Abstract

Natural dyes extracted from the flower of rose and red cabbage were immobilized on filter paper as carrier to prepare a colorimetric sensor for application in intelligent packaging. Indicator sensor was based on natural flavonoids (anthocyanins) extracted from red cabbage and rose whose colour changed from red to green with increase in pH. On characterization of extracts by UV–Vis spectrophotometer, absorption maximum of 530 nm was observed which is ascribed to anthocyanin present in two extracts. The characteristics of sensor including response time, reproducibility, reversibility, stability towards light and the storage stability were also studied. Sensors were also kept in atmosphere of ammonia simulating total volatile basic nitrogen production which changed its colour from red to green with increase in pH. Since pH value of flesh foods concerns their freshness, the indicator sensor is expected to provide a convenient, non-destructive and visual method for flesh food spoilage in storage condition and also for the prediction of shelf life.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Until recent past, traditional methods were prevalent to determine the freshness and quality of food such as physicochemical (total volatile basic nitrogen (TVBN), ammonia, thiobarbituric acid-reactive substances (TBARS), etc.), sensory analysis and physical measurements (odour, texture and colour). Various methods based on microbiological criteria of food (total plate count), molecular methods (PCR, DNA microarray, etc.) and detection of metabolite concentration like ATP, glucose and derived compounds such as biogenic amines also provide an idea about the safety and quality of food [16]. But none of them provide real-time information about freshness and quality of food. Moreover, they are usually destructive and time-consuming and need extensive instrumentation and are not suitable for supermarkets.

But over the past decade, there has been increasing interest among scientific fraternity for development of different measures to ensure safety and quality of food [13]. Increasing demand for mildly preserved, minimally processed and ready-to-eat “fresher” foods along with the globalization of food business presents major challenges for food quality and safety. Therefore, there is special interest among food industry in developing a device that would be simple, non-invasive, non-destructive, natural and consumer friendly to evaluate real-time freshness and quality of food products. The answer to these questions is intelligent packaging.

According to EU [3], intelligent packaging contains a component that enables the monitoring of the condition of packaged food or the environment surrounding the food during transport and storage. Intelligent packaging is thus a system that provides the user with reliable and correct information on the conditions of the food, the environment and/or the packaging integrity. It is an extension of the communication function of traditional food packaging which communicates information to the consumer based on its ability to sense and record changes in the product or its environment.

Intelligent packaging in the form of indicator sensor is a major focus area. Different types of indicator solutions and carriers have been used to fabricate indicator sensors. A novel on-package indicator sensor containing methyl red was developed to determine the real-time freshness of broiler chicken cuts [5]. Curcumin [(1E, 6E)-1,7-bis (4-hydroxy-3-methoxyphenyl) hepta-1,6-3dione]-based indicator sensor was used to monitor production of TVBN in shrimp and spoilage prediction [6]. Mixture of bromothymol blue and phenol red was proposed for fabrication of indicator sensor for monitoring chicken meat spoilage responsive to TVBN released during storage [12]. Chitosan-based intelligent film mixed with anthocyanin was developed as fast pH–colorimetric device for spoilage detection of food based on pH variation [17].

Bromocresol green was used to monitor the production of TVBN and prediction of fish freshness by monitoring colour change during storage [10]. Myoglobin was used as indicator solution to monitor freshness of chicken broiler cuts [14]. An indicator sensor containing pH-sensitive dyes viz. bromothymol blue and methyl red was developed for monitoring freshness of intermediate-moisture dessert spoilage [8]. There are several researches where chemical indicator solutions have been used for fabricating indicator sensor, but very less work has been done on use of natural indicator solution for fabrication of indicator sensor to monitor the freshness and quality of food.

Flesh foods are more prone to spoilage and carry a major quantum of supermarkets and export. Thus, the present study was undertaken to develop an indicator solution capable of predicting flesh food spoilage and its integration into a suitable carrier to fabricate indicator sensor.

