Abstract

In this study, eri silk-based handloom fabrics were finished with Aloe vera gel employing maleic acid as a cross-linking agent using a pad-dry-cure method. Water-soluble Aloe vera gel of varying concentrations of 5 to 15% (w/v) was also used in the finishing bath for imparting antibacterial property to the finished fabric along with the anti-crease properties. Assessment of changes in the properties of finished fabric shows substantial improvement in wrinkle recovery of the finished silk fabric achieved at the expense of strength and flexibility at moderate levels. Changes in the chemical nature of silk fabric on such modifications have been studied by infrared (IR) spectroscopy and reported also in this research article. The study proposes a thermal curing system that is conducive to in-situ polymerization of maleic acid in presence of Aloe vera for the development of eco-friendly eri silk-based handlooms with antibacterial and anti-crease properties, without a significant loss in strength. The antimicrobial property appears to remain significant even when the fabric is subjected to wash up to 10 wash cycles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Silk is an important environment-friendly biodegradable protein fiber considered and identified to be the textile fiber of the future that supports most of the natural fibers the growing concept of sustainably regarding its production from the silkworm. Silk fiber also has some other advantages viz. Its high strength, appreciable moisture regains low specific gravity, appreciable elastic recovery, and good thermal stability. Silk is primarily appreciated for its luster, elegant appearances and soft feel particularly when the soluble globular protein or gum, as it is called, is removed from linear protein macromolecules called “fibroin” of silk fiber. The drawback of silk fiber lies in its poor crease resistance [1] and also susceptibility to attack by microbial organisms. The composition of different silk types [2] is shown in Table 1.

Out of the silk varieties, eri, Attacusriciniis known as peaceful silk or ‘the poor man’s silk’ in Assam, Manipur, Meghalaya and Mizoram states. Eri silk is highly valued not only for the environmentally friendly approach that is taken during its farming and production but also for its quality. In the summer, it provides a cooling effect, whereas on colder days it provides warmth and a feeling of coziness. There is a proverb in Assam ‘dairpani, erirkani’ which says that while yoghurt cools, eri cloth provides warmth. The slight imperfections of hand-spun yarn used to make eri textiles give them distinctive character silk [3].

The objectives of this study are to improve the anti-crease properties of silk using a vinyl monomer containing carboxylic acid in the presence of an initiator and catalysts. For such purpose, eri silk was treated with aqueous liquor containing a vinyl monomer such as maleic acid. Use of methanol extract of Aloe vera when incorporated in an aqueous finish bath, assessment of the development of antimicrobial property of the finished inconsequent to such use of Aloe vera also makes up an important aspect of our investigation.

Crease resistance finishing of cotton and silk textiles using resins from amine formaldehyde condensates such as dimethylol dihydroxy ethylene urea (DMDHEU), dimethylol propylene urea (DMPU), resins result in some odd disadvantages regarding relatively poor tensile strength retention despite significant improvement in wrinkle recovery. Such amine formaldehyde condensate resin finishes are also associated with the disadvantage of formaldehyde splitting during processing and use, endangering the health of processors and species and also as a probable carcinogen [4,5,6]. Finishing of cotton and silk with polycarboxylic acids as formaldehyde-free finishing agents such as butane-tetra-carboxylic acid, cyclopentane-tetra-carboxylic acid appear to be much more perspective in this respect. Such compounds have evoked immense interest in the recent past because of their environment-friendly and non-toxic characters. Such compounds are too expensive to be practically exploited and not widely available. Silk fabrics are often subjected to chemical finishing using amine formaldehyde condensate resin. Such treatment, although contributed toward improvement in fabric’s wrinkle resistance, resulted in discoloration and impairment of fabric strength and other mechanical properties [7]. Cross-linking between silk and resin has been reported to occur chiefly between the phenolic -OH and primary hydroxyl groups, respectively, of tyrosine and serine amino acids of silk and the n-methylol group of resin causing fiber embrittlement as a result that reduces the treated fabric's mechanical strength [8].

