Abstract

The aim of the present investigation was to develop and evaluate matrix tablet of mesalamine for colonic delivery by using Eudragit RSPO, RLPO and combination of both. The tablets were further coated with different concentration of pH-dependent methacrylic acid copolymers (Eudragit S100), by dip immerse method. The physicochemical parameters of all the formulations were found to be in compliance with the pharmacopoeial standards. The in vitro drug release study was conducted using sequential dissolution technique at pH 1.2 (0.1N) HCl, phosphate buffers pH 6.8 and 7.4, with or without rat cecal content mimicking different regions of gastro intestinal tract. The result demonstrated that the tablet containing Eudragit RLPO coated with Eudragit S100 (1 %) showed a release of 94.91 % for 24 h whereas in the presence of rat cecal content the drug release increases to about 98.55 % for 24 h. The uncoated tablets released the drug within 6 h. The in vitro release of selected formulation was compared with marketed formulation (Octasa MR). In vitro dissolution kinetics followed the Higuchi model via non-Fickian diffusion controlled release mechanism. The stability studies of tablets showed less degradation during accelerated and room temperature storage conditions. The enteric coated Eudragit S100 coated matrix of mesalamine showing promising site specific drug delivery in the colon region.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

For successful delivery of drugs to the target site, various drug delivery approaches have been explored and plays a challenging and crucial role. However, for sustained as well as controlled delivery system, the oral route of administration is considered to be the most convenient and preferred route for delivery of drug. Various drug delivery strategies have been employed to trigger the release of drug to the large intestine but however, they do not reach at the site of action in appropriate concentrations. Thus, to ensure an effective and safe therapy for the large bowel diseases, colon specific drug delivery system is considered to be the preferable approach (Mooter 2006). Targeted drug delivery into the colon is highly desirable for local treatment of bowel diseases such as ulcerative colitis, Crohn’s disease, amebiosis, carcinomas and infection, local treatment of colonic pathologies with high local concentration can be achieved while minimizing side effect that occur because of the release of the drug in the upper part of GIT or unnecessary systemic absorption. The colon is rich in lymphoid tissue, produces rapid local production of antibodies with uptake of antigen into the mast cell of the colonic mucosa and this help in efficient vaccine delivery (Chourasia and Jain 2004). Colon specific drug delivery system offers several advantages in the treatment of colonic diseases such as ulcerative colitis, amoebiasis, Crohn’s disease, irritable bowel syndrome, colorectal cancer (Bursemer et al. 2001). Delivery of drugs to the colon helps in reducing side effect thereby, achieving high local drug concentration at the afflicted site in the colon, hence results in optimal therapeutic effectiveness and good patient compliance (Singh 2007; Bautzova et al. 2011).

Majority Colon drug delivery is based on pH and time-dependent systems but in pH dependent systems similarities between pH of small intestine and colon makes it less reliable. In time-dependent formulations, location of initial drug release depends on the transit time of system in GIT track (Fu et al. 2011). The performance of time-dependent formulations can be affected by inter subject variation in GI transits times, pathophysiological conditions associated with GI tract Time-dependent drug release systems can be formulated by applying coats onto drug cores which are capable of delaying the release though different mechanisms (Vassallo et al. 1992; Von der et al. 1993; Sangalli et al. 2004).

However, drawback associated with these deliveries is the lack of site specificity due to large variation in gastric emptying time. Thus, time controlled and site specificity is difficult. A simple pH dependent approach is also not suitable to be used alone because of premature release of drug. Therefore, these problems can be overcome by using the combination of both time-dependent and pH-dependent polymers.

The release of water-soluble drug from a water-soluble polymeric platform is often rapid, and therefore hydrophobic polymer may be included within the matrix formulation to offer a greater control drug release. Among the various polymers, Eudragit RSPO and Eudragit RLPO are the hydrophobic polymers which have been used successfully to formulate appropriate sustained release matrix formulations (Patra et al. 2007). Matrix tablets have been developed by direct compression based on combination of hydrophobic polymers (RSPO and RLPO) and a gelling hydrophilic polymer, HPMC 60SH, to achieve a 20-h sustained release formulation of diltiazem hydrochloride. Film coated matrix tablets using Eudragit NE30D produce a delivery system in which the release of diltiazem hydrochloride is pH independent (from 1.2 to 7.4). Eudragit RSPO was employed to delay the penetration of dissolution medium into the matrix, thereby decreasing drug release rate (Boyapally et al. 2009).

