Abstract

For the preparation of phenolic extracts, heating is one of the treatments applied. The effect of this type of heat treatment on the phenolic composition and the antioxidant power of olive leaves extracts were studied. This study aims to assess the use of solar heating method, a revolutionary green technology for the efficient extraction of several phytochemicals from food by-products. Olive leaves (Olea europaea L.) were used as the source material for this study. Solar heating method has been used for the extraction of polyphenols and flavonoids compounds. The extracts of solar heating method, decoction, and maceration were characterized in terms of total phenolic compounds, total flavonoids compounds, and their antioxidant activity based on 2,2-diphenyl-1-picrylhydrazyl radical scavenging activity. The results showed that solar heating method extract provided a very satisfactory extraction yield in polyphenols, flavonoids compounds, and antioxidants (189.58 mg GAE/g DW, 87.53 mg QE/g DW, and 91.16% respectively), which was higher than that attained by decoction and maceration methods. Moreover, HPLC analyses showed an increase in rutin, oleuropein, hydroxytyrosol, vanillin, coumaric acid, quercetin, and caffeic acid levels in the solar heating method extract. Results indicated solar heating method as a good choice for green recovering polyphenols and antioxidants from the olive leaves. There was a positive linear correlation between antioxidants, polyphenols, and between antioxidants, flavonoids for solar heating method extract (coefficient r = 0.89 and 0.77, respectively). These results suggested that the polyphenols and flavonoids contributed significantly to the antioxidants of the investigated olive leaves.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

One of the most significant crops in the Mediterranean region is the olive tree (Olea europaea L.). In addition to olive oil as the primary product, the olive industry produces liquid (margins) and solid by-products (pomaces, leaves, and twigs). Leaves can be harvested along with olives during the harvest. In olive fields and oil mills, these by-products are separated from the olives. They are expected to account for 10% of the overall olive harvest (Aouidi 2012).

Because of their high phenolic content, olive tree leaves (Olea europaea) are known for their health advantages. The properties of these substances are antioxidant and anticancer (da Silva et al. 2019), anti-inflammatory, anti-bacterial (Ghomari et al. 2019), anti-diabetic, and antimicrobial powers that make them very important for health and the food industry (Guinda et al. 2015; Martín-García et al. 2019; Nicolì et al. 2019; Rosa et al. 2019b). Olive leaves contain a wide range of phenolic chemicals, with concentrations ranging from 2.8 mg g−1 dry matter (Altiok et al. 2008) to 158.7 mg g−1 DM (Martín-garcía et al. 2020). It is possible to exceed 250 mg g−1 of DM (Mylonaki et al. 2008).

The green extraction of olive leaves has been done in previous research with ultrasound (Ahmad-Qasem et al. 2013; Irakli et al. 2018; da Rosa et al. 2019a), microwaves (Rafiee et al. 2011; Taamalli et al. 2012), supercritical extraction with CO2 (Putnik et al. 2017) and superheated liquid extraction (Japón-Luján and Luque de Castro 2006) where it has been proven that these processes offer an excellent and innovative approach to traditional antioxidant extraction methods. The volatiles produced by the olive leaves were extracted by hydro-distillation using a Clevenger-type apparatus for 2 h (Flamini et al. 2003). This is the first time that a solar extraction method has been employed to extract antioxidants.

In 1986, Wolfgang Scheffler tested his reflector in India and Kenya for the first time (Scheffler 2006), and it has been used to distillate aromatic and medicinal plants to extract essential oils by combining a solar still, a second reflector, and a condenser. As a result, using this solar system is now a financially viable option, as the payback period on such an investment is less than two years (Jayasimha 2006). The solar distillation unit used in this work was previously used for the deodorization of rosemary leaves by solar steam distillation (Hilali et al. 2018); it was also used for solar hydro-distillation to extract essential oils from orange peels before treating them with an organic solvent to extract bioactive components (Hilali et al. 2019).

In the past, plants have been extracted of their bioactive compounds through maceration with liquid solvents, but this is a laborious process that requires extensive extraction durations. The goal of this research carried out in the National Center for Studies and Research on Water and Energy at Cadi Ayyad University in Marrakech, Morocco (31° 37′ 46 N, 7° 58′ 52 W), was to extract TPC and TFC from olive leaves, as well as their antioxidants using the SHM procedure by incorporating a green, energy-free process using solar energy. Another objective was to compare the obtained results with those of decoction and maceration with polar solvents, in particular distilled water or methanol, and the effect of temperature on the composition of each extract. The relationship between radiation intensity (Gb), the focal point temperature (Tf), the quantity of olive leaves (QO.L), the quantity of water (QW), TPC, TFC, and AA was also investigated statistically.

Materials and methods

Plant

The olive leaves (Olea europaea L.) were collected in Marrakech city in 2020 (altitude 466 m) located in the central part of Morocco. The olive leaves are cleaned in water, air-dried in the shade at room temperature, and weighed daily; after 22 days, their mass becomes constant, showing that the water they contain has been completely removed. The leaves had a moisture content of 49.10% after air-drying. The dried leaves were sealed in plastic pouches and stored in a dry, dark location until use.

Chemicals

Chemicals of analytical purity were employed in the testing. Sigma-Aldrich, Darmstadt, Germany, provided the Folin–Ciocalteu reagent, gallic acid, methanol, sodium carbonate (Na2CO3), aluminum trichloride (AlCl3), sodium hydroxide (NaOH), and sodium nitrite (NaNO2). Somaprol, Casablanca, Morocco, offered 2,2-diphenyl-1-picrylhydrazyl (DPPH), quercetin, and gallic acid.

