Abstract

This contribution describes the indirect electrochemical oxidation of wastewater laden with bromothymol blue and methyl red dyes using a laboratory-scale electrochemical reactor with a Ti/Ru0.3Ti0.7O2 anode and stainless-steel cathode. The influence of current density, pH, and electrolyte concentrations on the oxidative degradation pattern of the dyes in the wastewater was also investigated by coupling the electrochemical reactor with an Ultraviolet–Visible spectrometer. By indirect oxidation, 97% of the bromothymol blue at 10 mA cm–2 current density and pH 3.0 and 98% of the methyl red at 2 mA cm–2 current density at pH 3.0 were indirectly oxidized in 10 min Initial concentrations of each were 200 ppm. During the degradation of the dyes, electrochemically generated chlorine and hypochlorite ions (OCl)– played pivotal roles. Under the aforementioned ideal circumstances, the minimum energy consumption values for bromothymol blue and methyl red were 0.2025 and 0.0636 kW h m–3, respectively. The anode exhibited an excellent service life for treating dye wastewater, and repeated tests and surface analysis revealed no evident passivation. In this way, a variety of dyes in effluents can be cheaply degraded by electrolyzing with a Ti/Ru0.3Ti0.7O2 anode, utilizing readily available electrolytes and with minimal electricity requirements.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is a vital natural resource and is a basic need of living organisms. Due to human activity, population increase, climate change, urbanization, and industrialization, water quality is deteriorating day by day. Life on Earth is currently seriously threatened by water contamination. Natural organic matter is the principal pollutant in surface waters that is used for both agriculture and drinking (Andersson et al. 2020), but it is not the only pollutant. A variety of industries, including textiles, leather, paper, plastic, pharmaceutical, ink, ceramics, and food processing, use dyes to color their products and increase their value (Donkadokula et al. 2020). Tons of synthetic organic dyes are produced each year, according to estimates (Chequer et al. 2013). Textiles account for a significant portion of the developing world’s industrial landscape. Large amounts of water are used in textile processing for washing and dyeing. As a result, textile manufacturers pollute water bodies with effluents that contain dyes employed at various stages of the textile manufacturing process. Dye-containing effluents are widely established to have a deleterious impact on aquatic bodies. Insoluble dyes have been shown to leave a residue color that is very resistant to biological activity (Rápó and Tonk 2021). Bromothymol blue (BTB) a type of sulfonphthalein dye is an unrestricted textile dye derivative and is used as a pH indicator (Steinegger et al. 2020; Maamar et al. 2015). BTB can damage target organs when exposed over an extended period since it can irritate the eyes, skin, and respiratory system, attack the lungs and mucous membranes, and cause respiratory tract infections (Prakash et al. 2018). The colouring of paper, textiles, leather, cosmetics, inks, ceramics, and food-processing goods uses azo dyes of the methyl red (MR) type (Cockerham et al. 2022). The presence of MR in aquatic bodies causes an aesthetic issue and may be harmful to public health due to the production of aromatic amines, which are thought to be mutagenic or carcinogenic when they are broken down. If eaten or inhaled, MR may irritate the digestive tract and sensitize the skin and eyes (Iqbal et al. 2022; Takkar et al. 2017).

