/Number: ELECTRA EMS/5535 Country: India. Dielectric fluid used for the experiments is commercial grade EDM 30 oil. Each experiment is performed for five minutes. During the EDM experimentation, the parameters considered are types of tools such as AlSi10Mg RP tool, copper and brass tools and machining parameters like duty cycle, pulse-on-time and peak current. The parametric values of the machining parameters with different levels are shown in Table 1.

A design of experiment (DOE) method like Taguchi’s L18 is utilized to conduct the experiments. Here, 1-factor with 2-levels and 3-factors with 3-levels is used as shown in Table 2. The output responses considered are material removal rate (MRR), tool wear rate (TWR), average surface roughness (Ra) and radial over cut (ROC). The MRR and TWR are calculated by using Eq. 1 and 2, respectively.

In this equation \(W_{i}\) is weight of the work piece in grams, before machining.

\(W_{f}\) is weight of the work piece in grams after machining, and.

\(\rho_{w}\) is density of work piece material in g/mm.3

In this equation, \(W_{ti}\) is weight of the tool in grams, before machining.

\(W_{tf}\) is weight of the tool in grams, after machining and.

\(\rho_{t}\) is density of tool material in g/mm.3

In both of these equations, t is time of machining in minutes.

The density of D2 tool steel is 7.7 g/cm3. Similarly, the density of tools is 2.66 g/cm3, 8.96 g/cm3 and 8.56 g/cm3 for RP, copper and brass tools, respectively.

To measure average surface roughness (Ra) of machined surface, Taylor-Hobson make PNEUMO Surtronic 3 + profilometer is used. Surface roughness is measured at three different places of the machined surface and average of them is considered as Ra. Radial over cut (ROC) is the deviation in diameter of the machine cavity and diameter of the tool. It is calculated by using Eq. 3.

where \(D_{o}\) is diameter of cavity formed in the machined surface and \(D_{t}\) is diameter of the tool.

For measuring diameter of cavity in machined surface, optical images of 10 × magnification is taken using an optical microscope of make: SAMSUNG, model: SDC-314B having a least count of 0.001 mm. In the next step, image of cavity is viewed in Image Viewer App of MATLAB R2017a, and its diameter is measured through the App. The image of cavity diameter is measured at four different places and average of these is considered as diameter of cavity in machined surface. For each experiment, output responses are calculated and presented in the Table 2.

3 Results and discussion

Machining of high-carbon high-chromium steel is performed on EDM using tool made of ASi10Mg manufactured by rapid prototyping process and conventional copper and brass tools. The effect of input parameters on the output responses are explained in details as follows.

The influence of three machining parameters and one selected tool on MRR is shown in Fig. 1. The figure depicts that increase in duty cycle and peak current causes increase in MRR. This is due to the increase in spark energy with increase in duty cycle and peak current. Effect of pulse-on-time shows increase in MRR up to a certain level; however, further increase in pulse-on-time after level 2 (200 µs) MRR gets decreased. It is due to deposition of removed material on the machined surface with increase in pulse-on-time. Out of the three tools, use of copper tool provides highest MRR followed by RP tool and brass tool. Due to higher electrical conductivity of copper as compared to other tools, spark energy generated by the use of copper tool is more causing higher MRR.

The influence of the input parameters and tool type on TWR is shown in Fig. 2. Effect of peak current and pulse-on-time on TWR is similar in both cases, i.e. TWR increases with increase in peak current as well as pulse-on-time. It is due to fact that increase in spark energy with increase in any of the two parameters. However, increase in duty cycle causes spark energy to increase. But, TWR decreases with increase in duty cycle due to the formation of carbon layers on the surface of tools. The melting point of copper is more as compared to other tools. Hence, TWR of copper tool is lower followed by RP and brass tools.

The influence of the input parameters and tool type on Ra is shown in Fig. 3. It is observed that increase in parameters—duty cycle and peak current, surface roughness increases. It is due to the reason that increase in these two parameters causes increased spark energy which in turn result in increased material removal with larger size of crater. Hence, Ra increases with increase in duty cycle and peak current. A similar trend is observed with the parameter pulse-on-time, i.e. material removal rate first increases and then decreases with increase in pulse-on-time. Similarly, surface roughness also increases and then decreases with increase in pulse-on-time. RP tool shows lowest Ra followed by brass and copper tools.

The influence of the input parameters and tool type on ROC is shown in Fig. 4. With increase in peak current, ROC increases. However, increase in duty cycle and pulse-on-time causes ROC to decrease. The copper tool shows lower value of ROC followed by RP tool. However, brass tool has shown higher ROC.

