Abstract

The primary challenges of petroleum industries are to provide a secure quantity and quality of water resources and how to manage the generated wastewater adequately. Appropriate application of water treatment systems would play a substantial role in drilling operations. Therefore, wastewater management and controlling the amount of produced hazardous materials should be significantly taken into consideration. The objective of this extensive study is to calculate the required water for the waterflooding, polymer flooding, and hydraulic fracturing performances, and subsequently, the percentage of fresh water saving in a shale oil reservoir was calculated accordingly. First of all, the required water and treated water for each well were calculated, and then, the percentage of saving water was averagely calculated. As a result, the percentage of fresh water saving for waterflooding, polymer flooding, and hydraulic fracturing were 71.5%, 70%, and 83.7%, respectively. It was indicated that most of the injected water was treated again and reinjected in the fracturing operations. Furthermore, the total volume of required water for the drilling of Pazanan oilfield’s wells was approximately 125 million gallons that indicated the treatment processes provided about 95 million gallons of this volume. Consequently, the average volume of fresh water saving was relatively 70% which was clarified the accuracy of wastewater separation and purification in the treatment system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the coming decades, the reuse of water supplies is considered as the essential phenomenon which would alleviate the water demand challenges like environmental contamination by the hazardous materials in the produced water (Hagström et al. 2016; Smith et al. 2018). As a result, the adequate and sustainable supplementary of required water for several industries especially drilling operations would be considered as a major issue (Hickenbottom et al. 2013; Smith et al. 2017). The utilized water was used to circulate the drilling fluid which caused to cool the drilling systems such as drilling bit. Therefore, appropriate determination of complex chemical materials which were in the solution with water might be the major environmental concerns of petroleum industries (Bagheri et al. 2018; Bolis et al. 2018; Garg et al. 2017a). Hydraulic fracturing processes regarding the horizontal lateral length and number of cracking steps are considered as the principal water consumptions (Vengosh et al. 2014). Another significant source of water consumption in petroleum industries is enhanced secondary and tertiary oil recovery techniques such as steam-assisted gravity drainage (SAGD), water flooding, and polymer flooding (Davarpanah 2018; Taylor 2018). The management’s options of produced water are contained onsite reusing systems (not common), surface water discharge, injection disposal wells, and evaporation pits (Adham et al. 2018; Ersahin et al. 2018; Yu et al. 2017). In the recent decades, conventional sewage treatment technique is considered as the efficient way in the purification and separation of waste materials from produced water (Crini et al. 2018; Zhan et al. 2018). In this technique, the suspended materials and large floating particles are removed by the primary screening. Since then, about 55–60% of suspended solids would be removed in the primary sedimentation stage and subsequently regarding the biodegradability of the suspended solids, biochemical oxygen demand (BOD) has decreased about 35–40%. Next, biological performances are usually entailed in the treatment processes. In this process, the suspension of microorganisms is utilized to eliminate the biodegradable organics (Hansen et al. 2018; Hussain et al. 2018).

Artificial intelligence (AI) techniques are considered as the novel models to simulate the complex systems to ease these systems and rules. AI methods have entailed genetic programming (GP) and automated neural network (ANN) techniques. The working procedure of ANN method was contained the input layer which is entailed the neurons number as same as the input numbers, the output layer which is consisted of a single output of volume of flow-back water in the system. The last parameter which is called a hidden layer that has contained some unknown neurons and it has set a wide range of training algorithms. Therefore, the selectivity of activation functions in the output and hidden layer is based on the training algorithms. To ensure the validity and accuracy of the proposed ANN method, the volume of balanced water, the volume of each particle and material which is separated in each stage, and the limitations and possibilities of the developed approach are considered to the model (Alizadeh et al. 2017; Garg et al. 2017b). To perform the genetic programming for the developed model has consisted of the following stages; (1) before the implementation of GP method some parameters such as nonlinear functions and arithmetic operations of the proposed model, a set of terminal data included of four inputs, volume of water saving, volume of the produced water, possibilities of the genetic operations and threshold error must be defined. (2) The first generation of proposed model which is produced by the mixture of terminal and functional elements randomly. (3) Structural risk minimization (SRM) issue is also based on the complexities of the model to compare with the experimental error techniques and validate the model. Control the performances of the proposed model versus stopping criterion (maximum number of running the program and threshold error). Integrated water resources management (henceforth; IWRM) is schematically depicted in Fig. 1 (Asdak and Munawir 2017).