Therefore, by considering all the above data, the mesalamine was used as a model drug in colon delivery system using two different polymers: Eudragit RLPO and Eudragit RSPO coating with Eudragit S-100 in different concentrations, so that it can deliver the drug locally in colon. Such type of formulation also minimizes upper GI tract side effects of naproxen sodium and help in providing therapeutic benefits.

Materials and methods

Mesalamine was obtained as a gift sample from Micro labs, Bangalore, India. Polyvinyl pyrrolidone (PVP K-30) were obtained as gift samples from Helios Pharma, Baddi, India. Eudragit RLPO, Eudragit RSPO and Eudragit S-100 were obtained as gift samples from Evonik Laboratory, Mumbai, India. All other chemicals and reagents used in study were of analytical grade.

Formulation and development

Preformation study (Meier et al. 2008)

Quantification of mesalamine by UV spectroscopy

Stock solution (100 mg/mL) of Mesalamine was prepared in different buffer solutions (0.01 N HCl, phosphate buffer solution pH 6.8 and 7.4), which was then analyzed in the range 200–400 nm using a UV double-beam spectrophotometer (AU-2701, Systronics, Mumbai, India) for the determination of max. From the stock solution, standard solutions in the range 10–60 mg/mL were prepared, and the absorbance of each standard solution was determined spectrophotometrically at the max obtained. Using absorbance–concentration data, a calibration curve was constructed. The calibration curve was found to be linear in the concentration range of 10–60 mg/mL having different coefficient of regression values R2¼0.9993–0.9995 and slope y¼0.016 × 0.004–0.021 × 0.022.

FTIR spectroscopy

The infrared spectrum of pure drug (mesalamine), Eudragit RLPO, Eudragit RSPO, Eudragit S-100 and physical mixture of mesalamine-Eudragit RLPO–Eudragit RSPO–Eudragit S-100 were recorded using a FTIR spectrophotometer (Bruker IFS 66/S, Germany) according to the KBr disc technique. The smoothing of the spectra and the baseline correlation procedures were applied. The FTIR measurements were performed in the scanning range of 4000–400 cm−1 at ambient temperature.

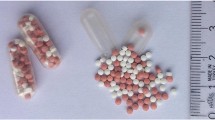

Preparation of mesalamine core tablets

Accurately weighed quantity of mesalamine, polymers Eudragit (RLPO or RSPO) were dry blended for 20 min using a pestle and mortar. The mixture was then granulated using a binder solution of PVP (5 % w/w) in isopropyl alcohol. The wet mass was passed though #22 sieve and the resulted granules were dried in a tray drier for 15 min at 50 °C. The dried granules were granules were mixed with the required amounts of magnesium stearate (2 %) and talc (2 %) and compressed using a single punch tablet machine, equipped with flat-faced punches of 12 mm diameter. Nine batches of formulation were prepared by using different concentrations of Eudragit (RSPO and RLPO) and Eudragit S100 as shown in Table 1.

Enteric coating of the prepared tablets

The mesalamine tablets were further coated with Eudragit S-100 solution. A different concentration (1, 1.5, 2, and 2.5 %) of coating solution of Eudragit S-100 was prepared in a mixture of Isopropyl alcohol: acetone (1:1). The coating solution followed by dip coating technique.

Evaluation of mesalamine granules

Mesalamine granules were evaluated for bulk density, tapped density, compressibility (% Carr’s index), Hausner’s ratio and angle of repose.

Physicochemical evaluation of mesalamine matrix tablets

For the estimation of weight variation 20 tablets of the each formulation were weighed using an electronic balance (Denver Instrument, Gottingen Germany) and the test was performed according to the official test. The thickness of the tablet was measured using a Digital Vernier Calliper (Mitutoya Digimatic Calliper, Japan). The hardness of the prepared tablet was measured by using Monsanto hardness tester. The tablet to be tested was held between a fixed and a moving jaw and reading of the indicator was adjusted to zero. The force applied to the edge of the tablet was gradually increased by moving the screw knob forward until the tablet broke. The reading was noted from the scale which indicates the pressure required in kg/cm2 to break the tablets. The friability of the tablets was determined in Roche Friablator. Six tablets were weighed accurately from each batch of the tablets and placed in the friablator and rotated at 25 rpm for a period of 4 min. Tablets were dedusted using soft muslin cloth and weighed again. The percentage weight loss was determined by using following formula:

Drug content

Tablets were finely powdered and quantity of the powder equivalent to 250 mg was accurately weighed and transferred to a 100 mL volumetric flask containing 50 mL of phosphate buffer, pH 7.4. The flask was shaken to solubilize the drug and the volume was made up to 100 mL with phosphate buffer 7.4. The solution was filtered though a membrane filter (0.22 µm) and analyzed for drug content using UV/Visible spectrophotometrically (AU-2701, Systronics, Mumbai, India) at 334 nm.

