Abstract

A novel nanocatalyst silica-bonded sulfuric acid supported on KIT-5 as an organic–inorganic hybrid with high activity was prepared successfully. The KIT-5 with high surface area was reacted with chlorosulfonic acid via simple and rapid method. This efficient and reusable heterogeneous catalyst sulfuric acid nanocatalyst catalyzed one-pot synthesis of β-dicarbonyl compounds, aldehyde and ammonium acetate in the presence of 0.05 g of nanocatalyst at room temperature via solvent-free conditions to afford excellent yields of 1,4-dihydropyridines. This nanocatalyst was fully characterized by XRD, SEM–EDXS and Map analyses. The morphology of the catalyst surface by SEM images shows all porous of KIT-5 after the reaction was filled with the SO3H groups. The average size determines around 22–24 nm. This catalyst can be reused five times without any significant loss of activity, too. The ease of separation, high activity, high surface area and reaction under open air condition are the main advantages of this catalyst.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, search on new heterogeneous catalyst due to unique properties is one of the attractive topics in industrial and academic research. Catalysis based on mesoporous materials has extreme importance in many areas such as adsorption, separation and catalysis especially (Hoffmann et al. 2006). In this heterogeneous catalysis, the quality of the surface area of the catalyst is very important for determining the availability of catalytic sites for the reactants. Silica is a good choice as a support in nanoscale for maximizing the surface area of catalyst (Maheswara et al. 2006). A literature survey revealed an enormous number of very different supports of mesoporous silica materials are used with different pore sizes such as SBA-16, SBA-1 (Kim et al. 2005; Kruk et al. 1999). Among them, 3D nanocage KIT-5 is an ideal support for this purpose. In the 3D pore supports, the ease of synthesis controls the pore size, which makes them ideal for shape-selective catalysis and gas separations. Solid-supported reagents (Ley et al. 2002) have been prepared and applied in organic reactions because of their excellent selectivity, simple process and reusability of catalysts.

1,4-dihydropyridines (1,4-DHPs) possess a wide range of bioactive molecules and drugs for the treatment of diseases, including hypertension (Bossert et al. 1981; Safak et al. 2006). Nifedipine drug is a commercial model of the 1,4-DHP structure which has been used extensively in both antihypertensive and antianginal treatments. (Janis and Triggle 1983). 1,4-DHPs have a wide range of biological activities, antidiabetic agents and antitumor Kılcıgil et al. (2000). Neuroprotectant (Klusa 1995) and platelet antiaggregator activity (Bretzel et al. 1993) have discovered that several other medicinal applications of 1,4-DHPs.

The first 1,4-DHPs were synthesized by Hantzsch (1882). The conventional method contains one-pot condensation of three or more components under harsh conditions using ammonia as the nitrogen source, in a refluxing alcohol for a longer period in acetic acid (Love and Sander 1965).

The green chemistry is an important subject in organic reactions that pollution effects are kept to minimum, in energy usage, consumption of raw materials, the better reactivity of the synthetic procedures with both reductions and decrease in reaction time. Different catalysts have been discovered with the purpose of improving the efficiency of Hantzsch DHPs synthesis, and many of them showed excellent catalytic activity (Agarwal and Chauhan 2005; Debache et al. 2008; Singh et al. 2008; Vivek et al. 2010; Dhruva and Jagir 2010), for example, l-proline (Shi et al. 2012), S-Valin (Jiang et al. 2009), Yb (OTf)3 (Wang et al. 2005a, b), I2 (Ko et al. 2005), TBAHS (Tewari et al. 2004), HOAc (Wang et al. 2009), Et3N (Wen et al. 2008), DBU (Shi et al. 2009), Py (Bagley et al. 2013).

Recently, solid acid catalysts—clay (Bahulayan et al. 2002) or silica (Bigdeli et al. 2007; Modarresi-Alam et al. 2008)—play an important role in organic reactions as an efficient and heterogeneous catalyst. The catalysts based on silica have some advantages, and they are very inexpensive and easy to prepare especially. They can be recycled from reactions easily due to insolubility in all organic solvents. Among various heterogeneous catalysts based on silica, solid sulfonic acid–silica due to its simple preparation method, low cost and reusability performs as an organic–inorganic hybrid catalyst in a variety of reactions (Mbaraka et al. 2003; Zareyee and Karimi 2007).

Synthesis of novel catalysis based on KIT-5 is in the center of our interest (Mirsafaei et al. 2015, 2016). In continuation of our research group, here, we report a new heterogeneous nanocatalyst protocol with high-active acid groups for the preparation of important biomolecules (1,4-DHP) under solvent-free conditions.

