Abstract

The hybrid method using a discrete element method (DEM) and an incompressible smoothed particle hydrodynamics (ISPH) method was developed to clarify the slag formation process during submerged arc welding. As a result, the weld pool formation and the slag formation processes were simulated simultaneously using the hybrid method. Moreover, the edge of the slag obtained by the simulation was thinner and the center of it was thicker, which were same tendency of actual slag. The maximum thickness of the slag near the weld line was equivalent to about 2.5 mm. Although the slag thickness obtained from the computation was a little thinner than the experiment, it supported the validity of this hybrid model. Thereafter, the ensemble average processing was carried out to discuss about the velocity field of a weld pool. The averaged result showed that velocity field of a weld pool was synchronized periodically with the transportation of a molten metal droplet.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Submerged arc welding (SAW) is an arc welding process which is applied to large structures such as buildings, ships, and bridges since this process can obtain deep penetration due to its high welding efficiency. Because the welding part including the arc plasma, the molten metal, and the weld bead is covered with flux powders, it is still hard to observe the welding phenomena. Recently, some groups have tried to visualize those phenomena. For example, Reisgen et al. visualized inside of a cavity under the flux (arc space) and investigated the molten metal droplet transfer during a SAW [1]. In their study, the heat source moved along with a wall which was made of a quartz glass. The molten metal droplet transfer process and the behavior of a weld pool were observed through the wall. Moreover, they inserted a ceramic tube into the flux. The arc plasma behavior was captured by a high-speed camera through the tube. They successfully visualized the molten metal droplet transfer and fluxes around the arc space as well. Gött et al. also inserted a ceramic tube into an arc space and investigated the molten droplet behavior [2]. In addition, it was indicated that the main gas components in the space were iron vapor and gasified flux. On the other hand, to understand SAW phenomena, there are also some studies using numerical simulation. Cho et al. investigated the weld pool convection during a SAW [3]. They calculated velocity fields in a weld pool using an arc model which was approximated from experimental data. The penetration depth obtained from their calculation agreed with an experiment. Meanwhile, Komen et al. and Tanaka et al. simulated arc phenomena in a SAW with a low welding current [4, 5]. They simulated the arc phenomena to compare with an X-ray observation using a low welding current. Although their model simply assumed an axial symmetry condition, they clarified the energy balance from a cathode to an anode during the welding and indicated that 80% of the emission loss of a plasma was transported to fluxes around the arc plasma. However, they did not consider the behavior of fluxes because it is difficult for traditional grid methods to simulate the behavior of flux powders. Since the flux compositions affected the penetration depth and the slag detachability [6], the flux is one of the important welding elements of a SAW. Therefore, the computational model considering the flux behavior is necessary to understand SAW phenomena deeply. In this study, an incompressible smoothed particle hydrodynamics (ISPH) method is used to simulate the molten metal behavior because the method is suitable to compute the dynamic behavior of fluid with large deformation. Moreover, it is difficult for traditional grid methods to simulate dynamic behavior of powders. On the other hand, a particle in discrete element method (DEM) can represent a particle of flux powder. Therefore, DEM is employed in this study because it can simulate dynamic behaviors of flux powders more accurately than grid-based methods. Then, the hybrid method using the ISPH method and DEM is developed to simulate weld pool formation and slag forming processes simultaneously during a SAW. However, the whole computational domain should be filled by SPH particles to simulate the arc behavior, which increases the computational time dramatically. So, the temperature distribution and current density distribution obtained by finite volume method [4, 5] are used as a heat source because of the limitation of Lagrange type computational methods for fluid like an ISPH method. This study focuses on SAW phenomena with a low welding current.

2 Governing equations

2.1 Momentum equations for DEM

In this computational model, behaviors of the powder flux, the melted slag, and the resolidified slag are treated using a DEM [7]. According to the Newton’s equation of the motion, the velocity of a particle a is determined by

where \( \overrightarrow{u} \) is the velocity vector of the particle, t is the time, m is the mass of a flux, and k is the spring constant. The subscript b is an index of particles which contacts with particle a. d is the diameter of a particle, r is the relative distance, \( \overrightarrow{n_{\mathrm{n}}} \) is the normal unit vector, \( \overrightarrow{F_{\mathrm{s}}} \) is the friction force vector, η is the damping coefficient, \( \overrightarrow{u^{\prime }} \) is the relative velocity vector at a contact point of particles, Farc is the arc pressure, S is the cross-sectional area of a particle, and \( \overrightarrow{g} \) is the acceleration vector of gravity. The angular velocity of a particle a is described as

Here, \( \overrightarrow{\omega} \) is the angular velocity vector, I is the inertia moment, and c is the contact point between particle a and b.

