Abstract

Magnetically separable Pd(0)/Fe3O4/ZnO catalyst was easily synthesized by immobilizing Pd on the surface of magnetic Fe3O4–ZnO nanoparticles. The nano-Pd/Fe3O4/ZnO was found as a magnetically separable and highly active catalyst for Suzuki–Miyaura as well as Heck cross-coupling reactions under ligand-free conditions. Under appropriate conditions, all reactions afforded the desired products in moderate to excellent yields. Moreover, this catalyst can be easily recovered using simple magnet and directly reused without significant loss of its activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The carbon–carbon bond formation is among the most fundamental reactions in organic chemistry. In many of these reactions, transition metals or their complexes have been used as a catalyst. Among the transition metals [1, 2], supported Pd catalysts have been found enormous applications in the Mizoroki–Heck [3, 4] and the Suzuki–Miyaura reactions [5]. These cross-coupling reactions have been recognized as fundamental tools and important area of interest in multiple organic transformations for industrial and academic processes [6, 7]. Generally, phosphine ligands are used to complex and active the palladium species, and excellent results have been reported for palladium-catalyzed cross-coupling reactions. The use of ligands is undesirable because of their toxicity, air, and moisture-sensitivity, and consequent conversion into phosphine oxide species. Recently, phosphine ligand-free cross-coupling reactions were reported [8, 9]. Although these reported papers are incentive, there are considerable methods for improvement in term of substrate scope, reaction conditions and reusability of the catalyst.

While traditional and homogeneous catalysts show higher catalytic activities than their heterogeneous counterparts, the problem lies in being costly and less green. So, chemists pay more attention to the designing of a catalyst that can be efficient and recoverable. Therefore, heterogeneous Pd-based catalysts will be a good alternative, owing to their air-stability, recoverability, reusability, and no residual properties [10]. In the past few years, numerous solid supports, such as mesoporous silica [11–13], metal oxides [14], clays [15], and carbon nanofibers [16], have been used for Pd-based heterogeneous catalysts. In this regard, magnetic nanoparticles (MNPs) as catalyst supports have been attracting more and more attention and they are very promising due to their large specific surface area and magnetic property [17–25]. It can be easily recovered from the reaction mixture simply using an external magnet to prevent loss of the catalyst. Thus, using MNPs eliminates the necessity of tedious centrifugation, filtration, or membrane separation steps [26–32]. Recently, numerous functioned MNPs have been employed in a range of organic transformations, showing excellent catalytic activities in C–C coupling [33–38].

ZnO-based magnetic semiconductors (MS) have received significant attention because of their unique properties and potential applications in electronic and light electronic devices such as gas sensors, light emitting diodes (LED), and solar cells [39, 40]. Many doping attempts into ZnO to form MS have been carried out, such as Co, Fe, and Ni [41]. However, there are still many difficult problems in ZnO-based MS, including the technique for crystal growth and film fabrication, the quality of materials, p-type doping and so on [42]. Alternatively, ZnO-based MS could also be achieved by fabricating hybrid nanoparticles. Meanwhile, the ZnO can prevent the aggregation of the Fe3O4 particles and provide surface Zn-OH groups for further modification.

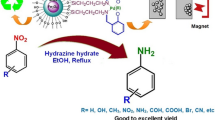

More recently, we reported for the first time a simple and low-cost method for the synthesis of Pd/Fe3O4/ZnO nanoparticles as a new catalyst and its application in the synthesis of benzoxazoles and 2-oxazolines [43]. Herein, we use this new catalyst for Suzuki and Heck coupling reactions. Previously immobilize Pd nanoparticles on Fe3O4 nanoparticles for C–C cross coupling reaction have been reported [44, 45]. According to the literature ZnO in this new catalyst system could play two roles. As described in the previous paragraph, ZnO can prevent the aggregation of Fe3O4 particles and provide surface Zn-OH groups. In addition, the free hydroxyl groups attached to the surface of ZnO nanoparticles were protonated and then Pd (II) was reduced to Pd (0) and located on the surface of ZnO via a surface interaction. So, ZnO could act as a reductant [46]. Thus new catalyst system can be well dispersed in the reaction medium, conveniently separated from the reaction mixture by using an external magnet, reused for several times without significant loss of its activity, and ligand-free conditions.

