Abstract

In this work, R134a and its alternatives refrigerant (R513A and R1234yf) have been experimentally investigated in a heat pump system. The exergy and environmental analyzes of refrigerants were performed for the heat pump. The new methods such as exergoenvironmental and exergoenviroeconomic were used to perform environmental analysis of the heat pump. No study was found in the literature on the application of these methods to heat pump systems using R134a, R513A and R1234yf. Therefore, this study is different from those that have already been carried out and will make an important contribution to the literature. When used R134a R513A, and R1234yf the exergy destruction of components of the heat pump is similar and comparable. The most exergy destruction for all refrigerants was seen in the compressor. At − 10 °C evaporator temperature, the exergy efficiency of R513A and R1234yf is 5.83% and 11.48% and higher than R134a, respectively. The exergy efficiency of R513A and R1234yf is 8.38% and 2.72% and higher than R134a, respectively, at − 5 °C evaporator temperature. The exergy efficiency of R513A and R1234yf is lower than R134a at 0 °C evaporator temperatures. At 0 °C evaporator temperature, the exergy efficiency of R513A and R1234yf is 9.69% and 2.28% and lower than R134a, respectively. So, according to the results of exergy (thermodynamics second law) analysis, R1234yf and R513A refrigerants which have low global warming potential rates are being used as a substitute to R134a, especially at low evaporator temperatures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Some arrangements such as the Montreal Protocol and Kyoto protocol have been made to decrease the adverse impacts (climate change and global warming) of hydrofluorocarbons (HFCs) in applications of refrigeration/heat pump systems (Sun et al. 2019). In order to eliminate the environmental damages of refrigerants, there is an increased interest in new generation or alternative refrigerant investigations that do not harm the environment (refrigerants which have lower GWP (Global Warming Potential) ratios and zero ODP (Ozone Depletion Potential)) (Sun et al. 2019). R134a (HFC) refrigerant is widely used in heating and cooling systems. The first alternative refrigerants developed to replace R134a are R1234yf and R1234ze (E). These synthetic environmentally friendly fluids are included in the hydro-fluoro olefins (HFO) group. The ODP of R1234ze (E) and R1234yf in the HFO group are zero and have no flammability properties. In addition, the GWP values of these fluids are lower than 1 (Mota-Babiloni et al. 2014; Feng et al. 2018).

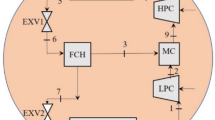

The comparison of pressure enthalpy graphs of R134a, R513A, and R1234yf is presented in Fig. 1. The heat pump model for refrigerants is also shown in Fig. 1. The modeled heat pump circuit has an evaporator, a compressor, a condenser, and an expansion device. The heat pump model is drawn for an evaporator temperature of − 10 °C and a condenser temperature of 35 °C (isentropic efficiency of the compressor 0.7 and superheat and subcooling temperatures of 5 °C).

According to the modeled results of the heat pump, the COP values of R134a, R513A and R1234yf were calculated to be 4.42, 4.32 and 4.30, respectively. Moreover, the outlet temperatures of R513A and R1234yf are lower by 12.84% and 20.26%, respectively, compared to R134a. The theoretical analyses carried out give a first assessment for the real applications of the system. However, they do not fully reflect the results of a real system. Therefore, the analysis of energy and life cycle climate performance (LCCP) of testing these refrigerants in a real system was investigated in a previous study conducted by Yıldız and Yıldırım (2021).

There are many studies related to the advantages and disadvantages of HFO refrigerants in the literature. The use of R1234yf in air conditioning systems does not increase energy efficiency (Zilio et al. 2011), and various changes are needed in the system before R1234ze can be used in vapor compression refrigeration systems (Mota-Babiloni et al. 2017b). Recently, R513A refrigerant is developed to eliminate the negative characteristics of HFOs and keep the GWP rate low. R513A contains a binary mixture of R134a and R1234yf (R134a(44)/R1234yf(56)) (Mota-Babiloni et al. 2017a; Llopis et al. 2017).

