Abstract

Some plants have been reported to have the water-induced shape memory effect (SME). Since the tissue system of most plant leaves is a biophysical sandwich-like structure composed of epidermis, mesophyll and veins, the leaves are actually bio-composites. In this paper, we experimentally investigated the contribution of different tissues to the SME in dried plant leaves (namely, soursop, sugar apple, and longan) and skeleton (i.e., cuticle and lamina removed) leaves (soursop only). Shape recovery in the leave strips, and skeleton soursop leave strips, all programmed (deformed) via rolling and drying, was activated by room temperature water, hot (90 °C) water, or pure heating (up to 230 °C) to uncover the influence of temperature in the SME. Although heating alone does not induce any apparent shape recovery, hot water causes much faster recovery than room temperature water. Besides, same as the influence of the maximum programming strain on the heating-responsive shape recovery in shape memory polymers, less programmed leaves (i.e., with smaller maximum programming strain) tend to recover faster. Together with other tests (including drying, wetting, drying/wetting, cyclic differential scanning calorimetry, etc.), the contributions/roles of different tissues on the phenomena observed in this study are revealed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Biophysically speaking, plants can be treated as a kind of biocomposites. Taking leaves as an example, the major tissue systems in most plant leaves include epidermis, mesophyll, and veins forming a sandwich-like structure (Fig. 1). The epidermis, which separates the plant's inner cells from the external world, is the outer layer of the cells to prevent liquid and vapor from infiltrating. It also serves several additional functions, such as to limit moisture loss in transpiration, to regulate gas exchange, and to secret metabolic compounds. Most of the interior between the upper and lower layers of epidermis is the mesophyll structure, which contains large amount of chlorophyll in cells and hemicellulose in cell walls. Its cellular microstructure ensures oxygen, carbon dioxide, and water vapor to diffuse into and out of leaves during respiration, photosynthesis, and transpiration. The veins in the spongy layer of the mesophyll are the vascular tissue of leaves and can be regarded as the skeleton of a leaf. Most cellulose is in the veins to form the fibers of vascular bundles. The core of each vascular bundle is a cluster of two different types of conductive cells, xylem which brings water and minerals from the roots into leaves and phloem which usually moves sap and dissolved sucrose (glucose to sucrose) produced by photosynthesis in and out of leaves.

Reproduced from https://en.wikipedia.org/wiki/File:Leaf_Structure.svg)

Medium-scale features of leaf (

Shape memory effect (SME) refers to the phenomenon that a piece of pre-deformed material is able to recover its original shape, but only at the presence of the right stimulus (Otsuka and Wayman 1999; Huang et al. 2010). Materials with the SME are known as the shape memory materials (SMMs). For engineering applications, polymers are much easier to be tailored to have the required properties than many other types of materials (Yakacki et al. 2008; Xie and Rousseau 2009; Sun et al. 2012; Dai et al. 2020). Therefore, numbers of shape memory polymers (SMPs) have been developed for various engineering purposes, such as biomedical engineering (Lendlein and Langer 2002; Cabanlit et al. 2007; Chen et al. 2009; Wischke and Lendlein 2010), textile engineering (Cho et al. 2004; Mondal and Hu 2007; Chenal et al. 2014), surface patterning (Liu et al. 2007; Zhao et al. 2011, 2012) and aerospace engineering (Sokolowski and Tan 2007). Cellulose, as a type of biopolymer that exists abundantly in plants, has also been found to have the water-responsive SME (Mendez et al. 2011; Han et al. 2012; Song et al. 2018). Its shape recovery is due to remarkable decrease in the glass transition temperature upon water absorption (Kelley et al. 1987; Szcześniak et al. 2008; Antoniow et al. 2012; Kulasinski 2017). Based on this feature, cellulose nanofibers have been blended with a polyurethane to produce shape memory composites, which can be programmed (i.e., to fix the temporary shape) and then shape-recovered via wetting–drying–wetting cycling (Luo et al. 2012). Furthermore, as reported in (Zhu et al. 2012), water-induced shape recovery (within 10 min) can be achieved in a cellulose/elastomer nanocomposite, in which the deformed elastic part, namely thermoplastic polyurethane, provides the elastic energy for shape recovery and cellulose nanowhiskers serve as the transition part to alter the stiffness in a wetting–drying–wetting cycle. It has been found that artificial cellulose foam has rapid water-responsive SME (within seconds for full shape recovery), while it’s heat-responsive SME is not apparent (Huang 2019).

