Abstract

The behavior of landfill depends upon the composition and characteristics of municipal solid waste (MSW) and climatic conditions of the region. MSW undergoes various complex mechanisms such as physical, chemical, thermal and biological processes during its life time in landfills which are difficult to understand. In the present study, an attempt has been made to understand such complex processes by setting up an anaerobic reactor in the laboratory. The reactor was monitored under the laboratory conditions for a period of 284 days and the obtained results from the experimental program are presented and discussed in this paper. The program includes monitoring of moisture content, pH, temperature, settlement, and quantity of leachate as well as landfill gas with respect to the simulation of measured quantity of rainfall during the experimental study. Further, physio-chemical characteristics of leachate samples were analyzed by laboratory experiments. The observed pH values were in the range of 8.5–9 and indicate the attainment of optimum condition for the degradation of MSW. The obtained total alkalinity was observed in the range of 5800–6000 mg/L with a maximum value of 7800 mg/L, The BOD to COD ratio of 0.312 ensured the gradual progress in the degradation of MSW. The average volumetric moisture content and temperature of MSW was 49.65% and 26.5 °C respectively which indicates the favorable conditions for the growth of microorganisms. Total settlement at two locations was found to be 7.6% (70.9 mm) and 9% (93.30 mm) of the initial thickness of MSW respectively. Total gas produced at the end of the 284 days is 7.8 L. The quantity of leachate generated was observed to be 77.84% of the total rainfall. The results presented in this paper could possibly be used to validate some of the existing gas generation models and other numerical models to predict the gas generation rates and the MSW behavior in landfills. The study also helps the planners and engineers in understanding the complex mechanisms to design and for the effective operation of landfills for the sustainable waste management.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Land filling is the most widely adopted method of disposing municipal solid waste (MSW) in the entire world. On the other hand, most of the MSW landfills in developing countries are either dump sites or conventional (partially) engineered landfills. Any engineered landfill must comprise of MSW contained between bottom liner system and top cover system. Improper design of containment system and operation practices at landfills could have adverse effect on the surrounding environment.

Generally, MSW consists of decomposable (organic) content such as food waste, leaves and non-decomposable content which includes metals, glass, plastics etc. The composition of MSW also varies with region and time. The rate of degradation and decomposition of the organic content in landfills depends upon the conditions favorable for the anaerobic bacterial growth in MSW. The conditions or factors include moisture content, temperature, pH, nutrients, and oxygen content. Understanding the variation in such critical factors becomes challenging, which is necessary to predict the overall time required for the complete decomposition of organic content and stabilization of landfill. This helps to plan and adopt waste management strategies in terms of utilizing extra volume of space for land filling of MSW in future.

The anaerobic condition prevails due to the depletion in oxygen content in the landfill. During the process of anaerobic degradation and decomposition, landfill generates significant quantity of leachate and Landfill gasses (LFG) which are harmful to the environment if released untreated. Therefore, by understanding the variation in critical factors, it is possible to predict potential LFG generation rates and plan for the proper utilization of LFG for power generation. The concentration of chemicals in leachate and LFG depends on the physical composition and degradation conditions of the MSW. The higher the organic content, more toxic will be the leachate and LFG over a period of time.

Typically, conventional engineered landfill consists of liner system at the bottom and cover system at the top of the MSW. The geotechnical properties of various components of containment system influence the performance of landfill as a whole. The water balance technique can be effectively used to predict or assess the total water (leachate) storage in the entire system by considering one of the hydrologic parameter, rainfall, as inflow to the system. Infiltration of rainfall in excess generates huge quantity of leachate. This could affect directly on the performance of liner system and stability of the landfill as a whole. The elevated temperature in landfills leads to the desiccation and cracking as well as reduces the life of geosynthetic materials in liner system. Evaluation of the behavior of landfill system with respect to the climatic conditions of the region is desirable to model and evaluate the landfill designs for an effective MSW management.

Literature

Moisture Content

Among various factors, moisture content is one of the critical factors for an effective degradation of MSW. The moisture content of MSW in landfills depends upon the age and composition of waste, degree of compaction, amount of organic content as well as infiltration rate of precipitation in the region [1]. Initially, moisture content is held by the surface tension forces and excess liquid drains out from the system as media after the MSW attains its field capacity. Typical field capacity of MSW reported in the literature are summarized and presented in Table 1. Generally, the field capacity of the MSW depends on the waste density [1]. The higher the density of MSW, lower would be the porosity as well as hydraulic conductivity. A critical review study conducted by [2] reports the moisture distribution in bioreactor as well as sanitary landfills, which was experimentally measured and numerically modeled by various investigators. The authors have summarized and presented various field monitoring techniques and mathematical models and the validations methods. A critical review by [3] also presents the previous investigations on the physical, chemical, thermal, biological process in MSW landfills as well as challenges involving in numerically modeling the MSW landfill undergoing coupled processes.