Integrated water resources management planning cycle (Asdak and Munawir 2017)

Although, accuracy of water treatment systems would play a significant role in the providing of required water in drilling performances and several studies have wide reported in literature to concentrated on the importance of these procedures, we tried to calculate the required water for waterflooding, polymer flooding and hydraulic fracturing operations and how much volume of fresh water was saved for the drilled wells in Pazanan oilfield in the Iranian’s oilfield during the years of 2001–2017. According to the results of this comprehensive study, the conventional treatment system was purified a proper value of treated water for each process that caused to virtually eliminate the vast expenditures of water supply from large distances. Therefore, it is of importance that appropriate treatment of produced water in the treatment system would be an essential issue to control the water scarcity due to the enormous demand for water supply for drilling industries.

Materials and methods

Rock and reservoir characteristics

Adequate measurement of reservoir and rock properties would play a significant role in the estimation of reservoir productivity. To provide a more reliable estimation which is adapted to the real operational performances, all the parameters are measured more than one time to obtain an average value. The porosity was measured by neutron logs, and the permeability was measured by production logging tools (Davarpanah et al. 2018). The average value of each parameter is shown in Table 1. Furthermore, the average value of oil production rate, gas production rate, and water cut is shown in Table 1.

Water treatment

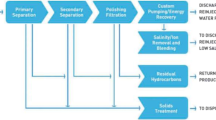

Water scarcity is considered as one of the main concerns of petroleum industries. As an example, providing the required water for the injectivity scenarios, and hydraulic fracturing is always a problem in upstream industries (Veil 2011). Therefore, petroleum industries have tried to find novel solutions for the efficient treatment of water to meet the needs of operational performances (Fig. 2). The water treatment techniques are being explained summarily in Table 2.

The process of water treatment system (Golestanbagh et al. 2016)

Results and discussion

Water flooding

Water flooding is one of the primary enhanced oil recovery techniques in shale oil layers. This technique is considered as one of the economic and preferred enhanced oil recovery techniques, and it has proposed the less serious impact on the environment (Moustafa and Shedid 2017). The studied oilfield was started to produce in the year 2001. Due to the oilfield evaluations which were obtained from the wells in the field, natural drive mechanisms would be able to provide a sustainable economic amount of oil and gas for 2 years up to 2003. By passing the productivity time, natural drive mechanisms were weakened, and production from the studied field was not profitable enough. In this situation, the administration of flooding performances was essentially required to improve the productivity of trapped reserve oil in the reservoir. Waterflooding processes were lasted about seven sequential years up to the year 2009. Since then, regarding the reduction of oil recovery, the secondary and tertiary techniques were played a substantial role in the oil recovery enhancement. Provide the required water for waterflooding performances is considered as the main issues of this process which should be taken into consideration. Due to the water scarcity in recent decades, water treatment and reuse it in the flooding performances is the main priority of drilling industries. To do this, total required water during this period was measured averagely according to the daily measurement of injected water in the surface. This total required water was calculated by Eq. 1 for each well separately.

As can be seen in Eq. 1, the total required injected water for the sequential waterflooding was calculated, and it is defined that the volume of required water for each year and how much water should be provided. Equation 1 calculated the total required water for each well. All the measurements are in a million gallons for 7 years of waterflooding. The produced water on the surface should be treated properly in the treatment systems. The produced water might contain the injected water and aquifer water that included many hazardous materials such as heavy metals and pollution materials. Therefore, to reinject this produced water, it was necessary to treat it in the conventional treatment system. The produced water was sent to the treatment systems near the drilling wells to avoid the transferring expenditures. The volume of treated water which could be reinjected to the wells was calculated by Eq. 2 averagely. In this equation, the input water is related to the produced water in the surface, and the output water is related to the treated water after treatment processes.

Subsequently, the total percentage of saving fresh water which is required for the waterflooding processes are calculated according to Eq. 3. Furthermore, the volume of required water treated water and saving water during waterflooding is shown in Table 3.

As can be seen in Table 3, total required water for the waterflooding processes was calculated about 56 million gallons that relatively 40 million gallons of this volume was provided by the treated water in the treatment system. Therefore, the average percentage of fresh water savings in all the oil wells was measured approximately 72%.

Polymer flooding

Due to the productivity reduction at the end of 2009, waterflooding was not considered as the efficient way of enhanced recovery technique. Therefore, among different recovery techniques, polymer flooding was chosen for the studied field (Salmo et al. 2017). Polymer flooding had started from 2010 up to 2016. The volume of required fresh water, treated water and saving water is calculated from Eq. 1–3, respectively. The volume of required water, treated water and saving water during waterflooding is shown in Table 4.

As can be seen in Table 4, total required water for the polymer flooding processes was calculated about 12 million gallons that relatively 8 million gallons of this volume was provided by the treated Water in the treatment system. Therefore, the average percentage of fresh water savings in all the oil wells was measured by approximately 70%.