As the chief constituent of the cell walls of plant leaves, cellulose performs a structural or skeletal function. Hence, it is expected that plants also have the water-responsive SME. In (Plaza et al. 2013), the water-responsive SME in loblolly pine (Pinus taeda) was investigated via atomic force microscopy. The observed high recovery force was suggested to be utilized for torsional actuation. However, the influence of temperature in the shape recovery has yet been revealed so far. Moreover, since there are several different types of tissues with different properties in plant leaves, each of them is supposed to impact particularly the SME of plant leaves, whereas their individual contributions to the SME remain unclear currently.

The objectives of this paper are twofold: One is to investigate the influence of different tissues on the shape memory performance of plant leaves. The other one is to reveal the effects of room temperature water, hot water and pure heating on the shape recovery. Three types of local plant leaves, namely soursop, sugar apple, and longan in Singapore, are used in this study. In addition, vein skeleton leaves of soursop are also prepared for comparison. Through a series of experiments, the contribution of different tissues to the temperature-sensitive SME of plant leaves is identified.

2 Materials and methods

2.1 Material/sample preparation

Three types of leaves from local plants in Singapore that are morphologically similar in their biostructures but slightly different in their exterior shapes, namely soursop (Annona muricata L.), sugar apple (Annona squamosa L.), and longan (Dimocarpus longan Lour.), were used for investigation to ensure good representative experimental results. Figure 2a shows the fresh leaves of all these three types just picked from local trees. They were reasonably flat.

a Fresh leaves without any treatment. Left: soursop; middle: sugar apple; right: longan. (Size: 120 to 140 mm in length, and 30 mm to 40 mm in width); b typical leaf strips (left) and skeleton leaf strips (right); c illustration of experimental process to study the SME activated by room temperature water, hot water (90 °C), or pure-heating to 100 °C and then to 230 °C; d experimental setup for water-responsive SME tests; e acrylic container (with water inside) and rolled sample fixed inside by a holder

In order to investigate the SME in the veins, some soursop leaves were firstly boiled in a solution of water (90% wt) and washing soda (“Super Washing Soda” from ARM and HAMMER™, USA) (10% wt) for two hours. After being rinsed with room temperature water for 10 s and then brushed gently using a soft toothbrush to remove cuticle and lamina (including epidermis and mesophyll), the remaining was vein skeleton (i.e., vascular bundle tissue, including midvein, i.e., primary vein, and secondary vein), which contains mostly cellulose. Such leaves are called skeleton leaf herein. Leaf strips and skeleton leaf strips of about 57 mm × 20 mm in size (Fig. 2b) were prepared by cutting from the fresh leaves and skeleton leaves, respectively.

Drying/wetting tests –

Referring to Fig. S1 in the Supplemental Material 3, the leaves are considered fully dried after three days. Therefore, in the following drying/wetting test, fresh leave strips were firstly dried in the dry cabinet for three days. Subsequently, they were immersed in room temperature water to observe their shape changes.

One piece of dried soursop leaf strip was wetted in room temperature water. Its weight was recorded after immersing for 0, 0.5, 1, and 2 h. The corresponding weight increase ratio, Ri’, was obtained using the following formula:

where w0′ and wi′ are the initial weight and weight at minute i, respectively.