Temperature

The temperature in MSW is another important factor which influences the microbial growth and its activity for an effective degradation of refuse. The temperature in the range of 30 ± 4 °C would be an optimal range for the microbial activity [17]. The placement and age of waste, depth and location of the waste, and the available moisture affects temperature significantly [18]. Also, thermal conductivity properties of MSW causes heat transfer to the immediate overlaying cover and underlying liner system. As a result, the matric potential of the compacted clay liner (CCL) reduces as soil shrinks and become highly vulnerable to desiccation and cracking. This often increases the total hydraulic conductivity of the containment system [19] and affects adversely on the integrity of various components by reducing its service life [20].

The study conducted by [21] showed that the average peak temperature near the base of a landfill cell was 60 and 57 °C at 4 m above the liner system. In North America, the temperature of MSW in landfills ranges from 19 to 60 °C; 12.9 and 17.5 °C in cover system and from 14.3 to 23.3 °C at 1 and 2 m depths of the cover system, respectively [22]. The temperature of liner system, MSW and cover system may exceed 30, 60 and 20 °C respectively. As reported by [23], the base liner temperature varies from 35 to 45 °C. Elevated temperature in landfills reduces the service life of liner system by increasing the rate of antioxidant depletion from HDPE geomembrane [24]. Also, [25] reported that the temperature of the liner system ranges from 30 to 40 °C. Seasonal variation of temperature in the cover system varies in the range of 0 °C (during winter)–30 °C (during summer) [26]. Summary of variation of temperature in the landfill is presented in Table 1.

Settlement and Landfill Gas Generation

The settlement rates in landfills depends upon various factors such as type and age of waste, time since placement, organic content, pH, temperature, moisture content, compaction density and compressibility characteristics of MSW [27]. The settlement of landfills is mainly attributed to: (a) physical and mechanical processes that include the reorientation of particles, movement of fine materials into the larger voids, and collapse of void spaces; (b) chemical processes that include corrosion, combustion, and oxidation; (c) dissolution processes that consist of dissolving soluble substances by percolating liquids and then forming leachate; and (d) biological decomposition of organics with time depending on humidity and the amount of organics present in the waste [28]. MSW also undergoes differential or uneven settlements due to its heterogeneous nature, which lead to formation of cracks in containment system and reorientation of leachate collection pipe network system. It is observed that, bioreactor landfills undergo rapid stabilization due to the periodic recirculation of leachate compared to conventional landfills. This is due to the excess availability of moisture and nutrients to the bacteria. In another study, Reddy et al. [29] investigated the effect of dynamic coupled hydro-bio-mechanical processes on response of MSW and liner system in bioreactor landfill and conventional landfill, using a newly proposed two-dimensional (2-D) mathematical mode. The study revealed that, bioreactor landfill reached stabilization at the end of 16 years with a vertical strain rate of 36% whereas, a conventional landfill required 50 years to attain strain rate of 37%. The prediction of rate of settlement in landfills becomes important as it provides surplus volume for MSW disposal in future. The measured settlement rates in various MSW landfills are presented in Table 1.

Continuous anaerobic degradation of organic constituent present in the MSW generates landfill gas (LFG) during the life of a landfill. LFG typically consists of 40–60% of methane (CH4, greenhouse gas) and the rest is carbon dioxide with traces of other toxic chemical compounds. The methane and carbon dioxide emission rate could be high for 2–3 year old landfill and less for 5 year old landfill [33]. A study conducted by [34] reports that 150 ton per day of MSW produces 14,000 m3 of biogas (which accounts to be 93 m3 per ton MSW) with 55–65% of CH4, by anaerobic digestion, from which 1.2 MW of power can be generated. The LFG efflux rates are higher during the summer and less during the winter season [35]. The cover system in landfills plays a major role in controlling the emission of LFG into the atmosphere. The presence of methane oxidizing microbes in the cover soil controls the CH4 emissions. Also, emission rate of CH4 being higher from landfills, the use of biologically active cover (biocovers) consisting of yard waste compost significantly reduces the LFG emissions. It is estimated that, 15–55% of methane oxidation from these biocovers, whereas only up to 35% of oxidation can be expected from normal soil covers [36].

Objectives

Based on the comprehensive review of literature, in the present study, an attempt has been to investigate the behavior of a conventional landfill system under the influence of rainfall using a large scale anaerobic reactor in the laboratory conditions. For this purpose, an anaerobic reactor was set up to monitor until the organic or decomposable matter undergo complete degradation. However, this paper presents the results obtained from the experimental program which includes physiochemical characteristics of leachate samples, seasonal variations in moisture content, temperature, leachate and gas production. In addition, a relationship between rainfall and leachate generation rate is derived from the obtained results.

