Abstract

Several studies have linked nosocomial transmission of airborne diseases to airflow in healthcare settings. Quasi-experimental methods are developed to observe the aerodynamic transport behavior of synthetic respiratory particles in the corridors of an actual hospital. Computational models are then developed to validate the experimental results and to explore the spatial relationships of supply–exhaust air ventilation under various ventilation rates in patient corridors. This work aims to study the effect of ventilation rate and arrangement on the containment and removal of airborne contaminates in patient corridors. Results suggest that distribution of bio-aerosols in hospital corridors could be exacerbated by introducing higher ventilation rates. Increasing ventilation rate appears to reduce aerosol concentrations; however, depending on release point and ventilation arrangement, the reduction may not be worth the extra cost of ventilation. Modified supply–exhaust air system configurations could reduce average particle concentration up to 30% and transport distance more than 60% without increasing air change rate. Best results were obtained by placing an air outlet grille between each two supply air intakes along the corridor.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Economic burden of healthcare associated infections (HAIs) is estimated to be $28–$45 billion per year (Stone 2009). Although the burden is very expensive, it is deemed to be preventable (Centers for Disease Control and Prevention 2016). Nonetheless, the costs have increased with more infectious agents developing drug resistance over time (Brady 2005). More than 70% of the bacteria that contribute to HAI are resistant to antibiotics (Marschall et al. 2008). For example, two meta-analyses have shown a significant burden increase when compared methicillin-resistant and methicillin-susceptible Staphylococcus aureus (Whitby et al. 2001; Cosgrove et al. 2003). Thus, seeking a preemptive solution to alleviate HAI has gained considerable attraction. Engineering solutions could be leveraged to dilute, remove, and disinfect pathogenic microorganisms. The role of ventilation has been emphasized by various agencies to control the spread of infection in hospital premises (AIA 2006; WHO 2007; ASHRAE Standard 170 2013). Contamination in hospitals could be controlled by the ventilation system through providing clean air, installing proper filters, and disinfectants (Aliabadi et al. 2011). In response, organizations such as the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) have developed standards for minimum ventilation rates that are deemed to affect the spread of viable pathogens (ASHRAE Standard 170 2013).

Implementing ASHRAE requirements significantly changes the energy consumption rates in healthcare facilities (Grosskopf and Mousavi 2014). Large energy consumption is another serious issue in healthcare facilities that, indeed, ensues from the prevention of HAIs. Unlike residential and office buildings, hospital heating, ventilation, and air-conditioning (HVAC) system is generally not ‘load’ driven, but is predicated on providing adequate ventilation air to maintain a wide range of pressure relationships and air change rates (Mousavi and Grosskopf 2015). The adequacy of these requirements has been extensively investigated in many space functions such as operating rooms (McNeill et al. 2013; Sadrizadeh et al. 2014), airborne infection isolation room (Rydock and Eian 2004; Mousavi and Grosskopf 2015), and protective environments (Humphreys 2004). However, evidence of the like is very scarce for patient corridors. Beggs et al. (2010) investigated the risk of airborne infection transmission in hospital waiting areas (Beggs et al. 2010). Using stochastic Monte Carlo techniques and assuming a well-mixed condition, the spread of TB, influenza, and measles was studied, and the risk of infection was calculated primarily as a function of exposure time. The conclusion was that with four (4) air change rates (ACH), the risk of acquiring a disease is truly negligible, while it becomes more pronounced when the duration of stay is doubled. It has been shown, however, that the concentration of pathogens is higher near the source and exhaust fans (Tung et al. 2009; Mousavi and Grosskopf 2016).

Corridors are unique space functions in the hospital. Operating rooms and other high risk environments are accessed from the corridor where mixing of air could result in infection transmission (Villafruela et al. 2016). Further, unlike a typical care unit, the source of infection is generally unknown and is not stationary. Research-based evidence to quantify engineering parameters (e.g., ventilation rate, etc.) in corridors is scarce and inconclusive (Li et al. 2007). Although many studies have observed a trend between ventilation rate and space cleanliness, the real relation and the attributed mechanisms have still remained ambiguous (Sundell et al. 2011). This study aims at testing the recommendations made by current codes relative to airborne particle dissemination within patient corridors. Specifically, the following questions will be addressed:

- 1.

