Abstract

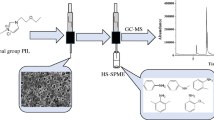

Polythionine was prepared by a simple electrochemical method and used as solid-phase microextraction coating for headspace extraction and analysis of four phthalate esters (dioctyl phthalate, benzyl butyl phthalate, di-n-butyl phthalate, and di-iso-butyl phthalate) by gas chromatographic-flame ionization detector. The thionine polymerization was performed at pH of 9 on a Pt wire. Made ready coating displayed a good thermal stability (up to 280 °C). The effects of three extraction parameters, containing salt effect, temperature and extraction time, on the extraction efficiencies of phthalate esters were evaluated. Under the optimized conditions, limits of detection were among 0.34–1.67 µg L−1. The inter-day and intra-day deviations of relative standard, attained at 50 µg L−1, were 7.64–10.62% and 10.14–12.84%, respectively. The method capability for analysis of the phthalates in real samples of cheese water and wastewater was evaluated and relative recoveries were between 82.63 and 119.50%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Thionine is a redox dye of organic chloride salt, composed of 3,7-diaminophenothiazin, and chloride ions in a 1:1 ratio. This dye is commonly used in inks, paints, or as an indicator or reagent. It has been also used for the Nicotinamide Adenine Dinucleotide Hydrogen (NADH) electrocatalytic oxidation [1, 2] by crosslinking onto a graphite electrode. A biosensor of hydrogen peroxide was developed [3] based on a thionine monomer doped on polymer of AQ55D [4]. Thionine has also been applied in the sensor of kanamycin [5], some endocrine-disrupting compounds [6] and lactate detection via NADH electrocatalysis [7].

Phthalate esters are chemical compounds which are applied as plasticizers for supplying flexibility and persistence to plastics like polyvinyl chloride (PVC). Phthalates are alkyl aryl or 1,2-benzene dicarboxylic acid dialkyl. Phthalates in the net form are commonly transparent liquids, some with a feeble sweet smell and some with the color of light yellow. Plastics that include phthalate esters are generally applied in applications consist materials of building, cosmetics, food, clothing, fragrances, toys, packaging, and products of vinyl (e.g., shower curtains, rain coat, and flooring); and in applications of medical that consist blood transfusion tubing and bags, tubing and fluid intravenous bags, and other devices of medical. The phthalate esters are mostly found in solvents, oils of lubricating and detergents. For the effect of health, phthalate esters are frequently categorized as disruptors of endocrine or agents of hormonally active due to their capability to intromit with the system of endocrine in the skeleton. Phthalate esters have been announced to result in augmented developmental abnormalities incidence like skeletal malformations and cleft palate, and augmented fetal death in investigations of experimental animals [8].

Various microextraction methods have been used for the phthalates determination in water or other samples, containing solid-phase microextraction [9,10,11,12], Low-density solvent-based vortex-assisted surfactant-enhanced-emulsification liquid–liquid microextraction [13, 14], bell-shaped extraction device assisted liquid–liquid microextraction [15], solvent-vapor-assisted liquid–liquid microextraction [15], vortex solvent bar microextraction [16], microextraction of ultrasound-helped emulsification [17] and floating drop microextraction solidification [18]. Solid-phase microextraction is one of the suitable pretreatment techniques for preconcentration and extraction of analytes from complex matrices. This technique is fast, and no solvent is used in the preconcentration step. It was mostly carried out by commercially available fibers covered with various sorbents with different polarities. The proposed temperatures of operating for these coatings are commonly within 200–270 °C range, which is not adequate in numerous cases. Furthermore, these coatings are mostly made by the physical deposition of a polymer on the fused silica fibers surface, which is the probable reason for their low chemical and thermal stabilities [19]. The fused silica coatings are expensive, brittle, and should be handled with great care. So, it is extremely favorable to have more low cost and relatively stable solid-phase microextraction (SPME) fibers. An ideal coating for SPME usage could have some common virtues, containing high adsorptive volume, good mechanical, chemical and thermal stability; cheapness; reproducibility and easy to build and ability to extract compounds with diverse polarities. Regrettably, most of the commercially available coatings for SPME have some limitations. Therefore, development of new coating for SPME is highly desired.