Materials and methods

Chemicals

All chemical materials were purchased from chemical companies (Fluka, Merck and Aldrich) and used without further purification. The yields and the melting point of all products have been determined followed by the comparison of their physical and spectral data with previously reported samples. KIT-5 as a mesoporous silica source was prepared in previous work (Mirsafaei et al. 2015). Table 1 shows some physical properties of KIT-5. As shown in this table, the surface area of KIT-5 is very high and makes it an ideal choice as a catalysis supporter.

Organic–inorganic hybrid catalyst preparation

Preparation of sulfonic acid-functionalized KIT-5

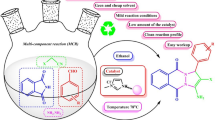

In a round-bottomed flask, to a mixture of KIT-5 (1.00 g) in CHCl3 (3 mL), chlorosulfonic acid (1 mL) was added very slowly under ice bath over 2 h. Then in order to complete elimination of HCl vapors, the reaction mixture was stirred for another 2 h. Finally, the mixture was filtered and washed with ethanol (2 × 20 mL) and dried at room temperature. The sample was denoted as SO3H-KIT-5 as a white powder (1.2 g) (shown Scheme 1). The number of H+ sites of SO3H-KIT-5 was determined by titration method and found to be 2.32 H+ sites per 1 g of solid acid at 25 °C. It is interesting that the reaction is simple, clean and not requiring any work-up process.

General process for the preparation of 1,4-DHPs

Into a tube equipped with a magnetic stirrer, a mixture of aldehyde (1.0 mmol), dimedone (1.0 mmol), ammonium acetate (1.5 mmol), ethyl acetoacetate (1.0 mmol) and 0.05 g SO3H-KIT-5 nanocatalyst was magnetically stirred at room temperature for appropriate time (Scheme 2, Table 2). For synthesis of sample 5a, the reaction was stirred for 60 min at 90 °C. The progress of the reaction was monitored by TLC (EtOAc: n-hexane; 7:3) when the reaction was completed; the products were washed with water and extracted with EtOAc and dried with anhydrous Na2SO4 and then purified by using column chromatography. Table 2 shows some derivatives of this product with good to excellent yield and reaction time. All of them were known compounds, and the melting points and spectral data were identical to those reported in the literature.

Results and discussion

Catalyst characterization

The FT-IR spectra (SHIMADZU) of the samples were recorded in the range of 4000–400 cm−1 using KBr pellet technique. X-ray diffraction (Bruker D8 advanced powder X-ray diffractometer) patterns of the materials were recorded using Cu Kα (λ = 1.54°A) as the radiation source in the 2θ range of 2–80°. Scanning electron microscope (Lecia Cambridge S 360, Cambridge) was used to observe the morphology of the modified and unmodified mesoporous silicas. Energy dispersive X-ray spectroscopy (Genesis), with an SUTW detector equipped with SEM equipment, was used to perform the EDXS analysis in order to confirm the presence of silica. The GC-Chrome method (GC-2550TG) for approving some known products with standard sample was recorded by Teif Gostar Faraz Co.

FT-IR analysis

In Fig. 1, the FT-IR peaks of pure KIT-5 (a) and SO3H-KIT-5 nanocatalyst (b) before and after the reaction by ClSO3H were confirmed. The broad major peaks for silica at 1300–1000 cm–1 (antisymmetric stretching Si–O–Si) and symmetric stretching (820–740 cm–1) were observed. In comparison with the pure KIT-5 (cure a), the distinguished features of SO3H/KIT-5 were the presence of a new absorption at near 1032 cm–1 in the spectrum, which is assigned to the symmetric stretching of S=O bond as a result of inducing the SO3H groups into the mesoporous silica and an absorption at 610 cm–1, which is due to the bending vibration of OH groups hydrogen bonded to SO3H moieties. FT-IR spectrum (b) shows the overlap symmetric and asymmetric stretching bands of Si–O–Si with O=S=O stretching bands in the SO3H-KIT-5 nanocatalyst. The SO2 asymmetric and symmetric stretching observed at 1170 and 1060 cm–1, respectively. The FT-IR also showed a broad OH-stretching absorption from 3600 to 3200 cm–1. Therefore, the mesoporous support can act as a chelate, resulting in the increase in the amount of acid group in the structure of catalyst.

