Abstract

In this paper, a novel polyaniline (PANI) nanofibers/ionic liquid-functionalized carbon nanotubes (IL-CNTs) composite-modified electrode was prepared, and its application on electrocatalytic oxidation of guanine of sequence-specific DNA was investigated. The surface morphology and the related electrochemical behaviors of the PANI/IL-CNTs composite film were characterized with scanning electron microscopy, electrochemical impedance spectroscopy and cyclic voltammetry, respectively. The PANI/IL-CNTs composite showed a good response current toward the direct electrooxidation of ssDNA due to the synergistic effect between PANI nanofibers and IL-CNTs. Based on this, it was adopted as an excellent sensing platform for highly sensitive determination of guanine. The detection limit was 3.1 × 10−9 mol/L.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ionic liquids (ILs) are entirely composed of organic cations and various inorganic anions, and exist in the liquid phase at room temperature. Due to their specific properties such as wide electrochemical windows, high thermal and chemical stability, negligible vapor pressure, high ionic conductivity, good biocompatibility and fine solubility [1–3], ILs have been widely used as the supporting electrolyte as well as solvent in electrochemical processes [4, 5]. In recent years, the combination of ILs and carbon nanotubes (CNTs) was under intense investigation, because of the easy preparation and high dispersibility and stability of IL-CNTs gel by “cation-π” interaction [6–8], and the hybrid showed a promising application in biosensor field [9–11]. Liu et al. [12] reported that the IL-CNTs gel-modified electrode exhibited effective electrocatalytic oxidation ability to biomolecules such as glucose oxidase, dopamine (DA), ascorbic acid (AA) and dihydronicotinamide adenine dinucleotide. Zhao et al. [13] provided a simple approach to detect DA selectively in the presence of AA and uric acid at IL-CNTs gel-modified electrode.

Recent development in nanomaterial and nanotechnology creates many opportunities to advanced biomolecular sensing [14] and gene detection [15, 16]. In particular, they can be used as the tools of signal amplification that attract a great deal of attention. PANI is one of the most attractive conducting polymers because of the following advantages: low-temperature synthesis, tunable conductivity, no need for purification and good environmental stability [17–20]. Compared with the traditional PANI, the nanostructured PANI maintained the above advantages and has a unique merit of high surface area [21–26]. Zhu et al. [27] reported an electrochemical DNA biosensor based on electrochemically fabricated PANI nanowire through a three-step electrochemical deposition procedure. Chang et al. [28] developed an ultrasensitive biosensor based on conducting PANI nanotube array for DNA hybridization detection. This DNA electrochemical biosensor demonstrated an extremely high sensitivity that could detect the presence of a target nucleotide at a concentration as low as 1.0 fM. However, as far as we know, there is no report yet about the determination of guanine in ssDNA based on PANI/IL-CNTs composite film. The use of the IL as the gelling medium and PANI nanofibers as the signal amplification element allows for the fabrication of a highly electroconductive composite material, which showed a substantial enhancement in guanine signal in the following section.

Experimental

Apparatus and reagents

A CHI 660C electrochemical analyzer (Shanghai CH Instrument Company, China), which was in connection with a homemade carbon paste electrode (CPE, Ф = 4 mm), a Ag/AgCl reference electrode and a platinum wire auxiliary electrode, was used for the electrochemical measurement. Scanning electron microscopy (SEM) was carried out using a JSM-5900 machine (JEOL, Japan). Copper sheet was used for SEM as the substrate. Ultrapure water was produced from Aquapro system (Chongqing Yihe Company, China).

1-Butyl-3-methylimidazolium hexafluorophosphate (BMIMPF6) was purchased from Hangzhou Kemer Chemical Co., Ltd. (Hangzhou, China).The PANI nanofibers were homemade [29] and provided by College of Material Science and Engineering, Qingdao University of Science and Technology and used without further purification. CNTs were purchased from Shenzhen Nanotech. Port Co. Ltd. (Shenzhen China). K3[Fe(CN)6] and K4[Fe(CN)6] were purchased from Shanghai No. 1 Reagent Factory (Shanghai, China) and Shanghai Heng Da Chemical Co., Ltd. (Shanghai, China), respectively. All the chemicals were of analytical grade, and solutions were prepared with ultrapure water.

Phosphoenolpyruvate carboxylase gene (PEP) is an important promoter in many genetically modified crops [14]. It was synthesized by SBS Genetech Co., Ltd. (Beijing, China) with the sequence: 5′- NH2-CAG CAC CTA GGC ATA GGT TC -3′.

