Abstract

Coagulation–flocculation technique is usually employed in wastewater treatment by applying conventional inorganic materials such as alum and ferric chloride. Due cost to environmental challenges associated with the use of inorganic flocculants, biopolymers are gaining ground as alternative water treatment materials. In the present study, native cellulose and hemicelluloses isolated from sugarcane bagasse were used in the removal of turbidity and biological oxygen demand from industrial wastewater. Isolated native cellulose was modified to form regenerated cellulose (RC). Also, native cellulose, hemicellulose and RC were carboxymethylated using Na-chloroacetate. Thereafter, the functional groups on the carboxymethylated biopolymers were examined using Fourier transform infrared spectroscopy and the carbon–hydrogen–nitrogen–sulfur–oxygen elemental analysis. The degree of substitution (DS) for regenerated and carboxymethylated cellulosic materials was measured using recommended standard methods. Carboxymethyl cellulose (CMC) with 1.3 DS reduced turbidity and biological oxygen demand by 62.2 and 64%, respectively. Carboxymethyl regenerated cellulose (CMC-II) at 1.1 DS reduced turbidity and by 55.6 and 60%, respectively. Carboxymethyl hemicellulose (CMH) with 1.4 DS was capable of reducing turbidity and biological oxygen demand by 45.7 and 47%, respectively. Carboxymethyl cellulose and hemicellulose have rarely been used in the treatment of brewery wastewater. In the present study, these two novel materials showed a good prospect in removing biological oxygen demand and turbidity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wastewater management has become a global problem due to industrialization, population increase, and rapid urbanization. Globally, industrialization has led to the discharge of large volumes of wastewater. If not well managed, this wastewater might cause negative impacts on environmental and human health (Wang and Yang 2016). The release of untreated wastewater from industries increases the levels of aquatic organics, heavy metals pollution, and eutrophication of fresh water bodies (Miao et al. 2015).

Wastewater is usually treated using a myriad of methods and techniques such as adsorption, evaporation, electro-precipitation, membrane separation, ion exchange, and coagulation-flocculation technologies (Yargıç et al. 2015). Research has indicated good results when such methods were used for water and wastewater treatment. For example, the adsorption–destruction technique was applied in the treatment of hexamine containing industrial wastewater. The treatment process that was based on adsorption and catalytic oxidation was capable of reducing hexamine in the form of total organic carbon by 57% (Zamani et al. 2014). Moreover, the adsorption technique was also coupled with ion-imprinted polymeric technology hence found to be very useful for the extraction of specific ions from wastewater (Rajabi et al. 2013; Shamsipur et al. 2013). Also, various studies have reported results on the use of catalytic photo-degradation technique for wastewater treatment, e.g., citric acid was used to prepare graphene quantum dots as catalyst for photo-degradation of cationic dye-based organic pollutant (Roushani et al. 2015). Similarly, electro-precipitation technique has been reported by various studies to be an effective method for wastewater treatment (Boye et al. 2005). For instance, Cr and other organic pollutants were removed from tannery wastewater using electro-precipitation (Kongjao et al. 2007). Likewise, membrane separation technique is widely applied for wastewater treatment due to its simplicity and low energy cost (Ravanchi et al. 2009). Membrane separation method coupled with adsorption technique has been used for effective treatment of palm oil wastewater effluents (Azmi and Yunos 2014).

However, the coagulation–flocculation technique is widely used in treatment of both industrial and domestic wastewater. The technique usually employs the application of metal coagulants that can be divided into two categories: (1) aluminum coagulants such as aluminum chloride, alum, and sodium aluminate, and (2) iron coagulants for instance, ferric chloride sulfate, ferrous sulfate, ferric chloride, and ferric sulfate (Teh et al. 2016). Furthermore, the coagulation–flocculation process in industrial wastewater treatment is usually applied as pre-treatment, post-treatment, or main treatment process due to its flexibility and multipurpose applicability (Szyguła et al. 2009).

Industrial, inorganic, and conventional wastewater treatment technologies have many limitations including environmental toxicity. For example, the application of Al-based materials has been associated with Alzheimer’s disease (Sinha and Mathur 2016). Additionally, coagulation–flocculation processes using conventional inorganic coagulants may result in the production of large volumes of sludge that act as a secondary pollutant (Ahmad et al. 2016; Xu et al. 2016). Inorganic coagulants are incapable of efficiently removing emerging contaminants, e.g., pharmaceuticals, pesticides, personal care products, food additives, and plasticizers of industrial origin (Adeleye et al. 2016). Conventional aluminum and iron-based coagulants have shown poor performance in removing heavy metals from industrial wastewater (Tang et al. 2016). Therefore, search for new, bio-based, and better alternative coagulants and flocculants is important.

Biopolymers are produced by living organisms, naturally occurring polymers that include polynucleotides, polysaccharides, and polypeptides. Biopolymers have attracted great attention in the scientific community due to their unique advantages that consist of excellent biodegradability, cost-effectiveness, availability, and eco-friendliness (Mousa et al. 2016). Polysaccharides, particularly chitosan and cellulose, are widely used in wastewater treatment. They are used as natural coagulants and flocculants with modified functional groups. Polysaccharide activity depends much on the DS, degree of polymerization and chain lengths (Kanmani et al. 2017).