Until now, different polymers including Polypyrrole [20], polyaniline [21], molecularly imprinted polymers [22] and etc. were used as SPME coatings. Among the polymers, ploythionine has never been used extensively in SPME applications. In this work, a SPME fiber was prepared by the electropolymerization of thionine and some phthalates are extracted and analyzed by this new introduced SPME coating as model compounds.

Experimental

Materials

Dioctyl phthalate (DOP), benzyl butyl phthalate (BBP), di-n-butyl phthalate (DnBP), di-iso-butyl phthalate (DiBP), sodium hydroxide (NaOH) and thionine were all purchased from Sigma-Aldrich (Mississauga, Canada). Sodium chloride salt (NaCl) with purity more than 99% and distilled water were used for preparing the solutions. A solution of the stock standard of each compound (500 mg L−1) was made in methanol (CH3OH). The solutions of working standard with appropriate concentration were prepared in methanol and applied to get ready the spiked aqueous solutions. The working standards and stock solutions were kept in the refrigerator before use. The solutions of aqueous were made ready daily by diluting the working solutions with distilled water and applied all over the tests.

Apparatus and instruments

Gas chromatographic analyses of phthalates were carried out by the system of Agilent 7890A GC (USA), equipped with a split-splitless injector, the system of flame ionization detector (FID), and column of SB5 (30 m × 0.25 mm I.D, the thickness of 0.25 µm film) (SGE, USA). The temperature program of the oven was as follows: 150 °C for 3 min, then reached at a velocity of 15 °C min−1 to 220 °C for 2 min, then ramped to 270 °C at 10 °C min−1 and retained at 270 °C for 2 min. The temperatures of the injector and detector were fixed at 280 °C and 300 °C, respectively. The injection mode was splitless. A generator of dry air and Parker Hannifin (England) G6010E Nitrogen generator was applied for supplying the oxidant gas and carrier gas, respectively. The system of Origalys with a three-electrode cell was applied for preparation of polythionine coating. The morphological and structural properties of the coatings were studied using a microscope of ZEISS SIGMA field emission scanning electron (FESEM) equipped with X-ray energy dispersive spectroscopy (EDS) detector (Oxford Company, England).

The Pt wire pretreatment

A Pt wire was used for deposition of the coating. Its surface (3.5 cm in length and 0.30 mm in diameter) was washed by a versatile oxidizing agent of H2SO4/H2O2 1:2 (piranha solution) and then followed by washing with large volume of distilled water.

Polythionine fibers preparation

For the electropolymerization of thionine, 2.87 mg thionine, 0.618 g KH2PO4, 0.871 g K2HPO4, 10 µL NaOH (1 M) at pH = 9 were sonicated (50 Hz-, 665 W) in 50 mL of distilled water for 8 min. In a three-electrode system, the platinum wire was applied as the working electrode, an Ag/AgCl (3 M) electrode was used as reference electrode, and a platinum bar was applied as the counter electrode. 2 cm of each fiber was submerged in the solution. The experimental parameters of cyclic voltammetry method were as scan velocity of 50 mV/s, potential limits of − 330–1100 mV, and number of scans of 50 cycles. A blue polythionine deposit was appeared on the platinum wire after electrodeposition. Later than the finish of fiber synthesis, the fiber was removed from the solution and dried at ambient temperature for 25 min. The coating was conditioned before use. For this purpose, the coating was injected in the GC inlet system at 240 °C, 260 °C, 280 °C, and 300 °C for 20, 10, and 30 min, respectively. After the process of conditioning, a blank was run for each fiber coating to examine for the extra peaks.

SPME procedure

The laboratory tools, glass vials and magnetic stir bars were cleaned many times with distilled water followed by propanone ((CH3)2CO or acetone) and eventually again with water. For the process of SPME, water samples spiked with a fix amount of the working standard were placed in 20 mL glass vials, including a small magnetic rotation bar and a determined amount of sodium chloride salt (150 g L−1). A water bath and magnetic stirrer were provided for the sample vials to regulate the temperature of extraction and stirring speed of the solution. The sample solutions were stirred at 950 rpm under the desired extraction temperatures for 25 min to attain an equilibrium, prior to each extraction. The extractions were performed by placing the 1.5 cm of the fiber on the headspace of the sample solution. After extraction, the coated fiber was extracted back into the needle, take out from the sample vial, and instantly introduced into the inlet of GC (280 °C) for thermal desorption. The fiber was kept in the GC inlet for 5 min.