The Scheffler solar heating system

The national center for water and energy studies and research (CNEREE) at Cadi Ayyad University in Marrakech, Morocco (31° 37′ 46 N, 7° 58′ 52 W), is where the solar thermal system is situated. A 10 m2 Scheffler concentrator with a fixed focus, a secondary reflector, and a solar still make up this solar thermal equipment (Fig. 1). The concentrator’s rotating axes are set to the relative local angle of latitude (31° 37′ 46) so that the rotational axes of the concentrator and the earth are aligned.

The available energy for the process of heating relies on the solar intensity availability and the solar still’s optical and thermal efficiency. The solar heating system’s performance is determined by the optical efficiency of the primary and secondary reflectors, as well as solar still absorption (Afzal et al. 2017). The primary reflector’s reflective surface is made up of glass mirrors, which account for 85% of the overall reflectance area. The solar still was insulated with 70 mm of rock wool to decrease heat loss. A small electronic photovoltaic (PV) plate and a mechanical mechanism for daily and seasonal solar tracking are included in the 10 m2 solar reflector. Sun radiation and temperature measurements were done using a pyranometer and thermocouples, which were linked to a computer by a data logger.

Extracts preparation by maceration

One gram of dried (or fresh) and powdered leaves was macerated for three hours in 20 mL of 96 percent methanol or distilled water each in a single step. After that, filter paper was used to filter the extracts. Reduced pressure evaporation in a rotating vacuum evaporator was utilized to eliminate the extraction solvents from the filtrate. Until they were needed, the concentrated extracts were stored at 4 °C.

Extracts preparation by decoction

For around three hours, one gram of dried and powdered leaves was boiled in 20 mL of distilled water. After that, the extract was filtered via filter paper. Lyophilization was used to separate the extraction water from the filtrate. Until it was used, the concentrated extract was maintained at 4 °C.

Extracts preparation by SHM

In 10 L of distilled water, 500 g of dried or dried and powdered leaves were macerated in the solar still for three hours. The remaining extract in the solar still was then filtered using a filter paper. Lyophilization was used to separate the extraction water from the filtrate, because we need to remove the water used in the extraction step, then dissolve the remaining organic matter in methanol to prepare the concentrations needed to determine the polyphenol, flavonoid, and antioxidant content. The 96% methanol-concentrated extract was maintained at 4 °C until it was used.

Determination of total phenolic compounds

To quantify the total phenolic compound (TPC) content of each extract, the Folin–Ciocalteu method is utilized, which uses gallic acid as a standard (Box 1983). 0.1 mg mL−1 of the extract was mixed with 0.5 mL of the Folin reagent, and after 5 min, 2 mL of 20% Na2CO3 was added. The mixture was then incubated for 30 min at room temperature in the dark. A spectrophotometer was used to measure the absorbance at 750 nm (Selecta). TPCs are calculated in milligrams of gallic acid equivalent per gram of dry vegetable matter (mg GAE g−1 DM) (N = 3).

Determination of total flavonoid compounds

The aluminum trichloride technique was used to determine the TFC concentration of each olive extract (Dewanto et al. 2002). 75 µL of a % NaNO2 solution were added to 250 µL of diluted extract (0.1 mg mL−1). 150 µL of a freshly made 10% AlCl3 solution were added to the mixture following a 6 min incubation time at room temperature. The mixture was allowed to stand for 5 min at room temperature before 0.5 mL of sodium hydroxide (NaOH, 1 M) was added. The final volume was changed to 2.5 mL using distilled water. At 510 nm, the absorbance of this solution was calculated. Parallel calibration curves using quercetin were performed under identical conditions. Milligrams of quercetin equivalent per gram of dry vegetable matter (mg EQ g−1 DM) (N = 3) are used to quantify TFC content.

Determination of total antioxidant capacity

Free radical DPPH (2,2-diphenyl-1-picrylhydrazyl) is colored violet when it is in its oxidation form and yellow when it is in its reduced form (Parejo et al. 2002). When antiradical chemicals are present, the DPPH radical is decreased and turns yellow. The absorbance at 517 nm, which is proportional to the antiradical power of the extract, was used to compute the percentage inhibition of the DPPH radical. Normally, 100 mL of methanol were used to dissolve 25 mg of DPPH, which was then diluted 1:10 with the same solvent. In a volume of 100 mL, the extract was added to 3.9 mL of methanolic DPPH solution. For 30 min, the combination was kept at room temperature and kept out of direct sunlight (Brand-Williams et al. 1995). At 517 nm, the absorbance was measured, and the antioxidant activity percentage (AA %) is calculated using the formula below:

Abs blank: Absorbance of DPPH at time zero before sample addition.

Abs simple: Absorbance of the test sample after 30 min of incubation.

Identification of phenolic compounds in each extract by HPLC

According to the IOOC approach (Class 2009), the phenolic components in olive leaf extract were identified and measured using a high-performance liquid chromatography technique. The extracts (10 mg) were diluted in 80% methanol (1 mL) and filtered through a 0.45 µm filter prior to HPLC (UV–vis) analysis. The phenolic components were separated at 40 °C using a C18HG Wakosil (5 µm, 4.6*150 mm). Elution was carried out in gradient mode with a binary solvent mixture of acidified water containing 0.2% phosphoric acid (solvent A) and 50/50 methanol/acetonitrile (solvent B). For 40 min, a linear gradient was passed from 96% (A) and 4% (B) to 50% (A) and 50% (B); for 5 min, it was passed to 40% (A) and 60% (B); for 15 min, it was passed to 0% (A) and 100% (B), after rebalancing for 12 min until the initial composition was reached. Each sample’s injection volume was 20 µL, and the mobile phase flow rate was 1 mL min−1. All phenolic compounds were identified by comparing their retention times and UV spectra to those of reference compounds. Peak regions in relation to standards were used to make quantitative measurements.

