Abstract

Denim fabrics are one of the best clothing fabrics worldwide, especially for youngsters. Denim fabric transmission properties have an effect on comfort for the wearer. The air permeability, wicking property, and water vapor permeability properties are the main fabric transmission properties studied in this research. Denim fabrics were manufactured mainly from cotton, but nowadays both spandex and polyester are used in denim production which has a great influence on fabrics’ transmission performance properties. For this study, eight denim fabrics were manufactured. The warp yarn was 100% cotton of 6.5 s count and eight different weft yarns of 100% cotton (10 s), 100% cotton (20 s), cotton/spandex (14 + 70D (5.4% spandex ratio)), cotton/spandex (14 + 70D (2.5% spandex ratio)), polyester/spandex (150 + 40D (12.5% spandex ratio)), polyester/spandex (150 + 40D (10% spandex ratio)), polyester (450D), and polyester (400D). This research aimed to explore the influence of yarn type on denim fabric transmission properties. The result revealed that the spandex ratio has a negative effect on air permeability, vertical wicking, and vapor transmission properties. Fabric A2 showed the highest air permeability (15 cm3/cm2/s) and vapor transmission (48.7%) properties. In the contrary A5 showed the lowest vapor (47.1%) and air transmission (4.5cm3/cm2/s) properties. The ANOVA analysis showed that the air permeability, wicking property, and water vapor permeability of denim fabrics had statistically significant at P values of 0.0, p < 0.05, for all.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Denim was originally manufactured from 100% cotton yarn with a twill structure of which the warp yarn is colored and the weft yarn is white predominantly used for jeans, and also for work clothes, and casual wear. Denim fabrics are now found in a variety of yarns, including different fibers blend with the same wonderful appearance as that of 100% cotton denim but with great extra characteristics [1,2,3]. Denim fabric was first introduced by Americans as a 3/1 twill of pure cotton fabric, becoming popular worldwide since1960s. Denim fabrics are widely used and accepted in apparel all over the world, with warp yarns dyed by indigo dyes and gray weft yarns [4].

Cotton yarn is the most widely used in denim manufacturing due to its comfort [5]. In addition to cotton yarn, spandex and polyester filament yarns as core-spun yarn or alone are used for manufacturing of denims to improve some functional performance characteristics mostly as weft yarns [6]. Spandex is an elastomeric with extension above 200% at a break. Spandex is chemically composed of long-chain polyglycol combined with short diisocyanate and contains at least 85% polyurethane. It is better than rubber due to its stronger, lighter, and more versatile [7]. Polyester is a manmade fibers manufactured from any long-chain synthetic polymer composed of at least 85% by weight of an ester of a substituted aromatic carboxylic acid, including but not restricted to substituted terephthalic units, p (-R-O-CO- C6H4-CO–O-)x and para-substituted hydroxyl-benzoate units, p(-R-O-CO-C6H4-O-)x [8].

Comfort is the very important requirement for fabrics used for apparel, i.e., clothing. It is a feeling by human skin which is dependent on fabric transmission properties. There are many parameters of fabrics (fabric transmission properties) that have direct relation to comfort such as thermal insulation, water vapor permeability, water vapor permeability, and thermal contact [1, 9, 10]. Water vapor transmission is essential for clothes used by people while doing hard activities. During hard work, the body generates sweat and will cool by evaporation systems. The evaporation need to be taken out through fabrics to keep comfort of the body. There are some studies about factors that influence vapor transmission ability of fabrics, such as fiber [10], fabric structure [11], and fabric porosity [12].

The water absorption, water vapor permeability, wicking property, and air permeability properties of fabrics made from Eri silk, mulberry silk, wool, and flax were compared and found that the highest air permeability is for flax, followed by wool and then silk fabrics and the lowest is Eri and mulberry silk fabrics. Wool fabrics showed the highest water vapor permeability. The highest wicking and absorbency has been observed in mulberry and Eri silk fabrics, respectively [13].

