Abstract

The dynamic mechanical relaxation behavior of Ti36.2Zr30.3Cu8.3Fe4Be21.2 bulk metallic glass with good glass-forming ability was investigated by mechanical spectroscopy. The mechanical relaxation behavior was analyzed in the framework of quasi-point defects model. The experimental results demonstrate that the atomic mobility of the metallic glass is closely associated with the correlation factor χ. The physical aging below the glass transition temperature Tg shows a non-Debye relaxation behavior, which could be well described by stretched Kohlrausch exponential equation. The Kohlrausch exponent \(\beta_{\text{aging}}\) reflects the dynamic heterogeneities of the metallic glass. Both concentration of “defects” and atomic mobility decrease caused by the in situ successive heating during the mechanical spectroscopy experiments.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Bulk metallic glasses have attracted extensive investigations for their excellent mechanical and physical properties due to their unique disordered atomic structure [1,2,3]. In contrast to the conventional amorphous materials (i.e., polymers or oxide glasses, etc.), metallic glasses have a relatively simple atomic packing structure, making them an ideal carrier for studying the origin of the amorphous nature and the phenomenon of glass transition [4, 5]. As metastable materials, the physical process approaching to the stable state always occurs in metallic glasses and then the structural relaxation (i.e., physical aging) becomes one of the most fundamental issues in metallic glasses [5,6,7]. However, how to describe the mechanism of mechanical relaxations in metallic glasses by suitable models with clear physical meaning is a challenging issue in glassy materials [8,9,10]? Mechanical relaxation processes (i.e., secondary β relaxation and main α relaxation) are closely associated with glass transition, diffusion phenomenon and mechanical properties in metallic glasses [5]. Dynamic mechanical analysis is an effective testing tool to study the internal atomic arrangement and microscopic mechanism of mechanical behaviors for amorphous materials [2, 11,12,13].

Compared with other typical metallic glasses, Ti-based metallic glasses show lower Young’s moduli and good corrosion behavior [14]. Interestingly, Ti-based metallic glasses show formation of a metastable phase after the first crystallization process [15]. As the candidate as application of engineering materials, to well realize the physical and mechanical properties of metallic glass, dynamic mechanical relaxation behavior could be investigated [16, 17].

In the current study, the dynamic mechanical relaxation of the Ti36.2Zr30.3Cu8.3Fe4Be21.2 (at.%) bulk metallic glass was investigated, which possesses exceptionally high glass-forming ability (GFA) and remarkable compressive plasticity as reported in the previous literature [18]. Based on the experimental results and theoretical analysis, the relationship between the dynamic mechanical relaxation and the atomic mobility as well as the “defects” in metallic glass was established.

2 Experimental Procedure

The sample of Ti36.2Zr30.3Cu8.3Fe4Be21.2 (at.%) metallic glass was prepared by arc melting under a Ti-gettered argon atmosphere. The purities of all the elements are higher than 99.6%, and each ingot was re-melted more than five times to ensure the chemical homogeneity. The samples of plate with a dimension of 3 mm × 10 mm × 80 mm were fabricated by suction casting into a water-cooled copper mold. The amorphous characteristics of specimens were then characterized by X-ray diffraction (XRD, D8, Bruker AXS Gmbh, Germany) with CuKα radiation. As for the thermal properties, both the glass transition temperature Tg and the onset temperature of crystallization Tx of the specimens were measured by differential scanning calorimeter (DSC, Pekin Elmer, DSC-7) under a constant heating rate of 20 K/min. The dynamic mechanical behavior of Ti36.2Zr30.3Cu8.3Fe4Be21.2 bulk metallic glass was studied by the commercial dynamic mechanical analysis (DMA, TA Q800) under the single cantilever mode. The specimens for the DMA experiments were prepared by using a low-speed cutting machine with water cooling and then polished surfaces carefully. Typical specimen dimension of the Ti-based metallic glass is approximately 1 mm × 3 mm × 30 mm. A sinusoidal stress was applied on the samples and then by measuring the corresponding strain of the specimens during the DMA experiments, the storage modulus E′ and loss modulus E″ as well as the internal friction (mechanical loss) tan\(\delta\) = E″/E′ could be obtained.

