Abstract

This research focuses on the removal of diclofenac in aqueous phase using chicken feathers and the evaluation of the subsequent biodegradation of the obtained adsorbate/adsorbent complex using a bacterial consortium. In the first stage, the conditions that affected adsorption were evaluated, in order to optimize the loading of the feathers. Afterwards, the equilibrium was evaluated by three adsorption isotherms at 8, 15 and 25 °C; the experimental data were explained by the Langmuir model, showing that, at 8 °C the highest load was obtained (614.8 mg/g). Additionally, the process was thermodynamically explained as spontaneous and exothermic and governed by chemical and physical processes, in addition to the occurrence of a decrease in molecular disorder at the adsorbate–adsorbent interface. Likewise, the kinetic behavior was studied at 8, 15 and 25 °C, detecting that the adsorption process occurs in two stages described by the intraparticle diffusion model. Finally, an FTIR analysis was carried out, in which the groups participating in the adsorption process were shown. The second stage was the evaluation of the biodegradation process of the adsorbate/adsorbent complex. The biodegradation of diclofenac was evidenced by monitoring laccase, lignin peroxidase, manganese peroxidase and polyphenol oxidase enzymatic activities and quantifying the 50% decrease in diclofenac concentration by HPLC. Simultaneously, the degradation of the chicken feather impregnated with diclofenac was analyzed, evaluating keratinolytic activity, the presence of soluble protein, amino acids and sulfhydryl groups; the positive results of these tests confirmed the biodegradation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

At the beginning of the current century, the presence of the emerging pollutants has been detected, which have caused damages to the environment (Poynton and Robinson 2018). These compounds are found in different products of daily use such as Pharmaceutical and Personal Care Products (PPCPs), plasticizers, pesticides and surfactants, and some of them are classified as endocrine contaminants (Wilkinson et al. 2017). Despite the damage and history of these pollutants, until now, there is no legislation that regulates the presence of these compounds globally; however, there are attempts to define which ones are of strong interest and priority (Taheran et al. 2018). Through government agencies at international level, there are already listings in which the main emerging pollutants are postulated, as well as chemical products that must be monitored; such is the case of the US Environmental Protection Agency (USEPA), which periodically publishes a list called the Contaminant Candidate List (CCL) (Lamastra et al. 2016), it includes a process to identify and list these compounds. On the other hand, the European Directive due to the pollution caused by certain dangerous substances discharged into the aquatic environment proposes to the member countries a list of substances that must be avoided, and another list with substances that should restrictive use; these lists use criteria such as toxicity, persistence, bioaccumulation, harmful effects and effects on groundwater.

The presence of pharmaceutical products in different water bodies has increased in recent years, due to their increased consumption for veterinary and human purposes (Boxall et al. 2012; Nikolaou et al. 2007), causing concentrations capable of producing effects to aquatic organisms. As a result, priority pollutant lists have been developed, being until 2007 when pharmaceutical products, such as diclofenac, iopamidol and carbamazepine, were considered as new priority candidates (Ebele et al. 2017).

The pharmaceutical products emission routes are diverse, one of them is through human waste; after being absorbed by the body, they are released reaching the sewer system or septic tanks, leading them to the wastewater treatment plant system. The low efficiency of these wastewater treatment plants makes them another source of drug emission, sometimes releasing active metabolites (Snyder 2008), since effluents are used as irrigation water and sludge as fertilizer in livestock activities.

Other emission routes that are also important include: directly from pharmaceutical manufacturing plants at the time the products are produced (Fick et al. 2009) and the veterinary use, where they are discarded by animals directly into the soil either in a solid or liquid manner and can enter water bodies through leaching or runoff. On the other hand, animal waste can be used as fertilizers and in this way their metabolites polluting the soil and can enter the food chain. Once the pharmaceutical products are in the environment, the transportation of the pollutant will depend on their physicochemical properties and the matrix in which they are found. For example, most of these products have low volatility, are polar and hydrophilic in nature; therefore, it is most likely that their main route is through water (Caliman and Gavrilescu 2009). As a result, pollutants are found in surface water bodies, sediments and aquifers, in concentrations of ng/L and µg/L (Chen et al. 2013).

It has been suggested that pharmaceutical products have a pseudo-persistent character and they can remain longer than other organic pollutants, such as pesticides, since their source or emission is continuously replenished, as new products are introduced to the market every year and increase their demand.

Non-steroidal anti-inflammatory drugs (NSAIDs) are the most widely prescribed pharmaceutical products worldwide, and they are marketed in the form of salt: sodium or potassium (Ulubay et al. 2018). Diclofenac sodium is a non-steroidal, analgesic and anti-inflammatory drug, generally used for treating acute and chronic pain, caused by different diseases (Beck et al. 2003).

The consumption level of diclofenac worldwide is 904 tons per year; in addition, 74 out of 100 evaluated countries consume this drug as a first-choice anti-inflammatory (McGettigan and Henry 2013). In Mexico, diclofenac is in the basic list of supplies by the health secretary, and according to a study carried out in a Family Medicine Unit of the State of Mexico, this drug is in 4th place in the total consumption of medications (Gómez-Olivan et al. 2010). Because of this high consumption rate, the presence of the drug has been detected in water resources worldwide as well as in Mexico (Rigobello et al. 2013).

Numerous studies have been conducted on the toxicological effects of drugs on aquatic organisms. The relationship between toxic mechanisms and ecophysiological responses to drugs remains a major challenge. However, in general, the main concern for drugs lies in their presence in aquatic environments and their ability to interfere with the endocrine system, and causing unwanted effects or interferin with homeostasis.

Oaks et al. (2004) reported the direct correlation between residues of the anti-inflammatory drug diclofenac and the renal failure vulture on population in Pakistan. In another study, it was found that rainbow trout suffer kidney damage and gill disorders when in contact with concentrations of 5 µg/L of this drug (Schwaiger et al. 2004). Regarding public health, the consumption of water with the presence of diclofenac causes cytotoxicity of the liver and kidney, gastrointestinal damage, platelet dysfunction and seizures (Fei et al. 2006; Tewari et al. 2013). Furthermore, when exposure is chronic in humans, thyroid tumors and hemodynamic changes can be developed (Boyd et al. 2003; Verlicchi et al. 2012).

The research carried out was aimed at a comprehensive evaluation of the elimination of diclofenac in the aqueous phase through the use of the adsorption and biodegrading process.

This study was conducted in the year 2019 in the Chemistry Department of the Autonomous University of San Luis Potosi, Mexico.

Materials and methods

Chicken feathers

The feathers were collected from an establishment dedicated to animal husbandry in Mexico City, and as a first treatment, they were washed with neutral detergent, and rinsed with tap water, then dried at room temperature for a period of 48 h. Subsequently, the feathers were placed in an oven at 35 °C for 24 h and stored for later use.

Diclofenac adsorption optimization

Box–Behnken experimental design was used to optimize three variables on adsorption process: temperature, pH and an initial concentration of diclofenac. For this, 15 systems were prepared in borosilicate tubes with 25, 50 and 75 mg/L of diclofenac solutions, temperatures at 25, 35 and 45 °C, and at pH 6, 7 and 8. The pH of the systems was daily adjusted with 0.05 M HCl, or 0.05 M NaOH, using an Oacton 300 series potentiometer. Each system with 10 mL of solution and 0.05 g of chicken feathers was incubated for 7 days at the designed conditions. The initial and residual concentration of diclofenac was quantified by UV/Vis spectrophotometry (Thermo Scientific GENESYS 105 Scanning Spectrophotometers) at 280 nm, the samples were centrifuged (Herml Z 216 MK) at 13,000 rpm for 8 min before quantification. A blank was prepared for each sample, containing 0.05 g of chicken feathers and water. The response surfaces were made using Statistica 6.0 software.

Adsorption isotherms

Three isotherms were evaluated at temperatures of 8, 15 and 25 °C with diclofenac concentrations of 100–2100; 100–3000; and 200–4000 mg/L, respectively. The systems were prepared in borosilicate tubes containing 10 mL of solution and 0.05 g of chicken feathers, and each system was adjusted daily at pH 6, remaining in incubation for 9 days, at which time equilibrium was reached. The initial and residual concentration was quantified as previously mentioned, at a wavelength of 280 nm, and the maximum load of diclofenac on the chicken feathers was calculated.

The experimental data of the isotherms were adjusted to the mathematical models of Langmuir (Eq. 1), Freundlich (Eq. 2), Temkin (Eqs. 3 and 4) and Dubinin–Radushkevich (Eqs. 5 and 6).

The mathematical expression for the Langmuir model can be represented as:

where qm (mg/mL) is the maximum adsorption capacity of the adsorbent, and KL (L/mg) is the Langmuir constant (Langmuir 1918).

On the other hand, the mathematical expression of the Freundlich model is given by Eq. 2.

Kf (mg/mL (L/mg) 1/n) is the Freundlich constant and 1/n is the heterogeneity factor (Freundlich 1926).