Experimental section

Chemicals were obtained from Fluka or Merck chemical company. Catalysts were characterized by power X-ray diffraction (XRD) on a Bruker D8-advance X-ray diffractometer with Cu Ka (1.54, 178 Å) incident radiation. The distribution and morphology of the product were analyzed by Leica Cambridge, model s360, version V03.03 scanning electron microscope (SEM) and transmission electron microscopy (Zeiss EM10C TEM) using an accelerating voltage of 80 kV. The amount of palladium on supports was determined by ICP analyzer (Varian, Vista-pro) and atomic absorption spectroscopy (AAS). X-ray photoelectron spectroscopy (XPS) measurements were conducted with a XR3E2 (VG Microtech) twin anode X-ray source using AlKα = 1486.6 eV). The specific surface areas [SSABET; (m2/g)] of the nanopowders were determined with the nitrogen adsorption measurement applying the BET method at 77 K (BELsorp-mini II). FT-IR spectra were run on a Shimadzu FTIR-8300 spectrophotometer. Melting points were determined in open capillary tubes in a Buchi-510 oil melting point apparatus.

Preparation of nano-Pd/Fe3O4/ZnO catalyst

Nano-Pd/Fe3O4/ZnO was synthesized as reported in our previous work [43]. The nitrate solution of palladium (0.0025 g/mL) and Fe3O4/ZnO (0.01 g/mL) were sonicated for 5 min. Then two solutions were mixed under vigorous stirring at room temperature. Subsequently, Na2CO3 solution (0.1 M) was added drop-wise to the mixed solution until the final pH of the solution was about 6.8. The products were washed with deionized water and ethanol two times and dried at 80 °C for 3 h.

General procedure for the Suzuki–Miyaura coupling reaction

A mixture of aryl halide (0.5 mmol), phenylboronic acid (0.5 mmol), K2CO3 (0.5 mmol), and nano-Pd/Fe3O4/ZnO (0.003 g, contain 9.7 × 10−5 mol% Pd), and H2O (1 mL) was stirred at 100 °C in an oil bath under air atmosphere. After completion of the reaction, the catalyst was removed by a magnet and the resulting mixture was quenched with water and extracted with EtOAc (2 × 10 mL). The combined organic layer was dried over anhydrous sodium sulfate (Na2SO4) and evaporated in a rotary evaporator under reduced pressure. Resulting product was purified by column chromatography on silica gel using n-hexane/ethyl acetate (5:1) as eluent to afford the pure product.

General procedure for the synthesis of (E)-ethyl cinnamate

A mixture of aryl halide (1 mmol), ethylacrylate (1 mmol), K3PO4 (1 mmol), nano-Pd/Fe3O4/ZnO (0.003 g), and DMF (1.0 mL) was put into a preheated oil bath at 100 °C for an appropriate period of time. Then, the reaction mixture was diluted with EtOAc and the catalyst was removed by a magnet. The filtrate was extracted with water and the organic layer dried over CaCl2 and evaporated under reduced pressure. Resulting products were purified by column chromatography over silica gel using n-hexane/ethyl acetate (5:1) as eluent to give the desired pure product with excellent yield.

General procedure for the synthesis of (E)-stilbene

A mixture of aryl halide (1 mmol), styrene (1 mmol), K3PO4 (1 mmol), nano-Pd/Fe3O4/ZnO (0.035 g), and DMF (1.0 mL) was put into a preheated oil bath at 100 °C for an appropriate period of time. All reactions were performed under inert atmosphere of N2. Then, the reaction mixture was diluted with EtOAc and the catalyst removed by a magnet. The filtrate was extracted with water, the organic layer dried over CaCl2 and evaporated under reduced pressure. The resulting products were purified by column chromatography over silica gel using n-hexane/ethyl acetate (5:1) as eluent to give the desired pure product with excellent yield. All compounds are known and were characterized by comparison of their physical and spectroscopic data with the authentic described in the literature.

