Abstract

Interactions of iron (Fe) with the nitrogen (N) cycle have emerged and contain elements of abiotic and biological reactions. One such abiotic reaction which has received little study is the reactivity of NO2 − and Fe(II) associated with a major clay mineral, kaolinite. The main objective of this study was to evaluate the reactivity of NO2 − with Fe(II) added to kaolinite under anoxic conditions. Stirred batch reactivity experiments were carried out with 10 g L−1 kaolinite spiked with 25 and 100 µM Fe(II) at pH 6.45 in an anaerobic chamber. Approximately 500 µM NO2 − was added to initiate the reaction with Fe(II)-loaded kaolinite. The rate of nitrite removal from solution was 2.4-fold slower in the high Fe(II) treatment when compared with the low Fe(II) treatment. A large portion of the NO2 − removed from solution was confirmed to be reduced to N2O(g) in the Fe(II)-kaolinite slurries. However, NO2 − reduction was also noticed in the presence of kaolinite-alone and to somewhat lesser extent in the presence of dithionite-citrate-bicarbonate (DCB)-treated kaolinite. Chemical extractions coupled with infrared spectroscopy suggest that Fe(III) oxide mineral impurities and structural Fe(III) in kaolinite may participate in NO2 − removal from solution. Furthermore, a magnetite mineral was identified based on X-ray diffraction analysis of untreated kaolinite and DCB-treated kaolinite. Our findings reveal a novel pathway of NO2 − transformation in the environment in the presence of Fe(II) associated (sorbed and impurity) with kaolinite.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitrite (NO2 −) is a soil anion that occurs as an intermediate in biological denitrification and nitrification. Incomplete NO3 − reduction can cause NO2 − accumulation in soils, sediments, and groundwater (Vaclavkova et al. 2015; Matocha et al. 2012). The presence of NO2 − can impact dissolved organic nitrogen production, uranium bioremediation, pyrite oxidation, and Fe(III) reduction (Obuekwe et al. 1981; Senko et al. 2002; Davidson et al. 2003; Picardal 2012, Yan et al. 2015). Regarding the latter process, several Fe(III)-reducing bacteria can simultaneously reduce NO3 − and Fe(III) (DiChristina 1992; Krause and Nealson 1997). The biologically produced Fe(II) and NO2 − can react chemically, producing Fe(III) and N2O (Moraghan and Buresh 1977). This chemical process has been invoked to explain the apparent inhibition of Fe(III) reduction in the presence of NO3 − in pure cultures (Obuekwe et al. 1981) and anoxic soil slurries (Komatsu et al. 1978; Matocha and Coyne 2007). Cleemput and Baert (1983) showed that this reaction was more rapid as pH decreased. This may be attributed to the greater proportion of protonated nitrite species (HNO2). Protonation promotes N–O bond breaking; thus, HNO2 is a stronger oxidant than NO2 − (Shriver et al. 1994).

The production of nitrous oxide (N2O) in the Don Juan Pond in Antarctica was attributed to abiotic processes involving oxidation of mineral-derived Fe(II) coupled to NO2 − reduction (Samarkin et al. 2010). In fact, many researchers previously studied and reported abiotic reduction of NO2 − by Fe(II) species such as Fe(II) minerals and sorbed Fe(II) on the mineral surfaces in laboratory studies (Sorensen and Thorling 1991; Hansen et al. 1994; Rakshit et al. 2008; Tai and Dempsey 2009; Dhakal et al. 2013). Solid Fe(II) minerals and sorbed Fe(II) species are more effective reductants than dissolved, hexaquo-Fe(II) (Fe(H2O) 2+6 ) species (Wehrli 1990; Stumm and Sulzberger 1992; Luther et al. 1992; Neumann et al. 2009; Klueglein et al. 2015).