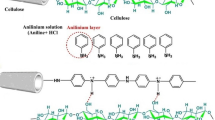

Cellulose is a homopolysaccharide consisting of a linear chain of several hundreds to many thousands of β-(1,4)-linked D-glucose units in parallel orientation (Mousa et al. 2016). The use of cellulose and its derivatives for the wastewater treatment process has become a topic of intense research (Singha and Guleria 2014). Likewise, a hyper-branched polyethyleneimine-grafted cellulose has demonstrated good performance as a natural flocculant with high removal efficiencies (Zhang et al. 2018a). CMC has been effectively applied as a coagulant in treating industrial wastewater effluents with good results (Ali et al. 2013).

Most of the available methods for modifying cellulose into CMC involve the use of holocellulose as the raw material (Aguir and M'Henni 2006). The end result of carboxymethylation is usually both CMC and CMH (Ren et al. 2008). The most effective solvents used in carboxymethylation reactions are isopropyl alcohol (CH3CHOHCH3) and sodium hydroxide (NaOH). During pretreatment, these solvents change some amounts of cellulose available in holocellulose into RC (Pushpamalar et al. 2006a).

There are notable chemical differences between native cellulose and RC. For instance, native cellulose has parallel orientation of microfibrils, whereas RC has a perpendicular orientation of microfibrils (O'sullivan 1997). In addition, RC has high available hydroxyl (OH) functional groups compared to native cellulose (Pushpamalar et al. 2006a). The availability of hydroxy groups along anti-parallel chains of RC offers many adsorption and substitution sites leading to inter-particle bridging (Teh et al. 2016). Moreover, RC is less crystalline compared to native cellulose, causing high solubility of RC (Qi et al. 2009). In synthesizing RC, other substances such as hemicelluloses and lignin are usually removed. This increases the concentration of cellulose with a high degree of polymerization compared to native cellulose (Jähn et al. 2002). Thus, RC can be easily carboxymethylated for various applications (Zhang et al. 2018b). Hemicelluloses have a different chemistry. The presence of different types of monomers on hemicelluloses makes the hydroxyl function groups highly available for substitution than those of native cellulose and RC. In a similar manner as for RC, the hemicelluloses are easily carboxymethylated to CMH with good solubility properties (Ren et al. 2008).

Not many published studies exist on the application of CMC as a flocculant in treating wastewater (Ali et al. 2013; Khiari et al. 2010). Furthermore, little information is available on the application of either CMC-II or CMH as flocculants in wastewater treatment. The aim of this study was to isolate hemicellulose, regenerate cellulose, and perform carboxymethylation of cellulose and its derivatives, thereafter, measure the efficiency of carboxymethylated lignocellulosic materials in removing turbidity and BOD from brewery wastewater. Brewery wastewater was collected, with permission, from Tanzania Breweries Ltd, Arusha Plant, Tanzania, in August 2019. The whole work was conducted in Tanzania from March 2019 to January 2020.

Materials and methods

Materials

In the present study, sugarcane bagasse was used as the main precursor for obtaining native cellulose and hemicellulose. It was used because it has good lignocellulosic composition for cellulose and hemicellulose that range from 40 to 50% and 25 to 35%, respectively (Sun et al. 2004). The selection of chemicals and reagents to be used in this study was based on their availability and their potential negative impacts on human and environmental health. All the chemicals and reagents used in this study, i.e., sodium chloroacetate (Cl-CH2COONa), isopropyl alcohol (CH3CHOHCH3), ethanol (CH3CH2OH), and sodium hydroxide (NaOH), were of analytical grade.

Methods

Materials preparation

Holocellulose was prepared from treating ground sugarcane bagasse of 250 µm pore size (15 g) with sodium chlorite. The resulting mixture was acidified using acetic acid to a pH of 3.8. This mixture was then placed in a water bath for 4 h with simultaneous addition of 4.5 g of sodium chlorite after every hour at a constant agitation and a temperature of 75 °C (Siqueira et al. 2013). Native cellulose was obtained by isolating hemicelluloses from holocellulose using 10% potassium KOH at a ratio of 1:20 for 10 h at constant agitation and room temperature. The alkaline hemicelluloses were then filtered to remain with alkaline residues of native cellulose which was neutralized with few drops of 10% HCl and freeze-dried (Peng et al. 2010). Hemicelluloses dissolved in KOH were neutralized using 10% HCl followed by KCl.

RC was prepared based on the green modification process that involved the addition of 2 g of native cellulose in a SCHOTT DURAN® laboratory glass bottle (100 mL). In the same bottle, appropriate amount of solution-mixture of urea, sodium hydroxide, and distilled water in the ratio of 12:7:81(v/v), respectively, was added. The dissolved mixture was re-crystallized using a solution of 0.5 M H2SO4 to form RC (Qi et al. 2009).

