Abstract

A monoenergetic neutron field is an attractive environment for neutron metrology and the development of novel neutron detectors. Deuterium–deuterium and deuterium–tritium (DT) reactions with an accelerated deuteron beam produce 2.5 and 14.8 MeV monoenergetic neutrons, respectively. The Korea Research Institute of Standards and Science (KRISS) is developing a monoenergetic neutron field facility with an accelerator that generates a deuteron beam to establish monoenergetic neutron measurement standards. An electrostatic accelerator with a maximum high voltage of 400 kV and beam current from 0.5 to 500 μA from High Voltage Engineering Europa BV was installed. For a tritiated titanium or deuterated titanium target deposited at 250 μg/cm2 on a 38 mm copper plate, a target chamber is developed by KRISS. The total neutron yield is limited to 5 × 108 n/s, which is the maximum allowed emission rate resulting from the shielding capacitance of a laboratory wall shield. The corresponding deuteron beam current of the DT reaction with the maximum emission rate is approximately 15 μA. Furthermore, various additional studies such as beam current monitoring, target temperature monitoring, air cooling for the target, and beam profile measurement have been performed for the stable generation of the monoenergetic neutron field.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A list of monoenergetic neutron reference fields in the energy range 1–20 MeV in the International Organization for Standardization (ISO) 8529–1 was utilized to establish neutron measurement standards [1]. Neutron energies of 2.45 and 14.8 MeV are monoenergetic neutron fields that are prioritized because they can induce neutrons with relatively low cost and low tritium consumption based on an electrostatic ion beam accelerator [2]. Neutrons of 14.8 MeV energy can be used for neutron research and calibration of neutron detectors [3]. Additionally, monoenergetic neutron fields are gaining attention for industrial applications such as neutron activation analysis, double differential cross-sectional measurement, nondestructive testing, medical imaging, and therapeutic research [4,5,6,7,8].

To produce monoenergetic neutron fields, the Korea Research Institute of Standards and Science (KRISS) installed a 400 kV electrostatic accelerator with a beam current of 0.5 to 500 μA from High Voltage Engineering Europa BV. A facility for monoenergetic neutron fields using an accelerated deuterium beam is being developed at KRISS to provide monoenergetic neutron fields and establish measurement standards. In this study, we investigated the properties of a deuterium beam emitted from an accelerator. The beam profile and beam current measurements at the target position confirmed that the ion beam reached the target position uniformly. The temperature of the copper plate on the target was measured to validate the effectiveness of an air-cooling system, preventing deuterated titanium (TiD) from evaporating. The neutrons generated by reactions with the deuterium beam were identified using an He-3 proportional counter with a Bonner sphere, Cs2LiYCl6:Ce (CLYC) scintillator, and a neutron survey meter.

2 Experiments and discussion

2.1 Monoenergetic neutron generation

The monoenergetic neutron fields targeted by KRISS are of 2.5 and 14.8 MeV energy. The energy of neutrons generated by nuclear reactions depends on the measurement angle and energy of the projectile particle in a two-body reaction. The reactions of accelerated deuterium with tritide and deuterium targets are called deuterium–deuterium (DD) and deuterium–tritium (DT) reactions, respectively. Additionally, DT and DD reactions are exothermic reactions with appreciable cross sections for deuterons with an incident energy of approximately hundreds of keV. The nuclear reaction equation and the Q-value are as follows:

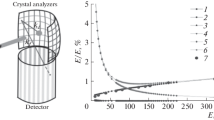

The neutron yield and energy distribution were estimated for various thicknesses and incident deuterium energies using the TARGET simulation code developed by PTB [9]. Based on the simulation results, the thicknesses of the tritiated titanium (TiT) and TiD targets were determined to be 250 μg/cm2 by optimization within the allowable neutron yield of < 5 × 108 at this facility and an energy resolution in the neutron energy distribution. When a deuteron is projected to the target, the produced neutron energy depends on the produced neutron angle with respect to the incident deuteron direction, which is calculated using two-body kinematic relations, as shown in Fig. 1 [10]. An incident deuterium beam with a minimum energy of 110 keV produced a 14.8 MeV monoenergetic neutron at 0° in the DT reaction. An incident deuterium beam produced a 2.5 MeV monoenergetic neutron at approximately 90° in the DD reaction. A Cockcroft–Walton accelerator with a maximum voltage of 400 kV is installed in KRISS to generate a monoenergetic neutron field based on the deuterium acceleration energy and measurement angle.

