Abstract

Effects of dyeing process variables on colour yield and colour fastness properties for dyeing cotton khadi fabric with Red Sandal wood (Pterocarpus Santalinius) waste (RSWW) as natural dye was studied in this work. Bleached cotton khadi fabric was subjected to pre-mordanting by initial treatment with harda(myrobolan) as mordanting assistant cum fixer followed by pre-mordanting with alum or other metallic mordants. Such dual pre-mordanted fabric was subsequently dyed with aqueous extract of de-oiled red sandal wood waste (RSWW). Effects of pre-mordanting with two different agents like harda and alum applied in sequence render better anchoring to make it more suitable for higher colour yield and better colour fastness properties. After finalizing the said dual pre-mordanting, all the dyeing process variables i.e. mordant conc., dye conc., dyeing time, temperature, MLR, pH, salt conc., for dyeing with RSWW extract were optimized. Colour fastness to washing, rubbing, light, perspiration against use of different combination of harda and other metallic mordants along with different dyeing process variables were also evaluated. It is observed that overall application of 15% of [Harda + KAl2 (SO4)3 in 50:50 ratio] in sequence (one after another) is found to be most suitable. MLR—1:40, pH-10, temperature 80°C and time 30 min were found as optimum for extraction of RSWW for maximum colour yield. Considering dyeing uniformity, colour fastness and economy, the optimized dyeing concentration is selected as 20% dye concentration (on the basis of dry weight of solid RSWW source). Other dyeing parameters are optimized as 80 °C dyeing temperature, 30 min dyeing time, 11.0 dyeing pH, 1:20 material-to-liquor ratio and 15 gpl common salt concentration. Interpretation from colour difference index (CDI) values clearly reveals that mordant concentration, dye concentration and pH of dye bath are the three most critical dyeing process variables, amongst all other parameters of dyeing process variables in this study.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dyeing of textiles with natural colours is known from ancient time, when synthetic dyes were not emerged [1,2,3]. With advent of synthetic dyes as ready dye-powder with standardized process conditions and overall lower cost, use of natural colourants declined sharply. However, production and application of synthetic dyes involves hazardous chemicals causing negative environmental impact associated with allergic, toxic, carcinogenic and harmful responses [4]. Hence, worldwide growing environmental and health concerns, eco-friendliness, non-toxic natural dyes have re-emerged as a potential viable option for colouration of textiles [5]. Besides eco-friendliness, natural dyes have huge number of advantages [6, 7] including their medicinal values, very uncommon soothing and soft shades as compared to synthetic dyes. Natural dyeing on natural fibre-based textiles like cotton or other fibres is gradually reviving at faster speed for growing environmental concern worldwide. For commercial exploitation of natural dyes, application on textiles in large-scale industry, there are essential needs of the followings:

(i) Identification of eco-friendly mordants/bio-mordants or mordanting assistant as fixer, to use less metallic mordants and to avoid few hazardous metallic mordants, (ii) Optimization of extraction conditions of natural bio-mordants and natural dyes, (iii) Optimization of mordanting process using single or dual mordanting with use of natural fixing agents like harda/tannates with or without metallic mordants, (iv) Optimization of dyeing conditions for reproducibility of the shades, (v) Understanding the chemistry of natural colour components and other component present in plant sources as bio-mordants, fixers and natural dyes and (vi) Effective utilization of natural materials for both mordanting and dyeing or dyeing cum finishing, maintaining its medicinal values and other beneficial criteria remain intact in such dyed clothes.

Hence, it has been felt essential to re-investigate and re-build the traditional process of natural colouration in a bit more scientific way to control each step of pre-treatment/pre-mordanting and dyeing process variables for re-producing different shades with overall better and balanced colour yield and better colour fastness. Insufficient scientific information and knowledge enhances the major difficulty which brings about strong challenge to the textile chemists and dyers [6,7,8,9] to solve it. Towards sustained and continuous effort in this direction, work on standardization of mordant, mordanting methods, standardization of extraction of natural dyes from plant source and optimization of dyeing process variables for cotton khadi fabrics is going on since last few years. At present, de-oiled Red Sandal wood waste (RSWW) has chosen as natural dye source material for the present work to study above said issues for colouration of cotton khadi fabric which is also known for its cancer preventative action and antiviral effects against herpes for simplex virus-1 and 2, indicating its medicative advantages.

Red sandal wood trees are widely available in western ghat pārbatmala covering Karnataka, Telangana and Kerala having variation of red sandal wood oil content with genetic variation in sandalwood (Santalum album) located in various parts of southern India and even in other parts of the world in different variety.

Recently, some physio-chemical studies of natural dyes with harda pre-treatment [10,11,12,13,14] followed by metallic mordanting was carried out separately in sequence before dyeing different textiles with selective natural dyes on cotton and other cellulosic/ligno-cellulosic natural fibres like jute as reported in earlier literature. This two-stage separate harda (being a complex formable natural tannate compound with very light-yellow colour) pre-treatment followed by natural metallic mordanting (Alum or else) before dyeing was termed as dual/double mordanting by other group of researchers [10,11,12,13,14].

However, such work with de-oiled red sandal wood waste (RSWW) natural colourants on cotton has not been reported so far, though similar work on physio-chemical studies of dyeing jute fabric with red sandal wood is reported earlier by Samanta, Agarwal and Datta [12, 13]. Moreover, the concept of using a natural mordant (natural alum) along with harda(haritaki/myrobolan) as bio-mordanting assistant cum fixer compound, both applied in sequence (one after another) prior to dyeing as pre-mordanting is thought to be a newer approach to improve colour yield and colour fastness [10,11,12,13,14]. Hence, in the present work, an attempt has been made to study the effects of harda pre-treatment followed by metallic pre-mordanting with natural potash alum or else so-called dual/double pre-mordanting applied in sequence. Optimization of extraction conditions of de-oiled red sandal wood waste (RSWW), effects of changing dyeing process variables on colour yield, colour fastness properties including optimization of dyeing conditions for dyeing of cotton khadi fabric using de-oiled red sandal wood (Pterocarpus Santalinius) waste extract as a natural colourant by varying metallic mordant combination with harda pre-treatment were studied in the present work.

Materials and Methods

Materials

Plain woven cotton khadi (hand spun yarn woven in handloom) fabric having 73 Nm warp, 70 Nm weft, 76 ends per inch, 53 picks per inch, areal density of 73.5 g/m2 and 0.075 mm thickness, obtained from Gram Sewa Mandal, Gopuri, Wardha, after bleaching with 3% H2O2 (30%) was used in this study.

Laboratory reagents (LR) grade aluminium sulphate, potash aluminium sulphate, stannous chloride, and commercial grade acetic acid, turkey red oil, green-zyme DSZL (enzymatic desizing agent), green scour RW (low foaming rewetting agent), green scour FC (conc. scouring agent), sodium hydroxide, sodium carbonate, hydrogen peroxide, pero-stab S.F (phosphate-based non-silicate peroxide stabilizer), green-zyme POK (Enzymatic peroxide killer) obtained from local suppliers were used.

Natural bio-agent i.e. myrabolan (harda, botanically known as Terminalia chebula) powder was used as a mordanting assistant. As natural dye powder, to obtain maroonish/brownish red colour shade on cotton fabric, de-oiled red sandal wood (Pterocarpus Santalinius) waste after sun-drying and crushing to dry powder form has been used for this study.

