Abstract

Thermal comfort properties of eri silk, mulberry silk, wool and linen fibres have been studied in this article. Four types of fabrics were made by using spun yarns of eri silk, mulberry silk, wool and linen fibres in weft direction and polyester multifilament yarn in warp direction. Thermal comfort properties of these fabrics have been studied by measuring the air permeability, moisture absorption, thermal and moisture transmission through the fabrics. The thermal properties were measured with Alambeta instrument and wicking of the fabrics was measured by using a vertical wicking tester. Among the four samples, wool fabrics exhibit highest thermal resistance and lowest thermal absorption value; whereas eri silk, mulberry silk and linen fabrics displayed lower thermal resistance values and also higher thermal absorption values, without much significant difference among them. It is observed that the linen fabrics have highest air permeability, followed by wool and then silk fabrics. Lowest air permeability properties of eri and mulberry silk are found to significantly influence the thermal behaviour of silk samples. Highest water vapour permeability was observed in case of wool fabric. Highest wicking and absorbency has been observed in case of mulberry and eri silk, respectively. The results emphasize that the eri silk and mulberry silk samples with high thermal absorbency, wickability, moisture absorbency and very good water vapour permeability coupled with low thermal resistance are suitable for summer wear clothing and at the same time these samples also possess very low air permeability and very good water vapour permeability signifying their appropriateness as thermal wear for windy conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ericulture is a traditional agro-based sericulture activity in North-eastern region of India from time immemorial. As any other silk fibre, eri is also a protein fibre and it is the second largest variety of silk fibre produced in India. Countries such as China and Paraguay produce eri silk as well. Eri silk constitutes approximately 20% of total silk produced in India [1]. Unlike other silk verities, eri silk is not available in continuous filament form and its fibres can be spun into a yarn through textile spinning process. Eri silk is known as ‘Non-violent Silk’ or ‘Ahimsa silk’. It is also called “Poor man’s Silk” as eri is the cheapest among the verities of silks available. It possesses unique dual characteristic of the softness of silk and the warmth of wool coupled with staple fibre availability unlike other commercial silks [2,3,4]. Wool fibres are known for its excellent thermal insulation properties and high moisture regain [5,6,7], which has created an established place for woollens as winter wear.

Clothing comfort is an extremely complex phenomenon and has drawn the attention of many textile researchers [8]. It is decided by the feeling of the wearer, at a particular environmental condition. Textile clothing comfort can be classified into three groups, i.e. Thermal, Aesthetic and Tactile comfort. Thermal comfort is primarily related to the efficiency of a clothing to maintain the body core temperature by dissipating/ insulating the produced heat [9,10,11].

Clothing creates a microclimate between the skin and the environment, which supports the body's thermoregulatory system to keep its temperature within a safe range, even when the external environment temperature and humidity changes to quite an extent. In a regular atmospheric condition and during normal activity level, the heat produced by the metabolism is liberated from body to atmosphere by conduction, convection and radiation and body perspires in vapour form to maintain the body temperature. At higher activity levels and/or at higher atmospheric temperatures, the production of heat is very high and /or transmission of heat from the body to atmosphere is less, it activates the sweat glands to produce liquid perspiration as well [12]. The vapour form of perspiration is known as insensible perspiration and the liquid form as sensible perspiration. When the perspiration is transferred to the atmosphere, it carries heat (latent as well as sensible) thus reducing the body temperature. The fabric being worn should allow the perspiration to pass through; otherwise it will result in discomfort. The perception of discomfort in the active case depends on the degree of skin wetness.

During sweating, if the clothing moisture transfer rate is slow, the relative and absolute humidity levels of the clothing microclimate will increase suppressing the evaporation of sweat. This will increase rectal and skin temperatures, resulting in heat stress. It is also important to reduce the degradation of thermal insulation caused by moisture build up. If the ratio of evaporated sweat and produced sweat is very low, moisture will be accumulated in the inner layer of the fabric system, thus reducing the thermal insulation of clothing [13] and causing unwanted loss in body heat, in winter condition. Thus along with the heat transmission, moisture transmission both in vapour and liquid form plays very important role in determining the comfort feeling for the wearer [14]. Thermal insulation, thermal absorptivity, air permeability, water vapour permeability, wetting/wicking, water absorbency, are some factors determining hot/cool feeling, thermal insulation and moisture management properties of the fabric, which are associated in determining the thermohpysiological/ thermal clothing comfort.

