Abstract

A huge amount of waste is generated through the food supply chain starting from the production stage to the household consumption phase. Wastage of food is a matter of concern because it is harmful to the environment and at the same time it poses a threat to sustainability goals. Food waste (FW) generation needs to be mitigated through waste-to-energy technologies to ensure food security, reduce economic loss, reduce resource depletion, and conserve energy. This study presents the quantification of FW on the campus of an educational institute in northeastern India. Eight kitchens are surveyed to assess the pattern and type of FW generation over a year. The quantification, segregation of waste into various subgroups, and characterization are performed to give a fair idea of each kitchen’s contribution to the net food waste generation on an educational institute’s campus. Also, the probable parameters such as the number of people eating, the taste of food, refrigeration, and miscalculated estimation by the kitchen runners that affect FW generation are identified. This study also estimates the CO2 emissions in each of the kitchens while preparing food. Besides, the recoverable energy potential of the food waste is also explored in the study, indicating the possible amount of energy that could be extracted from the food waste based on its characteristics. It is evident from the study that the nature of food items prepared plays a significant role in GHG emissions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

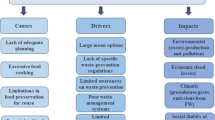

The consumption of food is necessary for the survival of human beings. Food is required for deriving nutrients and energy. But due to the non-sensical approach and mismanagement across the supply chain, food gets lost and wasted on a huge scale. Even though the phrases ‘food waste (FW)’ and ‘food loss’ may appear to be interchangeable, they are not. Harvest, storage, and transportation refer to the early stages of production where food is lost. On the other hand, food wastage refers to food that is fit for consumption but is dumped [1,2,3]. As the world’s population continues to rise, our challenge should be to feed more people while wasting less of what we already produce. Further, FW reduction and prevention can improve food security, enhance productivity and economic efficiency, promote resource and energy conservation, and address climate change-related issues [4]. Out of the total food production, 17% gets wasted. 43% of this wastage is derived from households, 26% comes from the food service, and the remaining 13% is from the retail sector [5]. FW is detrimental to our climate too. Food’s entire life cycle is marked by the release of greenhouse gases (GHGs) like CO2, NO2, and CH4. It is reported that the agriculture sector accounts for one-third of global GHG emissions, yet 30% of the food produced (almost 1.8 billion tonnes per year) is wasted [6]. Also, society is facing the enormous challenge of depleting resources as well as waste accumulation which needs to be addressed as soon as possible. Food supply chain-based (organic) waste has the potential to be utilized as a renewable energy resource [7]. Scientists across the world have come up with a few solutions to the food waste problem. Chemical processes like anaerobic digestion, incineration, liquefaction, and valorization could potentially extract the energy from food waste and turn it into a renewable energy resource [8]. It is found that studies have been initiated to assess FW indifferent segments/sectors [9, 10]. FW, which gets dumped in landfills, could be turned into an alternative energy resource for power in a developing nation like India. According to a study conducted by the United Nations Environment Programme (UNEP), 931 million tonnes of food was wasted in households globally in 2019. Of this estimate, India has a share of 7.4%. For a vast country like India, FW produced is very heterogeneous based on the geographical location, and the type of food is consumed in that area. It is evident from the literature review that most of the studies that have been conducted up till now consider commercial kitchens (like restaurants) and residential (household) areas [11,12,13,14]. Nevertheless, the hostel kitchens of educational institutes are also a potential location for FW generation. It is also found that hardly any study has highlighted the extent of FW generation in an educational institute in India and no study has been conceived yet for the educational institute located in the northeastern part of India where a lot of big institutions have been grown up in the last decades. Further, the kitchens in the educational institutions are very dynamic which may lead to an interesting study with great significance. Under this backdrop, the present work aims to quantify the overall FW generation and characterization, GHG emission analysis, recoverable energy potential estimation, etc., in the National Institute of Technology (NIT), Agartala, which is a centrally funded technical institution (CET) of the Government of India located in the northeastern part of India.

Concept and Conversion Techniques of FW into Useful Energy

Food waste disposal has become a growing challenge, with a significant portion of these waste materials being routinely deposited in landfills. While landfill disposal is often considered a convenient and cost-effective method, it is not sustainable and poses environmental concerns [15]. Several methods are utilized to harness energy from FW. Selecting the right approach for converting food waste into energy is essential to optimize energy production within economically sustainable parameters while also considering environmental constraints. Figure 1 shows the FW conversion techniques for useful energy resources. The methods employed to transform food waste into valuable energy can be broadly classified into biological and thermal techniques. The biological methods covered in this context include Anaerobic Digestion and Fermentation, while the thermal processes discussed encompass Pyrolysis, Incineration, Hydrothermal Carbonization, Transesterification, and Gasification.

