Abstract

Silica aerogel is a unique ultra light weight nano porous material which offers superior thermal insulation property as compared to the conventional thermal insulating materials. It can be applied not only for ground and aerospace applications but also in low and high temperatures and pressure regimes. Aerogel granules and monolith are synthesized by the sol–gel route while aerogel based composites are fabricated by the reinforcement of fibers, particle and opacifiers. Due to the characteristic brittleness (i.e., poor mechanical properties) of monolith or bulk aerogel, it is restricted in several applications. To improve the mechanical integrity and flexibility, usually different fibers are reinforced with aerogel and hence it can be used as flexible thermal insulation blankets. Further, to achieve effective thermal insulation behaviour particularly at high temperature, often opacifiers are doped with silica aerogel. In the present brief review, the prospects of bulk aerogel and aerogel based composites are discussed for the application of thermal insulation and thermal stability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Silica aerogel often known as ‘blue smoke’ or ‘frozen smoke’ is basically silica precursors derived nanoporous structure synthesized by the sol–gel route [1]. The pores will be filled with air which is more than 90% of the volume of aerogel. Aerogels are lightest solid material and it possess several unique characteristics such as ultra low density, lowest thermal conductivity, low dielectric constant, with adequate optical transparency and mechanical integrity. The word aerogel signifies that it is derived from gel and finally it is in the form of air or gas trapped nanoporous structure. Generally, the pore size of aerogel is in range of 1–100 nm.

The first ever report of aerogel was published by Samuel Stephens Kistler long back in 1932 [2], where he developed a porous silica structure filled with gas as replaced by liquid in the form of gel. Further, it was interesting to notice that Kistler also introduced a new technique i.e., supercritical drying technique for transformation of gel to the final porous solids.

In general, synthesis of aerogel involves two major stages e.g., (1) preparation of gel from sol–gel process and (2) drying by super critically or ambient pressure. However, several intermediate stages are involved which will be described briefly later.

If one looks into the aerogel market research report, one can find that projected compound annual growth rate (CAGR) for five years (2015–2020) in thermal and acoustic insulation sector is significantly higher [3]. Moreover, the prime driving factor for the growth of business market is due to the demand of industrial thermal insulation. Allied market research [4] also says the major (around 70%) market share of aerogel is mainly held by the commercial insulation blanket product. Now a days, aerogel in the form of particle/powder/granules, blocks, panels and composite blankets is experiencing the fastest growth in the market worldwide due to its versatile application in the sectors such as oil, gas, pharmaceuticals, building insulation, aerospace, automotive, health-care, chemical, electronics, apparel, textile etc.

Thermal Conductivity of Common Thermal Insulation Materials and Commercially Available Aerogels

Figure 1 summarizes the thermal conductivity values of common thermally insulating materials and commercially available aerogels [5–9]. The range of thermal conductivity is reported as 0.018–0.048 W/mK for common thermal insulating materials such as polyurethane foam, phenolic foam, mineral wool, polystyrene, fiber glass, rock wool, polystyrene and cork (Fig. 1). On the other hand, commercially available silica aerogel materials offer much lower thermal conductivity value i.e., in the range of 0.0034–0.022 W/mK (Fig. 1) as compared to common thermal insulating materials mentioned earlier. Hence, silica aerogel is found to possess the lowest thermal conductivity value of any insulator so far reported at atmospheric pressure. Further, it is well known that air possesses very low (0.025 W/mK) thermal conductivity. It is worthy to mention that no solid (non porous) is known to possess thermal conductivity as low as air before the invention of silica aerogel by Kistler [10]. The thermal conductivity value of aerogel is significantly lower than air which can be further explained with Knudsen effect [10]. According to the Knudsen effect, nanometric pore size of aerogel, which is comparable or lower than the mean free path of air, hinders the thermal conductivity due to the restriction of movement of the trapped gas inside the pore of aerogel [11].

Synthesis of Silica Aerogel Granules/Monolith and Composites

In general, silica aerogel is synthesized by sol–gel route [12–23]. Single-step (gelation via acid or base catalyst) or two-step (gelation via both acid and base catalysts) methods are utilized as reported in literature [12–23]. Silica aerogel synthesis process can be classified into five major stages such as: (1) sol preparation, (2) gelation, (3) ageing/solvent exchange, (4) silylation and (5) drying process.