Likewise, Temkin's mathematical model can be expressed as follows:

At is the constant of the Temkin isotherm (L/g), b is the heat of absorption (J/mol), R is the constant of the ideal gases and T is the temperature (Temkin and Pyzhev 1940).

The mathematical model for Dubinin–Radushkevich is represented by the mathematical expression of Eq. 5:

where qe is the amount of adsorbate in the equilibrium adsorbent (mg/g); qmax is the theoretical capacity of saturation of isotherms (mg/g); KD is the Dubinin–Radushkevich constant (mol2/kJ2); \(\varepsilon\) is the Polanyi potential that is related to the equilibrium concentration as Eq. 6.

R, T and Ce represent the gas constant, the absolute temperature (K) and the equilibrium concentration of adsorbate (mg/L), respectively (Dubinin 1960).

Thermodynamic parameters

The thermodynamic description of diclofenac adsorption on chicken feathers was described evaluating the Gibbs free energy (ΔG) using Eq. 7 (Gibbs 1948), in which Langmuir's K (KL) was used. Likewise, the linearized equation of Van’t Hoff (Eq. 8) (Van’t Hoff 1884) was used to obtain the values corresponding to entropy (ΔS) and enthalpy (ΔH).

Adsorption kinetics

The effect of temperature on the adsorption rate was evaluated, systems with a concentration of 5 mg/L were prepared and adjusted at pH 6 with 0.05 M HCl, and 0.015 g of chicken feathers were added; each system was incubated at different temperature (8, 15 and 25 °C) and pH was daily adjusted at 6. The systems were monitored by quantifying the concentration by UV/Vis spectrophotometry at 280 nm, at different interval of times.

The experimental data of the adsorption kinetics were analyzed comparing them with the mathematical model of Lagergren (1898) called pseudo-first order (Eq. 9), as well as with the pseudo-second-order model by Ho and McKay (1999) (Eq. 10), the mathematical model of Elovich and Schulman (1959) (Eq. 11), and finally the mathematical model of intraparticle diffusion proposed by Weber and Morris (1963) was used (Eq. 12).

The following equation expresses the pseudo-first-order model:

where qt and qe (mg/g) are the equilibrium adsorption capacities at time t, k (min−1) is the rate constant of pseudo-first-order adsorption. The pseudo-second-order model is represented as Eq. 10:

In this equation, k2 corresponds to the adsorption rate constant (g/mg min), qe is the total adsorbed amount at equilibrium (mg/g) and qt is the amount of sorbate on the surface of the adsorbent at any time (mg/g).

Likewise, for the Elovich model, the mathematical expression is represented as Eq. 11:

where α (mg/g min) is the initial rate of adsorption, b is related to the surface area and chemisorption activation energy and qt represents the amount of sorbate on the sorbent surface at any time (mg/g). Finally, the intraparticle diffusion model can be found as follows:

where k is the intraparticle diffusion constant (mg/g min) and qt is the load in mg/g.

FTIR analysis

An FTIR analysis (Agilent Technologies Cary 630 FTIR) was performed to find out the functional groups involved in the adsorption process. First, an analysis of pure diclofenac (25,000 mg/L) and chicken feather was carried out; subsequently, an adsorption system was prepared at 8 °C with 0.05 g of chicken feathers and diclofenac at 3200 mg/L, which was daily adjusted to pH 6 for 8 days, then the feathers were collected from the system and dried at 35 °C for 24 h. Once the feathers were completely dry, an FTIR analysis was performed, in a range of 4000 to 400 cm−1 with 64 scans at a resolution of 4 cm−1.

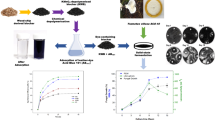

Biodegradation of the diclofenac–chicken feathers complex

A batch system was prepared to evaluate the biodegradation of the diclofenac–chicken feathers complex obtained from the adsorption process. The system consisted of 8 g of feathers with diclofenac load of 8.16 mg/g contained in 800 mL of a 0.05% peptone solution (in the hypothetical case of desorption, the concentration of diclofenac would be 81.6 mg/L). Additionally, an 800 mL batch system was prepared containing free diclofenac at 81.6 mg/L in 0.05% peptone solution. These systems were inoculated with 5 mL of a keratinolytic consortium, which was obtained from chicken feather residues, Bacillus amiloliquefaciens and Pseudomonas putida. Both systems were incubated at 36 °C for 121 days and were sampled for several days taking 16 mL aliquots, which were centrifuged at 10,000 rpm for 10 min. In both systems, the enzymatic activity of laccase was evaluated through the oxidation of ABTS (2,2′-azino-bis [3-ethylbenzthiazoline-6-sulfonic acid]) (Niku-Paavola et al. 1990); enzymatic activity of Lignin Peroxidase using 2–4 dichlorophenol and 4-aminoantipyrine (Ishida et al.1987); this enzyme was also evaluated using veratryl alcohol as substrate (Tien and Kirk 1984). Manganese peroxidase enzymatic activity was determined by using manganese sulfate according to Widiastuti and Wulaningtyas (2008), and the polyphenol oxidase enzymatic activity was determined by the reaction catechol reaction following the protocol of Queiroz et al. (2011). Finally, the degradation of the adsorbent was only evaluated in the system with the complex, this was done through the quantification of the keratinolytic activity (Ramirez et al. 2004), soluble protein content by the method of Bradford (1976), the content of positive ninhydrin products was quantified according to the Harding method (Block and Weiss 1956), sulfhydryl groups determination according to Onifade et al. (1998), and finally the lost mass of chicken feather was quantified by gravimetry.

Diclofenac quantification in both systems was performed by high-performance liquid chromatography HPLC (Waters e2695) with ultraviolet (UV) detection (HPLC–UV). A Waters XBridge BEH C18 Column, 130 Å, 3.5 µm, 4.6 mm × 50 mm was used, and the UV detector (2489 Waters Wavelength UV/Vis Detector) was set at 278 nm. The mobile phase consisted of methanol:water in a 60:40 ratio.

Results and discussion

Adsorption optimization

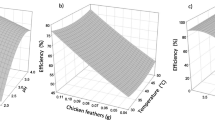

As mentioned, an experimental Box–Behnken design was used to find the best adsorption conditions, Fig. 1 shows the response surfaces, in which the effect of the variables on the load capacity of the adsorbent is observed. The effect of diclofenac concentration and pH is evidenced in Fig. 1a, showing that the adsorption was decreased at pH 8, that is, the adsorption decreases when the pH increases. This effect was more evident as the concentration increased, the highest load detected (18.37 mg/g) was obtained using pH 6 at the concentration of 75 mg/L. This result is similar to the results reported by de Luna et al. (2017) who achieved the removal of diclofenac sodium through the use of derived from the cocoa pod shell, detecting the opposite effect between pH and adsorption capacity, in which pH 3 was where the highest adsorption occurred. Zhao et al. (2017) also reported this effect, that is, as the pH increases, the amount of diclofenac removed by the adsorbent used decreases, finding that the optimal pH was 5.23. The authors attributed the effect to the positive charge that remains in the adsorbent surface due to the pH and the anionic nature of diclofenac, which coincides with this study; since the point of zero charge (pzc) of the chicken feathers is 6.8 (unpublished data), it is positively charged at pH < pHpzc and on the contrary at pH > pHpzc, the adsorbent will have a negative charge: since at low pH’s diclofenac is anionic, it would explain the good adhesion of the drug on chicken feathers in acid conditions.

Figure 1b shows the effect of temperature and pH on the adsorbent load; the combination of the conditions of pH 7 and temperature of 25 °C causes the minimum adsorption (4.32 mg/g); meanwhile, at pH 6 and 25 °C, the highest adsorption point is reached (13.47 mg/g). According to the tendency of the response surface, it would be expected that using a pH lower than 6 stimulates the adsorption capacity; however, diclofenac tends to precipitate at too acidic pH value due to its pKa (4.1) where it decreases in its neutral form and solubility, causing it not to be in the solution (Samah et al. 2018). Evaluating the adsorption process as a function of temperature, it can be seen how the load is favored as the temperature decreases, this behavior is observed in Fig. 1c, it is observed that the highest adsorbed load (14.24 mg/g) has an initial concentration of 75 mg/L and 25 °C; in contrast to this, it is also observed that at high temperatures (45 °C) the adsorbed load decreases to 13.39 mg/g; therefore, the adsorption process can be considered to be slightly favored as lower temperatures are applied.

It is important to mention that, this adsorption load was not yet the maximum because equilibrium had not yet been reached, this was achieved using the conditions at pH 6 and temperature at 25 °C at the equilibrium point in the isotherm.

