Abstract

The aim of this study was to prepare mosquito repellent textiles. To compare bio-based and synthetic mosquito repellent agents, limonene and permethrin were encapsulated with ethyl cellulose shell. Coacervation was employed, which is a simple and reproducible method for the encapsulation with high production efficiency. Morphological assessment showed that the capsules had smooth surfaces and their shape was spherical. The homogenous size distribution of the capsules was supported by laser diffraction analysis. The capsules showed narrow size distribution and the mean particle size of the optimum formulations for limonene and permethrin was 1 and 1.3 μm, respectively. The size of the produced capsules was considered suitable for textile applications. The FTIR spectra revealed the similarity of the chemical structure of capsules with shell material. Cotton fabrics were treated separately with limonene and permethrin capsules by padding method. The presence of capsules on the fabrics was determined after 20 washing cycles. Insecticide activity was evaluated against common house mosquitoes (Culex pipiens), with respect to cone bioassay of World Health Organization (WHO). Mosquitoes were tended to stay away from treated fabrics, and mortality rates of mosquitos were noted as 41% and 54% for limonene and permethrin, respectively. Although efficacy of fabrics decreased with increasing washing, the fabrics still showed repellency after 20 washing cycles. This study showed that the developed product might be used as an alternative to the other products in the market for avoiding mosquito-borne diseases.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Insects have many functions that can be considered both beneficial and harmful to human beings and they play a considerable part in human life. They transmit many diseases, which may adversely affect human life. They can cause significant damages to agricultural products and materials made from natural raw materials such as wool and cotton used in textile industry [1]. Some of them may be annoying by stinging or biting, and some can only disturb human beings with their sounds or appearance. On the other hand, they have a significant role in natural balance. They transfer pollen and help the cultivation of agricultural products, and serve as nutrients of many upper organisms in the food chain. They transform various organic wastes, and from time to time, they are useful as human food. By considering all the above points, their destruction by mass purge would damage our living environment and cause ecological disaster [2].

Mosquitoes are one of the most harmful insects. They carry and transmit arboviruses such as malaria, dengue fever, and zika [3]. There are numerous methods developed to protect humans from mosquitoes. Besides mass insecticide applications, there are several types of personal applications. One of the most common methods is to keep away the insects by a simple mosquito net. However, it can only be used when the person is motionless. Also, mosquito coils, which are insecticide-impregnated spiral shaped incenses, candles, lanterns, and torches, are generally used outdoors. Even they are relatively effective, the smoke of incense may contain contaminants that can cause health concerns, in addition to fire risk. There are also many commercial insect repellent products in different forms such as spray, aerosol, or lotion in the market. Because they are applied directly to the skin, they may cause undesired skin reactions. Encapsulation of insecticides is an alternative way to avoid excessive usage of insecticides. With using micro- and nano-sized capsules in textile finishing, it is possible to produce wash-resistant textile products that are effective even if less active substance is used [2, 4, 5].

Basically, encapsulation produces small spheres covered with a thin shell film to protect the active substance. With encapsulation technology, it is possible to protect easily perishable substances such as insecticides, antimicrobials, and antioxidants by environmental factors like oxygen, heat, and light. In addition, people are exposed to much lower doses of these substances. Encapsulation of insect repellents has become appealing not only by the above reasons but also because of prolonging the desired effect. It has been possible to preserve the functional properties through encapsulation [6, 7].

Ethyl cellulose (EC), which is chosen as shell material, is a rigid, thermoplastic, and hydrophobic material. This polymer is resistant to water, alkali, and salt. It is compatible with the coacervation technique and can be applied to textile surface [8, 9]. Permethrin is a poorly water-soluble synthetic insecticide in the pyrethroid group. It is determined as Class II, moderately hazardous according to hazard classification of WHO pesticides guideline and it is recommended for the finishing applications to mosquito nets. Permethrin is a contact and digestive effective insecticide. The mechanism of action is through neuronal membranes called neurotoxins. Due to its good solubility in oil, it is absorbed rapidly through cuticle of the insect and shows its toxic effect. The toxicity is low against non-target livings such as mammals and skin absorption is weak. Therefore, it is preferred in public health pest control [10,11,12]. Limonene is a highly volatile oil and is derived usually from citrus family. It has been widely used in food and cosmetic industries owing to its pleasant smell and flavor. This natural active agent is also employed in many products due to its insecticide feature. Limonene was found to be as effective as N,N-diethyl-m-toluamide (DEET), which is a potent synthetic insecticide, when used at the same dose. However, due to its volatile nature, it loses effectiveness by quick evaporation, and end-users become vulnerable against insects [6, 13].