Method validation

At first, the tests were carried out to optimize the original parameters affect the peak areas of the extracted phthalates from the solution of aqueous standard (including 50 µg L−1 of each ester of phthalate). These parameters were extraction temperature (Text), extraction time (text) and salt content (150 g L−1). The optimization of the parameters was performed by applying a “one-variable-at-a-time” method. All the extractions were performed in the headspace submersion (HS) manner at solution stirring velocity of 950 rpm. Gas chromatography-flame ionization detection was applied for quantitative analysis of the phthalates. In each real sample, the various volume of phthalates was spiked, and the recoveries were calculated based on found and added values.

Results and discussion

Polythionine characterization

Electropolymerization of thionine was carried out by applying the potentiodynamic (cyclic voltammetry) method. Thionine is a neutral monomer, and its solution is a suitable medium for electropolymerization to prepare thin polymeric films. The cyclic voltammograms (Fig. 1) attained by exchanging from various electro-oxidation potential ranges for thionine electropolymerization on the platinum electrode showed that the electro-oxidation potentials between − 330 and 1100 mV are appropriate to form thin films of polythionine.

Oxidation of thionine on the platinum working electrode occurs in the process of thionine electropolymerization at potentials between − 330 and 1100 mV (pH = 9.0) [23]. A grafting among N atoms of primary amine groups and C atoms of thio-diphenylamine ring is a feasible prevailing mechanism during of the thionine electropolymerization. Gao et al. [24] have describe that amine groups of polythionine can react with analytes via π–π interaction and hydrogen bonding through amine groups.

Figure 2 displays the image of polythionine coating on a wire of platinum microscope, attained by field emission scanning electron microscope (FESEM). As can be seen, the polythionine forms a nano-sized coating with porousness, which resulted in a high surface area for effective extraction of the analytes in application of SPME. The tape-like structure of polythionine has this potential to help the extraction analytes as well.

To investigate the thermal stability of the fiber, it was heated in the injector of GC for 20 min at different temperatures. It was revealed (Fig. 3) that the fiber is thermally stable up to 280 °C, while at higher temperatures (i.e., 300 °C) the fiber coating decompose at GC injector port.

The SPME method optimization

The investigations were carried out to study the interaction among variables affecting the responses of analyte, and no substantial interaction among variables on the responses of analyte was monitored only text must have optimized after other variables [11, 25]. So, the optimization of SPME conditions was performed using a “one-variable at-a-time” method. Furthermore, prior investigations, it has been observed that stirring velocity has an affirmative effect on extraction efficiency. Therefore, high velocity (950 rpm) of stirring was chosen for extraction [11]. Because of high boiling points of phthalates, headspace extraction manner was chosen for the extraction mode.

The salt amount optimization

The sodium chloride salt amount of the solutions on the extraction efficiency of phthalates in aqueous solution was investigated under various concentrations (0–250 g L−1) (Fig. 4). It was expected that salting out improves the extraction efficiency. Increasing NaCl concentrations up to 150 g L−1, increased the extraction efficiency. After that, the signals of BBP, DiBP, DOP, and DnBP decreased. The electrolyte presence in an adsorption method may affect the adsorption in two paths: variation the properties of the phase border and decrease the solubility of non-hydrophilic compounds in the aqueous phase. The second path was the dominant mechanism up to 150 g L−1 salt concentration and after that salting-in caused the decreasing in extraction efficiency. However, the concentration of 150 g L−1 was chosen as the optimized concentration of salt.

The extraction temperature optimization

Commonly, the temperature may affect the peak areas because of many various effects. On the one hand, the HS/sample partition factor of the analyte increases with increasing temperature. The high temperatures can have the non-positive result of a minor favorable coating/HS partition coefficient because the coating equilibrium procedure is a non-endothermic procedure, and any increment in sampling temperature will decrease the recovery [26]. On the other hand, upper temperature may reinforce the velocity of molecules movements in solutions and, therefore, increased extraction velocity. The efficiency of extraction temperature was investigated in a range of 25 °C (laboratory temperature) to 80 °C. Figure 5 displays the extraction temperature effect on the peak area of the analytes. The most peak areas for all phthalates were attained at 50 °C. For temperatures higher than 50 °C, the peak areas of DnBP, DiBP, BBP, and DOP started to decrease. Therefore, the temperature of optimum extraction was taken as 50 °C.