Yıldız and Yıldırım investigated the use of R134a and its two alternatives (R1234yf and R513A) refrigerants in a heat pump system theoretically and experimentally and they found that R513A and R1234yf had lower greenhouse gas emissions than R134a (Yıldız and Yıldırım 2021). Mota-Babiloni et al. investigated the use of R513A and R134a in a cooling system experimentally. They found that R513A refrigerant outperformed R134a (5% on average) and R513A had higher refrigerant capacity (Mota-Babiloni et al. 2017a). In another study, Mota-Babiloni et al. studied experimentally the exergy analysis of the use of refrigerants R134a and R513A in a cooling system. They noted that the greatest amount of exergy destruction occurred in the compressor, and then in the evaporator. In addition, they stated that the exergy efficiency of R134a is 0.4% lower than R513A and that R513A can be used instead of R134a in cooling systems according to the results of exergy analysis (Mota-Babiloni et al. 2018). Meng et al. explored experimentally both cooling and heating performance of the R1234yf/R134a (89/11 by mass) refrigerant mixture instead of R134a refrigerant in vehicle air conditioning systems. They stated that the heating and cooling capacities of the refrigerant mixture (R1234yf/R134a (89/11)) are almost the same as R134a. They explained that the energy performance of the R1234yf/R134a refrigerant mixture is 4% to 9% lower in cooling mode and 4% to 16% lower in heating mode than R134a. They stated that R1234yf/R134a (89/11) refrigerant mixture can be used instead of R134a refrigerant in the vehicle air conditioning system (Meng et al. 2018). Llopis et al. experimentally investigated R450A and R513A as replace to R507A and R134a in a commercial cooling system. They evaluated the experimental results according to the 24-h energy consumption of the compressor of the commercial refrigeration system. They noted that the compressor power consumption of the R450A and R513A is slightly higher than that of the R134a, but the R450A and R513A refrigerants are potent in reducing direct greenhouse gas emissions (Llopis et al. 2017). Aprea et al. experimentally explored the energy efficiencies of the R134a, R1234yf, and R134a/R1234yf mixture (10/90 by mass) refrigerants in a household refrigeration system. In the study, they noted that the mixture of R1234yf/R134a (10/90) exhibits behavior close to R134a in terms of temperature and pressure. They also stated that when the appropriate amount of R1234yf/R134a(10/90) refrigerant mixture is charged into the system, it saves 14% and 16% energy compared to R1234yf and R134a, respectively (Aprea et al. 2017). In another study, Aprea et al. R134a, R1234ze(E)/R134a (90/10 by mass), R1234yf/ R134a (90/10 by mass), R1234yf, R1234ze(E), refrigerants experimentally investigated in domestic refrigerators. They measured the power consumption of refrigerants for 24 h and calculated their annual energy consumption. Also, in this study, the environmental impact analysis of refrigerants has been performed (life cycle climate performance (LCCP) method was used). They found that the power consumption of R1234ze(E)/R134a (90/10) and R1234yf/R134a (90/10) refrigerant mixtures are 16% and 14% lower than R134a, respectively. They also stated that the R1234yf/R134a (90/10) refrigerant mixture has lower greenhouse gas emission (about 17%) than that R134a (Aprea et al. 2018). Lee et al. experimentally investigated using the R134a, R1234yf, and three different R1234yf/R134a refrigerant mixtures in a heat pump system. The R1234yf/R134a binary mixtures contain 5%, 10% and 15% R134a refrigerant. In their experimental results, they stated that the COP, heating/cooling capacities, and discharge temperatures of R1234yf/R134a mixtures and R1234yf were similar to R134a refrigerant. They also stated that the fluid charge amount of R1234yf and R1234yf/R134a mixtures is 11% lower than R134a (Lee et al. 2013).

There are many studies in the literature regarding the use of R134a, R513A and R1234yf in different mixing ratios in refrigeration and heat pump systems. However, most of the studies in the literature are related to energy and exergy.

Calıskan developed new methods based on exergy and economy to evaluate the environmental analysis of energy systems. This exergy based methods were named by Calıskan as exergoenvironmental (EXEN) and exergoenviroeconomic (EXENEC) (Caliskan 2015). The EXEN and EXENEC are new approaches and used in many studies (Aghbashlo and Rosen 2018a, b; Yousef and Hassan 2019; Elbar et al. 2019).

