Abstract

An analytical method for the simultaneous determination of flonicamid, imidacloprid, and its metabolites is established. The method developed herein uses a rapid extraction and cleanup procedure based on quick, easy, cheap, effective, rugged, and safe followed by liquid chromatography–tandem mass spectrometry. The effects of various experimental parameters, including extraction, salting-out agents, and purification sorbents, were investigated to optimize the sample-preparation method; the optimized method was then validated using fortified samples. Flonicamid, imidacloprid, and its metabolites spiked at three concentration levels: 0.05, 0.1, and 0.5 mg kg−1; the means of their recovery were determined by replicate analysis at each level. Under the conditions described, the mean recoveries of flonicamid, imidacloprid, and its metabolites were in the acceptable range 70–120 % with a satisfactory precision (RSD ≤20 %). This modified method provides improved recoveries of flonicamid metabolites and may be a useful analytical technique for the simultaneous determination of flonicamid, imidacloprid, and its metabolites in fruits and vegetables.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Flonicamid (N-cyanomethyl-4-trifluoromethylnicotinamide) and imidacloprid [1-(6-chloro-3-pyridylmethyl)-N-nitroimidazolidin-2-ylideneamine] belong to the class of systemic pesticides. Imidacloprid is the first member of neonicotinoid insecticides used against sucking pests such as aphids, whiteflies, and thrips. This pesticide acts as an agonist of the nicotinic acetylcholine receptors (which is the target of neonicotinoids) and has been widely used in agriculture owing to high insecticidal effectiveness (Tomizawa et al. 1995). Flonicamid, a pyridinecarboxamide compound, is a novel systemic pesticide for use against aphids and other sucking insects. This insecticide shows selective activity against similar insecticides that show cross-resistance. Because flonicamid’s mode of action does not involve the nicotinic acetylcholine receptor, and because flonicamid inhibits the feeding behavior of aphids, the use of this pesticide minimizes both the toxicity to beneficial arthropods and the development of cross-resistance in insects (Morita et al. 2007; Choi et al. 2009; Jansen et al. 2011).

When applied to crops, systemic pesticides reach the inner parts of the plant and convert into a variety of metabolites, many of which are toxic and show insecticidal activity. In case of flonicamid, the degradation of flonicamid produces several kinds of metabolites and some of these biologically active metabolites are retained to a considerable extent by plants and exhibit high toxicity (Son et al. 2013). In fact, this has resulted in a trade conflict in which paprika exported from the Republic of Korea to Japan contained levels of flonicamid residue that exceeded Japan’s maximum residue limit (MRL). The definition of the flonicamid MRL in the Republic of Korea is restricted to the parent compound, i.e., flonicamid, only; in contrast, in Japan, the MRL is based on the sum of flonicamid and its metabolites, 4-(trifluoromethyl)nicotinic acid (TFNA), and N-4-(trifluoromethyl)nicotinoyl glycine (TFNG) (KHIDI 2009; RDA 2012). Because the residue levels of flonicamid metabolites remain high for long periods, it is necessary to consider not only flonicamid but also the residual characteristics of its metabolites in the application of pesticides. Therefore, in 2010, the European Food Safety Authority (EFSA) established the definition of total flonicamid residue as the sum of the residual amount of the parent compound and its metabolites and has raised the MRL for flonicamid (EFSA 2010). Imidacloprid also converts into a variety of metabolites, imidacloprid-olefin, imidacloprid-guanidine, imidacloprid-urea, 6-chloronicotinic acid, in the inner parts of the plant (Sur and Stork 2003). These biologically active metabolites exhibit insecticidal activity and high toxicity to the honey bee. The application of imidacloprid poison honey bees through direct or oral contact with parent compound or its metabolites. The acute toxicity LD50 of imidacloprid to the bee is as high as 200 ng/bee and some of imidacloprid metabolites have higher toxicity than that of the parent compound (Nauen et al. 1998; Suchail et al. 2001; Bae et al. 2013). If the metabolites have a residual toxicity and are detected in significant amounts in crops, the safety of agricultural products is thrown into doubt. Therefore, it is essential that these metabolites are included in the residual analysis. However, the majority of analytical studies have focused on the parent compound and information about the determination of pesticide metabolites in crops is very limited. A reliable analytical method for the determination of these metabolites in fruits and vegetables is also needed.