Statistical analyses

Relative linear importance

To determine the variables that explain more the variation of AA, TPC, and TFC variation, analysis of the linear relationship degree between these output variables and the remaining investigated variables including the olive leaves quantity, solar radiation, and temperature at the focal point has been investigated through Pearson correlation coefficient. The Pearson correlation coefficient (r), a statistical metric that ranges from − 1 to + 1, expresses the strength of the linear relationship between two quantitative variables, X and Y. The degree of significant linear correlation was also determined using a p-value (p < 0.05).

Multiple linear regression

Given the amount of data, using multiple linear regression (MLR) models to describe the variables AA, TPC, and TFC remains a viable option. Thus, many studies have used this kind of model to establish a relationship between these output variables and candidate-related input variables. For instance, Tamasi et al. (2019) have used MLR to correlate antioxidant parameters with two components (hydroxytyrosol and luteolin) in olive fruits and pomace extracts using Unscrambler X software version 10.4. In the same context, Rafiee et al. (2011) have employed this method to simulate AA by use of SAS software, while Malenčić et al. (2008) have used MLR to formulate the correlation between AA and TPC. Thus, the model utilized in this study has the following formula:

where Yi is the explained variable, Xij is the explanatory variable, βj is the model parameters, and εi are unknown constants.

The error measures (mean absolute error (or MAE), root-mean-squared error (RMSE), and the R2), on the other hand, were utilized to calculate the difference between observed and anticipated values. The following is the mathematical formula for these metrics:

The expected value is yo, the real value is yt, and the number of data points is n. If R2 is close to one and MAE and RMSE are close to zero, the model is optimum. The R programming language was used to conduct all statistical analyses (version 3.5.2).

Results and discussion

Energy distribution at the different components of the Scheffler solar heating

The energy is distributed as absorbed and reflected radiation at the first reflector. The reflectivity of the material used determines the reflected radiation of energy (Erp). As a result, the energy produced by the first reflector can be expressed as follows:

In the equation, Etp and Rp are the total input energy and the mirror reflectivity of the primary reflector (Munir 2010):

The direct irradiance recorded by a pyranometer is Gb (W/m2), the reflector surface (10 m2) is At, the solar declination is δ, and the number of days in the year is n. A portion of the radiation is reflected away from the focal point by the main reflector. The majority of the time, the focal point fraction (Ff) is determined to be 0.85. As a result, the following formula is used to get the energy at the second reflector (Es):

To mitigate the losses, high-reflectivity aluminum sheets were used. The following equation can be used to estimate the energy available after secondary reflection (Esr):

where Rs indicates the secondary reflector’s reflectivity (0.83). To keep the secondary reflector in the best possible focal point location, a concrete foundation was built. All rays will be distributed and reflected by the secondary reflector’s parts until they reach the bottom of the solar still (Ebot).

The reflectivity due to partial absorption and the heat losses from the various sections of the solar still by conduction, convection, and radiation make up the usable energy and energy losses from the solar still. The system’s accessible thermal energy (Econd,b) is defined as follows:

where αb = 0.90 is the vessel’s absorbance.

The energy was calculated in the summertime on a specific day (July 14, 2020); it was found that the useful energy was 5.25 kWh in 3 h of functioning, as shown in Fig. 2, after each high value of solar radiation; a high floral volume is recovered every 30 min, which directly affects the process of extraction. Since the solar reflector mainly employs direct radiation, both daily solar radiation and cloud cover density have an impact on the effectiveness of solar extraction. More crucially, because of problems with solar radiation concentration, the temperature at the fixed focal point does not exceed 350 °C, even though it can approach 500 °C. In any event, the temperature reported is substantially greater than that required to bring water to a boil, perhaps decreasing the time required to extract antioxidants from olive leaves. When daily solar radiation is low due to dense cloud cover, a conventional heating system can be used, such as a butane injector placed at the bottom of the solar still.

Analysis of the total polyphenol and flavonoid contents

A comparison of the TPC and TFC values in the extracts was done in order to assess the effect of SHM on the extraction of TPC and TFC. TPC and TFC levels were 42.92 mg EAG g−1 DM and 40.47 mg EQ g−1 DM, respectively, in the dried olive leaf SHM extract. The TPC and TFC contents of the dried and ground leaves were also determined for SHM extract and had values of 189.58 mg EAG g−1 dry matter and 87.53 mg EQ g−1 dry matter, respectively (Fig. 3). Organic compounds known as polyphenols have one or more aromatic nucleus and one or more hydroxyl groups attached, so they have a high molecular weight and water steam cannot be charged with polyphenols. This explains the high amounts of TPC and TFC obtained by SHM.

It has been observed that the dried and ground leaves subjected to SHM had higher TPC and TFC values than the dried leaves, because in the first case, the grinding increases the surface exposed to water to extract the maximum of TPC and TFC. Moreover, drying eliminates the water contained in the leaves, causing the degradation of phenolic compounds, in particular oleuropein, by enzymatic actions (Malik and Bradford 2008; Silva et al. 2006). Therefore, the TPC and the TFC obtained by the maceration method were 12.78 and 3.34 in fresh olive leaves and 27.06 mg EAG g−1 dry matter, and 4.92 mg EQ g−1 dry matter in fresh crushed olive leaves, respectively. The low quantities obtained are explained by the fact that both samples were not dried, so the water was not removed, but the ground sample was much more exposed to the solvent, hence the difference in TPC and TFC.