2.2 Facility for a monoenergetic neutron reference field

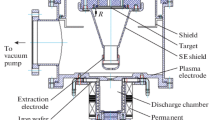

As a facility for monoenergetic neutron fields, the laboratory is primarily composed of three rooms: accelerator control, accelerator, and low-scattering neutron irradiation rooms. A low-scattering neutron irradiation room with dimensions of 12 × 12 × 12 m3 was the primary experimental hall with an aluminum mesh floor at the height of 3.5 m from the bottom. The target for the DD and DT reactions was located at the center of the irradiation room, and a beamline was installed on the aluminum mesh floor to minimize scattered neutrons and radioactivation by neutrons (Fig. 2a). In the accelerator room, the acceleration system was equipped with a 400 kV high-voltage ion beam generator (Fig. 2b). The positive ions generated in the plasma chamber were delivered to the accelerator tube at 30 kV by the extraction electrode, and it was further accelerated by 370 kV in the acceleration tube to generate a maximum 400 kV ion beam. The accelerator control room has a control system for the accelerator, a target monitoring system, and data acquisition modules with various cables, such as BNC, SHV, USB, and LAN, connected to a low-scattering neutron irradiation room (Fig. 2c). Figure 2d shows the layout of each room and the overall system. Interlocks and radiation dose monitoring systems have been established for accelerator facility safety.

2.3 Beam characteristics

Target chambers mounted at the end of the beamline are being developed at KRISS for monoenergetic neutron generation. A target chamber with an associated alpha-particle (AAP) measurement system was designed and simulated [10]. We design a simple cylindrical vacuum chamber to evaluate the characteristics of the accelerator beam and neutron generation before implementing the AAP system. The vacuum chamber was directly connected to the beamline, as shown in Fig. 3a. To maintain a vacuum, an O-ring was utilized between the chamber and target holder, as shown in Fig. 3b. The chamber was fabricated based on the drawing, and its production is shown in Fig. 4a. The prototype chamber was installed electrically floating at the end of the beamline to obtain preliminary data on the accelerated particles, such as the beam size, beam current, and temperature rise of the target.

Components for beam characterization were a electrically floated prototype cylindrical vacuum chamber, b TiT target deposited on a copper plate, c Cr/Au deposited quartz of the same size as the target, and d quartz on the holder of prototype chamber. e Energy deposition of 400 keV deuterium beam at quartz plate was simulated using the GEANT4 simulation toolkit

Quartz was installed to monitor beam size and shape at the target position. The quartz targets were designed to fit in the target holder of the prototype chamber. Thus, the diameter of the quartz was 38 mm, which was the same as that of the target (Fig. 4b). The thicknesses of the quartz targets were 5 and 10 mm. A quartz surface inside the chamber was deposited with 5/15 nm-thick Cr/Au using an e-beam evaporator to remove the charging caused by the ion beam (Fig. 4c). The GEANT4 simulation results show that the 400 keV proton particles passing through the Cr/Au deposition layer lost approximately 3.5 eV in the deposition layer. Therefore, a proton beam can be observed in the quartz target (Fig. 4e). Figure 4d shows the quartz blank target mounted on the target holder in the prototype chamber.

The fluorescence of the particles on quartz was captured using a CMOS microscope camera. Figure 5a–d shows images of various beam shapes on a quartz plate controlled by quadrupole (Q-pole) adjustment of the accelerator. Figure 5e, f shows the analysis results of the acquired image in Fig. 5d. By analyzing the beam shape and intensity, the correlation between various beam distributions and neutron generation can be studied.

A blank copper target was used to measure the beam current and analyze temperature variations. A compressed-air blower was installed to cool the target. The effect of blowing air on the target was confirmed by measuring the temperature when the cooling system was turned on and off. Figure 6 shows the temperature of the blank target. When 25 μA of the 400 keV proton ion beam was bombarded onto the blank target, the target temperature reached 49 °C in 30 min. The temperature dropped to under 35 °C when the cooling system was operated. When a proton beam of 100 W power was turned on, the blank target’s temperature increased to 90 °C. Because our concern is the evaporation of TiT or TiD deposited on the target above 200 °C, this cooling system will be sufficient for 100 μA of the 110 kV deuteron beam. Further quantitative measurements were performed.