Only a few analytical methods have been developed for the simultaneous determination of flonicamid, imidacloprid, and its metabolites in biological samples (Hengel and Miller 2007; Szczesniewski et al. 2009; Kamel 2010). However, the sample-preparation procedures in these methods are complex and time-consuming because of the multiple steps involving liquid–liquid extraction and cleanup by solid-phase extraction. In recent years, the QuEChERS method and its various versions have been used for the extraction of multiresidue pesticides from a variety of crops because of the simplicity and flexibility of sample preparation in this method (Anastassiades et al. 2003; Lehotay 2007; Lehotay et al. 2010). A few analytical methods for the determination of flonicamid, imidacloprid, and its metabolites in fruits and vegetables by using refined QuEChERS methods and LC–MS/MS have been developed (Lee et al. 2011; Xu et al. 2011). However, these methods show poor recoveries for the flonicamid metabolites, TFNG and TFNA.

In this study, a rapid analytical method for the simultaneous determination of flonicamid, imidacloprid, and its metabolites in crops was developed. This method, based on a QuEChERS procedure, was modified by optimizing the salting-out extraction and cleanup steps.

Materials and methods

Chemicals and standard solutions

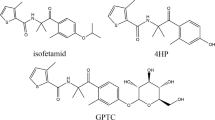

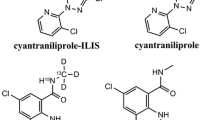

Flonicamid and its metabolites, TFNA, and TFNG, were obtained from Ishihara Sangyo Kaisha, Ltd. (Japan), and imidacloprid and its metabolites, imidacloprid-guanidine, imidacloprid-olefin, and imidacloprid-urea, were purchased from Dr. Ehrenstorfer (Germany) (Fig. 1). HPLC-grade acetonitrile was purchased from Merck (Merck KGaA, Germany). Formic acid (>98 % purity), anhydrous magnesium sulfate (MgSO4), and octadecysilane (C18) were purchased from Sigma-Aldrich (USA). The QuEChERS extraction salt package was purchased from Agilent Technologies (USA). Water was prepared using a Milli-Q reagent water system (Millipore, USA).

The individual stock standard solutions of the seven compounds (flonicamid, imidacloprid, and its five metabolites) were prepared in acetonitrile in a concentration of 100 mg/L. A multicompound intermediate standard solution was prepared via appropriate dilutions of the individual stock standards with acetonitrile; six mixed working solutions for calibration were prepared by several dilutions of the intermediate standard solution with acetonitrile. All the standard solutions were stored at −20 °C in a dark bottle before use.

LC–MS/MS analysis

Sample analysis was conducted using an LC–MS/MS instrument (AB SCIEX 3200 QTRAP mass spectrometer; Applied Biosystems, USA) coupled to an LC binary pump, an autosampler, and a degasser (Agilent 1200; Agilent, USA). The chromatographic separation was performed on a Kinetex C18 column (100 mm × 2.1 mm, 2.6-μm particle size; USA). The mobile phases A and B comprised water with 0.1 % formic acid and acetonitrile with 0.1 % formic acid, respectively. The initial mobile phase composition was 5 % B, which was held for 1 min, followed by a linear gradient of up to 60 % B in 5 min, and then was linearly increased to 95 % B in 5–10 min. The mobile phase gradient was programmed to the initial conditions at 10.1 min and was maintained at this proportion to 15 min. The flow rate was held constant at 0.2 mL/min throughout the entire process and 10 μL of the sample was injected.

Tandem mass spectrometric (MS/MS) analysis was operated in the positive electrospray ionization mode with a voltage of 5000 V at 500 °C. Nitrogen ion-source gases G1 and G2 were 40 and 45 psi, respectively, with a curtain gas at 25 psi. All the analytes were quantified using the multiple reaction-monitoring (MRM) mode. MRM transitions were monitored according to the parameters listed in Table 1. Analyst software version 1.5.1 from AB SCIEX was used for quantitation and confirmation calculations.