Reductive dissolution of Fe(III) (hydr)oxides by dissimilatory iron-reducing bacteria is an important process in biogeochemical iron cycling (Liu et al. 2001). Most of the Fe(II) produced during microbial Fe(III) reduction exists in precipitated or sorbed forms (Frederickson et al. 1998; Zachara et al. 2002). Regarding the latter, surface oxo- and hydroxo- ligands bonded to Fe(II) increase, the electron density at the Fe(II) center (Millero 1985; Stumm and Morgan 1996) thereby enhancing the potential of Fe(II) as a reductant of NO2 −. Sorensen and Thorling (1991) found that Fe(II) adsorbed to lepidocrocite (γ-FeOOH) reduced NO2 − at a faster rate than dissolved Fe(II). However, there is very little information available about the reactivity of NO2 − with Fe(II) sorbed to soil clay minerals such as kaolinite. Kaolinite has edge sites containing >Al–OH (aluminol) and >Si–OH (silanol) groups that can demonstrate pH-dependent surface charge and can adsorb metal cations such as Fe(II). In fact, Kukkadapu et al. (2001) reported that in Fe(III) oxide-rich subsoils with mixed mineralogy, dissolved biogenic Fe(II) adsorbed strongly to kaolinite. Other researchers also found there is close association between kaolinite and Fe(III) minerals in certain soil types (Jefferson et al. 1975; Golden and Dixon 1985).

Most studies evaluating the reactivity of adsorbed Fe(II)-kaolinite complexes use reference kaolinite minerals to mimic soil kaolinite. Georgia kaolinite (KGa-1b) is one of the most common reference kaolinite minerals used in research studies (Zachara et al. 1998; Foster et al. 1998). Accordingly, the objective of this study was to evaluate the reactivity of Fe(II) associated with kaolinite with NO2 −.

Materials and methods

Materials

Georgia kaolinite (KGa-1b, Clay Minerals Repository, University of Missouri) was purchased and used in this study. The kaolinite was sieved to less than 45 μm fraction size. Freshly prepared, acidified 0.1 M FeCl2, 4H2O stock solutions were used for preparing sorbed Fe(II)-kaolinite complexes. The source of NO2 − was derived from NaNO2 salt, and NO2 − reactivity studies were performed in an Ar/H2 purged anaerobic chamber (Coy Laboratory Products, Grass Lake, Michigan) (Klausen et al. 1995). The organic buffer MES [2-(N-morpholino) ethane sulfonic acid] with concentration of 0.3 M was added to control the pH (Alowitz and Scherer 2002). The MES buffer was titrated either with 1 M NaOH or with 1 M HCl to attain desired initial pH values for the NO2 − reactivity studies (pH 6.45 MES). The ferrozine [3-(2-pyridyl)-5, 6 bis(4-phenylsulfonic acid)-1, 2, 4-triazine, monosodium salt] reagent was used to complex the dissolved Fe(II) present in the aliquots (Stookey 1970). All the solutions were made anoxic by purging with Ar for 2.5 h and stored in an anaerobic glove box.

Preparation of mineral suspensions

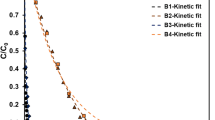

All the studies, until otherwise specified, were conducted in an anaerobic glove box (Coy Laboratory Products, Grass Lake, MI). For each experiment, 10 g L−1 KGa-1b was preequilibrated for 24 h with MES buffer at the desired pH. Mineral suspensions were made by adding calculated amounts of 0.1 M FeCl2 stock into 10 g L−1 KGa-1b, and the suspension was mixed with a rotator stirrer for 72 h. Suspensions were removed and filtered with 0.2-μm membrane filter paper (Fisher Scientific, Hampton, NH), and the aliquots were complexed with ferrozine reagent to measure the Fe(II) concentrations colorimetrically with a UV–VIS-NIR scanning spectrophotometer (Shimadzu, UV-3101 PC, Columbia, MD) at 562 nm wavelength. The initial added Fe(II) concentrations were 25 and 100 μM. These concentrations were chosen to mimic real environmental conditions. These Fe(II) levels were referred to as high Fe and low Fe, respectively. Kinetic experiments showed that almost all of added Fe(II) (approximately >98 %) was removed from solution by kaolinite within 72 h of reaction time (Fig. 1).