The purpose of this study is that the experimental investigation of exergetic and environmental analyses of a heat pump system for R134a and its two alternatives (R513A and R1234yf). In this study, refrigerants were tested in the heat pump system at 10 °C, − 5 °C, and 0 °C evaporator temperatures, and 35 °C condenser temperature (The tests were conducted in December 2019 in Isparta, Turkey). Wherein said evaporator temperature is the saturation temperature of the refrigerant corresponding to the evaporator pressure at which the expansion valve is adjusted. Also, a water regulator valve was used to adjust the saturation pressure corresponds the 35 °C condensing temperature of the refrigerant.

The EXEN and EXENEC analyses were used in this work for the environmental analysis. As mentioned earlier, EXEN and EXENEC methods have been used by many researchers for various applications. However, no study was found in the literature on the use of these new methods for heat pump systems. In this study, the EXEN and EXENEC analyses were applied to a heat pump for the first time. Therefore, this study is different from those that have already been conducted and will make important contributions to the literature.

Materials and methods

The heat pump system shown in Fig. 2 was employed to test performance R134a, R513A, and R1234yf refrigerants. The test system consists of 3 parts: (I) primary circuit (heat pump), (II) evaporator secondary circuit (closed loop), and (III) condenser secondary circuit (open loop). Hermetic compressor (1 HP), two plate heat exchanger (28 plates) for evaporator and condenser, and automatic expansion valve (AXV) were also employed in the primary circuit (heat pump system). The evaporator secondary circuit (close loop) consists of a circulation pump, a heater controlled by PID, and an axial turbine flow meter. The secondary circuit of the condenser was designed as an open-loop and it has a regulator valve (to ensure that the pressure of the condenser is constant) and an axial turbine flow meter. The evaporator (close loop) and condenser (open loop) secondary cycles were used ethylene glycol/water mixture (50/50 by mass) and water as a fluid, respectively.

The amount of refrigerant in the heat pump is one of the important parameters (Afshari et al. 2016). Direk and Yüksel experimentally investigated the refrigerants R1234yf and R134a in an automotive heat pump system. Based on the liquid densities of the refrigerants at 25 °C, the refrigerant charge amounts were determined (625 g for R134a, 575 g for R1234yf). Thus, they stated that mass equilibrium was achieved between the refrigerants (Direk and Yüksel 2020). The heat pump used in this study is designed for R134a refrigerant. The appropriate charge quantity for R134a is 450 g. Considering the liquid densities of the refrigerants, the charge quantity for R513A and R1234yf was determined to be 420 g and 405 g, respectively.

To measure temperatures, input and output of each component of the heat pump system K-type thermocouples were employed. The suction and discharge pressures were measured by Testo 570 digital manifold. A digital wattmeter was used to record power consumption. To measure the flow rate of secondary fluids of evaporator and condenser axial turbine flow meters have been used. The properties of measuring equipment used in the test system are shown in Table 1. All measurements were saved with a datalogger (sample period 1 s) for 15 min when the system is in the steady stage. In addition, the whole pipe and equipment of the heat pump test system are insulated to reduce heat losses and ensure accurate measurement.

Exergy analysis

Thermodynamic second law (exergy) analysis is used to identify exergy destruction and efficiency of each system component. The general exergy balance equation, according to thermodynamics second law, for control volume and steady-state is given Eq. 1. Here, \({\dot{\text{E}}}{\text{x}}_{{\text{d}}}\) shows exergy destruction rate. The exergy destruction rate of the heat pump can be calculated by Eq. 2 (Mota-Babiloni et al. 2018).

The specific exergy equation for refrigerants is given in Eq. 3 (Dincer and Kanoğlu 2010; Mota-Babiloni et al. 2018). In this equation, the effect of potential and kinetic energy is neglected. In Eq. 3, h0 and s0 show specific enthalpy and specific entropy of dead state conditions, respectively. Dead state pressure (P0) was accepted as 101.325 kPa and dead state temperature (T0) was 25 °C.