For polycarboxylic acid finishing, sodium salts of phosphorous-containing mineral acid used as esterification catalysts are not environment friendly. Such catalysts containing phosphorous influence the reproduction of fish and favor a kind of seaweed growth that consumes a large amount of oxygen from water, giving rise to eutrophication. Also, finishes based on such non-polymeric polycarboxylic acid cannot retain and/or improve the strength and moisture regain characters of cotton and silk [9, 10]. However, reports of the effect of polymerizable vinyl monomer for improvement in wrinkle recovery of cotton and silk fabrics are scanty. Carboxyl containing vinyl monomer like maleic acid under the influence of catalytic system shall produce anti-crease finishing on silk substrate [11].

In this context, it would be useful if we consider the mechanism of intended modification of eri silk with maleic acid following pad-dry-cure technique under the influence of ammonium persulphate used as the free radical polymerization catalyst and trisodium citrate used as esterification catalyst [11]. Hydroxyl groups of amino acids of silk are expected to bring about intended modifications under the sequence of reactions shown in Fig. 1. Such intended modification of silk fiber ultimately would lead to a notable gain in weight and changes in the chemical nature and physical properties of silk during the overall process.

Reaction 1 producing maleic acid esters of silk would be the direct consequence of the action of trisodium citrate used as an esterification catalyst. The said esterification reaction would also expectedly lead to cross-linking of silk as mentioned in reaction scheme 1. However, maleic esters of silk as shown by the structures (i) and (ii) may then react further with hydroxyl groups of silk, respectively, leading subsequently to linking of silk via an ester bridge formed by the maleic acid moiety as shown by reaction 1 during the drying and curing step.

Influence of free radical catalyst [(NH4)2S2O8] in pad-dry-cure technique would cause graft copolymerization of maleic acid under the treatment condition ultimately leading to the grafting of poly (maleic acid) chain on the chain molecule of silk under the treatment condition with ultimate cross-linking of silk besides peroxodisulfate induced free radical homopolymerization of maleic acid; not shown in the scheme) is another distinct possibility. Such peroxodisulfate induced graft copolymerization and cross-linking would cause enhancement of carboxylic group content of the maleic acid-modified silk via maleic acid and improvement in wrinkle recovery of silk inconsequent to expected cross-linking of polymeric chains of silk. Under the influence of two catalysts taken together for the maleic acid curing of silk, all the reactions shown and discussed above are likely to take place simultaneously or successively, leading to weight gain for the fabric system. Additional reactions leading to further graft copolymerization and esterification with consequent eventual complex network formation involving further unreacted hydroxyl groups of silk and also carboxyl groups and unsaturation of poly (maleic acid) moieties duly grafted to silk may also take place under the treatment condition leading to improved wrinkle recovery of maleic acid finished silk.

The microorganism which is unicellular in structure used to grow at a rapid pace under warmth and moisture. It grows rapidly in the presence of humidity, heat and food sources, whether it is gram-positive (S. aureus) or gram-negative (E. coli). The skin of a human being is very much conducive to bacterial growth because of the acidic or basic nature of perspiration. After antimicrobial finishing, silk fibers inhibit the supportive environment for microbial growth [12, 13].

In the present work, an attempt has been made to finish eri silk with Aloe vera gel in the presence of vinyl monomer containing carboxylic acid as a cross-linking agent under the influence of suitable esterification and free radical polymerization catalysts.

Experimental

Materials

Eri silk-based handloom fabric with warp count 32 Ne (18 tex) and well count 30 Ne (20 tex) having an average area density of 92 gm2 was used for the present study. In this experiment, we use silk, degummed eri silk fabric. Commercial grade maleic acid obtained from M/S Micromoles India was used with no treatment. All other chemicals used like trisodium citrate, ammonium persulphate were of laboratory grade. Aloe vera gel was extracted from Aloe vera trees locally available.

Methods

Degumming of Silk

To remove silk gum from the raw eri silk fabric, later on, the fabric was degummed at 90 °C for 1 h in an aqueous solution containing 20% soap and 2 g per liter sodium carbonate at fabric to liquor ratio 1:20. Degummed fabric was washed using hot water and then cold washed and finally dried in air.