Balance studies in the adsorption of diclofenac on chicken feathers

Three diclofenac adsorption isotherms were performed; the experimental data and the mathematical models of Freundlich, Langmuir, Temkin and Dubinin-Radushkevich are shown in Fig. 2. Specifically, in Fig. 2a, b, the experimental isotherms at 25 °C and 15 °C, respectively, have a close relationship to the Langmuir model. On the other hand, Fig. 2c shows the isotherm at 8 °C, where the experimental data showed a higher affinity with Freundlich's mathematical model; in this case, the saturation process is not so defined as that of the isotherms at 15 and 25 °C.

Table 1 shows the variables of the mathematical models that describe the adsorption process at each temperature. At temperatures 25 and 15 °C, the experimental data showed a high correlation to the Langmuir model (R2 = 0.99), this suggests that the process occurs only in the coverage of the monolayer on the adsorbent surface, where each site can only be occupied by an adsorbate molecule, and all the sites are energetically equivalent so that the surface is uniform, in addition to there being no interaction between adjacent molecules (Langmuir 1918; Sivaraj et al. 2001). According to Langmuir model, theoretical equilibrium loads of 434.3 and 503.19 mg/g were obtained at 25 and 15 °C, respectively, thus confirming favorable removal systems by decreasing the temperature as previously observed in the experimental design. Furthermore, the separation factor (RL) indicated that the adsorption process is favorable, since RL < 1 (Bhadra et al. 2016).

Meanwhile, the isotherm at 8 °C showed the highest correlation with the mathematical model of Freundlich, so this model better suggests the description of the process at this temperature, indicating that adsorption involves heterogeneity in the multilayer, where the adsorption sites have different energies (Pezoti et al. 2016). In this regard, the heterogeneity factor (n) was 2.48, which indicated that the adsorption process is favorable (n > 1) in a heterogeneous or a multilayer system according to Danmaliki and Saleh (2016) and Freundlich (1926). Similar results were reported by de Franco et al. (2018), who proposed the adsorption of diclofenac using commercially activated carbon and obtained an adsorption described by the Freundlich model and a value for the heterogeneity factor of 2.46 and KF of 2.71 mg1−1/n L1/n g−1. Lonappan et al. (2018) reported a process for the removal of diclofenac on activated carbon from manure, and found out that the model that best described the adsorption process was Freundlich; however, the adsorption is less favorable according to the heterogeneity factor, and as for the Freundlich constant of equilibrium (KF) they obtained a value of 16.61 mg1−1/n L1/n g−1. De Luna et al. 2017 described the adsorption of diclofenac on activated carbon from cocoa pod shells and found an equilibrium load of 5.53 mg/g with a higher correlation to the Freundlich model, unlike the present investigation, they observed that adsorption was more favorable, because n = 4.34; however, the KF value was 2.91 mg1−1/n L1/n g−1. As we know, the KF indicates the degree of adsorption capacity, so the larger this value, it indicates greater capacity (Ismail et al. 2013); therefore, comparing the KF value obtained (28.4 mg1−1/n L1/n g−1) in the present investigation using chicken feathers as adsorbent against the value reported by other authors can be inferred that the removal of diclofenac by keratinous residue is greater. The theoretical adsorption capacity at 8 °C was 614.8 mg/g, which is higher than the one obtained in the isotherms at 25 and 15 °C, confirming again that adsorption was increased at low temperatures.

Table 2 shows the amount of diclofenac adsorbed onto the adsorbent at equilibrium, which is compared with other materials already reported in the removal of diclofenac; its high adsorption capacity stands out, especially at 8 °C, in which the load of the chicken feather is higher than most of the reported cases. Until now, only the use of conventional adsorbents such as activated carbons, graphene, etc., has been reported for the removal of diclofenac.

The opportunity of using this material in water bodies at temperatures below ambient is a novelty, and, in addition to being an unconventional material, there is the possibility of a second treatment for the degradation of the formed complex.

Thermodynamic evaluation of diclofenac adsorption on chicken feathers

The negative Gibbs energy variation (ΔG) indicated that the adsorption process is spontaneous and favorable; in addition, the negative value of (ΔG) increased with the decrease in temperature (− 166.6 kJ/mol at 8 °C; − 119.46 kJ/mol at 15 °C, and − 22.71 kJ/mol at 25 °C), this implies that low temperatures facilitate adsorption. On the other hand, the negative enthalpy value (− 83.03 kJ/mol) suggests that the process is exothermic; hence, the energy adsorbed on the bond break is less than the total energy released in bond formation between adsorbate and the adsorbent, resulting in the release of additional energy through heat (Saha and Chowdhury 2011). The magnitude of the enthalpy can also describe whether the process occurs through fission or chemisorption; in general, if the adsorption is physical, it will be in the range of − 20 to − 40 kJ/mol, and if it is chemical adsorption, the value ranges from − 80 to − 400 kJ/mol (Bayramoglu et al. 2009); therefore, the value of − 83.03 kJ/mol obtained can describe the adsorption process of diclofenac on chicken feathers as chemisorption; however, it barely reaches this range; therefore, it would be better to consider that there can also be physical adsorption in the process. Respecting the adsorption entropy, the negative value (− 0.21 kJ/mol K) indicates that there is a decrease in the randomness of the solid/liquid interface as diclofenac is adsorbed on the chicken feathers, which coincides with Antunes et al. (2012), making it possible for multilayers to form, thereby causing randomness of the interface to reduce and improve the organization.

Similar results were reported by Lonappan et al. (2018), who found that the process of diclofenac removal on activated carbon from pig manure occurs spontaneously because of the negative values for ∆G. Similarly, the negative value of enthalpy (− 3,970 kJ/mol) suggested that the process is exothermic, but a positive value of entropy (16.13 J/mol K) was obtained, indicating randomness at the interface between the adsorbate and adsorbent molecules. The same authors investigated the removal of diclofenac on activated carbon from white pine wood, obtaining different results, since they explained that the process is not spontaneous given the positive value of Gibbs free energy, which required that an alternate energy source should be carried out. However, the positive value (1130 kJ/mol) in enthalpy suggested that the process is endothermic and that it is carried out through physical adsorption, they also mentioned that entropy (− 4404 J/mol K) indicated that there is a decrease in randomness at the adsorbate–adsorbent interface. In contrast to the present investigation, de Franco et al. (2018) reported the removal process of diclofenac on activated carbon as endothermic since the enthalpy was 27,760.5 J/mol and was a chemical adsorption, that obtained positive entropy, to which they concluded that there is randomness in the solid–liquid interface during the adsorption process. With the above, the process of adsorption of diclofenac on chicken feathers is carried out under the conditions of a spontaneous, favorable and exothermic process, which, unlike previous studies, is an advantage, since it would not require more energy supplies for the adsorption process.

Adsorption kinetics study

The influence of temperature on the adsorption rate was investigated by varying three different temperatures (8, 15 and 25 °C), and the results were analyzed according to the mathematical models described above. Figure 3a, b show that, after 73 h of contact time at 25 and 15 °C, the adsorbent reached loads of 5.05 mg/g and 4.8 mg/g, respectively. Unlike these results, the adsorption at 8 °C (Fig. 3c) was slower, reaching a load of 3.5 mg/g during the same time and achieving equilibrium up to 168 h.

Table 3 shows the parameters obtained from the mathematical models to which the experimental data were compared; as can be seen, all kinetics presented better correlation with the pseudo-first order; this model assumes that the occupying rate of the adsorption sites is proportional to the number of vacant sites available (Lagergren 1898); therefore, the pseudo-first-order model explains well the region where the adsorption process occurs very quickly, which corresponds in the first stage (Ali et al. 2016). The kinetics at 8 °C was the one that presented the lowest proportion between the reaction speed and the variables that affected it (k1 = 0.000202 min−1), likewise, the amount of solute adsorbed in equilibrium per unit mass of the adsorbent was slightly higher compared to the other temperatures (qe = 6.38 mg/g), an effect that had already been described in isotherms.

The second mathematical model that had a high correlation at 25 and 15 °C was Elovich's, which suggests that the adsorption process is mostly controlled by chemical adsorption (Namasivayam and Sureshkumar, 2008) and B (g/mg) is related with the scope of the activation energy and the coverage of the surface, so that the increase in the initial adsorption rate depends on the temperature and thus will decrease the adsorption surface for the adsorbate (Ali et al, 2016); this can be seen in Table 3, where it is observed that the value of B at 25 °C is higher (0.6085 g/mg) than at 15 °C (0.4128 g/mg), as well as in Fig. 3a, b, where can be seen that the increase in temperature causes an increase in the adsorption rate.

The kinetics at 8 °C also had a high correlation to the Intraparticle Diffusion model, which suggests that the adsorption can be divided into two stages. In the first stage, the rapid distribution of adsorbate molecules occurs on the outer surface of the adsorbent (Gil et al. 2018); the second stage represents intraparticle diffusion, a stage in which the binding of molecules occurs toward the internal active sites of the adsorbent, which is probably a slower process (Agarwal et al. 2015). This process is shown in Fig. 3c, where it is observed that in the first 6 h of contact between diclofenac and chicken feather correspond to the aforementioned first stage, while the second stage occurs after 6 h of contact, where it is observed that the adsorption rate decreased.