Figure 4 shows that the maceration process with methanol 96% gave the highest content of TPC (220.80 mg EAG g−1 dry matter) and TFC (125.88 mg EQ g−1 dry matter) in comparison with the maceration using distilled water (83.02 mg EAG g−1 dry matter) and TFC (66.08 mg EQ g−1 dry matter), respectively. This bio-solvent and relatively cheap non-toxic was used as it is a good extracting agent (Guinda et al. 2015) and to compare the quantities obtained in TPC and TFC with those obtained using SHM. Additionally, the use of polar solvents enhances the extraction of phenolic chemicals. Polar solvent (water) can interact with polar solids to promote their dissolution, while less polar solvent (methanol) is more effective at dissolving less polar molecular solids (phenols).

If we compare the extracts obtained by SHM and the decoction of the dried and ground olive leaves, we can see that SHM gives high TPC and TFC values of 189.58 and 87.53 against 113.05 mg EAG g−1 and 79.80 mg EQ g−1 dry matter for the extraction by decoction using electricity for heating (Fig. 5). Solar heating has mechanically affected the ultrastructure of the olive leaves. Hilali et al. (2018) studied the mechanisms induced by the same Scheffler parabola and which are implicated in the metabolite extraction from rosemary leaves. The temperature of 105 °C within the solar still caused an increase in porosity. The reason for this is that at higher temperatures, solvent viscosity decreases, and intermolecular interaction increases, giving rise to a higher molecular motion which increases solubility. The increasing temperature may also cause increases in intracellular pressure which may cause cell rupture. On the one hand, such a dramatic deformation enhances the diffusion of the solvent in the plant matrix, while on the other hand, it favors the liberation of cellular components. Therefore, SHM is a green method based on the exploitation of solar radiation to heat the water and olive leaves mixture.

SHM’s findings in this study are similar to earlier research. The TPC and TFC values are higher than 169.1 and 53.15 mg EAG g−1 dry matter and 98.15 and 16.51 mg EQ g−1 dry matter, respectively, reported by Ghomari et al. (2019) employing two-step maceration with ethanol and distilled water, and by Putnik et al. (2017) using supercritical extraction with CO2. Also, higher values than 66 and 37.44 mg EAG g−1 dry matter were reported by Ahmad-Qasem et al. (2013) and Irakli et al. (2018), respectively, using the ultrasonic-assisted extraction method. Martín-garcía et al. (2020) and Apostolakis et al. (2014), on the other hand, reported a value of 158.7 and 51.91 mg EAG g−1 dry matter using supercritical extraction with CO2 and heated water/glycerol mixtures, respectively. In addition, our result was somewhat lower than the previous findings indicating 253 and 386.42 mg EAG g−1 dry matter using water/ethanol-based solvent (Mylonaki et al. 2008) and supercritical extraction with CO2 (Rosa et al. 2019b), respectively. Furthermore, the TPC in SHM extract was comparable to 190.65 mg EAG g−1 dry matter extracted using the percolation method with methanol/H2O (50/50) (Ghasemi et al. 2018).

Analysis of the antioxidant activity

DPPH scavenging activity was used to examine the antioxidant activity of different extracts produced in various methods. The extracts’ antioxidant activity (AA) was estimated to range from 81.79 and 92.77% (Table 1). According to Rosa et al. (2019b), since the antioxidant action of phenolic compounds is caused by their structural characteristics, TPC levels can be linked to AA. Using microwave-assisted extraction, da Rosa et al. (2019a) show that olive leaves had an AA level up to 94%, but our results were better than the 78% that was stated by Goulas et al. (2010) using the ultrasonic method.

When comparing the antioxidant activity of SHM extract to that of other extracts, the antioxidant activity of the maceration technique with methanol (96%) was discovered to be higher than that of SHM extract, because in the first method, an organic solvent was used. Organic solvents in general need special handling considerations, they might be destructive to the environment and the health of the workers, and they are expensive. Contrarily, water has generally been suggested as an extraction solvent due to its low cost and advantages for the environment (da Rosa et al. 2019a). The results showed that the yields were comparable to those obtained with methanol, suggesting that water might be used as an extraction solvent in SHM. However, the AA of the extract obtained with the SHM was very high in comparison with the other extracts, especially the maceration of the olive leaves with water. The AA was found to rise as the temperature was raised. The reason for this is that as water viscosity decreases at higher temperatures, intermolecular contact increases, resulting in more molecular mobility and increased solubility. Temperature rises can cause intracellular pressure to rise, causing cell rupture and thereby increasing extraction rates (da Rosa et al. 2019a).