Different researchers have investigated the denim fabric characteristics. Most of the scholars studied on spandex effect on denim fabric properties such as the effect of Elastane ratio on tenacity and elongation at break [14,15,16], stretch and bagging properties [17]. The filament fineness and ratio effect on yarn breaking strength, elongation [8, 18], hairiness, liveliness, and diameter [18] was investigated. Double-core and core-spun weft yarn densities effect on denim fabric mechanical and dimensional properties was also studied by Bedez Ute, T. [19]. The yarn blend ratio (fiber composition), and weaving parameters influence on mechanical, abrasion resistance, air permeability, and low-stress tactile properties was investigated [9, 20].

Choudhary, A.K has studied that plain singe jersey fabric has the most porous leading best moisture management properties among rib and interlock knitted fabrics made from micro-polyester, texturized polyester and polyesters blend. In the study also, micro-polyester showed better liquid transport capability from the top surface to the bottom surface [21].

The finishing process effects on denim fabric performances have also been studied by different researchers. Eryuruk, S.H. [22], investigated the influence of bleaching, resin, and softener treatment finishes on thermal, water vapor permeability, air permeability, and transverse wicking properties of 100% cotton denim fabrics. Also coating effect on cotton/elastane blend denim fabric tear strength and stiffness properties was studied by Ustuntag, S., et al. [23]. Eryuruk, S.H [1], also studied the influence of different finishing processes on the performance properties of 100% cotton and 98% cotton/2% elastane denim fabrics. Repeated laundering and enzyme washing effect on air permeability and moisture management was investigated by Midha et al. [6].

As per knowledge on the influence of cotton, cotton/spandex, polyester/spandex, and polyester with different ratio on denim fabric transmission properties (air permeability, moisture vapor permeability and wicking properties) have not been yet investigated. Therefore, the aim of this paper is to investigate air permeability, moisture vapor permeability and wicking properties of denims made from cotton, cotton/spandex, polyester/spandex, and polyester, with different spandex percent and yarn count.

Method and Materials

Materials

A factory X is manufacturing eight denim fabric types at the time of this research. As a result, denim fabric samples were taken from this factory for the research purpose. Eight 3/1 Z twill structure denim fabric samples with 60 ends per inch and 40 picks per inch for all samples were used. The warp yarn was dyed 100% cotton and weft yarns of 100% cotton (10 s), 100% cotton (20 s), cotton/spandex (14 + 70D (5.4% spandex ratio)), cotton/spandex (14 + 70D (2.5% spandex ratio)), polyester/spandex (150 + 40D (12.5% spandex ratio)), polyester/spandex (150 + 40D (10% spandex ratio)) and polyester yarn (450 and 400D) were used in the study (Table 1). Table 1 shows the detailed specifications of denim fabrics with their coding. The fabrics are manufactured with loom specifications and settings as shown below:

S means cotton yarn count system which is Ne and D means denier yarn count system. Fabric (A1) is made from 100% cotton dyed warp and 100% cotton weft yarns of count 10 s, fabric (A2) is made from 100% cotton dyed warp and 100% cotton weft of 20 s count, fabric(A3) is made from 100% dyed warp and cotton/spandex weft yarn of 14 + 70D count (5.4% spandex ratio), fabric (A4) is made from 100% cotton dyed warp and cotton/spandex weft yarn of 14 + 70D count (2.5% spandex ratio), fabric (A5) is made from 100% cotton dyed warp and polyester/spandex of 150 + 40D (12.5% spandex ratio), fabric (A6) is made from 100% cotton dyed warp and polyester/spandex of 150 + 30D (10% spandex ratio), Fabric (A7) is made from 100% cotton dyed warp and 100% polyester weft yarns of count 450D, and Fabric (A8) is made from 100% cotton dyed warp and 100% cotton weft yarns of count 400D.

The sample fabrics are produced using Toyota air jet loom with a loom speed of 750 rpm and warp tension of 380kgf. The red width was 190 cm and fabric thread density is 60 ends per inch and 40 picks per inch.

Methods

Fabric transmission properties such as air permeability, wicking property, and water vapor transmission properties were evaluated according to ASTMD737, BS 3424, and ASTM E 96 test methods, respectively. Before the fabric property measurements, all samples were conditioned at 65% relative humidity and 20 °C for 24 h, following ASTM D1776-standard conditioning of textiles’ for testing, using sample conditioning chamber.

