Abstract

This study investigated the effect of extraction solvents on the concentrations of bioactive compounds in the colorant obtained from purple rice bran. Ten different solvents including 100% water (W), 100% W–HCl 95%, ethanol (EOH), 95% EOH–HCl, 50% EOH, 50% EOH–HCl, 95% methanol (MeOH), 95% MeOH–HCl, 50% MeOH, and 50% MeOH–HCl were used to extract the rice bran. Results indicated that the solvents had a significant effect on the concentrations of the bioactive compounds and visual color in the colorant. The 50% EOH–HCl and 50% MeOH–HCl showed the highest levels of cyanidin-3-O-glucoside, cyanidin-3-O-rutinoside, delphinidin, cyanidin, pelargonidin, and malvidin, total anthocyanins, (+)-catechin, caffeic, p-coumaric, ferulic, and total phenolic acids, whereas the highest level of gallic acid was observed when extracted using 50% EOH and 50% MeOH. The highest concentrations of the tocols, γ-oryzanol, zeaxanthin, lutein, and β-carotene were observed in the colorant extracted by 95% EOH. This suggests that aqueous alcohol with a small amount of HCl (0.1 N) was an effective solvent for extraction of purple rice bran and preparation of colorant containing high important compounds. This solvent has potential as an alternative bio-solvent for green extraction of functional colorants.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Currently, foods containing natural coloring agents have become popular in consumer markets, with increasing awareness of their long-term health benefits. Anthocyanins are a group of intensely colored pigments responsible for the red, purple, orange, and blue colors of many fruits, vegetables, and cereals [1, 2]. In the USA, anthocyanin pigments are now approved as a natural food colorant under categories that include fruits (21 CFR 73.250) and vegetables (21 CFR 73). Purple glutinous rice (Oryza sativa L.) bran contains abundant anthocyanin pigments [3]. The predominant anthocyanins include cyanidin-3-O-glucoside and peonidin-3-O-glucoside [4]. Bioactive compounds such as tocols, γ-oryzanol, and carotenoids also occur in very high amounts in the bran layer [5, 6]. These compounds are widely claimed to be beneficial to health. Epidemiological and in vitro studies indicated that anthocyanins have beneficial effects including antioxidant activity, anti-inflammatory, and hypoglycemic properties [7], and also other biological antimutagenic and anticarcinogenic activities [8]. However, in the extraction of anthocyanin, ethanol is preferred as a solvent since other solvents such as methanol is toxic [9]. The use of ethanol as a bio-solvent is also considered acceptable for extraction of products using natural methods because it is completely biodegradable [10]. However, the use of ethanol is limited because of the lower achieved color yield. To achieve the full potential of purple rice bran, development of new extraction processes using different solvents assisted by ohmic heating may result in higher anthocyanin and other bioactive compound concentrations. In ohmic heating, the electric energy applied induces the breakdown of the rice bran cell membranes (the electroporation effect), which enables mass transfer and release of intracellular compounds and consequently results in high yields of the valuable substances [6, 11]. Similarly, ohmic heating was also use to increase the capability of solute diffusion throughout the cell membrane in the extraction processes [12]. Therefore, the efficiency of different solvents on the extraction of anthocyanins, other valuable bioactive compounds, color, and yield of colorant powder were investigated.

Materials and methods

Plant materials and chemicals

The rice bran of purple glutinous rice sample was purchased from a rice miller in Roi Et Province, Thailand. The bran sample preparation followed the method of Loypimai et al. [6].

Standards of cyanidin-3-O-glucoside chloride, delphinidin, pelargonidin, cyanidin, malvidin, cyanidin-3-O-rutinoside chloride, α-tocopherol, γ-tocopherol, δ-tocopherol, γ-tocotrienol, (+)-catechin, p-coumaric acid, syringic acid, zeaxanthin, and β-carotene, and maltodextrin (DE 4-7) were purchased from Sigma–Aldrich Chemical Co. (St. Louis, Mo, USA). Standard gallic, caffeic, and ferulic acids were obtained from Fluka Chemical (Buchi, Switzerland). HPLC grades of methanol, acetonitrile, n-butanol, and ethanol were purchased from BDH Chemicals Limited (Poole, UK). γ-Oryzanol standard was sourced from Tsuno Food Industrial Co., Ltd. (Wakayama, Japan).

