Abstract

In this regard, a new sensitive electrochemical sensor has been introduced for direct detection of cholesterol (CHL). The proposed sensor was manufactured by modifying the pencil graphite electrode (PGE) with copper nanoparticles (CuNPs) and indole (IND). The chemical modifiers of CuNPs and IND were easily deposited on PGE via electrodeposition procedure. The designed sensor exhibited a desired catalytic response to CHL with the archived parameters of α = 0.62, log Ks = 3.42 and Γ = 2. 74 × 10–8 in the optimized pH of 7. The morphology of the constructed films was characterized by scanning electron microscopy technique. For this sensor, a linear calibration curve is plotted within the range of 15–195 nmolL−1, and the limit of detection was achieved 4.98 nmolL−1. Furthermore, the offered sensor was employed to direct measuring of CHL in human serums, and the acceptable accuracies were acquired for this method without any side interferences.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cholesterol (CHL), which is an important steroid in the body, acts a distinctive role between the many lipids in mammalian cells. In the US, based on age and gender, the average intake of dietary CHL in adults is common between 200–350 mg/day [1,2,3]. High CHL accumulation in the blood serum is strongly associated with increase the risk of coronary heart disease and heart attacks, atherosclerosis, myocardial infarction, cerebral clotting, impaired lipid metabolism, high blood pressure, etc. Accordingly, detection of blood CHL levels has great importance in clinical diagnosis [4, 5]. Various analytical methods have been performed to monitor CHL such as Fluorometry [6], HPLC [7, 8], spectrophotometry [9] and electrochemical analysis [10, 11]. Despite the virtually, all these analytical procedures are sensitive and selective analysis, but they have some restrictions and disadvantages such as expensive equipment, need for pretreatment steps, time-consuming sample preparation steps and the consumption of large sample quantities. Electrochemical sensors with all the merits have illustrated a relatively inexpensive option. These procedures often associated with an easy application, fast response time, great reproducibility, high sensitivity, which caused considerable attention toward these topics [12, 13]. Therefore, to prevail these difficulties, plenty of attempts have been accomplished to advance of new electrochemical sensors to CHL based on construction of novel sensors. In order to improvement of the sensitivity of sensors, multiple nanomaterials such as metal and metal oxide/hydroxid, carbon nanotubes (CNTs), graphene oxide (GO), molecularly imprinted polymers (MIPs) and polymeric films have been employed to construct the non-enzymatic CHL sensors [14,15,16,17,18,19,20,21,22]. Recently, heteroatom compounds such as indole (IND) and its derivatives due to their unique properties have been applied as modifier compounds and material coatings [23, 24]. These compounds based on electrochemical oxidation in different electrolytes could be produced conductive films on the electrode surfaces. The advantages of the electrochemical oxidation of IND as deposition of PIND on the electrode surface can be mentioned easy fabrication in a one-step method and correct control of the thickness. Up to now, there are a great deal of researches about the one-step electrochemical production of thin PIND films [25, 26]. The PIND films due to their distinctive properties and structure, including slow degradation rates compare with other polymers, good thermal stability and high redox stability and activity could be used for immobilization on the surface and so increase the direct electron transfer between the active sites on the surface electrode and species in solution [27,28,29,30]. The significant physicochemical properties of nanomaterials including the metallic Nanoparticles (MeNPs) in recent years, leading to their widespread application in the construction and development of sensors and biosensors. Recently, the MeNPs owing to their attractive properties such as unique chemical and physical attributes than other compounds have gained many research of nanotechnology fields [31,32,33]. The interesting optoelectronic properties of some MeNPs such as Au, Ag, Pt and Cu NPs lead to the researchers, attention to multiple utilizations in catalytic processes, systems of biomedical and printed electronics, sensors and biosensors [34,35,36,37]. CuNPs compared to other MeNPs are less expensive and also has analogous properties of surface plasmon resonance (SPR). Therefore, CuNPs could be an effective substitute than other MeNPs for a low-cost nanotechnology application in therapeutic and diagnostic fields [38, 39]. Modification of electrodes using of CuNPs has led to construction of sensors to measure and detection of substances, including biological and pharmaceutical systems at the respective quantities. The electrochemical properties and unique electro catalytic effects of CuNPs and associated compounds have been applied to an electrochemical detection of compounds [40]. In recent years, PGEs have been widely used for detection of different types of compounds with various matrices due to their unique economical and also electrochemical properties. These electrodes compared to other solid electrodes have suitable characteristics such as low-priced, more convenient, easily operated, lower background currents and also do not require to use time-consuming cleaning and polishing steps of the electrode surface. The use of various types of voltammetry techniques with PGEs to detect a wide range of different analytes can be presented the sensitive and reproducible signals. The use of PGEs also offered the stability, renewable surface and economical tool [41,42,43]. By considering the structure of IND and its probable interactions with CHL in solution, a π- conjugated ligand is created on the sensor surface, as well as the presence of active sites to interaction with CHL and ability to form a complex at the sensor surface for the electrochemical oxidation response of the target (CHL). In the present work, a sensitive sensor was therefore designed based on the electrochemical polymerization of IND and the electrodeposition CuNPs on the PGE surface. In order to investigate the applicability of the offered sensor for monitoring of CHL, human serum samples were examined. The obtained data revealed that there is a good accuracy and precision in analysis, and the proposed sensor is analytically recommendable for CHL monitoring in physiological pHs.