In vitro drug release studies

The in vitro dissolution studies were conducted for the mesalamine matrix tablet using USP dissolution apparatus II (Lab India, DS 8000, Mumbai, India). The dissolution medium consisted of 900 mL at 50 rpm, 37 ± 0.5 °C temperature. The drug release evaluation was conducted firstly in 0.1 N HCl (pH 1.2) due to the fact that the average gastric emptying time is supposed to be between 0.5 and 2 h. Then the dissolution medium was replaced by (900 mL) pH 6.8 phosphate buffer for 3 h. The reason behind that the average small intestine is 3 h. At the end of the time periods, the dissolution medium was replaced by pH 7.4 phosphate buffer (900 mL) at the selected times, samples were withdrawn and replaced by the same volume of the acceptor medium and filtered using Whatman filter paper (0.22 µm). The absorbance was determined using UV/Vis double beam spectrophotometer (AU-2701, Systronics, Mumbai, India) at 334 nm. The cumulative percentage drug release for mesalamine over the sampling times was calculated using Beer Lambert’s curve with different dissolution media. The mean cumulative percentage of drug releases calculated (±SD) and plotted against time. Therefore, experiments were carried out in triplicate (Hamza and Aburahma 2010). For the comparison of selected formulation evaluated in this investigation with marketed product, a commercially marketed mesalamine tablet i.e. Octasa MR (Tillotts Pharma Limited) were purchased locally and subjected to the in vitro release studies.

Preparation of rat cecal content for dissolution studies

The drug release studies were carried out in the presence of the colonic bacteria, to access the susceptibility of the prepared matrix tablets to undergo degradation in the presence of the colonic bacteria due to the fact that rat cecal have similar contents to that of human intestinal microflora. For this purpose Male Wistar rats weighing 100–150 g were selected. The rats were maintained at a normal diet. After this enzyme induction is done in order to stimulate the enzymes which specifically hydrolyse the Eudrgit RLPO. For the enzyme induction, 2 mL of a 1 % w/v dispersion of Eudragit RLPO in water was administered to the rats daily for 7 days. The abdomens were cut, the ceci were isolated, ligated at both ends, dissected. The cecal content was immediately weighed about 8 g and transferred into 200 mL of pH 7.4 phosphate buffer to provide 4 % (w/v) dilution. Carbon dioxide (CO2) was continuously passed thorough pooled content so as to keep the environment in anaerobic condition (Mundargi et al. 2007).

In vitro drug release studies in the presence of rat cecal content

The in vitro drug release studies were carried out using dissolution rate test apparatus in 900 mL dissolution medium at 50 rpm, 37 ± 0.5 °C with slight modifications. A beaker having capacity of 250 mL of 4 % rat cecal content medium was immersed in the dissolution vessel having water maintained at 37 ± 0.5 °C, which was also kept in the water bath of the apparatus. The initial studies were carried out in pH 1.2 HCl for 2 h. After completion of 2 h the matrix tablet was transferred pH 6.8 phosphate buffer. The study at a pH 6.8 was continued for 3 h. After 3 h, the matrix tablet was transferred to 200 mL of the phosphate buffer pH 7.4 diluted with 4 % (w/v) rat cecal content for 24 h. The experiment was carried with the continuous supply of carbon dioxide as the cecum is naturally anaerobic. At different time intervals 2 mL of the samples were withdrawn from the dissolution medium and 2 mL of the rat cecal content was replenished into the dissolution media. The samples were analyzed for drug content using UV-spectrophotometer at 334 nm (Ahmadi et al. 2011).

Release kinetics study

To study the mechanism of drug release from the matrix tablets, the release data were fitted to zero-order, first-order and Higuchi equation. The dissolution data was also fitted to the well-known exponential equation (Korsmeyer–Peppas equation), which is often used to describe the drug release behavior from polymeric systems.

where Mt is the amount of drug release at time t, M ∞ is the amount of drug release after infinite time; k is a release rate constant incorporating structural and geometric characteristics of the tablet and n is the diffusional exponent indicative of the mechanism of drug release.

If value of n falls between 0.5 and 1.0; it is termed as non-fickian release; while in case of fickian diffusion, n = 0.5. For zero order release case II transport n = 1; on the other hand if n > 1′ then it indicates supercase II transport (Lopes et al. 2006).

Swelling Studies

The dissolution behavior of the drug from the matrices can also be understood by conducting the swelling studies. The swelling studies were conducted under conditions similar to those used for dissolution studies.