How does ventilation rate influence the concentrations and distributions of airborne particles within patient corridors?

- 2.

What is the impact of ventilation arrangement on airborne particle dissemination for a given ventilation rate? In other words, how can engineers control the movements of airborne particles via altering inlet/outlet arrangements as opposed to increasing ventilation rate (i.e., more energy)?

As a result, a series of experiments were designed and conducted in the patient corridors of an actual hospital in the summer of 2013, Florida, USA (Mousavi and Grosskopf 2014). Computational fluid dynamics (CFD) models were consequently developed to simulate the experiments and provide more depth and breadth to the knowledge about contaminant spread in patient corridors. This study aims to answer the above-mentioned research questions by defining new ventilation design scenarios and testing them with validated CFD models.

Materials and methods

Experimental setup

To address the research questions, a series of experiments were conducted in the corridors of an actual hospital (Fig. 1). An oil-based substance (polyalphaolefin), with a specific density of 0.85, was aerosolized outside the 2.5-m-wide and 35.0-m-long corridor, at the entrance of the ward. Counts of 1.0-µm particles were measured in 3.0-m intervals along the two sides of the corridor and in three different heights, leading to six data points at the surface normal to the length of the hallway (x-axis). NUCON F-1000-DD forward light scattering photometric aerosol detectors were used to measure particle counts every 40 s for 3 h. The size of 1 μm was selected for three reasons: (1) Studies show that this size is the most difficult size to be captured and removed via the filtration system (Nazaroff 2016). (2) The movement behavior of 1 μm particles is very complex as it has a mix of submicron particles (moving with the streamlines of air) and larger particles that are highly affected by gravity (Lai 2002). (3) A wide range of harmful bacteria and viruses are found in the range of 1.0 μm (Memarzadeh 2011). A variable frequency drive (VDF) system controlled the airflow balance of the corridor by providing 4 ACH at its maximum capacity (60 Hz). The VDF was manipulated to reduce the ACH to half the maximum capacity (2 ACH), and the same test procedure was repeated. Experimental results were mainly used to validate the computer models, and more discussion can be found in a previous publications (Mousavi and Grosskopf 2014, 2018).

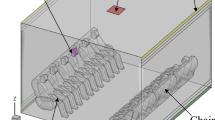

Computational scenarios

CFD models were constructed for four different ventilation rates. The rationale for choosing these ventilation rates was to investigate the current (2 ACH) and former (4 ACH) ASHRAE Standard 170 recommendations (ASHRAE Standard 170 2013). One value between the two recommended rates and one value beyond them were also selected. To replicate the experimental procedure, particles were released outside the ward behind the main entrance. However, an inside release point located 14 m away from the entrance, underneath the supply diffuser, was also studied. The release points were located in the middle of the hallways and 0.8 m above the floor. To address Research Question 2, a modified ventilation arrangement was proposed by rearranging the exhaust fans to provide a uniform air distribution system (Mousavi and Grosskopf 2018). The idea behind the proposed rearrangement was to (1) place an air outlet between each two supply diffusers in the corridor; and (2) avoid placing air outlets (exhaust) near the doorway as it may drag air from the outside of the ward (Fig. 2). Between the existing (EXT) and modified (MOD) ventilation arrangements and particle release inside (INS) and outside (OUT), computational scenarios consist of four cases: Case 1: EXT and OUT; Case 2: MOD and OUT; Case 3: EXT and INS; and Case 4: MOD and INS.