In the present study, carboxymethylation process was done by changing the ratio of Na-chloroacetate against a constant concentration of initial glycan type (Petzold et al. 2005). Approximately 2 g of cellulose, RC, and hemicelluloses were separately put into three different SCHOTT DURAN® laboratory glass bottles (50 mL). Into each bottle, 10 mL of 25% NaOH was added drop-wise while stirring for 30 min. Thereafter, about 40 mL of isopropyl alcohol was added and the mixture agitated for 30 min at room temperature. Then, 2 g of Na-chloroacetate was added in each bottle before raising the temperature to 65 °C for 71 min. This ended the 1:1 Na-chloroacetate/glycan concentration of the first experiment. Thereafter, another 2 g of Na-chloroacetate was added to account for 2:1 Na-chloroacetate/glycan concentration for the second experiment. The carboxymethylated glycans were then filtered and the residual suspended in 150 mL of methanol (CH3OH) for 12 h. The mixture was then neutralized with dilute acetic acid, filtered, freeze-dried, and activated in an oven at a temperature of 70 °C for 7 h (Ali et al. 2013). In the present study, the resulting materials were named as follows:

Abbreviation | Interpretation |

|---|---|

MCA | Sodium chloroacetate (Na-chloroacetate), carboxymethylation agent |

1 MCA | Carboxymethylation process using 2 g of Na-chloroacetate |

2 MCA | Carboxymethylation process using 4 g of Na-chloroacetate |

3 MCA | Carboxymethylation process using 6 g of Na-chloroacetate |

RC | Regenerated cellulose |

CMC | Carboxymethyl cellulose |

CMC-II | Carboxymethyl regenerated cellulose |

CMH | Carboxymethyl hemicellulose |

Determination of DS

For carboxymethyl and RC, into 250-mL beakers, 5 g of each CMC and CMC-II was added separately. Thereafter, 150 mL of HNO3 – methanol (1:1) v/v was added in all beakers followed by shaking. This mixture was then left to stand for 3 h. Excess acid in the mixtures was removed by a 70% solution of methanol, and all neutralized samples were freeze-dried for 12 h. Into separate conical flasks of 250 mL, 1.2 g of each freeze-dried sample was added followed by 120 mL of deionized water and 18 mL of 1 M NaOH. The mixture was then titrated against 1 M HCl. Finally, the DS of CMC and CMC-II was determined using Eqs. 1 and 2 adopted from Candido and Gonçalves (2016) and (Toğrul and Arslan 2003):

where A is an equivalent weight (g) of sodium hydroxide required per gram of CMC or CMC-II, B is volume of NaOH (mL), C is molarity of NaOH (M), D is volume of HCl solution (mL), E is molarity of HCl (M), and F is the weight of CMC or CMC-II.

For CMH, about 0.3 g of modified CMH was added into a beaker (250 mL) containing 6 mL of deionized water followed by gentle stirring. In the same flask, 6 mL of 1 N HCl was added and the mixture was agitated for about 10 min for its complete dissolution. Also, three drops of phenolphthalein indicator were added while stirring until the red color formed. Furthermore, 50 mL of 95% ethanol was put in portions in the same mixture while stirring. In the meantime, another 100 mL of ethanol was added, while stirring and mixture was left for 15 min to settle. The resulting supernatant was filtered and discarded (Ren et al. 2008). The remaining precipitates were washed up four times with 80% ethanol, and finally with 95% ethanol then dried in an oven at 105 °C for 4 h and re-weighed.

The acidimetric titration method was used for the determination of the DS for CMH, in which 0.1 g of CMH was weighed and added into a conical flask (100 mL) followed by addition of 25 mL distilled water and the mixture agitated for 10 min. Thereafter, 0.05 M NaOH was added drop-wise in the same flask until the pH of the solution reached 8.0. Then 0.05 M H2SO4 was used to titrate the solution until the pH dropped to 3.74. Finally, Eqs. 3 to 5 were used to quantify the DS:

where a is purity of CMH used, m’ is mass (g) of CMH after purification, m is mass (g) of CMH before purification, M is molarity (mol/L) of H2SO4 used, V is volume (mL) of H2SO4 used during titration, and B is mmol/g of H2SO4 consumed per gram of CMH.

Materials characterization

Characterization of glycans before and after modifications was done based on the functional group identification via attenuated total reflection Fourier transform infrared spectroscopy (ATR FT-IR) technique. The infrared spectroscopy (Bruker Alpha Model) with the resolution of 2 cm−1 and spectral range from 500 to 4000 cm−1 was used to analyze the samples. Before the analysis, the ATR crystal was cleaned by using a smooth tissue dipped in acetone, and then the background sample was allowed to run. Finally, a small amount of the sample was placed on ATR crystal, and anvil was allowed to contact the sample for measurements.

Elemental analysis for the determination of carbon (C), hydrogen (H), and oxygen (O) before and after carboxymethylation of cellulose, hemicellulose, and regenerated was conducted by using Thermo scientific Flash 2000 elemental analyzer (CHNS/O) with thermal conductivity detector (TCD). Helium was used as the carrier gas and oxygen was used as the combustion gas during the analysis of carbon and hydrogen. Onto three clean glass plates, a little amount of carboxymethylated glycans (CMH, CMC, and CMC-II) under different modification ratios separately was added. Then about 2 to 3 drops of distilled water (H2O) at room temperature (23 °C) were added on each plate (Khiari et al. 2010).

Wastewater sampling

Industrial wastewater was sampled from raw wastewater collecting pond of the Tanzania Breweries Limited (TBL), Arusha Plant, Tanzania. Approximately 10 L of raw wastewater was sampled, transported, and stored according to the recommended standard methods and protocols (APHA 2017). Physical–chemical characteristics, i.e., pH, conductivity, total dissolved solids (TDS), dissolved oxygen (DO), and temperature, were determined onsite using a HI-9829 multiparameter (Hanna Instruments, Italy). Turbidity was also determined onsite using HIS3703 microprocessor turbidimeter (Hanna Instruments, Italy), whereas BOD was quantified in the laboratory using OxiTop BOD device.