The exergy equations for each component of the heat pump system are as follows (Eqs. 4–11) (Dincer and Kanoğlu 2010):

Compressor:

Condenser:

Expansion valve:

Evaporator:

In Eqs. 4–11, h and s show specific enthalpy and specific entropy of related points. \(\dot{m}_{{{\text{ref}}}}\) shows mass flow rate of refrigerant. The exergy efficiency of the heat pump is calculated by Eq. 12 (Dincer and Kanoğlu 2010).

Exergoenvironmental (EXEN) analysis

The EXEN is a new approach developed by Caliskan (2017) to improve environmental analyses of thermal energy systems. There are three considerable points in the EXEN: (I) It is involved the exergy rate of the selected energy option. (II) It is to calculate the CO2 emission values (from the life cycle analysis) for the selected energy choice. (III) It is to determine the operating hours of the energy system. The EXEN is calculated by Eq. 13 (Caliskan 2015, 2017)

\(x_{{{\text{ex}},{\text{CO}}_{2} }}\) shows the exergetic greenhouse releasing (CO2) in a period (kgCO2 time−1), \(y_{{{\text{CO}}_{2} }}\) presents the greenhouse emission value of the energy choice (kgCO2 kWh−1), \({\dot{\text{E}}}{\text{x}}_{{{\text{in}}}}\) is related (useful) exergy rate of the energy option (kW) and \(t_{{{\text{working}}}}\) is running time of the system (h time−1).

There are many CO2 emission values in the literature for electrical energy production depending on the energy source. The electricity generation CO2 emission value is assumed as 0.523 (kgCO2 kWh−1) for Turkey (Atilgan and Azapagic 2016). In addition, it is assumed that the heat pump operates 12 h in a day and the useful exergy rate of the heat pump is 1 kW.

Exergoenviroeconomic (EXENEC) analysis

The EXENEC analysis was developed by Calıskan (Caliskan 2015) and is combined with exergetic, economic, and environmental analyses. The EXENEC parameter (\(C_{{{\text{CO}}_{2} }}\)) is determined by EXENEC analysis (\(C_{{{\text{ex}},{\text{CO}}_{2} }}\)) (Caliskan 2015, 2017):

\(x_{{{\text{ex}},{\text{CO}}_{2} }}\) shows the EXEN result (kgCO2 time−1), \(C_{{{\text{CO}}_{2} }}\) presents the CO2 price ($ kgCO2−1), and \(C_{{{\text{ex}},{\text{CO}}_{2} }}\) shows the EXENEC result ($ time−1). The emission price of CO2 was assumed 0.0145 ($ kgCO2−1) in this work (Caliskan 2017).

Results and discussion

This study presents the testing of R134a, R513A, and R1234yf refrigerants in a heat pump. During the experimental study, the compressor power consumption and the temperatures and pressures at the input and output of each component of the heat pump system have been measured. The average measurement and calculation values obtained by testing the refrigerants in the heat pump are presented in Table 2.

The results of the exergy analysis using the data in Table 2 are shown in Fig. 3.

At − 10 °C evaporator temperature: exergy input (\({\dot{\text{E}}}{\text{x}}_{{{\text{in}}}}\)), exergy destruction (\({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{system}}}}\)), and transiting exergy rate (\({\dot{\text{E}}}{\text{x}}_{{{\text{trans}}.}}\)) of R134a are 616 W, 518 W, and 98 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{in}}}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{system}}}}\), and \({\dot{\text{E}}}{\text{x}}_{{{\text{trans}}.}}\) of R513A are 668 W, 556 W, and 112 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{in}}}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{system}}}}\), and \({\dot{\text{E}}}{\text{x}}_{{{\text{trans}}.}}\) of R1234yf are 652 W, 537 W, and 115 W, respectively. The exergy efficiency (\(\eta_{{{\text{ex}},{\text{system}}}}\)) of R134a, R513A, and R1234yf is 15.89%, 16.81%, and 17.71%, respectively. At − 10 °C evaporator temperature, the \(\eta_{{{\text{ex}},{\text{system}}}}\) of R513A and R1234yf is 5.83% and 11.48% and higher than R134a, respectively.