Lonappan et al. (2018) investigated the removal of diclofenac using activated carbon from pig manure, finding that at 25 °C, and from an initial concentration of 2 mg/L, the model that best described the process was pseudo-second order, so they assumed that the result is a chemisorption and that the adsorption rate of activated carbon depends on the availability of the sorption sites rather than the concentration of diclofenac in the solution. They also explained that, when the 48 h contact was completed, equilibrium was obtainable at a load of 0.995 mg/g; at this same time, the kinetics at 8 °C had already exceeded this load, obtaining 2.93 mg/g, which suggested that the chicken feathers adsorbs faster than the activated carbon, this is confirmed by rate values. Also, de Luna et al. (2017) evaluated the kinetics of diclofenac adsorption on activated carbon from cocoa pod shells, finding that the model that best described the process was the pseudo-second order. This activated carbon has a higher adsorption rate than the chicken feathers, since it reaches equilibrium at 120 min and reaches an experimental load of 5.53 mg/g, it is probable that the fast adsorption rate is related to the chemical activation that the carbon had, due to the number of pores on the adsorbent surface and therefore the availability of adsorption sites depends on this.

FTIR analysis of diclofenac sodium and chicken feather

The FTIR analysis was carried out to determine the functional groups present on the surface of the chicken feather and the modification that occurs when the feather–diclofenac complex is formed. Figure 4a shows the infrared spectrum of diclofenac and the groups and associated bonds are described. The bonds of the main functional groups (C–N, C=C, C=O, O–H and C–Cl) detected in the infrared spectrum of this work is similar to that reported by other authors, such as the case of Sathishkumar et al. (2015), who performed the FTIR analysis of a diclofenac solution in water, to observe the adsorption process of this drug on activated carbon from fruit peels, another similar case is the study by Ramachandran and Ramukutty (2014), who carried out an IR analysis of diclofenac in an aqueous solution, and also the representative bands of the N–H, C–N and C=C bonds is similar in the same region. In this work, they identified the bond C–Cl, which is similar to the one identified in the present investigation. Likewise, Nayak and Pal (2011) reported the same bonds detected in diclofenac sodium.

Chicken feather is mainly made up of a protein called keratin with different functional groups, especially –COOH, NH2, S–S– (Khosa et al. 2013). In Fig. 4b, the infrared spectrum of the chicken feather is shown, detecting the main functional groups. The infrared spectrum of the chicken feather after a time of contact with diclofenac is also shown (Fig. 4b), in which it can be observed that, due to the interaction, the intensity of some bands decreased, such as the characteristic band of the O–H bond; likewise, the formation of new bands is observed, for example in the region 1046 cm−1 that is related to the C–N bond, 989 cm−1 represents the bending vibration of the C-H bond located out of the plane and the intensification of the band 923 cm−1 which is associated with the out-of-plane bending vibration of the O–H bond, the formation of the 834 cm−1 band is also observed, which reflects the bending vibration of a C–H bond in the aromatic ring and the 741 cm−1 band corresponding to a stretching vibration of the C–Cl bond.

Leone et al. (2018) suggested that an ion–dipole interaction can occur between the O− of diclofenac in its anionic form (pH > pKa of diclofenac), and the O–H bond present on the surface of an adsorbent. This could happen between diclofenac and chicken feather, since the O–H bond of the phenolic groups present in the feather can interact with the free radical on the carboxylic group of diclofenac. On the other hand, Bhadra et al. (2016) suggested that there may be an interaction between the C=O bond and the O–H group through hydrogen bridges; this can explain the mode of adsorption of diclofenac on the chicken feather since there can be interaction of the O–H bond of the phenolic groups on the surface of the feathers and the C=O bond of diclofenac causing the change in the intensity of the 1623 cm−1 band.

Regarding the formation of the new band at the frequency 1046 cm−1, it is associated with the presence of a C–N bond due to the secondary amine in the diclofenac molecule. This bond may because of an electrostatic interaction between the negatively charged amine in the anionic molecule of diclofenac and a protonated amine present in the amino acids of the feathers, there is no history of this possible adsorption mechanism for diclofenac; however, Ling et al. (2016) explained how the interaction between the secondary amine in the sulfamethoxazole molecule and the primary amine in the amine-modified polystyrene–divinylbenzene adsorbent can occur.

These three possible mechanisms are represented in Fig. 5 and can explain the high adsorption of diclofenac on the chicken feather, which is similar to the one reported by Hiew et al. (2019) who removed diclofenac using oxidized graphene and obtaining a load similar to this work (653.91 mg/g); these authors reported that the possible mechanism for the adsorption of the drug occurred through hydrogen bridges, between the electronegative sites of the diclofenac molecule and the functional groups of graphene. Likewise, Barczak et al. (2018) investigated the removal of diclofenac on functionalized mesoporous silica and obtained a load of 925 mg/g. These authors attributed the high capacity of the adsorbent mainly to electrostatic forces between the protonated surface and the electronegative form of diclofenac; they also mentioned that the presence of hydrogen bridges can be a factor that influences high adsorption due to the presence of organic groups on the surface of the adsorbent.

Biodegradation of the adsorbate/adsorbent complex

After completing the physicochemical study of diclofenac adsorption on the chicken feather, the feasibility of a second treatment such as biodegradation for the elimination of the diclofenac–feather complex was analyzed.

Determination of enzymatic activities during the biodegradation of free diclofenac and diclofenac–feather complex

Figure 6 shows the profiles of enzymatic activities present during the biodegradation process of the adsorbate/adsorbent complex and free diclofenac. The enzymatic laccase activity fluctuated as a function of time, and there were differences in the level activity between the two kinetics (Fig. 6a); this can be attributed to the presence of the chicken feather that could act as a substrate for the enzyme. Laccases act mainly in the extraction of hydrogen from hydroxyl groups present in phenolic groups, generating phenoxy radicals (Agematu et al. 1993). This enzyme also acts on non-phenolic substrates such as 2,2′-azinobis (3-ethylbenzothiazoline-6-sulfonate) (ABTS) producing ABTS+ acting on the aromatic amine (Johannes and Majcherczyk 2000). Diclofenac is not an optimal substrate for laccase; however, Marco-Urrea et al. (2010) investigated the degradation of diclofenac through the use of purified laccase and provided a possible mechanism, obtaining 4-(2,6-dichlorophenylamino)-1,3-benzenedimethanol as the final product. Another possible action of the laccase enzyme has been described by Lloret et al. (2013) who explained that laccase could act on the carboxylic group in diclofenac in the presence of oxygen. Likewise, based on what was reported by Huang et al. (2014), who investigated the degradation of 2,4-dichlorophenol by immobilized laccase, they found that a quinone could be formed in the molecule due to the oxidation of the hydroxyl group and the dechlorination of the aromatic ring forming 2-chloro-1,4-quinone. According to the above, it is possible to propose another theoretical mechanism, in which the dechlorination of the diclofenac molecule occurs and thus the formation of quinones in the aromatic ring, as shown in Fig. 7.

Another enzyme that was studied during the biodegradation was lignin peroxidase, and it was monitored for 152 days using two substrates; the results are represented in Fig. 6b. The detection through 2,4-dichlorophenol substrate showed that the highest activity was during the first six days, reaching 945 units in the degradation of the complex system, while in the free diclofenac system was 1486.48 units on the third day. Meanwhile, the enzyme detected that the second substrate (veratryl alcohol) was produced until day 91 in both systems, which suggested that lignin peroxidase acted on the exposed hydroxyl groups, probably after previous oxidation carried out by another enzyme. The enzyme detection by veratryl alcohol technique refers to the oxidation of the hydroxyl groups of the substrate.

The enzyme lignin peroxidase normally oxidizes phenolic compounds turning them into the corresponding phenoxy radical (Kawai et al. 1987), such as the substrate 2,4-dichlorophenol where the hydroxyl group is oxidized and the phenoxy radical is made, giving rise to the formation of a benzoquinone. Enzymes not only act on the initial substrate, but also on the products of previous oxidation caused by another enzyme. That said, it is possible to consider that lignin peroxidase can act on the product generated after laccase oxidation, for example, on the product reported by Marco-Urrea et al. (2010), after the degradation of diclofenac with laccase (4-(2,6-dichlorophenylamino)-1,3-benzenedimethanol) (Fig. 7). According to Valli and Gold (1991), who studied the degradation of 2,4-dichlorophenol through the use of lignin peroxidase and proposed a route in which the two chlorine atoms are removed by oxidation forming a quinone. It is possible to suggest a second path since diclofenac also has two chlorine atoms which can be oxidized by lignin peroxidase and form a benzoquinone, as shown in Fig. 7. There is no report of a mechanism of the effect of lignin peroxidase on diclofenac; however, Zhang and Geißen (2010) have studied the degradation of carbamazepine and diclofenac by crude lignin peroxidase and found that diclofenac can be completely degraded by the enzyme, thus confirming that the drug can function as a substrate for lignin.