Anaerobic Digestion (AD)

It stands out as a promising technology for managing food waste effectively. AD systems typically require significant capital investment, with their primary sources of revenue stemming from fees for collecting organic waste and producing biogas. Ensuring increased food waste loading and system stability is of paramount importance for the economic feasibility of AD when dealing with food waste. One common practice to enhance AD for food waste is co-digestion with animal manure or sewage sludge [16]. The excellent biodegradability of food waste makes it an attractive organic substrate for anaerobic digestion (AD). However, when food waste is digested alone (mono-digestion), it can frequently result in digester instability and, in some cases, failure, particularly when operating at higher organic loading rates, especially in thermophilic conditions. This instability is often attributed to the accumulation of volatile fatty acids and ammonia inhibition [17]. The biochemical decomposition process can be viewed as a cooperative process involving a diverse range of microorganisms. These stages are Hydrolysis, Acidogenesis, Acetogenesis, and Methanogenesis. In the initial stage, complex organic compounds undergo hydrolysis through the activity of extracellular enzymes produced by hydrolytic bacteria. This process leads to the formation of simpler soluble molecules, including amino acids from proteins, long-chain fatty acids from lipids, and simple sugars from complex carbohydrates. The smaller molecules generated in the previous stage are subsequently transformed into short-chain volatile fatty acids (VFAs), alcohols, carbon dioxide, and hydrogen during the acidogenesis phase. The type of products formed in this step is influenced by the partial pressure of hydrogen, which helps regulate the expected outcomes [18]. In the subsequent stage, known as the acetogenesis step, specialized hydrogen-producing bacteria convert VFAs with more than two carbon atoms and alcohols with more than one carbon atom into acetate, hydrogen, and carbon dioxide [19]. In the last stage of anaerobic digestion (AD), various groups of methanogens play a crucial role by consuming acetate and converting these intermediate products into methane which is the main component of biogas [20].

Fermentation

Focused fermentation holds great promise as a method with strong potential for practical applications due to its high efficiency, robustness, and the production of valuable end-products. Various fermentation types result in distinct products, and these outcomes can be influenced by modifying fermentation conditions such as the inoculum, pH levels, oxidation–reduction potential (ORP), organic loading rate (OLR), and nutrient levels. The efficiency of ethanol fermentation can be enhanced by introducing suitable hydrolases or strains. However, it is worth noting that ethanol can also be produced from food waste through fermentation without the addition of specific strains and pH adjustments, relying on the activity of indigenous microorganisms [21]. In the process of ethanol fermentation, the efficiency of conversion is contingent upon the degree of carbohydrate hydrolysis [22]. In ethanol fermentation, a primary challenge lies in the timely removal of ethanol and other by-products from bioreactors, as these substances can act as inhibitors to fermentative bacteria when their concentrations reach certain levels. Preparation before fermentation, which includes actions such as heating, enzyme addition, soaking, and more, readies the food waste for the fermentation process. This initial step predominantly yields products such as ethanol and carbon dioxide (CO2). Subsequently, distillation aids in the creation of highly concentrated ethanol, while ethanol purity can be further improved through a dehydration process [23].

Pyrolysis

The thermal degradation of organic food waste into its fundamental structural components is achieved through pyrolysis conducted in an inert atmospheric environment. Pyrolysis is a highly versatile technique that is increasingly gaining popularity in commercial applications due to its adaptability. The entire process can be finely tuned to achieve the desired results by adjusting operational parameters. Altering factors such as the temperature and the size of the particles being introduced can influence the heating rate within the reactor. Pyrolysis serves as a viable method for the production of bio-oil, although there have been limited initial reports regarding the generation of bio-oils from food waste [24]. In the case of slow pyrolysis, organic waste undergoes pyrolysis within a temperature range of 400–500 °C, with the heating rate controlled between 0.1 and 1 °C per second. This particular process is well-suited for the production of biochar, and the duration typically falls within a 30-min timeframe. On the other hand, fast pyrolysis operates at higher temperatures, typically in the range of 850–1250 °C, with a much shorter duration of 1–10 s. The primary product generated through this method is bio-oil. In contrast to fast pyrolysis, flash pyrolysis is an improved and modified version, specifically designed for the production of both bio-oil and char [25].

Hydrothermal Carbonization (HTC)

It is another thermal conversion method that transforms food waste into a valuable, energy-dense resource. This technique holds promise in addressing numerous issues linked to the treatment of food waste. Carbonization through HTC has the potential to reduce the necessary treatment space, enhance the efficient conversion of mixed waste, and achieve greater reductions in waste volume. During the HTC process, wet feedstocks undergo a series of simultaneous reactions, encompassing hydrolysis, dehydration, decarboxylation, aromatization, and recondensation [26]. Given that food waste comprises a significant 75% moisture content, hydrothermal carbonization (HTC) emerges as an advantageous treatment process as it does not necessitate extensive drying. Furthermore, this method is regarded as favorable for carbon sequestration in efforts to mitigate climate change, especially when compared to alternative processes, as it effectively incorporates the majority of the carbon present in food waste into hydrochar (Huu Son [27].