Experimental Methods

Extraction of Colour Components of RSWW and Optimization of Extraction Conditions

Sun-dried de-oiled red sandal wood waste (RSWW i.e. dry Rakta-chandan wood after de-oiling) trunk/branch part grinded to powder was taken in hot water for extraction of its colour component under varying extract conditions, such as pH 4–12, MLR 1:20–1:80, time period 15–90 min and temperature 60–90 °C in order to optimize the conditions of extraction of colour component from RSWW. Absorbance (optical density) at a particular wavelength (λmax.530 nm) of maximum absorbance, for the aqueous extract of the RSWW was determined using Shimadzu –UV 2450 UV–VIS absorbance spectrophotometer. The usual pH of aqueous extract of red sandal wood without adding anything was found to be 11; which, as per necessity, was either acidified with acetic acid or alkalized with dilute caustic soda solution for altering or varying the pH from 4 to 12. The UV–Vis Spectral scan of aqueous extract of Red sandalwood waste (RSWW) is given in Fig. 1a. This UV scan of RSWW shows two major UV–Vis peaks at 250 nm and 370 nm at UV zone indicating its strong UV absorption and max. absorbance at 530 nm invisible zone, vide- Fig. 1a, indicating light reddish-brown hue.

Extraction of Harda as Mordanting Assistant Cum Fixer

Harda i.e. myrabolan grinded powder was soaked in water (1:10 volume) for overnight (12 h) at room temperature to obtain the swollen myrabolan gel. This harda gel was then mixed with a known volume of water and heated at 80 °C for 30 min. The solution was then cooled and filtered in a 60 mesh nylon cloth and the filtrate was used as final mordanting solution (10–40%)—as an additional mordanting assistant (with other metallic mordant like natural alum used) cum fixer using MLR of 1:20.UV–Vis spectral scan of diluted aqueous extracted solution of harda (myrabolan) was determined using Shimadzu –UV 2450 UV–Vis absorbance spectrophotometer as in Fig. 1b, shows UV–Vis spectral sharp peaks at 250 nm, 310 nm and 373 nm in the UV-Zone along with one steep peak at 603 nm with a broader hump at 553 nm in the visible region indicating its main hue as light yellow colour. Chemical structure of chebulinic acid present in harda/myrabolan is shown in Fig. 2a

Chemical Constitution of De-Oiled Red Sandal Wood Waste Used as Natural Dye:

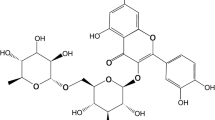

De-oiled Red Sandal wood waste (RSWW) extract comprises nos. of colouring compounds. Perkin and Everest [15] isolated the colouring matter and suggested that there are at least more than two colouring components in the red sandal wood viz, Santalin and Deoxysantalin, of which santalin is the main colouring component [16,17,18]. Ravindranath and Sheshadri [19] and Arnone et al [20] confirmed the presence of three colouring components like, Santalin—A, B & C (Deoxy- Santalin), the chemical structures of which are shown in Fig. 2b.

Single Mordanting and Sequential Double/Dual Pre-Mordanting

Mordanting of cellulosic textiles using metallic salt for natural dyeing is known from ancient time. The process of natural dyeing with metallic pre-mordanting in jigger/winch machine in large-scale industry has become unsuccessful mainly due to solubilization of water soluble metallic mordant in aqueous dye bath and thus complexing/precipitation of mordantable natural dyes happens in the dye bath solution itself before it enters in the fibre. Recently, a scientific process of fixing metallic mordant temporarily inside the fibre/fabric with the use of natural bio-agents (using suitable catcher/fixer compound like harda or gall nut tannates for fixing metallic mordant on cotton/jute fabric preventing it to dissolve or leaching out in water) has been developed and reported in literature [10,11,12,13,14] using harda pre-treatment to fabrics followed by metallic mordanting of harda pre-treated fabric in sequence. Hence, use of harda (haritaki/myrobolan) having lots of –COOH and –OH groups in ortho-position in its chebulinic acid component are able to make complex with aluminium (from natural alum/fitkari) or other metallic mordants inside the fibre in situ. They restrict alum/metallic mordant salt to be dissolved in dye bath water and remain temporarily arrested/fixed inside the fibre/fabric. Before natural dyeing, when these two agents are applied separately in sequence i.e. harda pre-treatment followed by alum mordanting, calling it as dual/double mordanting applied in sequence (one after another), form a complex between harda and the metallic mordant. When such pre-mordanted fabric is subsequently dyed with any mordantable natural dye like RSWW (red sandal wood waste) having lots of phenolic –OH groups in it, it can form further more bigger (fibre-mordanting assistant(harda)-Al-mordant -natural dye) complex with dye anions. In recent literature [10,11,12,13,14], there are many good publications with scientific evidences to use tannic acid (gall nut tannate)/chebulinic acid (harda) pre-treatment, known popularly as bio-mordant, but actually such fixer compounds like harda or gall nut are to be scientifically called as mordanting assistant cum fixer agent. Use of gall nut as bio-mordant (truly bio-mordanting assistant) even without metallic mordant/with metallic mordant, are used by others for their fixing/catching power towards metallic salt/natural dyes are reported recently in dyeing of cotton with babul bark [21]. Similarly, on the same principle, harda was used with natural alum applied in sequence in many of the earlier works [10,11,12,13,14] and [22, 23] for natural dyeing of selective natural fibres. Harda and alum application in sequence for pre-mordanting for dyeing silk with anar peel and also for dyeing of cotton with tesu was used [24] in recent work. Subsequently extended study was carried out on improving colour fastness to wash and light as well as to improve functional properties like UV protection factor along with antimicrobial properties by suitable post-treatment with other natural agents. However, for better understanding, the mechanism of working of harda and alum combination applied in sequence (one after another) as a pre-mordanting treatment (so-called dual/double mordanting applied in sequence) with subsequent natural dyeing is shown in Fig. 3a, b shown, which is now an established method of dual/double pre-mordanting using harda and alum pre-mordanting applied in sequence, published by the same and other research groups [10,11,12,13,14, 22,23,24].

Now, one may argue why these two mordant and mordanting assistants are not applied together as a mixture. The answer is simple, these two agents (harda and alum) make complex forming compounds with each other if these two agents are mixed and added in one bath for pre-mordanting. Thus, harda and alum, if applied in the same bath as mixture, they form complex and precipitates immediately in the dye bath and cannot be used to diffuse inside the fibre/fabric, serving no purpose. As these two agents are not chemically identical in nature and both are not cationic (where harda is anionic and alum is cationic). Hence, they will combine in the bath before they can enter inside the fibre/fabric. On the other hand, if harda is pre-applied on cotton and later alum is applied in sequence, this aluminium-harda insoluble complex is formed in situ inside the fibre/fabric making aluminium pre-fixed temporarily inside the fibre/fabric. Later, after subsequent addition of natural dye like RSWW as usual, can form further bigger complexes with already formed Al-harda complex, forming fibre -Al-Harda mordant-RSWW dye as much bigger complexes improving colour yield and wash fastness.

So, jigger dyeing with natural dyes following this process of so-called dual/double pre-mordanting considering first pre-treatment with mordanting assistant like harda as fixer and then alum as metallic mordant applied in sequence, become more successful than conventional single Al-mordant or harda treatment alone before natural dyeing. With the above background information, the process of dual/double pre-mordanting with harda and alum or else metallic mordant were used in the present work following earlier literature [10,11,12,13,14, 22,23,24].

First Pre-Treatment/Pre-Mordanting with Harda As mordanting Assistant Cum Fixer

Pre-wetted conventional H2O2 bleached khadi cotton fabric was treated with the filtered myrobolan (harda) gel solution in separate bath initially at 40–50 °C with MLR 1:20 and then temperature was raised to 80 °C. Harda pre-treatment or harda bio-mordanting was continued for 30 min. After this harda pre-treatment, fabric samples were dried in air without washing to keep it ready for either subsequent second mordanting or dyeing.