Removal efficiency experiments

Wastewater was neutralized from a pH of 11.9 to approx. 7.0 using 0.5 M HCl. This wastewater (100 mL each) was added into a series of several 200-mL beakers. Into each beaker CMC, RC, and hemicelluloses were added to account for the concentration of 70 to 130 mg/L. Furthermore, the mixture of wastewater and modified glycan in a beaker was fast stirred at 600 rpm for 5 min then slowly stirred at 200 rpm for another 15 min (Hassan et al. 2009). The analysis for the turbidity and BOD was conducted after 30 min of settling, and their respective removal efficiencies were calculated based on Eq. 6. However, the analysis was carried out only by varying flocculant concentration at constant pH, stirring time and settling time (Péerez et al. 2007).

where pi is the initial concentration and Pf final concentration (mg/L) after treatment for BOD. Turbidity values were measured in NTU.

Results and discussion

Brewery wastewater characteristics

The sampled raw wastewater was too polluted and required treatment before being discharged to the environment (Table 1). The BOD and pH values were higher than those recommended by water utilities authority the Tanzanian regulatory authorities.

Characteristics of cellulose and hemicelluloses

In the present study, native cellulose was successfully isolated from holocellulose. Isolation of both native cellulose and hemicelluloses was confirmed by FT-IR spectra (Fig. 1) (Łojewska et al. 2005; Peng et al. 2010). The hydroxyl (–OH) functional group occurs in hemicelluloses as a flat curve band with absorbance ranging from 3375.90 to 3364.25 cm−1, while in the cellulose the –OH group occurs as a pointed curve band at the absorbance of 3330.25 cm−1. The band at 892.41 cm−1 in the hemicellulose spectrum is associated with the presence of xylose residues which is missing in the cellulose spectrum. The strongest peak at the absorbance of 1600.67 cm−1 which is seen in hemicelluloses spectra and slightly seen in cellulose spectra is due to the adsorbed water molecules. Thus, the hemicellulose molecule, because of its chemistry, adsorbs more water molecules compared to cellulose molecule (Olsson and Salmén 2004).

Characteristics of regenerated cellulose

The hydrogen bonds resulting from native cellulose were of intramolecular hydrogen bonding due to the parallel orientation of glucose molecules. A few hydroxyl functional groups were exposed leading to adsorption of infrared radiations at lower absorbance with low transmittance. This was unlike the hydrogen bonds that resulted from RC which tended to have inter-hydrogen bonds due to anti-parallel orientation of glucose molecules. Therefore, the highest number of hydroxy functional groups were highly exposed and resulted to adsorptions of infrared radiations at high absorbance and transmittance range compared to those of native cellulose (Zhang et al. 2005). The results observed in Fig. 2a demonstrated the presence of a band of hydroxyl (–OH) functional groups in RC at an absorbance of 3330.24 cm−1 with high transmittance range. For native cellulose, the – OH band had an absorbance of 3326.00 cm−1 and a lower transmittance range. Likewise, in Fig. 2a, the absorbance of CH2 bending peak shifted from 1429.27 cm−1 in native cellulose to 1423.60 in RC may be indicative of a cleavage of hydrogen bonding in C6-OH (Lan et al. 2011). The intensities around band signals (2896.63, 1423.60, 1029.81, and 892.41 cm−1) in Fig. 2a were almost similar in both native cellulose and RC. Conversely, the band intensity at signal 1644.58 cm−1 indicates that the presence of adsorbed water was stronger in RC than in native cellulose. This phenomenon might be due to the amorphous nature of RC (Mohan et al. 2011; Naka1mura et al. 1981).

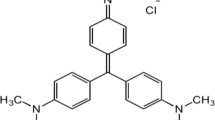

Influence of carboxymethylation

In the present study, glycans were successfully carboxymethylated (Fig. 2b–d). This was indicated by the presence of an adsorption band at a wavelength of 1740 cm−1. The intensification of transmittance around the absorbance of 1740 cm−1 exhibited that carboxymethylation of cellulose and hemicelluloses increased with the increase in the concentration of sodium Na-chloroacetate (Petzold et al. 2005). Contrary to these polysaccharides, RC showed a different trend which was associated with the decrease in the carboxymethylation process with the increase in the amount of sodium Na-chloroacetate. In this case, a ratio 1:1 of RC to sodium Na-chloroacetate was enough for the completion of the carboxymethylation reaction. Such a decrease in the transmittance in RC may be associated with the anti-parallel orientation of microfibrils of RC indicating availability of –OH groups for substitution during the first step of esterification (Teh et al. 2016).