Gasification

Gasification stands as a substantial method for breaking down and transforming organic waste materials into biochar, bio-oil, and syngas. These products have the potential to be utilized for energy generation (including hydrogen and heat production) as well as environmental applications, such as the removal of pollutants and enhancing soil quality [28]. Food waste contains a significant amount of energy, making it a promising feedstock for gasification in power plants too. Gasifying food waste serves a dual purpose by addressing two major issues simultaneously. It mitigates landfill problems by diverting food waste from disposal sites and, at the same time, enables the recovery of energy from this valuable resource [29]. During gasification, food waste undergoes partial oxidation, producing combustible gas mixtures typically at temperatures ranging from 800 to 900 °C [30].

Incineration

Incineration is a thermal method for treating waste, characterized as a controlled combustion process primarily focused on reducing volume and harnessing energy from the waste. It is the most widely adopted waste-to-energy (WTE) technique, where the heat generated during combustion can be harnessed and transformed into electrical power. During the incineration process, the organic components of the waste are burned, generating heat, while the inorganic constituents contribute to the creation of ash [31].

However, for food waste to be suitable for incineration, it must meet specific essential criteria. Key factors include food waste composition, along with considerations for moisture content and calorific value [32].

Transesterification

Transesterification of lipids extracted from lipid-rich FW results in the formation of biodiesel [33] is another route of extracting energy. The lipid portion extracted from solid food waste can be transformed into biodiesel or fatty acid methyl esters (FAME) through a process known as transesterification. To achieve this, an initial step involves extracting lipids from the solid food waste (SFW), which can be accomplished using either a traditional Soxhlet extraction method or by employing supercritical extraction techniques [34]. To determine the commercial viability of "food waste to energy" processes, it is essential to conduct a techno-economic evaluation. This evaluation involves analyzing the processes' technical feasibility and economic aspects to assess their profitability and sustainability in practical applications.

Materials and Methods

Study Location

The National Institute of Technology (NIT), Agartala, is located in northeastern India. It is one of the institutions of national importance of the Government of India and is located on the outskirts of the city of Agartala, Tripura.

Longitude: 91D25′22"0.661 (E339387.823 m).

Latitude: 23D58′26"0.904(N2637495.384 m).

Campus area: 135 hect.

Climate: Moderate, with high moisture content.

There are around six hostels on the campus, namely Aryabhatta, Gomati, Dhalai, Rabindranath Tagore, Howrah, and Gargi.

Food Waste Resources

The material of this particular study comprises data collected from eight kitchens located within the campus area of the institute. These kitchens were selected because of their readiness to participate in addition to their onsite location which eased the survey’s process. The number of kitchens surveyed, their running time, type of cuisine served are included in Table 1. Two quantification periods are chosen from January to December 2019. The first quantification period comprised the months starting from January to April 2019. The second quantification period is from August to December 2019. May–August has not been considered due to summer vacation, and this is the period when student activities, as well as activities in hostel kitchens, are found almost insignificant. Quantifications are conducted for breakfast, lunch, and dinner in the hostel kitchen, whereas, in the case of the food shops, data are collected throughout its running time. For both the hostel kitchens and eateries, per-day data have been recorded. The hostel kitchens are accessible to the residents for the entire week, whereas the food shops are open only during the weekdays. In the case of the hostel mess, the number of eaters per day per meal remains constant. The food is prepared for a fixed number of residents present in the hostel’s kitchens. Outsiders are not allowed to have food prepared in the hostel kitchens without prior intimation given to the kitchen runners, whereas the food shops are open for all during their operating hours. Eight of the kitchens prepare food on-site for their service users. The amount of food portion served and total food waste generated in the process (comprising both the cooked and uncooked food waste produced throughout two quantification periods) are reported. The number of people eating throughout the day per meal is also recorded. The hostel kitchens have a fixed menu (with slight variations depending on the availability of the produce) for a fixed number of eaters, whereas for the food shops the number of customers eating per day fluctuates and they accept orders based on the preference of the individual customer. The present work considers the amount and pattern of food waste generation at these eight kitchens located in the campus area and also analyzes the sub-categories of food waste generation. This assessment of data in the study is restricted to the food preparation stage only. The other stages of the food supply chain have not been included in this study considering the scale and nature of the kitchens surveyed. Moreover, the waste co-efficient used in this work is mainly based on direct measurements, and data have been collected through field surveys and interviews.

