Abstract

Industrial wastewater is one of the most significant environmental pollutants, and most industry owners shirk this responsibility due to the excessive expenses. Thus, the present research attempts to provide a suitable and highly efficient method with lower investment expenses in order to encourage industry owners to use this system and propose the best option for industrial wastewater treatment. The research aims to control water pollution, maintain ecosystem balance and reuse wastewater in industry. In this study, the process of reducing Nitrogen, Phosphorus, Total Suspended Solids and Chemical Oxygen Demand from wastewater with high Organic load has been investigated by fixed-bed sequencing batch reactors (biological, adsorption) with a volume of 24 L. The minimum and maximum system efficiencies were 43 and 88% in terms of Chemical Oxygen Demand for the removal of organic matter, 30 and 81% for the removal of Nitrogen, 88 and 99% for the removal of Phosphorus and 43 and 77% for removal of Total Suspended Solids, respectively. Anaerobic Filters system showed good efficiency for removing the organic matter, Nitrogen and Phosphorus from industrial wastewater with high organic load. Results show a very long Solids Retention Time for essential microorganisms in the decomposition of toxic and inhibitory compounds, absorption of shock loads or non-biodegradable toxic compounds, the possibility of higher volumetric loading compared to aerobic processes and lower cell mass efficiency followed by important economic and environmental benefits in relation to the recycling and disposal of the produced cell mass.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Industrial productions with biological wastewater such as dairy and food plants use a very high volume of water and different chemicals daily and thus produce wastewater with various pollutants that can lead to serious environmental problems (Sappi 2012; Banat et al. 2007). Among different techniques of industrial wastewater treatment, flocculation, aeration, adsorption and reverse osmosis are widely used, which in most cases due to the variety of production lines of factories, these techniques suffer from severe microbial or hydraulic shocks, create many problems in the treatment process and significantly influence the treatment plant wastewater quality, which will ultimately not meet environmental standards for discharging wastewater to the receiving reservoirs. Chemical processes such as oxidation and chemical coagulation are less considered due to their high energy requirement and low cost-effectiveness (Meriç et al. 2005; Abou Elela et al. 2014). The anaerobic biosorption process, like other anaerobic biological systems, is more attractive than aerobic biological processes and has advantages including low energy requirements, biogas production, high microbial shock tolerance, high loading tolerance and less sludge production (Tchobanoglous et al. 2013; Leitão et al. 2006; Rincón et al. 2008).

Overall, the increase in population and the community requirement for developing industries on the one hand and the increase in wastewater production from these industries on the other hand, caused water, air and soil pollution, which requires management measures and strategies to address environmental concerns (Mohd Udaiyappan, et al. 2017).

The use of adhesive growth process in aerobic and anaerobic systems by stabilizing microorganisms on the packing, which increases the mass of biomass by sticking and suspending, while increasing the efficiency of bioremediation, also reduces the required volume of treatment (Wiesner, & Bottero, 2017).

A review of previous studies has also demonstrated the application of this technique for the biological wastewater treatment in industries, among which the following can be mentioned. In the study process, using anaerobic biological treatment in consecutive reactors, the amount of pollutant reduction was compared based on the type of filter bed material in different operating conditions. In selecting the materials used in the filter bed, plastic media was used in order to create a high contact surface. Siliceous rock materials also formed other materials used in triple reactors to trap suspended solids and granular activated carbon as adsorbents. In Table 1, there are some examples of operating and functional conditions for anaerobic attach growth. Tables 2, 3, and 4 show the trend changes in the removal percentage of parameters in the flow rates of 2, 3, and 4 L per hour and the initial concentration of 1500 Mg/L, respectively. Tables 5 and 6 show the trend changes in the removal percentage of parameters in the flow rates of 2 and 3 L per hour and the initial concentration of 3000 Mg/L, respectively.