At − 5 °C evaporator temperature \({\dot{\text{E}}}{\text{x}}_{{{\text{in}}}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{system}}}}\) and \({\dot{\text{E}}}{\text{x}}_{{{\text{trans}}.}}\) of R134a are 664 W, 560 W, and 104 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{in}}}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{system}}}}\), and \({\dot{\text{E}}}{\text{x}}_{{{\text{trans}}.}}\) of R513A are 724 W, 601 W, and 123 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{in}}}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{system}}}}\), and \({\dot{\text{E}}}{\text{x}}_{{{\text{trans}}.}}\) of R1234yf are 704 W, 591 W, and 113 W, respectively. The \(\eta_{{{\text{ex}},{\text{system}}}}\) of R134a, R513A, and R1234yf is 15.68%, 17.00%, and 16.11%, respectively. At − 5 °C evaporator temperature, the \(\eta_{{{\text{ex}},{\text{system}}}}\) of R513A and R1234yf is 8.38% and 2.72% and higher than R134a, respectively.

At 0 °C evaporator temperature \({\dot{\text{E}}}{\text{x}}_{{{\text{in}}}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{system}}}}\), and \({\dot{\text{E}}}{\text{x}}_{{{\text{trans}}.}}\) of R134a are 708 W, 593 W, and 115 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{in}}}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{system}}}}\), and \({\dot{\text{E}}}{\text{x}}_{{{\text{trans}}.}}\) of R513A are 776 W, 662 W, and 114 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{in}}}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{system}}}}\), and \({\dot{\text{E}}}{\text{x}}_{{{\text{trans}}.}}\) of R1234yf are 752 W, 633 W, and 119 W, respectively. The \(\eta_{{{\text{ex}},{\text{system}}}}\) of R134a, R513A, and R1234yf is 16.25%, 14.68%, and 15.88%, respectively. At 0 °C evaporator temperature, the \(\eta_{{{\text{ex}},{\text{system}}}}\) of R513A and R1234yf is 9.69% and 2.28% and lower than R134a, respectively.

As shown in Fig. 3, the \(\eta_{{{\text{ex}},{\text{system}}}}\) of R1234yf and R513A is higher than that of R134a at − 10 °C and − 5 °C evaporator temperatures. The \(\eta_{{{\text{ex}},{\text{system}}}}\) of R513A and R1234yf is lower than that of R134a at evaporator temperatures of 0 °C. This is because R513A and R1234yf have lower irreversibility than R134a at low evaporator temperatures. According to the results of exergy analysis (second law of thermodynamics), R1234yf and R513A, which have low GWP values, can be used as substitutes for R134a, especially at low evaporator temperatures.

The exergy destruction rate in the heat pump components (compressor (\({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{comp}}.}}\)), condenser (\({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{cond}}.}}\)), expansion valve (\({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{AXV}}.}}\)) and evaporator (\({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{evap}}.}}\)) is illustrated in Fig. 4. It can be seen that the irreversibilities of the heat pump components are the same for R134a, R513A, and R12134yf. As seen in Fig. 4, the majority of exergy destruction occurs in the compressor. For all refrigerants, the lowest exergy destruction rate occurred in the expansion valve and the condenser.

At − 10 °C evaporator temperature the \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{comp}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{cond}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{AXV}}.}}\) and \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{evap}}.}}\) of the R134a are 211 W, 67 W, 57 W, and 184 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{comp}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{cond}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{AXV}}.}}\) and \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{evap}}.}}\) of the R513A are 274 W, 50 W, 69 W, and 162 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{comp}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{cond}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{AXV}}.}}\) and \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{evap}}.}}\) of the R1234yf are 287 W, 47 W, 57 W, and 146 W, respectively.

At − 5 °C evaporator temperature the \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{comp}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{cond}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{AXV}}.}}\) and \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{evap}}.}}\) of the R134a are 299 W, 62 W, 44 W, and 155 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{comp}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{cond}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{AXV}}.}}\) and \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{evap}}.}}\) of the R513A are 326 W, 58 W, 62 W, and 156 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{comp}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{cond}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{AXV}}.}}\) and \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{evap}}.}}\) of the R1234yf are R1234yf are 356 W, 50 W, 48 W, and 136 W, respectively.