Differential scanning calorimetry tests –

A series of differential scanning calorimetry (DSC) tests were carried out using a DSC 214 machine from NETZSCH Group, Germany, on small sized soursop samples (9 mm long and 7 mm wide) cut out from a piece of dried soursop leaf strip. Five thermal cycles (all from 0 °C to 40 °C, 80 °C, 100 °C, 140 °C, and 200 °C in ascending order, respectively) were conducted at a constant ramping rate of 10 °C /min. One dry and three wet (rehydrated) samples, which have been pre-immersed in room temperature water for 0.5, 1 and 2 h, respectively, were tested.

Water-responsive shape memory effect –

Four types of strips including soursop, sugar apple, longan, and skeleton soursop (four pieces of each type) were prepared and then used to study the water-responsive SME.

A typical shape memory cycle includes two processes, namely programming and recovery (Wu et al. 2013). As illustrated in Fig. 2c, in this study, in the programming process, a piece of flat strip was rolled around a circular shaft with a diameter of 8 mm or 12 mm and then fixed to the shaft with tape. Subsequently, it was placed in the dry cabinet for three days to dry. After the removal of the tape, a piece of rolled sample with a diameter of about 8 mm or 12 mm was obtained. In the next recovery process, the programmed sample was immersed in room temperature water or hot water (around 90 °C).

The experimental setup to record the shape recovery in the rolled strips is presented in Fig. 2d. A piece of programmed (rolled) strip was fixed to a holder inside the acrylic container and water (room temperature or 90 °C) was added into the container. The computer-controlled camera captured the image of the tested strip at a predetermined interval. From the moment that the strip was fully immersed in water, the camera started to capture images of the strip every 15 s for a duration of 120 min for room temperature water or every 1 s for a duration of 3 min for 90 °C water. Every 40th image (a total of 12 images) for room temperature water test or every 15th image (totally 12 images) for 90 °C water test was extracted out for processing to determine the shape recovery ratio as a function of time.

The shape recovery ratio (SRR) may be defined in two ways based on the rotation angle (Θi) (refer to Fig. 2e) or curvature (Ki), where subscript i is meant for a particular time when the image was taken. Taking Fig. 2e for instance, a circle that best represents the rolled strip was firstly created using AutoCAD Mechanical and two radial lines (white lines in Fig. 2e) that indicate the start (where the strip was fixed onto the leaf holder) and end points of the strip were subsequently drawn. The clockwise angle between the start and end lines, and the diameter (Ø) of the circle were then obtained. Both strips rolled around the 8 mm and 12 mm shafts were found to be less than two rounds on the holder. Hence, in order to determine ϑ (accumulated angle when the strip was rolled around the shaft), the clockwise angle plotted (e.g., 110° in Fig. 2e) was subtracted from 720° (e.g., ϑ = 720°—110° = 610°). Thus, SRR (Θi) is defined as,

where ϑ0 is the initial accumulated angle and ϑi is the accumulated angle at interval i.

Diameter (Øi) at each interval was converted to curvature (ki) by,

The SRR (Ki) at each interval was worked out according to,

where k0 is the initial curvature and ki is the curvature at interval i.

Referring to Fig. S2 in the Supplemental Material 3, minor difference was found between SRR (Θi) and SRR (Ki), and hence in this study, only SRR (Θi) was used hereinafter to indicate the shape recovery.

Heating-induced shape recovery –

To identify the actual influence of pure heating on shape recovery, instead of using 90 °C hot water (Fig. 2c), two leaf strips of each type of non-skeleton leaves were programmed using 8-mm and 12-mm-diameter shafts, respectively, following the programming process mentioned in Sect. 2.4. Subsequently, one batch of them were heated in an oven at 100 °C for three minutes and then further heated at 100 °C for one hour.

As reported in (Plaza et al. 2013), the glass transition temperatures, Tgs, of hemicellulose and lignin under dry condition are around 150 to 220 °C and 130 to 200 °C, respectively. Water acts as a plasticizer to reduce their Tgs. Lignin at water saturated condition has a Tg of about 70 °C, whereas for hemicellulose, its Tg falls below room temperature at about 60 to 80% relative humidity. Hence, the other batch were heated in the oven from room temperature to 230 °C.