Even though there is no history on the biodegradation of diclofenac through the direct action of the enzyme manganese peroxidase, this was evaluated since it is known that, like lignin peroxidase, it has a powerful oxidant capacity (Bogan et al. 1996). In particular, manganese peroxidases act through the oxidation of Mn2+ to Mn3+, which oxidizes phenol to phenoxy radicals, in the presence of H2O2 (Widiastuti and Wulaningtyas 2008). Manganese peroxidase can act on chlorinated substrates, as reported by Gold and Joshi (1993), who studied the degradation of 2,4,5-trichlorophenol using Phanerochaete chrysosporium. The authors explained that the first step in the oxidation of this compound is dechlorination of the molecule, resulting in 2,5-dichloro,1,4-benzoquinone. On the other hand, Hofrichter (2002) reported some substrates where manganese peroxidase can act, among carboxylic acids that are mentioned and explain that the action of manganese is mainly focused on the subtraction of hydrogen from the hydroxyl group and forming its corresponding radical, whose the presence is the starting point of other spontaneous reactions that depends on the external conditions, leading to different products (Hatakka 2001). Based on this, it is possible to propose a theoretical mechanism in the biotransformation of diclofenac, since, as previously mentioned, diclofenac has two chlorine atoms, which can be extracted from the molecule giving rise to a benzoquinone, in addition to the formation of the radical in the carboxylic group, as seen in Fig. 7.

According to the enzyme kinetics, it is possible to confirm the presence of the enzyme in the biodegradation process of diclofenac both in free form and in complex form, the main difference between the two graphs lies in the fact that the system with free diclofenac has a higher enzymatic activity than that of the complex (Fig. 6c), which suggests that the enzyme acts easily on the substrate that is completely in the solution.

Finally, the activity of the polyphenol oxidase enzyme was detected to evaluate its possible participation in the degradation of diclofenac and it was found that its activity fluctuated during the process with three main increases in both systems (Fig. 6d). Polyphenol oxidases are oxidoreductase enzymes, and they are present in the removal of aromatic pollutants; they catalyze mainly the oxidation of hydroxyl groups from monophenols to diphenols and, subsequently, lead them to the formation of quinones (Singh et al. 2015). To date, there is no information on the degradation of diclofenac sodium by oxidation, catalyzed by polyphenol enzyme; however, based on the kinetics obtained, it is possible to confirm the presence of the enzyme in the degradation process, and therefore, a probable mechanism of action on the drug can be proposed based on the operation of the enzyme on other substrates already reported. Such is the case proposed by Chai et al. (2017), where they presented the biotransformation of L-DOPA to indole-5,6-quinone through the action of polyphenol oxidase, which is attacked by the enzyme and transformed into a quinine. It is also observed that the carboxylic acid of the L-DOPA molecule is removed through the action of polyphenol enzyme. According to the aforementioned, it is possible to deduce a route of action of the enzyme on diclofenac, since like, L-DOPA, the drug has a carboxylic group in its molecular structure, which can justify the enzymatic activity detected during the biodegradation process of the adsorbate/ adsorbent complex and free diclofenac, Fig. 7 shows the possible route of action of the enzyme on diclofenac.

In addition to evaluating the biodegradation of the adsorbate (diclofenac), the biodegradation of the adsorbent (chicken feather) was also evaluated; it was analyzed through quantification of keratinolytic activity, soluble protein, positive nihydridine products and free –SH groups.

Figure 8a shows the keratinolytic activity as a function of time, here it is observed that in the first nine days the presence of the enzyme was not detected; however, from day 14 a slight increase in activity is observed, but it is not until day 38 that a notable increase in the enzyme was manifested. This trend was maintained until day 91, where the highest point of the enzymatic activity reached 72.5 U/mL; finally, in the following 30 days declined activity was observed. This behavior is similar to the feather fragmentation process, which began to appear with greater intensity from the first month of incubation. According to He et al. (2018), keratin undergoes different modifications due to the action of microorganisms; first, the disulfide bonds of keratin cysteine are broken, which leads to the formation of a stable secondary structure of keratin, that is also destroyed, and finally, the protease acts on the porous structure of keratin and the feathers completely degrade. Some authors reported the presence of keratinase activity during the degradation of chicken feathers, such as the case of Bohacz (2017), who confirmed that the activity of proteases with keratinolytic properties is correlated with the release of proteins and peptides. Likewise, Moreira-Gasparin et al. (2009) reported that keratinase can degrade the feathers or β-keratin, releasing soluble amino acids and peptides without the need for chemical or enzymatic reduction of disulfide bonds.

Regarding the detection of soluble protein, it is possible to show its existence in the degradation system (Fig. 8b). It is observed that the trend of the graph is increasing and with oscillations throughout the process, the highest point of the increase after day 70 reaching 40.38 µg/mL; afterwards, a notable reduction is observed in the last days of the kinetics. This can be attributed to the fact that the products of keratin hydrolysis acquired a role of substrate for other enzymes, resulting in a carbon source for the present microbiota, as explained by Veselá and Friedrich (2009), who investigated the dependence of amino acids and protein soluble in residual keratin hydrolyzed by a fungal keratinase from Paecilomyces marquandii.

Since the chicken feather protein is made up of amino acids, positive ninhydrin products were quantified to show their biodegradation. The results are reflected in Fig. 8c; it is observed that the maximum point (81.46 µg/mL) is reached at 21 days, followed by the observation that the concentration of amino acids began to decrease periodically until day 91, where it started increasing again. Due to the high concentration of amino acids obtained, the degradation of the feather is confirmed again; this correlation agrees with Gousterova et al. (2005) who indicated that, when the feather is degraded by the action of microorganisms, peptides and amino acids are released, which are accumulated in the medium; these products in turn are metabolized by the same microorganisms as they now play a role as a source of additional carbon.

Keratin is rich in sulfur amino acids, due to the packing of the α-helix and β-folded protein chain in a polypetidic chain, which has a high degree of crosslinking caused by the extensive formation of disulfide bonds (Onifade et al. 1998). Therefore, the quantification of possible free -SH groups was carried out because of the degradation of the chicken feathers. These results are shown in Fig. 8d where the concentration of sulfhydryl groups was detected with several oscillations in the kinetics. As already mentioned, the stability of the chicken is related to the structure of the protein chain which owes its resistance to disulfide bonds, Hubalek (2000) explained the process of sulfitolysis, where the disulfide bonds of the keratin, which leads to destabilization of the protein structure, allow keratinolytic proteases to attack and the excess sulfur from cystine to be released. Likewise, Singh (2003) in his work for the bioremediation of keratinolytic waste confirmed again the relationship that exists between keratinase activity and the division of disulfide bonds and, therefore, the degradation of keratin.

Additionally, the degradation of diclofenac was quantified in both systems (Fig. 9); the system with free diclofenac started at 80 mg/L and, on the ninth day, there was a decrease of almost 38% of the concentration, reaching 50 mg/L; during the rest of the kinetic, the decrease was observed until 33 mg/L, equivalent to 59% of degradation. Meanwhile, in the system with diclofenac adsorbed on chicken feathers, the initial concentration in the media was 50 mg/L, due to the natural desorption of the drug, then reached the release maximum (83 mg/L) on day 21, which was maintained until day 47, and later it was observed how the trend of the graph decreased until it reached a reduction of almost 55%.

Some authors have investigated the degradation of diclofenac and chicken feather; however, there have been individual studies, such as He et al. (2018) who investigated the biodegradation of feather keratin by the Bacillus subtilis strain; meanwhile, Łaba et al. (2018) reported new keratinolytic bacteria in the recovery of chicken feather waste and explained that, during the first 4 days of incubation, 52% of the keratinous residue was reduced. On the other hand, in the degradation of diclofenac, some authors such as Moreira et al. (2018) proposed the elimination of the drug using Labrys portucalensis F11 and concluded that 70% of the degradation of diclofenac was achieved after 30 days, starting at 10.81 mg/L as the initial concentration. Stylianou et al. (2018) investigated the biodegradation of diclofenac by Klebsiella sp. and found complete mineralization of the drug after 72 h using an initial concentration of 70 mg/L. Tiehm et al. (2011) described the biodegradation of pharmaceutical products, among which is diclofenac, using activated sludge and explained that the elimination of the drug was achieved in 85 days using an initial concentration of 5 µg/L. As can be seen in some investigations, there is a rapid elimination of the compounds using low initial concentrations.