Treatment of water contaminated with harmful chemicals such as dyes, herbicides, insecticides, pharmaceuticals, detergents, etc., is crucial since these substances pose a major threat to the local flora and wildlife (Al-Nuaim et al. 2023). Various methods including physical methods (adsorption, sedimentation floatation, etc.) (Kavindra et al. 2011; Zeb et al. 2020; Gul et al. 2022), chemical (Lin and Chen 1997), and biological processes (Takkar et al. 2017), are being employed for wastewater treatment. Other methods such as ozonation (Venkatesh et al. 2017), photocatalytic oxidation (Khan et al. 2020; Sartaj et al. 2020), and electrochemical oxidation (Hussain et al. 2021; Brito et al. 2018; Pieczyńska et al. 2019; Muhammad et al. 2020) are being employed by scientists which can be effective against textile dyes. Each of these approaches has distinct merits and demerits (Crini et al. 2019). Unfortunately, most of the treatments used currently use chemicals that are prohibitively expensive in most countries, have little effectiveness, and negatively impact the environment. Therefore, more sophisticated and economical water treatment technologies for desalination and water reuse are needed in order to boost water supplies. Green technologies have been emphasized as a long-term plan for preserving natural resources, lowering harmful effects on the environment, and accelerating social and economic development (Niknejad et al. 2023). In order to meet the growing demand for clean water and reduce adverse environmental effects, membrane-based technologies such as microfiltration, ultrafiltration, nano-filtration, and forward- and reverse-osmosis membranes are now being viewed as viable alternatives to traditional water and wastewater remediation techniques (Shehata et al. 2023). Although these technologies have many benefits, but they also have some significant drawbacks, such as expensive startup and high operating costs. Many water and wastewater treatment applications involve a variety of pollutants, such as pesticides and prescription medications that are challenging to eliminate using only physical, chemical, or biological methods. Due to their microscopic size, these contaminants are classified as micro-pollutants. They are very challenging to remove from water and wastewater using specific methods, in part because of their size alone. Advanced oxidation processes (AOP) are necessary for the removal of small-sized pollutants. These processes produce strong oxidizing agents, such as hydroxide (OH–) or its neutral variant, the hydroxyl radical (⦁OH), in sufficient quantities to degrade organic and some inorganic pollutants. These agents are produced by Ozone (O3), hydrogen peroxide (H2O2), and ultraviolet light (UV). Numerous advantages of AOP include its quick reaction times, small footprint, and ability to remove heavy metals, ability to convert organic materials in water into stable inorganic compounds like carbon dioxide and water, and lack of sludge production. It also does not introduce new hazardous substances into the water. AOP does, however, have certain drawbacks, such as relatively high startup and operating/maintenance costs, complex chemistry that necessitates customization to particular pollutants, and a problem with residual peroxide removal (Priyadarshini et al. 2022). The sequencing batch reactor (SBR) system is another useful method for treating landfill leachate and wastewater contaminants because of its cost-effectiveness, simplicity, tolerance to shock loads, and adaptability in terms of reaction time according to influent water quality. Long treatment cycles, frequent changes in the water’s entry and exit, and a high need for equipment automation are some drawbacks of SBR (Jagaba et al. 2021). For the treatment of wastewater, various other methods are used, each with advantages and disadvantages, including membrane filtration, membrane bioreactors, membrane PC-reactors, ballasted coagulation, sedimentation & filtration, sequencing batch bioreactors and sequencing batch PC-reactors, magnetic ion exchange (MIEX), coagulation, sedimentation and filtration, sequencing batch ion exchange, pre-ozonation, dissolved air flotation (DAF), and filtration (Wang and Wang 2023).

The electrochemical oxidation method either direct (Zeb et al. 2018) or indirect (Zhang et al. 2014) oxidation is a potentially green technology that is extensively used for the depletion of dyes and other contaminants from industrial or domestic wastewater. The electrochemical oxidation of dyes from wastewater has shown promising degradation results to eradicate these contaminants in a short period when compared to conventional methods (Rodríguez-Narváez et al. 2021; Wang et al. 2020; Pieczyńska et al. 2019; Martínez-Huitle and Panizza 2018). In the direct oxidation method, the pollutant is first adsorbed on the anode and then oxidized by a powerful oxidant such as the hydroxyl radical or chlorine/hypochlorite ion through the transmission of the anodic electron (Stupar et al. 2017; Zhang et al. 2014; Panizza and Cerisola 2009). Several research has been conducted based on the current literature to remove synthetic colored dyes from water using an electrochemical technique at various electrodes. The electrochemical decontamination of the dye Chromotrope 2R is carried out by Du et al. (2017) on a boron-doped diamond (BDD) anode. Fajardo et al. (2017) used individual or assembling of flow cells with Ti/Pt and Ti/Pt–SnSb anodes for the electrochemical abatement of amaranth dye solutions. Electrochemical degradation of methylene blue dye was carried out by Saadia et al. (2017) using the PbO2 electrode of a lead-acid battery, Indigo Carmine by Labiadh et al. (2017) using PbO2 and TiRuSnO2 anode, Acid yellow 36 by Aguilar et al. (2017) on Ir–Sn–Sb anode, etc.

Electrochemical degradation of methyl red has been reported by Ahmad et al. (2022) on zinc hydroxide and zinc oxide thin films and by Panizza and Cerisola (2008) on BDD and PbO2 anodes. Morais et al. (2013) studied the direct electrochemical degradation of methyl red using Ti/Ru0.3Ti 0.7O2 using cyclic voltammetry and achieved a total color removal by applying 20 and 30 mA cm−2 while, at 10 mA cm−2, only 78% was obtained. We did the indirect electrochemical degradation of the MR dye at Ti/Ru0.3Ti0.7O2 anode and achieved 99% color removal.

Maamar et al. (2015) report the electrochemical oxidation of Bromothymol blue in an aqueous medium (pH = 3) by the electro-Fenton process (EFP). Maamar and Bellakhal (2017) have reported the treatment of a Tunisian textile effluent containing BTB dye using anodic oxidation on a Boron-doped diamond electrode. In most of the literature, photocatalytic degradation of BTB is reported (Al-Asfar et al. 2018; Fui et al. 2016; Khan et al. 2016).