Hydraulic fracturing

Hydraulic fracturing performances are one of the mechanical techniques of opening the dead-end pores or increase the length of existed cracks by the purpose of oil recovery enhancement. This method would prefer when the recovery techniques were not efficient enough to provide sufficient oil and gas production. The volume of required water, treated water and saving water is calculated from Eq. 1–3 respectively. The volume of required water, treated water and saving water during waterflooding is shown in Table 5.

As can be seen in Table 5, total required water for the hydraulic fracturing processes was calculated to be about 55 million gallons of which relatively 47 million gallons of this volume was provided by the treated water in the treatment system. Therefore, the average percentage of fresh water savings in all the oil wells was measured approximately 84%. The required water for drilling performances is contained lubrication processes, cooling operations, and etc. which allocated a small volume of water than other consumed processing water. Subsequently, the total required water for waterflooding, polymer flooding, hydraulic fracturing, and drilling performances was calculated about 125 million gallons that relatively 96 million gallons of this volume was provided by the treated water in the treatment system. Therefore, the average percentage of fresh water savings in all the oil wells was measured approximately 69%. This water volume is explained in Table 6.

Conclusion

Water reuse in the unconventional oil shale reservoirs is considered as the principal issues of petroleum industries regarding the environmental aspects of hazardous materials in the produced water in the surface which needed to be treated in conventional treatment systems. In the studied oilfield, waterflooding, polymer flooding and, hydraulic fracturing performances were done sequentially from the year 2001 to 2017 in Pazanan oilfield. Subsequently, the fresh water saving was measured for waterflooding, polymer flooding, and hydraulic fracturing 71.5%, 70%, and 83.7%, respectively, which was illustrated that most of the injected water was treated again and reinjected in the fracturing operations. Moreover, the total volume of required water for drilling of these wells in Pazanan oilfield during 2001–2017 was relatively 125 million gallons that water treatment systems supplied about 95 million gallons of this volume. Consequently, the average volume of fresh water saving was relatively 70% which was clarified the accuracy of the treatment system in the separation and purification of wastewater.

References

Adham S, Hussain A, Minier-Matar J, Janson A, Sharma R (2018) Membrane applications and opportunities for water management in the oil & gas industry. Desalination 417:2–17

Ahmaduna F-R, Pendashteh A, Chuah Abdullah L, Awang Biak DR, Siavash Madaeni S, Zainal Abidin Z (2009) Review of technologies for oil and gas produced water treatment. J Hazard Mater 170:530–551

Alizadeh M, Shabani A, Kavianpour M (2017) Predicting longitudinal dispersion coefficient using ANN with metaheuristic training algorithms. Int J Environ Sci Technol 14:2399–2410

Asdak C, Munawir M (2017) Integrated water resources conservation management for a sustainable food security KnE. Life Sci 2:238–245

Bagheri M, Roshandel R, Shayegan J (2018) Optimal selection of an integrated produced water treatment system in the upstream of oil industry. Process Saf Environ Prot 117:67–81

Bassin JP, Dezotti M, Rosado A (2018) Molecular biology techniques applied to the study of microbial diversity of wastewater treatment systems. In: Dezotti M, Lippel G, Bassin JP (eds) Advanced biological processes for wastewater treatment: emerging, consolidated technologies and introduction to molecular techniques. Springer, Cham, pp 205–299

Bolis V, Capón-García E, Weder O, Hungerbühler K (2018) New classification of chemical hazardous liquid waste for the estimation of its energy recovery potential based on existing measurements. J Clean Prod 183:1228–1240. https://doi.org/10.1016/j.jclepro.2018.02.050

Crini G, Lichtfouse E, Wilson LD, Morin-Crini N (2018) Conventional and non-conventional adsorbents for wastewater treatment. Environ Chem Lett. https://doi.org/10.1007/s10311-018-0786-8

da Silva SS, Chiavone-Filho O, de Barros Neto EL, Foletto EL (2015) Oil removal from produced water by conjugation of flotation and photo-Fenton processes. J Environ Manag 147:257–263

Davarpanah A (2018) The feasible visual laboratory investigation of formate fluids on the rheological properties of a shale formation. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-018-1877-6

Davarpanah A, Mirshekari B, Behbahani TJ, Hemmati M (2018) Integrated production logging tools approach for convenient experimental individual layer permeability measurements in a multi-layered fractured reservoir. J Pet Explor Prod Technol 8(3):743–751

Ersahin ME, Ozgun H, Kaya R, Mutlu BK, Kinaci C, Koyuncu I (2018) Treatment of produced water originated from oil and gas production wells: a pilot study and cost analysis. Environ Sci Pollut Res 25:6398–6406