Usually, metal alkoxides are utilized as starting precursor for the preparation of the sol [12–15, 17, 18, 20–23]. The most common metal alkoxides reported to be utilized in aerogel synthesis are tetraethylorthosilicate [TEOS: Si(OCH2CH3)4] [12–15, 17, 18, 20, 23], sodium silicate [16, 19] and tetramethylorthosilicate [TMOS: Si(OCH3)4] [24, 25]. Though sodium silicate is a very familiar and cheaper material, during reaction it will form corresponding salts within the gel that are required to be removed by many repetitive washes [16, 19]. On the other hand, TMOS is identified as a toxic compound and the fumes may cause severe illness [12]. However, it is reported that comparatively TEOS is a safer reagent as compared to TMOS [12].

Figure 2 illustrates the flow chart which shows major stages in the synthesis of silica aerogels. Different stages of aerogel synthesis are now briefly described here after.

Sol preparation is the first stage of aerogel synthesis. In this stage, solution of various reactants undergoes hydrolysis and condensation reactions [12]. The reaction of a metal alkoxide (M–OR) with water forms a metal hydroxide (M–OH) as following: M–OR + H2O = M–OH + H–OR. In contrast, a condensation reaction occurs when two metal hydroxides (M–OH + HO–M) combine to give a metal oxide species (M–O–M). One water molecule is formed in this process. The reaction is as following: M–OH + M–OH = M–O–M + H2O. After sol preparation, the next stage is known as gelation. Actually here, the 3D network is generated to link oxide particles of the sol. Finally, it gets converted into a wet gel [12–23]. After formation of gel, the gel has to be aged to achieve desired solid structure. The ageing stage/solvent exchange is introduced to strengthen the gel and to eliminate un-reacted entities. Silylation stage is performed subsequently after ageing/solvent exchange stage to change the surface property of aerogel i.e., hydrophilic to hydrophobic surface and helps in retaining final structure of aerogel [13, 15–19, 22, 23]. Hexamethyldisilazane (HMDZ) chemical proved to be comparatively better silylation agent as compared to other chemicals reported in literature [13, 15–19, 22, 23]. The final stage is called as drying. There are two ways to carry out drying process for wet gel e.g., (1) super critical drying and (2) ambient pressure drying. Super critical drying process generally prevents the formation of cracking as reported by Kistler [10]. Here, the formation a liquid–vapor meniscus can be avoided which ultimately results in an interrupted evaporation of solvent from the solid network [22]. Whereas, an ambient pressure drying is less complicated procedure as compared to the aforesaid process to develop un-cracked monolith aerogel by heating the alcogel at ambient pressure above boiling temperature of solvent which is used in sol formation.

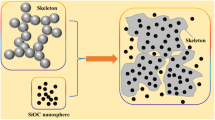

Further, fibers are usually utilized for the fabrication of aerogel composites. Basically, fiber gives the mechanical strength to the composite. In the reported literatures [26–35], most of the fibers are selected to reinforce in aerogels matrix are inorganic fibers, including aramid fibers [27–29], nomex fibers [26], glass fibers [36], carbon fiber [37], epoxy resins [30, 34] and opacifiers such as TiO2 [33], ZrO2 [38], carbon black [39] etc. which can improve the strength and flexibility of the aerogel composites as mentioned earlier. To improve further mechanical properties of aerogels cross-linking polymers are also used [40].

Thermal Conductivity and Stability of Monolith Silica Aerogel

Thermal conductivity and thermal stability of monolith or bulk aerogel reported in literature are summarized in Table 1 [12–22]. Thermal conductivity values are reported to be in the range of 0.036–0.417 W/mK [12–22]. On the other hand, thermal stability mentioned in literature is in the range of 100–550 °C [12–22]. Further, it is observed that density and porosity of the bulk/monolith silica aerogel have significant influence on its thermal conductivity shown in Fig. 3a, b, respectively. Thermal conductivity decreases with decrease in density as depicted in Fig. 3a because heat transfer through conduction will be decreased due to decrease in solid volume in aerogel [12]. Conversely, porosity will show opposite trend as illustrated in Fig. 3b. Here, thermal conductivity decreases with increase in porosity. This happens due to the increase in trapped air as in general thermal conductivity of air is much lesser as compared to any solid material [9, 10]. Further, increase in porosity results in decrease of solid network which ultimately hinders the heat conduction as mentioned earlier [16].