Results and discussion

Characterization of the catalyst

Recently we reported the efficiency of nano-Pd/Fe3O4/ZnO in the synthesis of benzoxazoles and 2-oxazolines [43]. This catalyst was synthesized and fully characterized by powder X-ray diffraction (XRD), transmission electron microscopy (TEM), scanning electron microscopy (SEM), X-ray photoelectron spectroscopy (XPS), BET surface area measurement, FT-IR spectroscopy, and ICP analysis and some of these results are shown in Table 1 [42]. Using Debye–Scherrer formula: D = 0.9λ/βcosθ (where D is the average crystallite size, λ is the wavelength of Cu Ka, β is the full width at half maximum (FWHM) of the diffraction peaks, and θ is the Bragg’s angle), the average sizes of Pd/Fe3O4/ZnO is estimated to be about ~25.9 nm. The TEM image and XPS spectra of Pd3d of the synthesized nano-Pd/Fe3O4/ZnO are shown in (Fig. 1). Calculating the size particles of Pd by XRD or TEM was impossible because of very small amounts of Pd loaded on Fe3O4/ZnO; so according to XRD the peak of Pd(0) is not strong.

Catalytic activity of nano-Pd/Fe3O4/ZnO

Suzuki–Miyaura

Initially, the catalytic activity of nano-Pd/Fe3O4/ZnO was tested in Suzuki–Miyaura reaction of boronic acids and aryl halides under ligand-free conditions. To standardize the reaction conditions, we performed a series of reactions with several bases, solvents, temperatures, and catalyst concentration to obtain the best possible combination using the reaction of 4-bromoacetophenone and phenylboronic acid as model compounds (Tables 2, 3).

According to Table 2, different catalyst loadings between 0.0005 and 0.003 g were investigated. When the amount of the catalyst was increased no changes were observed in the yield of product 3a (almost 95 %) but the reaction time was decreased (Table 2, entries 1–4). Obviously, there was no reaction without the use of any catalyst (Table 2, entry 11). As known, solvent plays a crucial role in the rate and the product distribution of Suzuki coupling reactions. So, we screened various solvents in the model reaction. Experiments carried out in DMSO, DMF, DCM, EtOH, Toluene, and Ethane-1,2 diol yielded only trace to 68 % of the cross-coupling product and ~30–95 % the undesired homocoupling by-product. However, when we switched to H2O, complete conversion of 4-bromoacetophenone was observed, with only 1–2 % of the homocoupling by-product. So, we found that H2O was more effective than other solvents (Table 2, entries 4–10).

Then a series of bases and also the temperature were taken into consideration. The results are shown in Table 3. The base was found to have a pronounced effect in this reaction, and both K2CO3 and Cs2CO3 were found more effective, with KOH being almost as good, and KF.2H2O and Na2CO3.H2O gave the product in low yield. So, because K2CO3 is cheaper than Cs2CO3, K2CO3 was chosen. As expected, no reaction occurred without using of a base (Table 3, entry 11). The temperature of the reaction is also an important parameter. The best temperature was found at 100 °C (Table 3, entry 1).

To investigate the generality of the catalytic protocol, we performed reactions using various aryl halides with arylboronic acids under the optimized conditions. The results are shown in Table 4. Various substituted aryl iodides, and bromides with deactivated (electron rich) and activated (electron poor) groups were converted efficiently to the desired products in good to excellent yields within 0.8–3.3 h (Table 4, entries 1–13). Also, the coupling reaction could be efficiently carried out using arylboronic acids bearing either electron-rich or electron-poor substituted groups (Table 4, entries 8, 9). We also investigated whether aryl chlorides were active for the Suzuki–Miyaura reaction under the same conditions. In this case, the corresponding products were obtained in poor or moderate yields (Table 4, entries 14–18).

According to Table 4, the turnover number (TON) and turnover frequency (TOF) values were determined on the basis of the yield of formation of final product. These results showed very high efficiency of this nanocatalyst compared to that in the literature (see Table 5).