Materials and Methods

Selection of Natural Indicator Solution

Anthocyanins, a group of flavonoid commonly available in natural products and known to undergo pH-sensitive colour change, were selected as indicator solution of choice for fabrication of indicator sensor. Among the locally available sources, it is found in appreciable quantities in rose and red cabbage. Indicator solution was extracted from both sources for preparation of indicator sensor.

Extraction of Natural Indicator Solution from Red Cabbage and Rose

Anthocyanins were extracted from red cabbage and rose by the method of Metivier et al. [7] with suitable modification. Fifteen grams red cabbage was finely minced in pestle and mortar by adding 10 ml of 1 % HCl–methanol. The mixture was transferred in a centrifuge tube and kept overnight in refrigerator for extraction of anthocyanins. Next day, 5 ml of chloroform and 4 ml of distilled water were added to the mixture. It was then centrifuged for 30 min at 3000 rpm. Supernatant thus obtained was transferred to an amber coloured bottle and kept in refrigerator for future use.

Determination of Absorption Spectra of the Indicator Solution to Validate Extraction Procedure

The absorption spectra of indicator solutions were studied in a UV–Vis spectrophotometer (Beckmann 640, USA) for determining the wavelength and absorbance responsible for difference in the colour of indicator solutions. The absorption spectra of extracted solutions were correlated with the available absorption spectra of anthocyanins to validate extraction process.

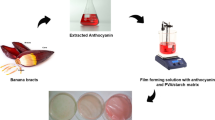

Fabrication of Indicator Solution Over Indicator Carrier

Agarose solution (4.5 %) was prepared in 10 ml of distilled water by heating in a microwave oven for 30 s. Five ml of indicator solution (anthocyanin) was added to the solution just before solidification, and the mixture was shaken well to completely mix the indicator solution with agarose. The mixture was then poured into a petri dish of 100 mm diameter and allowed to solidify at refrigeration temperature. A 2 cm × 2 cm strip was cut and packed in cling film to prepare indicator sensor (gel type).

Another type of indicator sensor using filter paper as carrier was also prepared. Filter paper no. 42 was made into strips having dimensions of 1.5 cm × 5 cm and centrifuged in indicator solution at 3000 rpm for 15 min and dried overnight at 60 °C. It was packaged in cling film and sealed to make indicator sensor (strip type).

Evaluation of Indicator Sensor in a Simulated Condition

Indicator sensors were assessed for their response in a simulated indicator metabolite reactive model system. Fifty milligrams (55 µl, 91 %) of ammonia (quantity similar to that produced in meat during storage) solution was taken in a transparent polyethylene terephthalate (PET) bottle of 150 ml. The indicator sensor was attached to the inner side of the lid of PET bottle. The bottle was closed, keeping the indicator sensor in atmosphere of ammonia, thus simulating the condition for volatile basic nitrogen produced during the storage of meat.

Determination of TVBN Concentration in Flesh Food During Storage

Buffalo meat was selected as standard flesh food. To compare TVBN concentration of buffalo meat produced during storage period and amount of ammonia used in simulated condition, TVBN concentration of buffalo meat was analysed according to micro-diffusion technique of Pearson [11].

Shelf Life and Stability of Indicator Sensor

Stability and shelf life of indicator sensor was analysed by keeping the indicator sensor at refrigeration temperature for observing the changes, if any.

Results

Validation of Extraction Process

The absorption maxima of anthocyanins extracted from rose and cabbage were recorded around 530 nm (Figs. 1, 2). Absorption maxima of 524–534 nm were recorded for anthocyanins extracted from red cabbage [15]. Recording of similar observation confirmed the extraction protocol was proper. Further, absorption spectrum of indicator solution from red cabbage was higher than rose which confirmed that extract from red cabbage had higher amount of anthocyanins in indicator solution than rose. Hence, indicator solution from red cabbage was used for further experiments.

