Abstract

Background

We have shown that a prototype marathon racing shoe reduced the metabolic cost of running for all 18 participants in our sample by an average of 4%, compared to two well-established racing shoes. Gross measures of biomechanics showed minor differences and could not explain the metabolic savings.

Objective

To explain the metabolic savings by comparing the mechanics of the shoes, leg, and foot joints during the stance phase of running.

Methods

Ten male competitive runners, who habitually rearfoot strike ran three 5-min trials in prototype shoes (NP) and two established marathon shoes, the Nike Zoom Streak 6 (NS) and the adidas adizero Adios BOOST 2 (AB), at 16 km/h. We measured ground reaction forces and 3D kinematics of the lower limbs.

Results

Hip and knee joint mechanics were similar between the shoes, but peak ankle extensor moment was smaller in NP versus AB shoes. Negative and positive work rates at the ankle were lower in NP shoes versus the other shoes. Dorsiflexion and negative work at the metatarsophalangeal (MTP) joint were reduced in the NP shoes versus the other shoes. Substantial mechanical energy was stored/returned in compressing the NP midsole foam, but not in bending the carbon-fiber plate.

Conclusion

The metabolic savings of the NP shoes appear to be due to: (1) superior energy storage in the midsole foam, (2) the clever lever effects of the carbon-fiber plate on the ankle joint mechanics, and (3) the stiffening effects of the plate on the MTP joint.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

We compared running mechanics in a prototype marathon shoe and two well-established racing shoes and showed that hip and knee joint mechanics were similar between shoes. |

Peak extensor moment, negative and positive work at the ankle, and dorsiflexion and negative work at the metatarsophalangeal joint were all reduced in the prototype shoes. |

Substantial mechanical energy was stored/returned in compressing the midsole foam of the prototype shoe, but not in bending its carbon-fiber plate. |

The metabolic savings of the prototype shoes appear to be due to: (1) superior energy storage/return in the midsole foam, (2) the clever lever effects of the carbon-fiber plate on the ankle joint mechanics, and (3) the stiffening effects of the plate on the metatarsophalangeal joint. |

1 Introduction

Previously, we reported that a prototype marathon racing shoe reduced the metabolic cost of running by 4% compared to two well-established racing shoes [1]. Our energetics findings have been largely replicated in two follow-up studies by two other laboratories [2, 3]. Subsequent to our study, the commercial version of those prototypes, the Nike Vaporfly 4%, was released, and some have suggested that the IAAF (International Association of Athletics Federations, the governing body for athletics) should ban the shoes from competition [4,5,6]. While running in the prototype shoes, the participants in our previous study generally exhibited slightly greater peak vertical ground reaction forces, slower step frequencies (longer steps), and longer contact times than in the control shoes at matched velocities; however, the differences were small (~ 1%) and could not explain the metabolic savings [1].

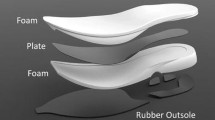

Here, to try to explain the metabolic savings, we compared the mechanics of the shoes, leg and foot joints during running in the same three shoe models tested previously. The Nike prototype shoes (NP) have two distinguishing features: a midsole comprising highly compliant and resilient foam and a carbon-fiber plate embedded in the midsole. Cushioning and carbon plates have individually been shown to reduce the metabolic cost of running [7,8,9,10], but the biomechanical mechanisms underlying these savings are not fully understood [11, 12].

In the 1980s, Frederick and co-workers demonstrated the metabolic energy savings of more compliant and resilient shoes [7, 13, 14]. Compliance is the amount of compression that occurs when a material is loaded with a certain force; resilience is the fraction of the stored mechanical energy that is returned [1]. Kerdok et al. [11] varied the compliance of a highly resilient treadmill surface and observed substantially reduced metabolic rates (− 12%) in the most compliant condition (0.026-m surface deflection). Their participants ran with less peak knee flexion during the stance phase. This reduced knee flexion presumably increased the effective mechanical advantage (EMA) of the muscles acting around the knee joints [15], which reduced the quadriceps muscle forces and thus metabolic requirements [16]. Tung et al. [17] attached ethylene–vinyl acetate (EVA) foam panels to the belt of a rigid treadmill, which allowed them to study the effects of compliance, independent of shoe mass. When their habitual midfoot striking participants ran barefoot on 10-mm thick EVA foam panels, their metabolic rates were ~ 1.6% lower than when they ran on the rigid treadmill surface. Contemporaneously, Worobets et al. [8] showed a 1% reduction in oxygen uptake for running in shoes with a more compliant and resilient midsole foam [adidas BOOST, made with thermoplastic polyurethane (TPU)], compared to otherwise identical, weight-matched shoes with EVA foam midsoles.