Garg A, Li J, Hou J, Berretta C, Garg A (2017a) A new computational approach for estimation of wilting point for green infrastructure. Measurement 111:351–358

Garg A, Vijayaraghavan V, Zhang J, Lam JSL (2017b) Robust model design for evaluation of power characteristics of the cleaner energy system. Renew Energy 112:302–313

Golestanbagh M, Parvini M, Pendashteh A (2016) Integrated systems for oilfield produced water treatment: the state of the art. Energy Sources Part A 38:3404–3411

Hagström EL, Lyles C, Pattanayek M, DeShields B, Berkman MP (2016) Produced water—emerging challenges, risks, and opportunities. Environ Claims J 28:122–139

Hansen É, Rodrigues MAS, Aragão ME, de Aquim PM (2018) Water and wastewater minimization in a petrochemical industry through mathematical programming. J Clean Prod 172:1814–1822. https://doi.org/10.1016/j.jclepro.2017.12.005

Hickenbottom KL, Hancock NT, Hutchings NR, Appleton EW, Beaudry EG, Xu P, Cath TY (2013) Forward osmosis treatment of drilling mud and fracturing wastewater from oil and gas operations. Desalination 312:60–66

Hussain S, van Leeuwen J, Aryal R, Sarkar B, Chow C, Beecham S (2018) Removal of organic matter from reservoir water: mechanisms underpinning surface chemistry of natural adsorbents. Int J Environ Sci Technol 15:847–862

Kurniawan TA, Chan GYS, Lo W-H, Babel S (2006) Physico–chemical treatment techniques for wastewater laden with heavy metals. Chem Eng J 118:83–98. https://doi.org/10.1016/j.cej.2006.01.015

Mahamuni NN, Adewuyi YG (2010) Advanced oxidation processes (AOPs) involving ultrasound for waste water treatment: a review with emphasis on cost estimation. Ultrason Sonochem 17:990–1003. https://doi.org/10.1016/j.ultsonch.2009.09.005

Moustafa E-AA, Shedid SA (2017) Effects of magnesium and potassium sulfates on oil recovery by water flooding. Egypt J Pet. https://doi.org/10.1016/j.ejpe.2017.09.007

Salmo IC, Pettersen Ø, Skauge A (2017) Polymer flooding at an adverse mobility ratio: acceleration of oil production by crossflow into water channels. Energy Fuels 31:5948–5958

Smith AP, Van De Ven CJ, Richardson SD (2017) Current water management practices, challenges, and innovations for us unconventional oil and gas development current sustainable/renewable. Energy Rep 4:209–218

Smith HM, Brouwer S, Jeffrey P, Frijns J (2018) Public responses to water reuse–understanding the evidence. J Environ Manag 207:43–50

Taylor SE (2018) Interfacial chemistry in steam-based thermal recovery of oil sands bitumen with emphasis on steam-assisted gravity drainage and the role of chemical additives. Colloids Interfaces 2:16

Veil JA (2011) Produced water management options and technologies. In: Lee K, Neff J (eds) Produced water: environmental risks and advances in mitigation technologies. Springer, New York, pp 537–571

Vengosh A, Jackson RB, Warner N, Darrah TH, Kondash A (2014) A critical review of the risks to water resources from unconventional shale gas development and hydraulic fracturing in the United States. Environ Sci Technol 48:8334–8348

Yayla S, Ibrahim SS, Olcay AB (2017) Numerical investigation of coalescing plate system to understand the separation of water and oil in water treatment plant of petroleum industry. Eng Appl Comput Fluid Mech 11:184–192

Yu L, Han M, He F (2017) A review of treating oily wastewater. Arabian J Chem 10:S1913–S1922. https://doi.org/10.1016/j.arabjc.2013.07.020

Zhan Y, Wei R, Zhou H (2018) Improvement on the treatment of thick oil sewage by using integrated biochemical treatment technology. Int J Environ Sci Technol 15:81–92

Acknowledgements

I would like to thank my supervisor Dr. Behnam Mirshekari for his guidance and support throughout this research.

Funding

There is no financial support provided from any specific governmental and institutional organization to complete this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Editorial responsibility: Ta Yeong Wu.

Rights and permissions

About this article

Cite this article

Ebadati, A., Davarpanah, A., Shahhoseini, A. et al. An experimental study to measure the required fresh water and treated water for drilling an unconventional shale reservoir. Int. J. Environ. Sci. Technol. 16, 7727–7734 (2019). https://doi.org/10.1007/s13762-018-02185-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-018-02185-3