HPLC–UV characterization of phenolic components in olive leaf extracts

The phenolic compounds founded in each extract is presented in Table 2. Numerous elements, including as the sampling period, cultivar, age of the olive tree, and environmental changes, have an impact on the composition of olive leaves (Souilem et al. 2017). The maceration in distilled water showed that oleuropein (44.03 mg g−1 DM), catechin (17.30 mg g−1 DM), and perogallic (16.65 mg g−1 DM) were major compounds. Besides, when the extraction was carried out by decoction method, it was found that the oleuropein content increased (77.69 mg g−1 DM), and caffeic acid (18.91 mg g−1 DM), chlorogenic (11.84 mg g−1 DM), and gallic acid (10.34 mg g−1 DM) were major compounds. For SHM extract, oleuropein was the main representative compound (110.07 mg g−1 DM) compared to other compounds like syringic acid (25.82 mg g−1 DM), tyrosol (24.23 mg g−1 DM), sinapic (18.14 mg g−1 DM), and rutin (11.99 mg g−1 DM). These findings were similar to those discovered by Irakli et al. (2018), using the ultrasonic-assisted extraction method with 50% acetone as a solvent, which showed that increasing temperature increases the amount of oleuropein (106.5 mg g−1 DM) extracted and deactivates enzymes involved in the transformation of oleuropein into other compounds. Therefore, Ghomari et al. (2019) indicated that oleuropein (19.3 mg g−1 DM), coumaric acid (16.5 mg g−1 DM), and caffeic acid (9.96 mg g−1 DM) were the primary components extracted in distilled water at 60 °C. Also, using the ultrasonic-assisted extraction method with 80% aqueous ethanol at 60 °C, Giacometti et al. (2018) found that the quantities of oleuropein, verbascoside, and luteolin-4-O-glucoside were 13.38, 0.36, and 0.52 mg g−1 DM, respectively. However, the level of oleuropein obtained in this study is still lower than that of oleuropein 139.48 mg g−1 DM that was obtained by Kamran et al. (2015) by maceration in a solvent in three steps (methanol and n-hexane) after 105 °C drying of olive leaves.

Influence of SHM on the composition of extract and antioxidant capacity

It was important to evaluate the extraction effectiveness as well as the quality of the extracted materials in order to complete the SHM feasibility study. Heat exposure may modify the composition of several bioactive chemicals, which could affect the extract’s composition. Therefore, the temperature of extraction is an influential factor to consider. In this work, the increase in the temperature to 100 °C increased the amount of TPC, TFC, and then the AA of the olive leaf extracts. These findings matched those previously published in the literature (Ahmad-Qasem et al. (2013) and Dewanto et al. (2002)) when they discovered that heat treatment at 88 °C for 2, 15, and 30 min boosted total AA considerably. In addition, Kamran et al. (2015) showed that the highest phenol recoveries and antioxidant activity were found in extracts from leaves that were oven-dried at 105 °C. According to Darvishzadeh and Orsat (2022), the yield of TPC and TFC recovery in all extracts was improved by increasing the extraction temperature to 97.5 °C. Increased temperature may improve the extraction solvent’s diffusivity in the plant matrix, resulting in better phenolic and flavonoid solubility, as well as reduce the solvent’s viscosity, allowing these compounds to dissolve more quickly. Furthermore, the energy produced by the Scheffler reflector was about 23.84 kWh, considering optical losses, the energy available at the bottom of the solar still was Ebot = 11.92 kWh, and the solar still’s thermal efficacy was ηstill = 94.61%, thus the useful energy was 11.28 kWh exploitable by water and olive leaves (Ezzarrouqy et al. 2021). The energy consumed by the decoction method has not been calculated, but by comparison with SHM, we can estimate it at 11.28 kWh. The maceration method consumes no energy as there is no heating. The technique used in this work is based on the heating of water and olive leaves by the concentration of solar radiation at a focal point at the bottom of the still. The temperature at the focal point can reach 400 °C, and the energy produced exceeds 23 kWh during operating hours. Knowing that the water consumes only 1 kWh for evaporation (the steam produced is not condensed since olive leaves have no essential oil content), the remaining energy is consumed by the olive leaves. This causes total erosion of the leaves by emptying them of their contents and, of course, an indirect increase in antioxidant activity by increasing the amount of Oleuropein (110.07 mg g−1 DM), which is the molecule responsible for the antioxidant effect. Because SHM is a renewable source and is free, energy consumption has been minimized to zero. While, during the extraction time, the decoction method requires approximately 11.28 kWh of electricity (in 4 h), resulting in 9.54 kg of CO2, SHM can be described as an effective, long-lasting, and cost-effective method for extracting TPC, TFC, and antioxidants.

Relative linear importance

As previously mentioned, Pearson coefficient was used to measure the intensity of the linear relationship between each pair of investigated variables. The results are illustrated in a correlation matrix (Fig. 6). Each square includes two values, where the values in parentheses indicate the value of the calculated p-value, while the other represents the value of the Pearson coefficient. In addition, a positive correlation is displayed using blue color, while red presents a negative correlation. We can observe some low correlation (r-Pearson < 0.7 or r-Pearson > − 0.7) to strong correlation (r-Pearson > 0.7 or r-Pearson < − 0.7). As a result, AA and TPC have a high significant positive relationship of 0.89 (p-value 0.05), while AA and TFC have a strong correlation of 0.77 (p-value 0.05). These findings support previous research that suggests a high TPC is linked to AA in ethyl acetate extract (r = 0.997; p = 0.053) (Brahmi et al. 2012). Terpinc et al. (2012) showed that TPC of oil cakes had a statistically significant negative association with AA, according to Pearson’s correlation coefficients of (− 0.76) suggesting that TPC is not the only contributor to the AA of the oil cakes. In the same, Tawaha et al. (2007) discovered that there was a positive linear correlation between AA and TPC in both methanolic and aqueous extracts (coefficients r = 0.892 and 0.851, respectively). These findings suggest that phenolic chemicals played a substantial role in the AA of the plants investigated. We also clearly see that TPC is more correlated with TFC (r-Pearson = 0.87, p-value < 0.05) compared to the other variables showing that the variation of each one of these variables is explained by the other remaining two variables. In the same, Brahmi et al. (2012) showed that ethyl acetate extract (r = 1.000; p = 0.000), followed by hexane, chloroform, and methanol as extraction solvents (r = 0.976; p = 0.139, r = 0.434; p = 0.714, and r = 0.597; p = 0.592, respectively), exhibited a substantial and positive correlation between TPC and TFC. In addition, the Tf and Qw are highly influenced by the Gb and QO-L with a highly significant positive relationship of 0.90 (p = 0.00) and 0.98 (p = 0.00), respectively.