Hence, in order to modify the porosity and density of silica aerogel to achieve desired thermal conductivity various attempts are made by several researchers [12–23] as listed in Table 1. The tailoring of thermal conductivity property can be achieved by using different type of precursors such as TEOS [12–15, 17, 18, 20, 23], TMOS [24, 25], SS [16, 19], and co-precursor [12–14, 17, 18] as well, various chemicals e.g., ethanol [20, 23], methanol [21, 22] used for ageing, silylation agents such as methyltrimethoxysilane (MTMS), methyltriethoxysilane (MTES), vinyltrimethoxysilane (VTMS), phenyltrimethoxysilane (PTMS), phenyl triethoxysilane (PTES), dimethyldimethoxysilane (DMDMS), trimethylmethoxy silane (TMMS), trimethylchlorosilane (TMCS), bis(trimethylsilyl)acetamide (BTSA) and hexamethyldisilazane (HMDZ) [16] and alteration of molar ratio of precursors [20, 23], ageing/solvent exchange [20–23] and silylation agents [16–20]. TMOS increases health hazards due to its toxic release of fumes which restricts its popularity [16]. On the other hand, comparatively cheaper sodium silicate (SS) produces impurities in the form Na ion and removal of it requires additional washing steps [16, 19]. Among the other precursors, TEOS is reported to be most popular one [12–15, 17, 18, 20, 23]. Further decrease in thermal conductivity e.g., 0.042–0.086 W/mK [12] can be achieved by using various combination of co-precursors and variation in molar ratio as well [12, 13, 17, 18].

Thermal Conductivity and Stability of Silica Aerogel Composites

Thermal conductivity and thermal stability of composite aerogel reported in literature are summarized in Table 2 [26–35]. Thermal conductivity values are reported to be in the range of 0.0221–0.19 W/mK [26–35]. Further, thermal stability is documented in literature in the range 280–470 °C [26–28, 34].

It is observed that thermal conductivity and thermal stability properties are strongly dependent upon the fiber content [26–29], fiber alignment [28, 29] and type of opacifier/whisker [30–35]. Though monolith or bulk silica aerogel possesses low thermal conductivity (in particular at low temperature application) as compared to aerogel composites. However, it lacks in mechanical flexibility which restricts their applications for insulation purpose in particular.

The density and porosity of the aerogel composites are reported to be in the range of 0.05–1.35(g/cm3) [26–35] and 65.3–93.6% [26–35], respectively. In general, the density is increased for aerogel composites as compared to bulk silica aerogel while porosity shows opposite trend. Similar to bulk aerogel, the thermal conductivity of aerogel composite decreases with decrease in density as summarized in Fig. 4.

Further, it is reported [26, 27] that thermal conductivity increases (up to 5%) with increase in fiber content. However, the increase in fiber content provides significant enhancement (more than 150%) of mechanical properties such as bending modulus and bending strength. This information signifies that the flexibility of the aerogel composites has significantly improved without compromising thermal insulating property. The improvement of flexibility of aerogel composites can be achieved by altering fiber alignments [28, 29]. However, there is no noticeable degradation in thermal insulation property [28, 29]. Further, enhancements of mechanical properties are also reported with incorporation of particulate hard ceramic such as Si3N4 [35].

It is reported that pure silica aerogel is highly transparent in IR region particularly from 3 to 8 μm which increases the possibility of radiative heat transfer [33]. So, to improve thermal insulation property of aerogels for high temperature applications they are reported to be doped with opacifiers such as TiO2 [33], K2Ti6O13 whisker [33], carbon [39] etc. Thus, transparent aerogel can be fabricated in the form of opaque and it can be useful in spacecraft application because heat transfer by radiation is dominated in space rather than other two modes of heat transfer i.e., conduction and convection.

Thermal stability is also depending upon the reinforcing materials with the aerogel matrix. In general, aramid fiber [27, 28] and glass fiber [36] show comparatively higher (285–600 °C) melting temperature as compared to copolyolefin fiber (110–150 °C) [41].