Experimental Program

Design of Anaerobic Reactor

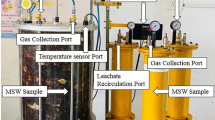

A prototype of a conventional landfill system of size 75 cm width, 75 cm length and 175 cm height was fabricated in the laboratory to study and understand the behavior of landfill system. The set up was made of 1.2 cm thick acrylic sheets. The system consists of MSW layer between the liner system and cover system. The specification for the landfill liner and cover system [37] was downscaled for the laboratory set up. The Specifications include 120 cm thick cover system and 105 cm thick liner system. Accordingly, the cover system and liner system was reduced to 21.66 and 15.23% of the above mentioned specifications respectively. Considering waste thickness of 5 m at the field, it was downscaled to 104 cm (21%) for the purpose of laboratory investigations. The downscale ratio was chosen based on the height of the rector. In order to avoid clogging of drainage layer from soil particles and mixing of materials of different layers, a 100 GSM non-woven, needle punched geotextile of 1 mm thick was placed as a separation layer at the interface of top cover, MSW layer and bottom liner system. Geotextile was reduced to the rector size in terms of length and breadth keeping the thickness unvaried. The reactor was also made air tight using silicone gel to avoid leakage of leachate and gas. Placement and properties of various components of the system are explained in the subsequent sections. Schematic view and photograph of the anaerobic reactor is as show in Fig. 1a, b.

At the bottom of the reactor, a 9 cm thick gravel layer was placed to ease the flow of leachate into the leachate collection tank. An acrylic perforated plate of 1 cm thick was placed just above the gravel layer to separate the liner system and the leachate collection layer. The liner system of 16 cm thick consists of a drainage layer and compacted clay layer. Gravel of 6 cm thick, weighing 37 kg with particle sizes between 12.5 and 9 mm was used for the drainage layer. The layer was compacted to a density of 18.43 kN/m3. The locally available clay soil was used as a barrier material in the liner system. Clay soil of thickness 10 cm was compacted to achieve 14.7 kN/m3 density at 26.13% natural water content. A HDPE geomembrane of 1 mm thick was reduced to the rector size and sandwiched between the clay barrier and drainage layer as a component of composite liner. In order to replicate the field conditions, the geomembrane was punctured with a rectangular hole of size, 5 cm in length to 1 cm in width, at the center. The barrier layer was laid at a slope of 2% to collect the leachate above the liner system. This could reduce the leachate head inside and leakage through the liner system.

Municipal solid waste (MSW, compost reject) collected from a nearby landfill site (Mavallipura landfill, Bangalore) was used for the experimental studies. Physical composition of the MSW was studied on the dry MSW samples and its composition is presented in the Table 2.

The collected refuse from the landfill was approximately 6 months old by the time experiments started. The reactor was filled with 434.5 kg of MSW to a total thickness of 104 cm in five layers. Waste particles of sizes less than 36 mm was filled at natural water content of 44% and compacted uniformly to achieve a density of 7.26 kN/m3. Small scale laboratory tests were conducted to determine the hydraulic conductivity of MSW. The obtained values of hydraulic conductivity of MSW from constant head and falling head test methods was 6.4 × 10−4 and 4.35 × 10−4 cm/s [38]. The reactor also consists of two acrylic perforated plates of 10 mm thick and geotextile of 1 mm thick, are placed at the bottom and top of the MSW to avoid clogging of drainage material and mixing of clay with MSW.

The cover system of thickness 26 cm consisting of three different layers was placed above the MSW layer. Earthen red soil of thickness 8 cm was used as a top soil layer. Indian red earthen soil of weight 74.6 kg with volumetric water content of 8% and passing through a 4.75 mm sieve was filled and compacted to a density of 16.27 kN/m3. Red earthen soil used in this study contains non-expansive kaolinite clay as the chief clay mineral and hydraulic conductivity of the soil was 5 × 10−6 cm/s [39]. Gravel of 8 cm thick was placed at a density of 18.43 kN/m3 as a drainage layer below the red earthen soil layer. Gravel (84.75 kg) with particle sizes between 12 and 9.5 mm was used as a drainage material. Clay barrier of 10 cm thick was provided with the same specification as provided for liner system. An outlet valve was provided at the side to collect drained water from the drainage layer.