Model development

ANSYS Fluent 15.0R was used to construct the computational models. Extensive discussions on the fundamental equations and solution approach of CFD models can be found in (Srebric and Chen 2002a; Norton and Sun 2006; Tu et al. 2018). The first series of CFD models were constructed to simulate experimental procedures. Sections of the corridors from the main door up to the nurse station area were modeled. Model geometries replicated those of the actual hospital. Supply diffusers and exhaust fans were placed according to the mechanical plan. Infiltration and exfiltration from the patient rooms and ancillary spaces were neglected. Simulations were isothermal due to the absence of heat sources in the unoccupied hospital. Also, radiation heat transfer was not factored in since the corridors were not exposed to direct sun light. Models were solved assuming the steady-state condition since there was no time dependence in the variables. Four types of boundary conditions existed: walls, supply air system (velocity inlet), air exhaust system (flow outlet), and a pressure outlet (Fig. 1). Both the normal and tangential components of the velocity field were set to be zero at walls. The log-law was implemented in the viscous sublayer as well as the buffer layer. Airflow rates and the diffuser size were adopted from the experiments (Table 1).

The realizable K-ε was used to model turbulence as several previous works have suggested that it is appropriate for airflow modeling in enclosed spaces. Interested readers can refer to (Novoselac and Srebric 2002; Lin et al. 2012; Sadrizadeh and Holmberg 2016) for excellent discussion about indoor air turbulence. Results of the duct traverse measurements show that the turbulence level at the inlet boundaries was 10%. This is consistent with findings in previous studies (Turan and Azad 1993). The realizable K − ε is considered a Reynold-averaged-Navier–Stokes (RANS) model where average turbulence fluctuations are attributed to the total kinetic energy of the flow (White 2000). The SIMPLE algorithm was utilized to iterate toward the solution. The number of iterations was initially set to 2500. However, convergence was achieved after approximately 1900 iterations. A second-order upwind scheme was used to approximate the first and second derivatives.

Supply air contaminant level was zero since it was 100% outdoor air. The box method was used to model the diffusers (Srebric and Chen 2002b). Air was removed from the space and through the exhaust system by the same mass flow rate measured in the experiments. Particles were presumed to escape from the exhaust fans (removal). The Eulerian–Lagrangian method was selected to model particle movements within the corridors. In addition to the drag force and gravity, the Brownian force, Saffman’s lift force, virtual mass force, and the pressure gradient force were also considered. However, Zhao et al. (2004a, b) show that the effect of last two forces is proportional to the ratio of air density to particle density (≈ 10−3). The Cunningham slip correction factor was applied since the relative velocity may not be zero at the surface of small particles. Particles were presumed to ‘trap’ when colliding with solid surfaces (e.g., walls and ceilings). Interested readers can find excellent discussions about the Lagrangian approach, its application, and numerical calculations (Zhao et al. 2004b; Chen and Zhao 2010; Wang et al. 2012).

Corrections were made to control the effect of the velocity fluctuations (ú) in the direction normal to the wall as suggested by Matida et al. (2000). The discrete random walk (DRW) model with 500 number of tries was employed as the stochastic tracking scheme. Hathway et al. (2011) showed that using the DRW model improves the accuracy of deposition in the model. Particle generation rate (1.0 g/min at 0.4 L/s airflow rate) and properties (e.g., density) were adopted from the experiments.

Mesh assessment and model validation

A mesh refinement process continued until the volume-averaged velocity across the model became independent of the grid size. This resulted in approximately 3.34 × 106 cells in a tetrahedral meshing scheme with an element volume range from 1.13 × 10−8 m3 to 1.25 × 10−4 m3. The maximum aspect ratio and the minimum orthogonal quality were 2.3667 and 0.20264, respectively. Iterations continued until the normalized residuals for velocity and turbulence components fell below 10−4. Specifically, the largest normalized residual belonged to the continuity equation (\(9.2 \times 10^{ - 5}\)) where other fundamental equations (conservation of momentum in three directions, and K-ε variables) were generally much smaller (e.g., \(10^{ - 6}\)). Accordingly, the smallest under-relaxation parameter was applied to the continuity equation (γ = 0.55). This parameter for the conservation of momentum equations was 0.8, and no relaxation parameter was applied to the turbulent variables.

Since data were collected at six points (three heights and two sides) at every sampling station across the length of the hallway, the average concentration, as well as the standard error of the experimental data, was calculated with respect to the distance (x) from entrance. Next, results of the CFD models were compared against the experimental outcomes (EXP). To that end, both clusters of data were normalized by dividing the average concentration (Cave) at the sampling point by the concentration at the entrance (C0). The normalized concentration (C*) of the 2 ACH and 4 ACH CFD models were validated against the experimental results (Fig. 3). The fluctuations of the experimental data can be due to confounding variables such as turbulence intensity at the air inlets, slight variations in particle generation, and noise in data collection.