At 0 °C evaporator temperature the \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{comp}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{cond}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{AXV}}.}}\) and \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{evap}}.}}\) of the R134a are 349 W, 65 W, 37 W, and 142 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{comp}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{cond}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{AXV}}.}}\) and \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{evap}}.}}\) of the R513A are 293 W, 82 W, 71 W, and 217 W, respectively. The \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{comp}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{cond}}.}}\), \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{AXV}}.}}\) and \({\dot{\text{E}}}{\text{x}}_{{{\text{d}},{\text{evap}}.}}\) of the R1234yf are R1234yf are 361 W, 61 W, 49 W, and 162 W, respectively.

The results of EXEN and EXENEC for the heat pump are shown in Fig. 5. At − 10 °C, − 5 °C and 0 °C evaporator temperatures; The EXEN result of the R134a is 39.50 kgCO2/day, 40.05 kgCO2 day−1, and 38.61 kgCO2 day−1, respectively; The EXEN result of the R513A is 37.33 kgCO2 day−1, 36.92 kgCO2 day−1, and 42.75 kgCO2 day−1, respectively; The EXEN result of the R1234yf is 35.43 kgCO2 day−1, 38.96 kgCO2 day−1, and 39.51 kgCO2 day−1, respectively.

At − 10 °C and − 5 °C evaporator temperatures, the EXEN results of R513A are 5.51% and 7.73% lower than R134a, respectively, while the EXEN result of R513A at 0 °C evaporator temperature is 10.72% higher than R134a. When we compare the EXEN results of R1234yf and R134a; At − 10 °C and − 5 °C evaporator temperatures, the EXEN results of R1234yf are 10.29% and 2.65% lower than R134a, respectively, while the EXEN results of R1234y at 0 °C evaporator temperature are 2.34% higher than R134a.

The EXENEC results depend on CO2 price that mentioned in the Sect. 3.3. At − 10 °C, − 5 °C and 0 °C evaporator temperatures; The EXENEC result of the R134a is 0.573 $ day−1, 0.580 $ day−1, and 0.560 $ day−1, respectively; The EXENEC result of the R513A is 0.541 $ day−1, 0.535 $ day−1, and 0.620 $ day−1, respectively; The EXENEC result of the R1234yf is 0.514 $ day−1, 0.565 $ day−1, and 0.573 $ day−1, respectively.

The RSS (Taylor 1997) method was used to calculate uncertainty. The uncertainties of calculated parameters are shown in Table 3.

Conclusion

The refrigerants R513A and R1234yf have a much better GWP value than R134a, making these refrigerants a likely good alternative to R134a. However, a low GWP value of the refrigerant alone is not sufficient to reduce the environmental impact of heat pump systems. It should also have good energy and exergy performance. To evaluate the replacement of R134a with R513A and R1234yf in a heat pump system, exergy, EXEN, and EXENEC analyses of the refrigerants R134a, R513A, and R1234yf were experimentally investigated in this study. Based on these analyzes, the main findings of the study are as follows:

-

In the case of using R134a refrigerant in the heat pump system, the highest exergy destruction happens in the compressor, while the lowest exergy destruction happens in the expansion valve.

-

Similar to R134a, in the case of using R513A and R1234yf in the heat pump, the most exergy destruction is formed in the compressor. However, low exergy destruction is formed in the condenser and expansion valve depending on the evaporator temperature.

-

The exergy efficiency of R1234yf and R513A is higher than that of R134a at − 10 °C and − 5 °C evaporator temperatures. The exergy efficiency of R513A and R1234yf is lower than R134a at 0 °C evaporator temperatures. So, according to the results of exergy (thermodynamics second law) analysis, R1234yf and R513A refrigerants which have low GWP rates are being used as a substitute to R134a, especially at low evaporator temperatures.

-

At − 10 °C and − 5 °C evaporator temperatures, the EXEN and EXENEC results of R134a are higher than R513A and R1234yf. The EXEN and EXENEC results of R1234yf and R513A at 0 °C evaporator temperature are higher than R134a.

The results of the exergy (second law of thermodynamics), EXEN and EXENC analysis show that R1234yf and R513A with low GWP values can be used instead of R134a, especially at low evaporator temperatures. In addition, the EXEN and ENENEC analyzes are based on the exergy analysis. Therefore, these analyzes provide more reliable results when assessing the environmental impact of thermal systems.