Air permeability: Air permeability is the degree of how well the fabric allows air through it under a differential pressure between the two surfaces. It is well-defined as the volume (milliliters) passed through 100 mm2 fabric in one second at air pressure difference of 125 Pascal (Pa). The air permeability of denim fabrics was tested by Textest FX3300 air permeability tester according to ASTM D 737 standard [24]. In the course of the test, fabric sample was fastened over an air inlet of the device and air was drawn through it by means of pump. The air valve is adjusted to provide pressure difference of 125 Pa and the air flow is then measured using a flow meter. Ten specimens were used each with a test area of 25 cm2 (5 cm diameter) and the mean air flow in cubic centimeter per square centimeter per second (cm3/cm2/s) was calculated from the ten results.

Wicking property: It was measured by vertical wicking BS 3424 test method [25]. Fabric sample stripe of 10 cm × 2 cm was suspended vertically and 2 cm lower part immersed in a tank of purified water for 5 min. After 5 min immersion, the wick-up action of water spreading by capillary was observed.

Water vapor permeability: The water vapor permeability of fabrics is one of the main factors that determine comfort of the wearer. The water vapor permeability of the samples were tested by SDL water vapor permeability tester according to ASTM E 96 M-22 test method [26]. The relative water vapor permeability (RWVP) in % is calculated using Eq. 1, where Qs is means density of heat flux evaporated from the skin (W.m−2) and Qo means density of heat flux passing through the uncovered measuring head (W.m−2).

Analysis of variance: The test data were statistically analyzed and evaluated using SPSS (IBM SPSS Statistics v21) software by analysis of variance (ANOVA). The one-way ANOVA analysis was used to determine whether the fiber composition and count of weft yarn have an effect on air permeability, wicking, and vapor transmission properties of denim fabrics. The P-value is the indicator of the significance level of the tested results of the experiments. P values less than 0.05 indicate that the variables are important (p < 0.05). Analysis of variance (ANOVA) was used to see the significant effect of yarn types and spandex ratio on denim fabric’s air permeability, wicking property, and vapor permeability properties statically at a 95% confidence interval by SPSS 21.

Result and Discussion

The air permeability, water vapor transmission, and vertical wicking properties of the different denim fabrics are studied. These fabric properties are presented as shown in Table 2.

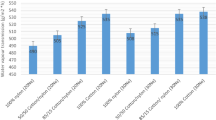

Air permeability is a very important factor in the performance of some textile materials in the comfort point of view. Especially it is taken into consideration for clothing, parachutes, sails, vacuum cleaner, air bags, and industrial filter fabrics. The result of air permeability property of different denim fabric samples is presented in Fig. 1. Denim fabric A2 made from 100% cotton of coarser weft count 20 s had the highest air permeability property (15cm3/cm2/s) as compared to other fabrics, and the lowest is for fabric A5 made from polyester/spandex with higher spandex percentage (12.5%). This may be because fabric with spandex will shrink more in the weft direction after removing the fabric from the weaving machines. This shrinkage will reduce the porosity of the fabric, which in turn leads less permeable to air flow.

In fabric A3, 5.4% of spandex was added to cotton yarn resulting in a decrease in denim fabric air permeability property from 15 to 9.4cm3/cm2/s. The difference is 5.6cm3/cm2/s as compared to A2. In fabric A4, 12.5% of spandex was added to the cotton resulting in a decrease in the air permeability of denim from 13.3 to 10.6cm3/cm2/s, a difference of is 2.7cm3/cm2/s as compared to A1. The count of yarn also has an influence as the courser the yarn is the higher the air permeability, which may be due to higher coverage. From Table 3, ANOVA analysis, air permeability, the yarn type has a significant difference on air permeability of all denim fabrics’ (F = 1285.275, p = 0.00, p ≤ 0.05).