Report of Data Collection

The kitchen staff collects the primary data using kitchen scales (here electronic weighing machines, and measuring jars are used). Pen and paper are used for noting down the data. The mass of food waste produced is recorded first and then transferred to statistical software for obtaining the figures. As sauces and soups are not separately served, the volume of liquid has not been quantified in this study. The amount of water wasted during the preparation of various food items is also not taken into account, and the density of food is assumed to be uniform for all the kitchens. The cooked food waste and uncooked food waste generation are documented for this study.

Quantification Methodology for Food Waste Generation

For both the quantification periods (QP1 and QP2), the average number of service users is recorded in addition to the average food waste generated per month at the facilities. The amount of uncooked food waste generation is assessed primarily for the inedible and discarded portions of various food items. Contrary, cooked food waste assessment includes incurred storage losses and plate leftovers. The segregation of food waste into sub-categories is performed to get a fair idea of wasted food items. Out of the eight kitchens that are surveyed (four hostel kitchens, and kitchens of the four food shops located within the campus), total waste has been segregated into four main subcategories. These are fresh fruit waste, fresh vegetable waste, carbohydrate-rich food waste, and protein-rich food waste. In the case of fresh fruits and vegetables only the uncooked portions comprising of peels, seeds, rotten items (due to lack of storage or refrigeration facility), and inedible portions are considered, whereas in the case of the carbohydrate-rich portions (chapatti, rice, paratha, etc.) and protein-rich items both the cooked leftovers and uncooked portions (scales of fish, unused portions of meat cut, unused fish filets, etc.) are taken into account. In the present study, the considered inedible fractions of fruits and vegetables are based on the literature values [35].

Computational Methodology

GHG Emission

Each year, one-quarter of the GHGs surged into the atmosphere come from the food system. The production, transportation, processing, and preparation of food items emit a significant amount of GHGs (CH4, CO2, NO2, etc.). United Nations Organisation refers to food, energy, and water as the ‘nexus of development’ that would ensure sustainability [36]. It is reported that 26% of global emissions (13.7 billion tonnes of CO2) are from the food industry [37]. In this study, the entire life cycle assessment of food items is not performed. Rather the focus of this work is strictly on the food preparation process. Here, the GHG emission refers to the amount of CO2 (g kg−1of fresh product) produced while cooking food in the campus kitchens. CO2 is the most significant gas released into the environment while preparing food, whereas the portion of other gases is negligible and hence has not been included in the analysis. In this study, it is assumed that 1 kg of Liquefied Petroleum Gas (LPG) which is the most commonly used commercial fuel for cooking in India, would emit 2.95 kg of CO2 [38], and the burning rate for an LPG stove is 0.13 kg h−1 [39].

The methodology for estimating the possible GHG emission during food preparation under this study is described below.

The portion of each food item served in grams (g) = \(P\)

Total number of eaters = \(n\)

It is assumed that the portion of each food item served is of the same proportion for all the eaters.

The total mass of freshly prepared food items in grams (g) = \(P\times n\)

The total mass of freshly prepared food items in kilograms (kg) = \(\frac{P\times n}{{10}^{3}}\)

CO2 (GHG emission) in g kg−1of fresh product = \(C\)

The items directly available for consumption like instant noodles, canned drinks, chips, butter, bread, etc. are taken into account for the evaluation of GHG emissions. Due to the lack of data two food items, namely cottage cheese (paneer) and soybeans, are also precluded from the calculation.

The value of C of food items considered [40] for the study is presented in Table 2. The total amount of CO2 emission recorded while preparing each food item in grams (g) is \(= \frac{P \times n}{{10^3 }} \times C\)

Recoverable Energy Potential

Waste-to-energy technologies have been considered an integral component of the waste management hierarchy, prioritized for resource recovery before dealing with the disposal of inert waste materials [41]. In this context, the recoverable energy potential (Rep) plays a pivotal role as a crucial parameter for assessing the extractable energy from organic wastes. Recoverable energy generated from waste is a major source of environmentally sustainable energy that has not yet been explored. Rep serves as an indicator of the potential energy that can be generated from the waste, taking into account its specific characteristics. To calculate the value of Rep, a theoretical approach is employed. For food waste, the recoverable energy potential (Rep) in megajoules per month (MJ month−1) is determined using the following equation [42]:

where

MFW is the average mass of food waste produced in the kitchen for each month and.

CVFW is the calorific value of food waste which is assumed to be 6.7 MJ kg−1 [43] for food waste. To accomplish this, the value assessments were utilized to predict the availability of equivalent energy from the waste, in kilowatt-hours (kWh) of energy units.

Also, 1kWh = 3.6 MJ = \(3.6\times {10}^{6}\) J.

The equivalent energy (in kWh month−1) is

Although food waste has a higher mass-based generation of waste, its recoverable energy potential is lower. This is primarily because food waste has a significantly lower calorific value in comparison with other types of waste. It is estimated that approximately 20–50% (\(f)\) of this energy may be reclaimable, depending on the amount of energy that can be extracted from the waste and the technique adopted for the same is [44].