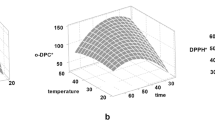

Prediction results

The MLR approach was used to predict the concentrations of AA, TPC, and TFC. In this study, significant predictors were chosen based on the degree of linear correlation, and the MLR results for each investigated variable were compared to the real dataset. Graphs were generated by plotting the z-axis response against two independent variables. Figure 7a–c depicts the interactions between the AA and each of the two other factors (TPC and TFC). The AA of olive leaves increased from 87.50% to 91.16% with the increase in TPC from 165.78 to 189.58 mg EAG g−1 of dry matter and TFC from 72 to 87.53 mg EQ g−1 of dry matter. Thus, the metrics (RMSE, MAE, and R2) employed to measure the gap between the real and predicted values for AA were 0.333, 0.440, and 0.804, respectively. Close results were observed for TPC (RMSE = 2.056, MAE = 2.321 and R2 = 0.881) and TFC (RMSE = 1.884, MAE = 2.246 and R2 = 0.757) between predicted and real values. These results show good performance for the MLR in predicting these output variables. These results were agreed with (R2 = 0.86, 0.98, and 0.85 for AA, TPC, and TFC, respectively) reported by Darvishzadeh and Orsat (2022) using microwave-assisted extraction of Russian olive leaves. Similarly, Tawaha et al. (2007) showed a coefficient of determination (R2) = 0.80 and (R2) = 0.72 for aqueous and methanolic extracts, respectively. Moreover, Dahmoune et al. (2015) showed that the determination coefficient (R2) was 0.93 and RMSE = 4.433 of TPC from myrtle leaves between predicted and real values.

Conclusion

The impact of solar heat treatment on the phenolic content and antioxidant capacity of an aqueous extract from olive leaves was examined for the first time in this study. This processing increases TPC, TFC, and AA. The originality of this work also resides in its explanation of how heat treatment affects the antioxidant chemicals in olive leaves. Using HPLC–UV analysis, we have demonstrated an increase in the quantity of phenolic compounds and antioxidant activity due to the high oleuropein content. Using SHM to increase the extraction of phenolic compounds from olive leaves could be an innovative new approach. The effectiveness of direct radiation in the workplace was a major factor in how well SHM operated. When compared to other conventional approaches, temperature has an obvious impact on extraction kinetics; SHM extraction can be regarded of as a more successful process because it employs green energy. Therefore, in this study, a linear relationship was found between AA, TPC, and TFC. In addition, there is a positive linear correlation between AA and TPC, and between AA and TFC for SHM extract (coefficient r = 0.89 and 0.77, respectively). These results suggested that the TPC and TFC significantly contributed to the AA of the studied olive leaves.

References

Afzal A, Anjum M, Abdul G, Jorge LA (2017) Development of hybrid solar distillation system for essential oil extraction. Renew Energy 113:22–29. https://doi.org/10.1016/j.renene.2017.05.027

Ahmad-Qasem MH, Cánovas J, Barrajón-Catalán E, Micol V, Cárcel JA, García-Pérez JV (2013) Kinetic and compositional study of phenolic extraction from olive leaves (var. Serrana) by using power ultrasound. Innov Food Sci Emerg Technol 17:120–129. https://doi.org/10.1016/j.ifset.2012.11.008

Altiok E, Bayçin D, Bayraktar O, Ülkü S (2008) Isolation of polyphenols from the extracts of olive leaves (Olea europaea L.) by adsorption on silk fibroin. Sep Purif Technol 62(2):342–348. https://doi.org/10.1016/j.seppur.2008.01.022

Aouidi F (2012) Etude et Valorisation des feuiles d’Olivier Olea Europaea dans l’Industrie Agro-Alimentaire. Dissertation, University of Carthage

Apostolakis A, Grigorakis S, Makris DP (2014) Optimisation and comparative kinetics study of polyphenol extraction from olive leaves (Olea europaea) using heated water/glycerol mixtures. Sep Purif Technol 128:89–95. https://doi.org/10.1016/j.seppur.2014.03.010

Box JD (1983) Investigation of the Folin-Ciocalteau phenol reagent for the determination of polyphenolic substances in natural waters. Water Res 17(5):511–525. https://doi.org/10.1016/0043-1354(83)90111-2

Brahmi F, Mechri B, Dabbou S, Dhibi M, Hammami M (2012) The efficacy of phenolics compounds with different polarities as antioxidants from olive leaves depending on seasonal variations. Ind Crops Prod 38(1):146–152. https://doi.org/10.1016/j.indcrop.2012.01.023

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci Technol 28(1):25–30. https://doi.org/10.1016/S0023-6438(95)80008-5

Class A (2009) Determination of biophenols in olive oils by HPLC. Int Olive Counc 29:1–8

da Rosa GS, Vanga SK, Gariepy Y, Raghavan V (2019a) Comparison of microwave, ultrasonic and conventional techniques for extraction of bioactive compounds from olive leaves (Olea europaea L.). Innov Food Sci Emerg Technol 58:102234. https://doi.org/10.1016/j.ifset.2019.102234

da Silva ACP, Paiva JP, Diniz RR, dos Anjos VM, Silva ABSM, Pinto AV, dos Santos EP, Leitão AC, Cabral LM, Rodrigues CR, de Pádula M, Santos BAMC (2019) Photoprotection assessment of olive (Olea europaea L.) leaves extract standardized to oleuropein: in vitro and in silico approach for improved sunscreens. J Photochem Photobiol B Biol 193:162–171. https://doi.org/10.1016/j.jphotobiol.2019.03.003