Mizoroki–Heck

Having established the efficacy of the nano-Pd/Fe3O4/ZnO in the Suzuki–Miyaura coupling reactions, we next turned our attention to Heck coupling reaction. In an effort to develop a good catalytic system, the coupling of iodobenzene and ethyl acrylate was investigated to optimize the reaction conditions (Table 6). Efficiency of this reaction is mainly affected by the amount of catalyst, temperature, and reaction time. For getting the best conditions, initially we started the condensation of iodobenzene and ethyl acrylate in the presence of nano-Pd/Fe3O4/ZnO (0.003 g) as a catalyst and K2CO3 (0.5 mol) H2O as solvent, at 100 °C, which led to a trace amount of product 5a. To enhance the yield of the desired product the base and solvent were changed. Different bases (Cs2CO3, KOH, Na2CO3, NaOt−Bu, and K3PO4) and solvents (DMSO, DMF, EtOH, CH3CN, THF, and DMF) were investigated. The results are summarized in Table 5. According to Table 6, K3PO4 is the most effective base in terms of the yield (85 %) and DMF indeed gave the best value for the reaction. Under the optimized reaction conditions, the reaction of ethyl acrylate with different aromatic halides was investigated (Table 7). The reaction proceeded smoothly with the formation of E-isomers with 60–90 % yields. The E-isomers products, as confirmed by 1H NMR spectroscopic analysis due to coupling constant, were obtained exclusively in all cases and comparing to the authentic results reported in the literature. In addition, it was found that aromatic halides with withdrawing groups were more active than that of electron donating groups.

Then we tried to study the Heck reaction between aryl halides and styrene to synthesize stilbene derivatives. Initially, we started the reaction of iodobenzene (1 mmol) and styrene (1 mmol) using K3PO4 (1 mmol) as base, DMF (1 mL) as solvent, and nano-Pd/Fe3O4/ZnO (0.003 g) as catalyst at 100 °C under air atmosphere (the same reaction conditions between 1h and 4a), which led to low yield (7 %) of E-1,2-diphenylethene. To enhance the yield of the desired product the reaction was carried out under N2 atmosphere. So, the reaction time decreased and the productivity of the reaction increased but was not very high. Hence, it was thought worthwhile to carry out the reaction in the presence of higher amount of the catalyst. As indicated in Table 8, maximum yield was obtained (73 %) when the reaction was loaded with 0.035 g of the catalyst (entry 2). A further increasing of catalyst loading does not affect the yield (entry 1). Detailed observations of all the reactions are given in Table 9. We observed that the catalyst was very active for the Heck reaction under such conditions.

For practical applications of heterogeneous catalysts, especially in industry, the heterogeneity and level of reusability are very important. To clarify this, the heterogeneity of the catalyst was evaluated to study whether the reaction using solid Pd catalysts occurred on the Fe3O4/ZnO surface or was catalyzed by Pd species in the liquid phase. To address this issue, two separate experiments were conducted with 4-bromotoluene and phenylboronic acid. In the first experiment, the reaction was terminated after 2 h; at this juncture, the catalyst was separated from the reaction mixture by an external magnet and the reaction was continued with the filtrate for an additional 3 h. In the second experiment, the reaction was terminated after 2 h. In both cases, the desired product was obtained in the same yield (30 %). Pd was not detected in the filtrate in either experiment by ICP analyzer. These studies demonstrate that only the Pd in the surface of Fe3O4/ZnO during the reaction is active, and the reaction proceeds on the heterogeneous surface.

The recovery and reusability of nano-Pd/Fe3O4/ZnO catalyst were also investigated in the Suzuki reaction of 4-bromoacetophenone and phenylboronic acid and Heck reaction of iodobenzene with ethyl acrylate. The results are shown in Fig. 2. In both reactions, after completion for the first reaction to afford the corresponding product, the catalyst was recovered magnetically, washed with EtOAc and water, and finally dried at 80 °C. A new reaction was then performed with fresh solvent and reactants under the same conditions. As can be seen in Fig. 3, nano-Pd/Fe3O4/ZnO catalyst could be used more than four times without change in activity. Also, the XRD pattern of the catalyst after fourth recovery is shown in Fig. 3, and no changes or impurities were observed.

Furthermore, metal leaching was studied by ICP analysis of the catalyst before and after (fourth times) the reaction. The Pd concentration was found to be 9.7 × 10−5 mol% before the reaction and 7 × 10−5 and 6.5 × 10−5 mol% after the fourth cycle for Suzuki and Heck reactions, respectively, which confirmed insignificant Pd leaching. However, no Pd metal was detected in the final coupled products.