Application of Maleic Acid on Silk

Pre-soaking of degummed silk fabric with ammonium persulphate solution of concentration 1% following an application of maleic acid monomers formulation on the pre-soaked silk fabric was performed separately by padding technique in a laboratory two bowl padding mangle. After two successive fabrics dipping in the maleic acid formulation, the pressure between the squeezing rollers was adjusted to enable an overall pick up of 100%. The pH of the monomer solution was adjusted at different specified levels with the use of the required dose of soda ash and caustic soda. The aqueous monomers formulation usually contained a known dose of trisodium citrate and Aloe vera gel with varying concentrations of 5% to 15% (w/v), respectively. By finishing silk with maleic acid and Aloe vera gel, the silk fabric also has an antimicrobial property. The padded squeezed fabrics were subjected to drying in an oven at 950C for (10–15) minutes. The dried fabrics were then cured at 140 °C for 5 min. Untreated and maleic acid-treated silk fabrics were assessed for change in the properties as listed below following standard procedures.

Determinations of Moisture Regain and Weight Gain after Treatment

Moisture regains of the initial and treated silk fabrics were determined following a standard procedure mentioned in ASTM Standards [14]. For the determination of weight gain upon finishing treatments using maleic acid, the finished fabric samples were first soap washed and then extracted under reflux in a water bath for 8–10 h successively using water to ensure removal of traces of unreacted maleic acid monomer along with polymeric maleic acid that remains unbound to the chain molecules of silk fabric samples. The extracted fabric samples were then oven-dried to a constant weight (W1) at 100 °C. The weight gain (%) was calculated based on the initial dry weight of degummed silk (W2), using the following relationship: weight gain = (W1-W2) / W2 × 100.

Tensile Properties

Breaking strength of some selected fabric samples was measured in a Zwick 1445 CRT Universal Tensile Testing Machine, following the method prescribed by IS: 1969–1968 and described in [15]. The results obtained were based on an average of 10 tests in the warp direction of each sample. The test strip specimens were raveled to a size of 50 mm x 20 mm between the jaw of the machine, and the test was performed with a traverse speed of 100 mm min−1 at a pretension of 0.5 N.

Determination of Wrinkle Recovery Angle

The dry wrinkle recovery angle (warp + weft) of selected fabric specimen having size 25 mm × 200 mm was determined by a SASMIRA Wrinkle Recovery Tester following the method prescribed in ASTM-D-1295–67.

Porosity Analysis

The porosity of untreated fabrics and treated fabrics is measured by a Capillary Flow Porometer (CFP-1100-AEHXL, PMI Inc.). All measurements are done by dry up/wet up test mode using distilled water to saturate the samples after the dry test. Minimum, maximum, average pore diameters and pore size distribution of all samples were measured following the Annual Book of Pore Size and Air Permeability of ASTM Standards [16].

Evaluation of Antibacterial Property of the Textile Fabric

Antibacterial susceptibility testing was done using the good diffusion assay, as prescribed by the National Committee for Clinical Laboratory Standards. The antibacterial activity was quantitatively assessed against gram-negative bacteria E.coli (Strain No.-ATCC 9637) and gram-positive bacteria S. aureus (Strain No.-ATCC 6538) according to the AATCC 100–2004 test method. The fabric samples with 2.5 ± 0.1 cm in diameter were placed in a 250 ml glass jar with a screw cap and absorbed with 1.0 ± 0.1 ml of bacterial inoculums. Then, 100 ml of sterilized saline water (prepared by dissolving 0.85 g of NaCl in 100 ml of distilled water) was added to the jar which was then shaken for 24 h in a shaker at 100 rpm. After incubation over contact periods of 24 h, the solution was then serially diluted. The diluted solution was placed on nutrient agar and incubated for 24 h at 37 °C ± 2 °C. Colonies of bacteria recovered on the agar plate were counted, and the per cent reduction of bacteria (R) was calculated by the following equation: R% = [(B–A)/B] × 100. Where A is the number of bacterial colonies from the treated specimen after inoculation over 24 h of the contact period, and B is the number of bacterial colonies from the untreated specimen after inoculation at zero contact time.

IR Spectroscopy

IR spectra of unmodified and selectively modified silk samples were obtained following the KBr pellet technique by using a Perkin-Elmer FTIR spectrometer. The dried fiber samples were crushed to a finer size up to 20 meshes, before palletizing with KBr. Four KBr pellets contained about 1% powdered fibers as test specimens were prepared separately for unmodified eri silk and eri silk modified with maleic acid in the presence of different catalytic systems as specified[9].