Preparation of purple rice bran colorant powder (PCP) using different extraction solvents

The raw purple rice bran sample was ohmically heated following the optimal conditions reported by our previous studies ([5, 6] for more details). In brief, the moisture content of the rice bran (180 g) was adjusted to 40% (% wet basis) by adding deionized water, and then, it was heated by ohmic heating at 50 V/cm of electrical field strength. Immediately after heating, the bran sample was removed from the chamber and cooled to room temperature. The ohmically treated bran sample was then extracted using ten different solvents, with and without a small amount (1% v/v) of 0.1 N HCl following the method reported by Duangmal et al. [13] with some modifications. The solvents used were 100% water (W), 100% W–HCl, 95% ethanol (EOH), 95% EOH–HCl, 50% EOH, 50% EOH–HCl, 95% methanol (MeOH), 95% MeOH–HCl, 50% MeOH, and 50% MeOH–HCl. Each 20 g sample was extracted with 100 mL of solvent in a 250-mL Erlenmeyer flask. The samples were then processed to obtain purple rice bran colorant powder by following the method reported previously by Loypimai et al. [6]. In this study, the extraction process was validated by mixing standards (e.g., various phenolic compounds and anthocyanins) with ten extraction solvents and passed through the same extraction process before the experiment. The PCP samples obtained were weighed and calculated as % color yield by the following equation:

Anthocyanin analysis

The anthocyanins were extracted following the method of Sarkis et al. [14] and Loypimai et al. [6]. The supernatant was injected into the reverse phase high-performance liquid chromatography with a photodiode array detector (RP–HPLC–PDA) system for anthocyanin analysis. The HPLC was a Shimadzu (Kyoto, Japan), incorporating an LC-20AC series pumping system, SPD-M20A diode array detector, and SIL-10AD series autoinjector. Each extract sample was tested on an Apollo C18 (Alltech Associates, Deerfield, IL, USA) (∅4.6 mm × 250 mm, 5 μm) column protected with a guard column Inertsil ODS-3 (∅4.0 mm × 10 mm, 5 μm; GL Science Inc., Tokyo, Japan). Elution conditions followed those described by Durst and Wrolstad [15]. The mobile phase consisted of solvent A (acetonitrile, CH3CN) and solvent B (4% phosphoric acid, H3PO4) with the following gradient: 94–75% B from 0 to 65 min, 75–94% B from 65 to 70 min, and isocratic at 94% B from 70 to 75 min, to equilibrate the column for the next injection. Spectral data were recorded from 200 to 600 nm, and the anthocyanin chromatograms. Operating conditions were: column temperature 40 °C, injection volume 20 µL, and flow rate 1.0 mL/min. The total anthocyanin content of the PCP was calculated from the sum of each anthocyanin and converted as μg/g of colorant.

Determination of phenolic compound

The colorant powder extract was prepared according to Uzelac et al. [16]. The supernatant was passed through a 0.45-µm syringe filter before injection into the HPLC aperture. The extract preparation was performed in triplicate. Analysis of phenolic acids in the extract was carried out using a Shimadzu HPLC (LC-20AC pump) connected to a diode array detector (SPD-M20A) following the method reported by Butkhup et al. [17]. The separation was performed using an Apollo C18 (∅4.6 mm × 250 mm, 5 μm) column equipped with an Inertsil ODS-3 guard column (∅4.0 mm × 10 mm, 5 μm; GL Science Inc., Tokyo, Japan). The solvent system, operating conditions, and calculations followed the method reported by Loypimai et al. [11].

The total phenolic contents (TPC) were determined according to Iqbal et al. [18] and calculated as gallic acid equivalent in microgram (µg GAE) per gram (g) of PCP.