Results and Discussion

Quantification Analysis

Figure 2a, b, c, and d represents the average amount of FW generation at the food shops to the average number of customers eating per month. The mass of the FW generation is tallied for each of the four food shops. The maximum amount of waste in FS1 was observed in April (94.75 kg). In FS2, FS3, and FS4 the values are maximum for September (58.8 kg), January (79.56 kg), and January (56.74 kg), respectively. A higher number of customers do not always indicate a linear increase in FW generation. For example, in FS2 in September, the average customer was 100 which resulted in the generation of 58.8 kg, whereas in December the average customer of 110 resulted in the generation of 58.2 kg FW. It is perceived that the amount of waste generation depends on the type of food item ordered. As per the observations, non-veg food items resulted in the generation of more FW. Also in some cases, a combination of meat-based food items along with egg-based items contributed to more FW production. In the case of the few kitchens, avoidable wastage is higher for the meat-based recipes. A substantial portion of the flesh is left unutilized contributing to the overall waste generation. Poor kitchen management and the taste of the food are important factors in determining the volume of plate leftovers. The kind of seasonal produce cooked also plays a role in the aftermath of waste production. Figure 2e highlights the total amount of food waste generated in each of the four kitchens, namely EK (East kitchen), SK (South kitchen), CK (Combined kitchen), and GK (Gargi kitchen) throughout two quantification periods. For March, EK has the maximum amount of FW generation of 737.8 kg and the least for November (730.2 kg). Individually SK generates the maximum amount of FW (538.1 kg) in September, whereas the least FW generation happens in April (498.2 kg). In the case of CK, a maximum amount of 1548.8 kg of FW gets generated in February; the least value is for March (1492.5 kg). For GK, 540.2 kg of FW is generated in April and the lowest value is 527.5 kg as observed in December. In the case of the hostel kitchens, FW generation is dependent on the volume of food prepared to feed all its residents. As observed in GK, although the number of eaters is less, the generated waste is disproportionate to the number of eaters. Overestimation of items while preparing food results in surplus FW generation. It is to be noted that the kitchens with refrigeration facilities ended up with lesser FW production.

Waste Generation Categorization

Figure 3a represents the contribution of each FS to various types of waste generation. FS1 contributed the maximum to total vegetable wastage generation (37%) followed by FS3 (25%), FS2 (24%), and FS4 (14%). The highest amount of fresh fruit wastage is observed in FS4 (50%), succeeded by FS2 (25.4%), FS3 (14.6%), and FS1 (10%). Similarly, the total FW is segregated as carbohydrate-rich wastage (highest share of 31% for FS4) and protein-rich wastage (highest share of 47% for FS1). Figure 3b reflects the contribution of each of the hostel kitchens to various waste generation.CK has the highest share of vegetable waste (44%), whereas GK produces the least share (10%). A similar pattern is seen in the case of fruit wastage. CK has the highest share (53%), whereas SK generates the least share (10%). Carbohydrate-rich component wastage is maximum for CK (39%) followed by SK (23%), EK (21%), and GK (17%).The maximum number of protein-rich components gets wasted in CK (40%).

GHG Emission Analysis

Figure 4a, b, c, and d shows the relative contribution of each of the food items to CO2 emissions in the hostel kitchens. In the case of SK, poultry meat contributes the largest share of CO2 emissions (31.5%) followed by Dosa (19.7%) and pulse (13.1%). In EK, mutton has a lower share (8.9%) than poultry meat (33.3%). Though mutton has higher CO2 emissions (g kg−1 fresh product) than poultry meat, more eaters consume poultry meat, resulting in a larger share of the total emission. Compared to the other kitchens CK prepares more of a meat-based diet for the eaters; hence, the overall CO2 emission in it is higher than in the other kitchens.

Figure 4e, f, g, and h indicates a similar trend of meat-based items contributing a larger share to the overall CO2 emission at the food shops. For FS1, poultry meat has the largest share (33.2%) and idli contributes the least (0.8%). Comparing the data observed in the other kitchens it is seen that for FS2 mutton has the largest share (22.8%) and chapatti contributes the least (12.1%). In FS3 poultry meat has the highest share (30%) and the least contributor is cauliflower (7.4%), whereas, for FS4, mutton contributes the highest share (33.3%) and the sambar generates the least share (4.8%) in CO2 emission.

Figure 4i represents a comparative analysis of the overall CO2 generated in the food shops and hostel kitchens. Hostel kitchens in general produce more CO2 than that of the food shops. The figure shows that CK has the highest share of CO2 generation (48%) followed by SK (19.9%) and others contributing 31.2%. Data comparison among the various food shops shows that FS1 has a bulk share of above 56% and FS2 has the least contribution of 4.6% in possible CO2 emission. Apart from the total volume of food prepared on a daily basis, the share of non-veg items cooked also adds to the overall carbon footprint.