Preparation of modified electrode

IL-CNTs gel was prepared readily. High-purity CNTs in BMIMPF6 was ground with an agate mortar and then centrifuged. A black lower gel phase containing BMIMPF6 and CNTs was separated from the transparent liquid phase. No phase transition was observed for the suspension of CNTs in BMIMPF6 upon sonication for 2 h at 30 °C, indicating that it was gelated enough. Then, 1 mL IL-CNTs gel and 1-mg PANI nanofibers were dispersed in 50 mL DMF by sonication for 5 min.

The fabrication of CPE was carried out using a method according to the Ref. [30]. Five microliters of PANI and IL-CNTs mixed solution was dropped onto the fresh surface of CPE and naturally dried in the air to form PANI/IL-CNTs/CPE. IL-CNTs/CPE and PANI/CPE were obtained by dripping 5 µL IL-CNTs gel and PANI nanofibers on the surface of CPEs, respectively.

Electrochemical measurements

CV and differential pulse voltammetry (DPV) were performed on a CHI 660C electrochemical analyzer. The following parameters were employed for CV and DPV: CV—scan rate 100 mV/s; DPV—amplitude 50 mV, pulse width 60 ms and pulse period 0.2 s. Supporting electrolyte solution of CV and DPV was the 0.1 M PBS buffer solution (pH 7.0).

The EIS measurements were also carried out with the CHI 660C electrochemical analyzer. The AC voltage amplitude was 5 mV, and the voltage frequencies ranged from 10 kHz to 0.01 Hz. The applied potential was 172 mV versus SCE (formal potential of the redox probe [Fe(CN)6]3−/4−).

The reported result for every electrode in this study was the mean value of three parallel measurements.

Results and discussion

Characterization of the PANI/IL-CNTs composite film

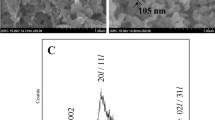

SEM was used to characterize the morphology of different kinds of modified materials. Typical SEM images of dendritic PANI are displayed in Fig. 1a. A small portion of PANI nanofibers with diameters of 100 nm and length of 3–8 µm could be obtained, and most of the products were nanoparticle aggregate. The shape of CNTs was easy to identify in Fig. 1b, and some of them individually existed, and some agglomerated together. From Fig. 1c, the homogeneous dispersion PANI/IL-CNTs composite could be observed, and most of the composite was interconnected to form a relative uniform film. The use of IL as the solvent essentially resulted in the formation of PANI/IL-CNTs composite with a mean diameter of about 50 nm, indicating that the IL could serve as both the solvent and the stabilizer for the fabrication of PANI/IL-CNTs [31].

Electrochemical impedance spectroscopy (EIS) was employed to study the impedance changes of the electrode surface. By using [Fe(CN)6]3−/4− redox couples as the electrochemical probe, the Nyquist plots of different electrodes were shown in Fig. 2 with the frequencies ranging from 0.1 Hz to 10 kHz. At the bare CPE, the electron-transfer resistance (R et) can be estimated to be 7000 Ω (curve a). Compared with the bare CPE, the R et values of PANI/CPE (curve b) and the IL-CNTs/CPE (curve c) both decreased, which could be attributed to the enhanced conductivity of the modified electrode. For PANI/IL-CNTs/CPE (curve d), the R et decreased dramatically, nearly to zero, indicating the excellent electrocatalytic capability of the PANI/IL-CNTs for the 5.0 mmol/L [Fe(CN)6]3−/4−. Because the PANI/IL-CNTs were an ideal electric conducting material, they can accelerate the electron transfer, resulting in the plunge of Ret.

Electrochemical behavior of ssDNA

The cyclic voltammograms of different electrodes in ssDNA solution (0.1 mol/L phosphate balanced solution, PBS, pH 7.0) were illustrated in Fig. 3. At the IL-CNTs/CPE electrode (curve c), the guanine gave an oxidation peak at 1.1 V, while the responses at the bare CPE and PANI/CPE were very poor (curves a and b). Compared with the electrochemical response on the IL-CNTs/CPE electrode, the peak current signal of guanine on the PANI/IL-CNTs/CPE (curve d) enhanced significantly with the oxidative potential moving positivity. No cathodic peaks were observed on the reverse scan within the investigated potential range, which indicated that the oxidation of guanine was an electrochemically irreversible process [32].