The insect repellents, such as DEET and permethrin, do not have good water solubility. In direct use, some insecticidal agents especially natural oils stain the textile products. Beside that, they may cause allergic reactions in the skin due to direct contact. Moreover, the washing resistance of these products is limited. Thus, studies on encapsulation are carried out to overcome these disadvantages. Polyurea capsules containing diazinon were formed by interfacial polymerization. Mean diameter of the capsules was determined as 36 µm and pH-triggered insecticide release was up to 130 days [14]. Eucalyptol was encapsulated with sodium alginate by interfacial insolubilization reaction. Release of the active agent was assessed by estimating the finger forces [15].

In another study, citronella was encapsulated with chitosan using modified orifice method [16]. DEET melamine capsules were applied to a polyester net fabric. The insecticidal effect was examined using tunnel test against Anopheles gambia mosquitoes [17]. The MCT-β-CD complexes containing cypermethrin and prallethrin were produced separately and applied to the fabrics. Bioassays against mosquitoes (non-defined) have shown that the fabrics treated with these complexes are more effective even after washing than those fabrics soaked only into solutions of these insecticidal agents [18]. MCT–β-CD complexes with limonene were formed. Insecticidal effect of fabrics grafted with inclusion complexes was compared with those of fabrics impregnated and coated with limonene solutions. As the concentration and exposure time increased, the toxicity on mosquitoes was recorded to increase [6]. Gelatin–gum Arabic capsules containing citronellal were produced with complex coacervation and the long-lasting insecticidal effect of the fabrics treated with these capsules was determined [19]. In a later study, citriodiol and citronella essential oil, encapsulated into gelatin–arabic gum polymer, mixed, and compared with commercial melamine–formaldehyde capsules containing citriodiol [20]. In vivo behavior of DEET–β-CD and eucalyptol–β-CD complexes-treated fabrics on Hyalomma marginatum ticks was investigated by Inceboz et al. [21]. Sittipummongkol et al. used spray dying method to encapsulate neem oil in three different shell polymers: PVA, gum Arabic, and whey protein isolate/maltodextrin [22]. Eucalyptus oil and cedar wood oil were encapsulated with gum arabic by simple coacervation method. Insect repellency behavior of fabrics treated with capsules tested against silverfish (Lepisma saccharina) insect was defined [23].

In this study, one chemical (permethrin) and one natural (limonene) insecticidal agents were used as core materials and they were encapsulated with ethyl cellulose (EC) shell by coacervation method. Microcapsule formulations were examined by scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), and particle-size distribution analyses. The optimum formulas were applied to cotton fabrics separately by the impregnation method. To evaluate the effect of active agent and capsule endurance on fabric, in vitro mosquito repellency assays were conducted before and after washing.

Today, insect-borne diseases are affecting human life enormously. Therefore, it is necessary to maintain such studies to prevent mosquito-borne diseases. There are different studies regarding mosquito repellency of fabrics in the literature. In many of these studies, synthetic active agents were employed as insecticide. This study is focused on encapsulation and comparison of synthetic and natural insecticidal agents. It shows that natural products can be as effective as synthetic products. Also, it is important to obtain wearable insect repellent product ensuring sufficient durability against domestic washing. In addition, this study is essential because of in vitro tests performed with Culex pipiens.

Experimental

Materials

In this research, desized, mill scoured, and bleached plain weave cotton fabric (specific weight 130 g/m2) was used. The shell material EC Premium 4 was donated from Dow Chemicals, Istanbul, Turkey. Limonene (Sigma-Aldrich) and permethrin (Farmatek, Turkey) were employed as core materials. Tween 20 was used as a surfactant. The surface active agent, ethanol and ethyl acetate (EA) were supplied from Merck, Darmstadt, Germany. Acrylic-based commercial binder “ORGAL NA 366” (Organik Kimya A.Ş) was used. All other auxiliary chemicals used in the study were of laboratory-reagent grade.