Recoverable Energy Potential Estimation

The estimated value of recoverable energy potential per month (from food waste) for the food shops and hostel kitchens is presented in Tables 2 and 3, respectively. Moreover, the equivalent energy is also mentioned for each of the kitchens spanning over two quantification periods. In the case of QP1, the highest Rep for the food shops is recorded for April in FS4 (634.83 MJ), followed by FS1 (624.172 MJ) for February. For QP2, the highest value of Rep is recorded for FS1 in December (627.8 MJ) and the second-highest value is obtained for FS1 in August (608.092 MJ). For the hostel kitchens, Rep is maximum at CK in March for QP1 (4943.26 MJ) and for QP2 the maximum value of Rep is observed for CK (10,225.54 MJ) in August. Since the equivalent energy potential is linearly dependent on the value of Rep, a similar trend of values is observed for this parameter in all the cases.

Figure 5 represents the characteristic months of the year that witnessed the maximum waste generation in the hostel kitchens as well as in the food shops. For the QP1, CK registered the maximum FW generation in February as chronicled in Fig. 5a. It records the highest FW generation of 1558 kg on the 10th working day of the month (Rep is 10,438.6 MJ, Eenergy is 2899.6 kWh). In the case of QP2 also CK registered the highest FW generation among all the hostel kitchens in August as indicated in Fig. 5b. The highest FW generation is 1530.6 kg recorded on the 8th working day (Rep is 10,255.02 MJ, Eenergy is 2848.62 kWh). For the food shops, in QP1, the maximum FW generation of 110 kg (Rep is 737 MJ, Eenergy of 204.72 kWh) is observed on the 20th day of April for FS1 as portrayed in Fig. 5c. In QP2 also FS1 repeats the maximum FW generation of 111 kg in December (Rep is 743.7 MJ, Eenergy is 206.58 kWh) which is outlined in Fig. 5d.

Conclusions

Food waste characterization has been performed under this work using the FW produced in eight of the primary kitchens located in the campus area of the National Institute of Technology, Agartala. This classification is useful for understanding the various subgroups of waste generation. It is reflected in the average FW generation to the number of eaters for two QPs. This study also highlights the amount of CO2 released in the kitchens while preparing food items. Finally, the recoverable energy potential analysis is performed for the overall food waste production. The present study indicates that the FW generation does not necessarily follow a linear relationship with the average number of eaters/customers. The taste of the food, proper menu planning, and the micromanagement of kitchen runners are crucial parameters that dictate the amount of FW production. In the case of the hostel kitchens, the number of eaters remains constant, but the generation of FW is not fixed. The fluctuating number of customers in the food shops adds to a more dynamic pattern of FW production depending on the random orders placed. Also, it is observed that kitchens serving meat-based cuisine contribute more to the avoidable waste category, whereas fresh fruit and vegetable waste contribute to the unavoidable waste. Moreover, CO2 emission is higher for the meat-based cuisines served in comparison with their vegetarian counterparts. Possible recoverable energy potential is also indicative of the energy that could be harnessed from FW for satiating energy needs. Further FW produced is an organic waste that has the potential of being utilized as an energy alternative which will ensure food security, better management of waste accumulated, and waste-to-energy conversion. This work thus highlights the various factors impacting the FW generation in a dynamic setup of an educational institute (Table 4).

Nonetheless, though the paper delves into the factors impacting the generation of the FW within the campus area, it may not comprehensively account for external factors like inefficiencies in the food supply chain or societal attitudes toward food waste. The type of seasonal produce chosen for the menu is also an important factor in waste generation. Throughout the study, it became evident that emphasizing the importance of thoughtful menu planning, which considers the availability of seasonal produce, is essential. This approach can help reduce waste since fresher ingredients are more likely to be consumed. Additionally, it is crucial to implement measures such as awareness campaigns and educational programs aimed at kitchen staff, students, consumers, and other stakeholders. These efforts are imperative for raising awareness about the environmental consequences of the FW, the advantages of waste reduction, and the significance of making sustainable food choices.

