Abstract

A fast and simple ultrasound-assisted dispersive liquid–liquid microextraction method for determination of Sodium Closantel has been developed. High-performance liquid chromatography with ultraviolet detector has been used for the determination of Sodium Closantel. The effect of influencing parameters such as type and volume of extraction and disperser solvents, pH of sample solution, extraction time and amount of salt was also investigated. Optimization of method was performed using Plackett–Burman experimental design and surface response methodology. Under the optimal conditions, the linear dynamic range of Sodium Closantel was from 10 to 3000 µg L−1 with a correlation coefficient of 0.997 and a detection limit of 1.0 µg L−1. The relative standard deviation was less than 3.5% (n = 5). The method has been successfully applied for determination of Sodium Closantel in real samples. The enrichment factor was 48 under optimal conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

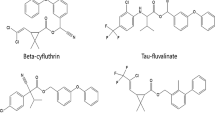

Sodium Closantel (Scheme 1, a sodium salt of salicylamide) is an anthelmintic drug which is a strong uncoupler of oxidative phosphorylation, can inhibit the phosphorylation of mitochondria of the parasite, nematode and arthropod or blood-sucking insects close contact with blood circulation drive to kill insects have efficient effect, is an efficient, low toxicity broad spectrum anthelmintic. It is effective drug against Taenia pisiformis in rabbits. Ancylostoma caninum and Fasciola hepatica have prolonged effect on Haemonchus in sheep [1]. Some analytical methods including spectrometric methods [2, 3], densitometric method [4] and HPLC [5,6,7,8] have been reported for the determination of Sodium Closantel (Closantel-Na). Dispersive liquid–liquid microextraction (DLLME) is a simple and fast microextraction technique based on ternary component systems. Extraction by DLLME can be performed by rapidly injecting a mixture of extractant and disperser solvent into the aqueous sample. The formation of a cloudy solution then occurs, and the surface area between the extractant and the sample becomes very large, so that equilibrium is obtained quickly. Thus, the extraction time is very short. The extractant phase can be separated from the aqueous phase by centrifugation. Since a few microliters of extractant are used, a high enrichment factor can be achieved. DLLME has been successfully applied in the preconcentration of various analytes from different samples [9,10,11,12,13,14].

An easy and novel approach for increasing the efficiency of DLLME is the use of ultrasound radiation in combination with DLLME, known as ultrasound-assisted emulsification–microextraction (UAEME). Ultrasound (US) radiation facilitates the emulsion phenomenon and accelerates the mass transfer process; thus, it provides a high extraction efficiency in a short period of time. Although there are a number of publications on the applications of DLLME and US for the extraction of biogenic amines [9], only a few reports have concerned real samples [15,16,17].

In the present survey, an ultrasound-assisted DLLME combined with HPLC method was developed for the determination of Sodium Closantel-Na in human urine and plasma samples. In addition, the effects of different parameters, including type of extraction solvent, dispersive solvent and corresponding volumes, pH and ultrasonic time on the efficiency of UA-DLLME method, were systematically investigated by Plackett–Burman experimental design and response surface methodology.

Experimental

Instruments, chemicals and reagents

HPLC separation was performed with Shimadzu liquid chromatography system equipped with ultraviolet detector (Shimadzu, Japan). The analytical column used for reverse phase liquid chromatographic analysis was a Capital hypersil C18 BDS 10 cm 4.6 mm I.D. (Capital HPLC Ltd. West Lothian, UK) packed with 3.0-μm particles. Centrifugations were performed with a Heraeus centrifuge model biofuge (Germany). All pH measurements were made at 25 ± 1 °C with Metrohm instrument Model 744 (Switzerland) using combined glass electrode. A Selecta 3000617 ultrasonic bath (200 W, 40 kHz) purchased from Selecta (Barcelona, Spain) was used for ultrasonication treatments. Analytical grade sodium chloride, phosphoric acid, ammonium acetate, sodium hydroxide, acetone, chlorobenzene, dichloromethane and chloroform were purchased from (Merck, Germany). HPLC-grade acetonitrile and methanol were purchased from Dae-Jung Chemical Reagent Co., Ltd (Republic of Korea). Double-distilled deionized water was produced by a Milli-Q system (Millipore, Bedford, MA, USA). Working standard of Closantel sodium dihydrates was purchased from Yabang Chemicals Ltd. (P.R. China).