2.2 Momentum equation for ISPH

The velocity of a melted metal particle a is calculated by the Navier-Stokes equation based on the previous study for the weld pool convection during a gas metal arc welding process [8], which is written as

Here, p is the pressure, ρ is the density, W is the kernel function, δ is the dimension number and λ is the parameter [9]. n is the number density, μ is the viscosity coefficient, j is the current density, B is the magnetic flux density, h is the kernel radius which is the same as the particle diameter, f attract is the attractive force [10], V is the volume of a particle, and Parc is the arc pressure on the base metal surface. The current density, the magnetic flux density, and the arc pressure are obtained by the previous study [4]. b′ is an index of particles in the kernel radius of particle a. In this simulation, the density homogenizing algorithm [11] is used to express the incompressibility using the pressure gradient term in Eq. (3).

2.3 Energy transfer equation

Temperature changes of all particles are determined by the energy transfer equation, which is described as

T is the temperature, C is the specific heat, κ is the thermal conductivity, Hc is the contact conductance [12], Hg is the gas conductance [12], and Q is the heat generation rate. The heat generation rate acting on flux and slag particles is described as

Here, subscript CO indicates CO gas and dz means the distance through which the heat flux from CO gas passes, which is 0.09 mm. Figure 1 shows the temperature distribution on a base metal surface obtained from the previous study [4, 5]. TCO for Eq. (5) is obtained from this distribution. Uarc is radiation from the arc plasma obtained by previous study [4, 5], which is 5781.8 W. Narc is the number of flux and slag particles on the arc space surface; α is the Stefan-Boltzmann coefficient. εflux is the emission coefficient of flux.

In this study, it is assumed that the radiations emitted from flux, slag, and weld pool surface reach to the outside of flux and they are finally absorbed in atmosphere outside the flux. The heat generation rate acting on the base metal surface is expressed as,

dz′ shows the mean distance between an arc space surface and a gas, which is 0.13 mm. In this equation, Tarc is obtained from Fig. 2. This figure shows the temperature distribution on an arc space surface obtained from the previous study [4, 5]. je is the electron current density. In this study, it is estimated using the Richardson-Dushman equation as the same as the previous studies in which a consumable electrode was used [13, 14]. ϕc is the work function of a base metal, ji is the ion current density which is calculated by the subtraction of the current density and the electron current density, Vi is the ionization voltage of CO which is a major component of the atmosphere in an arc space [15], and εmetal is the emission coefficient of the base metal.

3 Computational conditions

Figure 3 shows the vertical cross-section of the computational domain. The box (20 mm × 50 mm × 20 mm) which consists of four side walls and one base metal plate is filled up by flux particles. The wire with the diameter of 1.5 mm consists of solid particles. This wire moves at 5 mm/s in the welding direction and it also moves at wire feed rate in y-direction. Moreover, wire particles within three particles in y-direction from the tip of a wire become droplet particles every 15 ms. The velocity of a droplet particle is set to be 1.5 m/s and the droplet falls vertically. Temperature change of a wire is not considered and the temperature of a droplet particle is set to be 2500 K. The space which is equivalent to the arc space is formed at tip of a wire. It is the half-ellipsoid shape shown in Fig. 4 and it is described as

(x, y, z) are positions of an arc space and (xarc, yarc, zarc) are those of the center of a heat source. yarc is the same as the thickness of a base metal and zarc equals to the half of width of it. lx, ly, lz are the axes of the ellipsoid for each direction. lx, lz are 4.3 mm and ly is 4.5 mm. The gage pressure (3500 Pa) is given to flux and slag particles on the elliptical surface as the arc pressure Farc, which is written as

raarc is the relative distance between particle a and the center of a heat source.