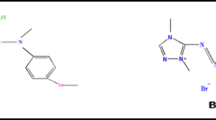

In the current study, BTB and MR (Fig. 1) were indirectly electrochemically oxidized (EO) by using a composite anode, Ti/Ru0.3Ti0.7O2, and a cathode made of stainless steel. The influence of several parameters such as the pH of the solution, current density, electrolyte concentration, and nature of supporting electrolyte during the process were assessed. To the best of our knowledge, a Ti/Ru0.3Ti0.7O2 anode has not previously been employed for the indirect electrochemical oxidative degradation of BTB and MR dyes from wastewater effluents. Seema Sartaj et al. 2020 have reported the use of a titanium ruthenium oxide anode for the electrochemical degradation of Allura red and erythrosine dyes. Our study significantly diverges from the reported work by addressing distinct dyes (bromothymol blue and methyl red), utilizing a Ti/Ru0.3Ti0.7O2 anode, and establishing novel optimal degradation conditions. The work of Seema Sartaj et al. 2020 is basically focused on comparing of Photolytic degradation and electrochemical degradation of two food dyes namely Allura red and Erythrosine, they applied statistical approaches to optimize the variables. Whereas our research emphasizes experimental optimization of electrochemically influence parameters for the degradation of pH indicator dyes (Bromothymol blue and methyl red). As current density, NaCl concentration and pH are fundamental parameters for any electrochemical process and both work study the influence of these variables. These aspects collectively delineate a considerable departure from the previous study, underscoring our contribution in advancing the understanding and practical application of electrochemical degradation processes for dye-laden wastewater treatment.

Date and location of the research:

A part of this research work was carried out in 2019 and due to COVID-19 closures, the remaining experimentation was carried out in 2020–21 at the Institute of Chemical Sciences, University of Peshawar Khyber-Pakhtunkhwa, Pakistan. Currently, in July 2023, some experiments were re-conducted at the Faculty of Materials and Chemical Engineering, Ghulam Ishaq Khan (GIK) Institute of Engineering Sciences and Technology Topi, Khyber-Pakhtunkhwa, Pakistan.

Materials and methods

Materials

All of the compounds were of analytical quality when they were received, and they were all used without any additional purification. BTB (> 95.0%), MR (> 95.0%), NaCl (> 99.5%), and Na2SO4 (> 99.0%) were purchased from Merck Millipore and NaNO3 (> 99.0%) and H2SO4 (97–98%) were from Sigma Aldrich.

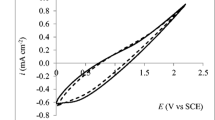

The titanium/ruthenium–titanium oxide, Ti/Ru0.3Ti0.7O2 composite electrode was obtained from De Nora Brazil. The electrode was electrochemically characterized using cyclic voltammetry and matched characterization first seen by co-authors of this article (Zeb et al. 2018).

Instruments used

A power supply DAZHENG DC model ps-303D, China was employed for the quantification of voltage and current, and a double beam UV–VIS spectrophotometer model UV 1602, USA was used to measure the concentration of the dyes.

Solutions preparations

All the solutions for the experiment were prepared in double distilled de-ionized water. To make a 200 ppm solution, 0.1 g each of the dyes BTB, and MR was dissolved in distilled water and then diluted up to 500 mL. This was used as a stock solution from which various samples of variable concentrations were prepared. The absorbance of these solutions was determined by using a UV–VIS spectrophotometer. The data is taken in triplicate and the average data is reported and the percent error bar (± 5%) is applied to each data.

Electrochemical debasement

Using a Ti/Ru0.3Ti0.7O2 composite anode, aqueous solutions of the BTB and MR dyes were subjected to electrochemical degradation in a Pyrex glass reactor. The current and voltage were measured using the aforementioned DC power supply. A 400 mL of a 200 ppm mixture of each of the BTB and MR solutions was electrolyzed in the presence of various electrolytes in each test. The effect of pH and electrolyte concentration as well as of the current density on the degradation of the dye from their aqueous solutions was studied. At various time intervals, 1 mL of the aliquots were taken out of the solutions and analyzed via a UV–VIS spectrophotometer at an ambient temperature and pressure. The % electrochemical degradation of the dyes was calculated using an Eq. (1).

where At is the absorbance at the lambda maximum (max) after t minutes of the experiment, and Ao is the absorbance at t = 0 min. Equation (2) provided the estimation of energy consumption for both dyes.

where I denotes the applied current (A), V denotes the average voltage (V), t is the oxidation time (h), and Vs denotes the solution volume (400 mL).

Results and discussion

Wavelength of maximum absorbance (λmax.) and calibration curves

Figure 2 displays a wavelength versus absorbance plot for (a) BTB and (b) MR dyes. The absorbance of the dyes is measured at different wavelengths by passing UV–visible light from a definite concentration of the two dye solutions (20 μg mL−1 solution of BTB and 20 μg mL−1 solution of MR) using a UV–VIS spectrophotometer. Examining the absorbance of BTB and MR over the visible spectrum, it can be seen from the figure that the highest absorbance for BTB and MR occurs at 615 and 515 nm, respectively. This wavelength at which the highest absorbance occurred is called the wavelength of maximum absorbance or the absorbance maximum or λmax and is read as lambda max.