Conclusion

In conclusion, small Pd supported on Fe3O4/ZnO as a magnetic nanoparticle catalyst was prepared through a very simple and low-cost method. In this work, the catalyst exhibited excellent activities for the Suzuki–Miyaura and Heck reactions. The catalyst has the advantage to be completely recoverable with the simple application of an external magnet, while without considerable deactivation in catalytic activity during the reuse process. Furthermore, the Pd/Fe3O4/ZnO catalyst not only solves the basic problems of catalyst separation and recovery but also avoids the use of phosphine ligands in comparison with the homogeneous Pd catalyst system.

References

P.M. Maitlis, A. Haynes in Metal Catalysis in Industrial Organic Processes, ed. by G.P. Chiusoli, P. M. Maitlis (RSC Publishing, Cambridge, 2006) pp. 146–162

F. Calderazzo, M. Catellani, G.P. Chiusoli in Metal-catalysis in Industrial Organic Processes, ed. by G.P. Chiusoli, P.M. Maitlis (RSC Publishing, Cambridge, 2006), pp. 163–175

R.F. Heck, J.P. Nolley, J. Org. Chem. 37, 2320–2322 (1972)

H.A. Dieck, R.F. Heck, J. Am. Chem. Soc. 96, 1133–1136 (1974)

N. Miyaura, K. Yamada, A. Suzuki, Tetrahedron Lett. 20, 3437–3440 (1979)

M. Larhed, A. Hallberg, in Handbook of Organopalladium Chemistry for Organic Synthesis, ed. by E. Negishi (WileyInter-science, New York, 2002)

I.P. Beletskaya, A.V. Cheprakov, Chem. Rev. 100, 3009–3066 (2000)

A. Corma, H. Garcia, Adv. Synth. Catal. 348 1391–1412 (2006)

J.A. Widegren, R.G. Finke, J. Mol. Catal. A: Chem. 198, 317–341 (2003)

L.X. Yin, J. Liebscher, Chem. Rev. 107, 133–173 (2007)

B. Karimi, S. Abedi, J.H. Clark, V. Budarin, Angew. Chem., Int. Ed. 45 4776–4779 (2006)

V. Polshettiwar, P. Hesemann, J.J.E. Moreau, Tetrahedron 63, 6784–6790 (2007)

A.K. Nezhad, F. Panahi, Green Chem. 13, 2408–2415 (2011)

S.S. Prockl, W. Kleist, M.A. Gruber, K. Kohler, Angew. Chem. Int. Ed. 43, 1881–1882 (2004)

M. Poyatos, F. Marquez, E. Peris, C. Claver, E. Fernandez, New J. Chem. 27, 425–431 (2003)

J. Zhu, J.H. Zhou, T.J. Zhao, X.G. Zhou, D. Chen, W.K. Yuan, Appl. Catal. A 352, 243–250 (2009)

L. Zhou, C. Gao, W. Xu, Robust Langmuir 26, 11217–11225 (2010)

J.M. Thomas, B.F.G. Johnson, R. Raja, G. Sankar, P.A. Midgley, Acc. Chem. Res. 36, 20–30 (2003)

Y. Zhu, L.P. Stubbs, F. Ho, R. Liu, C.P. Ship, J.A. Maguire, N.S. Hosmane, Chem. Cat. Chem. 2, 365–374 (2010)

V. Polshettiwar, R.S. Varma, Org. Biomol. Chem. 7, 37–40 (2009)

S. Shylesh, V. Schünemann, W.R. Thiel, Angew. Chem. Int. Ed. 49, 3428–3459 (2010)

M. Kawamura, K. Sato, Chem. Commun. 45, 4718–4719 (2006)

C.W. Lim, I.S. Lee, Nano Today 5, 412–434 (2010)

K.I. Tanaka, Catal. Today 154, 105–112 (2010)