A standard cylindrical type rain gauge instrument was placed at an open place where there was no obstruction from trees or buildings near the laboratory, to measure the amount of rainfall. Quantity of rainfall collected in the graduated funnel placed inside the cylinder was recorded manually a day after rainfall. A small tank of 15 L capacity was placed above the experimental unit as a water reservoir in the laboratory to simulate the rainfall. A measured amount of rainfall was added through the inlet valve provided at the top of the experimental unit, as input to the system. A water distribution pipe network was placed at the top of the cover system to distribute the water uniformly over the area.

Variation in moisture content at various locations in MSW layer and liner system was observed using GS1 rugged volumetric water content sensors which are procured from the Decagon devices. EM 50 data logger was utilized to read and store the data during the monitoring duration. The moisture content sensor determines volumetric water content (VWC) by measuring the dielectric constant of the medium using capacitance and frequency domain technology. It supplies a 70 MHz oscillating wave to the sensor prongs that charges according to the dielectric of the material. The 70 MHz frequency minimizes salinity and textural effects, making the sensor accurate in almost any soil or soilless medium. It arrives with generic calibrations for mineral soils and soilless media. Three sensors are installed in the MSW layer each at a depth of 25 cm (top right farther corner), 50 cm (exact centre), and 75 cm (bottom left closest corner) from the top surface of the MSW layer (see Fig. 1a). Another pair of sensor was placed inside the clay barrier in the liner system. All the five sensors are calibrated using MSW samples in the laboratory before installation. Errors from the calibration test were found to be in the range of ±0.07% which was considered to be acceptable. These five sensors are connected to the data logger and the recorded data can be retrieved using the software which was installed in a computer.

Variation of temperature inside the cover system and MSW layer was observed using six 2k-type sensor probes during the monitoring period. Four sensors are placed in the MSW layer; one sensor at a depth of 25 cm (top left closest corner), two sensors are placed diagonally at a depth of 50 cm (centre) and one sensor was placed at a depth of 75 cm (bottom right farther corner) from the top of the MSW layer two more sensors are placed in the clay soil layer of the cover system (see Fig. 1a). The temperature was monitored and recorded using a data logger before each rainfall simulation.

The experimental unit was equipped with two dial gauges, which are mounted to two separate rods and fixed at the top of the experimental unit in order to monitor the settlement of MSW. The rods are placed at two edges above the MSW layer through the inserted pipes. Settlement of MSW was observed and recorded manually using the dial gauges before each rainfall simulation. Meanwhile, dial gauges need to be reset to zero after reaching the maximum count.

The reactor was made leak proof and facilitated with outlet valves to collect leachate and gas generated from the degradation of MSW. Leachate was periodically collected through an outlet valve provided at the bottom which was kept open during the monitoring period and the quantity of leachate was recorded. The leachate samples are collected on a monthly basis and stored in capped plastic bottles at room temperature in the dark place until they were tested. The reactor was equipped with an air tight PVC cylindrical pipe of 15 cm diameter and 110 cm height, to collect gas through an outlet valve provided at the top. The cylinder was marked with a graduated scale and the collected volume of gas can be quantified by water displacement method during the monitoring.

Results and Discussion

This section presents and discusses the results obtained from the monitoring of the large scale anaerobic reactor from the beginning of the program up to 284 days (from 1st August 2015 to 15th May 2016). The reactor was set up for continuous monitoring until the organic content in the filled MSW completely degrades and reaches stabilization stage.

Water Balance and Leachate Quality Analysis

The amount of rainfall at the location (Centre for Sustainable Technologies, IISc, Bangalore) was measured and recorded using a standard cylindrical rain gauge instrument (see Fig. 1a) and simulated using the water reservoir (see Fig. 1b) since the beginning of the experimental program. A plot of observed monthly total rainfall in the region during the monitoring period is presented in Fig. 2. It was observed that the region has received maximum rainfall of 169.20 mm in November 2015 and no rainfall was observed during December 2015, February, March and April 2016.

The observed amount of rainfall was simulated to the reactor on a daily basis depending on the day of rainfall event. The quantity of leachate generated was collected and measured before the simulation of the next rainfall. The water balance model for the system can be given by Eq. 1. The model considers rainfall (P) as inflow to the system, leachate as outflow from the system and δS as the water storage in the system. The evaporation and evapotranspiration losses are considerably significant in the field. These factors depends upon the climatic conditions (season, temperature, humidity etc.) and vegetation conditions (type of plant, root depth etc.) in the field. In the present study, the experiment was carried out in a closed reactor placed inside the laboratory. Therefore, evaporation and evapotranspiration losses are negligible and not accounted for the analysis.