Scanning Electron Microscopy analysis

Morphological analysis of composite fabric is carried out by Scanning Electron Microscopy (SEM), (JEOL JSM-6510LV) at a magnification of 1000X. Samples were sputter-coated with gold before the measurement.

Results and Discussion

Effect of Dual Catalyst on the Maleic Acid Cure of Eri Silk Fabric

To study the role of esterification catalyst and free radical polymerization catalyst for the pad-dry-cure technique of silk fabric with maleic acid, the silk fabric was treated with maleic acid in absence of either of the two catalysts with varying concentrations of Aloe vera gel @ 5% to 15% (w/v), (Table 2). In each experiment, maleic acid dose levels were maintained at 10% (w/w). Treatment of silk fabric in the presence of peroxodisulfate as the free radical polymerization catalyst only resulted in poor weight gain and wrinkle recovery angle with retention of a high order of tensile strength. Such effects appear to be the consequence of only graft copolymerization induced by ammonium peroxodisulfate (as shown in the chemical reaction scheme 2.a. (i) and (ii), 2.b. and 2.c. In Fig. 1 in the introduction section) and limited self-catalyzed esterification reaction effected only at a high temperature of drying and curing. Silk fabric finished with maleic acid in the presence of only esterification catalyst also resulted in poor weight gain with only marginal improvement in wrinkle recovery angle with high retention of tensile strength inconsequent to the establishment of ester linkages under the influence of esterification catalyst (as shown in reaction Scheme 1 in Fig. 1) with limited thermally induced graft copolymerization of maleic acid in absence of free radical polymerization catalyst. Under the influence of two catalysts taken together (ammonium persulphate and trisodium citrate) for the maleic acid cure of silk, substantial weight gain and wrinkle recovery angle is achieved. Retention of tensile strength, however, suffers from the maleic acid cure of silk under the influence of a dual catalyst system was noted in our study. However, to increase the antimicrobial efficiency, the tear strength and tensile properties were brought down because of a reduction in chain flexibility after graft polymerization under dual catalytic effect at higher temperature curing. Although the crease recovery angle was increased to some extent at an initial concentration of Aloe vera gel up to 10% (w/v) and thereon, it started decreasing as the flexibility of chain molecules reduces at a higher concentration of Aloe vera gel, i.e., 15% (w/v) and so on. Results in Table 2, clearly show the retention or improvements in weight gain, wrinkle recovery angle and tensile strength are optimal on pad-dry-iron-cure of silk with maleic acid under the influence of a dual catalyst system.

Effect of Variation in Batching Time and pH variation

In each experiment, the maleic acid dose level was Maintained at 10% (w/w) for batching at 300C room temperature for 60 min. With the dual catalyst system and subsequent drying by heating at 950C for 5 min, followed by curing at 140 °C for 5 min, there is a notable weight gain, wrinkle recovery angle, tear strength retention, breaking load retention and elongation at break. However, the bending length remained level for the entire batching time. The batching for an extended time distinctly favors higher incorporation of maleic acid moieties in silk by ammonium persulphate induced graft copolymerization. Initial peroxodisulfate induced homopolymerization of maleic acid, to increase extents over increasing batching periods, at ambient temperature 300C and further polymerization of free maleic acid and silk bound maleic acid moieties during subsequent drying at 950C cause an overall change in environment and proximity of the hydroxyl groups of silk and carboxyl groups of the unbound or silk bound maleic acid or poly (maleic) acid moieties that finally causes an enhanced degree of trisodium citrate catalyzed esterification and further chain polymerization leading to substantial cross-linking during curing at 140 °C as revealed by the relevant data for wrinkle recovery in Table 3.

The esterification reaction that becomes more prominent at the high processing temperature (140 °C) in the final stage appears to somewhat depend on the initial batching time. An increase in batching time favors improved transformation of the grafted maleic acid/poly (maleic) acid units to ester moieties at the high curing temperature of 140 °C under the influence of the esterification catalyst in the final stage of processing. Optimum batching time (45–60) minutes also allows improved diffusion of finishing agent maleic acid within the chain molecules of silk.