Determination of tocols and γ-oryzanol

The colorant sample (1.0 g) was extracted twice with 5.0 mL of methanol at a ratio of 1:10 (w/v) [6]. The tocols α-tocopherol, γ-tocopherol, δ-tocopherol, γ-tocotrienol, and γ-oryzanol in the extract were identified and quantified by reverse phase HPLC with PDA system following the method reported previously by Gimeno et al. [19] with slight modifications. The HPLC system consisted of an autosampler (Shimadzu CL-10), photodiode array (PDA) detector, and column oven equipped with a Phenomenex C18 (Phenomenex Inc, CA, USA) (∅4.6 mm × 150 mm, 4 µm) column. The gradient applied was methanol, water, and 1-butanol [92:4:4, (%v/v)] at a flow rate of 1.0 mL/min for 12 min. The mobile phase was then changed to methanol:water:1-butanol [92:3:5, (%v/v)] with a flow rate of 1.5 mL/min for 25 min. Injection volume was 20 µL at a column temperature of 40 °C. The peak was identified by comparison of retention time and UV spectra at 292 nm for α-tocopherol, δ-tocopherol, γ-tocopherol, and γ-tocotrienol and at 325 nm for γ-oryzanol for each standard.

Determination of carotenoids

The method of Nhung et al. [20] was adapted to extract carotenoids from the PCP sample. The supernatant was passed through a 0.45-µm nylon filter prior to analysis. Carotenoid compositions in the PCP extracts were analyzed using a Shimadzu HPLC system equipped with UV–Vis photodiode array detector (PDA) scanning from 200 to 600 nm, and an autosampler (Shimadzu LC-20AC). Separation of carotenoids was performed using a C18 column (Phenomenex, ∅4.6 mm × 150 mm, 4 µm) and maintained at 40 °C. Mobile phases consisted of water (solvent A) and methanol (solvent B), according to Pereira-Caro et al. [21]. The solvent gradient program and carotenoid identification were performed according to Loypimai et al. [11].

Visual color analysis

A color meter (CR-300, Minolta Co., Ltd., Tokyo, Japan) was used to measure the PCP obtained from different solvent extractions following the method of Loypimai et al. [6]. The results were expressed as Hunter color values of L*, a*, and b*. The L* represents lightness (L* = 0 yields black and L* = 100 indicates diffuse white). The chroma (C*) represents color intensity, which is the distance of a color from the origin (a* = b* = 0) in the a* and b* plane. Hue angle (h°) expressed in degrees ranges from 0° to 360°, where 0° (red) is located on the +a* axis, then rotating anticlockwise to 90° (yellow) for the +b* axis, 180° (green) for −a*, and 270° (blue) for −b*.

Statistical analysis

Analytical data were reported as mean values and standard deviations (SD) of three independent extractions for each replication. Statistical software (SPSS program) was used to perform a one-way analysis of variance (ANOVA). Means were compared using Duncan’s multiple range tests. Differences with p < 0.05 were considered significant.

Results and discussion

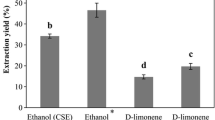

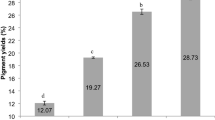

Extraction yield of PCP

The extraction solvents that were used had a significant effect on the yield of the PCP (p < 0.05) (Fig. 1). Overall, the PCP extraction by all solvents that included HCl gave a higher yield than those without HCl. Results showed that anthocyanin pigments are highly stable in acid conditions because their functional properties and chemical structure have greater stability [22, 23]. Anthocyanins are stable at pH values between 1 and 3, but at pH > 4 the structure becomes unstable and may undergo transformation. Acid conditions may also support the ability of maltodextrin (used as a binder and stabilizer for the preparation of the PCP) to reduce reactant mobility and prevent the change of state from powder to a sorption gel as reported by Chronakis [24]. Flavylium cation forms of anthocyanins combine with dextrin fractions to protect their transformation to other less stable forms [25]. They could form a denser and more oxygen-impermeable wall system, indicating better storage stability for pigments [22]. This could be the reason for the increase in the extraction yield of PCP obtained from acidified solvents.