Metal Salt Mordanting or Second Pre-Mordanting with Natural Alum Or Other Metallic Mordants

H2O2 bleached khadi cotton fabric or 1st mordanted (harda pre-treated) cotton khadi fabric was further mordanted using 5–20% aqueous solution of natural potash alum [KAl(SO4)2] i.e. fitkari and some other metallic mordant like aluminium sulphate [Al2 (SO4)3] and stannous chloride [SnCl2], etc., separately at 70–80 °C for 30 min using material-to-liquor ratio of 1:20. After this single or so-called dual/double pre-mordanting, the fabric samples were finally dried in air without washing to make them ready for subsequent dyeing. In all single and dual/double pre-mordanting, harda as fixer cum 1st bio-mordanting assistant pre-treatment was applied one after the other in separate bath, respectively, for the subsequent study of dyeing with RSWW extract to optimize dyeing process variables at later stage.

Dyeing of Harda Plus Alum or Harda Plus Other Metal Salt Pre-Mordanted Cotton Khadi Fabrics

Bleached and differently pre-mordanted (single and double pre-mordanted) cotton khadi fabrics were dyed using the aqueous coloured extract of de-oiled red sandal wood waste (RSWW) powder either at specific or varying conditions of mordanting to optimize mordant combination along with its concentrations and at specific or varying conditions of dyeing process variables to optimize the dyeing process parameters. In first phase, the study was carried out with varying concentrations (5–20 %) of single mordants, then with overall 15% combination of varying ratio of double mordants and finally with 15% overall concentration of harda +alum [KAl (SO4)2]combination (in 50 :50 ratio) which were subsequently dyed with aqueous extract of specific concentration of RSWW dye-liquor [20 % on the weight of dye source material, using MLR-1:20; common salt-15% owm; at pH-11.00 (with requisite amount of caustic soda/Na2CO3); dyeing temperature- 80 °C and dyeing time − 30 min, unless otherwise mentioned].

In the second phase, to study the effects of dyeing process variables on colour yield for optimizing the dyeing conditions, the dyeing process variables/parameters were varied as dyeing time 15–120 min, dyeing temperature 50-95 °C, material to liquor ratio 1:10–1:50, conc. of aqueous extract of de-oiled red sandal wood waste powder (as natural dye) 10–50%, common salt conc, 5–20 gpl and pH 3-13. The selective/optimized mordant system has been finally selected and used for the study of dyeing process variables. It was double pre-mordanted with 15% overall concentration of the combination of harda as first pre-treatment or first mordanting + KAl (SO4)2 (natural potash alum) as second mordanting (maintaining 50:50 ratio) applied in sequence on bleached cotton khadi fabric. After the dyeing is over, the dyed cotton khadi fabric samples were repeatedly washed thrice with hot and cold water and then dried in air. Finally, the dyed samples were subjected to soaping with 2 gpl soap solution at 50 °C for 30 min, followed by repeated water wash (thrice) followed by drying under sun. Unless otherwise stated, after optimization of the dyeing process variables, all other experiments of dyeing with red sandal wood waste extract were carried out at optimum dyeing conditions, as observed later.

Test Methods

Testing of Tensile and Bending Properties of Untreated and Treated (mordanted) Cotton khadi Fabric.

Warp-way breaking load (Kgf) and breaking extension (%) values of the selective pre-mordanted cotton fabrics were comparatively measured according to ASTM: D 5035-11,2015 by cut strip method of tensile strength testing [25] (after prior conditioning of the samples at 65± 2% RH and 27± 2 °C temperature for 48 h as per the IS: 6359- 1971 method [26]).

Measurement of Fabric Stiffness

Fabric stiffness has been measured as per IS: 6490–1971(Cantilever test) method [25] using cantilever-type Paramount make local fabric stiffness tester.

Measurement of Surface Colour Strength and Other Colour Interaction Parameters

K/S values (surface colour strength) of undyed and dyed cotton khadi fabrics were determined by measuring surface reflectance of the corresponding samples using X-rite (Gretag Macbeth) portable spectrophotometer, following well-known Kubelka–Munk equation [27] with relevant computer-aided colour measurement software. CIE-Total colour difference (∆E) values were determined by measuring corresponding L*, a*, b* values before and after the treatments/mordanting/dyeing using above said computer-aided reflectance spectrophotometer along with associated colour measuring software employing CIE-Lab equations as per CIE standard-1976 [27], to compare the shade depth of one sample produced with comparative standard sample. General metamerism index (MI) was calculated employing LABD equation [27] for metamerism index. Brightness Index (BI) was also measured using following relationship as per ISO-2469 and 2470 method [28]

Determination of Colour Difference Index Value (CDI)

After application of selective natural dyes, the magnitudes of respective ∆E, ∆C, ∆H and MI values irrespective of their sign and direction were utilized to obtain a single index of colour difference parameters in all respect called as colour difference index (CDI) values. CDI value indicates overall dispersion of colour variation against any varying parameter of a dyeing process variable, as per the following relationship [13].

where ∆E, ∆C, ∆H and MI indicate corresponding CIE colour interaction parameter, irrespective of their sign and direction, as mentioned above.

Evaluation of Wash, Light, Rubbing And Perspiration Fastness.

The colour fastness to wash for dyed cotton fabrics was evaluated according to IS: 3361-1979 method [25].

IS: 2454-1985 method [25] RA 2013 was used for evaluating the fastness to light for dyed cotton fabric. Dry and wet rubbing fastness of the dyed cotton fabric was evaluated as per IS: M766-1988 method [25]. Colour fastness to perspiration for dyed cotton fabric samples was carried out as per IS method 971-1983[25]: RA 2009, at two different pH levels i.e. pH–5.5 and pH -8 using freshly prepared standard perspiration liquor.

FTIR Analysis

Fourier Transform Infrared Spectroscopy (FTIR) of un-treated, pre-mordanted and dyed cotton khadi fabric samples were examined using a FTIR spectrophotometer (Make: Perkin Elmer Pvt. Ltd, Model: Spectrum-II) by KBr disc method and later FTIR spectral scans were analysed as per BTRA spectroscopic table [29].

Results and Discussion

Optimization of Conditions of Aqueous Extraction of De-Oiled Red Sandal Wood Waste

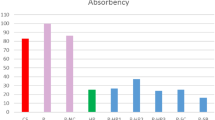

Aqueous extraction was made from dried de-oiled red sandal wood waste (RSWW) powder under differently varying extraction conditions with MLR 1:30–1:80, pH 4–10, time period 15–90 min and temperature 60–90 °C. The observed results for optical density of coloured solution after aqueous extraction of colour component from RSWW are shown in Table 1. The maximum values obtained for optical density at maximum absorbance wavelength ((λmax=530 nm) are identified and marked in bold letters for considering corresponding extraction conditions as optimum showing maximum colour yield for best extraction conditions.

Thus, it may be summarized that when extraction of RSWW is done with MLR - 1:40, pH-10, temperature 80 °C and time 30 min, the optimum conditions of extraction of RSWW for maximum colour yield are achieved.