Abbreviations

- \(C_{{{\text{CO}}_{2} }}\) :

-

CO2 price ($ kgCO2−1)

- \(C_{{{\text{ex}},{\text{CO}}_{2} }}\) :

-

Exergoenviroeconomic result ($ time−1)

- \(\eta_{{{\text{ex}}}}\) :

-

Exergy efficiency (–)

- \(t_{{{\text{working}}}}\) :

-

Working time of the system (h time−1)

- \(x_{{{\text{ex}},{\text{CO}}_{2} }}\) :

-

Exergoenvironmental result (kgCO2 time−1)

- \(y_{{{\text{CO}}_{2} }}\) :

-

Greenhouse emission value of the energy option (kgCO2 kWh−1)

- \({\dot{\text{E}}}{\text{x}}\) :

-

Exergy rate (kW)

- \(\dot{Q}\) :

-

Heat energy (kW)

- \(\dot{W}\) :

-

Power consumption (kW)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- e i :

-

Specific exergy (kJ kg−1)

- h :

-

Specific enthalpy (kJ kg−1)

- P :

-

Pressure (kPa or bar)

- s :

-

Specific entropy (kJ kg−1 K−1)

- T :

-

Temperature (℃ or K)

- x :

-

Quality (–)

- 0:

-

Dead state reference point

- AXV:

-

Automatic expansion valve

- comp.:

-

Compressor

- cond.:

-

Condenser

- d:

-

Destruction

- evap.:

-

Evaporator

- EXEN:

-

Exergoenvironmental

- EXENEC:

-

Exergoenviroeconomic

- GWP:

-

Global warming potential

- H:

-

High

- HFC:

-

Hydrofluorocarbon

- HFO:

-

Hydro fluoro olefin

- L:

-

Low

- LCCP:

-

Life cycle climate performance

- ODP:

-

Ozone depletion potential

- ref.:

-

Refrigerant

References

Afshari F, Comakli O, Adiguzel N, Karagoz S (2016) Optimal charge amount for different refrigerants in air-to-water heat pumps. Iran J Sci Technol Trans Mech Eng 40:325–335. https://doi.org/10.1007/S40997-016-0028-2/FIGURES/21

Aghbashlo M, Rosen MA (2018a) Exergoeconoenvironmental analysis as a new concept for developing thermodynamically, economically, and environmentally sound energy conversion systems. J Clean Prod 187:190–204. https://doi.org/10.1016/j.jclepro.2018.03.214

Aghbashlo M, Rosen MA (2018b) Consolidating exergoeconomic and exergoenvironmental analyses using the emergy concept for better understanding energy conversion systems. J Clean Prod 172:696–708. https://doi.org/10.1016/j.jclepro.2017.10.205

Aprea C, Greco A, Maiorino A (2017) An experimental investigation of the energetic performances of HFO1234yf and its binary mixtures with HFC134a in a household refrigerator. Int J Refrig 76:109–117. https://doi.org/10.1016/j.ijrefrig.2017.02.005

Aprea C, Greco A, Maiorino A (2018) HFOs and their binary mixtures with HFC134a working as drop-in refrigerant in a household refrigerator: energy analysis and environmental impact assessment. Appl Therm Eng 141:226–233. https://doi.org/10.1016/j.applthermaleng.2018.02.072

Atilgan B, Azapagic A (2016) Assessing the environmental sustainability of electricity generation in Turkey on a life cycle basis. Energies 9:31. https://doi.org/10.3390/en9010031

Caliskan H (2015) Novel approaches to exergy and economy based enhanced environmental analyses for energy systems. Energy Convers Manag 89:156–161. https://doi.org/10.1016/j.enconman.2014.09.067

Caliskan H (2017) Energy, exergy, environmental, enviroeconomic, exergoenvironmental (EXEN) and exergoenviroeconomic (EXENEC) analyses of solar collectors. Renew Sustain Energy Rev 69:488–492

Dincer İ, Kanoğlu M (2010) Refrigeration systems and applications, 2nd edn. Wiley