In 2016, the efficiency of consecutive anaerobic–aerobic reactors with a fixed bed was studied by Barzinmehr with the aim of removing phosphorus from wastewater. The case study in this project was the ability to remove phosphorus and Chemical Oxygen Demand (COD) by this system. In this project, wastewater with a concentration of COD equal to 1000 mg / l under different concentrations of phosphorus was studied, and then the effect of flow reversal was investigated. It has been observed that increasing the concentration of phosphorus to some extent improves the removal efficiency of phosphorus and then has an inhibitory effect. At best, for a concentration of 25 Mg/L, 92.04% of phosphate and 95.03% of COD were removed. The reverse flow study showed a significant effect of this factor on the removal of COD and phosphorus. The best case for COD removal occurred when the backflow was cut off, and up to 96.25% of the COD was removed (Barzinmehr, 2016).

An experiment was conducted by Periyasamy and Ramesh (2016) on comparing two methods of upstream reactors with sludge bed (UASB) and hybrid reactor (HUASB) on tannery and sago with input COD of 660 and 1390 Mg/L, respectively, with a COD reduction of 91.67% in the UASB reactor and 92.38% in the HUASB reactor, and a BOD reduction of 83.73% in the UASB reactor and 90.96% in the HUASB reactor at a hydraulic retention time of 45 h, respectively. This reactor was used at OLR = 4.210 mg COD/min L (Periyasamy, & Ramesh, 2016).

In 2015, in a study conducted by Tonon et al., in the first phase, 4 anaerobic filters with a diameter of 76 cm and a length of 1.68 m, made of stainless steel with a total volume of 500 L, with an input COD of 424 ± 982 Mg/L and the input BOD of 189 ± 385 Mg/L filled with coconut shell were used. The current in these reactors was considered high and HRT = 9 h. In the second phase, they introduced the effluent of anaerobic reactors to the surface of 4 sand filters with an internal diameter of 1 m. The average temperature of this process was 5.4 ± 24.5 °C, the pH of the incoming wastewater was equal to 0.4 ± 7.3, and the pH of the effluent of the anaerobic filters was measured equal to 0.2 ± 7.4. The results of this study showed that the percentage of BOD and COD removal in anaerobic filters alone is 15 ± 65%, while the simultaneous use of both anaerobic filters and sand filters produce a COD removal percentage of more than 95% (Tonon, et al. 2015).

In the study of Akhlaghi et al. (2014), the commercial activated carbon granules were used as adsorbents to remove organic matter and other contaminants from dairy wastewater with an input COD of 2510 Mg/L as a discontinuous system. The obtained results showed that increasing the contact time increased the adsorption capacity of activated carbon and reached equilibrium after 240 min (Akhlaghi et al. 2014).

In the study of Alizadeh and Borghei (2006), the activated carbon granules in the biocarbon process were used to remove organic matter and dye from a textile factory on the outskirts of Tehran with an average input COD of 1310 Mg/L in the pilot unit, causing a 96% reduction in COD and a 92% reduction in dye (Alizadeh and Borgheie 2006).

In 2017, a research conducted by Vignesh et al. examined the treatment of dairy wastewater by an Upflow Anaerobic Filter (UAF) reactor. The reactors made of PVC had a diameter, height and bed volume of 10 cm, 75 cm and 3.53 L, respectively. These reactors operated at different Hydraulic Retention Time (HRT) for a period of 130 days at mesophilic temperature conditions (29–35 °C). In this experiment, the amount of input COD was considered between 1350–1400 Mg/L, and HRTs were 8, 12, 16 and 24 h. The inoculation of these reactors was also done with cattle manure. The maximum removal percentage of COD in the reactor containing pebble stone media was observed as 76.72% at Organic Loading Rate (OLR) = 1.35 kg COD/m3.d, HRT = 24 h. In addition, the removal percentages of COD in 16-, 12- and 8-h HRTs were 74.60%, 68.25% and 45%, respectively. The maximum removal percentage of COD in the reactor containing aggregate media was 91.55% in OLR = 1.35 kg COD/m3.d and HRT = 24 h. Also, the removal percentages of COD in 16-, 12- and 8-h HRTs were 89.48%, 85.18% and 78.88%, respectively (Vignesh et al. 2017). It is worth noting that various parameters such as temperature, pH, characteristics of inlet sewage, alkalinity, acidity, hydraulic and cellular retention time, organic loading, etc. affect the efficiency of these systems (Tchobanoglous et al. 2013).