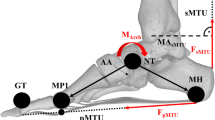

The other design feature of the NP shoes, the curved stiff midsole plate, is reminiscent of the flat plate tested by Roy and Stefanyshyn in 2006 [9]. They reported a 1% reduction in metabolic rate when participants ran in shoes with a flat embedded carbon-fiber plate in the midsole as compared to control shoes. Those savings have since been attributed to changes in metatarsophalangeal (MTP) and ankle joint mechanics, but the relative importance of these mechanisms remains unresolved [12]. Willwacher et al. [18] observed that midsoles with greater longitudinal bending stiffness limited MTP dorsiflexion and resulted in smaller moments and less negative work around the MTP joint. Oh and Park [10] found that the metabolically optimal longitudinal bending stiffness of a shoe plate is similar to a runner’s biological MTP joint rotational stiffness (the ratio of the MTP joint moment to the maximum MTP joint flexion). Willwacher et al. [19] observed that midsoles with greater longitudinal bending stiffness increase the moment arms of the ground reaction force vector around the hip, knee, ankle, and MTP joints, with the greatest increases at the distal joints. These changes in external moment arm decrease the EMA (the ratio of internal moment arm/external moment arm), which is equivalent to an increase in the joint gear ratio (i.e., the ratio of external moment arm/internal moment arm [20]). However, it is unclear how increases in gear ratio affect metabolic rate because the interactions between calf muscle forces, muscle shortening velocities, and energy storage and return in the Achilles tendon are complicated [21,22,23].

Based on the previous studies on cushioning, we hypothesized that: (1) The NP shoes would allow people to run with less knee flexion and smaller peak knee moments. Further, based on previous studies of carbon-fiber plates, we hypothesized that in the NP shoes (2) the peak ankle extensor moment would be greater, while (3) dorsiflexion and negative work at the MTP joint would be less.

2 Methods

2.1 Participants

We recruited ten male participants (aged 26.2 ± 4.0 years, mass 63.2 ± 3.1 kg; height 1.77 ± 0.06 m) through personal contacts, running clubs, and social media. Inclusion criteria consisted of: fitting a US men’s size 10 shoe, rearfoot strike pattern, and a recent sub-35-min 10-km (or equivalent) race performance. Six had participated in our prior metabolic study [1]. All participants gave written informed consent per the University of Colorado Boulder Institutional Review Board.

2.2 Shoe Conditions

Participants wore three pairs of shoes: a prototype of the Nike Vaporfly (NP), Nike Zoom Streak 6 (NS), adidas adizero Adios BOOST 2 (AB), in a randomized order. We have previously described the shoe properties in detail [1]. The NP midsole comprises highly compliant and resilient ZoomX foam made with polyether block amide (PEBA), combined with a stiff embedded carbon-fiber plate. The NS midsole is composed of lightweight EVA foam and a rearfoot air bag. The AB midsole is made of resilient BOOST foam made with TPU. By sewing lead pellets into the tongue of the NP and NS shoes, we equilibrated all shoes to 250 g/shoe (equivalent to the mass of the AB shoe; see Hoogkamer et al. [1] for details). This eliminated the potential confounding effects of shoe mass on metabolic rate [24,25,26]. Total running use for any pair of shoes did not exceed 70 km.

The longitudinal bending stiffness values of the shoes were measured at the Nike testing facilities (Nike Inc., Beaverton, OR, USA) with a rotational axis material testing machine (Instron ElectroPuls E1000, Norwood, MA, USA). The forefoot portion of the shoe was clamped down with a metal block onto a fixed platform set to align the rotational axis of the machine with the anatomical MTP joint bending axis (i.e., the rotational axis was aligned above the midsole). The rearfoot portion of the shoe was clamped to an actuating platform that rotated to simulate MTP bending. The average bending stiffness at 27° beyond the neutral position was determined from 20 30° loading cycles at 2.5 Hz. The NP (18.5 Nm/rad) was about twice as stiff as the NS (9.4 Nm/rad) and AB (7.0 Nm/rad).

2.3 Experimental Set-up and Protocol

Participants ran 5-min trials at 16 km/h (4.44 m/s) in each shoe condition on a motorized, force-measuring treadmill (Treadmetrix, Park City, UT, USA). Between trials, participants took a 5-min break while they changed shoes. We used a three-dimensional motion capture system (Vicon 512 System, Oxford, UK) to determine the positions of the joints relative to the force-measuring treadmill. We placed 44 reflective markers on the participant’s legs and shoes using a modified Helen Hayes marker set. Using double-sided tape, we adhered small, lightweight retro-reflective markers bilaterally to the skin over: the ASIS and PSIS of the pelvis, the greater trochanter, the medial and lateral femoral condyles, and the medial and lateral malleoli. We also glued markers on both shoes: one on the posterior of the heel, one below the lateral malleolus, one below the medial malleolus, one each above the tips of the first and fourth toes, and one over the fifth metatarsal head. Finally, we adhered one marker on the shoe over the first metatarsal head. To track the movements of the thigh and shank segments as rigid bodies, we glued sets of four reflective markers to four lightweight plastic plates. These markers were arranged on each plate in unique non-co-linear patterns (“clusters”) to ease recognition by the motion capture software. We secured a plate to each thigh and calf segment using elastic bandage material. With the participant standing, we recorded a static calibration trial before each running trial, after which we removed the greater trochanter, medial femoral condyle, medial malleolus, and first metatarsal markers because they were likely to be knocked off. The static calibration using the clusters allowed us to reconstruct the positions of the removed markers and hence define the hip, knee, ankle, and MTP joint centers. We defined the hip joint center at 1/4 and 3/4 of the line connecting the left and right greater trochanter markers, and the knee, ankle, and MTP joint centers as the midpoints of lines connecting the respective medial and lateral markers.