Experiential section

Substances

All reagents used in the present study were purchased from Merck Co. (Darmstadt, Germany). The pencil‐lead rods with 0.5 mm in diameter were procured through the local bookstore. Double distilled deionized water (DDDW) was used through the experiments. Britton-Robinson (B-R) buffer solutions were prepared by adding appropriate amounts of 0.2 molL−1 of Sodium hydroxide solution into solutions containing a mixture of 0.04 molL−1 of Boric acid, acetic acid and Phosphoric acid to produce the desired pHs values over 3.0–12.0. The stock solution of CHL (500 mmoLL−1) was prepared by dissolving the appropriate amount of CHL in (DDDW)/ Ethanol system (50/50 v/v%). All the chemical substances were of analytical grade and used without further purification as acquired.

Equipment

A three-electrode system consisted of the modified PGE as working electrode, the platinum wire as counter electrode and the silver/silver chloride (Ag/AgCl) in saturated potassium chloride as reference electrode was used for electrochemical records. Electrochemical data were acquired using the Autolab PGSTAT30 Potentiostat/Galvanostat (Eco Chemie, Utrecht and the Netherlands) equipped with NOVA 1.10 software. The pH measurements were carried out by a Metrohm pH meter (model 781). The morphology of the constructing sensor was characterized by a scanning electron microscopy (SEM) model of (MIRA Ш model, TESCAN Co., Czech).

Procurement and activation of PGE

The body surface of the bare PGE was completely and firmly coated with Teflon tape, before the sensor design processes. Then, the one tip of PGE was contacted to electrochemical system by a suitable copper wire, and another tip was in contact with the test solution. Besides, the free surface of bare PGE was polished on a weighing paper with the slow motions to reach the smooth surface before applying electrochemical deposition. Then, the polished PGE was immersed vertically in the electrochemical cell containing BR buffer solution (pH = 11), and the pre-treated electrochemical examination was accomplished by applying the potential between the −1.5 to 2.0 V at the scan rate of 50 mVS−1 to 20 consecutive cycles without stirring the solution to activate PGE [44].

The sensor fabrication steps

For construction of the proposed sensor, the individual material solutions of 30 mmolL−1 of Cu (NO3)2 and 50 mmolL−1 of dissolved IND in water/ethanol (70/30 v/v%) were prepared. At first, the PGE was immersed in 25 ml solution containing 30 mmolL−1 of Cu (NO3)2 and the supporting electrolyte of KClO4 (10 mmoL−1). Then, the PGE was cycled using CV mode in the potential range of -1.2 to 0.5 V at a scan rate of 30 mVs−1 versus Ag/AgCl for 18 cycles to obtain CuNPs/PGE. Subsequently, the PIND film was formed on CuNPs/PGE, with the electrochemical deposition method via CV mode. The PIND/CuNPs/PGE was prepared by the electro-polymerization of 50 ml solution containing IND (50 mmolL−1) and the supporting electrolyte of KClO4 (10 mmoL−1) on the CuNPs/PGE by applying the cyclic sweeps over the potential range of -1.2 to 1.2 V with the scan rate of 30 mVs−1 for 16 cycles. After the polymerization process, the final electrode structure was designed in the form of PIND/CuNPs/PGE, it was washed with DDDW and stored at ambient temperature until use. The procedure for construction of the sensor is depicted in Fig. 1.