Sample preparation

Fresh fruit samples were chopped, mixed well, and then homogenized with dry ice using a high-speed blender (Artlon Gold Mix DA338-G, Korea) and stored at −20 °C until used for analysis. Extraction and cleanup were conducted using the QuEChERS method introduced by Lehotay et al. (2010) and modified as follows: Homogenized control samples (10 g) were fortified at appropriate concentrations and extracted with acetonitrile (10 mL) using a combi-shaker (N-BIOTEK, NB-101MT, Korea) at 250 rpm for 30 min. Anhydrous MgSO4 (4 g), NaCl (1 g), sodium citrate (1 g), and disodium citrate sesquihydrate (0.5 g) were added and the tube was shaken for 5 min, followed by 5 min of centrifugation at 3500 rpm. An aliquot of the MeCN phase (1 mL) was transferred to a 2-mL plastic centrifuge tube containing anhydrous MgSO4 (150 mg) and C18 (25 mg). After shaking vigorously on vortex for 30 s, the tube was centrifuged at 10,000 rpm for 5 min. The cleaned extracts were diluted to 1:1 with water and then filtered through a 0.2-µm PTFE syringe filter (Pall Corporation, USA) before injecting them into the LC–MS/MS.

Recovery experiment

To evaluate the validity of precision and accuracy of the developed method, the recovery studies were conducted at three concentration levels: 0.05, 0.1, and 0.5 mg kg−1. A homogenized control sample (10 g) was fortified with the standards of flonicamid, imidacloprid, and its metabolites in triplicate at each level. The samples were allowed to stand for 30 min prior to extraction and processed later according to the above extraction procedure and then analyzed by LC–MS/MS. This study was conducted under the same condition with 1 day for investigating inter-day precision and accuracy.

Results and discussion

Extraction and cleanup

The QuEChERS approach includes an extraction and partitioning step, followed by a dispersive solid-phase extraction procedure. This method is highly flexible with regard to the analyte properties and pH of the matrix, in addition to the amounts and types of solvent, salts, and sorbents. The QuEChERS method has recently been modified to produce its several different versions depending on the type of various experimental parameters used, including salts and sorbents. Different versions of QuEChERS based on the original unbuffered method and two modified versions, acetate-buffered version (AOAC Official Method 2007.01) and citrate-buffered version (CEN Standard Method EN15662), have been evaluated to improve the results and efficiency of the determination of a wide range of pesticides in crops. In particular, the QuEChERS method using salts that provide pH buffering on the matrix during extraction is widely used for certain pH-dependent pesticides (Lehotay et al. 2005; Lehotay 2007). Lehotay et al. found that the acetate-buffered method of QuEChERS afforded higher recoveries for the pH-dependent pesticides than the citrate-buffered version did (Lehotay et al. 2010). For this reason, and because of the polar properties of TFNG and TFNA, we initially performed the recovery assay of flonicamid, imidacloprid, and its metabolites by using the acetate-buffered method. The average recovery percentages of pesticides are listed in Table 2. Good extraction recoveries were obtained for flonicamid, imidacloprid, and imidacloprid metabolites, whereas TFNG and TFNA yielded low recoveries (5.5–51.0 and 3.1–18.0 %, respectively). Therefore, we investigated how the extraction and cleanup factors in sample preparation step affected the recovery of flonicamid metabolites, TFNG and TFNA.

Optimization of extraction conditions

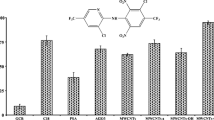

We conducted a comparison study of the three versions of QuEChERS (the original unbuffered method, acetate-buffered version, and citrate-buffered version) to determine the best method and the choice of salt type to afford high recoveries of TFNG and TFNA. The effect of salts in the QuEChERS partitioning step was investigated from the recovery studies of flonicamid metabolites in paprika by combining NaCl (unbuffered), sodium citrate (trisodium citrate dehydrate, disodium hydrogen citrate sesquihydrate; citrate-buffered), and NaOAc (acetate-buffered) with MgSO4. The mean recoveries of the target analytes at 0.1 mg/kg spiked level are presented in Fig. 2. In the case of NaCl and sodium citrate, acceptable high recoveries were obtained, while the mean recoveries of TFNG and TFNA were only 26.0 and 32.7 %, respectively, when NaOAc was added to MgSO4. These results demonstrate that the citrate buffer affords better and more consistent recoveries for two analytes than the other tested versions. The salts used herein are likely to be important for conducting the salting-out extraction of analytes from the aqueous layer to the organic layer. In addition, the pH in the partitioning step of the extraction procedure may have an impact on the recoveries of polar pesticides, TFNG and TFNA. Therefore, we selected the citrate-buffered version for high extraction efficiency of TFNG and TFNA and performed further investigation on the simultaneous determination of flonicamid, imidacloprid, and its metabolites.