Relevant data for the change of pH show that under neutral conditions (pH 7), optimum grafting and esterification leading to much-improved wrinkle angle and substantial weight gain are achieved with no loss of breaking strength and with over 90% retention of tear initial fabric. With the moderate acidic condition, (pH 5.6), moderate improvement in extensibility with over 80% retention of the tear strength of the initial fabric was achieved.

Again, moderate alkaline conditions (pH 8–9) result in poor retention of breaking strength (< 70%), and tear strength (< 75%), despite substantial weight gain much because of weakening of the silk fiber in the fabric by alkali attack. Under the slightly acidic condition, (pH 5.6), improvement in wrinkle recovery angle is comparatively poor even though tear strength and breaking strength retention are good, (pH 7), therefore, apparently provides the most optimum condition for the finishing process.

This work is aimed at establishing optimum conditions for the application of maleic acid evaluating attainable changes or improvements in the fabric’s nature and properties, including crease resistance, stiffness, strength, and moisture regain antimicrobial properties. Results of such studies are reported in the present article.

Effect of Aloe Vera Gel Concentration

Figure 2 shows the effect of Aloe vera gel concentration from 5 to 15% (w/v) on the performance properties of eri silk, viz., wrinkle recovery angle and tear and tensile strength of the treated fabric. The finishing baths were prepared to contain Ammonium persulphate 1% and trisodium citrate: 6%. The fabrics treated thus with 100% pick up were dried and then exposed to curing at 140 °C for 5 min. It is clear (Fig. 2) that the wrinkle recovery angle of the treated fabrics which were cured was pronounced as Aloe vera gel concentration increased up to 10% (w/v) and then decreased sharply whereas, there was a notable increase in weight gain with the increase of dose level of Aloe vera gel concentration.

The enhancement in wrinkle recovery angle of the finished fabrics by increasing Aloe vera gel concentration suggests that Aloe vera gel performed two functions: (1) it reacts with maleic acid in the fiber molecules; (2) Aloe vera gel undergoes cross-linking with the fabric to form a network matrix. The water-soluble Aloe vera gel with its low molecular weight penetrates the fiber more easily, promoting anti creasing in the treated eri silk fabrics. Water-soluble Aloe vera gel generates an ether reaction with the hydroxyl groups in the fibers, forming a two-dimensional structure that improved the crease resistance of the fabrics. Decrement in wrinkle recovery angle by increasing the Aloe vera gel concentration above 10% (w/v) could be associated with increased basicity of the finishing environment at higher Aloe vera gel concentrations. Logically, basicity would stand as an inverse function to the acidity of the catalytic system of the cross-linking peptide molecule with maleic acid under the dual catalytic influence. Lower catalysis would certainly lead to decreased wrinkle recovery angle. Regarding tensile strength penetration or encapsulation of Aloe vera gel, molecules would improve the strength properties of the treated fabrics. As shown in Fig. 2, the tensile strength and elongation at break increased by increasing Aloe vera gel concentration up to 10% (w/v) which decreases thereafter. Rigidity conferred on the structure of silk by including Aloe vera gel through various interactions with silk and maleic acid may account for the decrease in tensile strength at higher Aloe vera gel concentrations and also, tear strength retention shows a monotonic fall with increases in Aloe vera gel dose level. It is also probable that higher concentrations of Aloe vera gel n create more fibers bridging and are more likely to cause stress accumulation, decreasing the tensile strength. Breaking load increased by increasing Aloe vera gel concentration up to 10 g/l, which decreases thereafter. Rigidity conferred on the structure of silk by including Aloe vera gel through various interactions with silk and maleic acid may account for the decrease in tensile strength at higher Aloe vera gel concentrations and also, tear strength retention shows a monotonic fall with increases in Aloe vera gel dose level. It is also probable that higher concentrations of Aloe vera gel create more fibers bridging and are more likely to cause stress accumulation, decreasing the tensile strength.

Pore size Analysis of Treated and Untreated Samples of Silk

Pore Size Analysis of the Aloe vera untreated and Aloe vera treated silk treated Reports like smallest pore diameter (micron), largest pore diameter (micron), mean flow pore diameter (micron), as well as first bubble point diameter (micron), are given below in Table 4.