4 Optimization of EDM process

In EDM process, multiple performance measures need to be satisfied simultaneously so that parts produced by such process can be seamlessly applied in practice. Therefore, it is intended to maximize MRR but TWR, Ra and ROC are minimized at the same time. From the main effect plots of output responses (Figs. 1–4), it is found that the effect of machining parameters on different output responses is different. It is generally found that improvement in one output response may lead to degradation of other output responses. To study this type of multi-response optimization problem, a multi-response optimization method like grey relational analysis (GRA) can be useful. The GRA method is already used for optimization of the manufacturing processes like turning, EDM, wire-EDM, micro machining, electro-chemical drilling, etc. [25, 33,34,35,36,37,38,39,40,41,42]. Therefore, the GRA method is used to convert all the output responses into a single response. The different steps involved to perform GRA are described as follows [37, 40,41,42].

4.1 Grey relational analysis (GRA)

The procedure of GRA process is explained in details as follows.

1. Normalize the output responses

where, Yij is normalize out response, yij is observed output response,\(y_{j}^{\max }\) is maximum value of output response and \(y_{j}^{\min }\) is minimum value of output response. For the machining operation higher value of material removal rate is expected with smaller values of tool wear rate, surface roughness and radial overcut. Therefore, in case of MRR higher the better criterion is chosen while for other three responses smaller the better criterion is chosen. Calculate the grey relational coefficient (\(\gamma_{ij}\))

where, \(\Delta_{ij}\) is the deviation sequence and \(\xi\) is the distinguishing coefficient.

The calculated deviation sequence is presented in Table 3 and calculated grey relational coefficient is presented in Table 4.

2. Calculate the grey relational grade (GRGi)

where, \(w_{j}\) is weighting value of output responses and for this study it is considered as 0.25 for each output responses. The grey relational grade is calculated and presented in Table 4.

The grey relational grade (GRG) as presented in Table 4 is used to generate the objective function. The objective function is generated by a statistical software (Systat 13) with coefficient of determination (R2) value of 97.3% and presented in Eq. 8.

Three meta-heuristic optimization algorithms like simple optimization (SOPT), particle swarm optimization (PSO) and teaching-learning-based optimization (TLBO) algorithms are used to find out the optimum parametric settings. All these algorithms start with some randomly generated solutions. These solutions move in a well-defined manner within the search space and in due course expected to reach the best possible solution.

4.2 Simple optimization (SOPT)

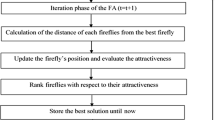

Simple optimization algorithm (SOPT) is a meta-heuristic algorithm, which is easy to understand and can easily be coded in programming language like MATLAB to obtain the optimum value of an objective function [30,31,32]. In the first step of algorithm, a set of solutions generated randomly, and solutions are sorted best to worst in the set. After sorting of solutions, two new solutions are generated in each iteration according to the Eq. 9 and 10, respectively.

In the Eq. (9) and (10), the ith parameter of new solution is calculated based on the ith parameter of best available solution in the set and two control parameters c1 and c2 along with Ri. The value of c1 is set between 1 to 2 and c2 will take half of the value of c1. Ri is a random number, which is normally distributed with mean zero and standard deviation σi the standard deviation of ith parameter of all the members in the solution set. The new solutions are compared with the worst solutions of the set and if any of these new solutions is better than the worst solution of the set then replace the worst solution by the new one. This process of generating new solutions and comparing them with worst solutions of the set and replacing the worst solution if required is continued till the maximum number of iterations is not completed. In this experiment, maximum number of iterations is set to 30 iterations. Optimum solution is expected to be obtained within this number of iterations. The flowchart of the SOPT algorithm is shown in Fig. 5.

4.3 Particle swarm optimization (PSO)

In PSO, randomly generated initial solutions are termed as particles. These solutions are updated in each iteration using two simple mathematical formulae (Eq. 11, and 12). Equation (11) represents the position and Eq. (12) represents velocity of the particle. Updating of the solution is governed by the two best solutions achieved so far known as pBest (\(\vec{p}\)), which is the best known solution obtained by an individual particle and gBest (\(\vec{g}\)), which is the best solution obtained by the entire swarm [43,44,45].

Here, ω represents the inertia weight, which is used to control the magnitude of the previous velocity while calculating the new velocity whereas φp and φg determine the significance of \(\vec{p}\) and \(\vec{g}\), respectively, rp and rg are the random numbers generated in the range [0,1]. The flowchart of the PSO algorithm is shown in Fig. 6.