The number of leaf samples used in each test is summarized in Table 1. In the drying/wetting test, one non-skeleton leaf sample of each type was used to observe the shape change phenomenon and one extra soursop sample was tested to reveal the weight change along with immersion time. For the DSC test, four soursop samples were tested including one dry and three wetted, which were pre-immersed in room temperature water for 0.5, 1 and 2 h, respectively. For the water-responsive SME test, two different sized shafts (8 mm and 12 mm) were used for rolling and two water temperatures (room temperature and 90 °C) were applied. Four samples of each type of leaves were used. Similarly, in the heating induced shape recovery test, there were two shaft diameters (8 mm and 12 mm) and two heating temperatures (100 °C and 230 °C), resulting in four samples of each type of non-skeleton leaves.

3 Results

Drying/wetting-induced shape change –

As revealed in Fig. 1, a typical plant leaf consists of several different types of tissues. Therefore, upon drying, leaf curls (Fig. 3a) due to the difference in shrinkage ratio among different tissues. It appeared that the veins shrank relatively less. In terms of the overall dimensions, sugar apple and soursop strips appeared to become apparently shorter in length, while longan strip seemingly did not shorten too much.

a Leaf strips after drying. (Left: soursop; middle: sugar apple; right: longan); b soursop (i), sugar apple (ii), and longan (iii) leaf strips immersed in room temperature water after 1st hour (1), 2nd hour (2), 3rd hour (3), 5th hour (4), 7th hour (5), 9th hour (6), 11th hour (7); c soursop, sugar apple, and longan leaf strips upon immersing in room temperature water for 11 h

After drying, all leaf strips were immersed into room temperature water and the evolution of their shapes are presented in Fig. 3b. All leaf strips were observed to be able to recover their original flat shape in water. However, sugar apple leaf recovered most slowly as the whole process took around 11 h, while only 5 h were required for soursop and longan leaves to recover in room temperature water.

A closer look at all three leaf strips after immersing in water for 11 h is shown in Fig. 3c. As we can see, approximately all of them recovered their original sizes (57 mm long and 20 mm wide). As the mesophyll cells irreversibly lose turgor pressure upon drying, such drying/wetting induced shape change phenomenon is then resulted from the typical deswelling/swelling of the cell walls in mesophyll (Lee and Bowling 1993).

The weight increase ratio of a dried soursop leaf strip upon immersing into room temperature water is plotted in Fig. 4. It appears that the weight increase ratio is not a linear function of immersion time. It gradually decreases within 120 min of immersion.

Results of differential scanning calorimetry –

DSC results of small sized soursop samples (9 mm long and 7 mm wide) cut out from a piece of dried soursop leaf strip are presented in Fig. 5, in which (a) is the dried sample, while (b), (c) and (d) are the results of dried samples upon immersing in room temperature water for 0.5 h, 1 h and 2 h, respectively.

As we can see, for each individual sample, their DSC curve in the 2nd heating process (heated to 80 °C) is only slightly different from that in the 1st heating process (heated to 40 °C). In the subsequent three cycles (cycles 3 to 5), the DSC curves are very close, but are apparently different from those in the first two cycles (cycles 1 and 2).

The DSC curves of the dried sample (a) in the 1st thermal cycle and the heating part of the 2nd thermal cycle are remarkably different from those of the rehydrated samples (b, c and d). While all rehydrated samples are featured by a peak at around 65 °C in the heating process of the 2nd thermal cycle, which is seemingly missing in the dried sample, the DSC results of all rehydrated samples are essentially the same. This finding indicates that 30 min of immersion is seemingly sufficient to completely change the thermal property of leaves, although according to Fig. 4, weight increase continued upon further immersion. Therefore, we may conclude that the absorbed water in plant leaves may be divided into two portions: One can be revealed by DSC test and is absorbed rapidly within 30 min, while the other cannot be spotted by the DSC test and increases gradually and continuously over a much longer period of time.