Two different approaches were used to address the similarity of EXP and CFD results. In addition to the paired t test, data linearization was utilized to assure that non-normality of the data did not produce β-type error (i.e., rejecting the null hypothesis while it is true). The data were linearized by taking the natural logarithm of the dependent variable, and a linear function was fitted to it. The slope and intercept of the line were calculated with 95% confidence level. Similarity of the data clusters was accepted if the CFD trend line fell into the range of experimental results (Table 2).

Statistical analysis

In order to better characterize the dispersion of particles, a number of statistical metrics were defined:

BZ(%) was defined as the fraction of particles residing within the breathing zone of occupants [0.8–1.8 m]. This metric showed the vertical distribution of particles.

DR (%) was the distance from source that contained 90% of particles divided by the total length of the hallway (35 m). This metric indicated the lateral spread of particles.

DS (m) or distance from source was the mean average of particles from the release point, and it was in an indicative of lateral distribution. DS demonstrates how much, on average, particles could deviate from the release point.

In addition to the above metric, the standard deviation (σ), skewness (g), and kurtosis (β) of particle distributions, as well as the total distance (m) each particle travelled before its final fate, were also calculated and analyzed.

Results and discussion

Changes in the ventilation rate and arrangement influenced the concentrations and distributions of particles independently. The data for cases 1 and 2 showed that a small fraction of particles was able to migrate into the corridor and concentrations decreased linearly relative to ventilation rate. The decline, however, was more pronounced for the modified arrangement, suggesting that modifications were successful in particle removal. Expectedly, the average concentration increased when particles were released inside the corridor (cases 3 and 4) by two orders of magnitude.

Concentrations

Particle concentration peaked near the release point and then decreased relative to distance. However, unlike the release outside cases, the trend was no longer linear and the average concentration changed exponentially relative to ventilation rate.

In addition, the effect of modifications on the concentration of particles became more considerable for higher ventilation rates, suggesting that a better arrangement could justify an increase in ventilation rate (Table 3). Concentrations of particles declined considerably by rearranging the exhaust fans when particles were released inside (Fig. 4).

Under the existing ventilation arrangement, 2ACH did not provide sufficient flow rate to drag the particles toward the nursing station area and the Brownian motion of particles was the dominant transport mechanism. Since the release occurred right underneath the supply diffuser, particles were forced to the sides swiftly and moved toward the nearest exhaust fans. Particle concentrations decreased when higher flow rates were introduced. Although in a smaller amplitude, particle concentrations peaked at the whereabouts of the new exhaust fans (x = 11 m and x = 19 m) for the modified arrangement.

Distributions

Particle distribution parameters were studied relative to ventilation rate for all four cases. The average height of particles was determined by the balance between gravitational settling and the drag force. Since gravity was constant, higher ventilation rates yielded to a larger number of particles within the breathing zone (BZ). Although by increasing the flow rates over 3 ACH, the removal process became effective, such that the breathing zone concentration decreased. Data suggested that, when releasing outside, the increase in flow rates did not result in a better distribution of particles. In fact, despite using more energy, particles were scattered within the hallway and remained suspended even indefinitely (Table 4).

When particles were released inside and for the existing arrangement (Case 3), the average height of particles increased for higher rates. Accordingly, more particles were in the breathing zone range at higher rates, suggesting that higher flow rates may enhance particle suspension. Containment was not fully achieved given the relatively large dispersion ratios (Table 5).

Only 25% of particles were removed through the ventilation system under the 2ACH ventilation rate. This was mainly because of insufficient flow rates at the exhaust fans. The removal was increased with ventilation rate, though disproportionately. It should also be noted that particles were drawn to exhaust fans #2 and #3 when the flow rate was increased.