The real sample preparation

To measure of CHL in human serum sample, 10 ml of blood sample was obtained from a volunteer. The collected sample was then mixed with 2 ml of concentrated Ethanol and to remove serum protein. After vortexing of the serum sample, the precipitated proteins were pulled apart by centrifugation for 3 min at 6000 rpm. Then to acquire a protein-free human blood serum, a 0.45 μm Milli-pore filter was used for filtration of the clear supernatant layer from precipitating proteins. Then, a certain amount of the resulted serum (1 mL) was diluted to 25 ml with DDDW. After regulating the volume of the solution, 500 μL of the diluted serum was transferred to the electrochemical cell, and SWV signals were recorded in optimal conditions for calculating the CHL contents using the standard addition method.

Result section

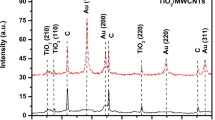

Evaluation of structure and morphology

For the study of the surface morphology and structure of the fabricated sensor, SEM technique was utilized. Figure 2 represents the SEM images of the surface of bare PGE, CuNPs/PGE and PIND/CuNPs/PGE. As it is seen from Fig. 2A, the surface of bare PGE is unique and unmodified and the electrodeposition of CuNPs on the PGE produced propagated Nanoparticles alongside graphite false. Consequently, the electro-polymerization of IND onto PGE/CuNPs has formed a cluster like shapes with spherical units. As documented from preceding studies, the growth of poly-indole thin films can be controlled using just molecular oxygen dissolved in the electrolytes during electrodeposition process [45]. Besides, co-polymerization of indole-6-carboxilic acid and 3–4 ethylenedioxythiophene as platinum catalyst support has evidenced easy producing cluster like composites involving indole and its utility for oxidation target analytes [46]. According to these findings, the cluster growth of Poly-indole on CuNPs support using electrodeposition is easy possible.

The electrochemical behavior of CHL

The CV technique was utilized to study the electrochemical behavior of CHL at the electrode’s surfaces. For this purpose, the CVs of the electrochemical response of 150 μmolL−1 of CHL in the test solutions containing BR buffer (pH = 7) and supporting electrolyte of KClO4 (10 mmolL−1) at the PGE, CuNPs/PGE, PIND/PGE and PIND/CuNPs/PGE surfaces were recorded in the range of 0.5 to 1.2 V (Fig. 3). As it is apparent in Fig. 3, at the bare PGE surface there is relatively apparent response to CHL electro-oxidation with current intensity of about 30 μA which should be improved in sensitivity for better CHL analytical detection. The low signal detected on bare PGE may be owing to high over potential associated with the oxidation process. So, the sensor surface coating with CuNPs would be a useful idea to increase the conductivity and sensitivity of the bare PGE surface to CHL monitoring (Fig. 3A), which was used as the middle layer for binding and the effective immobilization of the final layer (IND) to the PGE. Therefore, after modification of the PGE surface by CuNPs and PIND, the quasi-reversible peaks with intensified currents were observed than it on bare PGE, which convey the hypothesis that CuNPs and PIND modifiers play an effective mediator role in conductivity and electron transfer ability of constructed films in oxidizing of CHL (Fig. 3B-C). However, during the last two decades, the electrochemical oxidation of CHL, direct and indirect, was studied intensively. The first reports on cholesterol oxidation concerned indirect electrochemical methods with redox agents as electron mediators [47]. Besides, the electrodeposition of CuNPs and PIND increased the effective surface areas of modified electrodes than bare PGE ( as apparent in SEM images, Fig. 2). In addition to, the new bounds creating between CuNPs/PGE and PNID/CuNPs supply the establishing analytical responses and improving signals for CHL electro-oxidation. After the electro-polymerization of IND at the surface of CuNPs/PGE, the resulting electrode (PIND/CuNPs/PGE) showed a further enhancement in oxidation peak currents between 0.9–1.0 V (Fig. 3C). This illustrated the offered sensor surface provides easier adsorption of CHL toward its surface, and so increased the response of the sensor. Good acquired electrochemical activities aiming the enhanced signals may be due to the synergistic effects of CuNPs and IND in the structure of PIND/CuNPs/PGE. Furthermore, the CVs of the electrochemical response of PIND/CuNPs/PGE to different concentration values of CHL were recorded and compared to the background signal (as in Fig. 3B). As it is appeared, a catalytic effect is considerable for the proposed sensor while CHL concentrations are increased [48].