A portion of KGa-1b was chemically treated to remove well and poorly crystalline Fe(III) (hydr)oxides using the DCB (dithionite-citrate-bicarbonate) extraction method (Mehra and Jackson 1960). Untreated and DCB-treated kaolinite samples were characterized by X-ray diffraction. Additional extractions were conducted using 0.5 and 6 M HCl to determine Fe(II) and Fe(III). Approximately 30 mg of untreated kaolinite was homogenized with 300 mg of spectroscopic grade KBr and analyzed using a Nicolet 6700 Fourier Transform Infrared (FTIR) spectrometer equipped with a Thermo Fisher Smart Collector Diffuse Reflectance accessory. The FTIR spectra were collected over a range of 4000–600 cm−1 with continuous nitrogen purge. Two hundred scans were co-added together at a spectral resolution of 4 cm−1. Baseline corrections and further spectra processing were performed using GRAMS/32.

Nitrite reactivity experiments

Nitrite reactivity experiments were carried out using both untreated and DCB-treated kaolinite at a suspension density of 10 g L−1. Stirred batch reactivity experiments were conducted with duplicate 30-mL glass vials at a pH value of 6.45 in the high-Fe and low-Fe treatments by addition of 500 μM NO2 −. To identify the effect of Fe impurities in KGa-1b, experiments were included where Fe(II) was not added (control) and where NO2 − was added to KGa-1b and reacted outside the glove box (labeled oxic). DCB-treated kaolinite was reacted with NO2 − under anaerobic conditions without added Fe(II) (labeled DCB) to identify the effect of Fe impurities on NO2 − reduction. A blank experiment with no kaolinite (labeled blank) was included. The suspensions were filtered at predetermined time intervals using 0.2-μm filter paper and the filtrate was measured for NO2 − concentration with a Metrohm 792 Basic ion chromatograph (Herisau, Switzerland). In separate experiments, N2O(g) was measured in the head space of capped 30-mL glass vials using a Varian 3700 gas chromatograph with 2 M packed column, porapak Q, with TCD detector and 20 mL min−1 He carrier gas. The portion of N2O (g) dissolved in solution was accounted for using Henry’s Law constant.

Results and discussion

NO2 − reduction by Fe(II) associated with kaolinite

The rates of nitrite removal from solution in the various treatments are shown in Fig. 2. Negligible removal of nitrite occurred in blank experiments in which no kaolinite was added (nitrite-alone). The rate of nitrite removal, based on the initial linear fit of concentration versus time curves, was ~2.4 times slower for the high Fe(II) treatment when compared with the low Fe(II) treatment (Fig. 2). These results differed from the findings of other researchers who studied reactivity of sorbed Fe(II) with contaminants, where increased Fe(II) loading resulted in greater contaminant reduction rates (Klausen et al. 1995; Amonette et al. 2000). One possible reason for this phenomena could be surface oxidation of sorbed Fe(II) at the high Fe(II) treatment when preparing mineral suspensions. Recent studies by Soltermann et al. (2014) indicate that sorbed Fe(II) on edge sites of montmorillonite can be readily oxidized to secondary Fe(III) oxide minerals. Our kaolinite slurries would supply ample edge sites which might sorb and subsequently oxidize added Fe(II). If oxidized Fe(III) precipitates are forming on kaolinite, they might serve to passivate the surface, decreasing the rate of nitrite removal in the high Fe(II) treatment when compared with the low Fe(II) counterpart.

Nitrite reduction with Fe(II) associated with Georgia kaolinite. Kaolinite-alone and oxic represent reaction of NO2 − with KGa-1b under anoxic and oxic conditions, respectively, without any sorbed Fe on KGa-1b. DCB indicates reaction of NO2 − with DCB-treated KGa-1b. Low Fe and high Fe represent reaction of 25 and 100 μM sorbed Fe(II) on KGa-1b with NO2 −. Nitrite-alone indicates change of NO2 − in solution in absence of any solid phase. All the conditions are buffered by MES at pH = 6.45, and at a KGa-1b concentration of 10 g L−1

Nitrite removal from solution by kaolinite and Fe(II)-treated kaolinite slurries can involve both sorption and electron transfer processes. Nitrous oxide (N2O(g)) was identified as a two-electron reduction product and accounted for approximately 20–80 % of the NO2 − removed from solution in the Fe(II)-reacted kaolinite treatments (Fig. 3). Ammonium (NH4 +) was below detection limits. Thus, the production of NO(g), N2(g), and/or sorbed nitrite might account for unrecovered N.