The results of the water balance of the system presented in Fig. 3 shows 324.66 mm (182.62 L) of generated leachate for a total rainfall of 417.10 mm (234.62 L). The quantity of leachate generated was observed to be 77.84% of the total rainfall. The residual amount of 22.16% can be considered as the total water storage in the system. Also, less water storage was observed in the initial period of the experimental program until the end of the peak rainy season, November 2015, and increased during the non rainy season. This is due to the dry–wet cycle of the system between rainfall simulations. It can also be observed that, total water storage is 19.15% of total rainfall during peak rainy season. Then after, storage was increased to 51.80% of the total rainfall during the non rainy season until the occurrence of rainfall in May 2016. A relationship established between cumulative rainfall and cumulative leachate generation presented in Fig. 4 shows, a correlation coefficient value (R) of 0.989 between two water balance components. The observed result shows that the quantity of leachate generated is positively well correlated with the rainfall and water storage in the system was reduced during the non-rainy season compared to monsoon season. This indicates that, infiltration of rainfall into the system significantly increases the quantity of leachate generation. The leachate was generated due to the degradation of organic fraction present in the MSW. However, it was comparatively negligible when compared to the leachate generated due to the rainfall. In the study, the total leachate generated as a result of both degradation and the rainfall was being considered and not separately.

The leachate samples were collected from the reactor during the monitoring period of 284 days and stored in a dark place. These samples were analyzed for physiochemical characteristics which include pH, alkalinity, total dissolved solids (TDS), electrical conductivity (EC), BOD, and COD, according to the Standard methods for APHA (1965).

pH

Figure 5 presents the variation in pH of leachate samples. The obtained results showed an increasing trend in pH values from 8.5 to 9. The observed value of pH was 8.4 during the rainy season and reached a peak value of 9.35 at 197th day since the waste placement and reduced to a value of 9 after 30 days during the summer season. The pH value of leachate generally varies from 4.5 to 9 [40]. The values in the range of 4.5–7.5 indicates acidic phase of the refuse in which gas production was minimum. Whereas, pH value in the range of 7.5–9 indicates optimum condition for degradation of refuse and considerable quantity of gas production. During this stage, volatile fatty acids (organic matter) in the waste start to decompose and produces landfill gas which contains methane and carbon dioxide. The pH in the range of 5.6–8.3 is the optimum range for the biodegradation of MSW [41].

Total Alkalinity

Meanwhile, variation in total alkalinity as CaCO3 presented in Fig. 6 also indicates onset of degradation activity and the alkaline phase of the filled refuse. The variation of alkalinity as CaCO3 in the leachate was increased from 5800 to 6000 mg/L with peak values of 7600 and 7800 mg/L in dry season and a lowest value of 4300 mg/L in rainy season, with increasing time. The higher amount of alkalinity could be attributed to the production of bicarbonates during the degradation process.

Total Dissolved Solids (TDS)

The variation in total dissolved solids (TDS) is presented in Fig. 7. The dissolved solids in leachate mainly comprises of calcium, magnesium, sulphate, chloride, potassium and bicarbonates. The results showed reduction in TDS from 26,440 to 16,492 mg/L with increasing time. The observed reduction in TDS values is due to the microbial activity [42]. It was also observed that TDS values reduced during the rainy season and increased during the summer season (when no rainfall was observed) of the monitoring period.

Electrical Conductivity (EC)

This parameter refers to the ability of leachate to carry electric current based on the concentration of ions. The variation in EC of the analyzed leachate samples showed reducing trend over the monitoring period as presented in Fig. 8. During the initial period of the experiment, the value of EC was observed to be 30,200 mΩ/cm and significantly reduced to 18,600 mΩ/cm with increasing age of refuse. The observed reduction in EC indicates the solubility of salts in leachate.

Chemical Oxygen Demand (COD)

This refers to the amount of oxygen demand for the degradation of organic content. Figure 9 shows the variation in COD values in the MSW. The obtained results revealed that, COD value increased from 6600 to 8600 mg/L during the first 2 weeks from the waste placement. This increase in COD indicates deficiency in the oxygen for the degradation of organic content in the MSW and the attainment of anaerobic degradation. The concentration of COD was 7200 mg/L during the summer season and finally reduced to 3280 mg/L.

Biological Oxygen Demand (BOD)

The BOD tests were conducted for 5 days at 20 °C on leachate samples and related with COD as a ratio to obtain the amount of biodegradable matter present in the MSW. A ratio <0.1 indicates stabilization of MSW in the landfills [43]. A plot of ratio of BOD to COD is presented in Fig. 10. The ratio was reduced from 0.394 to 0.312 which indicates the progress in biodegradability of organic content in the MSW.