UA-DLLME procedure

10.0 mL of human plasma and urine samples solution was placed in a 10-mL glass conical tube. The pH of the sample solution was adjusted to an appropriate value (pH 7.0) by use of NaH2PO4–NaOH buffer solution. Chloroform as extraction solvent (127 μL) and ethanol (736 μL) as disperser were then added to the sample solution. The mixture was sonicated for 4 min at 25 °C. An emulsion was formed in the conical tube. The tube was then centrifuged for 3 min at 4000 rpm and the organic phase sedimented to the bottom of the centrifuge tube. The sedimented organic phase was entirely transferred into another conical tube by use of a micropipette and then evaporated to dryness under a stream of nitrogen (99.999%). The residue was dissolved in 200 μL acetonitrile, and 10 μL was injected for HPLC analysis.

Real sample preparation

Blood samples were obtained from Imam Reza Hospital. (Kermanshah, Iran). The blood samples were stored at 4 °C and were not further pretreated before use. In the serum analysis, 500 μL acetonitrile was added to 100 μL serum to remove the protein and some impurities. The serum supernatant (300 μL) was spiked with 1 mL of Closantel-Na solution (1000 mg/L), and the sample was diluted to 5 mL with ultrapure water as the sample solution for determination of Closantel-Na. The extraction procedure was the same as that described above for UA-DLLME. Urine samples were only ultrafiltered and spiked by this drug.

Chromatography

The mobile phase consisted of acetonitrile, water and ammonium acetate buffer of pH 4.3 (45:45:10, v/v/v). It was filtered by nylon membrane filters (0.45 μm) and degassed prior to use. Buffer solution of pH 4.3 was prepared with 0.77 g ammonium acetate in 100 mL water and adjusting pH with phosphoric acid (85%). A flow rate of 1.5 mL min−1 was used. All chromatographic procedures were conducted at 25 °C. Volumes 20 μL from all solutions were injected onto the column. The peaks were monitored at wavelength of 240 nm.

Data analysis and statistical methods

Minitab Trial software version 16 was used (Minitab, Inc.) for optimization of the effective independent parameters and their possible interactions based on central composite design for microextraction of Closantel-Na. At first, some experiments were done to evaluate the level of variables used for recovery of the Closantel-Na. The main variables were determined as follows: volume of extraction solvent, volume of dispersive solvent and extraction time. The variables give us statistical analysis, a quadratic equation, response surface and contour plots to find out optimal condition of the mentioned extraction.

Results and discussion

Selection of dispersive and extraction solvents

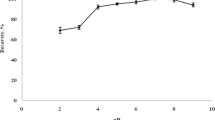

The selection of dispersive and extraction solvents used in DLLME is important for efficient extraction. The extraction solvent should be higher density than water, high extraction capability of the interested compounds and low solubility in water, and dispersive solvent should be miscible with both water and the extraction solvent. Type of the extraction and disperser solvents will be figured out by the elementary examination. Therefore, acetonitrile, acetone and methanol were tested as the dispersive solvents, and chloroform, CCl4 and chlorobenzene were studied as the extraction solvents. For determination of type of extraction and disperser solvents, 9 experiments were performed as shown in Fig. 1. Through the experiments, the most suitable dispersive and extraction pairs of solvent were selected as ethanol–chloroform solvent pair.

Experimental design

After determining the type of the dispersive and extraction solvents, experiments were designed to find the interaction of four variables. Plackett–Burman design was used as the most powerful tools [18, 19] for optimization of multivariable system; this approach was employed to screen the main parameters affecting the extraction recovery. The factors and their levels were selected according to the data available and experience obtained in screening experiments. Table 1 represents the high and low values of the experimental variables. Then, a Plackett–Burman factorial design with 5 factors and 21 nonrandomized runs was performed. The factorial design matrix and the obtained recovery results are shown in Table 2. All experiments for DLLME were performed as three replicates. The effects of the variables in the screening experiments are shown in Fig. 2 in the form of a Pareto chart. The vertical line in the chart defines the 95% confidence level. The bar length is proportional to the significance of the variables for the recovery. As results shown in Table 2 and Pareto chart (Fig. 2), the most significant effects were observed for volume of extraction solvent. Extraction time, volume of disperser solvent and three-order interactions between them presented significant effects on the recovery of Closantel-Na. Volume of extraction solvent has a positive effect on the recovery of Closantel-Na. In experiments 16, 92% Closantel-Na recoveries were observed at maximum level of ESV, where the other two factors, i.e., DSV and time, were also at their maximum level. It can be seen in experiments 6 and 10 that time and DSV are at higher level, while ESV is at lower level; the recoveries of Closantel-Na were 75 and 72%, respectively. The obtained results showed that ESV has the most significant effect on the extraction of Closantel-Na and DSV and the extraction time lower significant effects on the percent recovery of Closantel-Na (Fig. 2 Pareto chart). From the graphical model, it can be concluded that the two factors pH and salt amount had no significant effect on the recovery of Closantel-Na and were fixed at 7.0 and 1.0%, respectively. Dispersive and extractive solvents volume and extraction time effect were considered in surface response methodology.