3 Results and Discussion

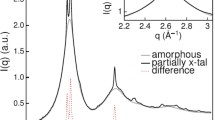

3.1 Structural and Thermal Properties

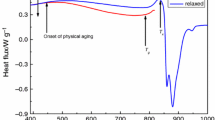

As demonstrated in previous literature [18], Ti36.2Zr30.3Cu8.3Fe4Be21.2 bulk metallic glass processes exceptionally high GFA, and the amorphous structure could be obtained by naturally cooling with an ingot of about 150 g. In the current work, the amorphous nature of the as-cast specimen was confirmed by XRD as shown in Fig. 1a, exhibiting a typical amorphous “hump” in the XRD pattern without any crystalline peaks. The XRD result indicates a fully amorphous alloy of the sample. Figure 1b illustrates the DSC curve of as-cast Ti36.2Zr30.3Cu8.3Fe4Be21.2 bulk metallic glass. During DSC measurements, the alloy was heated to 850 K with a constant heating rate of 20 K/min. The glass transition temperature Tg and the onset of crystallization temperature Tx can be measured to be around 581 K and 651 K, respectively. The width of the supercooled liquid region (SLR) defined as \(\varDelta T\) = Tx − Tg is determined as 70 K, which is relatively comparable with many other good glass formers [19, 20].

3.2 Dynamic Mechanical Analysis

Figure 2 shows variations of the normalized storage modulus E′/Eu and loss modulus E″/Eu during heating with a frequency of 0.3 Hz. Two regions can be observed as marked in Fig. 2, which is very similar to the results reported in other metallic glasses [6, 21,22,23]: (1) from room temperature to ~ 500 K, the normalized storage modulus E′/Eu is high and keeps a constant while the normalized loss modulus E″/Eu is almost zero and can be ignored. The present metallic glass in this region is dominated by elasticity. As continually heating to ~ 630 K, the normalized loss modulus E″/Eu begins to increase to its maximum value corresponding to the main α relaxation. Meanwhile, the normalized storage modulus E′/Eu also drops as the temperature increases, and the viscoelastic component reaches its maximum value; (2) when the temperature is above 630 K, it is found that both the storage modulus and loss modulus show an evident temperature dependence. There are several crystallization events based on the DMA measurement, which is in good accordance with the DSC result.

Temperature dependence of the normalized storage modulus E′/Eu and loss modulus E″/Eu of the Ti36.2Zr30.3Cu8.3Fe4Be21.2 bulk metallic glass. The driving frequency is set to be 0.3 Hz, and the heating rate is 3 K/min. The unrelaxed modulus Eu is estimated as the storage modulus at ambient temperature

Figure 3 shows the natural logarithm of tan\(\delta\) as a function of the reciprocal of temperature 1000/T. A linear relationship can be observed at the low temperature region, and it is deviated near the Tg as temperature increases. The characteristic temperature at the turning point of the curve is marked as Tg in Fig. 3, which is in good agreement with the DSC results.

In order to better understand the dynamic mechanical relaxation process, the quasi-point defect (QPD) model proposed by Perez [24, 25] is adopted. In the framework of QPD model, the micro-domains corresponding to the fluctuations in enthalpy or entropy in glass-forming liquids are defined as quasi-point defects [26]. In the framework of the QPD model, the characteristic time \(\tau^{*}\) corresponds to the average time required for the structural units to move over its own distance, which is expressed as [27]:

where \(\tau_{\beta }\) represents the mean duration required for the thermal–mechanical driven transitions of structural units, and \(t_{0}\) is a pre-exponential factor, which reflects the time scale. It should be mentioned that \(\tau_{\beta }\) can be described by an Arrhenius law:

where Ea is the activation energy of the process, k is the Boltzmann constant, τ0 is a scaling factor. It should be noted that the correlated parameter χ, which is closely associated with the concentration of quasi-point defects (Cd) in glassy materials [25]. According to the QPD theory, atomic or molecular mobility of the glassy materials can be described by the correlation factor χ: for the correlated parameter χ = 0, it can be considered as a perfect crystal where any movement of a structural unit is constrained by other structural units, and the atoms are at the maximum degree of order. On the other hand, when the correlated parameter χ equals to 1, the system stays in totally disordered, which corresponds to the ideal gas where any structural movement is independent. As described above, the correlation factor χ ranges from 0 (fully constrained) to 1 (constraint free). On the basis of the QPD model, the concentration of these defects is strongly temperature dependent. Below the glass transition temperature Tg, the amorphous material is frozen in an iso-configuration state where the concentration of quasi-point defects remains constant since the correlation factor χ keeps constant below the Tg.