XRD analysis

Figure 2 clearly shows the wide-angle XRD (WAXRD) pattern of the solid acid catalyst (2θ = 5–70°), the reflections at 23°; the crystallite size of nanoparticles was evaluated using Bragg’s equation (nλ = 2dsinθ), found to be approx. 39 nm in size. As shown in XRD patterns, the decreases in the peak intensity of solid acid approved the presence of SO3H group in the modified mesoporous KIT-5. The reduced intensity approved that organic moieties were filled in the pores of KIT-5. Further, this also confirmed the immobilization of SO3H inside the mesoporous of KIT-5. This may be confirmed that by loading with guest matter in the ordered mesoporous KIT-5, host silica symmetry destroyed.

SEM analysis

Morphology of the surface of nanocatalyst was investigated by SEM microscope equipped with EDXS. Figure 3 shows the morphology images of pure KIT-5 and SO3H-KIT-5 nanocatalyst. Clearly, changes in the morphologies show all porous of KIT-5 after introduction of acid was filled by SO3H groups. The average size determines around 22–24 nm. The EDXS analysis of SO3H-KIT-5 nanocatalyst confirms the addition of the S group of ClSO3H to the host KIT-5, which suggested the formation of acid group with the anchored ligand (Fig. 4). Finally, the map graph showed uniform dispersion of the solid acid group onto KIT-5 (Fig. 5).

Preparation of 1,4-DHPs

In fact, Hantzsch method obtains the low yields of 1,4-DHPs. For overcoming to disadvantages of this method, several effective methods have been improved, such as the use of ionic liquid, metal triflates, microwaves, refluxing in high temperatures.

As shown in Table 2, various aromatic aldehydes containing electron-withdrawing groups and electron-donating groups were tested. The reaction time is not depended on the substituent on the benzaldehyde. This new catalyst efficiently catalyzed these reactions in good to excellent yields (63–91 %) and prevents several problems with solvent use, such as handling, cost, safety and pollution.

Reusability of this catalyst was also tested (Fig. 6). A model reaction 5a was conducted five times with recycled catalysts under similar conditions, and only non-appreciable loss of weight was observed in the obtained desired compound. After each reaction, the catalyst was filtered, washed with water (10 mL) and dried in an oven at 70 °C and reused further in the next reaction without any further modification.

The high efficiency of novel SO3H-KIT-5 heterogeneous acid nanocatalyst is shown in Table 3. These data show the reaction conditions for syntheses of sample 5a were compared with various catalysts, reported previously. The data show our catalyst shows easy filtration and reusability like heterogeneous catalysis and high performance in reaction in comparison with homogeneous catalysis, regarding the yields and reaction times. So, this new catalyst is very valuable for various organic reactions too.

Conclusion

In the present work, our research team synthesized a novel and highly effective recoverable heterogeneous nanocatalyst by simple method and clean reaction. This new nanocatalyst catalyzed the one-pot multicomponent important 1,4-DHPs from aromatic aldehydes, dimedone, ethyl acetoacetate and ammonium acetate in the presence of 0.05 g of organic–inorganic hybrid nanocatalyst via solvent-free media effectively. All products were prepared in pure form by high yield in short reaction time. The prepared heterogeneous catalyst found being highly active and recyclable which is desired for catalyzed Hantzsch reaction in high yields and the required reaction time shorter than many of the previously described methods. It is worthwhile to mention that this catalyzed reaction is facile, clean and any tedious work-up procedure and separation technique is non-required. Therefore, the highly mesoporous silica KIT-5 should be considered and examined as a smart support for other nonocatalyst being used in different catalyzed organic reactions.

References

Agarwal A, Chauhan PMS (2005) Solid supported synthesis of structurally diverse dihydropyrido[2,3-d] pyrimidines using microwave irradiation. Tetrahedron Lett 46(8):1345–1348

Bagley MC, Fusillo V, Jenkins RL, Lubinu MC, Mason Ch (2013) One-step synthesis of pyridines and dihydropyridines in a continuous flow microwave reactor. Beilstein J Org Chem 9:1957–1968

Bahulayan D, Narayan G, Sreekumar V, Lalithambika M (2002) Natural bentonite clay/dilute HNO3 (40%)—a mild, efficient, and reusable catalyst/reagent system for selective mono nitration and benzylic oxidations. Synth Commun 32(23):3565–3574

Bigdeli MA, Heravi MM, Mahdavinia GH (2007) Silica supported perchloric acid (HClO4–SiO2): a mild, reusable and highly efficient heterogeneous catalyst for the synthesis of 14-aryl or alkyl-14-H-dibenzo [a, j] xanthenes. J Mol Catal A Chem 275(1–2):25–29