A The recorded CVs of 150 μmolL-1 of CHL at (A) PGE, (B) CuNPs/ PGE and (C) PIND/ CuNPs/ PGE in BR buffer solution (0.04 M, pH = 7) and scan rate of 400 mVs-1 B CV responses of PIND/ CuNPs/ PGE in BR buffer solution (0.04 M, pH = 7) and scan rate of 400 mVs-1 in the presence of varying values of CHL

The study of pH effect

The effect of pH on the electrochemical oxidation of 150 μmolL−1 of CHL was examined in BR buffer solutions, varying pHs from 3 to 12 (Fig. 4A). As it is observed from Fig. 4A, the peak currents increased with the pH increasing from 3 to 7 and then decreased from 7 to 9. Current depletions in highest acidic or highest alkaline values may be due to the possibility of interference of H+ and OHˉ ions and their attack to the electrode surface [49]. So, pH value of 7 was chosen for further investigations as an optimal pH condition. The variations of oxidation peak potentials vs. pH (Ep-pH) diagram comprise a linear segment at pH values 3 to 7 (Fig. 4B). The linear variation equation for anodic peak is given by Epc (V) = 0.045 pH + 0. 6517 (R2 = 0.9838). Based on the obtained slope value, the equal number of transferred electrons and protons was expected at the surface of the offered sensor for CHL electro-oxidation. It has recently been documented that the electrochemical cholesterol oxidation in phosphate buffer pH of 6.86 involves the mechanism of one electron/one proton transfer [50].

The effect of scan rate

The scan rate effect on the oxidation peak current of 150 μmolL−1 of CHL in BR buffer solution (pH = 7) was evaluated in the range of 50—650 mV/s as shown in Fig. 5A. As it is seen, the peak currents were increased by enhancing the sweep rates (Fig. 5A). With regard to Fig. 5, the anodic peak currents had linear and direct relation with the sweep rates (Fig. 5B), which indicates the electrode operates based on the adsorption controlled process. From the linear variation plot of peak potentials vs. Logarithm of scan rate (Fig. 5C) and in accordance to Laviron theory [51], the electron transfer rate constant (Ks) and transfer coefficient (α) for the electrochemical process of CHL could be determined. Based on the slope of this plot for the anodic peaks, α could be found 0.62. Afterward, the electron transfer rate constant (Ks) was calculated from the following equation (Eq. 1):

By introducing α value in the Eq. (1), the electron transfer rate constant of 3.42 s−1 was obtained. Furthermore, the active surface concentration value of species (Γ) could be obtained from the slope of peak currents vs scan rates as follows:

where n is the number of electrons involved in the redox reaction, F is Faraday constant (C mol−1), A is the area of the electrode (cm2), Γ is active surface concentration (mmol cm−2), Q is peak space (C), and ν is the scan rate (V s−1), the value of Γ was 2.74 × 10–8 mol cm−2. The acquired outcomes revealed that the composite surface of the proposed sensor is good for effective adsorption of CHL to increase the concentration of CHL on the surface of the sensor, thereby led to the increasing the sensitivity.