It is also observed that even in the dried sample, upon cyclic heating, the DSC curves in the heating process continuously flatten, which should be associated with further drying upon heating. Apparently, in all samples, heating to 80 °C induces remarkable change in the DSC curve in the next heating process.

Water-responsive shape memory effect –

Programmed leaf strips are presented in Fig. 6. Refer to Table 2 for the abbreviations for the types of strips. The diameters of the rolled strips are mostly slightly larger than that of the shaft used in programming.

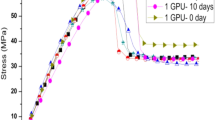

The evolution of SRR (Θi) as a function of immersion time of all rolled strips is plotted together in Fig. 7a for room temperature water test and Fig. 7b for hot water test, respectively. Refer to Supplementary Material 1 and Supplementary Material 2 for video clips of room temperature water test and hot water test, respectively.

Comparing Fig. 7a (room temperature water) and Fig. 7b (90 °C water), it is apparent that the recovery is much faster in hot water for all strips. While soursop skeleton strips always recover faster than all leaf strips, different leaf strips have different recovery speeds, which is as expected.

Additionally, as we can see, shape recovery in soursop skeleton strips always has two phases. Most of the recovery occurs in the 1st phase, which is rapid (the initial 20 min and 0.5 min in room temperature and hot water, respectively). In the 2nd phase, recovery is much slower and much less. Although the actual recovery speed is higher in hot water, there is no apparent difference in the final shape recovery ratio in soursop skeleton strips tested. Either in room temperature water or in hot water, it is all about 80%, which is the highest when compared with all leaf strips within the same maximum immersion time. Although Fig. 3b, c confirm that without programming, the dried leaf strips are able to slowly recover their original shape in room temperature water, it appears that shape recovery in programmed (rolled) strips is reduced.

Except longan leaf strips, all other strips programmed using 12-mm-diameter shaft recover faster than those programmed using 8-mm-diameter shaft. Since the maximum programming strain in a strip programmed using a larger sized shaft is smaller, the underlying mechanism for the influence of shaft diameter used in programming should be similar to that in heating-responsive SMPs reported in (Huang et al. 2012), i.e., SMPs programmed with a smaller programming strain recover faster upon heating.

Shape recovery under pure-heating –

The rolled leaf strips upon heating at 100 °C is revealed in Fig. 8. A Singapore coin (10 cents, 18.50 mm in diameter) was placed underneath each rolled strip. Slight diametral expansion is only found in the longan leaf strip programmed using 12-mm-diameter shaft upon heating for three minutes.

Comparison of rolled leaf strips (top row), after heating to 100 °C for three minutes (middle row) and after further heating for 1 h (bottom row). a Programmed using 8-mm-diameter shaft; and b programmed using 12-mm-diameter shaft. A 10 cents Singapore coin was placed underneath each rolled strip as reference

The other batch of rolled leaf strips were heated from room temperature to 230 °C. As shown in Fig. 9, again only limited expansion is observed in both rolled longan leaf strips.

At this point, we may conclude that heat is not an effective way to trigger shape recovery in rolled strips even upon heating to 230 °C.

4 Discussion

Although plant leaves are biopolymers, as “no two leaves are alike,” it is expected that even leaves from the same tree, their experimental results may vary quite a lot.

Since there are several different types of tissues in leaves (Fig. 1), we should consider plant leaves as natural shape memory composites and roughly divide these tissues into three types according to their specific impact to shape recovery. The first type is the rapid water-responsive shape memory part (e.g., veins), which is mostly made up of cellulose, and has the capability for rapid water absorption (enhanced by the vascular network). The second one is the coating layers (e.g., epidermis), which control the water absorption rate of the entire leaf. The last type is the water-responsive swelling part (e.g., mesophyll) including large amount of chlorophyll and hemicellulose that gradually absorb water upon immersing in room temperature water.

Based on the results of above experiments, the water-content-dependent response of plant leaves can be schematically sketched as shown in Fig. 10.