At the λmax of BTB (λmax = 615 nm) and MR (λmax = 515 nm) absorbance for different concentrations (20–50 ppm solutions for BTB and 2–20 ppm solutions for MR) was discovered at max for the working curve of BTB and MR) of these dyes were measured and plotted as the concentration (in ppm on the x-axis) and the absorbance for both the dyes and are shown in the inset of Fig. 2a for BTB and Fig. 2b for MR. The plot is known as a working curve or calibration curve which was linear for both the dyes confirming Beer–Lamberts law. As can be seen from the plots when the concentration (i.e. the amount of solute) increased for each of the dye solutions, more light was absorbed following Beer–Lamberts law. These calibration curves were used to calculate the unknown concentrations of each dye solution using their known absorbance values from the linear plot.

Electrochemical degradation

On the rate of electrochemical oxidation of BTB and MR dyes, the effects of various working parameters, such as current density, electrolyte concentration, and pH, were investigated.

Influence of current density on the degradation of BTB and MR dyes

The production of oxidative species like aqueous chlorine, ClO–, and HOCl are critical for the oxidative degradation of dyes using a DSA anode. These species are generated at the anode surface and move into the bulk of the solution to degrade organic pollutants, therefore the current density is expected to be a key factor in the process. The data is plotted as % color removal versus time (minutes) and shown in Fig. 3a at a range of current densities. The electrochemical debasement of BTB was carried out at 5, 10, 15, and 20 mA cm–2 current densities with 0.1 M of NaCl electrolyte at a pH of 3. At a current density of 5 mA cm–2, a degradation of 97% occurred in 44 min while a degradation of 95% took place in 8 min at a current density of 20 mA cm−2. This shows that as current densities rise, more chlorine, hypochlorite ions (OCl) as well as •OH radicals are generated, which speeds up the process of color removal as per reactions (3–6).

In the bulk solution:

It is also obvious from Fig. 3a that more than 97% of dye degraded at 10 mA cm−2 in just 20 min of electrolysis. Therefore, a current density of 10 mA cm–2 was selected, as it showed the most promising results in terms of cost and color eradication. Further increases in current density had no appreciable impact on the effectiveness of dye degradation. By comparison, the removal of reactive blue 19 dye at a titanium-based DSA anode investigated by Rajkumar and Kim (2006), resulted in a linear increase in the debasement of the dye rose at current densities range, 7.22–36.10 mA cm–2, in the presence of NaCl.

The degradation of MR was also investigated, this time at current densities of 0.5, 0.1, 1.5, and 2.0 mA cm–2 and a pH of 3.0. We can see in Fig. 3b that the Methyl Red dye degradation is small at a low current density, as we increase the current density the removal of MR dye increases. 16 min of electrolysis at 2 mA cm–2 resulted in MR being oxidized up to 87%. The enhancement of degradation depends on the current density and subsequently on the generation of •OH radicals/OCl– ions. The optimum current density was determined to be 2 mA cm–2 to remove the most color for minimum cost. Similar tests were conducted for acid blue and basic brown dyes by Awad and Galwa (2005) using a Pb/PbO2 electrode, and they found that after 30 min of electrolysis, almost a complete removal had been achieved in the presence of NaCl at 30 mA cm–2.

The impact of different pH levels on BTB and MR deterioration

Methyl Red and Bromothymol Blue are both pH indicators that change color as we change the pH of the solution. The colors and lambda max of these indicators vary at different pH ranges. Therefore the concentration of BTB was measured at different wavelengths i.e. 430 nm for the acidic solution and 615 nm for the basic solution and for MR 515 nm and 425 nm were used to quantify the residual concentration in the treated solution. The acidity and basicity of both dye solutions were maintained constant during electrolysis by adding NaOH and HCl and putting the pH electrode in the electrochemical reactor. Figure 4 illustrates how pH affects (a) BTB and (b) MR’s oxidative degradation. By adding NaOH or H2SO4 the pH of the dye solution was adjusted from 3 to 10. In the case of BTB electrolyte also contained 0.1 M NaCl, and a d 10 mA cm−2 current density was applied during electrolysis. With rising pH from 3 to 9 the removal of color diminished (Fig. 4a). At pH 3, the dye was degraded by > 90% after 15 min. More alkaline solutions were less effective for dye removal as we can observe that degradation of BTB at pH 9 is negligible. Alves et al. (2010) attained 70% degradation of industrial dye. For MR dye removal four different pH was tested, i.e. 3, 5, 8, and 10, and Fig. 4 displays the findings from the 15-min examination of MR oxidation while maintaining constant current density and electrolyte content. Figure 4b shows that acidic condition (pH 3 and pH 5) is more favorable for dye removal, and up to 97% removal was achieved in just 8 min of electrolysis. However, pH 8 and 10 did not show any degradation. The data represent that the rate of color removal per cent increases as pH decreases, indicating that more acidic media are more favorable for MR oxidation. At acidic conditions, chlorine exists as a hypochlorous acid, with a higher oxidation potential (1.49 V) compared to hypochlorite (0.94 V) (Hussain et al. 2015). As a consequence, this led to high degradation of dye molecules.