Effects of scan rate and solution pH

The cyclic voltammograms of the PANI/IL-CNTs/CPE in 0.1 mol/L PBS (pH 7.0) containing 1 μmol/L ssDNA at various scan rates were investigated. Over the range of 10–200 mV/s, the peak currents were directly proportional to the scan rate, and the formal potential was approximately independent of the potential scan rate in the range below 100 mV/s, suggesting facile charge-transfer kinetics over this range. While at higher scan rates, the peak current became proportional to the square root of the scan rate, indicating diffusional behavior in charge transport at these scan rates.

The effect of pH on the electrochemical response of ssDNA was also investigated. In the pH range from 4.0 to 8.0, the oxidation peak currents at the modified electrode showed a linear decrease with increasing pH value. The regression equation was Y = − 0.0507X + 1.106 (Y = Ep, X = pH), with the regression coefficient (R) of 0.9932. The slope of 50.7 mV/pH showed that two protons take part in the rate-determining step. The slope was near to the theoretical value of 59 mV/pH, indicating that a same number of protons and electrons are exchanged during guanine oxidation [33].

Analytical performance of the sensor

The experiments were carried out using the DPV mode. Figure 4 shows the DPV of different concentrations of ssDNA at the PANI/IL-CNTs/CPE. The well-defined DPV peak was obtained at 1.0 V, corresponding to the oxidation of guanine. The DPV showed that the curves of current versus the logarithm of the concentration of ssDNA exhibited good linearity in the range of 1.0 × 10−8–1.0 × 10−3 mol/L, as depicted in Fig. 5. The regression equation for guanine was Ipa (μA) = −7.4623 Log[SSDNA] −73.6495 (n = 11), with a correlation coefficient of 0.9971. The detection limit was 3.1 × 10−9 mol/L.

The analytical performance of this prepared sensor was compared to the previously published relevant electrochemical sensors for guanine detection (Table 1). It showed that the PANI/IL-CNTs/CPE offered a relative wider linear range and a lower detection limit, which further proved the PANI/IL-CNTs composite film had fine electrocatalytic performance for oxidation of guanine.

Reproducibility and stability

In this work, the reproducibility of our sensor was achieved by the peak current values of 1.0 × 10–8 mol/L on the surface of five independent PANI/IL-CNTs/CPEs in the 0.1 mol/L PBS (pH 7.0). And the standard deviation (R.S.D) of 4.18 (n = 5) was estimated, showing the high reproducibility of the sensor. The stability of the biosensor was tested. No significant change in Ipa values were observed after 24-h storage at 4 °C. After a week, the ssDNA electrode could retain 94 % of the initial sensitivity, indicting the fine stability of the sensor.

Conclusions

In this communication, the electrocatalytic activity of PANI/IL-CNT-modified CPE toward the oxidation of guanine was demonstrated. Significantly electrochemical response to trace the amount of ssDNA on the modified electrode had been observed in this work. The modified electrode showed fine stability, low detection limit and proposed an excellent platform for electrochemical biosensing.

References

A.R. Hajipour, F. Rafiee, J. Iran. Chem. Soc. 647, 6 (2009)

M. Du, T. Yang, C.Z. Zhao, K. Jiao, Anal. Chim. Acta 169, 690 (2011)

W. Zhang, T. Yang, X. Li, D.B. Wang, K. Jiao, Biosens. Bioelectron. 428, 25 (2009)

R.F. Souza, G. Loget, J.C. Padilha, E.M.A. Martini, M.O. de Souza, Electrochem. Commun. 1673, 10 (2008)

J.Y. Dai, J.J. Cheng, J. Jin, Z.G. Li, J. Kong, S.P. Bi, Electrochem. Commun. 587, 10 (2008)

T. Fukushima, A. Kosaka, Y. Ishimura, T. Yamamoto, T. Takigawa, N. Ishii, T. Aida, Science 2072, 300 (2003)

H.B. Kim, J.S. Choi, S.T. Lim, H.J. Choi, H.S. Kim, Synth. Met. 189, 154 (2005)

Z.W. Zhao, Z.P. Guo, J. Ding, D. Wexler, Z.F. Ma, D.Y. Zhang, H.K. Liu, Electrochem. Commun. 245, 8 (2006)

F. Xiao, F.Q. Zhao, J.J. Zeng, B.Z. Zeng, Electrochem. Commun. 1550, 11 (2009)

Y. Zhao, H. Liu, Y. Kou, M. Li, Z. Zhu, Q. Zhuang, Electrochem. Commun. 2457, 9 (2007)

C.L. Xiang, Y.J. Zou, L.X. Sun, F. Xu, Electrochem. Commun. 38, 10 (2008)