4.4 Teaching–learning-based optimization (TLBO)

In TLBO algorithm, best solution from the randomly generated solutions is termed as teacher and other solutions are termed students. In the teacher phase of algorithm, teacher guides the students to be more knowledgeable. This is done by changing the decision variables of each solution (student) in the set based on the value of decision variables of best solution (teacher) [46, 47]. Equation 13 is used for this purpose.

where, xnew, xold are vectors of new and old decision variables, Diff is the vector of Differnce_mean values, which is calculated by the Eq. 14

Here, n represents the number of decision variables, ri is a random number in the range [0,1], xi,best is the ith parameter of best solution that is teacher, TF is a factor that control the quantity of change in mean (it can be assigned a value of either 1 or 2 randomly) and Mi is the mean of all ith variable of population set. If the new solution so obtained is better than the old one then old solution will be replaced by the new one. This is to be done for all the solutions of population in each iteration. In learner phase, students increase their knowledge not only from the input from teacher but also from interactions between themselves. In this phase, each solution (student) is compared with the randomly selected another solution of the population. Let the solution xa is compared by randomly selected another solution xb and if f(xa) better than f(xb) use Eq. 15 otherwise use Eq. 16 to calculate new solution

In this phase also if new solution is better, then old solution is replaced by the new one. This phase is repeated for all the solutions in population. These two phases are continuously applied in each iteration till the termination criterion, which is normally taken as maximum number of iterations is not reached. The flowchart of the TLBO algorithm is shown in Fig. 7.

4.5 Optimization by different optimization algorithms

In these algorithms, control parameters greatly influence the quality of solutions and the time to reach those solutions. Therefore, these parameters are set according to the previously reported values to obtain best results in less time [43, 46]. Population size of 50 is taken in all the algorithms. In PSO, the values of φp and φg in Eq. 11 are set to 1.8. Inertia weight ω is taken as 0.6. Only setting required in TLBO is size of initial population, which is taken as 50.

The SOPT, PSO and TLBO algorithms are coded and executed in MATLAB (version: 2017a). During the execution of the algorithms the tool are considered as 1 for AlSi10Mg RP tool, 2 for copper tool and 3 for brass tool. The optimum parametric setting for maximization of grey relational grade (GRG) is presented in Table 5 with optimum GRG for different optimization algorithms. The convergence curves for the SOPT, PSO and TLBO algorithms are shown in Fig. 8. Optimum value is obtained by PSO and SOPT before 30 iterations while TLBO algorithm is unable to get the optimum value within 30 iterations. Comparing PSO with SOPT both reaches to optimum value within 15 iterations. However, by this time, objective function is evaluated about 750 times by PSO and about 70 times by SOPT. It indicates that SOPT algorithm is able to obtain optimum solution of this type of problem with less computational effort.

By use of this parametric setting presented in Table 5, the optimum machining performance of EDM process can be achieved considering MRR, TWR, Ra and ROC together.

4.6 Experimental validation

Experimental validation has been performed to validate the predicted values and experimental values of the output responses at the optimum parametric setting obtain by SOPT algorithm. The detail of the validation result obtained is presented in Table 6. The error between experimental value and predicted value of MRR, TWR, Ra and ROC are 1.22%, 5.21%, 1.45 and 0.79%, respectively.

5 Conclusion

The experiment on EDM is conducted using different types of tools and high-carbon high-chromium steel (D2 tool steel) as the work piece. The performance of the newly prepared RP tool is studied in comparison with commonly used tools like copper and brass. Four machining performances like MRR, TWR, Ra and ROC are considered in this work and are simultaneously optimized using grey relational analysis and simple optimization algorithm. Here, all the four machining performances are converted into a single performance, i.e. grey relational grade and simultaneously optimized by three different metaheuristic algorithms. The following conclusions can be drawn from the present study.

-

1.

Comparison of three different metaheuristic optimization algorithms used to solve the present problem on EDM indicates that SOPT and PSO algorithms are quite efficient in obtaining optimum parametric setting with less computational effort and cost.

-

2.

The SOPT algorithm is not only a simple algorithm but also efficient because it possesses only one effective controlling parameter making it very easy in tuning the algorithmic parameters and also incorporates both exploration and exploitation strategies.

-

3.

It has been observed that SOPT algorithm needs fewer function evaluations compared to other well-known meta-heuristic algorithms in obtaining near optimum solution.