Prospect of Aerogel Based Thermal Insulation and Its Challenges

The aerogel composite blankets are widely used as thermal insulation for various ground and aerospace applications [42, 43]. The aerogel composite thermal insulator blanket or wrap are commercially available from vendors such as Aspen Inc., Cabot etc. and they are mainly used in industrial pipeline for gas and oil. Further, in construction and building fields [4, 44, 45] aerogel based thermal insulation elements are often used in the current decade. Aerogel thermally insulated composite panels are now widely used, particularly in European countries and North America [4], which saves energy and thus global warming can be minimized. Recently, aerogel is also reported to be used as thermal insulation in textile industry [46].

Apart from the ground thermal insulation application, bulk aerogel and aerogel composite blankets are also used in space applications [42, 47]. For example, aerogel based thermal insulation blankets are successfully implemented in cryogenic propulsion tank [48, 49], Mars rovers e.g., Sojourner in 1997, Spirit and Opportunity in 2003 by NASA [42]. Further, the possibility of replacement of Kapton based multilayer insulation (MLI) blanket is also studied and reported by several researchers [32, 50, 51]. The aforesaid research results [32, 50, 51] concluded that MLI shows much effective thermal insulation behaviour in high vacuum environment as compared to aerogel blanket. However, because of the presence of an environment rich in CO2 at Martian surface, aerogel based thermal insulation may perform better than conventional MLI [32, 50, 51]. Further, due to light weight, superior outgassing behaviour and flexibility made aerogel blankets more attractive for spacecraft thermal control applications. It is also reported that aerogel blankets can be applied for micrometeorite protection particularly for the spacecraft in low earth orbit (LEO) besides its thermal protection [32, 50, 51].

Though nowadays aerogel has become popular for its super insulating behaviour with ultra low weight, but it suffers from high production cost and poor mechanical properties [43]. However, several research and developmental attempts are ongoing for economic scale up with improved mechanical properties [52].

Conclusion

Based on the above brief literature review, it can be concluded that both silica based aerogel monolith and composites are promising material for thermal insulation as compared to the present insulating materials available. This review provides an idea about the major synthesis stages and chemistry behind silica aerogel and it’s composite. To achieve desired thermal insulation properties with adequate mechanical flexibility, the process parameters of monolith and composite aerogel can be tailored. Thermal conductivity and thermal stability of different silica aerogel monolith and composites reported in literature are summarized thoroughly. Further, the alteration of thermal conductivity of aerogel materials with porosity and density are also illustrated. Also, uses of aerogel for ground and space applications and market analysis are discussed in the present review.

References

S.S. Kistler, Coherent expanded aerogels. J. Phys. Chem. 36, 52–64 (1932)

BCC aerogel report, published on March 2016, www.bccresearch.com

Allied market research report, published on June 2014, www.alliedmarketresearch.com

E. Cohen, Thermal properties of advanced aerogel insulation. M.S. dissertation, Massachusetts Institute of Technology (2011)

L. Huang, Feasibility study of using silica aerogel as insulation for building. M.S. dissertation, KTH School of Industrial Engineering and Management (2012)

Product data sheet, Aspin lnc., http://www.aerogel.com

Product data sheet, Cabot Corp., http://www.cabot-corp.com

A.C. Pierre, G.M. Pajonk, Chemistry of aerogels and their applications. Chem. Rev. 102, 4243–4265 (2002)

S.S. Kistler, A.G. Caldwell, Thermal conductivity of silica aerogel. Ind. Eng. Chem. 26, 658–662 (1934)

B. Hosticka, P.M. Norris, J.S. Brenizer, C.E. Daitch, Gas flow through aerogels. J. Noncryst. Solids 225, 293–297 (1998)

S.D. Bhagat, A.V. Rao, Surface chemical modification of TEOS based silica aerogels synthesized by two step (acid-base) sol–gel process. Appl. Surf. Sci. 252, 4289–4297 (2006)

U.K.H. Bangi, C.-S. Park, S. Baek, H.-H. Park, Improvement in optical and physical properties of TEOS based aerogels using acetonitrile via ambient pressure drying. Ceram. Int. 38, 6883–6888 (2012)

H. Yu, X. Liang, J. Wang, M. Wang, S. Yang, Preparation and characterization of hydrophobic silica aerogel sphere, products by co-precursor method. Solid State Sci. 48, 155–162 (2015)