Effect of electrolytes on the oxidative degradation BTB and MR

Figure 5 shows the impact of different electrolytes on the oxidation of BTB, Fig. 5a, and MR, Fig. 5b. Using 200 ppm solutions of BTB at pH 3 and with a 10 mA cm–2 current density, and MR solutions of 200 ppm at pH 3 and a 2 mA cm–2 current density, degradation was only observed in NaCl solutions, and not NaNO3 or Na2SO4 containing solutions. In the presence of sulphate and nitrate, the oxidation process takes place directly on the electrode surface. The H2O molecule is simply electrolyzed in the direct anodic mechanism, and the OH radical physically adsorbs on the anode surface as shown in the equation reported by Zhang et al. (2014) and is shown below. The metal oxide is designated as MOX, and the physisorbed hydroxyl radical generates the chemisorbed active oxygen (oxygen in the lattice, MOx+1).

MOx+1 oxidizes the organic pollutants found in wastewater. However, we observed no evidence of this process taking place. Likely, the electrodes displayed poor electrocatalytic activity due to either the formation of an adherent film on the anode surface or the creation of stable intermediates that could not be directly oxidized in this conductive electrolyte (Ghalwa et al. 2013). Additionally, it was shown by Do and Yeh (1996) that the O2 evolution was the primary anodic process due to the absence of chloride. The production of O2 does not help degrade the dyes, and negligible performance was observed in the Na2SO4 and NaNO3 electrolytes. However, 87% of the color was removed by electrolysis using NaCl as the supporting electrolyte. This is due to the working anode surface’s formation of chlorine and hypochlorite species, which ensures indirect oxidation. In indirect oxidation, chloride-containing wastewater transforms into electrically generated HOCl oxidant species on the anode surface.

The discussion above has shown that NaCl was thought to be the best electrolyte because a degradation of almost 87% was accomplished in just 16 min. By contrast, in solutions of Na2SO4 and NaNO3 no degradation was observed. Therefore, it was found that 0.1 M NaCl worked the best for BTB and MR electrochemical oxidation. Similarly, Miwa et al. (2006) described how, within 60 min of electrolysis, pesticides completely degrade in 0.1 M NaCl.

Effect of NaCl concentrations on the degradation of BTB and MR

Based on the degradation performance of various electrolytes, NaCl exhibits a superior removal of dyes, therefore it is essential to investigate the influence of NaCl concentration on the electrochemical removal of dyes. The electrochemical oxidation of BTB dyes was investigated for 10 min at 10 mA cm–2 constant current density and with various concentrations of NaCl studied in this work (0.02–0.1 M NaCl), as depicted in Fig. 6a. It is clear from the figure that as the concentration of the electrolyte NaCl in the dye solution increases, its ability to remove color also increases. Indeed, ~ 70% of the degradation of the dye was achieved in 10 min for BTB at a concentration of 0.1 M of NaCl. Similarly, the MR degradation was also determined at 0.005–0.013 M NaCl at a constant current density of 2 mA cm−2. The degradation of MR dye was fast as compared to BTB, and it was observed that increasing the NaCl concentration enhances the oxidation of MR dye, and only 8 min of electrolysis is required to completely remove the MR dye from the solution. This is due to the high rate of generation of Cl2/OCl– species at the anode, which ensures indirect oxidation. The higher concentration of NaCl results in an increased chlorine concentration at the anode surface causing greater degradation of the dyes26. The optimal concentration of NaCl in this work was 0.1 M.

Energy consumption for the degradation

Electric energy plays a crucial role in all processes relying on electrical potential. The consumption of energy was deduced from the degradation data using Eq. (2), which demonstrates as electrical energy in kW h m−3 is required to degrade dye from waste solution. Figure 7 shows plots of the energy consumption (EC) versus current densities for the electrochemical degradation of (a) BTB and (b) MR dyes from a 200 ppm solution each. EC increased from 0.2025 to 16.704 kW h m–3 as the current densities rose from 5 to 20 mA cm–2 for BTB (Fig. 7a) demonstrating that the energy expenditure at 5 mA cm–2 is much lower in comparison to 20 mA cm–2. However, the dye degradation process becomes more rapid as the current densities increase. As a result, it can be shown that the calculated energy consumption was 4.992 kW h m–3 at 10 mA cm–2.

The electrical energy required for the electrochemical degradation of MR dye at 200 ppm versus current densities is also shown in Fig. 7b. Similar to the BTB data, the degradation of the dye increased as the current density increased, and the energy cost rose from 0.0636 to 0.349 kW h m–3. Compared to 2 mA cm–2, 0.5 mA cm–2 has a lower energy consumption but a slower rate of dye degradation is observed at 0.5 mA cm–2. In the same way, Sartaj et al. (2020) reported that the Allura red dye had a minimum electrical energy consumption of 0.196 kW h m–3 and the erythrosine dye had a minimum electrical energy consumption of 0.941 kW h m–3 at a current density of 5 mA cm–2 at pH 5.0 and 8 mA cm–2 at pH 6.0, respectively.