Effects of Different Single Pre-Mordanting for Dyeing of Cotton Khadi Fabric with RSWW Extract

Relevant results for single mordanting and subsequent dyeing with RSWW are shown in Table 2. It indicates the effects of varying percentage (5–20% ) of different single mordants i.e. aluminium sulphate [Al2 (SO4)3], potash alum [KAl (SO4)2], stannous chloride [SnCl2] and harda/myrobolan applied at 60 °C for 30 min using material-to-liquor ratio of 1:20 followed by dyeing of cotton fabric with 20% RSWW extract(based on % weight of dye source material), using a standard pre-fixed conditions of dyeing [MLR- 1:20; common salt- 15% owm; pH-11 (with requisite amount of caustic soda/Na2CO3); dyeing temperature − 80 °C and dyeing time -30 min, unless otherwise mentioned]. Effects of different single mordants on changes in tensile strength, breaking elongation, stiffness (bending length) of the corresponding fabric sample after pre-mordanting changes in surface colour strength (K/S values, along with CV% of K/S values) and other colour interaction parameters i.e. ∆E, ΔL, Δa, Δb, ∆C,∆H , BI , MI and CDI values after dyeing were determined. The respective results are also shown in Table 2.

It is evident from data in Table 2, that there is a reasonable increase in the K/S values of the dyed sample when pre-mordanted with 15 to 20 % aluminium sulphate separately or 15–20 % harda separately as single mordant as compared to same per cent application of potash alum and stannous chloride [SnCl2] on the same cotton khadi fabric at comparable conditions of treatment followed by dyeing at the comparable conditions with 20% RSWW. Application of the mordant with concentrations up to 15%, increases the K/S values significantly for harda in comparison to the metallic salts. Hence, considering an overall balance in all the factors including costs, etc., pre-mordanting with 15–20% harda, renders a better option towards optimum colour yield than all other single mordants used in this work. However, usage of harda above 15% is discouraged for higher loss of tensile strength of fabric. Presence of chebulinic acid in harda however makes cotton khadi fabric weaker in tensile strength due to consequent acidic degradation.

It is known that considering the reasonable cost and minimization of tensile strength loss, minimum mordant concentration is always preferable. But considering colour yield or K/S (surface colour strength) values, higher mordant concentration of harda for 15–20% (on weight of fabric) renders overall better balance amongst application of all single pre-mordanting system used in the present work.

Harda is though not a metallic mordant, but is a very good mordanting assistant (as fixer for alum salt as well as for mordantable natural dyes) having chebulinic acid in it with mordantable –COOH and –OH groups. It has high potential of formation of coordinated covalent bond with metallic mordants and mordantable natural dyes with –OH groups of poly-phenolic/mordantable natural dye like extract of RSWW as well as it can create unlimited hydrogen bonding with –OH, CH2OH group of cellulose of cotton. It also improves colour yield even without metallic mordant, while only metallic mordants are able to form coordinated complex of fibre-metallic mordant-natural dye complexing utilizing the coordinating power of metal present. Thus, higher colour yield with only harda pre-treated cotton fabric than same (equal) amount of alum pre-treated cotton is justified and understood, with the expectation that these two in combination may yield better result as per mechanism of their combined action is shown in Fig. 3a, b, but these two are to be applied one after another in sequence for the reasons, as mentioned in subsection 2.2.4.

Effects of Harda Plus Alum or Others Dual/Double Pre-Mordanting for Dyeing Cotton with RSWW

Table 3 shows the effects of harda plus alum or other double pre-mordanting system applied in sequence, on changes in tensile strength, breaking elongation and stiffness (bending length) of the corresponding cotton fabric sample. It also shows the results of surface colour strength (K/S values, along with CV% of K/S values), colour interaction parameters i.e. ∆E, ΔL, Δa, Δb, ∆C, ∆H, BI, MI and CDI values after subsequent dyeing of the said specific/differently double/dual pre-mordanted cotton khadi fabric. So-called Dual or Double pre-mordanting with 15% overall combination of pre-treatment with selective bio-mordant/mordanting assistant like harda and subsequent any metallic mordant concentration like potash alum or other metallic mordants applied in sequence with varying ratio (0:100, 25:75, 50:50, 75:25, and 100:0) on cotton khadi fabrics were further studied for subsequent dyeing with aqueous extract of de-oiled red sandal wood waste (RSWW) at pre-fixed and comparable dyeing conditions. Amongst all the double pre-mordanting system used, combination of 15 % overall application of harda and potash-alum (in 50:50 ratio) shows best results, as shown in Table 3.

As per the mechanism given in Fig. 3a, b, in subsection 2.2.4 for so-called dual or double pre-mordanting using harda as fixer and potash alum as natural metallic mordant satisfies the most desirable stoichiometric ratio and hence is found to be most effective for complexing as “fibre-harda (mordanting assistant) –Al from potash alum metallic mordant-RSWW natural dye” forming a bigger giant insoluble complex formation in situ in the cotton fabric so treated and dyed. This fabric has maximum surface colour depth (K/S value), compared to that obtained using either of the above said single bio-mordants like harda or any other metallic pre-mordants or any other double pre-mordanting combinations used at comparable conditions of mordanting and dyeing of bleached cotton khadi fabric with red sandal wood waste. Thus, in this case harda having lot of –OH and –COOH groups in it can help to act as catcher/fixing assistant (by utilizing its high coordinating complex forming ambience of hydroxy chebulinic acid) with Al metallic mordant and cotton cellulosic fibre having sufficient -OH groups in it to participate in this complexing and also for H–bonding. When both the pre-mordanting compounds (harda and potash alum) are applied in sequence (one by one) on cotton fabric by dual or double pre-mordanting technique for cotton or other fabric [10,11,12,13,14, 21,22,23,24], myrabolan (harda) acts as a mordanting assistant cum fixer along with Al-mordant, as shown in Fig. 3a, b in subsection 2.2.4, whereas only harda as single mordanting assistant can only fix natural dye through hydrogen bonding.

After dyeing of differently pre-mordanted cotton fabric with de-oiled red sandal wood waste (RSWW) extract, harda alone as a single mordant or mordanting assistant renders a light ocher brown tone with a bit dull shade, whereas potash alum and aluminium sulphate as single mordant give bright shades of varying colour ranging from light to medium pinkish red shades. So-called Dual/Double pre-mordanting with harda and aluminium sulphate (15% overall concentration in 50:50 ratio) show medium maroonish brown shade (for use of 20 % extract of RSWW dye). There is increase in K/S value after increase in the concentration of harda as mordanting assistant (with fixed concentration of alum). When harda plus potash alum combination is used for dual/double pre-mordanting system with subsequent dyeing with pre-fixed 20% concentration of RSWW, an effect of additional yellow colour of harda is observed, showing medium to darker reddish brown tone. But, higher extent of harda reduces the tensile strength to a higher extent, due to acidic degradation of cellulose by chebulinic acid (present in harda) treatment. Besides K/S values and tensile strength, the double mordant of harda plus alum pre-mordanting in sequence always show some decrease in corresponding brightness index value after dyeing with fixed concentration of RSWW irrespective of increase in potash alum concentration. Harda plus potash alum (Al from natural potash alum) applied in sequence combination can also form additional coordinated complex of these two agents together fixed with natural dye on cotton (after double pre-mordanting) and then can form more bigger insoluble complex with phenolic –OH groups of RSWW dye making it more wash fast with higher colour yield too. This remains as insoluble fixed mass inside the fibre/fabric, showing good colour strength and good wash fastness at a particular ratio of harda and potash alum (overall 15% application with 50:50 ratio).

Effect of Varying Single and Double Pre-Mordanting on Colour Fastness of RSWW Dyed Cotton Fabric

Data on fastness properties of dyed cotton khadi fabric samples pre-mordanted with varying type of single mordant and different ratio of double pre-mordanted samples (with application of overall 15 % single and so-called 15% dual/double mordants of different combination at different ratio), subsequently dyed with 20% red sandal wood waste extract is reported in Table 4.