2.4 Data Analyses

We collected ground reaction force (GRF) data at 1000 Hz and kinematic data at 200 Hz during the last 30 s of each biomechanics measurement trial and analyzed ten strides (20 steps). Due to cluster plate slippage during some trials for six participants, we could only include their left or right side, i.e., ten steps in the final analysis. For the other participants we averaged the values between their left and right sides. We used a recursive fourth order Butterworth low-pass filter (14 Hz) to process both GRF and kinematic data (Visual 3D, C-Motion Inc., Germantown, MD, USA) [27]. We calculated contact time and stride frequency using a custom MATLAB script (MathWorks Inc, Natick, MA, USA) with a 30 N vertical GRF force threshold. Visual inspection for the presence of an impact peak in the vertical GRF traces confirmed that all participants were rearfoot strikers. For the hip, knee, ankle, and MTP joints, we calculated joint angles, angular velocities, moments, powers, and work during the stance phase, using Visual 3D and its associated anthropometric model with six degrees of freedom joints, and MATLAB scripts. We time-normalized all data curves to the stance phase duration. We defined the MTP joint moment and power to be equal to zero until the resultant GRF vector originated distal to the MTP joint center [18, 28]. Further, because reliability of the center of pressure (CoP) location is poor at low force values, especially during treadmill running, we evaluated all outcome parameters that depend on the CoP location (joint moments, powers, and work) only for 5–95% of the stance phase [18, 29].

We estimated the mechanical energy stored and returned during midsole compression and rebound, based on the peak vertical GRF and the known force–displacement curves and resilience of the different shoe models (for details see Hoogkamer et al. [1]). To estimate the energy stored per step for each runner, in each shoe condition, we calculated the area under the loading curve for that shoe condition up to the force value equal to the peak vertical GRF for each runner in that shoe condition. Then, we multiplied that value by the corresponding resilience (87.0% for NP, 65.5% for NS, and 75.9% for AB) to estimate the energy returned per step. In addition, we estimated the contribution of the shoe to the external MTP joint moments by multiplying the MTP dorsiflexion angle beyond neutral (i.e., when the resultant GRF vector originated distally from the MTP joint center) by the longitudinal bending stiffness of each shoe model. Next, we multiplied these moments by the angular velocity at the MTP joint to quantify the mechanical bending power at the shoe. From this, we quantified negative and positive mechanical bending energy stored in and returned by the shoes. Multiplying energy changes per step (at the midsole and at the joints) by step frequency allowed us to quantify average mechanical work rate values in W/kg.

2.5 Statistics

We calculated means and standard deviations (mean ± SDs) for all tested variables. We compared all biomechanical outcome parameters between the three shoe conditions using one-way repeated measures ANOVAs. When we observed a significant main effect for shoe, we performed Bonferroni corrected paired t tests to determine post hoc which shoe-by-shoe comparisons differed significantly. We used traditional levels of significances (α = 0.05 and αpost-hoc = 0.0167) and performed analyses with MATLAB.

3 Results

Step frequency was slower for running in the NP shoes (2.91 ± 0.11 steps/s) than in the NS and AB shoes (2.96 ± 0.09 and 2.95 ± 0.10 steps/s, respectively; Table 1). Since the treadmill velocity was fixed, that means the runners chose ~ 1.7% longer steps in the NP shoes than in the other shoes. Contact time was not statistically different between shoes, but aerial time was ~ 3.2% longer in the NP versus AB shoes (Table 1). Ground reaction force patterns were quantitatively different in the NP shoes versus the other two shoes (Fig. 1a, b). Specifically, peak vertical GRF (Fz) was slightly greater in the NP versus AB shoes, and the vertical impulse per step (integral of force with respect to time) in the NP shoes was greater than both of the other two shoes (Table 1). In the NP shoes, the propulsive phase started relatively earlier in the stance phase (52.1 ± 1.3%) versus NS and AB shoes (54.3 ± 1.9% and 54.0 ± 1.6%, respectively; Table 1). Braking and propulsive impulses were equal and opposite, as required for constant velocity, level treadmill running. Overall, braking and propulsive impulses were both greater in the NP (22.3 ± 1.9 × 10−3 BW s) versus AB shoes (21.5 ± 1.7 × 10−3 BW s) but braking and propulsive impulses in the NP and AB shoes were not significantly different from the NS shoes (21.9 ± 1.9 × 10−3 BW s; Table 1).