The distilled water of surface tension 72 mN/m was used for wetting the samples and test pressure was kept at 0.5 bar. The smallest and largest flow pore size of the untreated sample was measured at 7.89 and 336.21 µm, respectively. The smallest and largest flow pore size of the treated sample was found as 7.68 and 332.22 µm, respectively, when the sample was treated with 5% Aloe vera gel. The mean pore diameter was found at 232.52 µm for the same sample. The smallest and largest pore size of the treated sample with 10% Aloe vera gel was found to be 7.55 and 321.28, respectively, and the mean pore diameter was observed as 219.03 µm. It is observed that there is a slight decrease in the mean pore diameter after-treatment of the 5% Aloe vera gel and the decrease of mean pore diameter further continues with higher application doses of Aloe vera.

Evaluation of Antibacterial Property of Textile Fabric

The antibacterial activity was quantitatively assessed against gram-negative bacteria E. coli: Strain No-ATCC 9637 and gram-positive bacteria S. aureus: Strain No-ATCC 6538), according to the AATCC 100–2004 standard test method. The test of microorganisms is grown in liquid culture. The concentration of the test microorganism is standardized. The microbial culture is diluted in a sterile nutritive solution. Untreated and treated fabric swatches are inoculated with microorganisms. The inoculation is performed such that the microbial suspension touches only the fabric. Bacteria levels on both untreated and treated fabrics are determined at 'time zero' by elution in a large volume of neutralizing broth, followed by dilution and plating. A control is run to verify that the neutralization/elution method effectively neutralizes the antimicrobial agent in the fabric. Additional inoculated control and test fabrics may incubate, undisturbed in sealed jars, for 24 h. After incubation, microbial concentrations are determined. The reduction of microorganisms relative to initial concentrations and the control fabric is calculated. Percent reduction of bacteria by the specimen treatments was calculated using the following formula: R = 100 (B–A)/B where R is % reduction A is the number of bacteria recovered from the inoculated treated test specimen swatches in the jar incubated over the desired contact period. B is the number of bacteria recovered from the inoculated treated test specimen swatches in the jar immediately after inoculation (at '0' contact time).

The inoculation is performed such that the microbial suspension touches only the fabric. The photographs of bacterial growth on untreated and maleic acid-treated samples in presence of Aloe vera gel with varied concentrations, i.e., 5% (w/v) and 10% (w/v) under dual catalytic effect are also given in Fig. 3.

Photographs of the development of different bacterial growth; a E. coli on untreated eri silk; b E. coli on treated eri silk with 5% (w/v) Aloe vera gel concentration; c E. coli on treated eri silk with 10% (w/v) Aloe vera gel concentration; d E. coli on treated eri silk with 10% (w/v) Aloe vera gel concentration after 10 wash cycle; e S.aureus on untreated eri silk; f S.aureus on treated eri silk with 5% (w/v) Aloe vera gel concentration; g S.aureus on treated eri silk with 10% (w/v) Aloe vera gel concentration; h S.aureus on treated eri silk with 10% (w/v) Aloe vera gel concentration after 10 wash cycle

Maleic acid treatment, when suitably done with Aloe vera gel reduced the growth of microorganisms in treated samples assessed in terms of colonies recovered. The finished is normally tested for antibacterial properties and finish stability is tested even after 10 washing cycles after washing the fabric with non-ionic detergent at mild Alkaline PH. From the result, it can be inferred that the eri silk fabric finished with Aloe vera showed over 90% antimicrobial property against both bacteria. Even after 10 washes, it shows over 80% of antimicrobial efficiency. This may be because of the significant loss of active ingredients in Aloe vera after 10 machine washes. Cross-linking is deteriorated paving the way for the active ingredients to leach out of the fabric during washing.