Anthocyanins

The anthocyanins responsible for the purple–dark color in purple rice distributed in the aleurone and pericarp layers of the purple rice bran fraction are major valuable compounds [3]. Six anthocyanins, namely cyanidin-3-O-glucoside (Cy-3-glu), cyanidin-3-O-rutinoside (Cy-3-rut), delphinidin (De), cyanidin (Cy), pelargonidin (Pe), and malvidin (Mv), were found in raw purple rice bran (untreated rice bran) and in PCP (Fig. 2A, B). The main anthocyanin present in both the raw purple rice bran and the PCP was Cy-3-glu at 1838.3 and 764.1–6706.4 µg/g, respectively (Table 1). Interestingly, the concentrations of both Cy-3-glu and total anthocyanins in the PCP were three to four times higher than in the raw purple rice bran. This result was in accordance with the results reported by Nontasan et al. [26] who demonstrated that total anthocyanin content (9.48, mg/g) in the colorant powder obtained from purple rice bran by enzymatic extraction had a threefold increase compared with raw purple rice bran. Cy-3-glu was the major anthocyanin, often constituting over 90% of the total rice bran anthocyanins [4] whereas [27] reported that purple rice bran anthocyanin extraction comprised only three types as Cy-3-glu, Cy-3-gal, and Pe-3-glu.

HPLC chromatogram of anthocyanin standards (A) and anthocyanins in purple rice bran colorant powder extracted by 50% EOH–HCl (B). Peak: (1) cyanidin-3-O-glucoside (Cy-3-glu), (2) cyanidin-3-O-rutinoside (Cy-3-rut), (3) delphinidin (De), (4) cyaniding (Cy), (5) pelargonidin (Pe), and (6) malvidin (Mv)

The solvents used had a significant effect on the extraction of anthocyanins from PCP (p < 0.05) (Table 1). Solvents 50% EOH–HCl and 50% MeOH–HCl showed the greatest capability of extracting each anthocyanin and total anthocyanin concentration. This may be due to the different solubility of purple rice bran anthocyanins in water and alcohol, related to the hydroxyl (OH) or hydrogen (H) groups at the 3′, 4′, and 5′ bonds within their molecular structures. Higher solubility of anthocyanins in EOH and MeOH can be explained by the existence of two OH groups in the cyanidin molecular structure [28]. Addition of HCl assisted with the hydrolysis of glycons from the flavylium ion of the anthocyanin structure which released the major anthocyanidins (aglycons). Generally, anthocyanins are naturally polar compounds; therefore, their recovery is more effective in solvents of similar polarity. Similar results were observed by Sharifi and Hassani [29] who reported that the maximum extraction of anthocyanins from barberry was achieved with a mixture of EOH and MeOH solvent. Lapornik et al. [30] found that MeOH showed better characteristics as a solvent for polyphenols and anthocyanins than EOH. However, EOH and MeOH are not efficient in cell wall and seed breakdown, which have nonpolar characteristics and limit the release of anthocyanin and other polyphenols from cells. In this study, the purple bran sample was ohmically treated before solvent extractions to increase solvent extractability. The characteristics of MeOH and EOH relative to water are similar to anthocyanin pigments. Therefore, an aqueous mixture of acidified MeOH or EOH enhanced their effectiveness in penetrating the aleurone cells and other areas of rice bran tissue, resulting in higher anthocyanin extraction. However, EOH is more acceptable than MeOH as an extraction solvent for anthocyanin pigments in both functional food products and within the food industry.