Colour Change in Indicator Sensor in Simulated Indicator Metabolite Reactive Model System

In atmosphere of ammonia, red colour of both indicator sensors (gel type and strip type) changed to green (Figs. 3, 4). The change in colour was due to conformational changes in anthocyanins caused by increased concentration of volatile basic metabolites (ammonia) which was due to degradation of anthocyanin at different pH [9]. The colour variations of anthocyanin were associated with the different chemical structures which were dependent on different chemical structure at different pH [4]. At acidic pH [1–3], the anthocyanin exists predominantly as flavylium cation which contributes to red and purple colours. In the pH range of 4–6, the quinoidal blue species are predominant. As the pH increase to 5–6, there is a decrease in the colour intensity and concentration of the flavylium cation, which undergoes hydration to produce colourless carbinol pseudobase and chalone, respectively. The equilibrium is shifted towards a purple quinoidal anhydrobase at pH < 7.0 and deep blue ionized anhydrobase at pH < 8.0. Further increase in pH gives light yellow chalcone. Anthocyanins have a range of different equilibrium forms depending on pH [1].

Comparison of Colour Change in Indicator Sensor with Increase in Amount of Volatile Bases in Stored Flesh Foods

Colour change in indicator sensor in simulated condition was compared with the amount of volatile base actually produced during storage of buffalo meat at refrigerated storage. The buffalo meat recorded TVBN concentration of 8.43 mg/100 g on day 1 of refrigerated storage, 11.03 mg/100 g on day 3, 13.65 mg/100 g on day 5, 15.40 mg/100 g on day 7 and 20.30 mg/100 g on day 9 of refrigerated storage. Since 50 mg of ammonia (55 µl, 91 %) was used to simulate production of volatile bases, the amount matched with the concentration of volatile bases produced in buffalo meat in actual refrigerated condition, if meat block of 500 g was supposed to be used for storage. In further course of storage period, the concentration of volatile bases increased, thus bypassing the concentration of 50 mg (55 µl, 91 %) of ammonia used in simulated conditions. During experimental studies, it was observed that minimum amount of ammonia required for colour change in indicator was recorded around 5 mg, which was nearly ten times lower concentration than used for observation of colour change in simulated condition. Moreover, seafood contains higher amount of TVBN than meat so that indicator sensor shall work better for such types of foods with higher sensitivity and specificity. Therefore, the developed indicator sensor has excellent sensitivity to monitor spoilage of flesh foods on real-time basis and can detect volatile bases in low concentration usually present in flesh foods, a necessary prerequisite for indicator sensor.

Shelf Life and Stability of Indicator Sensor

Indicator sensor kept in refrigerator for 4 weeks of time did not show any change in appearance. When it was used for the experimental purpose, similar results were observed as obtained with the freshly prepared indicator sensor. Thus, indicator sensor can be successfully kept for future use without any undesirable changes.

Discussion

On the basis of evaluation of indicator sensor in simulated indicator metabolite reactive model system, its use for monitoring food quality on real-time basis can be successfully made. The indicator sensor has important use in monitoring freshness of protein-rich food especially muscle foods like fish, meat and other seafoods. The test results indicated the ability of sensor in assessing food’s freshness, as colour change in anthocyanins, which is a manifestation of sensor response and spoilage of protein-rich food during storage follows a similar trend (when the sensor changed green from red, the quality of muscle food deteriorates). Since upper limit of TVBN for spoilage of beef was around 20 mg/100 g [2], the amount of ammonia used for evaluation of indicator sensor was very low as compared to that produced in meat, fish, shrimp and different molluscs commonly available in India (protein-rich food). Hence, indicator sensor can be successfully used to evaluate food quality on real-time basis.

Moreover, indicator sensor prepared from natural sources is free from any toxic effect even if consumed. The sensor may act as shelf-life-indicating device by mentioning the “best before” labelling, when attached to individual product units. This indicator sensor allows the food product to have an effective shelf life by permitting its quality and freshness to be monitored visually, consequently decreasing margins of error. It can also reduce the economic loss suffered by manufacturers due to spoilage of food during transport and storage as they can withdraw their product before it reaches to consumers and help to maintain their brand value in the market.