The swelling studies were carried out of all the formulation. For the determination of swelling in order to avoid deformation one planar base of the tablets was covered with water-insoluble coating (1 % Eudragit S100) and glued to a piece of glass slide. The glass slide and tablets were weighed initially (W1). The tablets were placed in a different dissolution media (pH 1.2, 6.8 and 7.4) using USP dissolution apparatus II (Lab India, DS 8000, Mumbai, India) in 900 mL dissolution medium at 50 rpm, 37 ± 0.5 °C. The swollen tablets were taken out at predetermined time intervals and using tissue paper excess of water on their surface was carefully removed and tablets were reweighed (W2). The study was carried out over a period of 12 h and the tablets were observed for swollen. (Gaikwad et al. 2014).

The % swelling index was calculated using the following formula:

All values presented in this study are average of triplicate experiments for the same time points. Differences in % swelling index values of mesalamine tablets were calculated statistically using one-way analysis of variance (ANOVA) followed by Dunnett’s test at different level of significance using GraphPad Prism 6.

Scanning electron microscopy

The morphology and surface appearance of mesalamine matrix tablets before and after the release were examined using a scanning electron microscope (JSM 6100 Jeol. Japan) equipped with an image analysis system. Prior to examination, samples were gold sputter-coated to render them electrically conductive.

Stability study

The stability study was conducted according to ICH guidelines. All the formulations were stored in aluminum packaging laminated with polyethylene and kept in humidity chamber at accelerated (40 ± 2 °C, 75 ± 5 % RH) and room temperature conditioned for 6 months. The samples were withdrawn at a specified time intervals of 0 days, 3, 6 weeks, 3 and 6 month. The samples were evaluated for their physical characteristics (color) and drug content.

Results and discussion

Preformation study

FTIR Spectroscopy

FTIR spectra of the drug, polymers and their physical mixtures are depicted in Fig. 1. The drug sample showed characteristics peaks at 1651.5 cm−1 due to C=O bending, at 1620.5 cm−1 due to presence of N–H bending, the C–N stretch at 1354.9 cm−1 and due to the presence of O–H the peak was found at 3433.1 cm−1. FTIR spectrum of Eudragit RLPO showed the peak at 3432.1 cm−1 due to the presence of tertiary amine, at 1731.4 cm−1 due to the presence of C=O (ester) and at 1450.2 cm−1 due to –CH3 bend. FTIR spectrum of Eudragit RSPO showed the peak at 3287.7 cm−1 due to the presence of tertiary amine, at 1636.3 cm−1 due to the presence of C=O (ester) and at 1430.2 cm−1 due to –CH3 bend. FTIR spectrum of Eudragit S-100 showed the peak at 2953.9 cm−1 due to presence of O–H, at 1450.7 cm−1 due to -CH3 bend and 1731.2 cm−1 due to the presence of C=O (ester). FTIR spectrum of the physical mixture of drug-Eudragit RLPO-Eudragit RSPO-Eudragit S100 showed the peak at 1728.61 cm−1 due to the presence of C=O (ester), at 1174.81 cm−1 due to presence of C–O stretch, the C=C (aromatic stretch) at 1604.14 cm−1, –CH3 bend at 1453.19 cm−1, at 2960.92 cm−1 due to presence of O–H (carboxylic acid). The spectrum confirmed that there is no significant change in chemical integrity of the drug.

Evaluation of mesalamine granules (Love and Miller 2012)

The results of micromeritics properties of mesalamine granules are depicted in Table 2. From this all values, it’s clearly indicates all the formulations had adequate flow properties.

Physicochemical evaluation of mesalamine matrix tablets

The formulated tablets were evaluated for physical characterization like weight variation, thickness, hardness, friability and drug content. Maximum % weight deviation was found to be 1.29 %. Hence, all the formulation passed the test criteria for weight variation as per USP. The weight variation (Table 3) of all formulations was found to be 526.05 ± 2.23 to 529.05 ± 2.43 mg. The thickness (Table 3) of the tablets was measured by the digital vernier calliper (Mitutoya Digimatic Calliper, Japan). The thickness of formulation F1 was found between 3.48 ± 0.02 mm and F2–F9 was in the range 3.50 ± 0.05 to 3.54 ± 0.07 mm. The thickness of the tablets in formulation F2–F9 increased due to coating of the Eudragit S-100 over the entire surface of the tablet than the uncoated tablet formulations (F1). The hardness (Table 3) of formulation F1 was found in the range 5.83 ± 0.73 kg/cm2 and F2–F9 was in the range 6.00 ± 0.48 to 6.11 ± 0.63 kg/cm2. The hardness of tablets in formulation F2–F9 increased due to coating of the Eudragit S100 over the entire surface of the tablet than the uncoated tablets formulation F2–F9. The friability (Table 3) of all tablet formulations was in acceptable range of less than 1 %, ranging from 0.32 ± 0.01 to 0.41 ± 0.02 % which indicates that the tablets have the ability to withstand shocks which may be occurred during transport.