Bossert F, Meyer H, Wehinger E (1981) 4-Aryldihydropyridines, a new class of highly active calcium antagonists. Angew Chem Int Ed Engl 20(9):762–769

Bretzel RG, Bollen CC, Maeser E, Federlin KF (1993) Nephroprotective effects of nitrendipine in hypertensive tune I and type II diabetic patients. Am J Kidney Dis 21(6):53–64

Debache A, Boulcina R, Belfaitah A, Rhouati S, Carboni B (2008) One-pot synthesis of 1,4-dihydropyridines via a phenylboronic acid catalyzed Hantzsch three-component reaction. Synlett 4:509–512

Dhruva K, Jagir S (2010) Efficient, solvent-free, microwave-enhanced condensation of 5,5-dimethyl-1,3-cyclohexanedione with aldehydes and imines using LiBr as inexpensive, mild catalyst. Synth Commun 40(4):510–517

Hantzsch A (1882) Ueber die synthese pyridinartiger verbindungen aus acetessigäther und aldehydammoniak. Justus Lieb Ann Chem 215(1):1–82

Hoffmann F, Cornelius M, Morell J, Fröba M (2006) Silica-based mesoporous organic–inorganic hybrid materials. Angew Chem Int Ed 45(20):3216–3251

Janis RA, Triggle DJ (1983) New developments in calcium ion channel antagonists. J Med Chem 26(6):775–785

Jiang HF, Mai RH, Cao H, Zhu QH, Liu XH (2009) l-Proline-catalyzed synthesis of highly functionalized multisubstituted 1,4-dihydropyridines. Org Biomol Chem 7(23):4943–4953

Kılcıgil GA, Tuncbilek M, Ertan R, Erol K, Yıldırım E (2000) Synthesis of a new dihydropyridine derivative containing a known vasodilator khellin. Turk J Chem 24(3):255–259

Kim TW, Ryoo R, Gierszal KP, Jaroniec M, Solovyov LA, Sakamoto Y, Terasaki O (2005) Characterization of mesoporous carbons synthesized with SBA-16 silica template. J Mater Chem 15(15):1560–1571

Klusa V (1995) Cerebrocrast. Neuroprotectant, cognition enhancer. Drugs Future 20(2):135–138

Ko S, Sastry MNV, Lin C, Yao CF (2005) Molecular iodine-catalyzed one-pot synthesis of 4-substituted-1,4-dihydropyridine derivatives via Hantzsch reaction. Tetrahedron Lett 46(34):5771–5774

Kruk M, Jaroniec M, Ryoo R, Kim JM (1999) Characterization of high-quality MCM-48 and SBA-1 mesoporous silicas. Chem Mater 11(9):2568–2572

Ley SV, Baxendale IR, Brusotti G, Caldarelli M, Massi A, Nesi M (2002) Solid-supported reagents for multi-step organic synthesis: preparation and application. IL Farmaco 57(4):321–330

Love B, Sander KM (1965) The Hantzsch reaction. I. Oxidative dealkylation of certain dihydropyridines. J Org Chem 30(6):1914–1916

Maheswara M, Siddaiah V, Rao YK, Tzeng YM, Sridhar C (2006) A simple and efficient one-pot synthesis of 1,4-dihydropyridines using heterogeneous catalyst under solvent-free conditions. J Mol Catal A Chem 260(1–2):179–180

Makone S, Mahurkar S (2015) Innovative protocol for the synthesis of acridine derivatives using ionic liquid. Int J Sci Res 4(5):2493–2496

Mbaraka IK, Radu DR, Lin VS, Shanks BH (2003) Organosulfonic acid-functionalized mesoporous silicas for the esterification of fatty acid. J Catal 219(2):329–336

Mirsafaei R, Heravi MM, Ahmadi S, Moslemin MH, Hosseinnejad T (2015) In situ prepared copper nanoparticles on modified KIT-5 as an efficient recyclable catalyst and its applications in click reactions in water. J Mol Catal A Chem 402:100–108

Mirsafaei R, Heravi MM, Ahmadi S, Hosseinnejad T (2016) Synthesis and properties of novel reusable nano-ordered KIT-5-sulfamic acid as a heterogeneous catalyst for solvent-free synthesis of 2,4,5-triaryl-1H-imidazoles. Chem Pap 70:418–429

Modarresi-Alam AR, Nasrollahzadeh M, Khamooshi F (2008) Al(HSO4)3 mediated for the preparation of primary carbamates under solvent-free conditions. Sci Iran 15(4):452–455