This study adopts several assumptions as follows. In SPH method, particles cannot express continuous body when number of liquid particles is low. Therefore, particles do not immediately move when the particles change their layer from solid to liquid. When 120 particles change their layer from solid to liquid, the motions of liquid particles start. In this study, convection inside of melted slag are not simulated accurately because melted slag behavior is calculated by a DEM for simplification. So, the heat conductivity of a molten slag is assumed to be three times as large as that of flux powders to consider the effects of the convection [16]. When the temperature of a base metal or a flux particle reaches the melting point, the temperature does not change during the phase change. After the particle gains the latent heat, the temperature starts to change again. However, the gasification of the molten slag is not considered. Table 1 shows the welding conditions of a heat source. In the previous study [4, 5], the welding current was set to be 250 A to compare with the X-ray observation and 1.2 mm diameter wire was used because the observation was a laboratory-scale experiment in which a power source for a gas metal arc welding was used. Table 2 shows the other computational conditions. In this study, material properties of the mild steel are given to all SPH particles and material properties of the melted flux are given to DEM particles according to the previous study [4, 5].

4 Results and discussion

Figure 5 shows temperature distribution and particle property distribution at each time. This figure shows the vertical cross-section along with the weld line. In the temperature distribution, particles in light gray color represent those with temperatures that are lower than the melting point of a flux (1486 K); they in dark gray color express those with temperatures which are lower than the melting point of a base metal (1750 K), while blue and red particles show those with temperatures that are higher than the melting point of a base metal. In the particle state distribution, base metal, wire, and walls are shown by dark gray, a molten metal is expressed by blue. The molten metal droplet is expressed by red and the powder flux is colored by brown. When once the temperature of the flux becomes higher than the melting point of it, the flux particle is regarded as a slag particle and it is colored by white. From the result, base metal and powder fluxes are heated by the heat source, and the molten metal starts to move around t = 0.5 s (Fig. 5a). The mass of the weld pool increases by the droplet transfer and the reinforcement is formed at the back of the weld pool (Fig. 5b, c). After that, the flux particles are melted at the back of the wire and a slag is formed with the bead formation, which covers a weld bead (Fig. 5d). These results show that the weld pool formation and slag forming processes are able to be simulated simultaneously using this hybrid method.

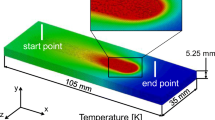

To discuss about the velocity field of a weld pool, the ensemble average processing is carried out using 66 cycles of droplet transfers after t = 3.0 s. The data are processed on the coordinate system moving with the drop position. Figure 6 shows ensemble averaged velocity fields on a weld pool surface at each time. In Fig. 6, the color shows magnitudes of the velocity at each coordinate. The magnitude of the velocity in the figure is calculated by only x and y components. Tc is the period of a droplet transfer time (15 ms) and tc/Tc = 0~1 means 1 cycle of a droplet transfer. x = 0.0 shows the center of a heat source. When a droplet reaches to a weld pool, a weld pool surface is pushed down and the velocity of a weld pool at center of the heat source increases (Fig. 6a, b). Then, the velocity of a weld pool surface around the center of a heat source also increases (Fig. 6c). The region which has a large velocity reduces its size from inside of a weld pool (Fig. 6d). Since a weld pool surface which is dented by the metal droplet transfer flows back in y-direction, the velocity near the center of a heat source decreases. However, that near the weld pool surface is still large because of the electromagnetic force. After that, the velocity field such as Fig. 6e, f is kept until the next droplet transfer. Thus, it is showed that velocity field of a weld pool is synchronized periodically with the transportation of a molten metal droplet. Figure 7 shows the slag appearances at t = 4.0 s. The color of particle shows its temperature. Figure 7a is the bird’s eye view and black dash line in the figure shows the center of a heat source. Figure 7b is the figure to see the slag from a weld bead surface and black circle in the figure shows the center of a heat source. Moreover, Fig. 7c shows the cross-section at x = 0.03 m in Fig. 7b. From Fig. 7a, b, a slag is formed like a dome-shape which covers a weld bead. In this simulation, the maximum thickness of this slag near the weld line is equivalent to about five particle layers. Edge of the slag is thinner and the center of it is thicker, which are the same tendency of actual slag (Fig. 7c). On the other hand, it was made clear that the slag thickness on this welding condition was 4.5 mm by the X-ray observation [4, 5]. Although the slag thickness obtained from the computation is a little thinner than the experiment, these results support the validity of this hybrid model.

5 Conclusions

A hybrid method using a DEM and an ISPH method was developed and behaviors of flux and molten metal during a SAW were simulated simultaneously. The conclusions of this study are summarized as follows:

-

1.

The weld pool formation and the slag forming processes with the time evolution were simulated simultaneously using the hybrid model.