Dahmoune F, Nayak B, Moussi K, Remini H, Madani K (2015) Optimization of microwave-assisted extraction of polyphenols from Myrtus communis L. leaves. Food Chem 166:585–595. https://doi.org/10.1016/j.foodchem.2014.06.066

Darvishzadeh P, Orsat V (2022) Microwave-assisted extraction of antioxidant compounds from Russian olive leaves and flowers: optimization, HPLC characterization and comparison with other methods. J Appl Res Med Aromat Plants 27:100368. https://doi.org/10.1016/j.jarmap.2021.100368

Dewanto V, Xianzhong W, Adom KK, Liu RH (2002) Thermal processing enhances the nutritional value of tomatoes by increasing total antioxidant activity. J Agric Food Chem 50(10):3010–3014. https://doi.org/10.1021/jf0115589

Ezzarrouqy K, Hejjaj A, Idlimam A, Ait F, Laila M (2021) Study of the energetic, exergetic, and thermal balances of a solar distillation unit in comparison with a conventional system during the distillation of rosemary leaves. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-021-17612-1

Flamini G, Cioni PL, Morelli I (2003) Volatiles from leaves, fruits, and virgin oil from Olea europaea cv. Olivastra Seggianese from Italy. J Agric Food Chem 51(5):1382–1386. https://doi.org/10.1021/jf020854y

Ghasemi S, Koohi DE, Emmamzadehhashemi MSB, Khamas SS, Moazen M, Hashemi AK, Amin G, Golfakhrabadi F, Yousefi Z, Yousefbeyk F (2018) Investigation of phenolic compounds and antioxidant activity of leaves extracts from seventeen cultivars of Iranian olive (Olea europaea L.). J Food Sci Technol 55(11):4600–4607. https://doi.org/10.1007/s13197-018-3398-1

Ghomari O, Sounni F, Massaoudi Y, Ghanam J, Drissi Kaitouni LB, Merzouki M, Benlemlih M (2019) Phenolic profile (HPLC-UV) of olive leaves according to extraction procedure and assessment of antibacterial activity. Biotechnol Reports 23:e00347. https://doi.org/10.1016/j.btre.2019.e00347

Giacometti J, Žauhar G, Žuvić M (2018) Optimization of ultrasonic-assisted extraction of major phenolic compounds from olive leaves (Olea europaea L.) using response surface methodology. Foods 7(9):1–14. https://doi.org/10.3390/foods7090149

Goulas V, Papoti VT, Exarchou V, Tsimidou MZ, Gerothanassis IP (2010) Contribution of flavonoids to the overall radical scavenging activity of olive (Olea europaea L.) leaf polar extracts. J Agric Food Chem 58(6):3303–3308. https://doi.org/10.1021/jf903823x

Guinda Á, Castellano JM, Santos-Lozano JM, Delgado-Hervás T, Gutiérrez-Adánez P, Rada M (2015) Determination of major bioactive compounds from olive leaf. LWT-Food Sci Technol 64(1):431–438. https://doi.org/10.1016/j.lwt.2015.05.001

Hilali S, Anne Sylvie FT, Elmaataoui M, Emmanuel P, Hejjaj A, Ait Nouh F, Idlimam A, Magali JN, Antoine B, Mandi L, Chemat F (2018) Deodorization by solar steam distillation of rosemary leaves prior to solvent extraction of rosmarinic, carnosic, and ursolic acids. ACS Sust Chem and Eng 6(8):10969–10979. https://doi.org/10.1021/acssuschemeng.8b02347

Hilali S, Anne Sylvie FT, Karine R, Hejjaj A, Ait Nouh F, Idlimam A, Antoine B, Mandi L, Chemat F (2019) Green extraction of essential oils, polyphenols, and pectins from orange peel employing solar energy: toward a zero-waste biorefnery. ACS Sust Chem Eng. https://doi.org/10.1021/acssuschemeng.9b02281

Irakli M, Chatzopoulou P, Ekateriniadou L (2018) Optimization of ultrasound-assisted extraction of phenolic compounds: oleuropein, phenolic acids, phenolic alcohols and flavonoids from olive leaves and evaluation of its antioxidant activities. Ind Crops Prod 124:382–388. https://doi.org/10.1016/j.indcrop.2018.07.070

Japón-Luján R, Luque de Castro MD (2006) Superheated liquid extraction of oleuropein and related biophenols from olive leaves. J Chromatogr A 1136(2):185–191. https://doi.org/10.1016/j.chroma.2006.09.081

Jayasimha B (2006) Application of Schefer refectors for process industry. Int Solar Cooker Conf 8:1–2

Kamran M, Hamlin AS, Scott CJ, Obied HK (2015) Drying at high temperature for a short time maximizes the recovery of olive leaf biophenols. Ind Crops Prod 78:29–38. https://doi.org/10.1016/j.indcrop.2015.10.031

Malenčić D, Maksimović Z, Popović M, Miladinović J (2008) Polyphenol contents and antioxidant activity of soybean seed extracts. Bioresour Technol 99(14):6688–6691. https://doi.org/10.1016/j.biortech.2007.11.040

Malik NSA, Bradford JM (2008) Recovery and stability of oleuropein and other phenolic compounds during extraction and processing of olive (Olea europaea L.) leaves. J Food Agric Environ 6(2):8–13