Improvements were obtained upon modifying the ventilation arrangement (Case 4). For instance, 47% of particles were removed through the modified ventilation system under 2ACH. This was nearly twice the corresponding value under the existing arrangement. Increasing ventilation rate, however, did not necessarily enhance the removal process mainly because particles with higher velocities were prone to deposit more easily. In all ventilation rates, particles were removed by the exhaust fans that were closer to the source. Admittedly, by entraining more air, particles migrated further and eventually removed by the farther exhaust fans. Thus, the removal rate for exhaust fans #3 and #7 increased for higher ventilation rates (i.e., 4ACH and 5ACH), whereas most of the particles were removed by exhaust fan #8 under lower rates (i.e., 2ACH and 3ACH). Figure 2 illustrates the location of these exhaust fans.

As suggested by data, a proper design of exhaust–supply ventilation configuration may result in considerable improvements in particle containment and removal. All distribution parameters greatly improved upon modifying the ventilation arrangement. Considering the outcomes of this work, increasing ventilation rate is not necessarily a remedy to contaminant spread in hospital corridors. Instead, a premeditated and efficient design can culminate in favorable results without consuming more energy.

Conclusion

This work is designed to address the issue of airborne infection in hospital corridors. Specifically, questions are asked concerning ventilation arrangement and ventilation rates where a minimum ventilation rate is required in patient corridors by current codes. Both concentrations and distributions of airborne particles are affected by the flow rates at boundaries. Concentrations of a contaminant decrease when more air is entrained into the space. This, however, comes with a price. Results suggest that the ventilation rates depend on the source position. If released outside the corridor, 2ACH is effective and increasing the ventilation rate has little effect on particle concentrations, while 4ACH seems to be optimum for an internal source. In both cases, the modified arrangements return better results to the extent that the average concentration of particles under 2ACH and modified arrangement was comparable to that of 4ACH under the existing arrangement.

These findings are consistent with the literature. However, previous studies are mostly performed under the well-mixed condition where the contaminants are assumed to have a uniform concentration in the space (Beggs et al. 2010). While this paper further investigates the distribution of contaminants with respect to ventilation design, the results pertaining to the distribution of particles are clear-cut. Lower ventilation rates produce less perturbations and cause better containment. By increasing flow rates, and consequently air velocity, particles tend to move farther and faster (Fig. 5). The modified arrangement enhances the removal process through ventilation system and mitigates particle distributions. Thus, 2ACH demonstrates to have caused distributions that are more desirable with less risk of particle transmission.

This study produced several interesting results; however, it also has some limitations. First, air motion in hospital corridors might be affected by people and equipment movements. These movements have not been accounted for in this study. The rationale was that, movements of people and equipment are random and independent from the ventilation rate. Thus, similar movements, with similar outcomes, are likely to happen under each case. Second, a source of infection can be present at any point in the corridor, with a likelihood distribution. Placing the internal source right underneath the supply diffuser may result in the most unfavorable outcome. The reason is that when air is directly blowing to the source, air moves with high velocities in the vicinity of the source. Higher velocity gradients carry particles farther from the source. To a degree, this study analyzes a worst-case scenario pertaining to source location, to provide a better insight into the problem.

References

AIA (2006) Guidelines for design and construction of health care facilities. AIA, Washington, DC

Aliabadi AA, Rogak SN, Bartlett KH, Green SI (2011) Preventing airborne disease transmission: review of methods for ventilation design in health care facilities. Adv Prev Med 2011:1–21. https://doi.org/10.4061/2011/124064

ASHRAE Standard 170 (2013) Ventilation of healthcare facilities. ASHRAE Stand 170:1–26

Beggs CB, Shepherd SJ, Kerr KG (2010) Potential for airborne transmission of infection in the waiting areas of healthcare premises: stochastic analysis using a Monte Carlo model. BMC Infect Dis 10:247. https://doi.org/10.1186/1471-2334-10-247

Brady MT (2005) Health care–associated infections in the neonatal intensive care unit. Am J Infect Control 33(5):268–275. https://doi.org/10.1016/j.ajic.2012.06.004

Centers for Disease Control and Prevention (2016) National and State Associated Infections Progress Report. Centers for Disease Control and Prevention (March). 10.1002/yd.282