The addition of Fe(II) was not necessary for nitrite removal to occur based on disappearance of nitrite in control slurries (kaolinite-alone) (Fig. 2). The pattern of nitrite disappearance in the control was complex; nitrite levels resembled high Fe(II) treatments at early time points and low Fe(II) treatments at longer times (>24 h). It is possible that Fe impurities in kaolinite were responsible for NO2 − removal from solution.

Role of impurities in kaolinite

Chemical extractions were performed on kaolinite anoxic slurries in order to identify the nature of potential impurities which might be removing nitrite from solution without added Fe(II). The 0.5 and 6 M HCl extractions conducted under anoxic conditions indicated that Fe(II) and Fe(III) were present in kaolinite (Table 1). There was a notable decrease in 6 M HCl-extractable Fe(III) after DCB extraction. Furthermore, both mineral acid extractions showed that Fe(II) was present in greater amounts than Fe(III). It is possible that discrete Fe(III) (hydr)oxide mineral impurities are present in close association with kaolinite.

Some of the Fe(III) associated with kaolinite might also exist as structural Fe(III) which has substituted for Al3+. An infrared spectrum in the OH-stretching region of untreated kaolinite show the OH-stretching bands at 3695, 3667, 3651, and 3618 cm−1, diagnostic of well-crystalline kaolinite (Fig. 4). In addition, there is a weak shoulder near 3590 cm−1 which has been assigned by Beauvais and Bertaux (2002) as Fe3+ substituted for Al3+ in KGa-1b. Past studies have shown that trace impurities in this particular reference kaolinite (KGa-1b) can alter electron transfer and sorption behavior of inorganic contaminants. For example, it was shown that TiO2(s) impurities in reference kaolinite participated in As(III) oxidation to As(V) (Foster et al. 1998). In addition, Zachara et al. (1998) found that a DCB extraction affected the ability of this reference kaolinite to sorb chromate (CrO4 2−).

To verify that Fe(II) associated with kaolinite was responsible for NO2 − removal from solution, additional experiments were performed by adding 500 μM NO2 − to KGa-1b under oxic conditions and after treatment with DCB under anoxic conditions at pH 6.45. It was found that DCB-treated KGa-1b reduced NO2 − at a slower rate and lower amount than that of the control (kaolinite-alone) (Fig. 2). Moreover, untreated KGa-1b did not react with NO2 − under oxic conditions, outside the glove box (Fig. 2). These data provide further support that Fe(II) impurities in kaolinite were responsible for NO2 − removal from solution. Further experiments characterizing nitrous oxide in control slurries would be useful to evaluate whether the nitrite removed from solution is sorbing or undergoing electron transfer to form products.

The stoichiometric equivalence of Fe(II) available to NO2 − reduced could not be obtained even after these experiments. The Fe(II) values in kaolinite, as determined from 0.5 to 6 M HCl extractions, were not high enough to explain the amount of NO2 − reduced. From Table 1, one can find that 6 M HCl extraction of KGa-1b resulted in about 2 μmol of Fe(II) per g of KGa-1b. Converting that amount to a value relevant to the experimental conditions used here yields 20 μM Fe(II). The added 25 μM Fe(II) can add to this value to make it 45 μM Fe(II). It is evident that, if a 2:1 molar ratio of Fe(II) to NO2 − is considered, this amount along with the added amount cannot explain the amount of NO2 − lost in the case of low Fe treatment (368 µM NO2 − lost). For DCB extracted and KGa-1b-anoxic treatments, the amounts of NO2 − lost were 137 and 276 µM, respectively, and the amount of extractable total Fe available to react were ~32 and 20 µM, respectively.