It is evident from the data in Table 4, that for all mordant concentrations subsequently dyed with 20 % RSWW extract shows reasonably acceptable grade of colour fastness to wash, but corresponding light fastness ratings are much poor under accelerated MBTF-UV light exposure. Fastness to dry crocking though appears to be good, but colour fastness to wet crocking for corresponding sample always appears less irrespective of the concentrations of mordants used in pre-mordanting including potash-alum.

Moreover, there is hardly any significant difference in colour fastness to washing, light and rubbing for use of the different single mordants, but there are some clear differences on colour fastness ratings to washing, light and rubbing, when the so-called dual/double pre-mordanting systems are used. Amongst different combinations of double mordanting systems used, 15% overall application of harda followed by potash alum (harda+ potash alum in 50:50 ratio) applied in sequence shows reasonably better colour fastness rating to washing, light and rubbing amongst all double mordanting combinations used. This may be presumed to be due to some synergistic effect of the combination of potash alum with harda, where the latter is used as mordanting assistant having additional high coordinating power of –OH and –COOH groups of chebulinic acid of harda facilitating to form more bigger/giant complex formation amongst the said fibre-mordanting assistant-Al-dye. Myrabolan (harda) containing chebulinic acid and potash alum containing aluminium, are proved to be good complex former with both cotton fibre and mordantable RSWW natural dye. The harda pre-treated and subsequent alum pre-mordanted cotton fabric sample is found to be less bright but more yellower showing measurably higher ΔE value (total colour difference) as compared to other combinations of dual/double pre-mordanting system used. Hence, the colour/shades developed by different combinations of different double mordants show different ΔE values for subsequent dyeing with fixed per cent of 20% RSWW as natural-dye.

For use of single mordant, perspiration fastness results in terms of the loss in depth of shade for the cotton khadi fabric samples dyed with red sandal wood waste extract is average to good for both acidic and alkaline perspiration when potash alum is used as mordant. While the same is poor when harda or SnCl2 is used as single mordant. Whereas, perspiration fastness with respect to loss of depth of shade is extremely good for the dyed cotton khadi fabric samples pre-treated/pre-mordanted with 15% overall application of harda + potash alum(in 50:50 ratio) applied in sequence, which facilitates better anchoring/fixing of the colour components (Santalin A , B & C –deoxy-Santalin ) of red sandal wood waste extract to the cotton khadi fabric due to formation of insoluble and strong complex “cotton fibre-harda- alum –RSWW” on cotton. Due to harda pre-treatment before alum mordanting, RSWW dyed cotton fabrics always show good wash fastness in each case. For harda pre-treatment as mordanting assistant, with increase in per cent of harda, keeping fixed dye concentration of 20% RSWW, the K/S value is found to be increased to a small extent along with light fastness. The increase in light fastness by 1/2 to 1 grade for increase in concentration of harda may be viewed as an effect of UV-absorbing nature of harda (probably chebulinic acid/benzoic acid, with –COOH and ketonic functional group leads to its UV-absorbance criteria), as evident from UV–Vis spectral scan of extract of harda, earlier shown in Fig. 1b with UV-absorbance peaks at 250 nm, 310 nm and 373 nm in the UV-region.

Effects of Dyeing Process Variables on Colour Yield and Colour Fastness Properties

Results of effect of different dyeing process variables on colour interaction parameters are reported in Table 5.

The objective of this part of study is to standardize/optimize the dyeing conditions to obtain maximum surface colour strength (in terms of K/S value), uniform colour distribution (to obtain minimum CV % of K/S values, preferably within 5% CV of K/S values) for 15% harda + KAl2(SO4)2 (50:50) dual/double pre-mordanted cotton khadi fabric , subsequently dyed with 20% RSWW extract. The effects of dyeing process variables on surface colour strength (K/S value), total colour differences, L, a and b values, dye uniformity i.e. uniform colour distribution (CV % of K/S values) and other colour interaction parameters are shown in Table 5 and the corresponding colour fastness ratings/properties are also shown in Table 6.

It is observed that when all other dyeing variables are kept fixed, with the increase in time of dyeing (15–120 min), K/S value initially increases up to 30 min dyeing time and then starts decreasing on further increase in dyeing time up to 60 min and again it starts increasing from 60 to 120 min. This may be explained by the possibility of achieving dyeing equilibrium at a very faster rate within 30 min, by quicker absorption of highly an-ionizable de-oiled RSWW dye extract. Dye absorption is reduced due to start of desorption of dyes after 30 min and up to 60 min dyeing time and thereafter continues to increase the dye up take until further dyeing equilibrium is reached completing "cotton fibre-harda- alum –RSWW" complex formation inside the fibre and the dyeing rate is saturated and levelled off.

Comparing corresponding results of observed colour fastness properties (Table 6), it is observed that 30 min dyeing time renders the dyed fabric over-all better-balanced colour fastness to wash, light, rubbing and perspirations. For dyeing time higher than 30 min i.e. for 60–90 min, offers lesser or at par colour fastness grade for wash, light, rubbing and perspiration fastness. So, 30 min dyeing time may be considered as economical and optimum result out of all experiments of varying dyeing time carried out in the present work.

On increase in the dyeing temperature (40–95 °C), keeping other variables constant, the surface colour strength (K/S values) is found to show a slow increase from 40 to 50 °C and then further reduced when temperature is increased from 50 to 65 °C. However, a gradual increase in the surface colour strength is noticed during increase in temperature from 65 to 80 °C, whereas further increase in the temperature from 80 to 95 °C drastically reduces the surface colour strength value. Increase in temperature of dyeing inevitably supplies more energy for transportation of dye molecules thus facilitating the higher dye striking rate increasing dye sorption and diffusion up to 50 °C, however, this rate does not alter much even after increasing temperature up to 80 °C. At around 95 °C, the desorption of dye starts at relatively high temperature (95 °C) and K/S value decreases noticeably. While comparing corresponding colour fastness data in Table 6, it is observed that overall colour fastness data for different types/agency show a better balance for dyeing temperature at 80 °C than those obtained for dyeing temperature at 50 °C.

Hence, considering K/S value and also colour fastness properties, 80 °C temperature may be considered as better choice for fixing optimum dyeing temperature for this fibre-mordant-dye for red sandal wood waste extract. However, dyeing of cotton with red sandal wood waste extract at warm conditions i.e. at 50 °C cannot be excluded fully for decentralized sector for energy saving purposes.

Observed data in Table 5 shows increasing level of dye up take in terms of surface colour strength (K/S value) with the variation of pH (keeping other dyeing process variables constant) from 3 to7. While for increase in pH from 7 to 9, the surface colour strength (K/S value) values start slowly reducing and it shows further an upward trend at pH 11. Consequently, the K/S value drastically reduces with the increase in pH above 11. Thus, pH may be considered as one of the critical variables as it gives maximum dispersion of CDI value showing highest differences of maximum CDI and minimum CDI amongst varying pH of dye bath. Considering, colour fastness data, as shown in Table 6, it is further understood that pH 11 render batter overall balance of all types of colour fastness results even better than that obtained at pH 5 or 7. So, pH 11 may be considered as optimum value in this case of said "cotton fibre-harda- alum –RSWW" complex formation system in this natural dyeing of cotton khadi fabric. It may be presumed that at higher pH i.e. at pH 11, there is higher chances of ionization of phenoxy-hydroxyl groups of colour components of red sandal wood waste extract (Santalin–A & B and Deoxy–Santalin as Santalin–C) and hence better chances of complex formation with both harda and potash alum as dual/double mordants forming much bigger giant insoluble "cotton fibre-harda- alum –RSWW" complex. This complexing finally results not to leach out RSWW coloured molecules by more favourable anchoring to cotton fibre by complexing amongst fibre, harda as mordant-1(mordanting assistant cum fixer), Aluminium as metallic mordant -2 and RSWW mordantable natural dye forming big giant insoluble complex in situ with cotton fibre in this case, mechanism of which is schematically shown in Fig. 3a, b in section 2.2.4.