Native cellulose, RC, and hemicelluloses have the ability to adsorb water molecules due to the availability of hydroxyl functional groups (Fringant et al. 1996). The FT-IR spectra in Fig. 2b indicate that CMHs adsorbed more water compared to CMC and RC. This was demonstrated by having intense absorbance at the wavelength of 1586.51 cm−1 and a high transmittance range with a modification ratio of 1:1 hemicellulose mass to the mass of Na-chloroacetate (1 MCA), respectively. Carboxymethylation of hemicellulose increases its ability to bind water. This, however, depends on the DS—the higher the DS, the lower the capability to adsorb water molecules (Postma 2012). Similarly, RC adsorbed more water molecules compared to native cellulose (Fig. 2a). This was because RC is highly hydrophobic (Godbillot et al. 2006). An increase in the concentration of Na-chloroacetate during the carboxymethylation process of RC did not affect the amount of water molecule adsorption (Fig. 2c). This was probably caused by the presence of limited hydroxyl groups on the CMC-II (Guo et al. 2016). On the other hand, for CMC, increasing concentration of Na-chloroacetate led to increased amount of adsorbed water molecules (Berthold et al. 1998). However, for CMC and RC, increasing the concentration of Na-chloroacetate did not have a significant influence on its capacity to adsorb water molecules.

Elemental composition

Elemental composition results (Table 2) indicate an increase in oxygen concentration and a simultaneous decrease in carbon and hydrogen content after carboxymethylation. Carboxymethylation of native cellulose led to decrease in C and H content (Maity and Sa 2014).

The increase in oxygen in carboxymethylated glycans maybe is due to substitution reactions of CH2COONa to the replaceable –OH groups (Kaity and Ghosh 2013). Comparatively, the decrease in carbon and hydrogen concentrations was probably because of distortion of cellulose, RC, and hemicellulose chains, i.e., stirring and formation of water molecules (Chakravorty et al. 2016).

Degree of substitution (DS)

Depending on the solvent, the concentration of functionalization reagent, contact time, and NaOH concentration, usually the DS of cellulose, RC, and hemicelluloses ranges from 0.0 to 2.2 (Wach et al. 2003). In the present study, the DS of the cellulose and hemicellulose improved with the increase in the concentration of Na-chloroacetate (MCA) and it ranged from 0.9 to 1.4 (Table 3).

Such an increase in the DS with respect to increasing concentration of Na-chloroacetate might be caused by the presence of a large number of acetate ions as compared to the available hydroxyl function groups in glycans to be substituted (Pushpamalar et al. 2006b). In the present study, hemicelluloses were highly substituted compared to native cellulose and RC, hence CMH had the highest DS of 1.4 that was obtained with 1:2 hemicellulose and Na-chloroacetate ratio, respectively. This was expected due to the anatomy of hemicellulose and the presence of a wide variety of monosaccharides on the hemicellulose structure with a hydroxyl function group available for chemical substitution (Sun 2010). Under normal circumstances, the DS of glycans should increase with increasing concentration of Na-chloroacetate (Casaburi et al. 2018; Joshi et al. 2015). However, in the present study, the substitution behavior of RC was different. In this case, low Na-chloroacetate resulted in higher DS than compared to when high Na-chloroacetate concentration was used. This behavior can be explained by the fact that RC has improved surface chemical and physical properties, i.e., high hydrophilicity and freely available hydroxyl functional groups to be replaced by carboxymethyl groups (Dinand et al. 2002; Marks 2015; Peršin et al. 2012; Yamane et al. 2006). This would mean that even with low Na-chloroacetate concentration, RC would still register a high DS.

Solubility test

In the present study, all of the carboxymethylated glycans were soluble in water, except for the CMC-II that was obtained with 2:1 ratio of Na-chloroacetate against regenerated cellulose (Table 3). This may be due to its relatively low DS (0.9) compared to other glycans. These soluble CMC, RC, and hemicellulose with high DS were taken to the next step of applications as flocculants for treating brewery wastewater.

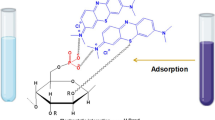

Turbidity and BOD removal efficiencies

Brewery wastewater was treated using the carboxymethylated glycans: CMH, CMC, and CMC-II for the assessment of efficiency of these glycans in removing the BOD and turbidity.

Turbidity removal efficiency

Generally, all carboxymethylated glycans indicated high efficiency to remove turbidity from brewery wastewater (Fig. 3).

For turbidity removal, CMC achieved the highest removal efficiency (> 60%) when the material concentration was between 95 and 100 mg CMC/L wastewater (Fig. 3). CMC-II attained the highest removal efficiency (> 55%) when its concentration in brewery wastewater was between 110 and 115 mg CMC-II/L wastewater (Fig. 3). Of all the glycans, CMH achieved the lowest turbidity removal efficiency across all the applied concentration ranges. It was also found that CMH followed a linear sequence in its turbidity removal—removal efficiency increased with increasing CMH concentration. The trend shown by CMC, diminishing removal efficiency with increasing material concentration after 105 mg CMC/L wastewater is a common phenomenon (Khiari et al. 2010).

BOD removal

The carboxymethylated glycans were also studied for their ability to reduce the BOD from wastewater.

The BOD removal efficiency (Fig. 4) followed a similar trend to that of turbidity removal (Fig. 3). CMC achieved the highest removal efficiency followed by CMC-II (Fig. 4). CMH performed poorly compared to the other two highly substituted glycans. For both CMC and CMC-II, the tipping point was at a concentration of 105 mg/L after which removal efficiencies started to diminish (Fig. 4). Like CMC-II and CMC, the increase in CMH concentrations also increased its BOD removal efficiency. Unlike CMC-II and CMC, the BOD removal efficiency for CMH was still increasing at 130 mg CHM/L. Therefore, at CMH concentrations > 130 mg/L, it is most likely that the maximum BOD removal efficiency for CMH would probably exceed the maximum removal efficiencies of CMC-II and CMC.