Conclusion

The results show that wastewater containing BTB and MR dyes can be successfully degraded by an indirect electrochemical oxidation method using a Ti/Ru0.3Ti0.7O2 composite anode under optimal conditions. The degradation was highly efficient in NaCl solutions, but not observed in NaNO3 or Na2SO4 solutions. It has been shown that the rate of color loss increases as NaCl concentration increases, current density increases and solution pH decreases. When NaCl is used as the electrolyte, the Ti/Ru0.3Ti0.7O2 anode has a good capacity to produce chlorine species such as hypochlorite, OCl– that have strong oxidative power, and which contribute to the removal of more than 90% of the dyes from wastewater while requiring little electricity. The electrochemical oxidation of organic pollutants is advantageous because of it is a low-cost, versatile, and environmentally benign method with excellent energy efficiency.

References

Aguilar ZG et al (2017) Evidence of Fenton-like reaction with active chlorine during the electrocatalytic oxidation of Acid Yellow 36 azo dye with Ir-Sn-Sb oxide anode in the presence of iron ion. Appl Catal B Environ 206:44–52. https://doi.org/10.1016/j.apcatb.2017.01.006

Ahmad et al (2022) Electrochemical degradation of methyl red in zinc hydroxide and zinc oxide thin films, physical and chemical activation. Mater Chem Phys 280:125793. https://doi.org/10.1016/j.matchemphys.2022.125793

Al-Asfar A, Zaheer Z, Aazam ES (2018) Eco-friendly green synthesis of Ag@ Fe bimetallic nanoparticles: antioxidant, antimicrobial and photocatalytic degradation of bromothymol blue. J Photochem Photobiol B Biol 185:143–152. https://doi.org/10.1016/j.jphotobiol.2016.01.016

Al-Nuaim MA, Alwasiti AA, Shnain ZY (2023) The photocatalytic process in the treatment of polluted water. Chem Pap 77(2):677–701. https://doi.org/10.1007/s11696-022-02468-7

Alves PA et al (2010) Photo-assisted electrochemical degradation of real textile wastewater. Water Sci Technol 61(2):491–498. https://doi.org/10.2166/wst.2010.870

Andersson A et al (2020) Selective removal of natural organic matter during drinking water production changes the composition of disinfection by-products. Environ Sci Water Res Technol 6(3):779–794. https://doi.org/10.1039/C9EW00931K

Awad H, Galwa NA (2005) Electrochemical degradation of acid blue and basic brown dyes on Pb/PbO2 electrode in the presence of different conductive electrolytes and effect of various operating factors. Chemosphere 61(9):1327–1335. https://doi.org/10.1016/j.chemosphere.2005.03.054

Brito CN et al (2018) Electrochemical degradation of Azo-dye Acid Violet 7 using BDD anode: effect of flow reactor configuration on cell hydrodynamics and dye removal efficiency. J Appl Electrochem 48(12):1321–1330. https://doi.org/10.1007/s10800-018-1257-4

Chequer FD et al (2013) Textile dyes: dyeing process and environmental impact. Eco-Friendly Text Dye Finish 6(6):151–176. https://doi.org/10.5772/53659

Cockerham C et al (2022) Azo-dye-functionalized polycarbonate membranes for textile dye and nitrate ion removal. Micromachines 13(4):577. https://doi.org/10.3390/mi13040577

Crini G, Lichtfouse E (2019) Advantages and disadvantages of techniques used for wastewater treatment. Environ Chem Lett 17:145–155. https://doi.org/10.1007/s10311-018-0785-9

Das DK et al (2012) Methyl red: a fluorescent sensor for Hg2+ over Na+, K+, Ca2+, Mg2+, Zn2+, and Cd2+. Environ Eng Res 17(S1):75–78. https://doi.org/10.4491/eer.2012.17.S1.S75

Do JS, Yeh WC (1996) Paired electrooxidative degradation of phenol with in situ electrogenerated hydrogen peroxide and hypochlorite. J Appl Electrochem 26(6):673–678. https://doi.org/10.1007/BF00253467

Donkadokula NY et al (2020) review on advanced physicochemical and biological textile dye wastewater treatment techniques. Rev Environ Sci Biotechnol 19(3):543–560. https://doi.org/10.1007/s11157-020-09543-z

Du X et al (2017) Definitive screening design applied to electrochemical degradation of Chromotrope 2R with BDD anodes. Chemosphere 171:362–369. https://doi.org/10.1016/j.chemosphere.2016.12.100

Fajardo AS et al (2017) Electrochemical abatement of amaranth dye solutions using individual or an assembling of flow cells with Ti/Pt and Ti/Pt-SnSb anodes. Sep Purif Technol 179:194–203. https://doi.org/10.1016/j.seppur.2017.01.029