In the studied process, using anaerobic biological treatment in consecutive reactors, the amount of pollutant reduction was compared based on the type of filter bed material in different operating conditions. In selecting the materials used in the filter bed, plastic media was used to create a high contact surface. Siliceous rock materials also formed other materials used in triple reactors in order to trap suspended solids and granular activated carbon as adsorbents.

Biological treatment is an economical method that eliminates contaminants does not require the addition of chemicals and does not produce secondary contaminants (Ahmadpour, et al. 2014).

Today, absorbents have attracted special attention due to their effectiveness in various fields. The most important characteristics of an adsorbent for any application include: adsorption capacity, selectivity, reproducibility, kinetics, compatibility and cost (Gowon, et al., 2015).

The activated carbon is one of the absorbents widely used in different areas (Geena, et al., 2016). It is a non-graphite microcrystalline form of carbon that has a very high internal porosity and surface area (Gummas, & Okpeke, 2015).

Carbon is widely used in various areas for drinking water treatment, food and beverage processing, odor removal, etc., and is one of the most effective media for removing a wide range of contaminants from wastewater (Geena, et al., 2016).

OLR influences parameters such as removal percentage of COD, biogas (methane and hydrogen) and fatty acids production rate and alkalinity, which play a critical role in the use of anaerobic processes (hydrolysis and acidification phase). The optimal amount should be determined so that it can treat the maximum flow of wastewater at the right time and without leaving sludge from the system (Leitão et al. 2006; Latif et al. 2012; Wijekoon et al. 2011; Mohan et al. 2007; Van Ginkel and Logan 2005). Due to the necessity of supplementary treatment for industries with high organic load, the present study was conducted to introduce a cheap and effective method in bringing the effluent to the existing standards. This study aims to evaluate the efficiency of fixed-bed sequencing anaerobic batch reactor (biological, adsorption) in reducing the high organic load of industrial wastewater. This research was carried out on a laboratory scale in the laboratory of Ghaemsazan Afra Company located in Rasht and for a period of 18 months on artificial wastewater with biological conditions.

Materials and methods

Place and time of conducting research

The present research was performed on artificial wastewater with biological conditions on a laboratory scale in the laboratory of Ghaemsazan Afra Company located in Rasht for 18 months. By keeping the variations in temperature and pH constant, the trend of variations in the removal percentage of COD, Total Suspended Solids (TSS), TN and TP parameters at flow rates of 2, 3 and 4 L per hour was investigated.

Pilot specifications

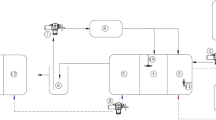

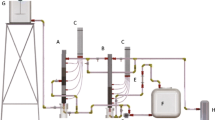

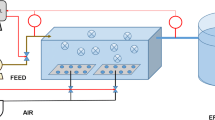

In the construction of biological sequencing batch reactors, three cylinders made of PVC and a useful volume of 24 L (internal diameter of 20 cm and a height of 80 cm) were used. The first column is filled with plastic media (hose pipe) with a diameter of 1.1 cm and a length of 2.5 cm with a porosity of 90%; the second column is filled with industrial pumice with a special weight of 624 kg/m3 and a porosity of 62%; and the third column is filled with the granular activated carbon. The inlet and outlet valves in each reactor were installed as two valves at the top and two valves at the bottom to make the up and down flows possible in addition to the sampling. The lattice plates were placed at a distance of 5 cm from the valves to prevent the sludge from escaping and the flow path obstruction due to aerated water and help distribute the flow evenly. The reactors’ doors are closed, and a gas outlet pipe is installed on top of each reactor. The pilot schematic is shown in Fig. 1.