The activity of carboxymethylated glycans is usually dependent on its DS. Thus, CMC had higher turbidity and BOD removal efficiencies because the CMC sample used for wastewater treatment in the present had a high DS value (1.3). On the other hand, the CMC-II sample used for brewery wastewater treatment in the present study had a DS value of 1.1. Despite its high DS (1.4), CMH registered lower turbidity and BOD removal efficiencies in the studied CMH concentration range. This observed removal pattern for CHM could be partly attributed to its lower density and powdery (amorphous) nature, meaning that higher amount of CMH would be needed to reach removal efficiencies > 47% (Oun and Rhim 2016).

Conclusion

Tanzania, where this study was conducted, produces its sugar from sugarcane. Thus, sugarcane bagasse, a sugar production by-product, is found in high quantities in the country. In the present study, bio-flocculants were successfully synthesized from sugarcane bagasse. Cellulose and hemicelluloses were isolated from sugarcane bagasse. Cellulose was successfully modified to regenerated cellulose. Native cellulose, hemicellulose and regenerated cellulose were further carboxymethylated to successfully form carboxymethylated glycans. These materials were applied in the removal of turbidity and BOD from brewery wastewater with good results. CMC had the best performance for both turbidity and BOD removal. However, CMH attained the worst efficiencies in both cases. Increasing the dosage of CMH above 130 mg/L that was used in the present study would probably improve its performance. Further studies are therefore recommended to investigate factors that may contribute to increased turbidity and BOD removal efficiencies of the materials applied in the present study.

References

Adeleye AS, Conway JR, Garner K, Huang Y, Su Y, Keller AA (2016) Engineered nanomaterials for water treatment and remediation: Costs, benefits, and applicability. Chem Eng J 286:640–662

Aguir C, M’Henni MF (2006) Experimental study on carboxymethylation of cellulose extracted from Posidonia oceanica. J Appl Polym Sci 99:1808–1816

Ahmad T, Ahmad K, Ahad A, Alam M (2016) Characterization of water treatment sludge and its reuse as coagulant. J Environ Manage 182:606–611

Ali ZM, Mughal MA, Laghari AJ, Ansari A, Saleem H (2013) Polymeric Cellulose Derivative: Carboxymethyl-Cellulose as useful Organic Flocculant against Industrial Waste Waters. Int J Adv Res Technol 2:14–18

APHA (2017) Standard methods for the examination of water and wastewater. American Public Health Association, American Water Works Association, Water Pollution Control Federation, and Water Environment Federation., USA

Azmi NS, Yunos KFM (2014) Wastewater treatment of palm oil mill effluent (POME) by ultrafiltration membrane separation technique coupled with adsorption treatment as pre-treatment. Agric Agric Sci Procedia 2:257–264

Berthold J, Olsson RJ, Salmén L (1998) Water sorption to hydroxyl and carboxylic acid groups in carboxymethylcellulose (CMC) studied with NIR-spectroscopy. Cellulose 5:281–298

Boye B, Farnia G, Sandona G, Buso A, Giomo M (2005) Removal of vegetal tannins from wastewater by electroprecipitation combined with electrogenerated Fenton oxidation. J Appl Electrochem 35:369–374

Candido R, Gonçalves A (2016) Synthesis of cellulose acetate and carboxymethylcellulose from sugarcane straw. Carbohyd Polym 152:679–686

Casaburi A, Rojo ÚM, Cerrutti P, Vázquez A, Foresti ML (2018) Carboxymethyl cellulose with tailored degree of substitution obtained from bacterial cellulose. Food Hydrocolloids 75:147–156

Chakravorty A, Barman G, Mukherjee S, Sa B (2016) Effect of carboxymethylation on rheological and drug release characteristics of locust bean gum matrix tablets. Carbohydr Polym 144:50–58. https://doi.org/10.1016/j.carbpol.2016.02.010

Dinand E, Vignon M, Chanzy H, Heux L (2002) Mercerization of primary wall cellulose and its implication for the conversion of cellulose I→ cellulose II. Cellulose 9:7–18

EWURA (2014) Tanzania Water and Wastewater Quality Monitoring Guidelines for Water Utilities, December 2014:1–29

Fringant C, Desbrieres J, Milas M, Rinaudo M, Joly C, Escoubes M (1996) Characterisation of sorbed water molecules on neutral and ionic polysaccharides. Int J Biol Macromol 18:281–286. https://doi.org/10.1016/0141-8130(95)01087-4

Godbillot L, Dole P, Joly C, Rogé B, Mathlouthi M (2006) Analysis of water binding in starch plasticized films. Food Chem 96:380–386

Guo X, Qing Y, Wu Y, Wu Q (2016) Molecular association of adsorbed water with lignocellulosic materials examined by micro-FTIR spectroscopy. Int J Biol Macromol 83:117–125. https://doi.org/10.1016/j.ijbiomac.2015.11.047

Hassan MA, Li TP, Noor ZZ (2009) Coagulation and flocculation treatment of wastewater in textile industry using chitosan. J Chem Natural Res Eng 4:43–53