References

FAO. Food Wastage Footprint: Impacts on natural resources, Summary Report (2013).<https://www.fao.org/3/i3347e/i3347e.pdf> (accessed on 15.05.2022)

FAO. The state of food insecurity in the world 2015. Meeting the 2015 international hunger targets: Taking stock of uneven progress. Rome (2015).<https://www.fao.org/3/i4671e/i4671e.pdf> (accessed on 10.05.2022)

K. Schanes, K. Dobernig, B. Gözet, Food waste matters - a systematic review of household food waste practices and their policy implications. J. Clean. Prod. 182, 978–991 (2018)

Y. Wang, Z. Yuan, Y. Tang, Enhancing food security and environmental sustainability: a critical review of food loss and waste management. Resour. Environ. Sustain. 4, 100023 (2021)

H.K. Jeswani, F.-T. Gonzalo, A. Adisa, The extent of food waste generation in the UK and its environmental impacts. Sustain. Prod. Consump. 26, 532–547 (2020)

FAO. Food and agricultural organization of the United Nations. Food wastage footprint and climate change (2011).<https://www.fao.org/3/bb144e/bb144e.pdf> (accessed on 14.05.2022)

L.A. Pfaltzgraff, M. De Bruyn, E.C. Cooper, V. Budarin, J.H. Clark, Food waste biomass: a resource for high-value chemicals. Green Chem. 15(2), 307 (2013)

K. Slopiecka, F. Liberti, S. Massoli, P. Bartocci, F. Fantozzi, Chemical and physical characterization of food waste to improve its use in anaerobic digestion plants. Energy Nexus 5, 100049 (2022)

A.E. Adeniran, A.T. Nubi, A.O. Adelopo, Solid waste generation and characterization in the University of Lagos for sustainable waste management. Waste Manag. 67, 3–10 (2017)

V. Filimonau, V.N. Nghiem, L. Wang, Food waste management in ethnic food restaurants. Int. J. Hosp. Manag. (2021). https://doi.org/10.1016/j.ijhm.2020.102731

F. Tatàno, C. Caramiello, P. Tonino, L. Tripolone, Generation and collection of restaurant waste: characterization and evaluation at a case study in Italy. Waste Manage. 61, 423–442 (2017)

L.-e Wang, G. Liu, X. Liu, Y. Liu, J. Gao, B. Zhou, Si. Gao, S. Cheng, The weight of unfinished plate: a survey-based characterization of restaurant food waste in Chinese cities. Waste Manage. 66, 3–12 (2017)

F. Zan, Ji. Dai, Y. Hong, M. Wong, F. Jiang, G. Chen, The characteristics of household food waste in Hong Kong and their implications for sewage quality and energy recovery. Waste Manage. 74, 63–73 (2018)

H. Zhang, H. Duan, J.M. Andric, M. Song, Bo. Yang, Characterization of household food waste and strategies for its reduction: a Shenzhen City case study. Waste Manage. 78, 26–433 (2018)

E.U. Kiran, A.P. Trzcinski, W.J. Ng, Y. Liu, Bioconversion of food waste to energy: a review. Fuel 134, 389–399 (2014)

C. Banks, Y. Zhang, Y. Jiang, S. Heaven, Trace element requirements for stable food waste digestion at elevated ammonia concentrations. Bioresour. Technol. 104, 127–135 (2012)

N. Nagao, N. Tajima, M. Kawai, C. Niwa, N. Kurosawa, T. Matsuyama, F. Yusoff, T. Toda, Maximum organic loading rate for the single-stage wet anaerobic digestion of food waste. Bioresour. Technol. 118, 210–218 (2012)

Y. Li, S.Y. Park, J. Zhu, Solid-state anaerobic digestion for methane production from organic waste. Renew. Sustain. Energy Rev. 15(1), 821–826 (2011)

B. Schink, Energetics of syntrophic cooperation in methanogenic degradation. Microbiol Mol Biol Rev 61(2), 262–280 (1997)

Y. Yang, K. Tsukahara, T. Yagishita, S. Sawayama, Performance of a fixed bed reactor packed with carbon felt during anaerobic of cellulose. Biores. Technol. 94, 197–201 (2004)

Q. Wang, H. Li, K. Feng, J. Liu, Oriented fermentation of food waste towards high-value products: a review. Energies 13(21), 5638 (2020)

E. Uçkun Kiran, A.P. Trzcinski, W.J. Ng, Y. Liu, Bioconversion of food waste to energy: a review. Fuel 134, 389–399 (2014)

X. Yang, S.J. Lee, H.Y. Yoo, H.S. Choi, C. Park, S.W. Kim, Biorefinery of instant noodle waste to biofuels. Bioresour. Technol. 159, 17–23 (2014)

S.-S. Kim, H. Heo, S. Kim, R. Ryoo, J. Kim, J.-K. Jeon, S. Park, Y.-K. Park, Catalytic pyrolysis of oil fractions separated from food waste leachate over nanoporous acid catalysts. J. Nanosci. Nanotechnol. 11, 6167–6171 (2011)

M. Tripathi, J.N. Sahu, P. Ganesan, Effect of process parameters on production of biochar from biomass waste through pyrolysis: a review. Renew. Sustain. Energy Rev. 55, 467–481 (2016)

L. Li, R. Diederick, J.R.V. Flora, N.D. Berge, Hydrothermal carbonization of food waste and associated packaging materials for energy source generation. Waste Manage. 33(11), 2478–2492 (2013)