Fui MLW, Hang NK, Arifin K, Minggu LJ and Kassim MB (2016) Photocatalytic degradation of bromothymol the blue with Ruthenium (II) bipyridyl complex in aqueous basic solution. In: AIP conference proceedings, vol 1784, no 1, AIP Publishing. https://doi.org/10.1063/1.4966746

Ghalwa NA et al (2013) Determination of electrochemical degradation of E102 dye at lead dioxide-doped carbon electrodes using some potentiometric and spectrophotometric methods. Chem J 3(1):1–6

Gul A et al (2022) Ficus religiosa bark an efficient adsorbent for Alizarin Red S dye: equilibrium and kinetic analysis. J Iran Chem Soc 19(5):1737–1746. https://doi.org/10.1007/s13738-021-02413-7

Hussain S et al (2015) Route of electrochemical oxidation of the antibiotic sulfamethoxazole on a mixed oxide anode. Environ Sci Pollut Res 22:15004–15015. https://doi.org/10.1007/s11356-015-4699-9

Hussain S et al (2021) Process modeling toward higher degradation and minimum energy consumption of electrochemical decontamination of food dye wastewater. Environ Techno Innov 22:101509. https://doi.org/10.1016/j.eti.2021.101509

Iqbal K et al (2022) Biodegradation of methyl red dye by a novel actinobacterium Zhihengliuella sp. ISTPL4: kinetic studies, isotherm and biodegradation pathway. Environ Technol Innov 26:102348. https://doi.org/10.1016/j.eti.2022.102348

Jagaba AH et al (2021) Sequencing batch reactor technology for landfill leachate treatment: a state-of-the-art review. J Environ Manage 282:111946. https://doi.org/10.1016/j.jenvman.2021.111946

Kavindra KK et al (2011) Physical methods in wastewater treatment. Int J Environ Technol Manag 14(1–4):43–66. https://doi.org/10.1504/IJETM.2011.039257

Khan et al (2016) Photocatalytic, antimicrobial activities of biogenic silver nanoparticles and electrochemical degradation of water soluble dyes at glassy carbon/silver modified past electrode using buffer solution. J Photochem Photobiol, B 156:100–107. https://doi.org/10.1016/j.jphotobiol.2016.01.016

Khan SU et al (2020) Electrochemical preparation of Nb2O5 nanochannel photoelectrodes for enhanced photoelectrocathe talytic performance in removal of RR120 dye. Chemosphere 257:127164. https://doi.org/10.1016/j.chemosphere.2020.127164

Klotz E et al (2011) The equilibrium constant for bromothymol blue: a general chemistry laboratory experiment using spectroscopy. J Chem Educ 88(5):637–639. https://doi.org/10.1021/ed1007102

Labiadh L et al (2017) Direct and indirect electrochemical oxidation of Indigo Carmine using PbO2 and TiRuSnO2. J Solid State Electrochem 21:2167–2175. https://doi.org/10.1007/s10008-017-3559-6

Lin SH, Chen ML (1997) Treatment of textile wastewater by chemical methods for reuse. Water Res 31(4):868–876. https://doi.org/10.1016/S0043-1354(96)00318-1

Maamar M, Bellakhal N (2017) Treatment of a Tunisian textile effluent containing Bromothymol Blue dye using anodic oxidation on boron doped diamond electrode. J Tunisian Chem Soc 19:32–42

Maamar M, Naimi I, Mkadem Y, Souissi N, Bellakhal N (2015) Electrochemical oxidation of Bromothymol blue: application to textile industry ial wastewater treatment. J Adv Oxid Technol 18(1):105–113. https://doi.org/10.1515/jaots-2015-0113

Martínez-Huitle CA, Panizza M (2018) Electrochemical oxidation of organic pollutants for wastewater treatment. Curr Opin Electrochem 11:62–71. https://doi.org/10.1016/j.coelec.2018.07.010

Miwa DW et al (2006) Electrochemical degradation of carbaryl on oxide electrodes. Water Res 40(17):3281–3289. https://doi.org/10.1016/j.watres.2006.06.033

Morais et al (2013) Electrochemical degradation of methyl red using Ti/Ru0.3Ti 0.7O2: fragmentation of azo group. Electrocatalysis 4:312–319. https://doi.org/10.1007/s12678-013-0166-x

Muhammad S et al (2020) Understanding the basics of electron transfer and cyclic voltammetry of potassium ferricyanide-an outer sphere heterogeneous electrode reaction. J Chem Soc Pak 42(6):813–817. https://doi.org/10.52568/000705

Niknejad N et al (2023) A bibliometric analysis of green technologies applied to water and wastewater treatment. Environ Sci Pollut Res 30(28):71849–71863. https://doi.org/10.1007/s11356-022-18705-1

Panizza M, Cerisola G (2008) Electrochemical degradation of methyl red using BDD and PbO2 anodes. Ind Eng Chem Res 47(18):6816–6820. https://doi.org/10.1021/ie8001292

Panizza M, Cerisola G (2009) Direct and mediated anodic oxidation of organic pollutants. Chem Rev 109(12):6541–6569. https://doi.org/10.1021/cr9001319