Drug content

The drug content (Table 3) of all formulations was found between 99.30 ± 0.11 and 99.74 ± 0.11 % indicate to be in acceptable range. The maximum drug content was obtained for formulation F2 which consists of Eudragit RLPO matrix coated with Eudragit S-100 (1 % w/v). The Eudragit RLPO is more permeable to the dissolution media which might result in increased drug content (Gohel et al. 2008).

In vitro Drug Release Studies

The in vitro dissolution profile of core tablet (F1) was studied in phosphate buffer, pH 7.4, to examine the release profile core tablet. The release of drug from core tablets was found to be 97.34 ± 0.98 % at 6 h in pH 7.4 media.

When the combination of Eudragit RLPO and Eudragit RSPO in matrix tablets formulation was used, the results showed that the maximum drug release was shown in stomach and small intestine before reaching the target site (colon) which occurs due to more permeable nature of Eudragit RLPO Meier et al. (2008). When Eudragit RLPO comes in contact with dissolution medium, it creates pores and channels, and it facilitates to penetrate the solvent and thus rate of drug release get enhanced (Patel et al. 2009). The formulations containing Eudragit RSPO showed that the drug release was decreased at the target site (colon) at the end of 24 h due to its less permeable nature in dissolution medium. Eudragit RSPO contains less number of internal quaternary ammonium compound (Patra et al. 2007). Therefore it was observed that for the drug to be release at the target site and to obtain the sustained drug release, the matrix tablets should be coated with varying concentration of Eudragit S100 (1, 1.5, 2, 2.5 %) over the entire surface area of the tablets (Table 1). Therefore, different dissolution media 0.1N HCl, pH 6.8 phosphate buffer and pH 7.4 phosphate buffer were used for remaining formulation batches of matrix tablets to perform in vitro drug release studies (Fig. 2).

The in vitro drug release studies of different formulations F2–F5 containing Eudragit RLPO in the matrix tablet were carried out in different dissolution media (pH 1.2, 6.8, 7.4). The formulated tablets were coated with different concentration of Eudragit S100 (1, 1.5, 2 and 2.5 %). The formulations F3, F4, F5 coated with different concentration of Eudragit S100 (1.5, 2, 2.5 % respectively) showed 90.21 ± 0.58, 85.01 ± 0.60, 81.04 ± 0.73 % drug releases within 18 h. So the drug release studies were carried out till 18 h because after that the drug release started decreasing. Furthermore, there was effect of Eudragit S100 coating in case of formulation F4, F5 (higher concentration) might be restrict the release of drug after 18 h. Whereas, formulation F2 showed maximum drug release i.e. 94.91 ± 0.63 % within 24 h. The formulation F2 consist coating concentration of Eudragit S 100 (1 %),which was optimized to provide suitable coat over the surface of the tablet to pass though the stomach and small intestine without any drug release and to target to colon site (Fig. 2) (Mehta et al. 2013).

Another reason of maximum release from F2 formulation might be effect by Eudragit RLPO, which is more swellable and permeable, when exposure to dissolution medium due to contains of higher amount of quaternary ammonium compounds.

The in vitro drug release studies of different formulations, F6–F9 containing Eudragit RSPO in matrix tablet coated with different concentration of Eudragit S100 (1, 1.5, 2 and 2.5 %) were carried out in different dissolution medium (pH 1.2 HCl, pH 6.8 PBS, pH 7.4 PBS). The formulation F6-F9 showed 88.82 ± 0.38, 83.71 ± 0.79, 77.89 ± 072, 75.91 ± 0.58 % drug releases within 24 h (Fig. 2). It can be explained due to the fact that Eudragit RSPO contains lesser quaternary ammonium compounds, and is less permeable and less swellable. As a result there is surface erosion occurring and formation of gel layer around the core tablet which leads to slow release of drug (Ebube et al. 1997). Another reason may also be due to high concentration of the coating of Eudragit S100, a methacrylates copolymer, which acts as enteric coated polymer (Wadher et al. 2011).