Ground reaction force traces were different for running in the prototype shoes (NP, orange) than in the Nike Zoom Streak 6 (NS, green) and the adidas adizero Adios BOOST 2 (AB, purple) shoes. Panel a shows the vertical ground reaction force trace and panel b show the anterior–posterior ground reaction force trace. Panel c shows the anterior–posterior distance between the center of pressure and the metatarsophalangeal (MTP) joint. Traces represent group averages; shaded areas indicate ± 1 standard error of the mean

Hip and knee joint kinematics (Fig. 2) and kinetics (Fig. 3) were similar between shoe models (Table 2), but some ankle mechanics were different. Peak ankle dorsiflexion during stance was less in the NP shoes than in the other two shoe models (Fig. 2, Table 2). The ankle angular velocity trace had a unique shape for the NP shoes (Fig. 2), but peak ankle dorsiflexion velocity was not significantly different between shoes. Peak ankle moment was smaller in the NP (254.5 ± 28.1 Nm) versus AB shoes (264.6 ± 27.7 Nm; Table 2). Negative ankle joint work (area under the negative part of joint power curve in Fig. 3) was 9.4% and 16.4% less in the NP versus the NS and the AB shoes, respectively (Table 2). Positive ankle work was 9.5–11.0% less in the NP versus the other two shoe models (Table 2).

Joint angles (left column) and joint angular velocities (right column) for the hip, knee, ankle, and metatarsophalangeal (MTP) joints while running in the prototype (NP, orange), the Nike Zoom Streak 6 (NS, green) and the adidas adizero Adios BOOST 2 (AB, purple). Note that the vertical scales differ between panels. Positive values indicate extension/plantar flexion. Traces represent group averages; shaded areas indicate ± 1 standard error of the mean

Joint moments (left column) and powers (right column) for the hip, knee, ankle, and metatarsophalangeal (MTP) joints, and shoe bending moment and power while running in the prototype (NP, orange), the Nike Zoom Streak 6 (NS, green) and the adidas adizero Adios BOOST 2 (AB, purple). Note that the vertical scales differ between panels. Positive values indicate extension/plantar flexion. Traces represent group averages; shaded areas indicate ± 1 standard error of the mean

We also found differences between shoe models in MTP joint kinematics. Peak MTP joint dorsiflexion was least in the NP and greatest in the NS shoes (Fig. 2, Table 2). Peak MTP dorsiflexion velocity was slower in the NP shoes versus the other two shoes (Fig. 2). Peak MTP moment was smaller in the AB shoes than in the NS shoes, but the pairwise differences between the other shoes were not significant. Negative MTP joint work was least in the NP shoes (− 0.13 ± 0.04 J/kg/step), ~ 50% greater in the AB shoes (− 0.20 ± 0.05 J/kg/step) and ~ 100% greater in the NS shoes (− 0.27 ± 0.07 J/kg/step; Table 2). Positive MTP joint work was not significantly different between the shoes (p = 0.055), but the joint power traces show positive power values in the NP shoes earlier at the end of stance phase. Some positive power might be performed during the last 5% of the stance phase, but this was not assessed due to the unreliability of the CoP location at low force values [18, 27]. Differences in ankle and MTP power between shoe models were not due to obvious differences in the progression of the CoP relative to the MTP joint (Fig. 1c), but during peak ankle moment, at ~ 60% of the stance phase, the moment arm of the ground reaction force around the ankle was smaller in the NP than in the AB shoes (Fig. 4).

Moment arm of the ground reaction force about the ankle joint during peak ankle moment (~ 60% of stance time) was smaller in the prototype shoes (NP, orange) than in the adidas adizero Adios BOOST 2 (AB, purple) shoes, but not significantly different from the Nike Zoom Streak 6 (NS, green). Traces represent group averages; shaded areas indicate ± 1 standard error of the mean

Mechanical compression energy storage in the shoe midsole was much greater in the NP (0.126 ± 0.008 J/kg/step) versus NS and AB shoes (0.071 ± 0.004 and 0.067 ± 0.005 J/kg/step, respectively), as were energy return estimates (0.109, 0.046, and 0.051 J/kg/step in the NP, NS, and AB shoes, respectively). Note that we could only properly estimate these values for eight participants because for two participants the peak vertical GRF values were above the loading range of the mechanical testing (0–2000 N) [1]. The amounts of mechanical bending energy stored in and returned by the shoe midsole (and plate) were substantially smaller. Mechanical bending energy storage was greater in the NS shoes (0.0142 ± 0.0053 J/kg/step) than in the NP and AB shoes (0.0076 ± 0.0032 and 0.0079 ± 0.0027 J/kg/step, respectively). Bending energy return was greatest in the NP (0.0025 ± 0.0019 J/kg/step), next in the NS (0.0011 ± 0.0011 J/kg/step), and least in the AB shoes (0.0003 ± 0.0005 J/kg/step).