V. Polshettiwar, B. Baruwati, R.S. Varma, Green Chem. 11, 127–131 (2009)

A. Hu, G.T. Yee, W.B. Lin, J. Am. Chem. Soc. 127 12486–12487 (2005)

N.T.S. Phan, C.S. Gill, J.V. Nguyen, Z.J. Zhang, C.W. Jones, Angew. Chem. Int. Ed. 45, 2209–2212 (2006)

R. Abu-Reziq, H. Alper, D. Wang, M.L. Post, J. Am. Chem. Soc. 128, 5279–5282 (2006)

C.O. Dalaigh, S.A. Corr, Y. Gun’ko, S. J. Connon Angew. Chem. Int. Ed. 46, 4329–4332 (2007)

A.H. Lu, E.L. Salabas, F. Schuth, Angew. Chem. Int. Ed. 46, 1222–1244 (2007)

F. Shi, M.K. Tse, S.L. Zhou, M.M. Pohl, J. Radnik, S. Hubner, K. Jahnisch, A. Bruckner, M. Beller, J. Am. Chem. Soc. 131, 1775–1779 (2009)

R. Luque, B. Baruwati, R.S. Varma, Green Chem. 12, 1540–1543 (2010)

S.H. Xuan, W.Q. Jiang, X.L. Gong, Dalton. Trans. 40 7827–7830 (2011)

J.M. Liu, X.G. Peng, W. Sun, Y.W. Zhao, C.G. Xia, Org. Lett. 10, 3933–3936 (2008)

B. Baruwati, D. Guin, S.V. Manorama, Org. Lett. 9, 5377–5380 (2007)

Z.F. Wang, P.F. Xiao, B. Shen, N.Y. He, Colloid. Surface A. 276, 116–121 (2006)

P.D. Stevens, G.F. Li, J.D. Fan, M. Yen, Y. Gao, Chem. Commun. 4435–4437 (2005)

Y. Zheng, P.D. Stevens, Y. Gao, J. Org. Chem. 71, 537–542 (2006)

A. Ashour, M.A. Kaid, N.Z. El-Sayed, A.A. Ibrahim, J. Appl. Surf. Sci. 252, 7844–7848 (2006)

T. Wakano, N. Fujimura, Y. Morinaga, N. Abe, A. Ashida, T. Ito, Physica E 10, 260–261 (2001)

J. Wan, H. Li, K. Chen, Mater. Phys. Chem. 114, 30–32 (2009)

M. Hosseini-Sarvari, A. Khanivar, F. Moeimi, J. Mat. Sci. 50, 3065–3074 (2015)

E. Nehlig, B. Waggeh, N. Millot, Y. Lalatonne, L. Mottea, E. Guénin, Dalton Trans. 44 501–505 (2015)

M.A. Zolfigol, V. Khakyzadeh, A. Moosavi-Zare, A. Rostami, A. Zare, N. Iranpoor, M.H. Beyzavie, R. Luquef, Green Chem. 15, 2132–2140 (2013)

X.-Y. Xue, Z.-H. Chen, L.-L. Xing, C.-H. Ma, Y.-J. Chen, T.-H. Wang, J. Phys. Chem. C 114 18607–18611 (2010)

L.-L. Xing, C.-H. Ma, Z.-H. Chen, Y.-J. Chen, X.-Y. Xue, Nanotechnology 22(215501) 7 (2011)

A.J. Amali, R.K. Rana, Green Chem. 11, 1781–1786 (2009)

B. Karimi, F. Mansouria, H. Valib, Green Chem. 16, 2587–2596 (2014)

M. Zhu, G. Diao. J. Phys. Chem. C 115, 24743–24749 (2011)

H.A. Elazab, A.R. Siamaki, S. Moussaa, B.F. Guptona, M.S. El-Shalla, Appl. Catal. A: General 491, 58–69 (2015)

Acknowledgments

We are grateful to Shiraz university research council for the support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hosseini-Sarvari, M., Khanivar, A. & Moeini, F. Palladium immobilized on Fe3O4/ZnO nanoparticles: a novel magnetically recyclable catalyst for Suzuki–Miyaura and heck reactions under ligand-free conditions. J IRAN CHEM SOC 13, 45–53 (2016). https://doi.org/10.1007/s13738-015-0710-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-015-0710-0