Preparation of nano- and micro- capsules

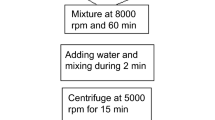

Encapsulation of active agents was performed by coacervation method. Coacervation method is one of the leading production methods of microencapsulation of water-insoluble active agents. Fundamentally, active agents dissolved in an aqueous system are separated to droplets with the help of high shear mixer. Each of these droplets, dispersed in the system, is coated by a thin film of polymer. The liquid film of polymer must be solidified before water removal of the system. Afterward, capsules are isolated [24,25,26]. In this process, capability of water-insoluble polymers to interact with water was used to form the capsules. The organic phase, composed of active agent and EC, was prepared by dissolving the appropriate amount of these ingredients in the solvent (EA) using a magnetic stirring bar. After that, the polymer-rich organic phase was added slowly to the polymer-free aqueous phase. The organic phase was separated into micro-droplets with a high shear homogenizer (Silverson) at 8000 rpm. Every single droplet was coated with a thin film of shell material, simultaneously. Subsequently, the liquid film was solidified by adding water into the system. A centrifuge machine was used at 5000 rpm (3689 RCF/g) for 15 min for removing water and obtaining microcapsule slurry. At the final step, the slurry was treated with an ultrasonic bath for having smoother structure and drying at laboratory conditions.

Characterization of nano- and micro- capsules

Several characterization analyses were performed to determine the specified formula. Encapsulation yield was calculated according to the ratio of practical mass to theoretical mass. Equation of production yield is as follows:

Morphological properties of insect repellent capsules were examined through scanning electron microscopy (SEM) images. The analysis was carried out with a Quanta 250 FEG SEM. Capsules were gold-coated to provide electrical conductivity (15 mA, 2 min). The images were taken at 10,000 × magnification.

Fourier transform infrared spectroscopy (FTIR) analysis was performed to determine encapsulation performance with the changes in the infrared spectrum. Measurements were taken at a wavelength range of 4000–400 cm−1 using a Perkin Elmer Frontier FTIR device. The obtained spectra were smoothed to remove the noises with official software of the device.

To determine the size of the resulting capsules, a Malvern Zeta sizer Nano-S particle-size distribution tester was used. Before measurement, an aqueous solution of capsules in a certain rate was prepared and sonicated in an ultrasonic bath until forming a good mixture. After that, the capsule dispersion was put in disposable cuvettes. Then, the light emitted by the laser Doppler passed through the dispersion.

Textile treatment

An application bath was prepared including insect repellent capsules (40 g/L) and acrylic-based binder (50 g/L). The fabrics were impregnated in the bath and squeezed through the rollers, so that wet pick-up became 90%. The fabrics were exposed to a one-step drying and fixation process (7 min at 120 °C) in a laboratory stenter [27,28,29].

Evaluation of treated fabrics and in vitro studies

The capsule-treated fabrics were washed separately for 1, 10, and 20 times at 40 °C for 30 min, according to ISO 105-C06:2010. An ECE non-phosphate reference detergent (A) (4 g/L) was used. The fabrics were rinsed and then dried in laboratory conditions.

Insecticidal activity of the limonene and permethrin capsules-treated fabrics was evaluated against female mosquitoes (Culex pipiens) in accordance with cone bioassays of WHO 2005 standard guidelines for laboratory and field testing of long-lasting insecticidal mosquito nets [30]. The test was conducted at 28 °C with 50–70% ambient humidity. For the trials, a 60° inclined test apparatus was designed. After the test fabrics were laid on the test set-up, transparent cones were placed on equal intervals. Mosquitoes were loaded into the test system from the narrow rim of the cones and contacted with the fabrics for 30 min. Afterwards, the mosquitoes were placed in a separate monitoring device with an aspirator system and life conditions were observed for 24 h. The experiments were repeated three times for each group of fabrics: untreated (control), treated, and washed (Fig. 1). The mosquitoes that cannot stand cannot fly in a coordinated manner, lie on its back, move legs and wings, but unable to take off, can stand, and take off briefly, but falls down immediately were defined as moribund. The mosquitoes that were immobile and did not show a sign of life were defined as knock-down with the assessment made after 30 min and were named as dead with the assessment made after 24 h. Mortality of the control fabric was found 5.00%. Corrected mortality should be calculated if the control mortality was ranged from 5 to 20%. Therefore, corrected mortality in percentage was calculated using Abbott’s formula [30,31,32]:

Results and discussion

Encapsulation studies were carried out at 1:1, 2:1, 4:1, and 10:1 polymer/active agent (w/w) ratio. Formulations of limonene and permethrin capsules and the production yield are given in Table 1. In the centrifuge step, no precipitate was formed for Li M1, Per M1, and Per M2 formulations. This may be due to the fact that the active substance concentration is too high, and therefore, the encapsulation does not occur. A relatively small quantity of sample was collected from the bottom of the centrifugal tube. Therefore, the production yield was not calculated for these formulations. For the other formulations, the yield of the capsules ranged between 41 and 85% (w/w), which can be considered relatively high (Table 1). A reduction in the amount of active substance in the formulation affected the production efficiency positively.