Sewage with specific COD is injected into the second and third reactors by injection pump with adjustable flow rate from the bottom of the first reactor and then enters the second and third reactors by gravity, and finally the treated effluent from the outlet valve installed at the end of the third reactor is discharged to the collection tank. To maintain the temperature, the reactors and the power supply were placed inside a room, and the ambient temperature was maintained in the mesophilic temperature range with heating devices (30 ± 2 °C). Sewage flow was passed continuously upwards and downwards through three reactors, respectively.

Sewage production and stabilization

Synthetic sewage was prepared from a combination of sugar beet molasses produced by Qazvin Sugar Factory and water, and diluted with water in order to supply different amounts of COD. In order to stabilize the system, the COD/N/P ratio of synthetic sewage was adjusted to 400/5/1, and the deficiency of primary nutrients was compensated by inoculating fresh cow manure diluted with water. Initial loading based on the proposed table of performance of the attach growth process mentioned in the book written by Metcalf and Eddy (2 to 13 kg COD/m3.d) equals to 2.23 kg COD/m3.d, flow velocity equals to 0.064 m/hr, and HRT was set equal to 36 h. The contents of the reactor were removed from it and re-introduced into the initial reactor to ensure stable conditions for the life of microorganisms.

With the start of the system operation phase, the increase in OLR caused a shock to the system and the COD removal efficiency decreased. Furthermore, the suspended particles in the initial wastewater inoculated with cattle manure created local clogs in the communication pipes of the reactor flow path and sometimes in the media bed removed by increasing the flow velocity and increasing the height difference between the reactors. With the increase of OLR, the speed of COD removal process increased, and the time required for stabilization became very short, so that by increasing the OLR from 2.23 to 3.21 kg COD/m3.d, the system showed the removal percentage of COD up to 81 in just 10 days. The reduction of incoming wastewater COD, showing compliance with the conditions, was monitored until a constant removal percentage (± 2%). During this period, pH and temperature were controlled daily. The system did not progress at the desired speed at the time of startup, so the OLR did not increase until the test results reached the desired level. After providing stable conditions, the system effluent was changed from batch mode to continuous mode for monitoring and comparing the performance of triple filters and its effect on the removal of pollutants. After recording the results, only by increasing the input concentration and not changing the flow rate, the removal percentage of pollutants with a surface loading rate of 4.51 kg COD/m3.d was monitored. In the next stage, with the increase of flow, the removal percentage of pollutants was monitored with a surface loading rate of 3.21 kg COD/m3.d, a flow rate of 0.095 m/hr and a hydraulic retention time of 24 h. Then, by increasing the input concentration and not changing the flow rate, the removal percentage of pollutants with a surface loading rate equal to 6.83 kg COD/m3.d was monitored, and in the next step, with the increase of flow, the removal percentage of pollutants with an equivalent surface loading rate 34.4 kg COD/m3.d, flow rate equal to 0.13 m/hr and hydraulic retention time equal to 18 h was re-monitored. Then, with increasing the input concentration and no change in flow rate, the removal percentage of pollutants with a surface loading rate equal to 8.56 kg KOD/m3.d, was monitored, and the results were recorded.

Method of testing and data analysis

All experiments were performed under constant conditions and according to the instructions of the 20th edition of the standard method book. Measurement of Chemical Oxygen Demand (COD) was performed using the closed reflux method by spectrophotometer model Cary 4000 UV–Vis made by Agilent Co. and according to 5220B instruction, determination of Total Suspended Solids (TSS) was done by TSS meter model 322LXV made by Hach Co. according to 2540D instruction, and Total Nitrogen (TN) and Total Phosphorus (TP) contents were measured according to 4500 N-B and 4500P-B instructions using Kjeldahl method and Zisco plus Kjeldahl Equipment, respectively. Temperature and pH were recorded by pH meter model 98,100 Hi made by Hanna Co. Due to the sensitivity of methane-producing bacteria to pH, this parameter was maintained in the range of 6.5–8. In case of need to adjust COD/N/P, urea and phosphorus and also baking soda powder were used to increase alkalinity. At all stages, especially when increasing the Organic Loading Rate (OLR), the desired parameters were measured until they reached less than 2% change to ensure that the microorganisms were fully adapted to the new conditions. All experiments were measured with at least twice repeated sampling. Finally, the results were analyzed by ECXEL statistical methods.