Analytical performance

Two quantifying SWV and differential pulse Voltammetry (DPV) techniques were used to construct the calibration curve and evaluate the analytical performances of the electrochemical CHL sensor. For this, SWV and DPV response voltammogrames of PIND /CuNPs/ PGE to 150nmoL−1 of CHL were recorded and compared in sensitivity over the range of 0.6 V to 1.1 V. The highest obtained currents were the basis of choosing the better mode, so, SWV was selected for evaluating calibration curve of CHL on the optimal conditions. The instrumental optimal conditions for SWV mode concern about CHL detection were the step potential of 55 mV, the amplitude of 55 mV and the frequency of 65 Hz that they all were kept during calibration curve construction. Besides, different supporting electrolytes such as NaCl, KCl, NaNO3 and KClO4 in the fixed concentration of 5 mmolL−1 were tested. SWV signal for CHL was convinced in KClO4 supporting electrolyte. For more achieving sensitivity and decreasing background current, the concentration of KClO4 was altered over the range of 0–20 mmolL−1 that 10 mmolL−1 of KClO4 was in the best for choosing. For calibration curve construction, different concentration values of CHL in the range of 5–300 nmolL−1 (nM) were analyzed by SWV in the attendance of PIND /CuNPs/ PGE sensor. The recorded SWV voltammogrames had linearity between current and concentration over the range of 15–195 nM (as in Fig. 6A). Besides, a linear calibration curve with the equation of I(μA) = 0.3279 CnM,CHL-21.39 (R2 = 0.9911) was extractable (as in Fig. 6B).This calibration equation was the basis for CHL content calculation in the real samples. The limit of detection (LOD), the limit of quantification (LOQ) and the sensitivity of this sensor in quantifying CHL were 4.98 nM, 14.97 nM and 0.3279, respectively. The compatibility of the proposed sensor with the sensitive electrochemical monitoring technique such SWV technique makes it so sensitive leading to excellent low detection limit. Furthermore, the repeatability of the proposed sensor to 150 nM of CHL using SWV mode was checked for 12 repeats, and the relative standard error (RSD% = 3.83) was obtained. The reproducibility of the proposed sensor to 150 nM of CHL was also examined, and RSD% of 3.75 was obtained (n = 3, fabricated sensors). Therefore, we strongly recommended this new electrochemical sensor for CHL detection in the real samples.

Interferences effects study

Based on the reported before strategy [52], the effect of several organic and inorganic substances on the tolerance limits of the response of the proposed modified electrode to CHL was examined. This study was performed under optimum conditions for a fixed amount of 150 nmoL−1 of CHL and varying amounts of the interferers (in nmolL−1) with a relative error of 5% in SWV signal currents with respect to the signal of the buffered solution containing only CHL. The results given in Table 1 suggest that the response signals of the proposed sensor are free from side serious interferences and common coexisting substances in the applied potential window.

Application of constructing sensor in real samples

To study the application of constructing sensor for CHL monitoring of in serum samples, SWV was performed. After sample preparation, the standard addition method was employed for evaluating the recoveries of the spiked CHL with the different concentrations (Tables 2 and 3). Based on these data, the recoveries of the analyte in spiked real samples are admissible, and they were in agreement with common HPLC method [53]. Therefore, this sensor could be applied as an effective instrument for analysis of CHL in real samples in complex matrices.

Conclusion

In this study, a new electrochemical sensor compatible with a sensitive analytical method of SWV has been introduced for CHL measurement. IND and CuNPs modifiers were easily electrodeposited using cyclic voltammetry mode at low sweep rates to produce durable films [54]. The good synergic between IND and CuNPs on PGE surface make the produced films sensitive, conductive and applicable for quantifying CHL in real samples. Moreover, the proposed sensor illustrated in this research, dedicated higher response level, accuracy, precision and sensitivity than other reported before sensors (as in Table 4). So, we have recommended this new electrochemical sensor for direct quantifying of CHL in physiological pHs without any side interferences and desirable analytical signals.

References

J. Hu, Z. Zhang, W.J. Shen, S. Azhar, Cellular cholesterol delivery, intracellular processing and utilization for biosynthesis of steroid hormones. Nutr. Metab. 7, 47 (2010)

J. Grouleff, S.J. Irudayam, K.K. Skeby, B. Schiøtt, The influence of cholesterol on membrane protein structure, function, and dynamics studied by molecular dynamics simulations. Biochim. Biophys. Acta 1848, 1783 (2015)

C.N. Blesso, M.L. Fernandez, Dietary cholesterol, serum lipids, and heart disease: are eggs working for or against you. Nutrients 10, 426 (2018)

S.S. Muthu, N. Chaturvedi, M. Toeller, B. Ferriss, P. Rebolidi et al., Risk factors for coronary heart disease in type 1 diabetic patients in Europe. Diab. Care 24, 530 (2004)