Keeping other variables constant, with the variation in material-to-liquor ratio (MLR) from 1:10 to 1:50 (Table 5), initially the K/S value show an increase in MLR of 1:10 to 1:20 and then there is a slow decrease from MLR 1:20 onwards till MLR 1:50. MLR 1:20 shows highest K/S value as compared to any other MLR used and gives more uniformity of colour in terms of CV % of K/S values. Hence the optimum MLR may be considered to be 1:20. Comparing corresponding colour fastness data in Table 6, it is observed that MLR 1:20 used show overall medium to good values of all types colour fastness data tested. Overall colour fastness data for all type of colour fastness properties are more or less found to be acceptable for MLR 1:10, 1:30 and 1:40.

But considering both colour yield and colour fastness data, MLR 1:20 gives a better balance having more uniform dyeing (Vide- CV% data of K/S values) and this may be considered as optimum dyeing conditions with respect to MLR.

Keeping other dyeing process variables constant, relevant results of K/S value and other colour parameters for use of varying percentage of dye concentration for selective RSWW natural dye extract from 10 to 50% (based on oven dry weight of source dye materials) are shown in Table 5. There is a gradual increase in K/S value with increase in dye conc. from 10 to 20% RSWW dye extract (on the basis of weight % of dry red sandal wood powder). There is a slow increasing trend of K/S value for dye concentration from 20 to 40% but that is too meagre in considering increased dye cost for increased dye % and thereafter it either levels off or drops down a little above 40% RSWW dye concentration. Increase in K/S value for increase in dye concentration from 10 to 20% is obvious and natural. But increase in RSWW dye concentration from 20 to 40% dye concentration, the observed slow or meagre increase may be related to reorientation of dye molecules for reaching saturation or levelling off action, allowing only few spaces of dye sites after reorientation, but not allowing more dye to be absorbed above saturation reached at 40% dye concentration. Hence, the respective K/S values may be viewed as an effect of reaching saturation of dye sites achieving dyeing equilibrium after 20% to 40% dye concentration, which is however not economical and however is found to be dropped down above 40 % to 50 % RSWW dye concentration. This slow increase after and above 20% dye concentration and drop-down effect above 40% dye concentration for RSWW, also may be looked into as an additional effect of some dye agglomeration (for use of more dye in bath above a certain level) making less dye available for ionization, transportation, absorption and diffusion at higher level of dye concentration. Comparing colour fastness results in Table 6 for 20% dye concentration and also CV % of K/S values, use of aqueous extract of 20 % RSWW dye concentration show overall good results from dye uniformity (CV % of K/S value), dye cost economy with lesser dye concentration and corresponding colour fastness point of view. Hence, 20% dye concentration of RSWW extract may be considered as optimum for this type of cotton khadi fabric for lighter pinkish/reddish brown shade with the said 15% overall application of harda +alum (50:50) pre-mordanting in sequence. This may be mention worthy here that increased dye concentration above saturation definitely lowers wash fastness due to more unfixed dye deposition on the fibre surface and hence colour fastness to wash is found lesser for 40% dye concentration than 20% dye concentration. Higher CV% for K/S values for 40% dye concentration may also be presumed to be due to non-uniform absorption/adherence of unfixed dyes on the surface of the cotton fibre.

The addition of an electrolyte (common salt) to the dyeing liquor expectedly increases the exhaustion of the anionic/mordantable natural dyes. Cellulose in water solution/aqueous dye bath acquires negative charges at its surface. Common salt (electrolyte) is dissolved completely in the aqueous liquor in the dye bath dissociating fully at a specific temperature of dyeing, thereby positive sodium ion of NaCl or Na2SO4 is attracted towards –ve cellulosic surface in water and neutralizes the –ve charge of cellulose moieties. Thus, anionic natural dye ions are able to be attracted to cellulose increasing exhaustion. But excessive amount of electrolyte/salt above a certain limit, causes a retardation effect in the dye absorption vis-à-vis reduces colour yield and renders lower colour depth. From the relevant data in Table 5, it is observed that with the increase in salt/electrolyte concentration from 0 to 15%, the colour yield in terms of K/S value increases for use of 0 to 5% salt concentration and starts decreasing for use of 10 % salt concentration and further increases at 15% salt concentration. K/S value reaches its peak/highest value during usage of salt concentration of 15%. However, comparing over all colour fastness properties for corresponding part, the overall all-round colour fastness properties are also found best for 15 % salt concentrations. Considering all the above matter, optimum concentration of common salt for dyeing cotton khadi fabric with de-oiled red sandal wood waste natural dye after said dual harda plus potash alum pre-mordanting of cotton khadi fabric is selected to be 15% as the K/S values are found to be maximum at this level, with moderate to good all-round colour fastness properties.

From this study, it may be summarized that the observed optimum conditions for dyeing of harda and potash alum double/dual pre-mordanted (with overall 15% concentration of harda and potash alum in 50:50 ratio in sequence) bleached cotton khadi fabric with aqueous red sandal wood waste extract are: dyeing time-30 min, dyeing temperature − 80 °C, MLR- 1:20, pH-11, mordant concentration- 15% (harda + potash alum in 50:50 ratio ) for pre-mordanting, RSWW dye concentration.- 20 % (on weight percentage of dried source material) and common salt concentration - 15%.

Besides, wash fastness, wet and dry rubbing fastness rating of bleached and pre-mordanted cotton khadi fabric dyed with red sandal wood waste extract in different conditions of dyeing, are found to be good for cotton khadi fabrics being rated as 4/5 for dry rubbing and 4 for wet rubbing (except few odd cases), respectively, and hence need no further after treatment. This good rubbing fastness (fastness to crocking) property confirms that almost no superficial loosely held dyes are attached at the fibre surface after thorough washing and soaping at 50 °C for 15 min.

Its light fastness is somewhat fair to medium and hence, there is a scope to improve the light fastness properties of de-oiled red sandal wood waste dyed cotton fabrics, with suitable UV-absorber agents.

Analysis of Colour Differences and Related Colour Interaction Parameters for Application of Red Sandal Wood Waste Extract Under Different Dyeing Conditions

Table 5 also shows the effects of different process variables on K/S values along with other colour interaction parameters, including total colour difference (ΔE), change in hue (ΔH), change in chroma (ΔC), general metamerism index (MI), Brightness index (BI) and colour difference index (CDI) values. It is interesting to observe that amongst the dyeing conditions (time, temperature, pH, MLR, Mordant, dye concentration, and salt concentration), the most important and predominating variables are identified as dye concentration, pH of dye bath and mordant concentration as indicated by wide dispersion of CDI values (higher value of differences of CDImaximum and CDI minimum i.e. the ranges of CDI values are either equal to or more than 0.50). For varying dye concentration, it is found as 0.57, for pH - it is 0.49 and for mordant concentration it is 0.44, while for all other dyeing process variables studied here, the range of dispersion of CDI is ≤ 0.20. The order of increasing CDI values therefore appears to be as follows:

Salt < MLR < Temperature < Time < Mordant concentration < pH < Dye concentration

Therefore, for uniform dyeing using red sandal wood waste extract for cotton khadi fabric, special care is to be taken for control of dye concentration, pH and concentration of mordants.