Effect of salting-out agents on the recovery of flonicamid metabolites from fortified paprika samples (0.1 mg kg−1). Three types of salts were investigated for the extraction procedure of the recovery experiment. This experiment was repeated three times with similar results. Error bars indicate mean ± SD of three independent experiments

Optimization of cleanup procedure

Several pesticides that yielded poor recoveries with the QuEChERS method were affected by the interference effects of the salts, as well as by the absorption to the sorbents in the cleanup step (Chen et al. 2013; Liang et al. 2013). Kwon et al. (2011) reported that polar pesticides such as 2,4-D, 4-CPA, dicamba, MCPA, oxolinic acid, and triclopyr were completely unrecovered when the QuEChERS approach is used. These results were attributed to the QuEChERS sorbent PSA: because PSA exhibits binding activity with organic acids and polar compounds, it may affect pesticides containing carboxylic acid groups. In addition, Ko et al. (2014) found that TFNG and TFNA yielded poor recovery when PSA was used, because of their chemical structures containing carboxylic acid group. Therefore, we evaluated the effect of purification sorbents on the recoveries of TFNG and TFNA. Satisfactory results were achieved for two analytes when C18 were utilized. On the other hand, the use of PSA negatively affects the recoveries of TFNG and TFNA (Table 3). There were significant adverse effects on the recoveries of TFNG and TFNA when small quantities of PSA were used and the average recoveries were reduced as the amount of PSA increased. Moreover, we conducted a similar comparison study of recoveries using 0, 50, and 150 mg of MgSO4. The mean recoveries of the target analytes at the 0.1 mg/kg spiked level were 108.8, 101.1, and 83.8 % for TFNG; and 89.3, 94.1, and 97.0 % for TFNA, respectively. Using these results, we modified the QuEChERS method for the simultaneous determination of flonicamid, imidacloprid, and its metabolites to use the citrate buffer in the partitioning extraction step, followed by a cleanup procedure using MgSO4 and C18.

Method validation

For flonicamid, imidacloprid, and its metabolites, the matrix-matched calibration curves were obtained by plotting the peak area versus the concentration of the analytes in 0.005–1 µg/mL. The linearities are listed in Table 4. Satisfactory linearities with correlation coefficients (R 2) above 0.999 were achieved for all analytes. The LODs for flonicamid, imidacloprid, and its metabolites, calculated as signal-to-noise (S/N) ratio of 3, were estimated to be 5–10 ng/g (Table 4).

Recovery studies were conducted by using blank samples of paprika fortified at three different concentrations: 0.05, 0.1, and 0.5 mg kg−1 in three replicates. The results from the recovery experiment are listed in Table 5. For flonicamid, imidacloprid, and its metabolites, the mean recoveries ranged from 78.4 to 109.3 % with the RSDs of 0.2–6.2 % in paprika. Inter-day precision and accuracy were determined by total RSD and average recovery percent of three concentrations studies in each pesticide. The mean recoveries ranged from 84.0 to 100.0 % with the RSDs of 2.4–8.1 %. With this method, all the analytes showed acceptable results with a satisfactory accuracy and precision (RSD for precision better than 20 % and recovery values for accuracy between 70 and 120 %); these results demonstrate that the optimized method described herein is reliable for the analysis of flonicamid, imidacloprid, and its metabolites in crops.