Chen C, Zhao B (2010) Some questions on dispersion of human exhaled droplets in ventilation room: answers from numerical investigation. Indoor Air 20(2):95–111. https://doi.org/10.1111/j.1600-0668.2009.00626.x

Cosgrove SE, Sakoulas G, Perencevich EN, Schwaber MJ, Karchmer AW, Carmeli Y (2003) Comparison of mortality associated with methicillin-resistant and methicillin-susceptible Staphylococcus aureus bacteremia: a meta-analysis. Clin Infect Dis 36(1):53–59. https://doi.org/10.1086/345476

Grosskopf K, Mousavi E (2014) Bioaerosols in health-care environments. ASHRAE J 56(8):22–31

Hathway EA, Noakes CJ, Sleigh PA, Fletcher LA (2011) CFD simulation of airborne pathogen transport due to human activities. Build Environ 46(12):2500–2511. https://doi.org/10.1016/j.buildenv.2011.06.001

Humphreys H (2004) Positive-pressure isolation and the prevention of invasive aspergillosis. What is the evidence? J Hosp Infect 56(2):93–100. https://doi.org/10.1016/j.jhin.2003.10.011

Lai ACK (2002) Particle deposition indoors: a review. Indoor Air 12(4):211–214. https://doi.org/10.1034/j.1600-0668.2002.01159.x

Li Y, Leung GM, Tang JW, Yang X, Chao CYHYH, Lin JZ, Lu JW, Nielsen PV, Niu J, Qian H, Sleigh AC, Su HJJ, Sundell J, Wong TW, Yuen PL (2007) Role of ventilation in airborne transmission of infectious agents in the built environment—a multidisciplinary systematic review. Indoor Air 17(1):2–18. https://doi.org/10.1111/j.1600-0668.2006.00445.x

Lin J, Pai JY, Chen CC (2012) Applied patent RFID systems for building reacting HEPA air ventilation system in hospital operation rooms. J Med Syst 36(6):3399–3405. https://doi.org/10.1007/s10916-011-9800-4

Marschall J, Agniel D, Fraser VJ, Doherty J, Warren DK (2008) Gram-negative bacteraemia in non-ICU patients: factors associated with inadequate antibiotic therapy and impact on outcomes. J Antimicrob Chemother 61(6):1376–1383. https://doi.org/10.1093/jac/dkn104

Matida EA, Nishino K, Torii K (2000) Statistical simulation of particle deposition on the wall from turbulent dispersed pipe flow. Int J Heat Fluid Flow 21(4):389–402. https://doi.org/10.1016/S0142-727X(00)00004-7

McNeill J, Hertzberg J, Zhai Z (2013) Experimental investigation of operating room air distribution in a full-scale laboratory chamber using particle image velocimetry and flow visualization. J Flow Control Meas Visual 1(1):24–32. https://doi.org/10.4236/jfcmv.2013.11005

Memarzadeh F (2011) The environment of care and health care-associated infections: an engineering perspective. American Society of Healthcare Engineering of the American Hospital Association

Mousavi ES, Grosskopf KR (2014) Transport of respiratory aerosols in patient corridors subject to a directional and non-directional airflow—a case study. ASHRAE transaction, Seattle, WA, vol 120, no 2

Mousavi ES, Grosskopf KR (2015) Ventilation rates and airflow pathways in patient rooms: a case study of bioaerosol containment and removal. Ann Occup Hyg 59(9):1190–1199

Mousavi ES, Grosskopf KR (2016) Secondary exposure risks to patients in an airborne isolation room: implications for anteroom design. Build Environ 104:131–137. https://doi.org/10.1016/j.buildenv.2016.05.010

Mousavi ES, Grosskopf KR (2018) Renovation in hospitals : a case study of source control ventilation in work zones. In: Advances in building energy research, Taylor & Francis, pp 1–14

Nazaroff WW (2016) Indoor bioaerosol dynamics. Indoor Air 26(1):61–78. https://doi.org/10.1111/ina.12174

Norton T, Sun DW (2006) Computational fluid dynamics (CFD)—an effective and efficient design and analysis tool for the food industry: a review. Trends Food Sci Technol 17(11):600–620. https://doi.org/10.1016/j.tifs.2006.05.004