The other colour parameter data for ∆E, ∆L, ∆a and ∆b indicate the differences in colour yield or surface colour strength for varying dyeing condition in each case, as compared to standard undyed pre-mordanted control cotton khadi fabric. The higher range of ∆E values (>38) is observed for the variation in dyeing temperature and MLR, indicating that these two are the next level of important controlling parameters responsible for uniform dyeing. So, next level of care is also required for temperature and MLR variation.

Changes in hue for all cases are found to be negative (Table 5) indicating that there is minor change in predominating hue. However, the maximum ∆H value is observed in case of the variation in mordant concentration from 5 to 10% which further indicates the high sensitivity of colour yield for this particular natural dye during dyeing. Red Sandal wood contains Santalin A & B along with deoxy-santalin, which is probably mordant sensitive for co-ordinated complex formation process with cellulose fibre and mordanting assistants. ΔL values in case of all process variables are found to be negative (Table 5) indicating more darker shades of the dyed cotton fabric due to higher dye absorption from RSWW extract. The Δa and Δb values are high in all the cases indicating more respective reddish and yellowish tone to the dyed cotton fabric showing increased colour yield towards pinkish/reddish or yellowish-brown colour for source colour of RSWW and harda. Between Δa and Δb values for each, the redness is always higher than the yellowish tone due to more colour absorption of Santalin–C i.e. De-Oxy Santalin along with small amount of yellow tone of tannins/chebulinic acid present in harda.

Changes in hue (ΔH) in all the cases are negative, indicating that there is no major change in predominating hue except some hypsochromic/bathochromic shift with increase/decrease in the dyeing process variables.

Brightness index of dyed products depends on reflectance value of dye and its orientation along the fibre axis after fixation. No appreciable reduction in brightness index is observed for red sandal wood waste dyed cotton khadi fabric after dyeing, irrespective of dyeing conditions used. However, it may be noted that at higher temperature of 80 °C, lower MLR (1:10) and higher dye concentration (40–50%), the reduction in brightness index is much higher than that observed in other conditions.

The general metamerism index (MI) indicates the metameric effect on the red sandal wood waste dyed cotton khadi fabric for different conditions of dyeing. In all these cases the MI varies from 4.74 to 7.35 (Table 5) and data are not much widely dispersed within a particular condition being varied, but varies to a noticeable degree from one condition to other, indicating its potent metameric nature from one condition to other. Therefore, use of standard conditions of dyeing is must to minimize metamerism for achieving least metameric dyed products for this fibre-mordant –dye system. However, MI values are much lower for variations in MLR and dyeing time

FTIR Analysis

FTIR spectra for (a) bleached control khadi cotton fabric (b) harda plus alum mordanted khadi cotton fabric and (c) harda + alum pre-mordanted with RSWW dyed khadi cotton fabric is shown in Fig. 4.

The FTIR spectra-a show as usual common peaks of control cotton fibre [21] matching with earlier reports in literature. The FTIR spectra-b shows some minor differences in the following peaks: at 1204 cm−1 and1697 cm−1 are –C–O stretching and –C=O stretching of carboxylic acid group of chebulinic acid are observed, respectively. At 1313 cm−1 ester/phenol-based alcohol (–OH) stretching, at 1400–1425 cm−1 for –COO stretching, at 1609cm−1 for C=C aromatic ring stretching of tannins/chebulinic acid of harda and at2576 cm−1 for carboxylic acid (–COO-) stretching are observed. The peak at 2956 cm−1 assigned to C-H vibration of CH3 group at 3288 cm−1 it is for –OH stretching of phenolic –OH, at 3000–3500 broader peak area is for –OH stretching in –COOH group and phenols in tannins/chebulinic acid. Some of the above peaks of phenolic–OH, C–H, –CH2 and –COO-functionality chebulinic acid of harda-based tannin are merged in FTIR spectra (b) with similar functional peaks of cotton cellulose [spectra-(a)]and hence are not appearing as separate peaks in spectra (b) to identification.

Similarly, FTIR spectra-(c) shows very similarity with spectra-(b) having similar peaks confirming presence of phenolic –OH, –COOH, phenols, ketones, aromatic compounds, etc., with some minor differences in peak areas and height. Apart from above said peaks of FTIR spectra –(b), the FTIR spectra –(c) for RSWW extract dyed cotton fabrics shows small peaks for –C=O and C–O stretching for carboxylic acid/ketones (at 1744–1700 cm−1), C–O–C in aliphatic ethers for tannins (1030–1040 cm−1) added to celluloses and-C-OH stretching of secondary alcohols (at 1095–1074 cm−1), etc., which were also merged with similar FTIR peaks of cotton and hence are not appearing separately.

However, a closer look and finer analysis indicate that a small hump at 2840–2850 cm-1 for C–H2 stretching (in association with some –OH bending and stretching vibration for hydrogen bonding) are merged with duplets at 2895– 2902 cm-1 for C–H stretching. CH2 stretching of cellulose appeared in both FTIR spectra –(b) and (c) as compared to spectra (a) of control cotton, indicating hydrogen-bonding of both harda and RSWW colour components with cotton celluloses. The same is also indicated by broadening of peak at 2359-2400 cm-1 in both FTIR spectra –(b) and (c) as compared to spectra (a) of control cotton having a smaller size peak in this wavenumber.

The reduction in peak area in both FTIR spectra –(b) and (c) as compared to spectra (a) of control cotton at 1425 -1433 cm-1 indicates utilization of -OH and –COOH functionality of chebulinic acid. The -OH functionality of deoxy-santalin (Santalin-C) forms ester linkages between –C–O–M coordinated covalent bonding with alum-based aluminium metallic mordant, as well as ester group formation is observed between –COOH functionality of chebulinic acid of harda and –OH group of cotton cellulose for attaching harda to cellulose forming fibre-harda adduct before alum is added thereafter. After addition of alum this forms F-m adduct represented as M present both in harda used (as the bio-mordanting assistant) harda +Alum + RSWW dyed samples. Moreover, FT-IR curve (c) i.e. for harda pre-mordanted and dyed cotton sample shows higher reduction in corresponding FTIR peak at 1720–1744 cm−1 (–C=O stretching of carboxylic acid forming ester). At 2850 cm−1 the same is evident as C–H2 stretching in association with some –OH bending and stretching for hydrogen bonding. Post dyeing, it indicates formation of bigger and giant adduct of harda -fibre-metallic mordant- RSWW (Deoxy-santalin as dye component) as natural dye as shown in reaction scheme in Fig.3a, b with harda plus alum pre-mordanted cotton by both –COO-ester formation. More hydrogen bonding is observed with cellulosic–OH groups besides coordinated covalent bond formation with metallic mordant present therein [21].

In FTIR spectra-(c), common peaks are observed for colour components of RSWW (Santalin–A, Santalin–B and Santalin–C i.e. De-oxy santalin).At 1338–1397 cm-1 a doublet for –C–O–H bending in primary and secondary alcohols of santalins is observed. At 1680 cm−1asmall doublet for –C=C stretching in non-conjugated –C=C for santalins of RSWW is observed. 6C benzene ring ketone vibrations are observed at 2354 cm−1 and 3008 cm−1 in santalins of RSWW. Peaks at 2815 cm-1 indicates a small –C–H stretching in –O–CH3 group in santalins. A small peak at 3563–3650 cm−1 shows –O–H stretching of phenolic –OH of santalins, all of which are partially or fully merged with the other peaks of cellulose and harda present. Hence, are not easily identifiable separately.