Şafak C, Doğan E, Erol K (2006) Studies on 2-ethyl-3-carbmethoxy-4-aryl-5-oxo-1, 4, 5, 6, 7, 8-hexahydroquinoline derivatives and calcium modulatory activities. Turk J Chem 30(1):109–117

Sapkal SB, Shelke KF, Shingate BB, Shingare MS (2009) Nickel nanoparticle-catalyzed facile and efficient one-pot synthesis of polyhydroquinoline derivatives via Hantzsch condensation under solvent-free conditions. Tetrahedron Lett 50(15):1754–1756

Shi F, Zhang G, Zhang Y, Ma N, Jiang B, Tu SJ (2009) A facile and efficient synthesis of N-substituted furo[3,4-b] indeno[2,1-e] pyridine analogues of azapodophyllotoxin via microwave-assisted multicomponent reactions. J Heterocycl Chem 46(5):965–970

Shi CL, Chen H, Shi DQ (2012) An efficient one-pot three-component synthesis of tetrahydrofuro[3,4-b] quinoline-1,8(3H,4H)-dione derivatives catalyzed by L-proline. J Heterocycl Chem 49(1):125–129

Singh L, Ishar MPS, Elango M, Subramanian V, Gupta V, Kanwal P (2008) Synthesis of unsymmetrical substituted 1,4-dihydropyridines through thermal and microwave assisted [4+2] cycloadditions of 1-azadienes and allenic esters. J Org Chem 73(6):2224–2233

Tekale SU, Pagore VP, Kauthale SS, Pawar RP (2014) La2O3/TFE: an efficient system for room temperature synthesis of Hantzsch polyhydroquinolines. Chin Chem Lett 25(8):1149–1152

Tewari N, Dwivedi N, Tripathi RP (2004) Tetrabutylammonium hydrogen sulfate catalyzed eco-friendly and efficient synthesis of glycosyl 1,4-dihydropyridines. Tetrahedron Lett 45(49):9011–9014

Vivek P, Surendra S, Mridul M (2010) Synthesis and molecular docking studies of 1-phenyl-4-glycosyl-dihydropyridines as potent antileishmanial agents. Eur J Med Chem 45(6):2381–2388

Wang LM, Sheng J, Zhang L, Han JW, Fan ZY, Tian H, Qian CT (2005a) Facile Yb(OTf)3 promoted one-pot synthesis of polyhydroquinoline derivatives through Hantzsch reaction. Tetrahedron 61(6):1539–1543

Wang LM, Sheng J, Zhang L, Han JW, Fan ZY, Tian H, Qian CT (2005b) Facile Yb(OTf)3 promoted one-pot synthesis of polyhydroquinoline derivatives through Hantzsch reaction. Tetrahedron Lett 61(6):1539–1543

Wang XH, Hao WJ, Tu SJ, Zhang XH (2009) Microwave-assisted multicomponent reaction for the synthesis of new and significative bisfunctional compounds containing two furo[3,4-b] quinoline and acridinedione skeletons. J Heterocycl Chem 46(4):742–747

Wen LR, Sun JH, Li M, Sun ET, Zhang SS (2008) Application of β-(2-chloroaroyl) thioacetanilides in synthesis: an unusual and highly efficient access to thiochromeno[2,3-b] pyridine derivatives. J Org Chem 73(5):1852–1863

Yosefzadeh M, Mokhtary M (2016) Polyvinylpolypyrrolidone supported chlorosulfonic acid: an efficient catalyst for the one-pot synthesis of hexahydroquinolines. Iran J Catal 6(2):153–159

Zareyee D, Karimi B (2007) A novel and highly efficient method for the silylation of alcohols with hexamethyldisilazane (HMDS) catalyzed by recyclable sulfonic acid-functionalized ordered nanoporous silica. Tetrahedron Lett 48(7):1277–1280

Acknowledgments

We are grateful for partial financial support from Iran National Science Foundation. The authors are thankful to Iran Polymer and Petrochemical Institute for providing the SEM–EDXS facility and Kashan University for providing XRD analysis and Yazd Islamic Azad University for providing IR analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mirsafaei, R., Delzendeh, S. & Abdolazimi, A. Synthesis and characterization of reusable nano-order SO3H-KIT-5 as a heterogeneous catalyst for eco-friendly synthesis of 1,4-dihydropyridines. Int. J. Environ. Sci. Technol. 13, 2219–2226 (2016). https://doi.org/10.1007/s13762-016-1037-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-016-1037-9