M.F. Piepoli, A.W. Hoes, S. Agewall, C. Albus, C. Brotons et al., European Guidelines on cardiovascular disease prevention in clinical practice. Eur. Heart J. 37, 2315 (2016)

Q. Sun, S. Fang, Y. Fang, Z. Qian, H. Feng, Fluorometric detection of cholesterol based on β-cyclodextrin functionalized carbon quantum dots via competitive host-guest recognition. Talanta 167, 513 (2017)

K.I. Kitahara, I. Yoshihama, T. Hanada, H. Kokuba, S. Arai, Synthesis of monodispersed molecularly imprinted polymer particles for high-performance liquid chromatographic separation of cholesterol using templating polymerization in porous silica gel bound with cholesterol molecules on its surface. J. Chromatogr. A 1217, 7249 (2010)

K. Hojo, H. Hakamata, A. Ito, A. Kotani, C. Furukawa, Y.-Y. Hosokawa, F. Kusu, Determination of total cholesterol in serum by high-performance liquid chromatography with electrochemical detection. J. Chromatogr. A 1166, 135 (2007)

M.S. Mashkour, N. Abd, A. Almatori, A.M. Brbber, Spectrophotometric determination of Cholesterol by using procaine as coupling reagent. Int. J. Chem. Tech. Res. 10, 630–640 (2017)

M.A.H. Nawaz, M. Majdinasab, U. Latif, M. Nasir, G. Gokce, M.W. Anwar, A. Hayat, Development of a disposable electrochemical sensor for detection of cholesterol using differential pulse voltammetry. J. Pharm. Biomed. Anal. 159, 398 (2018)

L. Yang, H. Zhao, S. Fan, G. Zhao, X. Ran, C.-P. Li, Electrochemical detection of cholesterol based on competitive host–guest recognition using a bcyclodextrin/poly(N-acetylaniline)/graphene modified electrode. RSC Adv. 5, 64146 (2015)

Z. Wang, Q. Han, J. Xia, L. Xia, S. Bi, G. Shi, F. Zhang, Y. Xia, Y. Li, L. Xia, A novel phosphomolybdic acid–polypyrrole/graphene composite modified electrode for sensitive determination of folic acid. J. Electroanal. Chem. 726, 107 (2014)

Y. Wang, H. Xu, J. Zhang, G. Li, Electrochemical sensors for clinic analysis. Sensors 8, 2043 (2008)

L. Yang, H. Zhao, Y. Li, X. Ran, G. Deng, Y. Zhang, H. Ye, G. Zhao, C.P. Li, Indicator displacement assay for cholesterol electrochemical sensing using a calix[6]arene functionalized graphene-modified electrode. Analyst. 141, 270 (2016)

L.C.S. Chou, C.C. Liu, Development of a molecular imprinting thick film electrochemical sensor for cholesterol detection. Sensor Actuat. B-Chem. 110, 204 (2005)

Riyanto and Laksono, T.A., , Validation method for determination of cholesterol in human urine with electrochemical sensors using gold electrodes. AIP Conf. Proc. 1911, 020032 (2017)

M. Saha, S. Das, Fabrication of a nonenzymatic cholesterol biosensor using carbon nanotubes from coconut oil. J. Nanostruct. Chem. 4, 94 (2014)

P. Goswami, K. Goswami, D.K. Das, A novel non-enzymatic sensing probe for detection of cholesterol in solution. J. Chem. Pharm. Res. 6, 603 (2014)

N. Agnihotri, A.D. Chowdhury, A. De, Non-enzymatic electrochemical detection of cholesterol using β-cyclodextrin functionalized graphene. Biosens. Bioelectron. 63, 212 (2015)

Y.-J. Lee, J.-Y. Park, Nonenzymatic free-cholesterol detection via a modified highly sensitive macroporous gold electrode with platinum nanoparticles. Biosens. Bioelectron. 26, 1353 (2010)

J. Yang, H. Lee, M. Cho, J. Nam, Y. Lee, Nonenzymatic cholesterol sensor based on spontaneous deposition of platinum nanoparticles on layer-by-layer assembled CNT thin film. Sens. Actuators B 171, 374 (2012)