Novoselac A, Srebric J (2002) A critical review on the performance and design of combined cooled ceiling and displacement ventilation systems. Energy Build 34(5):497–509. https://doi.org/10.1016/S0378-7788(01)00134-7

Rydock J, Eian P (2004) Containment testing of isolation rooms. J Hosp Infect 57(3):228–232. https://doi.org/10.1016/j.jhin.2004.01.032

Sadrizadeh S, Holmberg S (2016) Evaluation of various turbulence models for indoor airflow prediction: a comparison with experimental data. In: Indoor air quality ventilation and energy conservation in buildings, pp 1–7

Sadrizadeh S, Holmberg S, Tammelin A (2014) A numerical investigation of vertical and horizontal laminar air flow ventilation in an operating room. Build Environ 82:517–525. https://doi.org/10.1016/j.buildenv.2014.09.013

Srebric J, Chen Q (2002a) An example of verification, validation, and reporting of indoor environment CFD analyses (RP-1133). ASHRAE Trans 108 PART 2(2):185–194

Srebric J, Chen Q (2002b) Simplified numerical models for complex air supply diffusers. HVAC&R Res 8(3):277–294

Stone PW (2009) Economic burden of healthcare-associated infections: an American perspective. Expert Revf Pharmacoecon Outcomes Res 9(5):417–422. https://doi.org/10.1586/erp.09.53.Economic

Sundell J, Levin H, Nazaroff WW, Cain WS, Fisk WJ, Grimsrud DT, Gyntelberg F, Li Y, Persily AK, Pickering AC, Samet JM, Spengler JD, Taylor ST, Weschler CJ (2011) Ventilation rates and health: multidisciplinary review of the scientific literature. Indoor Air 21(3):191–204. https://doi.org/10.1111/j.1600-0668.2010.00703.x

Tu J, Yeoh GH, Liu C (2018) Computational fluid dynamics: a practical approach. Butterworth-Heinemann, Oxford

Tung YC, Hu SC, Tsai TI, Chang IL (2009) An experimental study on ventilation efficiency of isolation room. Build Environ 44(2):271–279

Turan ÖF, Azad RS (1993) Comparison of the zero-wire-length dissipation technique with spectral corrections and the effect of high turbulence intensity. Exp Therm Fluid Sci 6(3):292–308. https://doi.org/10.1016/0894-1777(93)90070-Y

Villafruela JM, San José JF, Castro F, Zarzuelo A (2016) Airflow patterns through a sliding door during opening and foot traffic in operating rooms. Build Environ 109:190–198. https://doi.org/10.1016/j.buildenv.2016.09.025

Wang M, Lin CH, Chen Q (2012) Advanced turbulence models for predicting particle transport in enclosed environments. Build Environ 47(1):40–49. https://doi.org/10.1016/j.buildenv.2011.05.018

Whitby M, McLaws ML, Berry G (2001) Risk of death from methicillin-resistant Staphylococcus aureus bacteraemia: a meta-analysis. Med J Aust 175:264–267

White FM (2000) Viscous fluid flow, New York, p 413

WHO (2007) Infection prevention and control of epidemic-and pandemic-prone acute respiratory diseases in health care. WHO, Geneva

Zhao B, Zhang Y, Li X, Yang X, Huang D (2004a) Comparison of indoor aerosol particle concentration and deposition in different ventilated rooms by numerical method. Build Environ 39(1):1–8. https://doi.org/10.1016/j.buildenv.2003.08.002

Zhao B, Zhang Z, Li X, Huang D (2004b) Comparison of diffusion characteristics of aerosol particles in different ventilated rooms by numerical method. ASHRAE Trans 110 Part 1:88–95. https://doi.org/10.1016/j.buildenv.2003.08.002

Acknowledgements

The author would like to thank Dr. Kevin Grosskopf for his comments on manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Shahid Hussain.

Rights and permissions

About this article

Cite this article

Mousavi, E.S. Toward an energy efficient healthcare environment: a case study of hospital corridor design. Int. J. Environ. Sci. Technol. 16, 7633–7642 (2019). https://doi.org/10.1007/s13762-019-02386-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-019-02386-4