Conclusion

The chicken feather can be used as a natural adsorbent for the removal of diclofenac in aqueous solution. The maximum adsorption capacity determined through the adsorption isotherms in equilibrium at 8 °C was 614 mg/g and was described by the Langamuir model, its load exceeds the adsorption capacity of other chemically modified materials and therefore it facilitates the use of this adsorbent. Based on the adsorption equilibrium, the thermodynamic parameters were analyzed, and it was found that the adsorption process is spontaneous and exothermic. The adsorption of diclofenac was also evaluated as a function of time, and the effect of temperature on it was observed, obtaining that at 8 °C the maximum load was reached and the intraparticle diffusion model is the one that best describes the kinetics; however, a higher charge is obtained at 8 °C, the feathers adsorb diclofenac faster at 25 °C. According to the modifications detected in the groups and bonds of the adsorbent, it was proposed that diclofenac can bind to the adsorbent through hydrogen bonds, ion–dipole bonds and electrostatic forces.

To propose a complete treatment of the adsorbate/adsorbent complex formed, it was decided to apply biodegradation technology using a bacterial consortium. The process of degradation of the complex as well as diclofenac was demonstrated through the detection of some enzymatic activities; with these results, the action pathway of these enzymes on the pollutant was proposed, which acted mainly in the dechlorination of the molecule, on the carboxylic acid group, and exposed OH groups, forming mostly quinones. Likewise, keratinolytic activity was detected, which is related to the presence of soluble protein, amino and sulfhydryl groups, since during the fragmentation of the feather the disulfide bonds were broken, releasing peptides and amino acids, confirming the degradation of the adsorbent. Also, the degradation of free diclofenac and adsorbed on chicken feathers was verified by HPLC, determining that the drug concentration was reduced by 50% in both systems.

Availability of data and materials

All experimental data and their processing are available.

Code availability

Not applicable.

References

Agarwal AK, Kadu MS, Pandhurnekar CP, Muthreja IL (2015) Kinetics study on the adsorption of Ni2+ ions onto fly ash. J Chem Technol Metall 50:601–605

Agematu H, Shibamoto N, Nishida H, Okamoto R, Shin T, Murao S (1993) Oxidative decarboxylations of 4-hydroxymandelic acid and 2-(4-hydroxyphenyl) glycine by laccase from Coriolus versicolor and bilirubin oxidases from Trachyderma tsunodae and Myrothecium verrucaria. Biosci Biotechnol Biochem 57:1877–1881. https://doi.org/10.1271/bbb.57.1877

Akhtar W, Edwards HGM (1997) Fourier-transform Raman spectroscopy of mammalian and avian keratotic biopolymers. Spectrochim Acta A Mol Biomol Spectrosc 53:81–90. https://doi.org/10.1016/S1386-1425(97)83011-9

Ali RM, Hamad HA, Hussein MM, Malash GF (2016) Potential of using green adsorbent of heavy metal removal from aqueous solutions: adsorption kinetics, isotherm, thermodynamic, mechanism and economic analysis. Ecol Eng 91:317–332. https://doi.org/10.1016/j.ecoleng.2016.03.015

Antunes M, Esteves VI, Guégan R, Crespo JS, Fernandes AN, Giovanela M (2012) Removal of diclofenac sodium from aqueous solution by Isabel grape bagasse. Chem Eng J 192:114–121. https://doi.org/10.1016/j.cej.2012.03.062

Barczak M, Wierzbicka M, Borowski P (2018) Sorption of diclofenac onto functionalized mesoporous silicas: experimental and theoretical investigations. Micropor Mesopor Mat 264:254–264. https://doi.org/10.1016/j.micromeso.2018.01.013

Bayramoglu G, Altintas B, Arica MY (2009) Adsorption kinetics and thermodynamic parameters of cationic dyes from aqueous solutions by using a new strong cation-exchange resin. Chem Eng J 152:339–346. https://doi.org/10.1016/j.cej.2009.04.051

Beck A, Krischak G, Sorg T, Augat P, Farker K, Merkel U et al (2003) Influence of diclofenac (group of nonsteroidal anti-inflammatory drugs) on fracture healing. Arch Orthop Trauma Surg 123:327–332. https://doi.org/10.1007/s00402-003-0537-5

Bhadra BN, Seo PW, Jhung SH (2016) Adsorption of diclofenac sodium from water using oxidized activated carbon. Chem Eng J 301:27–34. https://doi.org/10.1016/j.cej.2016.04.143

Block RJ, Weiss KW (1956) Amino acid handbook. Charles C. Thomas Publ., Springfield, pp 341–346

Bogan BW, Lamar RT, Hammel KE (1996) Fluorene oxidation in vivo by Phanerochaete chrysosporium and in vitro during manganese peroxidase-dependent lipid peroxidation. Appl Environ Microbiol 62:1788–1792. https://doi.org/10.1128/AEM.62.5.1788-1792.1996

Bohacz J (2017) Biodegradation of feather waste keratin by a keratinolytic soil fungus of the genus Chrysosporium and statistical optimization of feather mass loss. World J Microbiol Biotechnol 33:13. https://doi.org/10.1007/s11274-016-2177-2

Boxall AB, Rudd MA, Brooks BW, Caldwell DJ, Choi K, Hickmann S et al (2012) Pharmaceuticals and personal care products in the environment: what are the big questions? Environ Health Perspect 120:1221–1229. https://doi.org/10.1289/ehp.1104477

Boyd GR, Reemtsma H, Grimm DA, Mitra S (2003) Pharmaceuticals and personal care products (PPCPs) in surface and treated waters of Louisiana, USA and Ontario, Canada. Sci Total Environ 311:135–149. https://doi.org/10.1016/S0048-9697(03)00138-4

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. https://doi.org/10.1006/abio.1976.9999

Caliman FA, Gavrilescu M (2009) Pharmaceuticals, personal care products and endocrine disrupting agents in the environment—a review. Clean: Soil, Air, Water 37:277–303. https://doi.org/10.1002/clen.200900038

Chai B, Qiao Y, Wang H, Zhang X, Wang J, Wang C et al (2017) Identification of YfiH and the catalase CatA as polyphenol oxidases of Aeromonas media and CatA as a regulator of pigmentation by its peroxyl radical scavenging capacity. Front Microbiol 8:1939. https://doi.org/10.3389/fmicb.2017.01939

Chen W, Xu J, Lu S, Jiao W, Wu L, Chang AC (2013) Fates and transport of PPCPs in soil receiving reclaimed water irrigation. Chemosphere 93:2621–2630. https://doi.org/10.1016/j.chemosphere.2013.09.088

Danmaliki GI, Saleh TA (2016) Influence of conversion parameters of waste tiresto activated carbon on adsorption of dibenzothiophene from model fuels. J Clean Prod 117:50–55. https://doi.org/10.1016/j.jclepro.2016.01.026

de Franco MAE, de Carvalho CB, Bonetto MM, de Pelegrini SR, Féris LA (2018) Diclofenac removal from water by adsorption using activated carbon in batch mode and fixed-bed column: isotherms, thermodynamic study and breakthrough curves modeling. J Clean Prod 181:145–154. https://doi.org/10.1016/j.jclepro.2018.01.138

de Luna MDG, Budianta W, Rivera KKP, Arazo RO (2017) Removal of sodium diclofenac from aqueous solution by adsorbents derived from cocoa pod husks. J Environ Chem Eng 5:1465–1474. https://doi.org/10.1016/j.jece.2017.02.018

Ebele AJ, Abdallah MAE, Harrad S (2017) Pharmaceuticals and personal care products (PPCPs) in the freshwater aquatic environment. Emerg Contam 3:1–16. https://doi.org/10.1016/j.emcon.2016.12.004

Edwards HGM, Hunt DE, Sibley MG (1998) FT-Raman spectroscopic study of keratotic materials: horn, hoof and tortoiseshell. Spectrochim Aalicta A Mol Biomol Spectrosc 54:745–757. https://doi.org/10.1016/S1386-1425(98)00013-4

Elovich SJ, Schulman JH (1959) Proceedings of the second international congress on surface activity. Academic Press Inc, New York, vol 11, p 253

Fei XW, Liu LY, Xu JG, Zhang ZH, Mei YA (2006) The non-steroidal anti-inflammatory drug, diclofenac, inhibits Na+ current in rat myoblasts. Biochem Biophys Res Co 346:1275–1283. https://doi.org/10.1016/j.bbrc.2006.06.034

Fick J, Söderström H, Lindberg RH, Phan C, Tysklind M, Larsson DG (2009) Contamination of surface, ground, and drinking water from pharmaceutical production. Environ Toxicol Chem 28:2522–2527. https://doi.org/10.1897/09-073.1

Freundlich H (1926) Colloid and capillary chemistry. Methuen, London

Gibbs J (1948) The collected works, vol. 1, thermodynamics. Yale University Press, London

Gil A, Korili SL, SA, (2018) Removal of caffeine and diclofenac from aqueous solution by adsorption on multiwalled carbon nanotubes. Colloid Interface Sci Commun 22:25–28. https://doi.org/10.1016/j.colcom.2017.11.007