Results and discussion

Results

After stabilization, the operation of the system started with increasing Organic Loading Rate (OLR) and the diagram of varieties in the removal percentages of Chemical Oxygen Demand (COD), Total Nitrogen (TN), Total Phosphorus (TP) and Total Suspended Solids (TSS) within 108 days after setting up the system at flow rates of 2, 3 and 4 L per hour and different surface loads from 2.23 to 6.83 k/m3 per day was studied, the results of which are shown in Figs. 1, 2, 3, 4 and 5. It is worth mentioning that the operation of the system started with the highest Hydraulic Retention Time (HRT) and the lowest OLR, and in later stages, with increasing flow rate and initial concentration, the removal percentage of pollutants under different loading conditions was monitored.

As shown in Fig. 2, the system’s capability to remove pollutants under initial surface loading conditions of 2.23 kg COD/m3.d, flow rate of 0.063 m/hr and Hydraulic Retention Time of 36 h was evaluated. The highest removal percentages of COD, TN, TP and TSS were 84% on the 20th day, 71% on the 11th day, 99.5% on the 11th day, 68% on the 23rd day, respectively, after setting up the system Fig. 6.

In Fig. 3, varieties in the removal percentage of pollutants with new surface loading conditions equal to 3.21 kg COD/m3.d, flow rate equal to 0.095 m/hr and hydraulic retention time equal to 24 h were evaluated, and the highest removal percentages of COD, TN, TP and TSS were equivalent to 87% on the 9th day, 30% on the 4th day, 99% on the 4th day, an 56% on the 14th day, respectively, after setting up the system in new conditions.

In continuation of the test process, by increasing the flow according to Fig. 4, variations in the removal percentage of pollutants under surface loading conditions equal to 4.34 kg COD/m3.d, flow rate equal to 0.13 m/hr and hydraulic retention time equal to 18 h were evaluated. The highest removal percentages of COD, TN, TP and TSS were 87% on the 9th day, 30% on the 4th day, 99% on the 4th day and 56% on the 14th day, respectively, after setting up the system under new conditions.

In continuation of the research, the removal percentage of parameters was monitored with increasing pollution load and the following results were recorded. According to Fig. 5, in surface loading equivalent to 4.51 kg KOD/m3.d, flow rate equal to 0.063 m/hr and hydraulic retention time equal to 36 h, maximum removal percentages of COD, TN, TP and TSS were 88% on the 28th day, 65% on the 20th day, 84% on the 20th day and 43% on the 13th day, respectively, after setting up the system in new conditions.

By keeping the initial concentration constant and increasing the flow according to Fig. 6, new conditions prevailed, during which the surface load, the flow velocity, the hydraulic retention time were changed into 6.83 kg COD/m3.d, 0.095 m/hr and 24 h, respectively. The maximum removal percentages of COD, TN, TP and TSS were 44% on day 21, 81% on day 28, 88% on day 14 and 63% on day 28, respectively, after setting up the system.

The highest efficiency in reducing the pollution load (optimal conditions) for the COD parameter according to Fig. 5 was recorded in the maximum amount of hydraulic retention time equal to 36 h and surface load equal to 4.51 kg KOD/m3.d equal to 88%. The highest efficiency for the TN parameter according to Fig. 6 was recorded at the time of hydraulic retention equal to 24 h and surface load of 6.83 kg COD/m3.d equal to 81%. The highest efficiencies for TP and TSS parameters according to Fig. 2 at hydraulic retention time of 36 h and surface load of 2.23 kg COD/m3.d were recorded equal to 99.5% and 68%, respectively.