Phenolic compounds

Extraction using diverse solvents with different polarities significantly affected the yield of phenolic compounds (p < 0.05). Solvents 50% EOH and 50% MeOH with/without HCl gave significantly highest extraction of (+)-catechin, caffeic, p-coumaric, and ferulic acids (p < 0.05), ranging from 226.1 to 232.0, 237.3 to 245.9, 169.7 to 173.8, and 826.8 to 831.9 µg/g, respectively (Table 2). Similarly, the highest total phenolic concentration was observed in PCP extracted using 50% EOH (339.7 µg GAE/g) and 50% EOH–HCl (351.9 µg GAE/g). The aqueous mixtures of EOH and MeOH were more efficient at dissolving phenolics in purple rice bran than water, EOH, and MeOH alone. The efficiencies of solvent used depended on system polarity according to Tatiya et al. [31]. They arranged the different polarities of ten extraction solvents in the following order (starting from the lowest polar solvents): 95% EOH < 95% EOH–HCl < 95% MeOH < 95% MeOH–HCl < 50% EOH < 50% EOH–HCl < 50% MeOH < 50% MeOH–HCl < 100% W < 100% W–HCl. This result agreed with [30] who reported extraction of red and purple polyphenols with EOH or MeOH at double the extraction with water. Tatiya et al. [31] found that acetone–water (70%) and EOH–W (50%) were the most efficient solvents for polyphenolic extraction from stem bark of B. retusa Spreng. Similarly, [32] noted that adding water to EOH increased the extraction rate, but too much water resulted in increased concomitant extraction of other compounds with unwanted lower phenolic compounds in the extract. In contrast, [33] reported that aqueous MeOH (80:20 MeOH:W v/v) solvent was more efficient than aqueous or pure EOH, giving higher recovery of total phenolics from Pakistani rice extract. Solvents such as MeOH, EOH, acetone, propanol, and ethyl acetate have been widely used for extracting phenolics from fresh products [34].

Ohmic heat treatment of purple rice bran before extraction enhances the extraction process as discussed earlier. Previous studies by Loypimai et al. [5], and Loypimai et al. [6] found that ohmically treated rice bran with moisture addition gave higher amounts of extracted phenolic compounds than either untreated or steamed rice bran. In particular extraction processes, ohmic heating has been used to increase the efficiency of solute diffusion throughout the membrane resulting in a better quality product [12]. This phenomenon may be one reason for the increase in phenolic compounds extracted by the aqueous mixture of EOH. Other factors such as the chemical nature of phenolic compounds, the extraction method employed, the sample particle size, and the presence of interfering substances also affect the efficiency of the extraction methods.

Tocols and γ-oryzanol

The four major tocopherols in raw purple rice bran were γ-tocopherol (245.3 µg/g), γ-tocotrienol (187.6 µg/g), α-tocopherol (63.25 µg/g), and δ-tocopherol (31.10 µg/g) (Table 3), with also very high γ-oryzanol (1109.8 µg/g). After extraction of PCP, 95% EOH showed significantly highest tocols and γ-oryzanol concentrations (p < 0.05). There was a fivefold increase in γ-oryzanol concentration compared with the raw purple rice bran. The γ-oryzanol content in PCP from solvent extractions was lower than reported by Nontasan et al. [26]. δ-tocopherol and γ-tocotrienol in PCP were extracted using MeOH, EOH, and their mixtures were detected, but these were not found in the colorant extracted using water. This result was significant in the use of purple rice bran as a functional food colorant. Tocols and γ-oryzanol are lipophilic compounds and enable dissolution with closing nonpolar solvents. This result may not relate to the types of solvent used, but to biological and chemical changes of the bran sample after ohmic heating such as cell rupture, tissue shrinkage, loss of air bubbles, and melting changes in membrane permeability. Extraction of tocols and γ-oryzanol by solvents increased after ohmic heating.

Carotenoids

In addition to major anthocyanins, tocols and γ-oryzanol, minor components of carotenoids such as β-carotene, lutein, and zeaxanthin were also detected (Table 4). Total carotenoid compounds in PCP were 30% of the total anthocyanin content. PCP extracted using MeOH, EOH, and their aqueous mixtures showed higher amounts of zeaxanthin and lutein than water alone. The highest quantity of zeaxanthin (240.5 µg/g), lutein (88.2 µg/g), and β-carotene (5.28 µg/g) was achieved using 95% EOH. Differences among the solvents indicated that the carotenoids in purple rice bran are lipophilic compounds represented as tocols and mainly located in the bran layer. This result was consistent with [21] and [35]. Previous reports indicated that the majority of the bioactive carotenoids in raw purple rice bran and purple–purple rice were zeaxanthin, β-carotene, and lutein [36]. Here, zeaxanthin and lutein were measured as the major carotenoids of both raw purple rice bran and PCP (Table 4). The variations of both types and concentrations of these carotenoids might be due to different cultivars of purple–purple rice, variable growing conditions, and the growing location.