One reason for the unaccounted molar equivalence of NO2 − to Fe(II) may be that unextractable Fe (by 0.5 and 6 M HCl acid extractions) is present in KGa-1b. Researchers found that only 1–2.5 % of the Fe present in haematite (Fe2O3) and magnetite (Fe3O4) can be recovered by 0.5 M HCl extraction (Kennedy et al. 1998). They indicated one needs to use hot 12 M HCl extraction to account for the Fe-fraction containing Fe3O4. It is possible that even the 6 M HCl extraction could not recover all Fe from KGa-1b. In fact, the X-ray diffraction data showed weak peaks that correspond to magnetite, a mixed Fe(II)/Fe(III) mineral with a chemical formula of Fe3O4 (Fig. 5a, b). Hence, the unextractable Fe fraction coming from Fe3O4 may participate in NO2 − reduction, particularly if surface Fe(II) is associated with magnetite (Dhakal et al. 2013). In addition, the finding that DCB-treated KGa-1b actually reacted with NO2 −, although at a slower rate (Fig. 2), suggests an unextractable Fe fraction may be present and participate in NO2 − reduction.

Environmental implications

Although the reactivity study of sorbed Fe(II) on KGa-1b with NO2 − was confounded by the presence of Fe impurities in KGa-1b, this phenomenon can mimic the real environmental scenarios where complex mineral assemblages are present. This kind of environmental conditions is speculated by many researchers in the light of contaminant sorption processes (Bertsch and Seaman 1999). These authors identified the need of considering surface modifications of soil clay minerals by Fe– and Al– oxides. It has been well demonstrated that contaminant sorption process was largely changed by these surface modifiers (Bertsch and Seaman 1999). Our work demonstrates that the redox behavior of soil clay mineral can largely be affected by surface modifications as well. Therefore, our work can be very relevant to the environments where kaolinite and Fe associations may occur. In fact, there are numerous reports of Fe(II) and Fe(III) association with kaolinite (Kukkadapu et al. 2001; Jefferson et al. 1975; Golden and Dixon 1985). This process may be limited to subsurface environments where Fe(III)-reducing conditions prevail and oxygen is absent. In addition to the real environmental applications, our work is important because KGa-1b is one of the most common reference kaolinite minerals used by researchers.

Conclusion

Our laboratory experiments indicate for the first time that kaolinite supplemented with Fe(II) can remove nitrite from solution. In the Fe(II)-kaolinite experiments, about 80 % of the NO2 − was reduced to N2O as a product. Production of N2 (g), NO (g), or sorbed NO2 − may account for unrecovered N. Our findings are confounded by the fact that impurities, especially Fe(II) associated with KGa-1b, participated in NO2 − reduction as well without added Fe(II). Chemical extractions reveal the presence of Fe(II) and Fe(III) in association with kaolinite which might occur as free Fe(III) oxide minerals and/or structural Fe(III) substituted in kaolinite. Evidence for the latter is supported by infrared spectra which show an absorption band near 3590 cm−1. X-ray diffraction results from pristine and DCB-treated KGa-1b revealed the presence of mineral phases such as magnetite, which in turn could account for greater amount of NO2 − reduced than can be expected from theoretical stoichiometric equivalence of Fe(II) added plus extracted. Our findings not only mimic scenarios where Fe(II) kaolinite association could occur, but also provide insights into research findings that use KGa-1b as a reference kaolinite mineral.

References

Alowitz JM, Scherer MM (2002) Kinetics of nitrate, nitrite, and Cr(VI) reduction by iron metal. Environ Sci Technol 36:299–306

Amonette JE, Workman DJ, Kennedy DW, Fruchter JS, Gorby YA (2000) Dechlorination of carbon tetrachloride by Fe(II) associated with goethite. Environ Sci Technol 34:4606–4613

Beauvais A, Bertaux J (2002) In situ characterization and differentiation of kaolinites in lateritic weathering profiles using infrared microspectroscopy. Clays Clay Miner 50:314–330

Bertsch PM, Seaman JC (1999) Characterization of complex mineral assemblages: implications for contaminant transport and environmental remediation. Proc Natl Acad Sci USA 96:3350–3357

Cleemput OV, Baert L (1983) Nitrite stability influenced by iron compounds. Soil Biol Biochem 15:137–140