Wicking will occur when water (liquid) travels along the surface of the fiber without absorption by the fiber but a liquid wets fibers assembled with capillary spaces between them. The resulting capillary forces drive the liquid into the capillary spaces. Therefore, wicking is the flow of liquid spontaneously in a porous substrate driven by capillary forces, which is governed by the properties of liquid, liquid-medium surface interactions, and geometric configurations of the pore structure in the medium. Water spreading rate through capillary action for eight different denim fabrics through wicking test are shown in Fig. 2. Denim fabric A1 made from 100% cotton of weft count 10 s had the highest wicking property (330 mm) as compared to other fabrics. Fabric A5 polyester/spandex blend with higher spandex percentage (12.5% spandex) displayed the lowest wicking property. This may be due to the spandex ratio have an effect on the wicking property of denim, as the spandex ratio increases the wicking property decreases. Fabric A1 showed higher vertical wicking than A2, but the fabrics differ in their count only, A2 is courser than A1. As the yarn becomes courser, the wicking height decreases.

Fabrics water vapor permeability is mainly essential to assess comfort in a warm, moist situation. In the warm environment, fabrics must permit diffusion of greater amount moisture from the body, from the skin surface, to the environment than in cooler environments, since even a sedentary body will have increased its rate of water evaporation to aid in cooling. The transport of water within fabrics due to capillary action is directed by fiber surface properties, principally surface energy. The greater fiber surface energy is the greater its wicking capability [27].

The denim fabric moisture vapor transfer rate of eight types of denim tests is presented in Fig. 3. The highest moisture vapor transfer (48.7%) is found for denim fabric (A2) of course weft yarn. Both fabrics A1 and A2 are 100% cotton but the difference is in the weft yarns, the weft of A2 is coarser than A1. The lowest moisture vapor transfer rate is found on fabric A5 made from polyester/spandex with a spandex ratio of 12.5. Fabrics A5 and A6 are made from a spandex ratio of 12.5% and 10%, respectively. RWVP of A5 < A6 which indicates that as the spandex ratio increases the WVP% decreased. This was explained by Eryuruk, S.H.[1] study, which showed when adding spandex(elastase) on denim fabrics, the water vapor resistance was increased as compared to %100 cotton fabrics. Polyester also has low surface-free energy and poor wettability properties because of lacks polar groups in its molecular structure [28].

The ANOVA analysis is presented in Table 3. ANOVA analysis was performed to see the influence of yarn type on denim fabric air permeability, vertical wicking rate and water vapor permeability properties in terms of difference in fiber type and spandex ratio at 95% confidence interval confidence. Statistically all types of yarns had a significant difference on denim fabrics air permeability, wicking property and water vapor permeability properties with p = 0.00, p ≤ 0.05, for all yarn types. Therefore, the spandex ratio, count of yarn and polyester have an influence on the transmission of fabrics namely air permeability, vertical wicking, and vapor transfer properties.

Conclusion

It was observed that denim made from 100% cotton has higher air permeability, vertical wicking and water vapor permeability than denim fabrics made from cotton/spandex, polyester/spandex and polyester weft yarns. Fabrics made from courser yarns showed higher water vapor permeability but lower air permeability and wicking property. The demand of denims in the textile market is increasing from day to day not only for jeans but also for the production of shirts, T-shirts, bags, and different accessories. Therefore, the study will help to understand the effect of different yarns on air permeability, wicking property and water vapor permeability performance of denims in a better way. Based on the requirements of application area of denim fabrics, different cotton yarns with different blends of spandex and polyester can be used.

References

S.H. Eryuruk, The effects of elastane and finishing processes on the performance properties of denim fabrics. Int. J. Clothing Sci. Technol. 31(2), 243–258 (2019)

H.G. Türksoy, N. Yıldırım, and M. Ertek Avcı, Comparative evaluation of some comfort properties of denim fabrics including dual-core yarns containing wool and elastane yarn. J. Text. Inst. , p. 1–8 (2021)

B.F. Adamu, Denim Fabric Surface, Low-stress Tensile and Shear Properties Evaluation based on KES. J. Text. Appare, Technol. Manag. 12(2) (2021)

O. Babaarslan et al., Denim fabrics woven with dual core-spun yarns. Eng. fabrics, p. 19–39 (2018)

B.F. Adamu, B.T. Wagaye, Cotton Contamination, in Cotton Science and Processing Technology: Gene, Ginning, Garment and Green Recycling. ed. by H. Wang, H. Memon (Springer Singapore, Singapore, 2020), pp.121–141

V. Midha, S. Suresh Kumar, M. Nivas Kumar, Investigation on permeability and moisture management properties of different denim fabrics after repeated laundering. J. Text. Inst. 108(1), 71–77 (2017)