Gómez-Oliván LM, Cuero-Villalva C, Galar-Martínez M, Neri-Cruz N (2010) Estudio de Farmacovigilancia de Diclofenaco en el Instituto Mexicano del Seguro Social (UMF No 222) de la Ciudad de Toluca, Estado de México. http://docplayer.es/amp/21675122-Estudio-de-farmacovigilancia-de-diclofenaco-en-el-instituto-mexicano-del-seguro-social-umf-no-222-de-la-ciudad-de-toluca-estado-de-mexico.html

Gousterova A, Braikova D, Goshev I, Christov P, Tishinov K, Vasileva-Tonkova, et al (2005) Degradation of keratin and collagen containing wastes by newly isolated thermoactinomycetes or by alkaline hydrolysis. Lett Appl Microbiol 40:335–340. https://doi.org/10.1111/j.1472-765X.2005.01692.x

Hatakka A (2001) Biodegradation of lignin. In: Hofrichter M, Steinbuchel A (eds) Biopolymers. Lignin, humic substances and coal. Wiley-VCH, Weinheim, pp 129–180

He Z, Sun R, Tang Z, Bu T, Wu Q, Li C, Chen H (2018) Biodegradation of feather waste keratin by the keratin-degrading strain Bacillus subtilis 8. J Microbiol Biotechnol 28:314–322. https://doi.org/10.4014/jmb.1708.08077

Hiew BYZ, Lee LY, Lee XJ, Gan S, Thangalazhy-Gopakumar S, Lim SS et al (2019) Adsorptive removal of diclofenac by graphene oxide: optimization, equilibrium, kinetic and thermodynamic studies. J Taiwan Inst Chem Eng 98:150–162. https://doi.org/10.1016/j.jtice.2018.07.034

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465. https://doi.org/10.1016/S0032-9592(98)00112-5

Hofrichter M (2002) Review: lignin conversion by manganese peroxidase (MnP). Enzyme Microb Technol 30:454–466. https://doi.org/10.1016/S0141-0229(01)00528-2

Huang J, Chang Q, Ding Y, Han X, Tang H (2014) Catalytic oxidative removal of 2, 4-dichlorophenol by simultaneous use of horseradish peroxidase and graphene oxide/Fe3O4 as catalyst. Chem Eng J 254:434–442. https://doi.org/10.1016/j.cej.2014.05.136

Hubalek Z (2000) Keratinophilic fungi associated with free-living mammals and birds. In Kushwaha RKS, Guarro J (eds) Biology of dermatophytes and other keratinophilic fungi. Rev Iberoamer Micol Bilbao, pp 93–103

Ishida A, Ookubo K, Ono K (1987) Formation of hydrogen peroxide by NAD (P) H oxidation with isolated cell wall-associated peroxidase from cultured liverwort cells, Marchantia polymorpha L. Plant Cell Physiol 28:723–726. https://doi.org/10.1093/oxfordjournals.pcp.a077349

Ismail MGBH, Weng CN, Rahman HA, Zakaria NA (2013) Freundlich isotherm equilibrium equastions in determining effectiveness a low cost absorbent to heavy metal removal in wastewater (Leachate) At Teluk Kitang Landfill, Pengkalan Chepa, Kelantan, Malaysia. J Geogr Earth Sci 1:01–08

Johannes C, Majcherczyk A (2000) Laccase activity tests and laccase inhibitors. J Biotechnol 78:193–199. https://doi.org/10.1016/S0168-1656(00)00208-X

Kawai S, Umezawa T, Higuchi T (1987) p-Benzoquinone monoketals, novel degradation products of β-O-4 lignin model compounds by Coriolus versicolor and lignin peroxidase of Phanerochaete chrysosporium. FEBS Lett 210:61–65. https://doi.org/10.1016/0014-5793(87)81298-X

Khosa MA, Wu J, Ullah A (2013) Chemical modification, characterization, and application of chicken feathers as novel biosorbents. RSC Adv 3:20800–20810. https://doi.org/10.1039/C3RA43787F

Łaba W, Żarowska B, Chorążyk D, Pudło A, Piegza M, Kancelista A, Kopeć W (2018) New keratinolytic bacteria in valorization of chicken feather waste. AMB Express 8:9. https://doi.org/10.1186/s13568-018-0538-y

Lagergren SK (1898) About the theory of so-called adsorption of soluble substances. Sven Vetenskapsakad Handingarl 24:1–39

Lamastra L, Balderacchi M, Trevisan M (2016) Inclusion of emerging organic contaminants in groundwater monitoring plans. MethodsX 3:459–476. https://doi.org/10.1016/j.mex.2016.05.008

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403. https://doi.org/10.1021/ja02242a004

Larous S, Meniai AH (2016) Adsorption of Diclofenac from aqueous solution using activated carbon prepared from olive stones. Int J Hydrog Energy 41:10380–10390. https://doi.org/10.1016/j.ijhydene.2016.01.096

Leone VO, Pereira MC, Aquino SFD, Oliveira LCAD, Corrêa S, Ramalho TDC et al (2018) Adsorption of diclofenac on a magnetic adsorbent based on maghemite: experimental and theoretical studies. New J Chem 42:437–449. https://doi.org/10.1039/C7NJ03214E

Ling C, Li X, Zhang Z, Liu F, Deng Y, Zhang X et al (2016) High adsorption of sulfamethoxazole by an amine-modified polystyrene–divinylbenzene resin and its mechanistic insight. Environ Sci Technol 50:10015–10023. https://doi.org/10.1021/acs.est.6b02846

Lloret L, Eibes G, Moreira MT, Feijoo G, Lema JM (2013) On the use of a high-redox potential laccase as an alternative for the transformation of non-steroidal anti-inflammatory drugs (NSAIDs). J Mol Catal B Enzym 97:233–242. https://doi.org/10.1016/j.molcatb.2013.08.021

Lonappan L, Rouissi T, Brar SK, Verma M, Surampalli RY (2018) An insight into the adsorption of diclofenac on different biochars: mechanisms, surface chemistry, and thermodynamics. Bioresour Technol 249:386–394. https://doi.org/10.1016/j.biortech.2017.10.039

Marco-Urrea E, Pérez-Trujillo M, Cruz-Morató C, Caminal G, Vicent T (2010) Degradation of the drug sodium diclofenac by Trametes versicolor pellets and identification of some intermediates by NMR. J Hazard Mater 176:836–842. https://doi.org/10.1016/j.jhazmat.2009.11.112

Martinez-Hernandez AL, Velasco-Santos C, De Icaza M, Castano VM (2005) Microstructural characterisation of keratin fibres from chicken feathers. Int J Environ Pollut 23:162–178. https://doi.org/10.1504/IJEP.2005.006858

McGettigan P, Henry D (2013) Use of non-steroidal anti-inflammatory drugs that elevate cardiovascular risk: an examination of sales and essential medicines lists in low-, middle-, and high-income countries. PLoS Med 10:e1001388. https://doi.org/10.1371/journal.pmed.1001388

Moreira IS, Bessa VS, Murgolo S, Piccirillo C, Mascolo G, Castro PM (2018) Biodegradation of Diclofenac by the bacterial strain Labrys portucalensis F11. Ecotoxicol Environ Saf 152:104–113. https://doi.org/10.1016/j.ecoenv.2018.01.040

Moreira-Gasparin FG, de Souza CGM, Costa AM, Alexandrino AM, Bracht CK, Boer CG, Peralta RM (2009) Purification and characterization of an efficient poultry feather degrading-protease from Myrothecium verrucaria. Biodegradation 20:727–736. https://doi.org/10.1007/s10532-009-9260-4

Nam SW, Jung C, Li H, Yu M, Flora JR, Boateng LK et al (2015) Adsorption characteristics of diclofenac and sulfamethoxazole to graphene oxide in aqueous solution. Chemosphere 136:20–26. https://doi.org/10.1016/j.chemosphere.2015.03.061

Namasivayam C, Sureshkumar MV (2008) Removal of chromium(VI) from water and wastewater using surfactant modified coconut coir pith as a biosorbent. Bioresour Technol 99:2218–2225. https://doi.org/10.1016/j.biortech.2007.05.023

Nayak AK, Pal D (2011) Development of pH-sensitive tamarind seed polysaccharide–alginate composite beads for controlled diclofenac sodium delivery using response surface methodology. Int J Biol Macromol 49:784–793. https://doi.org/10.1016/j.ijbiomac.2011.07.013

Nikolaou A, Meric S, Fatta D (2007) Occurrence patterns of pharmaceuticals in water and wastewater environments. Anal Bioanal Chem 387:1225–1234. https://doi.org/10.1007/s00216-006-1035-8

Niku-Paavola ML, Karhunen E, Kantelinen A, Viikari L, Lundell T, Hatakka A (1990) The effect of culture conditions on the production of lignin modifying enzymes by the white-rot fungus Phlebia radiata. J Biotechnol 13:211–222. https://doi.org/10.1016/0168-1656(90)90106-L

Oaks JL, Gilbert M, Virani MZ, Watson RT, Meteyer CU, Rideout BA et al (2004) Diclofenac residues as the cause of vulture population decline in Pakistan. Nature 427:630–633. https://doi.org/10.1038/nature02317