4 Discussion

Our results indicate that, contrary to our first hypothesis, peak knee flexion and moments were not significantly different between the NP, NS, and AB shoes. We also reject our second hypothesis; peak ankle extensor moment was smaller, not larger, in NP shoes than in the AB shoes. Supporting our third hypothesis, dorsiflexion and negative work at the MTP joint were reduced when running in the NP shoes compared to the other shoe models.

After observing substantial reductions in metabolic rate for running in the NP shoes [1], we reasoned that this likely resulted from improved EMA at the knee as the highly compliant NP midsoles could allow athletes to run with less knee flexion during stance. However, here we observed no differences in knee joint kinematics and kinetics between the different shoe models. This could be related to the fact that the differences in midsole compliance between shoes resulted in displacement differences of ~ 6 mm when loaded with 2000 N [1], which is substantially less than that of the surface displacement (~ 26 mm) that resulted in reduced knee flexion in Kerdok et al.’s [11] compliant treadmill study.

We anticipated that the carbon-fiber plate in the NP shoes would cause the CoP to move forward under the foot faster, resulting in a larger moment arm of the resultant GRF vector acting at the ankle joint [10, 18, 19]. Thus, we expected that the peak extensor moment and negative work at the ankle joint would be greater in the NP shoes. Instead, peak ankle moment was smaller in the NP versus AB shoes. Based on the slightly greater peak Fz in the NP versus AB shoes and similar progression of the CoP relative to the MTP joint, this seems counter-intuitive. However, peak ankle moment occurred later in the stance phase than peak Fz, when Fz was no longer different between shoes, and the moment arm of the ground reaction force around the ankle was smaller in the NP than in the AB shoes (Fig. 4). We did not observe the anticipated faster CoP progression under the foot in the NP shoes (Fig. 1c). This might be because the carbon-fiber plate in the NP shoes was embedded in the midsole and curved, whereas previous studies used carbon-fiber insoles that were flat and atop the midsole [18, 19]. Furthermore, our baseline shoes (NS and AB) had substantially greater longitudinal bending stiffness than the baseline condition in those studies (< 1 Nm/rad [18, 19]). The reductions in ankle power in the NP shoes resulted from a combination of smaller moments and slower joint angular velocities. It is not straightforward to attribute these changes to either the more compliant midsole or the carbon-fiber plate, and they might result from interactions between the compliant midsole and its taller stack height (31 mm at the heel vs. 23 mm in the other shoe models [1]).

Peak dorsiflexion angle at the MTP joint was least in the NP shoes and greatest in the NS shoes. Peak dorsiflexion moments at the MTP joint were smaller in the AB versus NS shoes, but the differences between the other shoes were not significant. Negative work per step at the MTP joint was substantially less in the NP shoes than in either the AB or NS shoes. With comparable center-of-pressure traces and only minor differences between shoes in peak MTP moments, the differences in power and work resulted mainly from differences in dorsiflexion angular velocity. At the MTP joint, the foot and the longitudinal bending stiffness of shoe function in parallel. However, the shoes account for only 6.0, 5.3, and 3.9% of the average negative mechanical bending MTP work rates of − 0.37 W/kg in the NP shoes, − 0.79 W/kg in the NS shoes, and − 0.60 W/kg in the AB shoes, respectively.

In line with observations of Willwacher et al. [18], some positive work was performed at the MTP joint towards the end of the stance phase in the NP shoes. This positive work can result from return of energy stored in the arch of the foot [30], the midsole, the carbon-fiber plate [18], or from muscle contractions [31]. In the NP shoes, positive work during 5–95% of the stance phase was ~ 20 times less than the negative work, though some positive work could have occurred during the last 5% of the stance phase, which we did not quantify. We cannot be absolutely conclusive about the amounts of positive work performed at the end of the stance phase in any of the shoe models. We estimate that if mechanical energy is stored in and returned from the NP’s carbon-fiber plate at the MTP joint, this would be at a rate of about 0.007 W/kg at most, providing ~ 35% of the positive work rate at the MTP joint, but to put it in perspective, only ~ 0.3% of the positive work rate at the ankle (Table 3). This strongly suggests that, rather than being a spring, the carbon-fiber plate acts in parallel with the intrinsic foot muscles to stiffen the MTP joint.