T Nicholus, Q.S. ayari Akankwasa, Edwin Kamalha, Llyod Ndlovu, Cotton-elastane ring core spun yarn: A review. (2013)

E. Sarioğlu, O. Babaarslan, A study on physical properties of microfilament composite yarns. J. Eng. Fibers Fabr. 11(3), 155892501601100320 (2016)

N. Mandre, T. Plamus, A. Krumme, Impact of weft yarn density and core-yarn fibre composition on tensile properties, abrasion resistance and air permeability of denim fabrics. Mater. Sci. 27(4), 483–491 (2021)

J. Gao, B. Fentahun, Fashion and Text. 9(8), 10 (2022)

D.Y. Limeneh et al., Efect of weave structure on comfort property of fabric. J. Nat. Fibers 1, 1–8 (2020)

H.A. Kim, Water/moisture vapor permeabilities and thermal wear comfort of the Coolmax®/bamboo/tencel included PET and PP composite yarns and their woven fabrics. J. Text. Inst. 1, 1–14 (2020)

B. Das, N.V. Padaki, K. Jaganathan et al., Comparative studies on thermal comfort properties of eri silk, mulberry silk, wool and linen fibres. J. Inst. Eng. India Series E 102(1), 145–154 (2021)

A.B. Dhouib, S. El-Ghezal, M. Cheikhrouhou, A study of the impact of elastane ratio on mechanical properties of cotton wrapped elastane-core spun yarns. J. Text. Inst. 97(2), 167–172 (2006)

A. Kakvan et al., Effects of draw ratio and elastic core yarn positioning on physical properties of elastic wool/polyester core-spun ring yarns. J. Text. Inst. 98(1), 57–63 (2007)

C.-I. Su, H.-Y. Yang, Structure and elasticity of fine elastomeric yarns. Text. Res. J. 74(12), 1041–1044 (2004)

Özdil, N., Stretch and Bagging Properties of Denim Fabrics Containing Different Rates of Elastane,. FIBRES & TEXTILES in Eastern Europe 208. 16(1).

E. Emine, P. ÇELİK, A research on the parameters of the affecting yarn properties of cotton-polyester rigid core-spun yarns. Text. Apparel 24(2), 195–201 (2014)

T. Bedez Ute, Analysis of mechanical and dimensional properties of the denim fabrics produced with double-core and core-spun weft yarns with different weft densities. J. Text. Inst. 110(2), 179–185 (2019)

N. Uren, A. Okur, Analysis and improvement of tactile comfort and low-stress mechanical properties of denim fabrics. Text. Res. J. 89(23–24), 4842–4857 (2019)

A.K. Choudhary, Ramratan, The influence of yarn and knit structure on moisture management properties of sportswear fabric. J. Inst. Eng. (India) Series E 101(1), 77–90 (2020)

S.H. Eryuruk, Analyzing thermophysiological comfort and moisture management behavior of cotton denim fabrics. Autex Res. J. 21(2), 248–254 (2020)

S. Üstüntağ et al., Optimization of coating process conditions for denim fabrics by taguchi method and grey relational analysis. J. Nat. Fibers 19(2), 685–699 (2022)

ASTM, Standard Test Method for Air Permeability of Textile Fabrics, in ASTM International. 2018: West Conshohocken, PA. p. 5.

BS, Testing fabrics, in Vertical Wicking Test. 2018: London, UK.

ASTM, Standard Test Methods For Gravimetric Determination of Water Vapor Transmission Rate of Materials. 2022: West Conshohocken, PA.

In Vivo Cutaneous and Perceived Comfort Response to Fabric: Part I: Thermophysiological Comfort Determinations for Three Experimental Knit Fabrics. Textile Research Journal 2014.

A. Hajipour, A. Shams Nateri, The effect of weave structure on the quality of inkjet polyester printing. J. Text. Inst. 110(6), 799–806 (2019)

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Adamu, B.F. Permeability and Moisture Management Properties of Denim Fabric Made from Cotton, Spandex, and Polyester. J. Inst. Eng. India Ser. E 103, 253–258 (2022). https://doi.org/10.1007/s40034-022-00249-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40034-022-00249-1