Moisture Content

The variation of volumetric moisture content (%) in MSW and bottom clay liner system was measured by placing sensors, on a daily basis during the monitoring period. The monitoring of moisture content began from 1st August 2015, after 15 days of placement of MSW. During this period, arrangements were made for the measurement of settlements and gas collection. Figure 11a presents the variation of moisture content of MSW at three levels as mentioned earlier. Top zone refers to 25 cm, middle zone refers to 50 cm and bottom zone refers to 75 cm from the top surface of the filled MSW.

The results showed that the moisture content was comparatively more in the top zone than at middle and bottom zones. This can be attributed to the percolation of simulated rainfall through the cover system and its vertical downward movement into the MSW under gravity. The movement of water fully saturates the top zone along the preferential flow path and residual water moves downward to the subsequent zones after attaining its field capacity. Also, significant variation in moisture content was observed in the bottom zone due to the continuous cycle of saturation and outflow of leachate from MSW to the bottom liner system. The observed maximum values of moisture content are 58.1% (18th August 2015) at the top zone, 53.4% (7th November 2015) at the middle zone and 51.3% (11th August 2015) at the bottom zone of the MSW during the rainy season. The observed lowest moisture content value of 38.1% at the bottom zone on 30th August 2015 could be attributed to the vertical and/or lateral movement of liquid along the preferential flow paths creating unsaturated zones and suction. The increase in moisture content can be attributed to the generation of leachate during the summer season though there are no rainfall events.

The results obtained from the two moisture content sensors which were placed in the bottom clay liner system are shown in Fig. 11b. The obtained results showed that the moisture content increased abruptly to 46.5% during the rainy season and reduced immediately after the season for a period of about 40 days. Again, the moisture content increased gradually to 55%. However, significant variation at two locations was observed only during the peak rainy season and less variation in the non rainy season. The observed maximum moisture content value at location-1 and at location-2 was 56.5 and 55.5% respectively. Generally, water holding capacity of clayey soils varies from 45 to 55%. During the rainy season, moisture content was comparatively lower at location-1 than at location-2 up to 13th October 2015. This can be attributed to the change in preferential flow path of leachate towards location-2 during rainy season and towards location-1 during non rainy season. The obtained results are indicative of spatial and seasonal changes in preferential flow path for leachate migration in containment system.

Temperature

The variation in temperature was monitored by means of six thermocouples placed in the MSW layer as well as in the CCL of the cover system. Spatial and seasonal variation of MSW temperature in the reactor during the monitoring period is presented in Fig. 12a. The results showed significant variation of temperature at the middle zone of the MSW. Table 3 provides the statistical information regarding the MSW temperature regime. During the peak rainy season, observed temperature was in the range of 18.2 and 40 °C and variation was in the range of 19.6 and 41 °C during the non rainy season. The observed average temperature of 26.5 °C in the MSW layer was within the optimum range for the effective microbial activity. The activity would be ineffective within or beyond the optimum range. The raise in temperature during the summer season enhances the microbial activity which also accelerates the biodegradation rate of MSW.

Figure 12b and Table 3 depict the seasonal variation of temperature recorded from the two thermocouples placed in the CCL of the cover system. Observations from the Fig. 12b show that the thermal response of the CCL in cover system varied in the range of 19.5 °C during peak rainy season, to 41.2 °C during non rainy season.

Settlement and Gas Generation

The settlement of MSW under anaerobic condition in the reactor was monitored on a 15 day interval basis using the dial gauges and rods fixed at the two edges of the reactor. Figure 13 presents the observations of cumulative settlement with time during the monitoring period. This shows differential settlement of MSW at the two edges in the reactor. The total settlement at the location 1 and location 2 was about 7.6% (70.9 mm) and 9% (93.30 mm) of the initial thickness of MSW respectively. An abrupt settlement can be observed during the rainfall events, whereas settlement was gradually increased during non rainy season. This can be attributed to the pore water suction, degradation of MSW under favorable conditions and external mechanical forces.

Figure 13 also presents the total production of gas with time. The gas production also increased with increasing time which indicates the effective degradation of MSW. Total gas produced at the end of the 284 days was 7.8 L. The trend show significant increase in gas production during the rainy season and very gradual increase after rainy season until May 2016.

Conclusions

In this paper, behavior of the conventional landfill system is studied using the large scale anaerobic reactor in the laboratory conditions. The reactor consists of bottom liner system, MSW and the top cover system. The reactor was simulated with the measured amount of rainfall and monitored for leachate and gas generation, moisture content and temperature, and settlements. The paper presents the obtained results and observations from the first 284 days (1st August 2015 to 15th May 2016) of the monitoring program. The following conclusions can be drawn from the obtained results.

-

1.

The quantity of leachate generated was found to be positively well correlated (R = 0.989) with rainfall. The water storage in the system was reduced during the non-rainy season.

-

2.