The warm or cool feel at the touch of clothing is known as transient contact effect [15]. There are two aspects of these contact sensations, the purely thermal and the combined effects of heat and moisture. The purely thermal effect arises from the greater thermal conductivity of fibres than of air and the greater heat capacity and density. The other factor which is involved in warm and cool feel is the hygroscopicity. If the fibres absorb moisture they will become warmer releasing the sum of heat of condensation of the water and the heat of chemisorption. Moisture regain of fibre has a significant influence on moisture management properties of a fabric [16]. It is an intrinsic fibre property; at a given atmospheric condition it does not depend on the yarn porosity and fabric cover and it represents the hygroscopicity of the material. It has a direct influence on the water vapour transmission for non-Fickian diffusion [17]. In case of hygroscopic fibre, water vapour transfer through absorption and desorption method, has a significant contribution [18]. Type of fibre, shape and size of the fibre play very important role in determining moisture transmission properties of the fabric [19].

Linen is a cellulosic bast fibre, obtained from flax plant. It is known for its high moisture absorption capacity and linen textiles are valued for their exceptional coolness and freshness in summer [20]. Eri silk is reported to have similar properties as wool [2], its blends with animal proteins fibres such as wool, alpaca and cashmere enhance the next to skin properties of the fabrics [21] specifically good absorption and wicking property [23]. Several research studies have reported the physical and comfort properties of spun silks, eri silk and wool blended materials [21,22,23,24]. Kariyappa et al. [22] have developed brick red eri silk, wool and brick red eri silk-wool blended yarns (4 combinations) on worsted spinning system and studied the physical properties wool and eri silk blended yarns. Senthilkumar and Ramachandran have studied the influence of knitting process variables on the thermal comfort and wicking properties of eri silk knitted fabrics. It was observed that thermal conductivity of knitted single pique structure is better than the single jersey fabrics. The article also inferred that the thermal comfort properties of eri silk knitted fabrics were better compared with those of mulberry silk fabrics [25].

Rameshkumar et. al. [26] have reported work on polyester/waste silk core-spun yarns and fabrics. Thermal comfort and wicking behaviour of these fabrics were investigated with respect to fabric thickness, yarn structure and fibre properties in their work. Kulkarni has studied the quality characteristics of viscose rayon and eri silk union fabrics with respect to mechanical properties [27]. Wool Research Association has conducted work to blend wool with eri silk fibre by addition or alteration in the spinning apparatus or processes used and evaluated the properties of the blended material [2]. Javali [28] has worked on the characterization of eri silk and observed that the eri silk yarns were ideally suited for knitting. Further, it stated that eri silk fabric properties such as drape, air permeability, fabric mass, crimp, cover factor, crease recovery, fabric elongation show favourable results compared to mulberry.

De and Mitra [29] have compared the mechanical properties and thermal insulation value of er silk with cotton fabrics, in order to see its applicability in apparel. They observed tensile property, fabric assistance and thermal insulation value (T.I.V.) of eri fabric is better than cotton. Further, they [30] have carried-out an exhaustive study on mechanical properties and thermal behaviour of eri fabrics and compared it with wool fabrics to establish that eri can supplement good quality wool in apparels due to its better thermal insulation (T.I.V). Moisture management and wicking properties of eri silk knitted fabrics have been studied by Senthilkumar et. al. [31]. Three different knit structures were developed with the combination of two different yarn count and tightness level. The fabrics developed are analysed in terms of wetting time, spreading speed, absorption rate and maximum wetting radius, accumulative one way transport index (AOTI) and overall moisture management capacity (OMMC). The OMMC indexes of eri silk knitted fabric are found to range from ‘very good’ to “excellent’ category, which indicates the suitability of eri silk yarn to skin fit as well as active wear applications.