Direk M, Yüksel F (2020) Experimental evaluation of an automotive heat pump system with R1234yf as an alternative to R134a. Arab J Sci Eng 45:3. https://doi.org/10.1007/s13369-019-04140-x

Elbar ARA, Yousef MS, Hassan H (2019) Energy, exergy, exergoeconomic and enviroeconomic (4E) evaluation of a new integration of solar still with photovoltaic panel. J Clean Prod 233:665–680. https://doi.org/10.1016/j.jclepro.2019.06.111

Feng B, Yang Z, Zhai R (2018) Experimental study on the influence of the flame retardants on the flammability of R1234yf. Energy 143:212–218. https://doi.org/10.1016/j.energy.2017.10.078

Lee Y, Kang DG, Jung D (2013) Performance of virtually non-flammable azeotropic HFO1234yf/HFC134a mixture for HFC134a applications. Int J Refrig 36:1203–1207. https://doi.org/10.1016/j.ijrefrig.2013.02.015

Llopis R, Sánchez D, Cabello R et al (2017) Experimental analysis of R-450A and R-513A as replacements of R-134a and R-507A in a medium temperature commercial refrigeration system. Int J Refrig 84:52–66. https://doi.org/10.1016/j.ijrefrig.2017.08.022

Meng Z, Zhang H, Lei M et al (2018) Performance of low GWP R1234yf/R134a mixture as a replacement for R134a in automotive air conditioning systems. Int J Heat Mass Transf 116:362–370. https://doi.org/10.1016/j.ijheatmasstransfer.2017.09.049

Mota-Babiloni A, Navarro-Esbrí J, Barragán Á et al (2014) Drop-in energy performance evaluation of R1234yf and R1234ze(E) in a vapor compression system as R134a replacements. Appl Therm Eng 71:259–265. https://doi.org/10.1016/j.applthermaleng.2014.06.056

Mota-Babiloni A, Makhnatch P, Khodabandeh R, Navarro-Esbrí J (2017a) Experimental assessment of R134a and its lower GWP alternative R513A. Int J Refrig 74:680–686. https://doi.org/10.1016/j.ijrefrig.2016.11.021

Mota-Babiloni A, Navarro-Esbrí J, Mendoza-Miranda JM, Peris B (2017b) Experimental evaluation of system modifications to increase R1234ze(E) cooling capacity. Appl Therm Eng 111:786–792. https://doi.org/10.1016/j.applthermaleng.2016.09.175

Mota-Babiloni A, Belman-Flores JM, Makhnatch P et al (2018) Experimental exergy analysis of R513A to replace R134a in a small capacity refrigeration system. Energy 162:99–110. https://doi.org/10.1016/j.energy.2018.08.028

Sun Z, Wang Q, Xie Z et al (2019) Energy and exergy analysis of low GWP refrigerants in cascade refrigeration system. Energy 170:1170–1180. https://doi.org/10.1016/j.energy.2018.12.055

Taylor J (1997) An introduction to error analysis, the study of uncertainties in physical measurements, 2nd edn. University Science Books

Yıldız A, Yıldırım R (2021) Investigation of using R134a, R1234yf and R513A as refrigerant in a heat pump. Int J Environ Sci Technol 18:1201–1210. https://doi.org/10.1007/s13762-020-02857-z

Yousef MS, Hassan H (2019) Assessment of different passive solar stills via exergoeconomic, exergoenvironmental, and exergoenviroeconomic approaches: a comparative study. Sol Energy 182:316–331. https://doi.org/10.1016/j.solener.2019.02.042

Zilio C, Brown JS, Schiochet G, Cavallini A (2011) The refrigerant R1234yf in air conditioning systems. Energy 36:6110–6120. https://doi.org/10.1016/j.energy.2011.08.002

Acknowledgments

The authors wish to thank all who assisted in conducting this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Editorial responsibility: Maryam Shabani.

Rights and permissions

About this article

Cite this article

Yıldız, A., Yıldırım, R. Experimental investigation of exergy, exergoenvironmental and exergoenviroeconomic analysis of the heat pump system. Int. J. Environ. Sci. Technol. 19, 10737–10746 (2022). https://doi.org/10.1007/s13762-021-03890-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-021-03890-2