The beam current reading system was configured at the target to determine the exact amount of deuterium ions that reached the target. The expected beam current range was 0.1 to 500 μA. A Keithley 6517 B electrometer was used to measure the beam current at the target. The measured beam current without any bias voltage at the target was 197.9 μA, which was higher than the beam current measured at the Faraday cup (192 μA). The discrepancy is due to secondary electron emissions from the target in the opposite direction of the beam; when a magnet was placed on the top of the prototype chamber to collect back-scattering electrons, the current on the electrometer was 192.3 μA. Another method is to apply a bias voltage to the target. We further investigated the current reading system.

2.4 Neutron measurements in the beam tuning process

Neutron production using TiD and TiT targets will be performed after the completion of the beam tuning and validation processes. During the deuteron beam tuning process, neither TiD nor TiT target was mounted in the target chamber, and the injected deuterons were bombarded into the Faraday cup, which was made of tantalum. Deuterons projected onto the Faraday cup remained on its surface, and DD reactions could occur with arriving deuterons later. We set up two neutron measurement systems using an He-3 proportional counter with a Bonner sphere and CLYC scintillator [11]. Figure 6 shows the measurement results of the two neutron detectors installed in the irradiation room during deuteron beam tuning. Figure 7a shows the count rate (top) and pulse height spectrum (bottom) using an He-3 proportion counter with a Bonner sphere of diameter 20.32 cm. The spectral count rate measurement results showed that the amount of neutron generation was constant depending on the deuterium beam irradiation time. The 2D plot of pulse-shape discrimination (PSD) value over pulse height results using the CLYC-6 scintillator is shown in Fig. 7b, where neutrons and gammas can be distinguished. The CLYC detector is developing two fast and thermal neutron measurement methods for CLYC-6 and CLYC-7. The production of a monoenergetic reference field will be performed using TiD and TiT targets, including continuous beam monitoring with various monitoring detectors.

3 Conclusion

To produce the reference monoenergetic standard neutron fields of 2.5 and 14.8 MeV, KRISS has installed a 400 kV accelerator and designed a neutron reaction chamber. Initial system validation tests, such as beam profile monitoring, beam current measurements and target temperature validation with air cooling, were performed to characterize the ion beam on target. The neutron production induced by the accelerated deuterium beam on the Faraday cup was measured using an He-3 proportional counter with a Bonner sphere and CLYC scintillator. After beam optimization, monoenergetic neutron measurements using TiT and TiD targets and an AAP chamber test will be organized. Monoenergetic neutron production will proceed, and the development of monoenergetic neutron measurement techniques is ongoing. The 2.5 and 14.8 MeV monoenergetic neutron fields will be available in late 2024.

References

ISO8529–1, Neutron reference radiations fields part 1 (2021)

S. Vala, M. Abhangi et al., Nucl. Instrum. Methods Phys. Res. A 959, 163495 (2020)

A.V. Mozhavey et al., Radiat. Phys. Chem. 123, 87 (2016)

H.L. Swami et al., Plasma Sci. Technol. 21, 065601 (2019)

P.N. Maya et al., Nucl. Fusion 59, 076034 (2019)

M. Rajput et al., Fusion Eng. Des. 130, 114–121 (2018)

M. Rajput et al., Indian J. Phys. 92(1), 91–96 (2018)

S. Jakhar et al., Fusion Eng. Des. 95, 50–58 (2015)

Schlegel D, TARGET user’s manual, PTB Laboratory Report, PTB-6.42–05–2 (Braunschweig:PTB)

YS Yoon et al., Radiat. Prot. Dosim accepted (2022)

S.C. Kang et al., J. Korean Phys. Soc. 82, 586–594 (2023)

Acknowledgements

This study was supported by the National Research Foundation of Korea (NRF) (grant nos. 2015M2C5A104169026, 2021R1A2C109436912, and 2020R1A6A3A01099805). This work was supported by the Korea Research Institute of Standards and Science (KRISS-GP2022-0005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, H., Kang, S., Kim, J. et al. Development of a monoenergetic neutron field utilizing an accelerator deuteron beam. J. Korean Phys. Soc. 83, 634–639 (2023). https://doi.org/10.1007/s40042-023-00847-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40042-023-00847-1