T.-Y. Wei, T.-F. Chang, S.-Y. Luw, Preparation of monolithic silica aerogel of low thermal conductivity by ambient pressure drying. J. Am. Ceram. Soc. 90, 2003–2007 (2007)

A.P. Rao, A.V. Rao, G.M. Pajonk, Hydrophobic and physical properties of the ambient pressure dried silica aerogels with sodium silicate precursor using various surface modification agents. Appl. Surf. Sci. 253, 6032–6040 (2007)

N.D. Hegde, H. Hirashima, A.V. Rao, Two step sol-gel processing of TEOS based hydrophobic silica aerogels using trimethylethoxysilane as a co-precursor. J. Porous Mater. 14, 165–171 (2007)

A.V. Rao, R.R. Kalesh, G.M. Pajonk, Hydrophobicity and physical properties of TEOS based silica aerogels using phenyltriethoxysilane as a synthesis component. J. Mater. Sci. 38, 4407–4413 (2003)

P.M. Shewale, A.V. Rao, A.P. Rao, Effect of different trimethyl silylating agents on the hydrophobic and physical properties of silica aerogels. Appl. Surf. Sci. 254, 6902–6907 (2008)

A.P. Rao, G.M. Pajonk, A.V. Rao, Effect of preparation conditions on the physical and hydrophobic properties of two step processed ambient pressure dried silica aerogels. J. Mater. Sci. 40, 3481–3489 (2005)

A.V. Rao, M.M. Kulkarni, D.P. Amalnerkar, T. Seth, Superhydrophobic silica aerogels based on methyltrimethoxysilane precursor. J. Noncryst. Solids 330, 187–195 (2003)

N.D. Hegde, A.V. Rao, Physical properties of methyltrimethoxysilane based elastic silica aerogels prepared by the two-stage sol–gel process. J. Mater. Sci. 42, 6965–6971 (2007)

A.P. Rao, A.V. Rao, G.M. Pajonk, Hydrophobic and physical properties of the two step processed ambient pressure dried silica aerogels with various exchanging solvents. J. Solgel Sci. Technol. 36, 285–292 (2005)

A.V. Rao, M.K. Manish, Hydrophobic properties of TMOS/TMES-based silica aerogels. Mater. Res. Bull. 37, 1667–1677 (2002)

H. Tamon, T. Sone, M. Okazaki, Control of mesoporous structure of silica aerogel prepared from TMOS. J. Colloid Interface Sci. 188, 162–167 (1997)

S. Chakraborty, A.A. Pisal, V.K. Kothari, A.V. Rao, Synthesis and characterization of fibre reinforced silica aerogel blankets for thermal protection”. Adv. Mater. Sci. Eng. 2016, 8 (2016)

Z. Li, L. Gong, X. Cheng, S. He, C. Li, H. Zhang, Flexible silica aerogel composites strengthened with aramid fibers and their thermal behavior. Mater. Des. doi: 10.1016/j.matdes.2016.03.063 (in press)

Y. Lia, H. Wu, Y. Ding, S. Yin, M. Wang, A. Cao, Engineering thermal and mechanical properties of flexible fiber-reinforced aerogel composites. J. Solgel. Sci. Technol. 63, 445–456 (2012)

H. Wu, Y. Liao, Y. Ding, H. Wang, C. Peng, S. Yin, Engineering thermal and mechanical properties of multilayer aligned fiber-reinforced aerogel composites. Heat Trans. Eng. 35, 106–1070 (2014)

J. Zhao, D. Ge, S. Zhang, X. Wei, Studies on thermal property of silica aerogel/epoxy composite. Mater. Sci. Forum 546–549, 1581–1584 (2007)

I.-K. Jung, J.L. Gurav, T.-J. Ha, S.G. Choi, S. Baek, H.-H. Park, The properties of silica aerogels hybridized with SiO2 nanoparticles by ambient pressure drying. Ceram. Int. 38, 105–108 (2012)

W.L. Johnson, J.A. Demko, J.E. Fesmire, Analysis and testing of multilayer and aerogel insulation configurations, in Advances in Cryogenic Engineering: Transactions of the Cryogenic Engineering Conference, vol 55 (2010)

H. Zhang, C. Hong, Y. Qiao, Synthesis, structural and thermal properties of nano-porous sio2-based aerogels, in Advances in Nanocomposites—Synthesis, Characterization and Industrial Applications, ed. by B. Reddy (2011). ISBN:978-953-307-165-7