Onifade AA, Al-Sane NA, Al-Musallam AA, Al-Zarban S (1998) A review: potentials for biotechnological applications of keratin-degrading microorganisms and their enzymes for nutritional improvement of feathers and other keratins as livestock feed resources. Bioresour Technol 66:1–11. https://doi.org/10.1016/S0960-8524(98)00033-9

Pezoti O, Cazetta AL, Bedin KC, Souza LS, Martins AC, Silva TL, Santos Júnior O, Visentainer JV, Almeida VC (2016) NaOH-activated carbon of high surface area produced from guava seeds as a high-efficiency adsorbent for amoxicillin removal: kinetic, isotherm and thermodynamic studies. Chem Eng J 288:778–788. https://doi.org/10.1016/j.cej.2015.12.042

Poynton HC, Robinson WE (2018) Contaminants of emerging concern, with an emphasis on nanomaterials and pharmaceuticals. In: Green chemistry. Elsevier, pp 291–315. https://doi.org/10.1016/B978-0-12-809270-5.00012-1

Queiroz C, da Silva AJR, Lopes MLM, Fialho E, Valente-Mesquita VL (2011) Polyphenol oxidase activity, phenolic acid composition and browning in cashew apple (Anacardium occidentale, L.) after processing. Food Chem 125:128–132. https://doi.org/10.1016/j.foodchem.2010.08.048

Ramachandran E, Ramukutty S (2014) Growth, morphology, spectral and thermal studies of gel grown diclofenac acid crystals. J Cryst Growth 389:78–82. https://doi.org/10.1016/j.jcrysgro.2013.11.081

Ramirez MG, Avelizapa LR, Avelizapa NR, Camarillo RC (2004) Colloidal chitin stained with Remazol Brilliant Blue R®, a useful substrate to select chitinolytic microorganisms and to evaluate chitinases. J Microbiol Methods 56:213–219. https://doi.org/10.1016/j.mimet.2003.10.011

Rigobello ES, Dantas ADB, Di Bernardo L, Vieira EM (2013) Removal of diclofenac by conventional drinking water treatment processes and granular activated carbon filtration. Chemosphere 92:184–191. https://doi.org/10.1016/j.chemosphere.2013.03.010

Saha P, Chowdhury S (2011) Insight into adsorption thermodynamics. In: Mizutani T (ed) thermodynamics. IntechOpen, London, pp 349–364

Samah NA, Sánchez-Martín MJ, Valiente M, López-Mesas M (2018) Modelling the diclofenac and indomethacin recovery by molecularly imprinted polymer. J Phys Sci 29:67–74

Sathishkumar P, Arulkumar M, Ashokkumar V, Yusoff ARM, Murugesan K, Palvannan T et al (2015) Modified phyto-waste Terminalia catappa fruit shells: a reusable adsorbent for the removal of micropollutant diclofenac. RSC Adv 5:30950–30962. https://doi.org/10.1039/C4RA11786G

Schwaiger J, Ferling H, Mallow U, Wintermayr H, Negele RD (2004) Toxic effects of the non-steroidal anti-inflammatory drug diclofenac: part I: histopathological alterations and bioaccumulation in rainbow trout. Aquat Toxicol 68:141–150. https://doi.org/10.1016/j.aquatox.2004.03.014

Singh CJ (2003) Optimization of an extracellular protease of Chrysosporium keratinophilum and its potential in bioremediation of keratinic wastes. Mycopathologia 156:151–156. https://doi.org/10.1023/A:1023395409746

Singh RL, Singh PK, Singh RP (2015) Enzymatic decolorization and degradation of azo dyes—a review. Int Biodeterior Biodegrad 104:21–31. https://doi.org/10.1016/j.ibiod.2015.04.027

Sivaraj R, Namasivayam C, Kadirvelu K (2001) Orange peel as an adsorbent in the removal of acid violet 17 (acid dye) from aqueous solutions. Waste Manag 21:105–110. https://doi.org/10.1016/S0956-053X(00)00076-3

Snyder SA (2008) Occurrence, treatment, and toxicological relevance of EDCs and pharmaceuticals in water. Ozone Sci Eng 30:65–69. https://doi.org/10.1080/01919510701799278

Stylianou K, Hapeshi E, Vasquez MI, Fatta-Kassinos D, Vyrides I (2018) Diclofenac biodegradation by newly isolated Klebsiella sp. KSC: microbial intermediates and ecotoxicological assessment. J Environ Chem Eng 6:3242–3248. https://doi.org/10.1016/j.jece.2018.04.052

Taheran M, Naghdi M, Brar SK, Verma M, Surampalli RY (2018) Emerging contaminants: here today, there tomorrow! Environ Nanotechnol Monit Manag 10:122–126. https://doi.org/10.1016/j.enmm.2018.05.010

Temkin MI, Pyzhev V (1940) Kinetics of ammonia synthesis on promoted iron catalyst. Acta Phys Chim URSS 12:327

Tewari S, Jindal R, Kho YL, Eo S, Choi K (2013) Major pharmaceutical residues in wastewater treatment plants and receiving waters in Bangkok, Thailand, and associated ecological risks. Chemosphere 91:697–704. https://doi.org/10.1016/j.chemosphere.2012.12.042

Tiehm A, Schmidt N, Stieber M, Sacher F, Wolf L, Hoetzl H (2011) Biodegradation of pharmaceutical compounds and their occurrence in the Jordan Valley. Water Resour Manag 25:1195–1203. https://doi.org/10.1007/s11269-010-9678-9

Tien M, Kirk TK (1984) Lignin-degrading enzyme from Phanerochaete chrysosporium: purification, characterization, and catalytic properties of a unique H2O2-requiring oxygenase. Proc Natl Acad Sci 81:2280–2284. https://doi.org/10.1073/pnas.81.8.2280

Ulubay M, Yurt KK, Kaplan AA, Atilla MK (2018) The use of diclofenac sodium in urological practice: a structural and neurochemical based review. J Chem Neuroanat 87:32–36. https://doi.org/10.1016/j.jchemneu.2017.02.005

Valli K, Gold MH (1991) Degradation of 2,4-dichlorophenol by the lignin-degrading fungus Phanerochaete chrysosporium. J Bacteriol 173:345–352. https://doi.org/10.1128/jb.173.1.345-352.1991

Van’t Hoff JH (1884) Etudes de dynamique chimique. Frederik Muller, Amsterdam

Verlicchi P, Al Aukidy M, Zambello E (2012) Occurrence of pharmaceutical compounds in urban wastewater: removal, mass load and environmental risk after a secondary treatment—a review. Sci Total Environ 429:123–155. https://doi.org/10.1016/j.scitotenv.2012.04.028

Veselá M, Friedrich J (2009) Amino acid and soluble protein cocktail from waste keratin hydrolysed by a fungal keratinase of Paecilomyces marquandii. Biotechnol Bioprocess Eng 14:84–90. https://doi.org/10.1007/s12257-008-0083-7

Weber WJ, Morris JC (1963) Kinetics of adsorption on carbon from solution. J Sanit Eng Div 89:31–60

Widiastuti H, Wulaningtyas A (2008) Activity of ligninolytic enzymes during growth and fruiting body development of white rot fungi Omphalina sp. and Pleurotus ostreatus. Hayati J Biosci 15(4):140–144. https://doi.org/10.4308/hjb.15.4.140

Wilkinson J, Hooda PS, Barker J, Barton S, Swinden J (2017) Occurrence, fate and transformation of emerging contaminants in water: an overarching review of the field. Environ Pollut 231:954–970. https://doi.org/10.1016/j.envpol.2017.08.032

Zhang Y, Geißen SU (2010) In vitro degradation of carbamazepine and diclofenac by crude lignin peroxidase. J Hazard Mater 176:1089–1092. https://doi.org/10.1016/j.jhazmat.2009.10.133

Zhao Y, Liu F, Qin X (2017) Adsorption of diclofenac onto goethite: adsorption kinetics and effects of pH. Chemosphere 180:373–378. https://doi.org/10.1016/j.chemosphere.2017.04.007

Acknowledgements

This work was financially supported by the FAI 297950016 2019 project called Biodegradability of drugs as emerging pollutants in batch cultures supported by the Autonomous University of San Luis Potosi.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Consent to participate

All authors are available for it.

Consent for publication

All authors agree to the publication of the Results contained in this paper.

Ethics approval

Not applicable.

Additional information

Editorial responsibility: Jing Chen.

Rights and permissions

About this article

Cite this article

Rodríguez-Zamarripa, F.M., Trejo-Carrizalez, I. & Cervantes-González, E. Diclofenac sodium removal from aqueous phase using a keratinolytic waste and biodegradation of the adsorbate/adsorbent complex. Int. J. Environ. Sci. Technol. 19, 1227–1246 (2022). https://doi.org/10.1007/s13762-021-03214-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-021-03214-4