Visual color

In color analysis, the L*, C*, and h° values of the PCP were significant differences between extraction solvents used (p < 0.05) (data not shown). The highest C* value was found in the PCP extracted using 50% EOH (12.3 ± 0.14), 50% EOH–HCl (13.8 ± 0.31), 50% MeOH (11.7 ± 0.28), and 50% MeOH (10.9 ± 0.27). This may be due to C* value positively correlated with anthocyanin content in the PCP. The results were in agreement with the previous studies: Mozetic et al. [37] reported that changes in C* values strongly correlated to changes in anthocyanin contents and associated with anthocyanin concentration. Duangmal et al. [13] mentioned that the degradation of a drink with roselle anthocyanin powder added was a high correlation to changes in L* and C*. Similarly, degradation of individual anthocyanin and total content was positively correlated with C*, and h° values and the C* value showed high correlation with Cy-3-glu (R 2 > 0.9342) and total anthocyanin contents (R 2 > 0.9211) [38]. According to this study, visual color especially C* may be considered as a parameter to estimate the anthocyanin content of the PCP. However, future studies are still needed to prove these suggestions.

In summary, this study demonstrated the presence of six anthocyanins, namely Cy-3-glu, Cy-3-rut, De, Cy, Pe, and Mv, in either raw purple rice bran or PCP. The solvents 50% EOH–HCl and 50% MeOH–HCl showed the greatest capacity for color yield extraction, the C* value, the extraction of individual anthocyanins, total anthocyanins, phenolic acids [catechin, (+)-caffeic, p-coumaric, and ferulic acids], and total phenolic acids. The highest concentrations of tocols, γ-oryzanol, zeaxanthin, lutein, and β-carotene were found in PCP extracted using 95% EOH. In addition, these results suggested that 50% acidified ethanol was the most effective solvent for the extraction of natural food colorant from purple rice bran. This solvent has potential as an alternative bio-solvent for ‘green’ extraction of functional colorant.

References

Castañeda-Ovando A, Lourdes Pacheco-Hernández MDL, Páez-Hernández ME, Rodríguez JA, Galán-Vidal CA (2009) Chemical studies of anthocyanins: a review. Food Chem 113:859–871. doi:10.1016/j.foodchem.2008.09.001

Harborne JB, William CA (1995) Anthocyanins and other flavonoids. Nat Prod Rep 12:639–657

Yawadio R, Tanimori S, Morita N (2007) Identification of phenolic compounds isolated from pigmented rice and their aldose reductase inhibitory activities. Food Chem 101:1616–1625. doi:10.1016/j.foodchem.2006.04.016

Jang S, Xu Z (2009) Lipophilic and hydrophilic antioxidants and their antioxidant activities in purple rice bran. J Agric Food Chem 57:858–862. doi:10.1021/jf803113c

Loypimai P, Moonggarm A, Chottanom P (2009) Effects of ohmic heating on lipase activity, bioactive compounds and antioxidant activity of rice bran. Aust J Basic Appl 3(4):3642–3652

Loypimai P, Moonggarm A, Chottanom P, Moontree T (2015) Ohmic heating-assisted extraction of anthocyanins from black rice bran to prepare a natural food colorant. Innov Food Sci Emerg 27:102–110. doi:10.1016/j.ifset.2014.12.009

Nam SH, Choi SP, Kang MY, Koh JH, Kozukue N, Friedman M (2006) Antioxidative activities of bran extracts from twenty one pigmented rice cultivars. Food Chem 94:613–620. doi:10.1016/j.foodchem.2004.12.010