Response surface methodology

The response surface methodology based on central composite design (CCD) was carried out for optimization of the effective independent variables and their possible interactions on the microextraction of Closantel-Na. Three significant variables from Pareto chart including extraction solvent volume (X1, ESV), extraction time (X2) and dispersive solvent volume (X3, DSV) were considered to build the regression models between the variables and chromatogram peak area of Closantel-Na. Preliminary experiments were carried out, and subsequently, lower and upper levels for extraction solvent (50 and 200 μL), dispersive solvent (200 and 600 μL) and extraction time (1 min and 3 min) were selected. A central 23 star orthogonal composite design with 6 degrees of freedom involving 20 experiments was performed to optimize these variables (Table 3). Figure 3 shows the expected surface plots for simultaneous effects of pairs of variables on the recovery of Closantel-Na. Figure 3a shows the effects of extraction solvent volume and extraction time on the R% of Closantel-Na. At fixed value of dispersive solvent volume, the Closantel-Na recovery has good positive proportional with extraction solvent volume and attained its maximum value at 3.7 min. Figure 3b shows that increasing the disperser volume and sonication time leads to enhance in extraction recovery. It seems that lower disperser volume due to insufficient mixing and also non-complete cloudy formation leads to a quantitative transfer of analyte from source phase to extraction phase do not occur. At moderate extraction solvent volume, raising disperser volume leads to slightly increases in recovery and reaching a plateau (Fig. 3c). The extraction efficiency improved with the increasing extraction solvent while increasing the disperser solvent to 800 μL. The same results can be derived of contour plots. Maxima are best found from the contour plots as represented in Fig. 4. Estimated regression coefficients for the recovery of Closantel-Na for each pair of variables [DSV-ESV], [Time-ESV] and [Time-DSV] were calculated by the three-dimensional (3D) response surface model. Calculating the optimum point in the fitted model using quadratic Eq. (1) indicated that time, dispersive solvent volume and extraction solvent volume were 3.0 min, 526 and 157 µL respectively, required for maximum recovery of Closantel-Na [14, 20, 21].

The R 2 value for the response surface regression was 95.7% that indicates a proper modeling. After optimization of effective variables and providing a mathematical equation, the efficiency of prediction was confirmed by replication of similar experiments at pre-specified optimum conditions. Under the optimum condition, the observed extraction recovery was found to be 96.1% with RSD lower than 4% which is a good indicator of high efficiency of this model for well presentation of the mentioned method.

Plots of response surface methodology with the central composite design obtained for: a volume of extraction solvent versus extraction time (volume of disperser = 400 µL), b volume of disperser solvent versus extraction time (volume of extraction solvent = 125 µL), c volume of extraction solvent versus volume of disperser (extraction time = 2 min)

Analytical performance

Quantitative characteristics of the proposed method including linear ranges of calibration graphs, coefficient of determination (R 2), limit of detection (LOD), limit of quantification (LOQ), relative standard deviations (RSD) and enrichment factors (EF) were calculated. The calibration graph was linear in the range of 10–3000 µg L−1 with a R 2 more than 0.997. The limit of detection (LOD) calculated based on 3 S b/m (where S b and m are the standard deviation of the blank and the slope of the calibration graph, respectively) was 1.0 µg L−1. The enrichment factor was 48, and the relative standard deviation (RSD) was less than 3.5% (n = 5) [14, 20].