The dynamic mechanical relaxation process is sensitive to the driving frequency. In general, the loss modulus will move toward the higher temperature region as the frequency increases. Such changes can be easily interpreted as the raising frequency is equivalent to reduce the temperature from the perspective of time–temperature equivalence principle [28]. As illustrated in Fig. 4, the temperature dependence of loss modulus E″ of Ti36.2Zr30.3Cu8.3Fe4Be21.2 metallic glass varies with different driving frequencies. Similar to other metallic glasses [7], the main α relaxation (the first peak in E″) gradually shifts toward the high temperature region as the driving frequency raised from 0.1 to 3 Hz. The amplitude of the offset depends on the activation energy of the corresponding relaxation event. Importantly, the variations of the storage modulus E′ at different driving frequencies exhibit the same feature. The location of valley marked with dotted lines do not change as frequency increases, which may be related to the fast crystallization events of the Ti-based metallic glass at certain temperatures.

3.3 Heat Treatment on the Mechanical Relaxation

In order to further probe the influence of heating treatments on the dynamic mechanical relaxation behavior of the Ti36.2Zr30.3Cu8.3Fe4Be21.2 metallic glass, the sample was annealed under constant temperature during the DMA equipment. To avoid crystallization, the annealing temperature was set below the Tg. As shown in Fig. 5, the isothermal treatment at 523 K results in the increase in the storage modulus and the decrease in the loss modulus, respectively, which indicates that physical annealing increases the elastic component and reduces the viscoelastic component for metallic glasses. The results are in good agreement with other reports [21, 29].

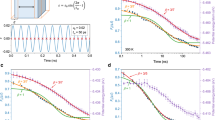

Figure 6 exhibits the evolution of internal friction tanδ over the annealing time for Ti36.2Zr30.3Cu8.3Fe4Be21.2 metallic glass. From the perspective of the QPD model, the physical aging would cause the reduction of the concentration of defects [30]. As for the annealing experiment, the decrease of defect concentration under the physical aging will lead to the reduction of the atomic mobility and then reduce the internal friction tan\(\delta\) of the present metallic glass. The evolution of the loss factor tanδ could be well described using the Kohlrausch–Williams–Watts (KWW) type of equation [31, 32]:

where \(\tau\) is the characteristic relaxation time required for the system to reach an equilibrium state, which is governed by the atomic mobility during the structural relaxation of amorphous alloys. The parameter A denotes the maximum magnitude of the relaxation. \(\beta_{\text{KWW}}\) is the Kohlrausch exponent with the value ranges from 0 to 1, reflecting the distribution shape of the relaxation time. Based on Eq. (3), the value \(\beta_{\text{KWW}}\) of this curve could be determined to be 0.374 (as shown in Fig. 6). In such a case, another parameter \(\varDelta\) changes with annealing time could be defined as follows [33]:

The inserted figure in Fig. 6 shows the correlation between \({ \ln }({ \ln }\left( { - \varDelta } \right)\) and logarithm of annealing time ln(t), from which a good linear relationship could be observed. The Kohlrausch exponent \(\beta_{\text{KWW}}\) could be adopted to describe the distribution of the relaxation time considering the relaxation in metallic glasses is non-exponential. The value of \(\beta_{\text{KWW}}\) reflects the deviation degree of the relaxation behavior away from a single Debye relaxation for which this value would be equal to 1.