Y. Tonga, H. Li, H. Guan, J. Zhao, S. Majeed, S. Anjum, F. Liang, G. Xu, Electrochemical cholesterol sensor based on carbon nanotube@molecularly imprinted polymer modified ceramic carbon electrode. Biosens. Bioelectron. 47, 553 (2013)

D. Deletioğlu, E. Hasdemir, A.O. Solak, Z. Üstündağ, R. Güzel, Preparation and characterization of poly(indole-3-carboxaldehyde) film at the glassy carbon surface. Thin Solid Films 519, 784 (2010)

W. Zhou, J. Xu, Progress in conjugated polyindoles: synthesis, polymerization mechanisms, properties, and applications. Polym. Rev. 57, 248 (2017)

X. Ma, W. Zhou, D. Mo, B. Lu, F. Jiang, J. Xu, One-step template-free electrodeposition of novel poly(indole-7-carboxylic acid) nanowires and their high capacitance properties. RSC Adv. 5, 3215 (2015)

R.J. Waltma, Electrically conducting polymers: a review of the electropolymerization reaction, of the effects of chemical structure on polymer film properties, and of applications towards technology. Can. J. Chem. 64, 76 (2017)

R. Mishra, N.R. Nirala, R.K. Pandey, R.P. Ojha, R. Prakash, Homogenous dispersion of MoS2 nanosheets in polyindole matrix at air-water interface assisted by Langmuir technique. Langmuir 33, 13572 (2017)

V. Guarino, S. Zuppolini, A. Borriello, L. Ambrosio, Electro-active polymers (EAPs): a promising route to design bio-organic/bioinspired platforms with on demand functionalities. Polymers 8, 185 (2016)

P.S. Abthagir, R. Saraswathi, Charge transport and thermal properties of polyindole, polycarbazole and their derivatives. Thermochim. Acta 424(1–2), 25–35 (2004)

G. Wang, A. Morrin, M. Li, N. Liu, X. Luo, Nanomaterial-doped conducting polymers for electrochemical sensors and biosensors. J. Mater. Chem. B 6, 4173 (2018)

P. Sondhi, M.H.U. Maruf, K.J. Stine, Nanomaterials for biosensing lipopolysaccharide. Biosensors 10(1), 2 (2020)

M. Pirzada, Z. Altintas, Nanomaterials for healthcare biosensing applications. Sensors 19(23), 5311 (2019)

R. Batool, A. Rhouati, M.H. Nawaz, A. Hayat, J.L. Marty, A review of the construction of nano-hybrids for electrochemical biosensing of glucose. Biosensors 9, 46 (2019)

L. Mohammadi-Behzad, M.B. Gholivand, M. Shamsipur, K. Gholivand, A. Barati, A. Gholami, Highly sensitive voltammetric sensor based on immobilization of bisphosphoramidate-derivative and quantum dots onto multi-walled carbon nanotubes modified gold electrode for the electrocatalytic determination of olanzapine. Mater. Sci. Eng. C 60, 67 (2016)

M.B. Gholivand, L. Mohammadi-Behzad, Fabrication of a highly sensitive sumatriptan sensor based on ultrasonic-electrodeposition of Pt nanoparticles on the ZrO2 nanoparticles modified carbon paste electrode. J. Electroanal. Chem. 712, 33 (2014)

S.H. Lee, B.H. Jun, Silver nanoparticles: synthesis and application for nanomedicine. Intn. Jn Moln Sci. 20, 865 (2019)

S. Soltani, R. Davarnejad, F. Rahimi, T. Matin, E. Ahmadi, Copper nanoparticles/poly-neutral red modified pencil graphite electrode for electroanalysis of folic acid. J. Chem. Pharm. Res. 10, 99 (2018)

J.A. Jiménez, Thermal effects on the surface plasmon resonance of Cu nanoparticles in phosphate glass: impact on Cu+ luminescence. Nanoscale Adv. 1, 1826 (2019)

E.G. Halevas, A.A. Pantazaki, Copper nanoparticles as therapeutic anticancer agents. Nanomed. Nanotechnol. J. 2, 119 (2018)