The in vitro release of optimised formulation F2 containing Eudragit RLPO coated with ES100 (1 %) was compared with in vitro release of marketed formulation Octasa MR (Tillotts Pharma Limited). The in vitro release study was found that F2 formulation showed 90.88 % within 24 h which showed a sustained release, whereas the marketed formulation i.e Octasa MR showed 98.38 % within 18 h as shown in Fig. 5. This concludes that in vitro release of Mesalamine from optimised formulation was maximum and sustained as compared to marketed formulation.

In vitro drug release studies in the presence of rat cecal content

The in vitro drug release studies were subjected to different dissolution media (0.1 N HCl, pH 6.8 phosphate buffer, pH 7.4 phosphate buffer) of optimized formulations F2–F5 containing Eudragit RLPO in the same proportion with different coating concentration (1, 1.5, 2, 2.5 %) of Eudragit S-100 in the presence of the colonic bacteria, since they are known to have to similar content to that of human intestinal microflora.

The swollen tablet, after placing in 0.1 N HCl for 2 h and in pH 6.8 phosphate buffers for 3 h, was transferred in 4 % rat cecal medium present in pH 7.4 phosphate buffer for 19 h to carry out dissolution studies. The formulation F2 showed maximum release 98.55 ± 1.17 % in rat cecal medium as compared to lower drug release about 94.91 ± 0.63 % without rat cecal medium. This shows that due to the presence of bacteria in it, coating material was eroded from the surface of tablet quickly and maximum drug release was observed (Gao et al. 2011).

The formulation F3, F4, F5 (coating with 1.5, 2, 2.5 % Eudragit S100) showed less drug release as compared to formulation F2 in the presence of rat cecal content i.e. 95.45 ± 0.20, 90.33 ± 0.71, 86.02 ± 0.48 % at 18 h (Fig. 3). This might be contribution of combination effect of Eudragit RLPO and Eudragit S100 present in matrix tablets, as per earlier discussed in the in vitro release studies.

Drug release Kinetics

To determine the quantitative analysis of the values obtained from drug release profile, various mathematical models are used. The goodness of fit was evaluated using regression coefficient (r2) values. The regression coefficient (r2) for all the formulations using different kinetics equation is listed in Table 4. The table data revealed that in vitro release from the tablets was better explained by the Higuchi equation, where the rate constants obtained from the slope provides the highest linearity. To explore the drug release mechanism, in vitro release results were further fitted to the K–P equation. This equation analyses the release of polymeric dosage forms, either in cases when the release mechanism is not well known or when more than one type of release phenomena is involved. The core tablet (F1) followed Fickian kinetics and the value of n (<0.45) as per the K–P model also compliment the same. The “n” value as per K–P model for the formulations F2–F9 was found to be between 0.45 and 0.89 that indicates anomalous release behavior of drug (Ceballos et al. 2005).

Swelling studies

The swelling studies of all formulations were carried out in different dissolution media (pH 1.2, 6.8, and 7.4). The swelling index of all formulations were obtain in order of F2 > F1 > F3 > F4 > F5 > F6 > F7 > F8 > F9 as depicted in Fig. 4. The swelling index of F2 formulation containing Eudragit RLPO coated with 1 % concentration of Eudragit S100 taken less time (p < 0.05) to rupture the outer wall of Eudragit S100 as compared with other formulations (coated with high concentrations of Eudragit S-100), which provide less barrier to swell the inner wall of Eudragit RLPO, which is a high permeable polymer. It occurs due to lesser amount of coating concentration around the tablet Von der et al. (1993). In F1(core) formulation (without coating of Eudragit S-100) containing combination of Eudragit RLPO and Eudragit RSPO provides less swelling index as compared with F2 formulation. This might be due to less concentration of Eudragit RLPO, which is water permeable polymer. The formulations F3–F5 containing RLPO coating with different concentrations of Eudragit S100 (1.5, 2, and 2.5 %) showed less swelling studies (p < 0.01) as well as less drug release. It occurs because on increasing the coating level of Eudragit S100 over the matrix tablet, there is formation of more barriers over the tablet and it takes more time to rupture the outer wall of Eudragit S100 when comes in contact with dissolution media. The formulations F6-F9 containing Eudragit RSPO when exposed to dissolution media showed least swelling index (p < 0.000) because of its less permeable nature and lesser amount of quaternary ammonium groups in its structure (Kuksal et al. 2006) (Fig. 5).