Capsules produced by the conservation method are usually characterized by their spherical shape and the mean particle diameter is determined using several factors such as aqueous phase to polymer ratio and the shearing rate. Typical photomicrographs obtained by SEM of the capsules show that the product is composed mainly of spherically shaped particles (Figs. 2 and 3). Although Li M1 capsules seem to have a spherical form, homogeneity was not observed in size distribution. Furthermore, this formulation is not applicable, because the capsule yield is very low. In the Li M2 formulation in which the amount of active substance was reduced, substantially homogeneous and spherical capsules were produced. In the formulations of Li M3 and Li M4, spherical and smaller capsules were successfully formed. It was also indicated that the capsules obtained from Li M2, Li M3, and Li M4 formulations have homogeneous characteristics with smooth appearance and do not show the presence of free active agents on their surfaces (Fig. 2).

In the encapsulation process, no capsules were precipitated in the Per M1 formulation and only a very small amount of Per M2 capsules was obtained. Therefore, Per M1 samples for SEM were prepared from oily supernatants. Technically, it was not possible to take the photomicrographs larger than 1000 × magnification for Per M1 formulation. Images of Per M1 and Per M2 showed that capsules were mostly aggregated and free permethrin was present on the surface of the capsules. This may be the reason why the capsules cannot be precipitated in these formulations. On the contrary, Per M3 capsules were found to be morphologically spherical, separated, and nano-meter sized. The particle-size distribution was determined to be consistent. Per M4 capsules were also found to be spherical and particle distribution of capsules was relatively homogeneous (Fig. 3).

The mean particle size and distribution of these particles are also important for the textile application. The mean particle size of capsules was determined by laser diffraction method and changes in the size due to changing polymer to active agent ratio were observed. When the particle-size distribution analysis of limonene capsules was examined, it was found that approximately 90% of the Li M1 and 80% of the Li M2 formulations were between 1.41 and 0.9 µm, respectively. Similarly, Li M3 and Li M4 were found to have an average particle size of 1 µm, representing approximately 90% of the total mass. It was seen that Li M3 capsules had a more uniform particle distribution than other formulations, with a slight difference with Li M4 (Fig. 4).

The particle-size distribution of permethrin capsules is given in Fig. 5. It was determined that Per M1 particles were distributed in different size ranges. It was found that 35%, 43%, and 22% of particles were concentrated at 89 nm, 0.4 µm, and 0.8 µm, respectively. Per M2 capsules were found to be relatively small, which showed a regular particle distribution, and 99% had an average particle size of 9 nm. It was found that Per M3 capsules had a relatively larger particle size than Per M2, but approximately 95% had an average size of about 1.3 µm. It was observed that the distribution of Per M4 capsules was less uniform than that of Per M2 and Per M3, and 91% of the capsules were collected in a particle-size range of 1 µm.

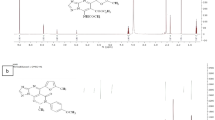

The FTIR spectra of limonene capsules and the materials forming them are given in Fig. 6. The limonene spectrum is in accordance with the related literature [33]. The characteristic peaks of limonene were obtained at 2918 cm−1 (–C–H stretching), 1645 cm−1 (–C=C stretching), 1436 cm−1 (–C − H bending), and 885 cm−1 (out-of-plane bending) When the IR spectrum of EC was examined, the stretching vibrations of characteristic –C–O–C– band and –C−H band were observed at 1054 cm−1 and at 2870 and 2972 cm−1, respectively. C−H bending was located at 1375 cm−1. When the spectra of the capsules were examined, both EC and limonene peaks were identified. The strong peak of EC at 1053 cm−1 aroused from –C–O–C– band was observed in all formulations. The C–H bands, obtained at 2973 and 2870 cm−1, were found to be deeper than EC peaks and close to the peak intensity of limonene. This may indicate successful encapsulation. In addition, the bands originating from the C=O stretch appear at 1735 cm−1. This may be due to the use of ethyl acetate.