Davidson EA, Chorover J, Dail DB (2003) A mechanism of abiotic immobilization of nitrate in forest ecosystems: the ferrous wheel hypothesis. Glob Change Biol 9:228–236

Dhakal P, Matocha CJ, Huggins FE, Vandiviere MM (2013) Nitrite reactivity with magnetite. Environ Sci Technol 47:6206–6213

DiChristina TJ (1992) Effects of nitrate and nitrite on dissimilatory iron reduction by Shewanella putrefaciens 200. J Bacteriol 174:1891–1896

Foster AL, Brown GEJR, Parks GA (1998) X-ray absorption fine-structure spectroscopy study of photocatalyzed, heterogeneous, As(III) oxidation on kaolin and anatase. Environ Sci Technol 32:1444–1452

Frederickson JK, Zachara JM, Kennedy DW, Dong H, Onstott TC, Hinman NW, Li S (1998) Biogenic iron mineralization accompanying the dissimilatory-reduction of hydrous ferric oxide by groundwater bacterium. Geochim Cosmochim Acta 62:3239–3257

Golden DC, Dixon JB (1985) Silicate and phosphate influence on kaolin-iron oxide interactions. Soil Sci Soc Am J 49:1568–1576

Hansen HCB, Borggaard OK, Sørensen J (1994) Evaluation of the free energy of formation of Fe(II)-Fe(III) hydroxide-sulfate (green rust) and its reduction of nitrite. Geochim Cosmochim Acta 58:2599–2608

Jefferson DA, Tricker MJ, Winterbloom AP (1975) Electron-microscopic and Mossbauer spectroscopic studies of iron stained kaolinite. Clays Clay Miner 723:355–360

Kennedy LG, Everett JW, Ware KJ, Parsons R, Green V (1998) Iron and sulfur mineral analysis methods for natural attenuation assessments. Bioremediat J 2:259–276

Klausen J, Tröber SP, Haderlein SB, Schwarzenbach RP (1995) Reaction of substituted nitrobenzenes by Fe(II) in aqueous mineral suspensions. Environ Sci Technol 29:2396–2404

Klueglein N, Picardal F, Zedda M, Zwiener C, Kappler A (2015) Oxidation of Fe(II)-EDTA by nitrite and by two nitrate reducing Fe(II)-oxidizing Acidovorax strains. Geobiology 13:198–207

Komatsu Y, Takagi M, Yamaguchi M (1978) Participation of iron in denitrification in waterlogged soil. Soil Biol Biochem 10:21–26

Krause B, Nealson KH (1997) Physiology and enzymology involved in denitrification by Shewanella putrefaciens. Appl Environ Microbiol 63:2613–2618

Kukkadapu RK, Zachara JM, Smith SC, Frederickson JK, Liu C (2001) Dissimilatory bacterial reduction of Al-substituted goethite in subsurface sediments. Geochim Cosmochim Acta 65:2913–2924

Liu C, Kota S, Zachara JM, Frederickson JK, Brinkman CK (2001) Kinetic analysis of the bacterial reduction of goethite. Environ Sci Technol 35:2482–2490

Luther GW III, Kostka JE, Church TM, Sulzberger B, Stumm W (1992) Seasonal iron cycling in the salt marsh sedimentary environment—the importance of ligand complexes with Fe(II) and Fe(III) in the dissolution of Fe(III) minerals and pyrite, respectively. Mar Chem 40:81–103

Matocha CJ, Coyne MS (2007) Short-term response of soil iron to nitrate addition. Soil Sci Soc Am J 71:108–117

Matocha CJ, Dhakal P, Pyzola SM (2012) The role of abiotic and coupled biotic/abiotic mineral controlled redox processes in nitrate reduction. Adv Agron 115:181–214

Mehra OP, Jackson ML (1960) Iron oxide removal from soils and clays by a dithionite-citrate system buffered with sodium bicarbonate. In: Swineford A (ed) Clays and clay minerals, Proceedings of 7th National Conference, Washington, D.C., 1958. Pergamon Press, New York, pp 317–327