Analysis of samples

To evaluate the applicability of the present method, three commercial cow milk samples (1.5% fats) from different companies were obtained from a local supermarket. Samples were spiked by appropriate amounts of Sodium Closantel, and then, 5.0 mL of 16% (w/v) trichloroacetic acid was added to 30 g milk and centrifuged at 4000 rpm for 10 min. The pH of solution was adjusted by adding sodium hydroxide (50%); 10 mL of the upper layer was used for UA-DLLME procedure. It can be seen (Fig. 5) that no significant interference peaks were found at the retention time of target compound in human plasma.

The other analysis was for tablets; in this case, five Sodium Closantel tablets (Hepatec 500) were purchased from Zagros Pharmed Pars Co. (Borujerd, Iran), labeled as containing 500 mg Sodium Closantel each, were weighed and the average mass per tablet was determined. An amount of the powder equivalent to 500 mg of Sodium Closantel was accurately weighed and dissolved in 20 mL of methanol and 30 mL ultra pure water. The solution was sonicated for 5 min and filtered into a 50-mL volumetric flask. Further dilutions were made up with ultrapure water to achieve a final concentration of 100 μg mL−1. In addition, appropriate dilution was performed for analysis.

The efficiency of the proposed method was further evaluated by determining the concentration of Closantel-Na in real plasma samples. Blood samples were spiked with drug and analyzed three times. Compound identification was performed by comparing the retention times with those of the spiked blank plasma standards. Same results were seen in human urine samples too. The spiked samples with drug (10.0, 50.0, 100.0 µg L−1) were analyzed three times, and the all obtained analytical results are summarized in Table 4. These results demonstrated that the recoveries of targets obtained from the cow milk, Hepatec tablet, plasma and the urine samples were in the range of 95.0–104.6%. The relative standard deviations varied between 2.0 and 3.25%. It can be considered that the current method provides acceptable recoveries and precision for the determination of Closantel-Na in all examined real samples.

Comparison with other works

Table 5 compares the main analytical characteristics (i.e., LR, LOD and mean accuracy) of the represented UA-DLLME-HPLC method for the determination of Closantel-Na with just two previous reported methods [22, 23]. Based on the results from Table 5, it can be concluded that the developed method is significantly improved over all the previously presented methods which indicates the fact that UA-DLLME-HPLC is a very sensitive technique and can be well used for the preconcentration and determination of Closantel-Na in real samples.

Conclusion

In this work, an UA-DLLME method combined with HPLC–UV was successfully applied to the determination of Closantel-Na in the cow milk, Hepatec tablet, human plasma and urine samples. The proposed method is fast and simple and shows good precision and accuracy. Under the best extraction conditions, low limit of detection at µg per liter level, good linearity and relatively high enrichment factor were achieved. The analysis of Closantel-Na in some actual samples indicated that the method was suitable for determination of trace amounts of Closantel-Na for these real samples in a simple way.

References

M.J. O’Neil, The merck index, 14th edn. (Merck & Co Inc, Whitehouse Station, 2006)

X.Q. Wang, J.F. Wu, C.Y. Zhou, Measurement of significant crystal and content of antiparasitic drug sodium closantel by infrared spectrometry. Chin. J. Anal. Chem. Fenxi Huaxue 26(9), 1162 (1998)

J. Wu, Z. Tian, Z. Li, D. Zhang, Ultraviolet spectrophotometric determination of closantel sodium in injection solution. Yaowu Fenxi Zazhi 13(3), 202–203 (1993)

L.J. Wu, J.F. Wu, Studies on the related impurities in closantel by thin-layer chromatography. Yaowu Fenxi Zazhi 16(6), 394–400 (1996)

Y.T. Wong, S.S.L. Lai, H.S. Yeung, W.O. Lee, C. Ho, Determination of closantel and rafoxanide in animal tissues by online anionic mixed-mode solid-phase extraction followed by isotope dilution liquid chromatography tandem mass spectrometry. J. Sep. Sci. 34(12), 1366–1374 (2011)

T.Y. Wong, W.O. Lee, H.S. Yeung, Screening of closantel and rafoxanide in animal muscle by HPLC with fluorescence detection and confirmation using MS. J. Sep. Sci. 33(2), 206–211 (2010)

H.W. Sun, F.C. Wang, L.F. Ai, Determination of closantel residue in milk and animal tissues by HPLC with fluorescence detection and SPE with oasis MAX cartridges. J. Chromatogr. Sci. 46(4), 351–355 (2008)

H.A. Benchaoui, Q.A. McKellar, Determination of rafoxanide and closantel in ovine plasma by high-performance liquid chromatography. Biomed. Chromatogr. 7(4), 181–183 (1993)