The properties of running shoe midsoles, however, are designed to be spring-like. The greater compliance of the NP midsoles, combined with their higher resilience [1], can be expected to have resulted in 0.059–0.063 J/kg/step greater compression energy return. Taking into account the step frequency differences between shoes, this would result in an average mechanical work rate of 0.32 W/kg in the NP shoes, versus 0.14 W/kg in the NS shoes and 0.15 W/kg in the AB shoes (Table 3). Can we relate between-shoe differences in average midsole compression energy return work rates to between-shoe differences in overall, whole-body metabolic rate? Focusing on the NP and the NS shoes, we observed a 0.18 W/kg greater rate of mechanical compression energy return in the NP shoes in this study and a 0.71 W/kg lower metabolic rate at 16 km/h in our earlier study [1]. Noteworthy, our earlier study also found that the absolute differences in average midsole compression energy return work rates between shoes were fairly constant across running velocities. Since the mechanical testing results were independent of loading rate, the energy return rate depends only on peak vertical force and step frequency, not on contact time. Over the velocity range of 14–18 km/h, peak vertical force and step frequency increased by ~ 7% and ~ 5%, respectively [1], suggesting an increase in between-shoe difference in mechanical compression energy return rate of ~ 12% (105% × 107%). In contrast, the between-shoe difference in metabolic rate increased by ~ 40%, from 0.60 W/kg at 14 km/h to 0.84 W/kg at 18 km/h [1]. Together, these calculations demonstrate that the differences in midsole energy return rates between shoes alone do not fully explain the metabolic savings.

Further insight into the metabolic savings was revealed by our analysis of the average mechanical work rates at the ankle and MTP joints and in the shoes (compression and bending). The highest work rates occurred at the ankle, with both negative and positive work rates being lowest in the NP shoes, 0.26–0.46 and 0.30–0.35 W/kg lower, respectively. The reduced negative work rate at the ankle in the NP shoe suggests that less energy was stored in the elastic structures of the triceps surae muscle tendon-unit. At the same time, the smaller ankle moment (NP vs. AB) suggests that the force was lower in the triceps surae muscle tendon-unit, reducing the metabolic cost of generating muscular force [16, 32]. Overall, net work rates at the ankle were positive, and not all negative work was stored/returned elastically, suggesting that the reduced positive work rate at the ankle in the NP shoes is an important factor in the reduced metabolic rate. The reductions in negative work rate at the MTP joint in the NP shoes were similar to those at the ankle, 0.23–0.42 W/kg. However, less than 6% of the negative work was returned as positive work at the MTP joint, with small non-significant differences between shoes. Note that negative work can be expected to be metabolically inexpensive as it is either absorbed in passive structures [33] or performed using eccentric muscle actions [31]. Between-shoe differences in shoe compression and bending work rates were smaller than at the joints. The NP midsole returned more than twice as much energy from compression as the other shoes, but the magnitude was only 0.17–0.18 W/kg more. Noteworthy, the NP midsole returned 0.318 W/kg from compression and just 0.007 W/kg from bending the carbon-fiber plate and midsole, almost 50 times more.

4.1 Limitations and Future Studies

Strictly interpreted, our conclusions are limited to males running at 16 km/h with a rearfoot strike pattern. Our relatively small sample size is a potential limitation, but none of our hypothesis tests were borderline in terms of p-values. When comparing our joint power curves to the literature, we noticed that the net summed joint work was negative, not positive as expected based on Riddick and Kuo [34]. Still, our joint power curves are within the range of those reported by others (e.g., Riddick & Kuo [34], Lai et al. [35], Schache et al. [36], and Stearne et al. [37]). Within the literature, substantial variability exists in reported hip and ankle joint power curves, due to methodological issues such as differences in foot strike pattern [37], non-matched filter cut-off frequencies for kinematic and kinetic data [38], and variability in hip joint center definitions [39]. Importantly, we only made comparisons between shoe conditions, so differences in the absolute magnitudes of our joint power data due to methodology would not change our overall conclusions. Previous exposure to running in NP shoes varied within our sample, but step frequency and contact time data from the first and second trial in the NP in our previous study [1] were similar, indicating this did not confound our results as there is a rapid immediate adaptation of running mechanics, and then no further adaptation over 10 min. We set out to investigate the biomechanics underlying the metabolic savings when running in the NP shoes. Ideally, we would have performed this biomechanical study simultaneously with the metabolic study, but we did not have access to motion capture equipment during the metabolic study. In the current study, we managed to recruit six of the eight rearfoot strikers who participated in the metabolic study. Numerically, we observed similar changes in step frequency, peak vertical ground reaction forces, and contact times between shoe models across both studies and the subset of runners who participated in both studies. Contact times were ~ 4% shorter in the current study, which could be related to the use of a different force-measuring treadmill in the two studies.