Swelling index (%) of all formulations of mesalamine matrix tablets. Data are represented as mean ± SD (n = 3). †Statistically significant difference at p < 0.05, ††Statistically significant difference at p < 0.01, †††Statistically significant difference at p < 0.001, ††††Statistically significant difference at p < 0.0001 from F1 (core tablet) as determined by one-way ANOVA followed by Dunnett’s test

Scanning electron microscopy of matrix tablets

Scanning electron microscopy (SEM) analyses were performed on the optimized batch (F2) with different dissolution media (pH 1.2, 6.8 and 7.4). SEM photomicrographs of the outer surface of the coated matrix tablet showed a homogenous and quite compact structure without any pore before dissolution as depicted in Fig. 6. The coated matrix tablet placed in pH 1.2 for 2 h showed the presence of limited eroded area and numerous pores and channels indicating limited swelling of the matrix tablet, drug diffusion could occur though a porous network filled by the solvent penetrated into the matrix. Then coated matrix tablet was transferred to pH 6.8 for 3 h which results in the formation of channels and pores occurs when the dissolution medium get penetrated in it. It occurs mainly due to RLPO polymer which was more permeable to the dissolution media. This caused the coating to break, producing deep fracture and irregular cavities which appear evident on the tablet surface. Then at last coated matrix tablets were transferred in pH 7.4 for 19 h showed increase in diameter of the pores and swelling of the tablets though the matrix with different time interval. The presence of both swelling and diffusion mechanism indicates formation of pores and gelling structure on the tablet surface showed sustained drug release from coated matrix tablets (Akhgari et al. 2010).

Stability studies

The stability studies of all formulations for targeting Mesalamine to the colon were carried out at 30 ± 2 °C/65 ± 5 % RH (room temperature studies) and at 40 ± 2 °C/75 ± 5 % RH (accelerated temperature studies) for 6 months as per ICH guidelines. After storage for 0 days, 3, 6 weeks, 3 and 6 months, the tablets were observed for physical appearance, color change and were subjected to drug content. The results indicated that no change in physical appearance was noticed upon visual inspection of the tablets. All the formulations showed more than 90 % of drug content during both accelerated and room temperature storage conditions. The graphical representation of drug content of all formulation batches of mesalamine matrix tablets at room temperature and accelerated temperature is shown in Fig. 7 (Ali Asghar et al. 2009).

Conclusions

From the investigation, it can be concluded that the appropriate combination of a pH dependent polymer (Eudragit S100) with a pH independent polymer (Eudragit RLPO) were suitable adequately sustained the drug release from mesalamine matrix tablet. The selected mesalamine tablets when compared with marketed formulation produced sustained release within 24 h which is prerequisite for colon drug delivery. The in vitro studies were characterized by negligible release in the initial phase followed by controlled release at specific site (colon). The drug release kinetics showed that the formulations were best fitted with Higuchi release model and the drug mechanism was followed Korsmeyer–Peppas equation with non-Fickian diffusion kinetics. The formulations when subjected to stability studies indicated no significant change in physical appearance and drug content. Controlled release system for colon specific drug was developed successfully.

References

Ali Asghar LF, Azeemuddin M, Jain V, Chandran S (2009) Design and in vitro evaluation of formulations with pH and transit time controlled sigmoidal release profile for colon-specific delivery. Drug Deliv 16:295–303

Ahmadi F, Varshosaz J, Emami J, Tavakoli N, Minaiyan M, Mahzouni P, Dorkoosh F (2011) Preparation and in vitro/in vivo evaluation of dextran matrix tablets of budesonide in experimental ulcerative colitis in rats. Drug Deliv 18:122–130

Akhgari A, Farahmand F, Afrasiabi Garekani H, Sadeghi F, Vandamme T (2010) The effect of pectin on swelling and permeability characteristics of free films containing Eudragit RL and/or RS as a coating formulation aimed for colonic drug delivery. Daru 18:91–96

Boyapally H, Nukala RK, Douroumis D (2009) Development and release mechanism of diltiazem HCl prolonged release matrix tablets. Drug Deliv 16:67–74

Bautzova T, Rabiskova M, Lamprecht A (2011) Multiparticulate system containing 5-aminosalicylic acid for the treatment of inflammatory bowel disease. Drug Dev Ind Pharm 37:1100–1109

Bursemer T, Otto I, Bodmeier R (2001) Pulsatile drug–delivery systems. Crit Rev Ther Drug Carrier Syst 18:433–458

Ceballos A, Cirri M, Maestrelli F, Corti G, Mura P (2005) Influence of formulation and process variables on in vitro release of theophylline from directly-compressed Eudragit matrix tablets. Farmaco 60:913–918

Chourasia MK, Jain SK (2004) Polysaccharides for colon targeted drug delivery. Drug Deliv 11:129–148