The development of indicator sensor provides an opportunity for further work in this aspect, to analyse response of indicator sensor in food system and to develop new indicator sensors with higher sensitivity and non-toxicity to consumers. Moreover, extraction process can be made more efficient to extract natural dye from its parent source. Anthocyanin from other sources and other natural solutions capable of response towards volatile bases can be tried to develop other types of indicator sensors. Development of indicator sensor responsive towards metabolites other than TVBN released from food can also be tried. Besides, process, methods and raw materials of developed indicator sensor can be altered to increase its sensitivity.

References

Bjroy O, Rayan S, Fossen T, Andersen OM (2009) Structural properties of anthocyanin: rearrangement of C-glycosyl-3-deoxy anthocyanidins in acidic aqueous solutions. J Agric Food Chem 57:6668–6677

Byun JS, Min JS, Kim IS, Kim JW, Chung MS, Lee M (2003) Comparison of indicators of microbial quality of meat during aerobic cold storage. J Food Prot 66:1733–1737

EC (2009) EU guidance to commission regulation on active and intelligent materials and articles intended to come into contact with food. European Commission

Kennedy KA, Waterhouse AL (2000) Analysis of pigmented high-molecular-grape phenolics using ion-pair, normal-phase high performance liquid chromatography. J Chromatogr 866:25–34

Kuswandi B, Jayus J, Oktaviana R, Abdullah A, Heng LY (2014) A novel on-package sticker sensor based on methyl red for real-time monitoring of broiler chicken cut freshness. Packag Technol Sci 27:69–81

Kuswandi B, Larasati TS, Abdullah A, Heng LY (2012) Real time monitoring of shrimp spoilage using on package sticker sensor based on natural dye of curcumin. Food Anal Methods 5:882–889

Metivier RP, Francis FJ, Clydesdale FM (1980) Solvent extraction of anthocyanin from wild pomace. J Food Sci 45:1099–1100

Nopwinyuwong A, Trevanich S, Suppakul P (2010) Development of a novel colorimetric indicator label for monitoring freshness of intermediate-moisture dessert spoilage. Talanta 81:1126–1132

Ovando AC, Hernández MLP, Hernandez MEP, Rodriguez JA, Vidal CAG (2009) Chemical studies of anthocyanins: a review. Food Chem 113:859–871

Pacquit A, Frisby J, Lau KT, Mclaughlin H, Quilty B, Diamond D (2007) Development of a smart packaging for monitoring of fish spoilage. Food Chem 102:466–470

Pearson D (1968) Methods related to protein breakdown. J Sci Food Agric 19(3):66–369

Rukchon C, Trevanich S, Jinkarn T, Suppaku P (2011) Volatile compounds as quality indicators of fresh chicken and possible application in intelligent packaging. In: 12th Asian Food Science Conference, Bangkok, Thailand

Smigic N, Djekic I, Tomasevic I, Miocinovic J, Gvozdevoni CR (2012) Implications of food safety measures on microbiological quality of raw and pasteurized milk. Food Control 25:728–731

Smolander M, Hurme E, Latva-Kala K, Luoma T, Alakomi HL, Ahvenainen R (2002) Myoglobin based indicators for the evaluation of freshness of unmarinated broiler cuts. Innov Food Sci Emerg 3:277–285

Xavier FM, Lopes TJ, Quadri MGN, Quadri MB (2008) Extraction of red cabbage anthocyanins: optimization of the operation conditions of the column process. Braz Arch Biol Technol 51:143–152

Xu Y, Cheung W, Winder CL, Goodacre R (2010) VOC based metabolic profiling for food spoilage detection with application to detect Salmonella typhimurium-contaminated pork. Anal Bioanal Chem 397:2439–2449

Yoshida CMP, Maceil VBV, Mendonca MED, Franco TT (2014) Chitosan biobased and intelligent films: monitoring pH variations. LWT food Sci Technol 55:83–89

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shukla, V., Kandeepan, G., Vishnuraj, M.R. et al. Anthocyanins Based Indicator Sensor for Intelligent Packaging Application. Agric Res 5, 205–209 (2016). https://doi.org/10.1007/s40003-016-0211-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40003-016-0211-0