-

4.

As far as the performance of the tools is concerned, copper tool produces highest MRR followed by RP tool and brass tool. Similarly, TWR obtained with copper tool is comparatively lower. However, TWR of the brass tool is highest among the three tools. The copper tool shows lower value of ROC followed by RP tool and brass tool.

-

5.

The RP tool shows lowest Ra followed by brass and copper tools because of removal of small amount of material from the machining cavity in each discharge in case of use of RP tool.

-

6.

Considering all four output responses simultaneously, the RP tool has shown better machining characteristics as compared to other tools.

-

7.

RP process is one of the most effective processes to produce any complex shaped tool for producing complex parts by EDM process so as to reduce the time of machining and cost of production of final parts.

References

Gülcan O, Uslan İ, Usta Y, Çoğun C (2016) Performance and surface alloying characteristics of Cu–Cr and Cu–Mo powder metal tool electrodes in electrical discharge machining. Mach Sci Technol 20:523–546. https://doi.org/10.1080/10910344.2016.1191031

Arthur A, Dickens PM, Cobb RC (1996) Using rapid prototyping to produce electrical discharge machining electrodes. Rapid Prototyp J 2:4–12

Dimla DE, Hopkinson N, Rothe H (2004) Investigation of complex rapid EDM electrodes for rapid tooling applications. Int J Adv Manuf Technol 23:249–255. https://doi.org/10.1007/s00170-003-1709-8

Padhi SK, Mahappatra SS, Das HC (2017) Performance of a Copper Electroplated Plastic Electrical Discharge Machining Electrode Compared to a Copper Electrode. Int J Pure Appl Math 114:459–469

Padhi SK, Mahapatra SS, Padhi R, Das HC (2018) Performance analysis of a thick copper-electroplated FDM ABS plastic rapid tool EDM electrode. Adv Manuf 6:442–456. https://doi.org/10.1007/s40436-018-0238-5

Equbal A, Equbal MI, Sood AK (2019) An investigation on the feasibility of fused deposition modelling process in EDM electrode manufacturing. CIRP J Manuf Sci Technol 26:10–25. https://doi.org/10.1016/j.cirpj.2019.07.001

Zhao J, Li Y, Zhang J, Yu C, Zhang Y (2003) Analysis of the wear characteristics of an EDM electrode made by selective laser sintering. J Mater Process Technol 138:475–478. https://doi.org/10.1016/S0924-0136(03)00122-5

Czelusniak T, Amorim FL, Lohrengel A, Higa CF (2014) Development and application of copper-nickel zirconium diboride as EDM electrodes manufactured by selective laser sintering. Int J Adv Manuf Technol 72:905–917. https://doi.org/10.1007/s00170-014-5728-4

Czelusniak T, Amorim FL, Higa CF, Lohrengel A (2014) Development and application of new composite materials as EDM electrodes manufactured via selective laser sintering. Int J Adv Manuf Technol 72:1503–1512. https://doi.org/10.1007/s00170-014-5765-z

Rizvi SAH, Agarwal S, Singh A, Bhardwaj U, Shukla R (2020) Modeling of Black Layer and Tool Wear in EDM of AISI 4340 using Cu-W electrode. Procedia CIRP 95:389–392

Rao PS, Dora SP, Purnima NS (2021) Influence of WC/Co powder metallurgy electrodes made by micron and nano particles on EDM performance. Met Powder Rep 76:52–58. https://doi.org/10.1016/S0026-0657(21)00304-0

Sivakumar K, Kumar PM, Amarkarthik A, Jegadheeswaran S, Shanmugaprakash R (2021) Empirical modeling of material removal rate and surface roughness of OHNS steel using Cu-TiB2 Tool in EDM. Mater Today Proc 45:2725–2729. https://doi.org/10.1016/j.matpr.2020.11.597

Uddin MP, Majumder A, Deb Barma J, Kumar P (2022) Study of the performance of Cu-Gr composite tool during EDM of AISI 1020 mild steel. Mater Today Proc 62:3886–3890. https://doi.org/10.1016/j.matpr.2022.04.542

Equbal A, Israr Equbal M, Badruddin IA, Algahtani A (2022) A critical insight into the use of FDM for production of EDM electrode. Alexandria Eng J 61:4057–4066. https://doi.org/10.1016/j.aej.2021.09.033

Shaikh MSNM, Ahuja BB (2020) Effects of primary and secondary metallization techniques on the performance of electric discharge machining (EDM) electrode produced by additive manufacturing and composite coating. Mater Today Proc 41:875–885. https://doi.org/10.1016/j.matpr.2020.09.441

Reddy RDP, Sahu AK, Mahapatra SS (2022) Investigation on performance of a copper coated hollow rapid electrode during electrical discharge machining. Sadhana - Acad Proc Eng Sci 47. https://doi.org/10.1007/s12046-022-01947-7.