Because we compared running biomechanics in three shoe models with substantial differences in several features, we cannot distinguish how much each feature [midsole compliance, midsole resilience, and longitudinal bending stiffness (carbon-fiber plate)] individually contributed to the substantial metabolic savings of 4% observed in the NP shoes [1]. The benchtop methods we used to measure midsole compression energy storage/return and longitudinal bending stiffness are state-of-the-art in the footwear industry, but they do not exactly replicate a human running in the shoes. Perhaps, in the future, robotic human foot emulators will be the best way to quantify midsole compression energy storage. X-ray video may be the best method for quantifying the bending of midsole-embedded plates. We have focused on midsole compliance and resilience and the embedded carbon-fiber plate, but other features such as midsole stack height, toe-spring, and uppers also differed between shoes. In that respect, future studies could compare prototype shoes that differ in only one feature, such as comparing shoes with identical foam midsoles, but with/without a carbon-fiber plate. Further, it would be useful to compare shoes with identical carbon-fiber plates but different midsole foams. Such studies could also measure muscle activation and muscle fascicle shortening velocities [22]. Using ultrasound measurements, Takahashi et al. [22] showed that insoles with greater bending stiffness slow muscle shortening velocities in the soleus muscle during walking. However, this did not result in a lower metabolic rate for stiffer insoles, most likely related to increases in the metabolic cost of generating greater soleus fascicle forces, resulting from increased external ankle joint moments. In contrast, in the present study, both ankle plantar flexion velocity and peak ankle moment were reduced in the NP shoes, suggesting muscle fascicles in the triceps surae shortened slower and with less force.

5 Conclusions

Running in the NP shoes did not change hip or knee mechanics, but reduced the positive and negative work rates at the ankle joint and negative work rates at the MTP joint, each by ~ 0.3 W/kg. Differences between shoes in bending energy return work rates (~ 0.005 W/kg) were much smaller than the differences in midsole compression energy return work rates (~ 0.17 W/kg), and only ~ 0.3% of the positive work rate at the ankle. Overall, the metabolic savings of the NP shoes can be attributed to the spring-like energy return from midsole compression, the clever lever effects of the carbon-fiber plate on the ankle joint mechanics, and the stiffening effects of the plate on the MTP joint.

References

Hoogkamer W, Kipp S, Frank JH, et al. A comparison of the energetic cost of running in marathon racing shoes. Sports Med. 2018;48:1009–19.

Hunter I, McLeod A, Low T, Valentine D, Ward J, Hager R. Running economy and marathon racing shoes. Rochester: American Society of Biomechanics; 2018.

Barnes KR, Kilding AE. A randomized crossover study investigating the running economy of highly-trained male and female distance runners in marathon racing shoes versus track spikes. Sports Med. 2018. https://doi.org/10.1007/s40279-018-1012-3.

Longman J. Do Nike’s new shoes give runners an unfair advantage? New York Times. 2017. https://www.nytimes.com/2017/03/08/sports/nikes-vivid-shoes-and-the-gray-area-of-performance-enhancement.html. Accessed July 27, 2018.

Quealy K, Katz J. Nike says its $250 running shoes will make you run much faster. What if that’s actually true? New York Times. 2018. https://www.nytimes.com/interactive/2018/07/18/upshot/nike-vaporfly-shoe-strava.html. Accessed July 27, 2018.

Ingle S. Nike’s lightning shoes hint at power of technology to skew elite competition. The Guardian. 2018. https://www.theguardian.com/sport/2018/jul/22/nike-shoes-vaporfly-sport. Accessed July 27, 2018.

Frederick EC, Howley ET, Powers SK. Lower O2 cost while running on air cushion type shoe. Med Sci Sports Exerc. 1980;12:81–2.

Worobets JT, Wannop JW, Tomaras E, et al. Softer and more resilient running shoe cushioning properties enhance running economy. Footwear Sci. 2014;6:147–53.

Roy JP, Stefanyshyn DJ. Shoe midsole longitudinal bending stiffness and running economy, joint energy, and EMG. Med Sci Sports Exerc. 2006;38:562–9.

Oh K, Park S. The bending stiffness of shoes is beneficial to running energetics if it does not disturb the natural MTP joint flexion. J Biomech. 2017;53:127–35.

Kerdok AE, Biewener AA, McMahon TA, et al. Energetics and mechanics of human running on surfaces of different stiffnesses. J Appl Physiol. 2002;92:469–78.

Stefanyshyn DJ, Wannop JW. The influence of forefoot bending stiffness of footwear on athletic injury and performance. Footwear Sci. 2016;8:51–63.

Frederick EC, Clarke TE, Larsen JL, et al. The effects of shoe cushioning on the oxygen demands of running. In: Nigg BM, Kerr BA, editors. Biomechanical aspects of sports shoes and playing surfaces. Calgary: The University of Calgary; 1983. p. 107–14.

Frederick EC, Howley ET, Powers SK. Lower oxygen demands of running in soft-soled shoes. Res Q Exerc Sport. 1986;57:174–7.

Biewener AA. Scaling body support in mammals: limb posture and muscle mechanics. Science. 1989;245:45–8.

Kipp S, Grabowski AM, Kram R. What determines the metabolic cost of human running across a wide range of velocities? J Exp Biol. 2018. https://doi.org/10.1242/jeb.184218 (In press).

Tung KD, Franz JR, Kram R. A test of the metabolic cost of cushioning hypothesis during unshod and shod running. Med Sci Sports Exerc. 2014;46:324–9.