In the study conducted on comfort properties of eri silk /wool blended fabrics, it is reported that thermal insulation (in absence of any convective flow) and air permeability decrese, whereas wicking and absorbency increase with increase in eri silk proportion [23]. Studies report that the physical and comfort properties of 100% wool and 100% eri silk spun yarn fabrics and they have been observed that the eri spun silk fabric is stronger, stiffer and durable [32,33,34,35]. Low stress mechanical properties of eri silk, wool and eri silk and wool blended fabrics have been studied and the studies exhibited increase in tensile energy, compression energy, shear properties and frictional properties of the blended fabric with increase in eri component. The study revealed that eri silk has properties like thickness at maximum load, shearing, geometric roughness hysteresis of bending moment, extensibility % and total hand value higher than wool fabric [32, 34]. It is reported that based on the total hand value eri cloth was suitable for dress material in summer as well as in winter [34].

Studies to understand the wear-ability of eri silk fabric for different seasonal conditions with respect to thermal comfort were very scant and hence in this article comparative study of eri silk and mulberry silk with wool and linen fibres have been attempted. This study aims to study the thermal comfort properties of eri silk fibre with wool fibre, which is outstandingly used for winter wear application and with linen fibre, which is a preferred one for summer wear and with its majorly used silk counterpart i.e. mulberry silk.

Materials and Methods

Materials

Yarns of 2/80s Nm prepared with eri silk, mulberry silk, wool and linen fibre in worsted spinning system have been used for the present studies. In order to carry-out comparative assessment of the thermo-physiological properties of eri silk, mulberry silk, wool and linen, four set of plain woven fabric samples have been developed on Flexible Rapier loom (G 6100 M) by changing the weft yarn and keeping the warp constant (polyester multifilament yarn). A neutral non-influencing warp of polyester fibre was used for weaving all the four varieties of samples mentioned above and thus ensured that the sample fabrics developed represented the weft fibre properties for comparative analyses. The details of the developed fabric samples have been given in Table 1.

Testing Methods

Fabric Constructional Parameters

Developed fabrics have been subjected to scouring/degumming process and all the fabric samples were conditioned and tested in standard atmospheric conditions. The fabric constructional parameters: warp thread density (ends per inch – EPI) and weft thread density (picks per inch – PPI), fabric weight per unit area, fabric thickness and fibre blend proportion were evaluated using ASTM standards [36]. Warp and weft densities were measured according to the ASTM D3775-12 standard, using counting glass. Yarn linear density and fabric weight per unit area were determined according to ASTM D1059-17 and ASTM D37776 M -09 (RA 2013) standards, respectively, using electronic weighing balance. The thickness of the fabrics was measured according to ASTM D1777-96 standard using gauge type thickness tester (Maker – Techno Instrument) at a pressure of 100 Pa. Amount of weft fibre in unit area in a fabric sample was evaluated using ASTM D629-15 standard.

Constructional parameters of the fabric samples are given in Table 1.

Thermal Properties

The thermal properties were tested on Alambeta instrument by following ASTM D1518-14 test standard [6, 36]. The measurement details are: fabric sample size = (100 × 100) mm, measuring head pressure = 200 Pa ± 10%, measuring head temperature = 32 °C, temperature of fabric = 18 to 23 °C and measuring area of head = 1 dm2. The instrument enables insertion of fabric specimen between parallel measuring plates. Both measuring heads are equipped with thermocouples and heat flow sensors. The lower measuring head (LH) is adjusted to the ambient temperature by suitable cooling means; the upper, heated measuring head (UH) is adjusted to a controlled constant differential temperature. The heat flow sensors act up at the contact faces of both LH & UH measuring heads. When UH is lowered on the measuring fabric specimen, the heat flow from the upper surface of LH through the test specimen is measured. The fundamental measuring principle adopted is that the measuring and processing of the heat flows is dependent on time. The instrument gives readings for six parameters i.e. thermal conductivity, thermal diffusion a, thermal absorption b, thermal resistance r, the ratio of maximal to stationary heat flow density ( qmax/qs) and stationary heat flow density qs at the contact point. The measurement has been done in absence of any convective flow.