Kohli A, Wadhwa A, Virmani T, Jain U (2012) Optimization of Material Removal Rate in Electrical Discharge Machining Using Fuzzy Logic. World Acad Sci Eng Technol 72:1674–1679

Özerkan HB (2018) Simultaneous machining and surface alloying of AISI 1040 steel by electrical discharge machining with boron oxide powders. J Mech Sci Technol 32:4357–4364. https://doi.org/10.1007/s12206-018-0834-0

Bhaumik M, Maity K (2017) Effect of machining parameter on the surface roughness of AISI 304 in silicon carbide powder mixed EDM. Decis Sci Lett 6:261–268. https://doi.org/10.5267/j.dsl.2016.12.004

Bhaumik M, Maity K (2018) Experimental investigation and finite element simulation of AISI 304 during electro discharge machining. Int J Model Simulation, Sci Comput 9:1–15. https://doi.org/10.1142/S1793962318500228

Ubaid AM, Dweiri FT, Aghdeab SH, Al-Juboori LA (2018) Optimization of electro discharge machining process parameters with fuzzy logic for stainless steel 304 (ASTM A240). J Manuf Sci Eng Trans ASME 140:1–13. https://doi.org/10.1115/1.4038139

Pradhan MK (2013) Estimating the effect of process parameters on MRR, TWR and radial overcut of EDMed AISI D2 tool steel by RSM and GRA coupled with PCA. Int J Adv Manuf Technol 68:591–605. https://doi.org/10.1007/s00170-013-4780-9

Kumar S, Grover S, Walia RS (2018) Effect of hybrid wire EDM conditions on generation of residual stresses in machining of HCHCr D2 tool steel under ultrasonic vibration. Int J Interact Des Manuf 12:1119–1137. https://doi.org/10.1007/s12008-018-0474-8

Jagadish KS, Soni DL (2021) Performance Analysis and Optimization of Different Electrode Materials and Dielectric Fluids on Machining of High Carbon High Chromium Steel in Electrical Discharge Machining. Proc Natl Acad Sci India Sect A - Phys Sci. https://doi.org/10.1007/s40010-020-00727-4

Majhi SK, Mishra TK, Pradhan MK, Soni H (2014) Effect of machining parameters of AISI D2 Tool steel on Electro discharge machining. Int J Curr Eng Technol 4:19–23

Tayyab M, Ahmad S, Akhtar MJ, Sathikh PM, Singari RM (2022) Prediction of mechanical properties for acrylonitrile-butadiene-styrene parts manufactured by fused deposition modelling using artificial neural network and genetic algorithm. Int J Comput Integr Manuf 00:1–18. https://doi.org/10.1080/0951192X.2022.2104462

Saffaran A, Azadi Moghaddam M, Kolahan F (2020) Optimization of backpropagation neural network-based models in EDM process using particle swarm optimization and simulated annealing algorithms. J Brazilian Soc Mech Sci Eng 42. https://doi.org/10.1007/s40430-019-2149-1.

Pandey AK, Gautam GD (2018) Grey relational analysis-based genetic algorithm optimization of electrical discharge drilling of Nimonic-90 superalloy. J Brazilian Soc Mech Sci Eng 40. https://doi.org/10.1007/s40430-018-1045-4.

Roy A, Sachin B, Raghavendra T, Rao CM, Naik GM, Soni H et al (2022) Optimizing machining responses of homologous TiNiCu shape memory alloys using hybrid ANN-GA approach. Mater Today Proc 62:4402–4410. https://doi.org/10.1016/j.matpr.2022.04.890

Hasancebi O, Kazemzadeh Azad S (2012) An Efficient Metaheuristic Algorithm For Engineering Optimization : SOPT. Int J Optim Civil Eng 2:479–487

Sahu AK, Thomas J, Mahapatra SS (2021) An intelligent approach to optimize the electrical discharge machining of titanium alloy by simple optimization algorithm. Proc Inst Mech Eng Part E J Process Mech Eng 235:371–383. https://doi.org/10.1177/0954408920964685

Thomas J, Sahu AK, Mahapatra SS (2018) Multi-objective optimization of water jet machining process using simple optimization algorithm(SOPT). Mater Today Proc 5:19034–19042. https://doi.org/10.1016/j.matpr.2018.06.255

Majhi SK, Pradhan MK, Soni H (2013) Application of Integrated Rsm-Grey-Entropy Analysis for Optimization of Edm Parameters. Adv Res Mech Eng 4–9.