The extraction time optimization

The extraction time effect on the SPME of phthalates was studied at 15, 30, 45, and 60 min. As can be seen in Fig. 6, the areas of the peak for all the phthalates increased with increasing in extraction time. The equilibrium arrived at 45 min. For times higher than 45 min, the peak areas of DnBP, DiBP, BBP, and DOP started to decrease. Therefore, the optimum time of extraction was obtained as 45 min.

The validation of the method

The analytical performance of the suggested solid-phase microextraction method was accredited via the determination of linear range, limit of detection (LOD), and intra-day and inter-day precisions of the method under the optimized conditions. The curves of linear calibration were created firmly fixed on 9 points. Limits of detection and quantitation were computed firmly fixed on signal/noise ratios of 3 and 10, respectively. The intra-day deviations of relative standard of the peak areas of all phthalates were appraised on a single day for three extractions from the aqueous solution spiked at 50 µg L−1. Inter-day deviations of relative standard were computed using three replicates at 50 µg L−1 concentration level for each phthalate ester over 3 days. The limits of detections of phthalates were in 0.34–1.67 µg L−1 range. The determination coefficients (r2 > 0.99) were attained for different phthalates. The phthalates liner range was in 0.5–1000 µg L−1 range for all phthalate esters. Also, as may be looked in Table 1, the inter-day and intra-day deviations of relative standard at 50 µg L−1 concentration levels were in the acceptable limits of 7.64–10.62% and 10.14–12.84%, respectively. Intra-day precisions were as well as studied at 50 µg L−1. Results displayed that the method has acceptable intra-day precision at this concentration too.

The robustness of the fiber was such that a single fiber could be applied up to 290 °C for extracted analytes desorption. Generally, the fibers are chiefly harmed at sequential extractions from aqueous solutions. By using an extraction solution containing mixed phthalates (50 µg L−1), high concentration of sodium chloride salt (150 g L−1) and high desorption temperature (280 °C), a single fiber illustrated that the coating may be applied more than 40 times without any substantial reduction in the extraction efficiency. It means the fiber reusability was excellent and comparable with many of the formerly suggested coatings applied for applications of solid-phase microextarction [27,28,29].

Table 1 supply a comparison among the suggested manner and prior investigations regarding the phthalates determination in water samples of water with SOME. The linear limits, limits of detections, and precisions detected in this investigation are comparable to or better than the values obtained by other commercial or handmade fibers, despite that all of them have used GC-MS for quantification.

Real sample analysis

The analytical results for the quantitation of phthalates displayed that DiBP was found in cheese water sample, but other phthalates were not found in it. DnBP and DOP were also detected in wastewater, which was ranged from 17.72 of 363.8 µg L−1. The results were organized in Table 2. The spiked phthalates recoveries in the sample of wastewater ranged from 81.3 to 102%, and in the cheese water sample ranged from 96.2 to 119.5%. The accuracy of the method was also investigated with an official method (EPA standard method). The EPA method involved liquid–liquid extraction with GC-ECD detection [33]. Table 2 shows that the data also confirmed each other. The chromatograms of the non-spiked and spiked wastewater and cheese water samples obtained by the developed SPME-gas chromatographic-flame ionization detector (GC-FID) technique are shown in the Fig. 7.

Conclusions

A new polythionine solid-phase microexraction coating was made by a CV deposition manner. The fiber had a porous surface, with high surface area and adsorption capacity for phthalates. The fiber displayed an excellent thermal stability in the gas chromatography inlet. The suggested method displayed fine intra-day and inter-day accuracy, good linear limit, low limits of detection, and high recoveries for the phthalates analysis. Although, this fiber can be used to extract compounds with different polarities, phthalates were selected as model compounds to assess the extraction capability of the fiber. Extraction of more compounds can be evaluated in the future works.