The leachate samples are analyzed for its physiochemical characteristics. Obtained values of pH in the range of 8.5–9 indicate acceleration of biodegradation activity in the MSW. Total alkalinity was increased from 5800 to 6000 mg/L with peak value of 7800 mg/L indicates production of carbonates during the degradation process of organic content. Total dissolved solids (TDS) reduced from 26,440 to 16,492 mg/L with increasing time. The observed reduction in EC from 30,200 to 18,600 μΩ/cm indicates the solubility of salts in leachate. Reduction in COD from 6600 to 3280 mg/L indicated onset of anaerobic condition. The reduction in BOD to COD ratio from 0.394 to 0.312 indicates the progress in biodegradability of organic content in the MSW.

-

3.

The observed average volumetric moisture content of 49.65% and temperature of 26.5 °C in the MSW indicates the attainment of favorable conditions for the microbial activity and degradation process. The moisture content in the liner system attained its field capacity during the monitoring period. The observed maximum temperature in the cover system was 41.1 °C.

-

4.

Total settlement at location 1 and location 2 was about 7.6% (70.9 mm) and 9% (93.30 mm) of the initial thickness of MSW respectively. The obtained results showed possibility of differential (uneven) settlements in the system, abrupt settlement during the rainfall events and gradual settlements during non rainy season.

-

5.

Total gas produced at the end of the 284 days was 7.8 L. The results showed significant increase in gas production during the rainy season.

The results presented in this paper could possibly be used to validate some of the existing gas generation models and other numerical models to predict the gas generation rates and the MSW behavior in landfills.

References

Blight GE, Ball JM, Blight JJ (1992) Moisture and suction in sanitary landfills in semiarid areas. J Environ Eng 118(6):865–877

Kulkarni HS, Reddy KR (2012) Moisture distribution in bioreactor landfills: a review. Indian Geotech J 42(3):125–149

Reddy KR, Kumar G, Giri RK (2017) Modeling coupled processes in municipal solid waste landfills: an overview with key engineering challenges. Int J Geosynth Ground Eng 3(1):1–21

Remson I, Fungaroli AA, Lawrence AW (1968) Water movement in an unsaturated sanitary landfill. J Sanit Eng Div 94(2):307–318

Holmes R (1984) Comparison of different methods of estimating infiltration at a landfill site in south Essex with implications for leachate management and control. Q J Eng Geol Hydrogeol 17(1):9–18

Straub WA, Lynch DR (1982) Models of landfill leaching: moisture flow and inorganic strength. J Environ Eng Div 108(2):231–250

Korfiatis GP, Demetracopoulos AC, Bourodimos EL, Nawy EG (1984) Moisture transport in a solid waste column. J Environ Eng 110(4):780–796

Oweis IS (2006) Estimate of landfill settlements due to mechanical and decompositional processes. J Geotech Geoenviron Eng 132(5):644–650

Bengtsson L, Bendz D, Hogland W, Rosqvist H, Åkesson M (1994) Water balance for landfills of different age. J Hydrol 158(3):203–217

Manna L, Zanetti MC, Genon G (1999) Modeling biogas production at landfill site. Resour Conserv Recycl 26(1):1–14

Mehta R, Barlaz MA, Yazdani R, Augenstein D, Bryars M, Sinderson L (2002) Refuse decomposition in the presence and absence of leachate recirculation. J Environ Eng 128(3):228–236

Hettiarachchi CH, Meegoda JN, Tavantzis J, Hettiaratchi P (2007) Numerical model to predict settlements coupled with landfill gas pressure in bioreactor landfills. J Hazard Mater 139(3):514–522

Chen IC, Hegde U, Chang CH, Yang SS (2008) Methane and carbon dioxide emissions from closed landfill in Taiwan. Chemosphere 70(8):1484–1491

Bleiker DE, Farquhar G, McBean E (1995) Landfill settlement and the impact on site capacity and refuse hydraulic conductivity. Waste Manag Res 13(6):533–554

Sethi S, Kothiyal NC, Nema KA, Kaushik MK (2013) Characterization of Municipal Solid Waste in Jalandhar City, Punjab, India. J Hazard Toxic Radioact Waste 17(2):97–106

Zeiss C, Major W (1993) Moisture flow through municipal solid waste: patterns and characteristics. J Environ Syst 22(3):211–231

Strous M, Van Gerven E, Zheng P, Kuenen JG, Jetten MS (1997) Ammonium removal from concentrated waste streams with the anaerobic ammonium oxidation (anammox) process in different reactor configurations. Water Res 31(8):1955–1962

Yesiller N, Hanson JL (2003) Analysis of temperatures at a municipal solid waste landfill. In: Proceedings of the ninth international waste management and landfill symposium, Sardinia, Cagliari, Italy