Soni H, R RM, (2015) Effect of Machining Parameters on Wire Electro Discharge Machining of Shape Memory Alloys Analyzed using Grey Entropy Method. J Mater Sci Mech Eng Issue 2:2393–9095

Soni H, Narendranath S, Ramesh MR (2017) ANN and RSM modeling methods for predicting material removal rate and surface roughness during WEDM of Ti50Ni40Co10 shape memory alloy. Adv Model Anal A 54:435–443

Reddy D, Soni H, Narendranath S (2018) Experimental investigation and optimization of WEDM process parameters for Ti50Ni48Co2 shape memory alloy. Mater Today Proc 5:19063–19072. https://doi.org/10.1016/j.matpr.2018.06.259

Mausam K, Sharma K, Bharadwaj G, Singh RP (2019) Multi-objective optimization design of die-sinking electric discharge machine (EDM) machining parameter for CNT-reinforced carbon fibre nanocomposite using grey relational analysis. J Brazilian Soc Mech Sci Eng 41. https://doi.org/10.1007/s40430-019-1850-4.

Hargovind S, Narendranath S, Ramesh MR (2019) Advanced machining of TiNiCo shape memory alloys for biomedical applications. Emerg Mater Res 8:14–21. https://doi.org/10.1680/jemmr.17.00066

Mashinini PM, Soni H, Gupta K (2020) Investigation on dry machining of stainless steel 316 using textured tungsten carbide tools. Mater Res Express 7. https://doi.org/10.1088/2053-1591/ab5630.

Porwal RK, Yadava V, Ramkumar J (2014) Modelling and multi-response optimization of hole sinking electrical discharge micromachining of titanium alloy thin sheet. J Mech Sci Technol 28:653–661. https://doi.org/10.1007/s12206-013-1129-0

Manikandan N, Kumanan S, Sathiyanarayanan C (2015) Multi response optimization of electrochemical drilling of titanium Ti6Al4V alloy using Taguchi based grey relational analysis. Indian J Eng Mater Sci 22:153–160

Tripathy S, Tripathy DK (2016) Multi-attribute optimization of machining process parameters in powder mixed electro-discharge machining using TOPSIS and grey relational analysis. Eng Sci Technol an Int J 19:62–70. https://doi.org/10.1016/j.jestch.2015.07.010

Eberhart R, Kennedy J (1997) A new optimizer using particle swarm theory. Proc IEEE Symp Micro Mach Hum Sci Nagoys, Japan 39–43.

Bergh FV, Engelbrecht A (2006) A study of particle swarm optimization particle trajectories. Inf Sci (Ny) 176:937–971. https://doi.org/10.1016/j.ins.2005.02.003

Helwig S, Wanka R (2007) Particle swarm optimization in high-dimensional bounded search spaces. Proc 2007 IEEE Swarm Intell Symp SIS 2007 198–205. https://doi.org/10.1109/SIS.2007.368046.

Rao RV, Savsani VJ, Vakharia DP (2012) Teaching–Learning-Based Optimization: An optimization method for continuous non-linear large scale problems. Inf Sci (Ny) 183:1–15. https://doi.org/10.1016/j.ins.2011.08.006

Rao RV, Kalyankar VD (2013) Multi-pass turning process parameter optimization using teaching–learning-based optimization algorithm. Sci Iran. https://doi.org/10.1016/j.scient.2013.01.002

Acknowledgements

Marco Leite would like to acknowledge the support provided by FCT, through IDMEC, under LAETA, Project UIDB/50022/2020. Saurav Goel greatly acknowledges the financial support provided by the UKRI via Grant No. EP/T001100/1 and EP/T024607/1 and Royal Academy of Engineering for assisting with the Grant No. IAPP18-19\295 and TSP1332.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Technical Editor: Adriano Fagali de Souza.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sahu, A.K., Mahapatra, S.S., Thomas, J. et al. Optimization of electro-discharge machining process using rapid tool electrodes via metaheuristic algorithms. J Braz. Soc. Mech. Sci. Eng. 45, 470 (2023). https://doi.org/10.1007/s40430-023-04380-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04380-x