In Fig. 7, the FTIR spectra of permethrin capsules are presented. Many sharp characteristic peaks of permethrin between 4000 and 550 cm−1 can be observed, which are defined earlier in the literature [34]. The C=O-stretching vibrations of carbonyl groups were seen at 1724 cm−1 and the asymmetric stretching vibrations of C–O–C were observed at 1283 cm−1. The peaks at 1214 and 1162 cm−1 indicate C–O-stretching vibration. In-plane and out-of-plane deformation vibrations occurred at 816 and 690 cm−1, respectively. When the spectra of capsules were examined, both EC and permethrin characteristic bands were observed. The missing permethrin and limonene bands in the spectrum of capsules were considered as a result of capsulation. Thus, it was considered that the active agents were captured inside the EC shell.

According to the performed analysis, optimum capsule formulas were determined as Li M3 and Per M3. These formulations were preferred for use in the textile finishing studies, since they had smoother surfaces and better particle-size distributions, and they were morphologically more uniform. Also, the production yield was relatively higher: 62% and 52% for Li M3 and Per M3, respectively. After that, the selected formulas were applied to cotton fabrics separately, and the capsule-treated fabrics were washed for 1, 10, and 20 times. The SEM micrographs of the fabrics including limonene and permethrin capsules are exhibited in Figs. 8 and 9, respectively. These images showed that capsule application succeeded for both formulations. It was observed that capsules were covered with the binder and fixed onto the textile surface. Also, the effect of repeated washings on capsules was evaluated. Capsules on the textile surface and also embedded in the binder were observed even after 20 washes for both formulations.

The fabrics including insect repellent capsules were also subjected to insect repellent activity test in accordance with WHO standard. The assays were performed for treated and washed fabrics. The results of knock-down and mortality rates are tabulated in Table 2. No knock-down (KD) was observed just after contact with the control fabrics. 24 h mortality rate was found to be 5.00%; therefore, the corrected mortality rate was calculated. The first observations after contact (30 min KD) showed that there were no significant knock-downs for all the fabrics treated with capsules. However, after 24 h, mortality was found to be 53.9% and 40.8% for fabrics finished with permethrin and limonene capsules, respectively. It is concluded that the insects were exposed to a relatively lower amount of insecticide after 30 min of exposure due to the polymer barrier. Yet, the fabrics showed delayed killing action in 24 h [6, 35]. Although the mortality rate of mosquitoes decreased with increased washing, insecticidal effect was detected even after 20 washes. After washings, 24 h mortality ratios were found to be similar in limonene and permethrin capsule-containing fabrics as 19.4% and 18.6%, respectively (Fig. 10). In addition, it was monitored that mosquitoes contacted with the capsule-containing fabrics were relatively more immobile than those contacted with control fabrics. Mosquitoes that have been in contact with the fabrics containing both active agents exhibited an inability to fly or stand on their legs.

Conclusion

The aim of this study was to develop an alternative method for prevention of mosquito-borne diseases. In this research, two different insecticidal active substances, one natural “limonene” and another synthetic “permethrin”, were encapsulated by coacervation method and then successfully applied on cotton fabrics. The capsules remained on the fabric and have been able to maintain the insecticidal effect at a certain rate after 20 washes. There was also a reduction in the ability of the mosquitoes’ fly or standing that contacted with fabrics containing both active substances. It was found that the fabrics containing limonene capsules showed relatively less mortality against Culex pipiens than those containing permethrin. With using active agents in capsular form, insecticides ensured with a considerably low dose of insecticides. In addition to that, because the active ingredient is surrounded by a polymer, the end-user would not be in constant contact with these agents like some products on the market (such as incest repellent aerosols and lotions). Thus, acute and long-term adverse effects can be avoided. Furthermore, since the active ingredients are resistant to washing and oxidation with encapsulation, there would be no need for repeated application with the developed product. In this way, end-users will be able to reduce or quit using the topical products. The results revealed that textile products treated with capsules containing limonene and permethrin exhibit appropriate properties for insect repellency, and they might be an effective and promising alternative to the products in the market.