Moisture Regain

The Moisture regain of a material is expressed as a percentage of the amount of moisture present in it to its moisture-free weight. Moisture regain of the samples were measured as per ASTM 2495–07 test method [36]. The samples were conditioned for 24 h at 65–67% R.H. and at 20 °C. Weight of the conditioned sample was noted down and then the sample was placed for drying. The weight of the oven dried sample was noted and moisture regain of the sample was calculated as per the formula given below.

where, D – Oven dry mass of sample.

M – Mass of conditioned sample.

Air Permeability

Prolific Inclined Tube Manometer was used for testing air permeability of the fabrics as per ASTM D737:04. RA 2016 [36] test standard. The method is based on the measurement of the rate of flow of air through a given area of fabrics by a given pressure drop across the fabric. A pressure drop of 10 mm of water column was kept, as per the standard for fabrics for garment. From this rate of air flow, air permeability of the fabric is determined.

Water Vapour Permeability

Water vapour permeability through fabric samples was determined using Textest TF 165 Water vapour permeability tester, as per BS 7209:1990 test standard [37]. This tester measures the water vapour transmission rate based on gravimetric method (dish method). Water vapour permeability of the fabric sample is calculated based on the following formula.

where M is the loss in mass (g); T, the time interval (h); and A, the internal area of the cup (m2).

Absorbency Test

The test for absorptive capacity and absorbency time has been conducted following the principles described in ISO 20,158 test standard [38]. Absorptive capacity provides a measure of the amount of liquid held within a test specimen after specified time of immersion and drainage. Absorbency time is the time required for complete wetting of a specimen strip. The liquid absorptive capacity is calculated using the following formula.

Wetting Behaviour by Drop Test

AATCC Test Method 79–2010 [39] is used to conduct this test. This test measures the wettability of textiles by measuring the time required for a drop of water placed on the fabric surface to completely sprayed/ absorbed into the fabric. A micro pipette has been used to put water drop (20 µl) on the fabric surface.

Wicking Test

The wicking test has been conducted as per DIN 53,924 [40] test standard using vertical wicking tester. Fabric samples were cut along weft direction (20 cm × 5 cm) and mounted on vertical wicking tester. Height reached by the wicking liquid along the fabric was noted for upto 20 min, at different time intervals.

Results and Discussion

Thermal Properties

The sensation of comfort is an unconscious reaction to the efforts of the body to cope with prevailing adjoining conditions. The perception of warmth is largely determined by an imbalance of the rate of heat loss from the human body’s skin surface and the heat flow produced at the skin by physical activity. The important parameters which explain the thermal properties of clothing are: thermal conductivity/ thermal resistance and thermal absorptivity [6, 41]. Thermal resistance of clothing decides, the insulation provided by the clothing to the wearer. A higher thermal resistance of the clothing means it will keep the body warmer. The test results on the thermal properties of the fabrics are presented in Table 2. Among the four samples, wool-union blended fabric sample exhibits highest thermal insulation as predicted, whereas eri, mulberry and linen union blended fabrics show lower thermal resistance values in a close range (Fig. 1). Ratio of maximal to stationary heat flow density has been observed highest in case of wool. Low thermal conductivity and absorptivity of wool union fabric signify that it offers warmth feel to the wearer. Higher thermal absorptivity of linen indicates that linen union fabric provides cool touch to the wearer, as expected (Fig. 2). Whereas absorptivity value of eri and mulberry is very similar and it comes closer to that of linen than wool, which signifies eri and mulberry will offer a cool touch to the wearer. Statistical significance analysis of the test results has been conducted and presented in Tables 3 and 4. Table 3 shows the ANOVA analysis (comparison among all the samples) of different properties of the fabrics; it shows whether there is significant difference in test results, when all four fabric samples are compared. Whereas Table 4 shows the ANOVA analysis, when multiple comparison is done, i.e. sample 1 has been individually compared with samle 2, 3 and 4, respectively.