Nam SH, Choi SP, Kang MY, Kozukue N, Friedman M (2005) Antioxidative, antimutagenic, and anticarcinogenic activities of rice bran extracts in chemical and cell assays. J Agric Food Chem 53:816–822. doi:10.1021/jf0490293

Patil SA, Surakasi VP, Koul S, Ijmulwar S, Vivek A, Shouche YS, Kapadnis BP (2009) Electricity generation using chocolate industry wastewater and its treatment in activated sludge based microbial fuel cell and analysis of developed microbial community in the anode chamber. Bioresour Technol 100:5132–5139

Chemat F, Vian AM, Cravotto G (2012) Green extraction of natural products: concept and principles. Int J Mol Sci 13:8615–8627. doi:10.3390/ijms13078615

Loypimai P, Moongngarm A, Chottanom P (2016) Phytochemicals and antioxidant capacity of natural food colorant prepared from black waxy rice bran. Food Biosci 15:34–41. doi:10.1016/j.fbio.2016.04.003

Puértolas E, Hernandez-Orte P, Sladana G, Alvarez I, Raso J (2010) Improvement of wine making process using pulsed electric fields at pilot-plant scale. Evolution of chromatic parameters and phenolic content of Cabernet Sauvignon red wines. Food Res Int 43(3):761–766. doi:10.1016/j.foodres.2009.11.005

Duangmal K, Saicheua B, Sueeprasan S (2008) Color evaluation of freeze-dried roselle extract as a natural food colorant in a model system of a drink. J LWT Food Sci Technol 41:1437–1445. doi:10.1016/j.lwt.2007.08.014

Sarkis JR, Jaeschke DP, Tessaro IC, Marczak LDF (2013) Effects of ohmic and conventional heating on anthocyanin degradation during the processing of blueberry pulp. J LWT Food Sci Technol 51:79–85. doi:10.1016/j.lwt.2012.1010.1024

Durst RW, Wrolstad RE (2001) Current protocols. In: Wrolstad RE (ed) Food analytical chemistry. Wiley, New York, pp 1–13

Uzelac DV, Pospišil J, Levaj B, Delonga K (2005) The study of phenolic profiles of raw apricots and apples and their purees by HPLC for the evaluation of apricot nectars and jams authenticity. Food Chem 91:373–383. doi:10.1016/j.foodchem.2004.09.004

Butkhup L, Jeenphakdee M, Jorjong S, Samappito S, Samappito W, Butimal J (2012) Phenolic composition and antioxidant activity of Thai and Eri Silk Sericins. Food Sci Biotechnol 21(2):389–398. doi:10.1007/s10068-10012-10050-10060

Iqbal S, Bhanger MI, Anwar F (2005) Antioxidant properties and components of some commercially available varieties of rice bran in Pakistan. Food Chem 93(2):265–272. doi:10.1016/j.foodchem.2004.09.024

Gimeno E, Castellote AI, Lamuela-Ravento RM, de la Torre-Boronat MC, Lopez-Sabater MC (2001) Rapid high-performance liquid chromatographic method for the simultaneous determination of retinol, alpha-tocopherol and beta-carotene in human plasma and low-density lipoproteins. J Chromatogr B Biomed Sci Appl 758(2):315–322

Nhung DTT, Bung PN, Nguyen TH, Phong TK (2010) Changes in lycopene and beta carotene contents in aril and oil of gac fruit during storage. Food Chem 121:326–331. doi:10.1016/j.foodchem.2009.12.032

Pereira-Caro G, Watanabe S, Crozier A, Fujimura T, Yokota T (2013) Phytochemical profile of a Japanese black–purple rice. Food Chem 141:2821–2827. doi:10.1016/j.foodchem.2013.05.100

Delgado-Vargas F, Paredes-López O (2003) Natural colorants for food and nutraceutical uses. CRC Press LLC, Boca Raton

Kong J, Chia L, Goh N, Chia T, Brouillard R (2003) Analysis and biological activities of anthocyanins. Phytochemistry 64:923–933. doi:10.1016/S0031-9422(03)00438-2