In amorphous materials, atoms or molecules in different regions have various ways to move to reach their equilibrium states, which leads to different relaxation time for different micro-domains, and then such phenomena is defined as dynamic heterogeneity [34]. Dynamic heterogeneity in amorphous materials has been observed from experimental studies [35] and could also be reflected by computational simulations on supercooled liquids [34]. The cooperative movement of rearranging structural units, resulting in the non-exponential feature in glass, reflects its wide distribution of the relaxation time and the degree of dynamic heterogeneity. Physical aging at different temperatures will result in different degrees of the structural relaxation. Figure 7 illustrates the physical aging experiments of Ti36.2Zr30.3Cu8.3Fe4Be21.2 BMG with different annealing temperatures below Tg. The amplitude of the relaxation of tan\(\delta\) is strongly related to the annealing temperature, while higher annealing temperatures lead to greater drops in the internal friction tan\(\delta\). In addition, the variations of tan\(\delta\) with annealing time at different annealing temperatures could also be well fitted by Eq. (3). As a result, the values of \(\beta_{\text{KWW}}\) are given in Fig. 7 for samples annealed at different temperatures. The Kohlrausch exponent \(\beta_{\text{KWW}}\) ranges from 0 to 1. \(\beta_{\text{KWW}}\) = 1 indicates a single Debye relaxation time rather than a distribution of relaxation time. A smaller \(\beta_{\text{KWW}}\) value corresponds to a greater deviation from a single exponential decay and then a broader distribution of the relaxation time. As a consequence, the smaller \(\beta_{\text{KWW}}\) generally represents the greater dynamic heterogeneity.

To study the effects of thermal history on the dynamic mechanical relaxation of Ti36.2Zr30.3Cu8.3Fe4Be21.2 metallic glass, experiments of progressive DMA heating and cooling cycles were carried out. There are totally four heating processes until finally heating to 800 K, each heating was performed after the cooling to room temperature. During the test, the DMA sample was cooled to the room temperature after each heating procedure, then reheated in the next run. Generally, successive heat treatment causes the increase in the storage modulus and the decrease in the loss modulus [36]. As shown in Fig. 8, the normalized loss modulus E′/Eu increases progressively while the peaks of loss modulus shift to higher temperatures simultaneously after previous heating. That implies that the heating and cooling cyclic treatment, similar to the effect of annealing, could lead the reduction of the quasi-point defects. Consequently, the atomic mobility in Ti36.2Zr30.3Cu8.3Fe4Be21.2 metallic glass decreases drastically during the progressive heating process. The result is consistent with previous investigations [36, 37].

4 Conclusion

The dynamic mechanical behavior of Ti36.2Zr30.3Cu8.3Fe4Be21.2 metallic glass has been studied by mechanical spectroscopy. The main α relaxation shown in the loss modulus is well associated with the glass transition phenomenon in metallic glasses. In the framework of QPD model, the relationship between atomic mobility and the concentration of defects has been established by incorporating the correlated factor χ. In addition, the structural relaxation in Ti36.2Zr30.3Cu8.3Fe4Be21.2 metallic glass has been investigated during annealing below the glass transition temperature Tg. The structural relaxation under annealing results in the increase in the storage modulus and the decrease in the loss modulus in metallic glasses, respectively. The variations of tan\(\delta\) as a function of annealing time could be well fitted by the stretched exponential relaxation equation, and the Kohlrausch exponent \(\beta_{\text{aging}}\) can reflect the degree of the dynamic heterogeneity in metallic glasses.

References

A.L. Greer, Y.Q. Cheng, E. Ma, Mater. Sci. Eng. R Rep. 74, 71 (2013)

W.H. Wang, Prog. Mater. Sci. 57, 487 (2012)

F.F. Wu, J.S. Wei, K.C. Chan, S.H. Chen, R.D. Zhao, G.A. Zhang, X.F. Wu, Sci. Rep. 7, 42598 (2017)

M. Chen, NPG Asia Mater. 3, 82 (2011)

H.B. Yu, W.H. Wang, K. Samwer, Mater. Today 16, 183 (2013)

J.C. Qiao, J.M. Pelletier, J. Mater. Sci. Technol. 30, 523 (2014)

J.C. Qiao, Q. Wang, D. Crespo, Y. Yang, J.M. Pelletier, Chin. Phys. B 26, 016402 (2017)

R. Richert, Phys. Rev. Lett. 104(4), 085702 (2010)

P. Luo, Y.Z. Li, H.Y. Bai, P. Wen, W.H. Wang, Phys. Rev. Lett. 116, 175901 (2016)

B. Ruta, Y. Chushkin, G. Monaco, L. Cipelletti, E. Pineda, P. Bruna, V.M. Giordano, M. Gonzalez-Silveira, Phys. Rev. Lett. 109, 165701 (2012)

Q. Wang, J.J. Liu, Y.F. Ye, T.T. Liu, S. Wang, C.T. Liu, J. Lu, Y. Yang, Mater. Today 20, 293 (2017)

S.V. Nemilov, Y.S. Balashov, Glass Phys. Chem. 42, 119 (2016)