Table 3 presents the analysis that shows there is significant difference (at 95% significance level) in the results of different properties when compared with all the samples. Table 4 shows the multiple comparisons of the individual samples. For thermal resistance and thermal absorption, no significant difference has been observed between eri silk, mulberry silk and linen samples. Whereas, there is significant difference in the thermal resistance and absorption value for wool sample (sample 3) when compared with all other fabric samples.

Moisture Regain

From the results (Table 2, Fig. 3), it has been observed that, wool union fabric is having highest regain value, followed by linen and silk. From the significance study (Tables 3 and 4), it has been observed that there is a significant difference in regain value of wool union with linen and silk union fabrics, whereas no significant difference has been observed in the moisture regain of eri silk, mulberry silk and linen union fabrics. Wool fibre possesses a higher regain of 16%, flax (linen) fibre 11–12% and silk 11% [4], the similar trend has been observed in the present results as well.

Air Permeability

Air permeability is an important parameter of the clothing which significantly determines the thermal comfort for the wearer. The result of air permeability, in terms of the amount of air passing through unit fabric area per unit time, has been outlined in Fig. 4. From the results it can be observed that linen union fabric offers very high air permeability, wool union fabric has comparatively less air permeability whereas, eri and mulberry possess lowest air permeability. The reason can be attributed to the structure of these fibres.

Linen fibres are polygonal in cross section and are also less flexible compared to wool and silk. Thus under air flow, the fibres does not alter much from their position and air escapes easily between the interstices. Polygonal cross section and higher fibre denier result in low packing factor and also the porous fibre structure fosters very high air permeability. The wool fibres are circular in cross section, possess natural crimp and are very flexible. Hence under air flow, the fibres realign due to crimp and flexibility restricting the air passage between them. Due to the triangular cross section and high flexibility, silk fibres tend to align very densely packed (high cover factor). Under air flow conditions, the eri and mulberry silk fibres can pack themselves very well creating a compact fabric structure and higher fabric cover, offering less pore area for air to pass through. It can be inferred the statistical analysis that both eri and mulberry silk behave similar with no significant difference in air permeability values of in air permeability aspects (Tables 3 and 4). It is very pertinent to note that eri silk and mulberry silks although have less thermal resistance compared to wool fibres (Table 2 and Fig. 1), but they could significantly demonstrate higher thermal insulation values due to reduced convective heat loss because of their low air permeability, specifically when silk fabrics have better packing factor and tested under air flow conditions as in Thermolabo. This low air permeability behaviour could provide explanation to the higher thermal insulation (T.I.V) observed in earlier studies [30, 32].

Water Vapour Permeability

Water vapour permeability is a very important clothing comfort parameter, which determines the breathability of the fabric, i.e. the ability of the fabric to allow the insensible perspiration to pass from the skin to the atmosphere and making the wearer comfortable. For comfort, the permeability to water vapour of clothing fabric should be as high as possible, to allow for the escape of water vapour, which is constantly being released from the skin [42]. Highest water vapour permeability has been observed in case of wool fabric sample (as shown in Fig. 5), although all samples offer reasonably good water vapour permeability. From the significance test, no significant difference has been observed in the water vapour permeability value of eri, mulberry and linen samples. Though silk fabrics show low thermal resistance when measured in ALAMBETA (which measures the heat transfer in absence of any air flow), its low air permeability and high water vapour permeability could be the reasons to offer a comfort feel to the wearer in a cold and windy conditions.

Water Absorbency %

The results on absorbency, wetting and wicking have been given in Table 5. From the experimental result it has been observed that wool union fabric has not shown any liquid water absorption. The tendency of wool to resist wetting is due to the existence of the surface barrier, i.e. scales. Even though linen is known for its fluid absorbing capacity, experimental result shows that eri silk can absorb significantly higher than linen (Fig. 6).

Wetting Time

During the drop test, spreading has not been observed in case of wool fabrics, whereas very quick spreading was observed in case of other three samples. The tendency of wool to resist wetting is due to the existence of surface barrier [17]. Time taken by the drop to spread in the fabric, was lowest in case of mulberry fabric sample (Fig. 7).