Method application

The method developed herein was applied to real samples of different fruits and vegetables collected from field sites. One samples each of apple, cucumber, pear, red pepper, and strawberry, for which MRLs for flonicamid have been established, were chosen (KFDA 2014). These field samples, which were confirmed as flonicamid and imidacloprid-free products based on pesticide-residue analysis, were used as the control sample. Each of the matrix-matched calibrations was settled on depending on the matrix and recovery experiments were conducted at three different concentrations: 0.05, 0.1, and 0.5 mg kg−1. The recoveries of all the analytes in the five samples were in the accepted range with relative standard deviations of <20: 78.9–105.8 % in apple, 88.1–111.5 % in cucumber, 72.5–107.8 % in pear, 79.5–113.1 % in red pepper, and 86.8–105.6 % in strawberry (Table 6). These results demonstrate that this optimized analytical method can also yield satisfactory recovery and precision in the analysis of flonicamid and its metabolites present in fruits and vegetables other than paprika.

We have developed a modified QuEChERS procedure coupled with LC–MS/MS for the simultaneous analysis of flonicamid, imidacloprid, and its metabolite residues in paprika. By investigating the effect of various experimental parameters, we were able to optimize the sample-preparation method, including extraction, salting-out agents, and purification sorbents. This method was validated with fortified samples and good precision and accuracy were obtained. Traditional analytical methods for flonicamid and imidacloprid also had a acceptable validation data (Hengel and Miller 2007; Szczesniewski et al. 2009; Kamel 2010). However, the sample-preparation procedures in these methods are complex and time-consuming because of the multiple steps involving liquid–liquid extraction and cleanup by solid-phase extraction. Compared with these methods, the preparation procedure in modified QuEChERS method was very rapid and simple. So QuEChERS method was thought to be a very useful method.

For the safe use of pesticides, it is essential that accurate analysis and management, both of the parent compound and its metabolites, is carried out. In addition, it is important to understand the residual characteristics of pesticides and their metabolites. Thus, we are currently investigating the residual patterns of flonicamid and imidacloprid in paprika by using the results obtained by comparing the residual amount of flonicamid, imidacloprid, and its metabolites in each part of the crop. Pesticide metabolites such as flonicamid metabolites remain in plants a long-period time and exhibit lasting toxicity. At present, however, studies on the residue level and toxicity of metabolites have been limited. The method developed and described herein may constitute a powerful tool to unravel the long-term fate of pesticide metabolites and would facilitate the safety evaluation of the pesticide.

References

Anastassiades M, Lehotay SJ, Stajnbaher D, Schenck FJ (2003) Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “dispersive solid-phase extraction” for the determination of pesticide residues in produce. J AOAC Int 86:412–431

Bae CH, Cho KW, Kim YS, Park HJ, Shin KS, Park YK, Lee KS (2013) Honeybee toxicity by residues on tomato foliage of systemic insecticides applied to the soil. Korean J Pestic Sci 17(3):178–183

Chen M, Collins EM, Tao L, Lu C (2013) Simultaneous determination of residues in pollen and high-fructose corn syrup from eight neonicotinoid insecticides by liquid chromatography–tandem mass spectrometry. Anal Bioanal Chem 405:9251–9264

Choi MY, Kim JH, Kim HY, Byeon YW, Lee YH (2009) Biological control based IPM of insect pests on sweet pepper in greenhouse in summer. Korean J Appl Entomol 48(4):503–508

European Food Safety Authority (2010) Reasoned opinion modification of the existing MRLs for flonicamid in various crops. Summ EFSA J 8:1610

Hengel MJ, Miller M (2007) Analysis of flonicamid and its metabolites in dried hops by liquid chromatography–tandem mass spectrometry. J Agric Food Chem 55:8033–8039

Jansen JP, Defrance T, Warnier AM (2011) Side effects of flonicamid and pymetrozine on five aphid natural enemy species. Biocontrol 56:757–770

Kamel A (2010) Refined methodology for the determination of neonicotinoid pesticides and their metabolites in Honey Bees and Bee products by liquid chromatography–tandem mass spectrometry (LC–MS/MS). J Agric Food Chem 58(10):5926–5931

Ko AY, Abd El-Aty AM, Musfiqur Rahman Md, Jang J, Kim SW, Choi JH, Shim JH (2014) A modified QuEChERS method for simultaneous determination of flonicamid and its metabolites in paprika using tandem mass spectrometry. Food Chem 157:413–420

Korea Food and Drug Administration (2014) MRLs for pesticides in food. <http://fse.foodnara.go.kr/residue/pesticides/pesticides_info.jsp>