Ebube NK, Hikal AH, Wyandt CM, Beer DC, Miller MG, Jones AB (1997) Sustained release of acetaminophen from heterogeneous matrix tablets: influence of polymer ratio polymer loading and coactive on drug release. Pharm Dev Technol 2:161–170

Fu J, Wang X, Xu L, Meng J, Weng Y, Li G, He H, Tang X (2011) Preparation and in vitro-in vivo evaluation of double layer coated and matrix sustained release pellet formulations of diclofenac potassium. Int J Pharm 15:84–90

Gaikwad SS, Thombre SK, Kale YK, Gondkar SB, Darekar AB (2014) Design and in vitro characterization of buccoadhesive tablets of timolol maleate. Drug Dev Ind Pharm 40:680–690

Gao P, Nie X, Zou M, Shi Y, Cheng G (2011) Recent advances in materials for extended-release antibiotic delivery system. J Antibiot (Tokyo) 64:625–634

Gohel MC, Parikh RK, Nagori SA, Dabhi MR (2008) Design of a potential colonic drug delivery system of mesalamine. Pharm Dev Technol 13:444–456

Hamza YS, Aburahma MH (2010) Innovation of novel sustained release compression-coated tablets for lornoxicam: formulation and in vitro investigations. Drug Dev Ind Pharm 36:337–349

Kuksal A, Tiwary AK, Jain NK, Jain S (2006) Formulation and in vitro, in vivo evaluation of extended- release matrix tablet of zidovudine: influence of combination of hydrophilic and hydrophobic matrix formers. AAPS PharmSciTech 3:E1

Lopes CM, Sousa Lobo JM, Costa P, Pinto JF (2006) Directly compressed mini matrix tablets containing ibuprofen: preparation and evaluation of sustained release. Drug Dev Ind Pharm 32:95–106

Love BL, Miller AD (2012) Extended-release mesalamine granules for ulcerative colitis. Ann Pharmacother 46:1529–1536

Mehta R, Chawla A, Sharma P, Pawar P (2013) Formulation and in vitro evaluation of Eudragir S-100 coated naproxen matrix tablets for colon-targeted drug delivery system. J Adv Pharm Technol Res 4:31–41

Meier M, John E, Wieckhusen D, Wirth W, Peukert W (2008) Characterization of the grinding behavior in a single particle impact device: studies on pharmaceutical powders. Eur J Pharm Sci 10:45–55

Mooter GV (2006) Colon drug delivery. Expert Opin Drug Deliv 3:111–125

Mundargi RC, Patil SA, Agnihotri SA, Aminabhavi TM (2007) Development of polysaccharide based colon targeted drug delivery systems for the treatment of amoebiasis. Drug Dev Ind Pharm 33:255–264

Patel MM, Shah TJ, Amin AF, Shah NN (2009) Design, development and optimization of a novel time and pH-dependent colon targeted drug delivery system. Pharm Dev Technol 14:62–69

Patra CN, Kumar AB, Pandit HK, Singh SP, Devi MV (2007) Design and evaluation of sustained release bilayer tablets of propranolol hydrochloride. Acta Pharm 57:479–489

Sangalli ME, Maroni A, Foppoli A, Zema L, Giordano F, Gazzaniga A (2004) Different HPMC viscosity grades as coating agents for an oral time and/or site-controlled delivery system: a study on process parameters and in vitro performances. Eur J Pharm Sci 22:469–476

Singh BN (2007) Modified-release solid formulations for colonic delivery. Recent Pat Drug Deliv Formul 1:53–63

Vassallo M, Camilleri M, Phillips SF, Brown ML, Chapman NJ, Thomforde GM (1992) Transit though the proximal colon influences stool weight in the irritable bowel syndrome. Gastroenterology 102:102–108

Von der, Camilleri OM, Kvols LK, Thomforde GM (1993) Motor dysfunction of the small bowel and colon in patients with the carcinoid syndrome and diarrhea. N Engl J Med 329:1073–1077

Wadher KJ, Kakde RB, Umekar MJ (2011) Formulation and evaluation of a sustained–release tablets of metformin hydrochloride using hydrophilic synthetic and hydrophilic natural polymers. Indian J Pharm Sci 73:208–215

Acknowledgments

All authors (P.K. Pawar, C. Gautam) declare that they have no conflict of interest. The author thanks to Dr. Madhu Chitkara, vice chancellor, Chitkara University Punjab for financial and infrastructure support for the project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pawar, P.K., Gautam, C. Design, optimization and evaluation of mesalamine matrix tablet for colon drug delivery system. Journal of Pharmaceutical Investigation 46, 67–78 (2016). https://doi.org/10.1007/s40005-015-0214-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40005-015-0214-z