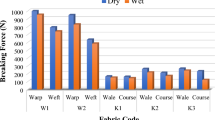

Vertical Wicking

Vertical wicking test results indicate that mulberry union fabric sample display highest wickability, followed by eri union fabric sample and linen (Fig. 8). Wicking was not observed in case of wool union fabric. Lower denier of mulberry fibre results in smaller and more number of pores and capillaries, which drag liquid faster, offering low wetting time and higher wicking. Whereas bigger pores in linen (due to higher fibre denier), allow the material to sink fast, but offer comparatively less wicking (Table 5).

Conclusions

Thermal comfort properties of eri silk, mulberry silk, wool and flax (linen) fibres in terms of thermal resistance, thermal absorption, air permeability, water absorption, water vapour permeability and water wicking properties have been compared in this article. Results validate the linen sample is having best summer wear application properties due to its low thermal resistance, excellent thermal absorptivity, air permeability and water absorption properties. Eri silk and Mulberry silk also have good performance in these characteristics for summer wear applications except the low air permeability characteristics. This research establishes that eri silk fabric can also be used very well as a summer wear for its good wetting, wicking, absorbency, water vapour permeability, low thermal resistance and cool at touch properties, provided high air permeable property is ensured through open fabric construction or by blending it with some porous fibres. The same statement holds good for mulberry silk fabrics as well.

Undoubtedly wool fibres have an outstanding winter wear property which is substantiated in this article as well, with respect to excellent thermal resistance, warm touch to skin, low air permeability and good water vapour permeable properties. This study also deciphers that, the thermal resistance of eri silk fabric is similar to mulberry silk and linen fabric rather than that of wool, when there is no convective flow. However, in case of windy atmospheric conditions, eri silk fabrics offer excellent thermal protection to the wearer, as low air permeability of eri silk fabric acts as a boon to protect the wearer from cold and in such conditions eri silk could provide much higher thermal insulation. Hence, it can be summarized that through fabric engineering approach, eri and mulberry silk fibres can be utilized for textile clothing for both summer and winter wear applications.

References

Sericulture Statistics (2018) CSB Annual Report 2017–18 (Central Silk Board, Ministry of Textiles, Govt. of India, Bengaluru, India), pp 75.

P.R. Kulkarni, R.S. Bahuguni, Wool Tech 01(02), 8 (2011)

P.K. Choudhuri, P.K. Majumdar, B. Sarkar, Manufacturing of eri silk yarn: A review. Man Made Textile in India. 39(10), 359–361 (2011)

Debasis Chattopadhyay, Arijit Chakraborty & S. M. Chatterjee (2020) Journal of Natural Fibers. https://doi.org/10.1080/15440478.2020.1821286.

V.A. Shenai, Technology of Textile Processing. Textile Fibres. 1, 31–35 (1995)

A. Engin, B. Monika, H. Lubos, Journal of Natural Fibers 16(2), 199–208 (2019)

R. Indu Shekar, N. Kasturiya, Hans Raj & S. Nigam (2001) 26 (9); 287–295.

R. Apurba Das, Alagirusamy, Book on Science in Clothing Comfort. Woodhead Publishing India Pvt Limited. 21(1), 27–32 (2010)

Y. Li, The science of clothing comfort. Textile Progress 31(1–2), 1–135 (2001)

Y. Li, Research Journal of Textile and Apparel. 1(1), 84–93 (1997)

B.P. Saville, Comfort in Physical Testing of Textiles (Woodhead Publishing Limited, Cambridge, UK, The Textile Institute, 1999), p. 227

K.C. Parsons, Book on Human Thermal Environments (Taylor & Francis Publishers, United Kingdom, 1993).

P. Zhang, Y. Watanabe, S.H. Kim, H. Tokura, R.H. Gong, J. Text. Inst. 92(1), 372–378 (2001)

B. Das, A. Das, V.K. Kothari, R. Fanguiero, M. De Araújo, AUTEX Research Journal. 7(2), 100–110 (2007)

L. Fourt, N.R.S. Hollies, Book on “Clothing: Comfort and Function” (Marcel Dekker Inc, New York, 1970), pp. 31–56

B. Das, A Das. VK Kothari, R Fangueir and M Araujo, Journal of Engineered Fibres and Fabrics 4(4), 20–28 (2009)

W.E. Morton, J.W.S. Hearle, Physical properties of Textile Fibres. The Textile Institute. 3, 178–185 (1986)

B. Das (2009) PhD thesis on Studies on moisture transmission through fabrics , Indian Institute of Technology Delhi, New Delhi, India.