Millero FJ (1985) Effect of ionic interactions on oxidation of metals in natural waters. Geochim Cosmochim Acta 49:547–553

Moraghan JT, Buresh RJ (1977) Chemical reduction of nitrite and nitrous oxide by ferrous iron. Soil Sci Soc Am J 41:47–49

Neumann A, Hofstetter TB, Skarpeli-Liati M, Schwarzenbach RP (2009) Reduction of polychlorinated ethanes and carbon tetrachloride by structural Fe(II) in smectites. Environ Sci Technol 43:4082–4089

Obuekwe CD, Westlake DWS, Cook FD (1981) Effect of nitrate on reduction of ferric iron by a bacterium isolated from crude oil. Can J Microbiol 27:692–697

Picardal F (2012) Abiotic and microbial interactions during anaerobic transformations of Fe(II) and NO −x . Front Microbiol 3:1–7

Rakshit S, Matocha CJ, Coyne MS (2008) Nitrite reduction by siderite. Soil Sci Soc Am J 72:1070–1077

Samarkin VA, Madigan MT, Bowles MW, Casciotti KL, Priscu JC, McKay CP, Joye SB (2010) Abiotic nitrous oxide emission from the hypersaline Don Juan Pond in Antarctica. Nat Geosci 3:341–344

Senko JM, Istok JD, Suflita JM, Krumholz LR (2002) In-situ evidence for uranium immobilization and remobilization. Environ Sci Technol 36:1491–1496

Shriver DF, Atkins P, Longford CH (1994) Inorganic chemistry, 2nd edn. W.H. Freeman and Co., New York

Soltermann D, Fernandes MM, Baeyens B, Dahn R, Joshi PA, Scheinost AC, Gorski CA (2014) Fe(II) uptake on natural montmorillonites. I. Macroscopic and spectroscopic characterization. Environ Sci Technol 48:8688–8697

Sorensen J, Thorling L (1991) Stimulation by lepidocrocite (γ-FeOOH) of Fe(II)-dependent nitrite reduction. Geochim Cosmochim Acta 55:1289–1294

Stookey LL (1970) Ferrozine—a new spectrometric reagent for iron. Anal Chem 42:779–781

Stumm W, Morgan JJ (1996) Aquatic chemistry, 3rd edn. John Wiley & Sons, New York

Stumm W, Sulzberger B (1992) The cycling of iron in natural environments: considerations based on laboratory studies of heterogeneous redox processes. Geochim Cosmochim Acta 56:3233–3257

Tai Y-L, Dempsey BA (2009) Nitrite reduction with hydrous ferric oxide and Fe(II): stoichiometry, rate, and mechanism. Water Res 43:546–552

Vaclavkova S, Schultz-Jensen N, Jacobsen OS, Elberling B, Aamand J (2015) Nitrate-controlled anaerobic oxidation of pyrite by Thiobacillus cultures. Geomicrobiol J 32:412–419

Wehrli B (1990) Redox reactions of metal ions at mineral surfaces. In: Stumm W (ed) Aquatic chemical kinetics. John Wiley & Sons, New York, pp 311–336

Yan R, Kappler A, Peiffer S (2015) Interference of nitrite with pyrite under acidic conditions: implications for studies of chemolithotrophic denitrification. Environ Sci Technol 49:11403–11410

Zachara JM, Frederickson JK, Li S, Kennedy DW, Smith SC, Gassman PL (1998) Bacterial reduction of crystalline Fe3+ oxides in single phase suspensions and subsurface materials. Am Mineral 83:1426–1443

Zachara JM, Kukkadapu RK, Fredrickson JK, Gorby YA, Smith SC (2002) Biomineralization of poorly crystalline Fe(III) oxides by dissimilatory metal reducing bacteria (DMRB). Geomicrobiol J 19:179–207

Acknowledgments

The authors thank KWRRI for providing funding to support the results presented here.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rakshit, S., Matocha, C.J., Coyne, M.S. et al. Nitrite reduction by Fe(II) associated with kaolinite. Int. J. Environ. Sci. Technol. 13, 1329–1334 (2016). https://doi.org/10.1007/s13762-016-0971-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-016-0971-x