The obtained results show that the treatment method under study works better against phosphorus removal. Adjusting the pH and increasing the ambient temperature had a significant effect on supplying such conditions. At a concentration of 3000 Mg/L, the efficiency of removal percentage of COD from the 29th day onwards decreased sharply from 88 to 70% with decreasing pH and ambient temperature. This problem occurred several times during the start-up time, which was controlled and eliminated by increasing the temperature of the experimental environment and adding baking soda powder in order to increase the pH and adjust the COD/N/P ratio to about 400/5/1. In addition, nitrogen and phosphorus deficiency in the mentioned ratio was eliminated by adding urea and phosphate to the sewage feed tank.

By studying the effect of hydraulic retention time on the phosphorus removal efficiency in various concentrations, was determined that with increasing input concentration, phosphorus removal efficiency has increased. This was due to the increase in the Mixed Liquid Suspended Solids (MLSS) due to the increase in organic load entering the system. With increasing the hydraulic retention time, the phosphorus removal efficiency increased so that at a concentration of 3000 Mg/L, with increasing the retention time of the whole system from 18 to 24 h, the phosphorus removal efficiency increased from 45 to 98%.

The effect of inlet concentration and hydraulic retention time on the nitrogen removal was different. As can be seen, with increasing the input concentration and increasing the hydraulic retention time, the nitrogen removal efficiency decreased and increased, respectively, so that at a concentration of 1500 Mg/L, the removal percentage was equal to 71% and with increasing concentration equivalent to 3000 Mg/L, the removal percentage was reduced to 65%. Also, with increasing the retention time of the whole system from 18 to 24 h, the nitrogen removal efficiency increased from 31 to 81%.

In describing the key findings of the present research, it is possible to remove pathogenic microorganisms from the effluent with the help of biological activities. Also, the analytical results of this research project showed that:

-

1.

A very long Solids Retention Time (SRT) is provided for microorganisms essential for the breakdown of toxic and inhibitory compounds.

-

2.

Shock-induced loads or biodegradable toxic compounds can be adsorbed inside the reactor containing activated carbon.

-

3.

The operation of the system is simple and reliable.

-

4.

Lower cell mass efficiency is provided which reduces the processing costs and sludge disposal, and consequently brings important economic and environmental benefits in relation to the recycling and disposal of the produced cell mass.

-

5.

It is possible to load a higher volume than aerobic processes.

Discussion

Comparison of the recorded results showed that by increasing the flow rate and consequently reducing the hydraulic retention time, the efficiency of the system decreased.

The effect of pH on the performance of system

The effect of pH on the efficiency of removal percentage of COD is significant, so that at a concentration of 3000 Mg/L and the efficiency of removal percentage of COD equal to 88%, the pH values recorded at the outlet of the first reactor, the outlet of the second reactor and at the end were equal to 7.8, 7.5 and 6.8, respectively. The reason can be investigated in terms of the continuous operation of the reactors and the increase in the microbial population in the reactor. Microbial ecology in both phases of acidification and methanisation depends on the type and amount of substrate present and environmental parameters such as pH and temperature (Peng and Ge, 2011; Hu et al. 2003). In the acidification zone (initial parts of the reactor), the rapidly growing bacteria are able to grow in a high amount of substrate, dominate the initial reactors and reduce the pH at the system outlet. Due to the high sensitivity of the anaerobic system to environmental parameters, any decrease in pH and temperature causes a decrease in efficiency, which is also consistent with the study of Chaparro et al. (2011) (Chaparro and Pires 2011).

The effect of TSS on the performance of system

The trend of TSS variations is also a function of the concentration of COD entering the system, so that the amount of TSS measured at the outlet of the first reactor was significant and in some cases even more than the TSS of raw wastewater in the feed tank, which was reduced at the outlets of the second and third reactors. Similar results were obtained in the study of the performance of anaerobic filters and Hybrid Anaerobic Baffle Reactors (HABR). The particle size depends on the amount of substrate. It can be stated that the particle size increases to the middle of the reactor and then decreases to the end of the reactor. According to Wesley et al., the size of the clots is a function of gas production and COD concentration in the reactor, so that the largest clots are formed when the concentration of COD is high enough and the gas production is low enough that the clots do not break.