B. Das, A. Das, V.K. Kothari, R. Fanguiero, M. De Araújo, Fibres and Polymers. 9(2), 225–231 (2008)

S. Debnath, Woodhead Publishing. 89, 69–85 (2017)

R. Van Amber, R. Rajkhowa, R. Remadevi, D. Barooah, M. Naebe, Journal of Textile and Apparel. Technology and Management 10(4), 1–12 (2018)

T.H. Kariyappa, S. Somashekar, Roy and Nanjunda Sastry. Man Made Textile in India. 13, 176–185 (2006)

B. Das, N. V. Padaki and K. Jaganathan (2016) 24th International Congress of ISC on “Sericulture and silk industry”. Thailand, Bangkok.

M. Senthilkumar and B. B. Jambagi (2008) The Indian Textile Journal.

Kumar B. Senthil, T. Ramachandran, Fibres & Textiles in Eastern Europe. 5(131), 47–53 (2018). https://doi.org/10.5604/01.3001.0012.2530

C. Rameshkumar, R.S. Rengasamy, N. Anbumani, J. Ind. Text. 38(3), 191–203 (2009)

Anjali A. Kulkarni, MSc (2007) Thesis on Quality characteristics of viscose rayon and eri silk union fabrics, University of Agricultural Sciences, Dharwad. India.

U. Javali, Eri Silk: Fibre (LAMBERT Academic Publishing, Yarn and Fabric Characterization, 2012).

S.K. De & Ashis Mitra (2005) Manmade textiles in India. 76; 430–434.

S.K. De & Ashis Mitra (2013) Manmade textiles in India. 162–166.

B. Senthil Kumar, M. Ramesh Kumar, T. Ramachandran & M. Parthiban (2019) Indian Journal of Fibre & Textile Research. 44; 389–395.

Kariyappa, K.P Shivakumar, P.M Damodara Rao, Subrata Roy (2009) Manmade textiles in India. 52(11); 393–396.

Mamoni Probha Borah, Binita Baishya Kalita and Dr. Ava Rani Phukan, International Journal of Chemical Studies 7(1), 2398–2401 (2019)

Kariyappa, K.P. Shivkumar, P.M. Damodara Rao S. Roy and T. H. Somashekar (2010) Man Made Textile in India. 161–166.

Kariyappa, Y.C. Radhalakshmi and K.P.Shivakumar, Sericologia, 54(1), pp. 59–65 (2014).

Annual book of ASTM standards (2016) ASTM International, Section 7, Textiles. 07.

BS 7209:1990 Specification for water vapour permeable fabric,British Standard International. 1990.

ISO 20158:2018 Determination of water absorption time and water absorption capacity of textile fabrics, Book of ISO standards.

AATCC 79- 2010 e2 (2018) e, Absorbency of Textiles, Technical Manual of the AATCC. 88. (2013).

DIN 53924: 1997, Testing of Textiles – Velocity of soaking water of textile fabrics (Method by determining the rising height), Published by Deutsches Institut fur Normung. E.V. (DIN).

B.R. Das, D. Bhattacharjee, K. Kumar, A. Srivastava, Research Journal of Textiles and Apparel. 17(1), 133–140 (2013)

V. K. Kothari (2000) in “Quality Control” book edited. by V. K.. Kothari (Indian Inst. of Tech., Delhi, India). 276–294.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Das, B., Padaki, N.V., Jaganathan, K. et al. Comparative Studies on Thermal Comfort Properties of Eri Silk, Mulberry Silk, Wool and Linen Fibres. J. Inst. Eng. India Ser. E 102, 145–154 (2021). https://doi.org/10.1007/s40034-021-00208-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40034-021-00208-2