Willwacher S, König M, Potthast W, et al. Does specific footwear facilitate energy storage and return at the metatarsophalangeal joint in running? J Appl Biomech. 2013;29:583–92.

Willwacher S, König M, Braunstein B, et al. The gearing function of running shoe longitudinal bending stiffness. Gait Posture. 2014;40:386–90.

Carrier DR, Heglund NC, Earls KD. Variable gearing during locomotion in the human musculoskeletal system. Science. 1994;265:651–3.

Scholz MN, Bobbert MF, van Soest AJ, et al. Running biomechanics: shorter heels, better economy. J Exp Biol. 2008;211:3266–71.

Takahashi KZ, Gross MT, van Werkhoven H, et al. Adding stiffness to the foot modulates soleus force-velocity behaviour during human walking. Sci Rep. 2016;6:29870.

van Werkhoven H, Piazza SJ. Does foot anthropometry predict metabolic cost during running? J Appl Biomech. 2017;33:317–22.

Frederick EC, Daniels JT, Hayes JW. The effect of shoe weight on the aerobic demands of running. In: Bachl N, Prokop L, Suckert R, editors. Curr Top Sports Med Proc World Congr Sports Med. Vienna: Urban and Schwarzenberg; 1984. p. 616–25.

Franz JR, Wierzbinski CM, Kram R. Metabolic cost of running barefoot versus shod: is lighter better. Med Sci Sports Exerc. 2012;44:1519–25.

Hoogkamer W, Kipp S, Spiering BA, et al. Altered running economy directly translates to altered distance-running performance. Med Sci Sports Exerc. 2016;48:2175–80.

Bisseling RW, Hof AL. Handling of impact forces in inverse dynamics. J Biomech. 2006;39:2438–44.

Stefanyshyn DJ, Nigg BM. Mechanical energy contribution of the metatarsophalangeal joint to running and sprinting. J Biomech. 1997;30:1081–5.

Bobbert MF, Schamhardt HC. Accuracy of determining the point of force application with piezoelectric force plates. J Biomech. 1990;23:705–10.

Stearne SM, McDonald KA, Alderson JA, et al. The foot’s arch and the energetics of human locomotion. Sci Rep. 2016;6:19403.

Kelly LA, Lichtwark G, Cresswell AG. Active regulation of longitudinal arch compression and recoil during walking and running. J R Soc Interface. 2015;12:20141076.

Kram R, Taylor CR. Energetics of running: a new perspective. Nature. 1990;346:265–7.

Hsu CC, Tsai WC, Shau YW, et al. Altered energy dissipation ratio of the plantar soft tissues under the metatarsal heads in patients with type 2 diabetes mellitus: a pilot study. Clin Biomech. 2007;22:67–73.

Riddick RC, Kuo AD. Soft tissues store and return mechanical energy in human running. J Biomech. 2016;49:436–41.

Lai A, Lichtwark GA, Schache AG, et al. In vivo behavior of the human soleus muscle with increasing walking and running speeds. J Appl Physiol. 2015;118:1266–75.

Schache AG, Brown NA, Pandy MG. Modulation of work and power by the human lower-limb joints with increasing steady-state locomotion speed. J Exp Biol. 2015;218:2472–81.

Stearne SM, Alderson JA, Green BA, et al. Joint kinetics in rearfoot versus forefoot running: implications of switching technique. Med Sci Sports Exerc. 2014;46:1578–87.

Kristianslund E, Krosshaug T, van den Bogert AJ. Effect of low pass filtering on joint moments from inverse dynamics: implications for injury prevention. J Biomech. 2012;45:666–71.

Schache AG, Blanch PD, Dorn TW, et al. Effect of running speed on lower limb joint kinetics. Med Sci Sports Exerc. 2011;43:1260–71.

Acknowledgements

We thank Jesse H. Frank and Claire Denny for help with data collection, Owen N. Beck and Stephen Allen for help with data analysis, Geng Luo and Emily M. Farina for fruitful discussions and providing the mechanical testing data, and the runners for their participation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical Approval

This study was performed in accordance with the ethical standards of the Declaration of Helsinki. Ethics approval was obtained from the University of Colorado Institutional Review Board (Protocol# 15-0114).

Informed Consent

Informed consent was obtained from all individual participants included in the study.

Funding

The running shoes used for this study were provided by Nike, Inc.

Conflict of Interest

Wouter Hoogkamer and Shalaya Kipp have no conflicts of interest relevant to the content of this article. Rodger Kram is a paid consultant to Nike, Inc.

Rights and permissions

About this article

Cite this article

Hoogkamer, W., Kipp, S. & Kram, R. The Biomechanics of Competitive Male Runners in Three Marathon Racing Shoes: A Randomized Crossover Study. Sports Med 49, 133–143 (2019). https://doi.org/10.1007/s40279-018-1024-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40279-018-1024-z