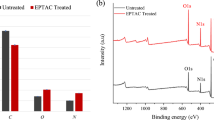

FTIR Analysis

The FTIR spectra of untreated silk fabric and eri silk treated with maleic acid and Aloe vera gel under conventional curing are shown in Fig. 4. A broad absorption band over 3200 cm−1 characteristic of hydrogen-bonded (N–H) stretching vibration and an absorption band between 1621 and 1637 cm−1 characteristic of amide stretching are common to all spectra [11]. Two notable absorption bands at 1316.14 cm1 and 1426.65 cm−1 appearing in different intensities in the spectrum of unmodified silk [spectrum 1 of Fig. 4] are characteristic of carboxylate anion stretching and phenolic (-OH) bending, respectively. Carboxylate anion stretching accounts for a free carboxylic acid group at the end of polypeptide chains and phenolic (-OH) bending accounts for residues of tyrosine fractions of amino acids in the unmodified silk. The strong absorption band at 1202.68 cm−l and 1156.89 cm−l also appears in the spectrum of unmodified silk and is attributed to the (C-N stretching) vibration of amine groups present at the end of polypeptide chains of silk. In the spectrum of unmodified silk, the absorption bands at 1621.16 cm-1 (ester stretching) and 962.44 cm−1 (vinyl unsaturation) are practically not existent.

The maleic acid finish on eri silk in presence of esterification catalyst, i.e., trisodium citrate only, however, result in intensification of the absorption band at 1510.19 cm−1 characteristics of vinyl ester stretching (spectrum 4 in Fig. 4), substantial weakening of absorption band at 1510.19 cm−1 characteristic of unsaturation present in the vinyl group as expected (spectrum 5 in Fig. 4). However, maleic acid finish on eri silk under the influence of dual catalyst system (spectrum 4 of Fig. 4) results in weakening of the band at 1023.74 cm−1 because of significant disappearance of the vinyl group unsaturation during final stage polymerization induced by heat and catalyst action along with sharp intensification of the band at 1621.14 cm−1 because of stretching with retention of the band corresponding to 1426.65 cm−1 for carboxylate (anion) stretching. Silk treated with maleic acid and Aloe vera gel (spectrum 5) exhibited a decrease in absorbance intensity at 1636.69 cm−1 and 1426.65 cm−1 after the curing method as compared to the untreated silk sample. A decrease in intensity at 1636.69 cm−1 and 1426.65 cm−1 could be attributed to a decrease in the total number of hydroxyl groups through cross-link formation between silk and maleic acid. Substantial weakening/disappearance of band 1426.65 cm−1 corresponded to phenolic (-OH) bending because of the significant disappearance of phenolic (-OH) groups. Silk Proteins attach to Aloe vera gel through carboxylate ions, which show antimicrobial potential. The results of the IR analysis are in tune with the mechanism proposed.

FTIR spectra of treated fabric showed that the intensity of this band is a measure of the total quantity of ester group created in the finished eri silk fabrics. The FTIR spectrum (spectrum 4 and 5 of Fig. 4) of Aloe vera treated fabric showed a little shift of the ester peak from 1623.50 (spectrum 4 of Fig. 4) cm−1 to 1621.16 cm−1 (spectrum 5 of Fig. 4) and also the intensity of this peak is lowered as compared to that of only maleic acid-treated fabric (spectrum 4 of Fig. 4). This shows a decrease in the average number of ester groups formed in the presence of Aloe vera. The lower intensity peak of Aloe vera with cross-linking agent treated eri silk is because of the interaction of Aloe vera active compounds with some of the amine (-NH) groups of the eri silk and also interaction with the free–COOH groups of carboxylic acid molecules which are supposed to form ester linkage with eri silk in absence of Aloe vera compounds. Hence, the extent of degree of direct chemical cross-linking between eri silk and maleic acid via ester linkage is effectively less in Aloe vera treated samples as some of the–NH groups of eri silk are actively occupied by some of the–OH groups of Aloe vera ingredients. Thus, active ingredients of Aloe vera containing–OH groups in their chemical structure can easily form H-bonding with either–NH groups of eri silk structure or chemically react with the maleic acid during curing of Aloe vera and silk molecules.

SEM Image Analysis

Surface deposition of finishing chemicals is depicted below in Fig. 5 using the following SEM image.