References

M. Ohtani, S. Kuwabata, H. Yoneyama, J. Electroanal. Chem. 422, 45 (1997)

K. Hajizadeh, H.T. Tang, H.B. Halsall, W.R. Heineman, Anal. Lett. 24, 1453 (1991)

X. Chen, J. Zhang, B. Wang, G. Cheng, S. Dong, Anal. Chim. Acta 434, 255 (2001)

S. Cosnier, S. Szunerits, R.S. Marks, J.P. Lellouche, K. Perie, J. Biochem. Biophys. Methods 50, 65 (2001)

B. He, S. Yan, Microchim. Acta 186, 77 (2019)

E. Dempsey, D. Diamond, A. Collier, Biosens. Bioelectron. 20, 367 (2004)

S. Warren, G. Munteanu, D. Rathod, T. McCormac, E. Dempsey, Biosens. Bioelectron. 137, 15 (2019)

E. Diamanti-Kandarakis, J.-P. Bourguignon, L.C. Giudice, R. Hauser, G.S. Prins, A.M. Soto, R. Thomas Zoeller, A.C. Gore, Endocr. Rev. 30(4), 293 (2009)

M.H. Dévier, K. Le Menach, L. Viglino, L. Di Gioia, P. Lachassagne, H. Budzinski, Sci. Total Environ. 443, 621 (2013)

Y. Ma, F. Zhao, B. Zeng, Talanta 104, 27 (2013)

M.H. Banitaba, S.S.H. Davarani, A. Pourahadi, J. Chromatogr. A 1283, 1 (2013)

Y.-F. Jin, Y.-P. Zhang, M.-X. Huang, L.-Y. Bai, M.L. Lee, J. Sep. Sci. 36, 1429 (2013)

Y. Zhang, H.K. Lee, J. Chromatogr. A 1274, 28 (2013)

G. Leng, W. Chen, M. Zhang, F. Huang, Q. Cao, J. Sep. Sci. 37, 684 (2014)

R. Čabala, M. Bursová, J. Chromatogr. A 1230, 24 (2012)

G. Huang, H.-F. Li, B.-T. Zhang, Y. Ma, J.-M. Lin, Talanta 100, 64 (2012)

F. Kamarei, H. Ebrahimzadeh, Y. Yamini, Microchem. J. 99, 26 (2011)

Y. Yamini, M. Ghambarian, M.R. Khalili-Zanjani, M. Faraji, S. Shariati, J. Sep. Sci. 32, 3201 (2009)

H. Bagheri, A. Es-haghi, M.R. Rouini, J. Chromatogr. B 818, 147 (2005)

A. Mehdinia, A. Ghassempour, H. Rafati, R. Heydari, Anal. Chim. Acta 587, 82 (2007)

I. Salimikia, R. Heydari, F. Yazdankhah, J. Iran. Chem. Soc. 15, 1593 (2018)

M. Rahimi, S. Bahar, R. Heydari, S.M. Amininasab, Microchem. J. 148, 433 (2019)

E. Topçu, M. Alanyalioǧlu, J. Appl. Polym. Sci. 131, 1 (2014)

Q. Gao, X. Cui, F. Yang, Y. Ma, X. Yang, Biosens. Bioelectron. 19, 277 (2003)

A. Mehdinia, F. Bashour, F. Roohi, A. Jabbari, Microchim. Acta 177, 301 (2012)

F. Yang, M. Wang, Z. Wang, Chemosphere 93, 82 (2013)

A. Mehdinia, H. Khani, S. Mozaffari, Microchim. Acta 181, 89 (2014)

J. Zou, X. Song, J. Ji, W. Xu, J. Chen, Y. Jiang, Y. Wang, X. Chen, J. Sep. Sci. 34, 2765 (2011)

H. Asadollahzadeh, E. Noroozian, S. Maghsoudi, Anal. Chim. Acta 669, 32 (2010)

A. Peñalver, E. Pocurull, F. Borrull, R.M. Marcé, J. Chromatogr. A 922(1–2), 377 (2001)

M. Polo, M. Liompart, C. Garcia-Jares, R. Cela, J. Chromatogr. A 1072(1), 63 (2005)

R. Stiles, I. Yang, R.L. Lippincott, E. Murphy, B. Buckley, Environ. Sci. Technol. 42, 2976 (2008)

EPA method, Methods for organic chemical analysis of municipal and industrial wastewater, Method 606, Phthalate esters (1984)

Acknowledgements

The authors thankfully acknowledge the University of Shahid Beheshti investigation affairs for their support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Moahammadi, A.A., Davarani, S.S.H., Jafari, M. et al. Preparation and evaluation of a new solid-phase microextraction fiber based on polythionine for analysis of phthalate esters in aqueous samples. J IRAN CHEM SOC 18, 385–391 (2021). https://doi.org/10.1007/s13738-020-02034-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-020-02034-6