As shown in Fig. 10, (B) represents a piece of fresh leaf without any treatment. Upon drying, the leaf turns to dehydrated and becomes dry and brittle (A). Because of the difference in the shrinkage ratio among different tissues, leaf curls and most likely the veins shrink relatively less (Fig. 3a). In fact, during drying from (B) to (A), the leaf appears to be listless (softening) and then hardens upon further drying. Such a kind of evolution in stiffness during drying is because in (B) the swelling part (mesophyll, etc.) has enough water and is stiff enough to support the leaf, while in (A) it is the dry cellulose in the veins that is hard enough to hold the leaf against the gravitational force. Between (B) and (A), cellulose is soft due to rehydration, so as the mesophyll. Since the mesophyll cells irreversibly lose the turgor pressure in the status of (A), upon immersing in water (wetting), the rehydration via water absorption and remarkable swelling actually happens in the cell walls of mesophyll so that the leaf is able to return to the shape of (B). Upon further wetting, water absorption continues in both veins and mesophyll, but there is no apparent shape/size difference between (B) and (C). Same as that in making tea, hot water is more effective for rapid water absorption.

While (A) is rather rigid and brittle, (B) and (C) are relatively soft and elastic, and could be programed to, e.g., circular shape (D) by rolling and then drying (Fig. 6). Similar to the hydrogels reported in (Zhang et al. 2014), leaf tissues become brittle and rigid after drying, and are able to largely maintain the programmed shape (D). Upon immersion in water, the veins absorbs water rapidly, as they are made of mostly cellulose (Huang 2019). Consequently, quick shape recovery (around 30 min) from (D) to (C) could be observed in Fig. 7a in skeleton leaves upon immersing in room temperature water. According to the DSC results of small sized wetted soursop leaves after immersing in room temperature water for 30 min in Fig. 5, their nearly identical DSC curves also confirms the quick water absorption in veins enhanced by the vascular network.

The shape recovery in normal (non-skeleton) leaves in room temperature water is much slower due to two major reasons. On the one hand, the water absorption rate in normal leaves is largely reduced because of the coating layers (epidermis). On the other hand, wetting of dried mesophyll is a slow process (takes hours to complete), thus slowly wetted mesophyll temporarily restrains the wetted veins to recover. Therefore, gradual and slow shape recovery (more than 120 min) from (D) to (C) are observed in normal leaves upon immersing in room temperature water (Fig. 7a).

The wax layer that coated on the epidermis is degradable by water at high temperature, so that water absorption is effectively accelerated, especially in epidermis and mesophyll, in hot water, which results in much faster shape recovery in normal leaves (Fig. 7b). Such a kind of difference in water absorption speed in different types of tissues in plant leaves implies that what is revealed in the DSC results (Fig. 5) is only the influence of the veins part.

Most strips programmed with less strain (using 12 mm shaft) recover faster, which is a phenomenon similar to that in the heating-responsive SME in many SMPs (Huang et al. 2012). This feature might be utilized to tailor the recovery speed, especially in leaves upon wetting in room temperature water. Incomplete recovery in programmed (rolled) leaves might be the result of over straining in programming (Huang et al. 2012). Further investigation is required to spot the programming strain limit.

5 Conclusions

Plants leaves are made of different tissues and should be considered as biopolymer composites. It is natural that plant leaves have the SME as most polymers, but their actual shape memory performance may vary quite a lot even for leaves from the same tree, since “No two leaves are alike.”

In this paper, we experimentally investigated the influence of different tissues on the SME in dried plant leaves and skeleton (i.e., cuticle and lamina removed) leaves. The SME in the programmed strips (via rolling and drying) made of plant leaves (soursop, sugar apple and longan) and skeleton leaves (soursop only) was activated by room temperature water, hot (90 °C) water, or pure heating (up to 230 °C).