D. Ge, L. Yang, Y. Li, J.P. Zhao, Hydrophobic and thermal insulation properties of silica aerogel/epoxy composite. J. Noncryst. Solids 355, 2610–2615 (2009)

H. Yang, F. Ye, Q. Liu, Y. Gao, Microstructure and properties of the Si3N4/silica aerogel composites fabricated by the sol–gel method via ambient pressure drying. Mater. Des. 85, 438–443 (2015)

B. Yuan, S. Ding, D. Wang, G. Wang, H. Li, Heat insulation properties of silica aerogel/glass fiber composites fabricated by press forming. Mater. Lett. 75, 204–206 (2012)

J. Feng, C. Zhang, J. Feng, Carbon fiber reinforced carbon aerogel composites for thermal insulation prepared by soft reinforcement. Mater. Lett. 67, 266–268 (2012)

Z.-G. Wu, Y.-X. Zhao, D.-S. Liu, The synthesis and characterization of mesoporous silica–zirconia aerogels. J. Microporous Mesoporous Mater. 68, 127–132 (2004)

D.M. Smith, A. Maskara, U. Boes, Aerogel-based thermal insulation. J. Noncryst. Solids 225, 254–259 (1998)

M.A.B. Meador, S.L. Vivod, L. McCorkle, D. Quade, R.M. Sullivan, L.J. Ghosn, N. Clark, L.A. Capadona, Reinforcing polymer cross-linked aerogels with carbon nanofibers. J. Mater. Chem. 18, 1843–1852 (2008)

Materials Safety Data Sheet of ‘Aerogel Thermal Wrap’. http://www.cabotcorp.com/solutions/products-plus/aerogel/blanket

N. Bheekhun, A.R.A. Talib, M.R. Hassan, Aerogels in aerospace: an overview. Adv. Mater. Sci. Eng. 2013, 18 (2013)

P.C. Thapliyal, K. Singh, Aerogels as promising thermal insulating materials: an overview. J. Mater. 2014, 127049 (2014). doi:10.1155/2014/127049

E. Cuce, P.M. Cuce, C.J. Wood, S.B. Riffat, Toward aerogel based thermal superinsulation in buildings: a comprehensive review. Renew. Sustain. Energy Rev. 34, 273–299 (2014)

R. Baetens, B.P. Jelle, A. Gustavsen, Aerogel insulation for building applications: a state-of-the-art review. Energy Build. 43, 761–769 (2011)

M. Venkataraman, R. Mishra, T.M. Kotresh, J. Militky, H. Jamshaid, Aerogels for thermal insulation in high performance textiles high-performance. Text. Prog. 48, 55–118 (2016)

M.J. Burchell, G. Graham, A. Kearsley, Cosmic dust collection in aerogel. Annu. Rev. Earth Planet Sci. 34, 385–418 (2006)

J.E. Fesmire, Aerogel insulation systems for space launch applications. Cryogenics 46, 111–117 (2006)

J.E. Fesmire, J.P. Sass, Aerogel insulation applications for liquid hydrogen launch vehicle tanks. Cryogenics 48, 223–231 (2008)

D.M. Smith, R.U. Boes, A. Maskara, Multilayer insulation composite. Patent No: US 6,485,805 B1, 26 Nov 2002

R.M. Trifu, G.L. Gould, K. Qassim, J.L. Clark, Ultra-lightweight aerogel superinsulation as an MLI replacement, in Proceedings ‘Engineering, Construction, and Operations in Challenging Environments: Earth and Space 2004’, ed by R. B. Malla, A. Maji, pp. 976–982

M.K. Matthias, L. Huber, S. Zhao, W.J. Malfait, Breakthroughs in cost-effective, scalable production of super insulating, ambient-dried silica aerogel and silica-biopolymer hybrid aerogels: from laboratory to pilot scale. J. Solgel. Sci. Technol. (2016). doi:10.1007/s10971-016-4012-5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hasan, M.A., Sangashetty, R., Esther, A.C.M. et al. Prospect of Thermal Insulation by Silica Aerogel: A Brief Review. J. Inst. Eng. India Ser. D 98, 297–304 (2017). https://doi.org/10.1007/s40033-017-0136-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-017-0136-1