J.C. Qiao, J. Cong, Q. Wang, J.M. Pelletier, Y. Yao, J. Alloys Compd. 749, 262 (2018)

F.X. Qin, Y. Zhou, C. Ji, Z.H. Dan, G.Q. Xie, S. Yang, Acta Metall. Sin. (Engl. Lett.) 29, 1011 (2016)

J. Mei, J. Li, H. Kou, J.-L. Soubeyroux, H. Fu, L. Zhou, J. Alloys Compd. 467, 235 (2009)

J. Qiao, S. Feng, J. Pelletier, D. Crespo, E. Pineda, Y. Yao, J. Alloys Compd. 726, 195 (2017)

H.B. Yu, K. Samwer, Phys. Rev. B 90, 114201 (2014)

L. Zhang, Z.W. Zhu, A.M. Wang, H. Li, H.M. Fu, H.W. Zhang, H.F. Zhang, Z.Q. Hu, J. Alloys Compd. 562, 205 (2013)

Y.H. Sun, A. Concustell, M.A. Carpenter, J.C. Qiao, A.W. Rayment, A.L. Greer, Acta Mater. 112, 132 (2016)

Y. Wu, W.L. Song, Z.Y. Zhang, X.D. Hui, D. Ma, X.L. Wang, X.C. Shang, Z.P. Lu, Chin. Phys. B 56, 3960 (2011)

J.C. Qiao, J.M. Pelletier, Intermetallics 28, 40 (2012)

J.C. Qiao, Y. Yao, J.M. Pelletier, L.M. Keer, Int. J. Plast. 82, 62 (2016)

Q. Wang, J.M. Pelletier, J.J. Blandin, J. Alloys Compd. 504, 357 (2010)

J. Perez, Polymer 29, 483 (1988)

J. Perez, Solid State Ion. 39, 69 (1990)

R. Rinaldi, R. Gaertner, L. Chazeau, C. Gauthier, Int. J. Non-Linear Mech. 46, 496 (2011)

M.B.M. Mangion, J.Y. Cavaille, J. Perez, Philos. Mag. A Phys. Condens. Matter Struct. Defect Mech. Prop. 66, 773 (1992)

K.P. Menard, Dynamic Mechanical Analysis: A Practical Introduction (CRC Press, Boca Raton, 2008)

D.P. Wang, Z.G. Zhu, R.J. Xue, D.W. Ding, H.Y. Bai, W.H. Wang, J. Appl. Phys. 114, 362 (2013)

J.C. Qiao, J.M. Pelletier, R. Casalini, J. Phys. Chem. B 117, 13658 (2013)

X.D. Wang, J.Z. Jiang, S. Yi, J. Solids Non-Cryst. 353, 4157 (2007)

J.C. Qiao, J.M. Pelletier, C. Esnouf, Y. Liu, H. Kato, J. Alloys Compd. 607, 139 (2014)

J.M. Pelletier, J. Non-Cryst. Solids 354, 3666 (2008)

L. Berthier, Physics 4, 42 (2011)

R. Richert, J. Phys.-Condens. Matter 14, 26721-1 (2002)

J.C. Qiao, J.M. Pelletier, H.C. Kou, X. Zhou, Intermetallics 28, 128 (2012)

J. Qiao, B. Sun, J. Gu, M. Song, J. Pelletier, J. Qiao, Y. Yao, Y. Yang, J. Alloys Compd. 724, 921 (2017)

Acknowledgements

The research was supported by the National Natural Science Foundation of China (Nos. 51611130120, 11772257, 11572249, 51871132). J.C. Qiao is also supported by the Fundamental Research Funds for the Central Universities (Nos. 3102018ZY010, 3102017HQZZ012).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://springerlink.bibliotecabuap.elogim.com/journal/40195

Rights and permissions

About this article

Cite this article

Qiao, J.C., Chen, Y.H., Lyu, G.J. et al. Mechanical Relaxation of a Ti36.2Zr30.3Cu8.3Fe4Be21.2 Bulk Metallic Glass: Experiments and Theoretical Analysis. Acta Metall. Sin. (Engl. Lett.) 32, 726–732 (2019). https://doi.org/10.1007/s40195-018-0860-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-0860-z