Figure 5 shows SEM images (a) untreated degummed silk (b) degummed silk treated with 5% Aloe vera gel (c) degummed silk treated with 10% Aloe vera gel. In the SEM image of untreated degummed silks, the smooth, well-separated filament of degummed silk appears with no surface deposition of any chemical agent. However, fibrillation of silk fibroin affected because of the degumming treatment can be traced in some portion of the silk fiber in the SEM of the degummed silk. Treatment of silk with 5% Aloe vera gel resulted in the deposition of Aloe vera gel on the surface of the silk fiber, as seen in the micrograph b. Such deposition of Aloe vera gel as appears in micrograph b, however, is less frequent, few and incapable of giving uniform distribution of such Aloe vera gel on the surface of the silk. Silk when treated with 10% Aloe vera gel shows a much more uniform and frequent distribution and presence of Aloe vera gel that covers almost all the surface area of the silk fibers which, however, retained by the silk fiber even when the silk was post washed following the method described in the experimental section. Aloe vera gel retained by the silk fibers appears to confer antimicrobial properties to the silk fibers. And the extent of such functional properties offered by the silk fibers in our experiment reported in this study appears to be in line with the deposition of Aloe vera gel in consequence of the different treatments of Aloe vera gels described in the present study.

Conclusions

Silk fabric finished with maleic acid in the presence of Aloe vera under the dual catalytic influence of ammonium persulphate and trisodium citrate brings about notable improvements in wrinkle recovery and antimicrobial properties with appreciable retention of its strength. Padding silk with an aqueous solution containing (10%) maleic acid, (1%) ammonium persulphate (%)trisodium citrate and (10%) Aloe vera at 100% wet pick up at a pH of 8, followed by batching of the padded fabric for 30 min and drying at 95 °C with subsequent curing at 150 °C for 5 min specifically imparts high order of wrinkle recovery, extensibility and antimicrobial property with retention of about 70% of its original strength. Antimicrobial efficacy of over 80% is observed to be retained by the finished fabric after 10 wash cycles. Maleic acid under the effect of the dual catalyst system undergoes simultaneous free radical polymerization and esterification reaction with the–OH groups of silk, which ultimately led to binding of Aloe vera gel to the polymaleic acid duly formed in-situ and grafted to silk under treatment conditions. An assessment of the surface morphology of modified silk fabric shows the overwhelming deposition of Aloe vera on the surface of silk. Such presence of tenaciously bound and deposited Aloe vera on the surface of silk appears to be more when silk is treated with a higher dose of Aloe vera.

References

Y. Yang, S. Li, Textile Asia. 23, 72–75 (1992)

K. Sen, K.M. Babu, Studies. J. Appl. Polym. Sci. 92(2), 1080–1097 (2004)

D. Chattopadhyay, R. Munshi, D. Chakravorty, J. Text. Inst. 109(9), 1202–1207 (2018)

G.L. Brodmann, Textile Chemists and Colorist. 22, 13–16 (1990)

R. Munshi, D. Das, A. Chowdhuri, J. Text. Inst. 105(1), 67–73 (2014)

W. Cao, Annual Colorage. 81, 81–90 (2000)

I.S. Kang, C.Q. Yang, W. Wei, G.C. Lickfield, Text. Res. J. 68(11), 865–870 (1998)

D. Das, R. Munshi, J. Text. Inst. 97(6), 519–525 (2006)

D. Das, A. Mukherjee, P. Bhattacharya, D. Chakrabarty, J. Appl. Polym. Sci. 121(2), 770–776 (2011)

D. Das, D. B. Datta, P. Bhattacharya, Int. Journal of Recent Research in Physics and Chemical Sciences. 1(2), 13–23 (2015).

D. Das, D.B. Datta, P. Bhattacharya, Cloth. Text. Res. J. 32(2), 93–106 (2014)

R. Munshi, S. Majumdar, Sericologia. 58(3 and4), 160–171 (2018).

S.W. Ali, R. Purwar, M. Joshi, S. Rajendran, Cellulose 21(3), 2063–2072 (2014)

Annual Book of ASTM Standards, 1974.

Handbook of tensile testing, 1981.

Annual Book Pore Size and Air Permeability of ASTM Standards, (1995).

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Banerjee, A.N.A., Datta, D.B. & Das, D. In-Situ Polymerization of Maleic Acid in Presence of Aloe vera Gel for Development of Eco-Friendly Eri Silk-based Handlooms. J. Inst. Eng. India Ser. E 103, 233–244 (2022). https://doi.org/10.1007/s40034-022-00237-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40034-022-00237-5