Jähn A, Schröder M, Füting M, Schenzel K, Diepenbrock W (2002) Characterization of alkali treated flax fibres by means of FT Raman spectroscopy and environmental scanning electron microscopy. Spectrochim Acta Part A Mol Biomol Spectrosc 58:2271–2279

Joshi G, Naithani S, Varshney V, Bisht SS, Rana V, Gupta P (2015) Synthesis and characterization of carboxymethyl cellulose from office waste paper: a greener approach towards waste management. Waste Manage 38:33–40

Kaity S, Ghosh A (2013) Carboxymethylation of locust bean gum: application in interpenetrating polymer network microspheres for controlled drug delivery. Ind Eng Chem Res 52:10033–10045

Kanmani P, Aravind J, Kamaraj M, Sureshbabu P, Karthikeyan S (2017) Environmental applications of chitosan and cellulosic biopolymers: A comprehensive outlook. Bioresour Technol 242:295–303. https://doi.org/10.1016/j.biortech.2017.03.119

Khiari R, Dridi-Dhaouadi S, Aguir C, Mhenni MF (2010) Experimental evaluation of eco-friendly flocculants prepared from date palm rachis. J Environ Sci 22:1539–1543. https://doi.org/10.1016/s1001-0742(09)60286-2

Kongjao S, Damronglerd S, Hunsom M (2007) Simultaneous removal of chromium and organic pollutants in tannery wastewater by electroprecipitation technique. Korean J Chem Eng 24:730–735

Lan W, Liu C-F, Yue F-X, Sun R-C, Kennedy JF (2011) Ultrasound-assisted dissolution of cellulose in ionic liquid. Carbohyd Polym 86:672–677

Łojewska J, Miśkowiec P, Łojewski T, Proniewicz L (2005) Cellulose oxidative and hydrolytic degradation: In situ FTIR approach. Polymer Degrad Stab 88:512–520

Maity S, Sa B (2014) Ca-carboxymethyl xanthan gum mini-matrices: swelling, erosion and their impact on drug release mechanism. Int J Biol Macromol 68:78–85

Marks JA (2015) Synthesis and Applications of Cellulose Derivatives for Drug Delivery. Virginia Tech

Miao X, Tang Y, Wong CW, Zang H (2015) The latent causal chain of industrial water pollution in China. Environ Pollut 196:473–477

Mohan T, Kargl R, Doliška A, Vesel A, Köstler S, Ribitsch V, Stana-Kleinschek K (2011) Wettability and surface composition of partly and fully regenerated cellulose thin films from trimethylsilyl cellulose. J Colloid Interface Sci 358:604–610

Mousa MH, Dong Y, Davies IJ (2016) Recent advances in bionanocomposites: Preparation, properties, and applications. Int J Polym Mater Polym Biomater 65:225–254

Nakamura K, Hatakeyama T, Hatakeyama H (1981) Studies on bound water of cellulose by differential scanning calorimetry. Text Res J 51:607–613

O’sullivan AC (1997) Cellulose: the structure slowly unravels. Cellulose 4:173–207

Olsson A-M, Salmén L (2004) The association of water to cellulose and hemicellulose in paper examined by FTIR spectroscopy. Carbohyd Res 339:813–818

Oun AA, Rhim J-W (2016) Isolation of cellulose nanocrystals from grain straws and their use for the preparation of carboxymethyl cellulose-based nanocomposite films. Carbohyd Polym 150:187–200

Péerez TZ, Geissler G, Hernandez F (2007) Chemical oxygen demand reduction in coffee wastewater through chemical flocculation and advanced oxidation. J Environ Sci 19:300–305

Peng X-W, Ren J-L, Zhong L-X, Cao X-F, Sun R-C (2010) Microwave-induced synthesis of carboxymethyl hemicelluloses and their rheological properties. J Agric Food Chem 59:570–576

Peršin Z, Vesel A, Kleinschek KS, Mozetič M (2012) Characterisation of surface properties of chemical and plasma treated regenerated cellulose fabric. Text Res J 82:2078–2089

Petzold K, Schwikal K, Günther W, Heinze T Carboxymethyl Xylan‐Control of Properties by Synthesis. In: Macromolecular symposia, 2005. vol 1. Wiley Online Library, pp 27–36

Postma D (2012) Chemical and physical modification of wood based hemicelluloses for use in the pulp and paper industry. Stellenbosch University, Stellenbosch

Pushpamalar V, Langford S, Ahmad M, Lim Y (2006a) Optimization of reaction conditions for preparing carboxymethyl cellulose from sago waste. Carbohyd Polym 64:312–318

Qi H, Chang C, Zhang L (2009) Properties and applications of biodegradable transparent and photoluminescent cellulose films prepared via a green process. Green Chem 11:177–184

Rajabi HR, Shamsipur M, Pourmortazavi SM (2013) Preparation of a novel potassium ion imprinted polymeric nanoparticles based on dicyclohexyl 18C6 for selective determination of K+ ion in different water samples. Mater Sci Eng C 33:3374–3381

Ravanchi MT, Kaghazchi T, Kargari A (2009) Application of membrane separation processes in petrochemical industry: a review. Desalination 235:199–244