K.J. Huang, C.Y. Wei, W.L. Liu, W.Z. Xie, J.F. Zhang, W. Wang, Ultrasound-assisted dispersive liquid-liquid microextraction combined with high-performance liquid chromatography-fluorescence detection for sensitive determination of biogenic amines in rice wine samples. J. Chromatogr. A 1216, 6636–6641 (2009)

C. Almeida, J.O. Fernandes, S.C. Cunha, A novel dispersive liquid–liquid microextraction (DLLME) gas chromatography-mass spectrometry (GC–MS) method for the determination of eighteen biogenic amines in beer. Food Control 25, 380–388 (2012)

Y.C. Fan, Z.L. Hu, M.L. Chen, C.S. Tu, Y. Zhu, Ionic liquid based dispersive liquid–liquid microextraction of aromatic amines in water samples. Chin. Chem. Lett. 19, 985–987 (2008)

M. Rezaee, Y. Assadi, M.R. Milani Hosseini, E. Aghaee, F. Ahmadi, S. Berijani, Determination of organic compounds in water using dispersive liquid–liquid microextraction. J. Chromatogr. A 1116, 1–9 (2006)

Q. Zhou, X. Zhang, J. Xiao, Ultrasound-assisted ionic liquid dispersive liquid-phase micro-extraction: a novel approach for the sensitive determination of aromatic amines in water samples. J. Chromatogr. A 1216, 4361–4365 (2009)

K. Alizadeh, H. Nemati, S. Zohrevand, P. Hashemi, A. Kakanejadifard, M. Shamsipur, M.R. Ganjali, F. Faridbod, Selective dispersive liquid–liquid microextraction and preconcentration of Ni(II) into a micro droplet followed by ETAAS determination using a yellow Schiff’s base bisazanyl derivative. Mater. Sci. Eng. C 33, 916–922 (2013)

Z. Lin, J. Li, X. Zhang, M. Qiu, Z. Huang, Y. Rao, Ultrasound-assisted dispersive liquid-liquid microextraction for the determination of seven recreational drugs in human whole blood using gas chromatography-mass spectrometry. J. Chromatogr. B 2017, 177–184 (1046)

S. Ahmed, N.N. Atia, M.F. Bakr, Ali, Ultrasound assisted dispersive liquid-liquid microextraction coupled with high performance liquid chromatography designated for bioavailability studies of felodipine combinations in rat plasma. J. Chromatogr. B 2017, 200–210 (1046)

S. Sajedi-Amin, K. Asadpour-Zeynali, M. Khoubnasabjafari, F. Rashidi, A. Jouyban, Development and validation of ultrasound assisted and dispersive liquid–liquid microextractions combined with HPLC-UV method for determination of bosentan in human plasma and urine. Braz. Chem. Soc. 28, 868–877 (2017)

R.L. Plackett, J.P. Burman, The design of optimum multifactorial experiments. Biometrika 33, 305–325 (1946)

J.C. Wang, C.F. Wu, A hidden projection property of Plackett–Burman and related designs. Stat. Sin. 5, 235–250 (1995)

R.H. Myers, D.C. Montgomery, Response surface methodology (Wiley, New York, 2002)

G. Hanrahan, Environmental chemometrics principles and modern applications (CRC Press, Taylor & Francis Group, Boca Raton, 2009)

M.S. Phatak, W. Vaidya, H.M. Phatak, Development and validation of a high performance liquid chromatography method for the simultaneous quantification of albendazole and closantel from veterinary formulation. Int. J. Res. Phar. Chem. 4(4), 972–976 (2014)

S.A.A. Razeq, A.O. El Demerdash, H.F. El Sanabary, Stability-indicating methods for the determination of closantel sodium by HPLC, densitometry, spectrofluorimetry and pH induced ΔA. Am. Chem. Sci. J. 5(1), 79–93 (2015)

Acknowledgements

The authors gratefully acknowledge from the college of science, Lorestan University, for supporting this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pourhossein, A., Alizadeh, K. Ultrasound-assisted dispersive liquid–liquid microextraction and multivariate optimization for determination of Sodium Closantel in biological samples and pharmaceutical formula. J IRAN CHEM SOC 15, 303–310 (2018). https://doi.org/10.1007/s13738-017-1232-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-017-1232-8