The effect of HRT of the performance of system

The effect of hydraulic retention time on phosphorus removal efficiency was such that with increasing inlet concentration and also hydraulic retention time, phosphorus removal efficiency increased, so that at a concentration of 1500 Mg/L and retention time of 18 h, the efficiency of phosphorus removal percentage was equal to 79%, but at a concentration of 3000 Mg/L and retention time of 36 h, the efficiency of phosphorus removal percentage was 84%. This procedure was different for nitrogen. It means that at a concentration of 1500 Mg/L, the removal percentage was equal to 71% and with increasing concentration equivalent to 3000 Mg/L, the removal percentage was reduced to 65%. Furthermore, with increasing the retention time of the whole system from 18 to 24 h, the nitrogen removal efficiency increased from 31 to 81% due to the predominance of microorganisms in the oxidation of carbon over nitrogen. Therefore, the lower the input COD concentration is, the more opportunity the system has for nitrification.

Conclusion

In general, it can be concluded that the Anaerobic Filters (AFS) system shows a good efficiency in removing the organic matter, nitrogen and phosphorus from industrial wastewater with high pollution load, so that the system has a very good efficiency in removing COD, TSS, TN and TP. At constant organic loading, the treatment efficiency increases with increasing the initial concentration, and if the hydraulic retention time increases, the reactor performance efficiency also increases. The reason for this is the use of biofilm system and discontinuous flow regime. The most important advantages of this process include the separation of acid-forming and methane phases, low hydraulic retention time, long retention time for sludge and relative resistance to organic and hydraulic shocks. For further development of this research, the use of aerobic biological process is proposed to achieve complementary treatment.

References

Abou Elela SI, Ali MEM, Ibrahim HS (2014) Combined treatment of retting flax wastewater using Fenton oxidation and granular activated carbon. Arab J Chem 9(4):511–517

A. Ahmadpour, F. Khazaali, and S. Hermasinejad (2014) Evaluation of the performance of membrane bioreactors for the purification of industrial effluents, presented at the Second scientific conference of process engineering, Tehran

Akhlaghi M, Yousefi Kebria D, and Amini Rad H (2014) Dairy wastewater treatment with activated carbon granule method. National conference on water crisis solutions in Iran and Middle East, Shiraz, Hamayeshnegar scientific conferences center

Alizadeh R, Borgheie SM (2006) Using granular activated carbon in the carboniferous process to removal organic materials and color of the textile industry wastewater. Chem Chem Eng J Iran 25(3):21–28

Banat F, Al-Asheh S, Al-Anbar S, Al-Refaie S (2007) Microwave-and acid-treated bentonite as adsorbents of methylene blue from a simulated dye wastewater. Bull Eng Geol Env 66(1):53–58

Barzinmehr H (2016) Evaluation of the efficiency of continuous anaerobic-aerobic reactors with a fixed bed for the purpose of removing phosphorus from sewage masters civil faculty. Sharif University of Technology, Iran

Chaparro TR, Pires EC (2011) Anaerobic treatment of cellulose bleach plant wastewater: chlorinated organics and genotoxicity removal. Braz J Chem Eng 28(4):625–638

Geena GP, Georgette G, Krishna Priya S, Febin M, Nisha M (2016) Removal of dissolved solids in waste water using activated carbon from coconut shell. J Res 2(7):5–7

Gowon J, Okunola OJ, Uduma AU, Ali T, Hamisu S (2015) Treatment of waste water by activated carbon developed from Borassus Aethiopum. Niger J Mater Sci Eng 6:301–307

Gummas RH, Okpeke I (2015) Production of activated carbon and characterization from Snail Shell Waste (Helix Pomatia). Adv Chem Eng Sci 5:51–61

Hu J, Ong S, Ng W, Lu F, Fan X (2003) A new method for characterizing denitrifying phosphorus removal bacteria by using three different types of electron acceptors. Water Res 37:3463e3471