Martín-García B, Verardo V, León L, De la Rosa R, Arráez-Román D, Segura-Carretero A, Gómez-Caravaca AM (2019) GC-QTOF-MS as valuable tool to evaluate the influence of cultivar and sample time on olive leaves triterpenic components. Food Res Int 115:219–226. https://doi.org/10.1016/j.foodres.2018.08.085

Martín-garcía B, Pimentel-moral S, Gómez-caravaca AM, Arráez-román D, Segura-carretero A (2020) Industrial Crops & Products Box-Behnken experimental design for a green extraction method of phenolic compounds from olive leaves. Ind Crops Prod 154(June):112741. https://doi.org/10.1016/j.indcrop.2020.112741

Munir A (2010) Design, development and modeling of a solar distillation system for the processing of medicinal and aromatic plants. Dissertation, University of Kassel

Mylonaki S, Kiassos E, Makris DP, Kefalas P (2008) Optimisation of the extraction of olive (Olea europaea) leaf phenolics using water/ethanol-based solvent systems and response surface methodology. Anal Bioanal Chem 392(5):977–985. https://doi.org/10.1007/s00216-008-2353-9

Nicolì F, Negro C, Vergine M, Aprile A, Nutricati E, Sabella E, Miceli A, Luvisi A, De Bellis L (2019) Evaluation of phytochemical and antioxidant properties of 15 Italian Olea europaea L. cultivar leaves. Molecules 24(10):1998. https://doi.org/10.3390/molecules24101998

Parejo I, Viladomat F, Bastida J, Rosas-Romero A, Flerlage N, Burillo J, Codina C (2002) Comparison between the radical scavenging activity and antioxidant activity of six distilled and nondistilled mediterranean herbs and aromatic plants. J Agric Food Chem 50(23):6882–6890. https://doi.org/10.1021/jf020540a

Putnik P, Barba FJ, Španić I, Zorić Z, Dragović-Uzelac V, Bursać Kovačević D (2017) Green extraction approach for the recovery of polyphenols from Croatian olive leaves (Olea europea). Food Bioprod Process 106:19–28. https://doi.org/10.1016/j.fbp.2017.08.004

Rafiee Z, Jafari SM, Alami M, Khomeiri M (2011) Microwave-assisted extraction of phenolic compounds from olive leaves; a comparison with maceration. J Anim Plant Sci 21(4):738–745

Rosa AD, Junges A, Fernandes IA, Cansian RL, Corazza ML, Franceschi E, Backes GT, Valduga E (2019b) High pressure extraction of olive leaves (Olea europaea): bioactive compounds, bioactivity and kinetic modelling. J Food Sci Technol 56(8):3864–3876. https://doi.org/10.1007/s13197-019-03856-w

Scheffler W (2006) Introduction to the revolutionary design of Schefer refectors. Int Solar Cooker Conf

Silva S, Gomes L, Leitão F, Coelho AV, Boas LV (2006) Phenolic compounds and antioxidant activity of Olea europaea L. Fruits and leaves. Food Sci Technol Int 12(5):385–396. https://doi.org/10.1177/1082013206070166

Souilem S, Fki I, Kobayashi I, Khalid N, Neves MA, Isoda H, Sayadi S, Nakajima M (2017) Emerging technologies for recovery of value-added components from olive leaves and their applications in food/feed industries. Food Bioprocess Technol 10(2):229–248. https://doi.org/10.1007/s11947-016-1834-7

Taamalli A, Arráez-Román D, Ibañez E, Zarrouk M, Segura-Carretero A, Fernández-Gutiérrez A (2012) Optimization of microwave-assisted extraction for the characterization of olive leaf phenolic compounds by using HPLC-ESI-TOF-MS/IT-MS2. J Agric Food Chem 60(3):791–798. https://doi.org/10.1021/jf204233u

Tamasi G, Baratto MC, Bonechi C, Byelyakova A, Pardini A, Donati A, Leone G, Consumi M, Lamponi S, Magnani A, Rossi C (2019) Chemical characterization and antioxidant properties of products and by-products from Olea europaea L. Food Sci Nutr 7(9):2907–2920. https://doi.org/10.1002/fsn3.1142

Tawaha K, Alali FQ, Gharaibeh M, Mohammad M, El-Elimat T (2007) Antioxidant activity and total phenolic content of selected Jordanian plant species. Food Chem 104(4):1372–1378. https://doi.org/10.1016/j.foodchem.2007.01.064

Terpinc P, Čeh B, Ulrih NP, Abramovič H (2012) Studies of the correlation between antioxidant properties and the total phenolic content of different oil cake extracts. Ind Crops Prod 39(1):210–217. https://doi.org/10.1016/j.indcrop.2012.02.023

Acknowledgements

The authors would like to thank the National Center for Studies and Research on Water and Energy (Cadi Ayyad University-Morocco) for the technical and financial support of this research.

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

KE involved in methodology, visualization, investigation, formal analysis, validation, and writing—original draft. SS involved in formal analysis, validation, data curation, and writing—original draft. AH involved in investigation and visualization. AI involved in methodology, visualization, and writing—review and editing. LM involved in conceptualization, project administration, resources, supervision, visualization, and writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflict of interest.

Additional information

Editorial responsibility: Maryam Shabani.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ezzarrouqy, K., Sbahi, S., Hejjaj, A. et al. A green extraction method of phenolic compounds from olive leaves (Olea europaea L.): evaluation and prediction using multiple linear regression. Int. J. Environ. Sci. Technol. 21, 3761–3774 (2024). https://doi.org/10.1007/s13762-023-05224-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-023-05224-w