Chronakis IS (1998) On the molecular characteristics, compositional properties, and structural–functional mechanisms of motrodextrins: a review. Crit Rev Food Sci Nutr 38(7):599–637. doi:10.1080/10408699891274327

Chandra A, Nair MG, Iezzoni AF (1993) Isolation and stabilization of anthocyanins from tart cherries (Prunus cerasus L.). J Agric Food Chem 41(7):1062–1065. doi:10.1021/jf00031a009

Nontasan S, Moongngarm A, Deeseenthum S (2012) Application of functional colorant prepared from black rice bran in yogurt. APCBEE Procedia 2:62–67. doi:10.1016/j.apcbee.2012.06.012

Zhang X, Shen Y, Prinyawiwatkul W, King JM, Xu Z (2013) Comparison of the activities of hydrophilic anthocyanins and lipophilic tocols in black rice bran against lipid oxidation. Food Chem 141:111–116. doi:10.1016/j.foodchem.2013.03.0

Francis FJ (1989) Food colorants: anthocyanins. Crit Rev Food Sci Nutr 28(4):273–314

Sharifi A, Hassani B (2012) Extraction methods and stability of color extracted from barberry pigments. Int J Agric Sci 2(4):320–327

Lapornik B, Prosek M, Golc Wondra A (2005) Comparison of extracts prepared from plant by-products using different solvents and extraction time. J Food Eng 71(2):214–222. doi:10.1016/j.jfoodeng.2004.10.036

Tatiya AU, Tapadiya GG, Kotecha S, Surana SJ (2011) Effect of solvents on total phenolics, antioxidant and antimicrobial properties of Bridelia retusa Spreng. stem bark. Indian J Nat Prod Resour 2(4):442–447

Spigno G, Tramelli L, Fraveri DM (2007) Effects of extraction time, temperature and solvent on concentration and antioxidant activity of grape marc phenolics. J Food Eng 81(1):200–208. doi:10.1016/j.jfoodeng.2006.10.021

Zubair M, Anwar F (2012) Effect of extraction solvents on phenolics and antioxidant activity of selected varieties of Pakistani rice (Oryza sativa). Int J Agric Biol 14(6):935–940

Durlinga NE, Catchpolea OJ, Greya JB, Webbya RF, Mitchella KA, Foo LY, Perry NB (2007) Extraction of phenolics and essential oil from dried sage (Salvia officinalis) using ethanol–water mixtures. Food Chem 101(4):1417–1424. doi:10.1016/j.foodchem.2006.03.050

Kong S, Lee J (2010) Antioxidants in milling fractions of black rice cultivars. Food Chem 120:278–281. doi:10.1016/j.foodchem.2009.09.089

Frei M, Becker K (2005) Fatty acids and all-trans-β-carotene are correlated in differently colored rice landraces. J Sci Food Agric 85:2380–2384. doi:10.1002/jsfa.2263

Mozetic B, Trebse P, Simcic M, Hribar J (2004) Changes of anthocyanins and hydroxycinnamic acids affecting the skin colour during maturation of sweet cherries (Prunus avium L.). LWT Food Sci Technol 37:123–128. doi:10.1016/S0023-6438(03)00143-9

Loypimai P, Moongngarm A, Chottanom P (2016) Thermal and pH degradation kinetics of anthocyanins in natural food colorant prepared from black rice bran. J Food Sci Tech 53(1):461–470. doi:10.1007/s13197-015-2002-1

Acknowledgments

We thank Mahasarakham University and Bansomdejchaopraya Rajabhat University, Thailand, for providing facilities and financial support. The authors are also grateful to Prof. Ian Warrington for his valuable comments on the manuscript and English revision.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Loypimai, P., Moongngarm, A. & Chottanom, P. Extraction solvents affecting phytochemicals in food colorant prepared from purple glutinous rice bran. Appl Biol Chem 60, 181–189 (2017). https://doi.org/10.1007/s13765-017-0266-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13765-017-0266-z