Y. Liu, X.Q. Zou, S.J. Dong, Electrochem. Commun. 1429, 8 (2006)

Y.F. Zhao, Y.Q. Gao, D.P. Zhan, H. Liu, Q. Zhao, Y. Kou, Y.H. Shao, M.X. Li, Q.K. Zhuang, Z.W. Zhu, Talanta 51, 66 (2005)

T. Yang, Q.H. Li, Q.Q. Kong, L. Meng, X.H. Wang, W.W. Chen, K. Jiao, ACS Appl. Mater. Interfaces 3495, 8 (2013)

T. Yang, D.M. Huang, Q.H. Li, W. Zhang, K. Jiao, Electroanalysis 392, 24 (2012)

T. Yang, X. Li, Q.H. Li, X.H. Guo, Q. Guan, K. Jiao, Polym. Chem. 1228, 4 (2013)

J. Yang, X.L. Wang, H.Q. Shi, Sens. Actuators B 178, 162 (2012)

X.X. Wang, T. Yang, X. Li, K. Jiao, Biosens. Bioelectron. 2953, 26 (2011)

M. Gerard, A. Chaubey, B.D. Malhotra, Biosens. Bioelectron. 345, 17 (2002)

A. Olad, M. Khatamian, B. Naseri, J. Iran. Chem. Soc. 141, 8 (2011)

T. Yang, N. Zhou, Y.C. Zhang, W. Zhang, K. Jiao, G.C. Li, Biosens. Bioelectron. 2165, 24 (2009)

S. Virji, J. Huang, R.B. Kaner, B.H. Weiller, Nano Lett. 491, 4 (2004)

G. Rehab, E.I. Sharkawy, J. Iran. Chem. Soc. 1027, 11 (2014)

T. Yang, Q. Guan, X.H. Guo, L. Meng, M. Du, K. Jiao, Anal. Chem. 1358, 85 (2013)

M. Du, T. Yang, X. Li, K. Jiao, Talanta 439, 88 (2012)

T. Yang, Q. Guan, Q.H. Li, L. Meng, L.L. Wang, C.X. Liu, K. Jiao, J. Mater. Chem. B 2926, 1 (2013)

N.N. Zhu, Z. Chang, P.G. He, Y.Z. Fang, Electrochim. Acta 3758, 51 (2006)

H.X. Chang, Y. Yuan, N.L. Shi, Y.F. Guan, Anal. Chem. 5111, 79 (2007)

C.Q. Zhang, G.C. Li, H.R. Peng, Mater. Lett. 592, 63 (2009)

C. Jiang, T. Yang, K. Jiao, H.W. Gao, Electrochim. Acta 2917, 53 (2008)

P. Yu, J. Yan, H. Zhao, L. Su, J. Zhang, L.Q. Mao, J. Phys. Chem. C 2177, 112 (2008)

M. Du, T. Yang, K. Jiao, J. Mater. Chem. 9253, 20 (2010)

Q. Li, C. Batchelor-McAuley, R.G. Compton, J. Phys. Chem. B 7423, 114 (2010)

R. Hallaj, A. Salimi, Anal. Methods 911, 3 (2010)

H.Y. Li, X.L. Wang, Z.X. Wang, Anal. Sci. 31, 1225 (2015)

S. Chatterjee, A. Chen, Electrochem. Commun. 29, 20 (2012)

V. Raj, J. Silambarasan, P. Rajakumar, RSC Adv. 33874, 4 (2014)

A.A. Ensafi, M. Mokhtari, B. Rezaei, Sens. Actuators B 528, 204 (2014)

A.A. Ensafi, M. Jafari-Asl, B. Rezaei, A.R. Allafchian, Sens. Actuators B 634, 177 (2013)

L. Svorce, K. Klacher, Sens. Actuators B 332, 194 (2014)

F. Xiao, F. Zhao, J. Li, B. Zeng, Electrochim. Acta 7781, 53 (2008)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 21275084, 21175059), Doctoral Foundation of the Ministry of Education of China (No. 20113719130001), Outstanding Adult-Young Scientific Research Encouraging Foundation of Shandong Province (No. BS2012CL013), and Scientific and Technical Development Project of Qingdao (No. 12-1-4-3-(23)-jch).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, J., Yang, T. & Hou, S.F. A sensor based on polyaniline nanofibers/ionic liquid-functionalized carbon nanotubes composite for electrocatalytic oxidation of guanine. J IRAN CHEM SOC 13, 1611–1615 (2016). https://doi.org/10.1007/s13738-016-0877-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-016-0877-z