Döll P (1997) Desiccation of mineral liners below landfills with heat generation. J Geotech Geoenviron Eng 123(11):1001–1009

Rowe RK (2005) Long-term performance of contaminant barrier systems. Geotechnique 55(9):631–678

Bouazza A, Nahlawi H, Aylward M (2011) In situ temperature monitoring in an organic-waste landfill cell. J Geotech Geoenviron Eng 137(12):1286–1289

Yeşiller N, Hanson JL, Oettle NK, Liu WL (2008) Thermal analysis of cover systems in municipal solid waste landfills. J Geotech Geoenviron Eng 134(11):1655–1664

Yoshida H, Rowe RK (2003) Consideration of landfill liner temperature. In: Proceedings of the ninth international waste management and landfill symposium, Sardinia 2003, Cagliari, Italy

Rowe RK, Islam MZ, Hsuan YG (2008) Leachate chemical composition effects on OIT depletion in an HDPE geomembrane. Geosynth Int 15(2):136–151

Rowe RK, Islam MZ (2009) Impact of landfill liner time–temperature history on the service life of HDPE geomembranes. Waste Manag 29(10):2689–2699

Koerner GR, Koerner RM (2006) Long-term temperature monitoring of geomembranes at dry and wet landfills. Geotext Geomembr 24(1):72–77

Elagroudy SA, Abdel Razik MH, Warith MA, Ghobrial FH (2008) Waste settlement in bioreactor landfill models. Waste Manag 28(11):2366–2374

Babu GS, Reddy KR, Chouksey SK (2011) Parametric study of MSW landfill settlement model. Waste Manag 31(6):1222–1231

Reddy KR, Kumar G, Giri RK (2017) Influence of dynamic coupled hydro-bio-mechanical processes on response of municipal solid waste and liner system in bioreactor landfills. Waste Manag 63:143–160

Bjarngard A, Edgers L (1990) Settlement of municipal solid waste landfills. In: 13th annual Madison waste conference, Madison, Wisconsin

Coduto DP, Huitric R (1990) Monitoring landfill movements using precise instruments. In: Geotechnics of waste fills—theory and practice: ASTM STP 1070, ASTM International, West Conshohocken, Pennsylvania, USA

Simões GF, Catapreta CA (2013) Monitoring and modeling of long-term settlements of an experimental landfill in Brazil. Waste Manag 33(2):420–430

Hegde U, Chang TC, Yang SS (2003) Methane and carbon dioxide emissions from Shan-Chu-Ku landfill site in northern Taiwan. Chemosphere 52(8):1275–1285

Sharholy M, Ahmad K, Mahmood G, Trivedi RC (2008) Municipal solid waste management in Indian cities—a review. Waste Manag 28(2):459–467

Park JW, Shin HC (2001) Surface emission of landfill gas from solid waste landfill. Atmos Environ 35(20):3445–3451

Barlaz MA, Green RB, Chanton JP, Goldsmith CD, Hater GR (2004) Evaluation of a biologically active cover for mitigation of landfill gas emissions. Environ Sci Technol 38(18):4891–4899

MoEF (1999) Municipal wastes (management & handling) rules-1999—the gazette of India extraordinary, PART II-section 3-sub-section (ii). Ministry of Environment and Forests, Government of India, New Delhi, India

Lakshmikanthan P, Sivakumar Babu GL, Chaitra P (2013) Estimation of the components of municipal solid waste settlements using laboratory methods. In: Indian geotechnical conference, Indian Geotechnical Society, Roorkee Chapter New Delhi, India

Sivapullaiah PV, Kantha HL, Kiran KM (2003) Geotechnical properties of stabilized Indian red earth. Geotech Geol Eng 21(4):399–413

Kjeldsen P, Barlaz MA, Rooker AP, Baun A, Ledin A, Christensen TH (2002) Present and long-term composition of MSW landfill leachate: a review. Crit Rev Environ Sci Technol 32(4):297–336

Chakma S, Mathur S (2013) Postclosure long-term settlement for MSW landfills. J Hazard Toxic Radioact Waste 17(2):81–88

Kylefors K, Lagerkvist A (1997) Changes of leachate quality with degradation phases and time. In: Sardinia 97, proceedings of the sixth international landfill symposium, Sardinia, Cagliari, Italy

Reinhart DR, Townsend TG (1998) Landfill bioreactor design & operation. Lewis Publishers, Boca Raton

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Santhosh, L.G., Lakshmikanthan, P. & Sivakumar Babu, G.L. Laboratory Investigation of Large Scale MSW Reactor Under Anaerobic Conditions. Indian Geotech J 47, 395–409 (2017). https://doi.org/10.1007/s40098-017-0263-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40098-017-0263-5