Additional drying, wetting, and drying/wetting tests were carried out to reveal the weight/morphology change in free-standing leaves. Together with cyclic DSC results of dried and wetted leaves (all soursop), it is concluded that we may divide the tissues in plant leaves into three types. The first type is the rapid water-responsive shape memory part (e.g., veins), which is mostly made up of cellulose, and is able to quickly absorb room temperature water for rapid shape recovery (as observed in skeleton leaves). The second type is the coating layers (e.g., epidermis) that slow down the speed of water absorption. The last is the water-responsive swelling part (e.g., mesophyll) that absorbs room temperature water in a rather gradual manner. While both the latter two slow down the recovery of the programmed dry leaves in room temperature water, the dried mesophyll might be more effective in preventing the already wetted veins from recovering. Water absorption is effectively accelerated, especially in epidermis and mesophyll, in hot water, which results in much faster shape recovery in leaves. However, heating along, even to 230 °C, is not sufficient to induced shape recovery in programmed dry leaves.

Different from free-standing leaves, programmed (via rolling and drying) leaves cannot fully return back to their original shape. Similar to the influence of the maximum programming strain on the heating-responsive shape recovery in SMPs, less programmed leaves (smaller maximum programming strain) tend to recover faster.

References

Antoniow JS, Maigret JE, Jensen C, Trannoy N, Chirtoc M, Beaugrand J (2012) Glass-transition temperature profile measured in a wood cell wall using scanning thermal expansion microscope (SThEM). Int J Thermophys 33:2167–2172

Cabanlit M, Maitland D, Wilson T, Simon S, Wun T, Gershwin ME, van de Water J (2007) Polyurethane shape-memory polymers demonstrate functional biocompatibility in vitro. Macromol Biosci 7:48–55

Chen MC, Chang Y, Liu CT, Lai WY, Peng SF, Hung YW, Tsai HW, Sung HW (2009) The characteristics and in vivo suppression of neointimal formation with sirolimus-eluting polymeric stents. Biomaterials 30:79–88

Chenal TP, Case JC, Paik J, Kramer RK (2014) Variable stiffness fabrics with embedded shape memory materials for wearable applications. IEEE/RSJ International Conference on Intelligent Robots and Systems, pp 2827–2831

Cho JW, Jung YC, Chun BC, Chung Y-C (2004) Water vapor permeability and mechanical properties of fabrics coated with shape-memory polyurethane. J Appl Polym Sci 92:2812–2816

Dai L, Tian CS, Xiao R (2020) Modeling the thermo-mechanical behavior and constrained recovery performance of cold-programmed amorphous shape-memory polymers. Int J Plast 127:102654

Han J, Zhu Y, Hu J, Luo H, Yeung L, Li W, Meng Q, Ye G, Zhang S, Fan Y (2012) Morphology, reversible phase crystallization, and thermal sensitive shape memory effect of cellulose whisker/SMPU nano-composites. J Appl Polym Sci 123:749–762

Huang WM (2019) Chapter 3: Shape memory polymers. In: Sokolowski WM (ed) Cold hibernated elastic memory structure: self-deployable technology and its applications. CRC Press, New York, pp 27–49

Huang WM, Ding Z, Wang CC, Wei J, Zhao Y, Purnawali H (2010) Shape memory materials. Mater Today 13:54–61

Huang WM, Zhao Y, Wang CC, Ding Z, Purnawali H, Tang C, Zhang J (2012) Thermo/chemo-responsive shape memory effect in polymers: a sketch of working mechanisms, fundamentals and optimization. J Polym Res 19:9952

Kelley SS, Rials TG, Glasser WG (1987) Relaxation behaviour of the amorphous components of wood. J Mater Sci 22:617–624

Kulasinski K (2017) Free energy landscape of cellulose as a driving factor in the mobility of adsorbed water. Langmuir 33:5362–5370

Lee J, Bowling DJF (1993) The effect of a mesophyll factor on the swelling of guard cell protoplasts of commelina communis L. J Plant Physiol 142:203–207

Lendlein A, Langer R (2002) Biodegradable, elastic shape-memory polymers for potential biomedical applications. Science 296:1673–1676