Ren J-L, Sun R-C, Peng F (2008) Carboxymethylation of hemicelluloses isolated from sugarcane bagasse. Polym Degrad Stab 93:786–793

Roushani M, Mavaei M, Rajabi HR (2015) Graphene quantum dots as novel and green nano-materials for the visible-light-driven photocatalytic degradation of cationic dye. J Mol Catal A Chem 409:102–109

Shamsipur M, Rajabi HR, Beyzavi MH, Sharghi H (2013) Bulk polymer nanoparticles containing a tetrakis (3-hydroxyphenyl) porphyrin for fast and highly selective separation of mercury ions. Microchim Acta 180:791–799

Singha A, Guleria A (2014) Chemical modification of cellulosic biopolymer and its use in removal of heavy metal ions from wastewater. Int J Biol Macromol 67:409–417

Sinha R, Mathur S (2016) Use of activated silica sol as a coagulant aid to remove aluminium from water defluoridated by electrocoagulation. Desalin Water Treat 57:16790–16799

Siqueira G, Várnai A, Ferraz A, Milagres AM (2013) Enhancement of cellulose hydrolysis in sugarcane bagasse by the selective removal of lignin with sodium chlorite. Appl Energy 102:399–402

Sun J, Sun X, Sun R, Su Y (2004) Fractional extraction and structural characterization of sugarcane bagasse hemicelluloses. Carbohyd Polym 56:195–204

Sun R (2010) Cereal straw as a resource for sustainable biomaterials and biofuels: chemistry, extractives, lignins, hemicelluloses and cellulose. Elsevier, Amsterdam

Szyguła A, Guibal E, Palacín MA, Ruiz M, Sastre AM (2009) Removal of an anionic dye (Acid Blue 92) by coagulation–flocculation using chitosan. J Environ Manage 90:2979–2986

Tang X et al (2016) Chemical coagulation process for the removal of heavy metals from water: a review. Desalin Water Treat 57:1733–1748

TBS (2005) Municipal and Industrial Wastewaters General Tolerance Limits for Municipal and Industrial Wastewaters. Government of Tanzania, Dar Es Salaam Tanzania

Teh CY, Budiman PM, Shak KPY, Wu TY (2016) Recent advancement of coagulation–flocculation and its application in wastewater treatment. Ind Eng Chem Res 55:4363–4389

Toğrul H, Arslan N (2003) Production of carboxymethyl cellulose from sugar beet pulp cellulose and rheological behaviour of carboxymethyl cellulose. Carbohyd Polym 54:73–82

Wach RA, Mitomo H, Nagasawa N, Yoshii F (2003) Radiation crosslinking of carboxymethylcellulose of various degree of substitution at high concentration in aqueous solutions of natural pH. Radiat Phys Chem 68:771–779

Wang Q, Yang Z (2016) Industrial water pollution, water environment treatment, and health risks in China. Environ Pollut 218:358–365. https://doi.org/10.1016/j.envpol.2016.07.011

Xu Y, Chen T, Cui F, Shi W (2016) Effect of reused alum-humic-flocs on coagulation performance and floc characteristics formed by aluminum salt coagulants in humic-acid water. Chem Eng J 287:225–232

Yamane C, Aoyagi T, Ago M, Sato K, Okajima K, Takahashi T (2006) Two different surface properties of regenerated cellulose due to structural anisotropy. Polym J 38:819

Yargıç A, Şahin RY, Özbay N, Önal E (2015) Assessment of toxic copper (II) biosorption from aqueous solution by chemically-treated tomato waste. J Clean Prod 88:152–159

Zamani N, Rajabi H, Taghdiri M, Fakhaei AS, Vatanpour V (2014) Comparative study of different systems for adsorption and catalytic oxidation of hexamine in industrial wastewaters. J Ind Eng Chem 20:37–45

Zhang H, Wu J, Zhang J, He J (2005) 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Zhang L-W, Hua J-R, Zhu W-J, Liu L, Du X-L, Meng R-J, Yao J-M (2018a) Flocculation performance of hyperbranched polyethylenimine-grafted cellulose in wastewater treatment. ACS Sustain Chem Eng 6:1592–1601

Zhang X, Xiao N, Wang H, Liu C, Pan X (2018b) Preparation and characterization of regenerated cellulose film from a solution in lithium bromide molten salt hydrate. Polymers 10:614

Acknowledgements

This work was funded by the African Development Bank (AfDB), through The Nelson Mandela African Institution of Science and Technology, Project No. P-ZI-1A0016 and grant No. 2100155032816 of The United Republic of Tanzania. We acknowledge Professor Thomas Lyimo, Principal College of Natural and Applied Sciences (CoNAS) of the University of Dar es Salaam for constant help during material characterization. Finally, our special thanks go to NM-AIST laboratory staff for their relentless support during laboratory works.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Ethical approval

This article does not contain any studies with human participants performed by any of the authors.

Additional information

Editorial responsibility: Samareh Mirkia.

Rights and permissions

About this article

Cite this article

Mwesiga, J.J., Rwiza, M.J. & Kalmykova, E.N. Regeneration and carboxymethylation of cellulose and its derivatives: application assessment for brewery wastewater treatment. Int. J. Environ. Sci. Technol. 19, 581–590 (2022). https://doi.org/10.1007/s13762-021-03190-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-021-03190-9