Y. Oztekina, M. Tok, E. Bilici, L. Mikoliunaite, Z. Yazicigil, A. Ramanavicienec, A. Ramanavicius, Copper nanoparticle modified carbon electrode for determination of dopamine. Electrochim. Acta 76, 201 (2012)

E. Alipour, M.R. Majidi, A. Saadatirad, S.M. Golabi, A.M. Alizadeh, Simultaneous determination of dopamine and uric acid in biological samples on the pretreated pencil graphite electrode. Electrochim. Acta 91, 36 (2013)

Z.Q. Gong, A.N.A. Sujari, S. Ab Ghani, Electrochemical fabrication, characterization and application of carboxylic multi-walled carbon nanotube modified composite pencil graphite electrodes. Electrochim. Acta 65, 257–265 (2012)

A. Kawde, N. Baig, M. Sajid, Graphite pencil electrodes as electrochemical sensors for environmental analysis: a review of features, developments, and applications. RSC Adv. 94, 91325 (2016)

S. Kouchakinejad, S. Babaee, F. Roshani, R. Kouchakinejad, S. Kaki, The performance of the new modified pencil graphite electrode in quantifying of insulin. Chem. Phys. Lett. 759, 137987 (2020)

B.B. Berkes, A.S. Bandarenka, G. Inzelt, Electropolymerization: Further insight into the formation of conducting polyindole thin films. . Phys. Chem. C 119(4), 1996–2003 (2015)

T.Y. Wu, C.W. Kuo, Y.L. Chen, J.K. Chang, Copolymers based on indole-6-carboxylic acid and 3, 4-ethylenedioxythiophene as platinum catalyst support for methanol oxidation. Catalysts 5, 1657–1672 (2015)

J.W. Morzycki, A. Sobkowiak, Electrochemical oxidation of cholesterol. Beilstein J. Org. Chem. 11, 392–402 (2015)

E. Ghanbary, Z. Asiabani, N. Hosseini, S.H. Kiaie, S. Kaki, H. Ghasempour, A. Babakhanian, The development of a new modified graphite pencil electrode for quantitative detection of Gibberellic acid (GA3) herbal hormone. Microchem. J. 157, 105005 (2020)

M.-M. Abolghasemi, A. Ghorbani-Cheghamarani, A. Babakhanian, A novel electrochemical sensing platform based on Pt/PPy/Eosin-Y for the determination of cadmium. New J. Chem. 41, 11335 (2017)

K. Derina, E. Korotkova, Y. Taishibekova, L. Salkeeva, B. Kratochvil, J. Barek, Electrochemical nonenzymatic sensor for cholesterol determination in food. Anal. Bioanal. Chem. 16, 5085 (2018)

E. Laviron, General expression of the linear potential sweep voltammogram in the case of diffusionless electrochemical systems. J. Electroanal. Chem. 101, 19 (1979)

Z. Azizi, A. Babakhanian, Fabricating a new electrochemically modified pencil graphite electrode based on acetophenone (2, 4-dinitrophenyl) hydrazone for determining selenium in food and water samples. Anal. Methods 10, 5205 (2018)

M. Murata, T. Ide, Determination of cholesterol in sub-nanomolar quantities in biological fluids by high-performance liquid chromatography. J. Chromatogr. B: Biomed. Sci. Appl. 579, 329–333 (1992)

S. Rostami-Javanroudi, A. Babakhanian, New electrochemical sensor for direct quantification of vitamin K in human blood serum. Microchem. J. 163, 105716 (2021)

M. Alagappan, S. Immanuel, R. Sivasubramanian, A. Kandaswamy, Development of cholesterol biosensor using Au nanoparticles decorated f-MWCNT covered with polypyrrole network. Arabian J. Chem. 13, 2001–2010 (2020)

S.J. Willyam, E. Saepudin, T.A. Ivandini, β-Cyclodextrin/Fe3O4 nanocomposites for an electrochemical non-enzymatic cholesterol sensor. Anal. Methods 12(27), 3454–61 (2020)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shahriarinour, M., Rahimi, F., Siahbani, E. et al. A new electrochemical modified graphite pencil electrode developed for cholesterol assessing. J IRAN CHEM SOC 19, 159–171 (2022). https://doi.org/10.1007/s13738-021-02296-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-021-02296-8