Korea Health Industry Development Institute (2009) MRLs for pesticides in foods

Kwon HY, Kim CS, Park BJ, Jin YD, Son KA, Hong SM, Lee JB, Im GJ (2011) Multiresidue analysis of 240 pesticides in apple and lettuce by QuEChERS sample preparation and HPLC–MS/MS analysis. Korean J Pestic Sci 15(4):417–433

Lee SW, Choi JH, Cho SK, Yu HA, Abd El-Aty AM, Shim JH (2011) Development of a new QuEChERS method based on dry ice for the determination of 168 pesticides in paprika using tandem mass spectrometry. J Chromatogr A 1218:4366–4377

Lehotay SJ (2007) Determination of pesticide residues in foods by acetonitrile extraction and partitioning with magnesium sulfate: collaborative study. J AOAC Int 90(2):485–520

Lehotay SJ, Mastovská K, Lightfield AR (2005) Use of buffering and other means to improve results of problematic pesticides in a fast and easy method for residue analysis of fruits and vegetables. J AOAC Int 88(2):615–629

Lehotay SJ, Son KA, Kwon HY, Koesukwiwat U, Fu W, Mastovska K, Hoh E, Leepipatpiboon N (2010) Comparison of QuEChERS sample preparation methods for the analysis of pesticide residues in fruits and vegetables. J Chromatogr A 1217:2548–2560

Liang X, Liu X, Dong F, Xu J, Qin D, Li Y, Tian Y, Zhang Y, Han Y, Zheng Y (2013) Simultaneous determination of pyrimethanil, cyprodinil, mepanipyrim and its metabolite in fresh and home-processed fruit and vegetables by a QuEChERS method coupled with UPLC–MS/MS. Food Addit Contam Part A 30(4):713–721

Morita M, Ueda T, Yoneda T, Koyanagi T, Haga T (2007) Flonicamid, a novel insecticide with a rapid inhibitory effect on aphid feeding. Pest Manag Sci 63:969–973

Nauen R, Tietjen K, Wanger K, Elbert A (1998) Efficacy of plant metabolites of imidacloprid against Myzus persicae and Aphis gossypii (Homoptera : Aphididae). Pestic Sci 52:53–57

Rural Development Administration (2012) Safe pesticide application manual for exporting agricultural products

Son KA, Kwon HY, Jin YD, Park BJ, Kim JB, Park JH, Kim TK, Im GJ, Lee KW (2013) The behaviour of residues of flonicamid and metabolites in sweet peppers. Korean J Pestic Sci 17(3):145–154

Suchail S, Guez D, Belzunces LP (2001) Discrepancy between acute and chronic toxicity induced by imidacloprid and its metabolites in Apis mellifera. Environ Toxicol Chem 20(11):2482–2486

Sur R, Stork A (2003) Uptake, translocation and metabolism of imidacloprid in plant. Sulltetin Insectol 56(1):35–40

Szczesniewski A, Culber E, Barry R (2009) Fast analysis of flonicamid and its metabolites in agricultural foods by RPLC–MS/MS. Available from: http://www.chem.agilent.com/Library/posters/Public/Fast.Analysis.of.Flonicamid.pdf

Tomizawa M, Otsuka H, Miyamoto T, Eldefrawi ME, Yamamoto I (1995) Pharmacological effects of imidacloprid and its related compounds on the nicotinic acetylcholine receptor with its ion channel form the torpedo electric organ. Pestic Sci 20:57–64

Xu Y, Shou LF, Wu YL (2011) Simultaneous determination of flonicamid and its metabolites in vegetables using QuEChERS and reverse-phase liquid chromatography–tandem mass spectrometry. J Chromatogr A 1218:6663–6666

Acknowledgments

This work was undertaken with the support of the Rural Development Administration (Grant No. PJ009185 and PJ010117).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seo, EK., Kwon, H., Hong, SM. et al. Simultaneous determination of flonicamid, imidacloprid, and its metabolites in paprika by QuEChERS and tandem mass spectrometry. J Korean Soc Appl Biol Chem 58, 603–610 (2015). https://doi.org/10.1007/s13765-015-0083-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13765-015-0083-1