Latif M, Ahmad A, Ghufran R, Wahid Z (2012) Effect of temperature and organic loading rate on upflow anaerobic sludge blanket reactor and CH4 production by treating liquidized food waste. Environ Prog Sustain Energy 31(1):114–121

Leitão RC, Van Haandel AC, Zeeman G, Lettinga G (2006) The effects of operational and environmental variations on anaerobic wastewater treatment systems: a review. Bioresour Technol 97(9):1105–1118. https://doi.org/10.1016/j.biortech.2004.12.007

Meriç S, Selçuk H, Belgiorno V (2005) Acute toxicity removal in textile finishing wastewater by Fenton’s oxidation, ozone and coagulation–flocculation processes. Water Res 39(6):1147–1153

Mohan SV, Babu VL, Sarma P (2007) Anaerobic biohydrogen production from dairy wastewater treatment in sequencing batch reactor (AnSBR): Effect of organic loading rate. Enzyme Microb Technol 41(4):506–515

Mohd Udaiyappan AF, Abu Hasan H, Takriff MS, Sheikh Abdullah SR (2017) A review of the potentials, challenges and current status of microalgae biomass applications in industrial wastewater treatment. J Water Process Eng 20:8–21

Peng Y, Ge S (2011) Enhanced nutrient removal in three types of step feeding process from municipal wastewater. Bioresour Technol 102:6405e6413

Periyasamy P, Ramesh N (2016) Bio-kinetic analysis of tannery and sago effluents treated in UASB and HUASB reactor. Asian J Res Soc Sci Humanit 6(7):152–169

Rincón B, Borja R, González J, Portillo M, Sáiz Jiménez C (2008) Influence of organic loading rate and hydraulic retention time on the performance, stability and microbial communities of one-stage anaerobic digestion of two-phase olive mill solid residue. Biochem Eng J 40(2):253–261

Sappi (2012) Water use and treatment in the pulp and paper industry. Sappi Fine Paper North America 5:1–7

Tchobanoglous G, Burton F, Stensel HD (2013) Wastewater engineering: Treatment and reuse. 4th edn. McGraw-Hill

Tonon D, Tonetti A, Coraucci Filho B, Bueno D (2015) Wastewater treatment by anaerobic filter and sand filter: Hydraulic loading rates for removing organic matter, phosphorus, pathogens and nitrogen in tropical countries. Ecol Eng 82:583–589

Van Ginkel SW, Logan B (2005) Increased biological hydrogen production with reduced organic loading. Water Rese 39(16):3819–3826

Vignesh P, Seenirajan M E, Khadka B, Priyadarshi K, and Chandra Shah S (2017) Treatment of dairy wastewater using upflow anaerobic filter. SSRG International Journal of Mechanical Engineering, vol. ICCREST’ No. 17, Special Issue

Wiesner MR, Bottero J-Y (2017) Environmental nanotechnology: applications and impacts of nanomaterials, 2nd Edition. McGraw-Hill Education: New York, Chicago, San Francisco, Athens, London, Madrid, Mexico City, Milan, New Delhi, Singapore, Sydney, Toronto. ISBN: 780071828444.

Wijekoon KC, Visvanathan C, Abeynayaka A (2011) Effect of organic loading rate on VFA production, organic matter removal and microbial activity of a two-stage thermophilic anaerobic membrane bioreactor. Bioresour Technol 102(9):5353–5360

Acknowledgements

The authors would like to thank the Ghaemsazan Afra Company for financial support of this study in terms of plan number 2143010982 and Iranian Health Test Laboratory in order to provide laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

There is no conflict of interest.

Additional information

Editorial responsibility: Babatunde Femi Bakare.

Rights and permissions

About this article

Cite this article

Ansari Joveini, H., Javid, A., Hassani, A. et al. Investigation on removal of high organic load of industrial wastewater by cascade filters (bio-filters with different media). Int. J. Environ. Sci. Technol. 19, 1765–1774 (2022). https://doi.org/10.1007/s13762-021-03317-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-021-03317-y