Liu N, Huang WM, Phee SJ, Fan H, Chew KL (2007) A generic approach for producing various protrusive shapes on different size scales using shape-memory polymer. Smart Mater Struct 16:N47–N50

Luo H, Hu J, Zhu Y, Zhang S, Fan Y, Ye G (2012) Achieving shape memory: Reversible behaviors of cellulose–PU blends in wet–dry cycles. J Appl Polym Sci 125:657–665

Mendez J, Annamalai PK, Eichhorn SJ, Rusli R, Rowan SJ, Foster EJ, Weder C (2011) Bioinspired mechanically adaptive polymer nanocomposites with water-activated shape-memory effect. Macromolecules 44:6827–6835

Mondal S, Hu JL (2007) Water vapor permeability of cotton fabrics coated with shape memory polyurethane. Carbohydr Polym 67:282–287

Otsuka K, Wayman CM (1999) Shape memory materials. Cambridge University Press, Cambridge, UK

Plaza N, Zelinka SL, Stone DS, Jakes JE (2013) Plant-based torsional actuator with memory. Smart Mater Struct 22:072001

Sokolowski WM, Tan SC (2007) Advanced self-deployable structures for space applications. J Spacecr Rockets 44:750–754

Song L, Li Y, Xiong Z, Pan L, Luo Q, Xu X, Lu S (2018) Water-induced shape memory effect of nanocellulose papers from sisal cellulose nanofibers with graphene oxide. Carbohydr Polym 179:110–117

Sun L, Huang WM, Ding Z, Zhao Y, Wang CC, Purnawali H, Tang C (2012) Stimulus-responsive shape memory materials: a review. Mater Des 33:577–640

Szcześniak L, Rachocki A, Tritt-Goc J (2008) Glass transition temperature and thermal decomposition of cellulose powder. Cellulose 15:445–451

Wischke C, Lendlein A (2010) Shape-memory polymers as drug carriers—a multifunctional system. Pharm Res 27:527–529

Wu XL, Huang WM, Tan HX (2013) Characterization of shape recovery via creeping and shape memory effect in ether-vinyl acetate copolymer (EVA). J Polym Res 20:150

Xie T, Rousseau IA (2009) Facile tailoring of thermal transition temperatures of epoxy shape memory polymers. Polymer 50:1852–1856

Yakacki CM, Shandas R, Safranski D, Ortega AM, Sassaman K, Gall K (2008) Strong, tailored, biocompatible shape-memory polymer networks. Adv Funct Mater 18:2428–2435

Zhang JL, Huang WM, Lu HB, Sun L (2014) Thermo-/chemo-responsive shape memory/change effect in a hydrogel and its composites. Mater Des 53:1077–1088

Zhao Y, Wang CC, Huang WM, Purnawali H, An L (2011) Formation of micro protrusive lens arrays atop poly(methyl methacrylate). Opt Express 19:26000–26005

Zhao Y, Huang WM, Wang CC (2012) Thermo/chemo-responsive shape memory effect for micro/nano surface patterning atop polymers. Nanosci Nanotechnol Lett 4:862–878

Zhu Y, Hu J, Luo H, Young RJ, Deng L, Zhang S, Fan Y, Ye G (2012) Rapidly switchable water-sensitive shape-memory cellulose/elastomer nano-composites. Soft Matter 8:2509–2517

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 11828201 and No. 11872207) and Natural Science Foundation of Jiangsu Province (Grant No. BK20200413).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study. YHG and SCW conducted all the experiments; TXW and WMH completed data analysis and discussions; WMH and XS provided financial support. TXW prepared the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest, and manuscript is approved by all authors for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 27850 kb)

Supplementary file2 (MP4 10873 kb)

Rights and permissions

About this article

Cite this article

Wang, T.X., Geng, Y.H., Wong, S.C. et al. Temperature-sensitive water-responsive shape memory effect in plant leaves. Braz. J. Bot 44, 929–940 (2021). https://doi.org/10.1007/s40415-021-00763-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40415-021-00763-3