Conclusions

It is observed that, 1:40 MLR,10 pH, 80 °C temperature and 30 min time are the optimized conditions for aqueous extraction of colour component from red sandal wood waste. It is also vital to note that 15% overall application of harda and alum in 50:50 ratio applied in sequence at 80 °C for 30 min is the optimum colour yielding dual mordanting technique for bleached cotton khadi fabric subsequently dyed with aqueous extract of de-oiled red sandal wood waste. The observed optimum conditions of dyeing of cotton khadi fabric with de-oiled red sandal wood waste are as follows: mordant concentration–15% (Harda + Potash alum in 50:50 ratio), dye concentration–20 %, dyeing time-30 min, dyeing temperature − 80 °C, MLR- 1:20, pH- 11 and common salt conc.15gpl. Interpretation from colour difference index (CDI) values clearly reveals that mordant concentration, dye concentration and pH of dye bath are the three most critical dyeing process variables, amongst all other parameters of dyeing process variables in this study and hence need to control for uniform dyeing results.

References

A.C. Dweck, Natural ingredients for colouring & styling. Int. J. of cos sci. 24, 1–16 (2002)

Z.M. Win, M.M. Swe, Purification of natural dyestuff extracted from mango bark for the application on protein fibres. World Acad Sci. Eng. Technol. 46, 536–539 (2008)

R. Siva, Status of natural dyes and dye yielding plants in India. Curr. Sci. 92(7), 916–925 (2007)

B. Lellis, C.Z. Fávaro-Polonio, J.A. Pamphile, J.C. Polonio, Effects of textile dyes on health and the environment and bioremediation potential of living organisms. Biotechnol. Res. Innov. 3(2), 275–290 (2019)

Md. Reazuddin Repon, Md. Abdullah Al Mamun, M. Tauhidul Islam, Optimization of dyeing timeof eco-friendly cotton colourationusing Banana (Musa Sapientum) floral stem sap. Chem. Mater. Eng. 4(3), 26–31 (2016)

A.K. Samanta, D. Singhee, M. Sethia, Application of single and mixture of selected natural dyes on cotton fabric: a scientific approach. Colourage. 50(10), 29–42 (2003)

M.L. Gulrajani, D. Gupta, Natural Dyes and Their Application to Textiles (Dept of Textile Technology, IIT, Delhi, 1992), pp. 25–26

S.G. Mahale, R.K. Sunanda, Silk dyed with Acalypha (Acalypha wilkesiana) and its fastness. Indian J Fibre Text Res 28, 86–88 (2003)

M.R. Katti, R. Kaur, N. Shrihari, Dyeing of silk with mixture of Natural dyes. Colourage 43(12), 37–39 (1996)

A.K. Samanta, P. Agarwal, S. Datta, Dyeing of Jute and cotton fabrics using jackfruit wood extract –Part –I, effect of mordanting and dyeing process variables on colour yield and colour fastness properties. Indian J Fibre Text. Res. 32(12), 466–476 (2007)

A.K. Samanta, P. Agarwal, S. Datta, Physico-chemical studies on dyeing of jute and cotton fabrics using jackfruit wood extract as natural dyes: Part-II: kinetic and thermodynamic studies. Indian J. Fibre Text Res. 33, 66–72 (2008)

A.K. Samanta, P. Agarwal, S. Datta, Physico-chemical studies on dyeing of jute textiles with natural dyes extracted from red sandal wood. J I E(I) Text. Engg. 87, 16–26 (2006)

A.K. Samanta, P. Agarwal, S. Datta, Application of Single and mixtures of red sandal wood and other natural dyes for dyeing of jute fabric: studies on colour parameters/ colour fastness and compatibility. J. Text Inst. 100, 565–587 (2009)

A.K. Samanta, P. Agarwal, S. Datta, Studies on colour interaction parameters and colour fastness properties for dyeing of cotton fabrics with mixture of jackfruit wood and other natural dyes. J. Nat. Fibres 6, 171–190 (2009)

A.G. Perkin, A.E. Everest, The Natural Organic Colouring Matters (Longmans Green & Co, London, 1918)

M.L. Gulrajni, S. Bhaumik, W. Oppermann, G. Hardtmann, Kinetic and thermodynamic studies on red sandal wood. Indian J. Fibre Text. Res 27, 91–94 (2002)

A.K. Samanta, P. Agarwal, Application of mixture of red sandal wood and other natural dyes for dyeing of jute fabric-studies on dye compatibility. Int. Dyer 3, 37–41 (2008)

A.K. Samanta, P. Agarwal, A. Konar, S. Datta, Characterisation and application of purified selective natural dyes on jute. International Dyer 193(3), 25–33 (2008)

B. Ravindranath, T.R. Sheshadri, Structural studies on santalin permethyl ether. Phytochemistry. 12(11), 2781 (1973)

A. Arnone, L.L. Camarda, L. Merlini, G. Nasini, Structures of the red sandalwood pigments santaline A and B. J. chem. Soc. Perkins Trans. 1, 186–194 (1975)

Y. Dhanania, D. Singhee, A.K. Samnata, Optimization of dyeing process variables for eco-friendly dyeing of cotton fabric with babul bark extract as a natural dye and gallnut extract as a bio-mordant. J. Nat. Fibres (2021). https://doi.org/10.1080/15440478.2021.1875955

H.D. Sinnur, D.K. Verma, R. Kaware, A.K. Samanta, Standardization of mordants and dyeing process variables for dyeing cotton khadi fabric with Indian madder as natural dye. Indian J. Nat. fibres 4(1), 21–38 (2017)

H.D. Sinnur, A.K. Samanta, D.K. Verma, R. Kaware, Studies on coloration and protective action of anar peel pomegranate rind as an effective natural colorant for cotton khadi fabric. J. IE (I) Chem Text Engg. Ser. E 99(1), 9–26 (2018)

A. K. Samanta, P. Samanta (ed.), New World of Textiles: Shaping for the Future (Allied Publishers Pvt Ltd, Delhi, 2021) pp. 45–73

ASTM D5035–11, Standard test method for breaking force &elongation of textile fabrics (Strip method) philadelpia, PA: American society for testing & material, 8–9(2015)

ISI (BIS) Handbook of textile testing, 1stedn. (SP-15–1981) (BIS, New Delhi, India, 1981), 221, 229, 255, 280 & 587 (1981)

H.S. Shah, R.S. Gandhi, Instrumental Colour Measurements and Computer Aided Colour Matching for Textiles (Mahajan Book Distributors, Ahmedabad, 1990), pp. 76–116

ISO 2469 & 2470, International Organization for Standardization (Geneva), 1–3 (1977)

I.G. Vasi, P.R. Shah, Spectroscopic Data Tables (Mahajan Brothers, Ahmedabad, 1980), pp. 4–11

Acknowledgements

Authors are thankful to Mahatma Gandhi Institute for Rural Industrialization (MGIRI), Wardha, India under Ministry of Micro, Small & Medium Enterprises (MSME), Govt. of India for encouragement and all administrative support to carry out the major part of R&D work at MGIRI. The authors also express thankfulness to MSME for the R&D Project Grant-in-Aid to carry out this Project on standardization of the process of dyeing cotton khadi fabric with natural dyes.

Funding

The authors declare that no such funding was received from any such funding agency for this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sinnur, H.D., Verma, D.K., Kar, T.R. et al. Effect of Dyeing Process Variables on Colour Yield and Colour Fastness Properties for Cotton Khadi Fabric Dyed with De-Oiled Red Sandal Wood Waste. J. Inst. Eng. India Ser. E 102, 273–292 (2021). https://doi.org/10.1007/s40034-021-00218-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40034-021-00218-0