-

2.

From ensemble average results, complicate velocity field with the molten metal droplet transfer was showed.

-

3.

Edge of the slag was thinner and the center of it was thicker, which were same tendency of actual slag.

-

4.

The maximum thickness of this slag near the weld line was equivalent to about 2.5 mm. Although the slag thickness obtained from the computation was a little thinner than the experiment, it supports the validity of this hybrid model.

References

Reisgen U, Schäfer J, Willms K (2016) Analysis of the submerged arc in comparison between a pulsed and non-pulsed process. Weld World 60(4):703–711. https://doi.org/10.1007/s40194-016-0336-6

Gött G, Gericke A, Henkel KM, Uhrlandt D (2016) Optical and spectroscopic study of a submerged arc welding cavern. Weld J 95(12):491–499

Cho DW, Song WH, Cho MH, Na SJ (2013) Analysis of submerged arc welding process by three-dimensional computational fluid dynamics simulations. J Mater Process Technol 213:2278–2291. https://doi.org/10.1016/j.jmatprotec.2013.06.017

Komen H, Matsui S, Konishi K, Shigeta M, Tanaka M, Kamo K (2017) Modeling of submerged arc welding phenomena and experimental study of the heat source characteristics. Q J Japan Weld Soc 35(2):93–101 (in Japanese). https://doi.org/10.2207/qjjws.35.93

Tanaka M, Shigeta M, Miyasaka F Kasano K (2015) A simplified numerical model of submerged arc welding. 68th IIW Annual Assembly and International Conference, Doc. 212-1376-15

Singh B, Khan ZA, Siddiquee AN (2013) Review on effect of flux composition on its behavior and bead geometry in submerged arc welding (SAW). J Mechanical Eng Res 5(7):123–127. https://doi.org/10.5897/JMER2013.0284

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Gèotechnique 29(1):47–65

Komen H, Shigeta M, Tanaka M (2018) Numerical simulation of molten metal droplet transfer and weld pool convection during gas metal arc welding using incompressible smoothed particle hydrodynamics method. Int J Heat Mass Transf 121:978–985. https://doi.org/10.1016/j.ijheatmasstransfer.2018.01.059

Koshizuka S, Oka Y (1996) Moving-particle semi-implicit method for fragmentation of incompressible fluid. Nucl Sci Eng 123(3):421–434. https://doi.org/10.13182/NSE96-A24205

Ito M (2015) Numerical simulation of flow phenomena in arc welding process by incompressible SPH method. Tohoku University, Sendai, Ph. D. thesis (in Japanese)

Shigeta M, Watanabe T, Fukunishi Y (2009) Incompressible SPH simulation of double-diffusive convection phenomena. Int J Emerg Multidisciplinary Fluid Sci 1(1):1–18. https://doi.org/10.1260/1756-8315.1.1.1

Vargas WL, McCarthy JJ (2002) Conductivity of granular media with stagnant interstitial fluids via thermal particle dynamics simulation. Int J Heat Mass Transf 45:4847–4856. https://doi.org/10.1016/S0017-9310(02)00175-8

Haidor J (1998) A theoretical model for gas metal arc welding and gas tungsten arc welding. I. J Appl Phys 84(7):3518–3529. https://doi.org/10.1063/1.368527

Ogino Y, Hirata Y, Asai S (2017) Numerical simulation of metal transfer in pulsed-MIG welding. Weld World 61(6):1289–1296. https://doi.org/10.1007/s40194-017-0492-3

Terashima H, Nishiyama N, Tsuboi J (1977) Influence of slag basicity on deoxidation in submerged-arc welding -deoxidation in submerged-arc welding (report 1). J Japan Weld Soc 46(3):165–171 (in Japanese). https://doi.org/10.2207/qjjws1943.46.3_165

Yamamoto T, Yamazaki Y, Tsuji Y, Miyasaka F, Ohji T (2005) Simulation software of MAG arc welding for butt joint. Q J Japan Weld Soc 23(1):71–76 (in Japanese). https://doi.org/10.2207/qjjws.23.71

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Study Group 212 - The Physics of Welding

Rights and permissions

About this article

Cite this article

Komen, H., Shigeta, M., Tanaka, M. et al. Numerical simulation of slag forming process during submerged arc welding using DEM-ISPH hybrid method. Weld World 62, 1323–1330 (2018). https://doi.org/10.1007/s40194-018-0655-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0655-x