Pieczyńska A et al (2019) Electrochemical degradation of textile dyes in a flow reactor: effect of operating conditions and dyes chemical structure. Int J Environ Sci Technol 16(2):929–942. https://doi.org/10.2166/wst.2020.182

Prakash S et al (2018) Green synthesis of copper oxide nanoparticles and its effective applications in Biginelli reaction, BTB photodegradation, and antibacterial activity. Adv Powder Technol 29(12):3315–3326. https://doi.org/10.1016/j.apt.2018.09.009

Priyadarshini M et al (2022) Advanced oxidation processes: performance, advantages, and scale-up of emerging technologies. J Environ Manage 316:115295. https://doi.org/10.1016/j.jenvman.2022.115295

Rajkumar D, Kim JG (2006) Oxidation of various reactive dyes with in situ electro-generated active chlorine for textile dyeing industry wastewater treatment. J Hazard Mat 136(2):203–212. https://doi.org/10.1016/j.jhazmat.2005.11.09610.2166/wst.2010.870

Rápó E, Tonk S (2021) Factors affecting synthetic dye adsorption; desorption studies: a review of results from the last five years (2017–2021). Molecules 26(17):5419. https://doi.org/10.3390/molecules26175419

Rodríguez-Narváez et al (2021) Electrochemical oxidation technology to treat textile wastewater. Curr Opin Electrochem 29:100806. https://doi.org/10.1016/j.coelec.2021.100806

Saadia S et al (2017) Use of a PbO2 electrode of a lead-acid battery for the electrochemical degradation of methylene blue. Sep Sci Technol 52(9):1602–1614. https://doi.org/10.1080/01496395.2017.1291681

Sartaj S et al (2020) Performance evaluation of photolytic and electrochemical oxidation processes for enhanced degradation of food dyes laden wastewater. Water Sci Technol 81(5):971–984. https://doi.org/10.2166/wst.2020.182

Shehata N et al (2023) Membrane-based water and wastewater treatment technologies: Issues, current trends, challenges, and role in achieving sustainable development goals, and circular economy. Chemosphere 320:137993. https://doi.org/10.1016/j.chemosphere.2023.137993

Steinegger A, Wolfbeis OS, Borisov SM (2020) Optical sensing and imaging of pH values: spectroscopies, materials, and applications. Chem Rev 120(22):12357–12489. https://doi.org/10.1021/acs.chemrev.0c00451

Stupar SL, Grgur BN, Onjia AE, Mijin DŽ (2017) Direct and indirect electrochemical degradation of acid blue 111 using IrOX anode. Int J Electrochem Sci 12(9):8564–8577. https://doi.org/10.20964/2017.09.44

Takkar S et al (2017) Dye decomposition by combined ozonation and anaerobic treatment: cost effective technology. J Appl Res Technol 15(4):340–345. https://doi.org/10.1016/j.jart.2017.02.006

Venkatesh S, Venkatesh K, Quaff AR (2017) Dye decomposition by combined ozonation and anaerobic treatment: Cost effective technology. J Appl Res Technol 15(4):340–345. https://doi.org/10.1016/j.jart.2017.02.006

Wang LK, Wang MHS (2023) New technologies for water and wastewater treatment. \evolutionary Prog Sci Technol Eng Arts Math (STEAM)/. https://doi.org/10.17613/wena-kx42

Wang J, Yao J, Wang L, Xue Q, Hu Z, Pan B (2020) Multivariate optimization of the pulse electrochemical oxidation for treating recalcitrant dye wastewater. Sep Purif Technol 230:115851. https://doi.org/10.1016/j.seppur.2019.115851

Zeb S et al (2018) Electrochemical oxidation of acid brown 98 using Ti/RuO.3TiO.7O2 composite anode. Int J Electrochem Sci 13:9428–9440. https://doi.org/10.20964/2018.10.06

Zeb S et al (2020) Silica-based nanomaterials as designer adsorbents to mitigate emerging organic contaminants from water matrices. J Water Process Eng 38:101675. https://doi.org/10.1016/j.jwpe.2020.101675

Zhang F et al (2014) Indirect electrochemical oxidation of dye wastewater containing Acid Orange 7 using Ti/RuO2-Pt electrode. Int J Electrochem Sci 9(2):943–954

Acknowledgements

The corresponding author is thankful to Dr. Sean Edward Goodwin, UK for editing and English corrections in the manuscript. The corresponding author is also thankful to Dr. Hammad Khan, Faculty of Material and Engineering, GIKI Pakistan for repeating some of the experimental work.

Funding

This research work has not received any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Editorial responsibility: PF Rupani.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hussain, S., Muhammad, S., Gul, S. et al. Efficient indirect electrochemical degradation of bromothymol blue and methyl red from aqueous phase at Ti/Ru0.3Ti0.7O2 anode. Int. J. Environ. Sci. Technol. (2024). https://doi.org/10.1007/s13762-024-05627-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13762-024-05627-3