H.S. Le, W.-H. Chen, S.F. Ahmed, Z. Said, N. Rafa, A.T. Le, Ü. Ağbulut, I. Veza, X.P. Nguyen, X.Q. Duong, Z. Huang, A.T. Hoang, Hydrothermal carbonization of food waste as sustainable energy conversion path. Bioresour. Technol. 363, 127958 (2022)

P. Murugesan, V. Raja, S. Dutta, J.A. Moses, C. Anandharamakrishnan, Food waste valorisation via gasification – a review on emerging concepts, prospects and challenges. Sci. Total. Environ. 851, 157955 (2022)

I.I. Ahmed, A.K. Gupta, Pyrolysis and gasification of food waste: syngas characteristics and char gasification kinetics. Appl. Energy 87(1), 101–108 (2010)

Z. Yang, S.K. Koh, W.C. Ng, R.C. Lim, H.T. Tan, Y.W. Tong, Y. Dai, C. Chong, C.H. Wang, Potential application of gasification to recycle food waste and rehabilitate acidic soil from secondary forests on degraded land in Southeast Asia. J. Environ. Manage. 172, 40–48 (2016)

D. Mallick, S. D. Sharma, A. Kushwaha, H. S. Brahma, R. Nath, & R. Bhowmik. Chapter 4 - Emerging commercial opportunities for conversion of waste to energy: aspect of gasification technology. In C. M. Hussain, S. Singh, & L. Goswami (Eds.), Waste-to-Energy Approaches Towards Zero Waste. Elsevier, pp. 105–127 (2022)

V. Rucha, P.G. Moharir, and S. Kumar. Chapter 4 - Waste Treatment Processes/Technologies for Energy Recovery, Current Developments in Biotechnology and Bioengineering, pp. 53–77 (2019).

S.K. Karmee, Liquid biofuels from food waste: current trends, prospect and limitation. Renew. Sustain. Energy Rev. 53, 945–953 (2016)

M. Carmona-Cabello, D. Leiva-Candia, J.L. Castro-Cantarero, S. Pinzi, M.P. Dorado, Valorization of food waste from restaurants by transesterification of the lipid fraction. Fuel 215, 492–498 (2018)

V. De Laurentiis, S. Corrado, S. Sala, Quantifying household waste of fresh fruit and vegetables in the EU. Waste Manage. 77, 238–251 (2018)

E.M. Biggs, E. Bruce, B. Boruff, J.M.A. Duncan, J. Horsley, N. Pauli, K. McNeill, N. Andreas, F. Van Ogtrop, J. Curnow, B. Haworth, S. Duce, Y. Imanari, Sustainable development and the water-energy-food nexus: a perspective on livelihoods. Environ Sci Policy 54, 389–397 (2015)

H. Ritchie, M. Roser, "Environmental Impacts of Food Production". <https://ourworldindata.org/environmental-impacts-of-food> (accessed on 18.05.2022) (2020)

C. Thomas, T. Tennant, J. Rolls, J. The GHG indicator: UNEP guidelines for calculating greenhouse gas emissions for businesses and non-commercial organizations. Paris: UNEP, 2000.<https://www.unepfi.org/fileadmin/publications/cc/ghg_indicator_2000.pdf> (Accessed on 20.05.2020) (2000)

V.K. Pantangi, A.S.S.R. Karuna Kumar, S.C. Mishra, N. Sahoo, Performance analysis of domestic LPG cooking stove with porous media. Int. Energy J. 8, 139–144 (2007)

H. Pathak, N. Jain, A. Bhatia, J. Patel, P.K. Aggarwal, Carbon footprints of Indian food items. Agr Ecosyst Environ 139, 66–73 (2010)

S. Kathirvale, M. Yunus, M. Noor, K. Sopian, A.H. Samsuddin, Energy potential from municipal solid waste in Malaysia. Renew. Energy 29, 559–567 (2004)

C.O. Ugwu, C.G. Ozoegwu, P.A. Ozor, Solid waste quantification and characterization in the University of Nigeria, Nsukka campus, and recommendations for sustainable management. Heliyon 6, e04255 (2020)

J. Okeniyi, E.U. Anwan, E. Okeniyi, Waste characterisation and recoverable energy potential using waste generated in a model community in Nigeria. J. Environ. Sci. Technol. 5, 232–240 (2012)

W. Shepherd, D.W. Shepherd, Energy Studies, 2nd edn. (Imperial College Press, London, 2003)

Funding

There was no funding for carrying out this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Roy Barman, D., Bhattacharjee, S. Characterization of Food Waste in An Educational Institute and Energy Recovery Possibilities. J. Inst. Eng. India Ser. B 104, 1257–1271 (2023). https://doi.org/10.1007/s40031-023-00941-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40031-023-00941-9