References

Shahid M, Mohammad F (2013) Perspectives for natural product based agents derived from industrial plants in textile applications—a review. J Clean Prod 57:2–18

Becker N, Petric D, Zgomba M, Boase C, Madon M, Dahl C, Kaiser A (2010) Mosquitoes and their control. Springer, Heidelberg

Benelli G, Mehlhorn H (2018) Mosquitoe-borne diseases. Springer, Dusseldorf

Agnihotri A, Wazed Ali S, Das A, Alagirusamy R (2019) 11 - Insectrepellent textiles using green and sustainable approaches. In: Islam S, Butola BS (eds) The impact and prospects of green chemistry for textile technology, The Textile institute book series. Woodhead Publishing, pp 307–325. https://doi.org/10.1016/B978-0-08-102491-1.00011-3

Chatha SAS, Asgher M, Asgher R, Hussain AI, Iqbal Y, Hussain SM, Bilal M, Saleem F, Iqbal HMN (2019) Environmentally responsive and anti-bugs textile finishes—recent trends, challenges, and future perspectives. Sci Total Environ 690:667–682

Hebeish A, Fouda MG, Hamdy IA, El-Sawy SM, Abdel-Mohdy FA (2008) Preparation of durable insect repellent cotton fabric: limonene as insecticide. Carbohyd Polym 74:268–273

Rodrigues SN, Martins IM, Fernandes IP, Gomes PB, Mata VG, Barreiro MF, Rodrigues AE (2009) Scentfashion®: microencapsulated perfumes for textile application. Chem Eng J149:463–472

Erkan G, Sarıışık M (2015) Antifungal microcapsules of ethyl cellulose by solvent evaporation and their application to cotton fabric. Fibres Tex East Eur 6:125–130

Badulescu R, Vivod V, Jausovec D, Voncina B (2008) Grafting of ethylcellulose microcapsules onto cotton fibers. Carbohyd Polym 71:85–91

World Health Organization (2009) The WHO recommended classification of pesticides by hazard and guidelines to classification 2009. WissenchaftlicheVerlagsgesellschaftmbH, Stuttgart

Anjali CH, Sudheer Khan S, Margulis-Goshen K, Magdassi S, Mukherjee A, Chandrasekaran N (2010) Formulation of water-dispersible nanopermethrin for larvicidal applications. Ecotoxicol Environ Sa 73:1932–1936

Li W, Lu B, Sheng A, Yang F, Wang Z (2010) Spectroscopic and theoretical study on inclusion complexation of beta-cyclodextrin with permethrin. J Mol Struct 981:194–203

Maia MF, Moore SJ (2011) Plant-based insect repellents: a review of their efficacy, development and testing. Malar J 10:1–14

Hirech K, Payan S, Carnelle G, Brujes L, Legrand J (2003) Microencapsulation of an insecticide by interfacial polymerization. Powder Technol 130:324–330

Chang CP, Dobashi T (2003) Preparation of alginate complex capsules containing eucalyptus essential oil and its controlled release. Colloids Surf B 32:257–262

Wen-Chuan H, Chih-Pong C, Ying-Lin G (2006) Controlled release properties of chitosan encapsulated volatile citronella oil microcapsules by thermal treatments. Colloids Surf B 53:209–214

N’Guessan R, Knols BGJ, Pennetier C, Rowlanda M (2008) DEET microencapsulation: a slow-release formulation enhancing the residual efficacy of bed nets against malaria vectors. Trans R Soc Trop Med Hyg 102:259–262

Abdel-Mohdy FA, Fouda MMG, Rehan MF, Aly AS (2008) Repellency of controlled-release treated cotton fabrics based on cypermethrin and prallethrin. Carbohyd Polym 73:92–97

MiróSpecos MM, García JJ, Tornesello J, Marino P, Della Vecchia M, Tesoriero MD, Hermida LG (2010) Microencapsulated citronella oil for mosquito repellent finishing of cotton textiles. Trans R Soc Trop Med Hyg 104:653–658

MiróSpecos MM, García J, Gutierrez AC, Hermida LG (2017) Application of microencapsulated biopesticides to improve repellent finishing of cotton fabrics. J Text I 108:1454–1460

İnceboz T, Erkan G, Türkoğlu GC, Sarıışık AM, Bakırcı S, Üner S, Üner A (2015) In-vivo and in-vitro tick repellent properties of cotton fabric. Text Res J 85:2071–2082

Sittipummongkol K, Chuysinuan P, Techasakul S, Pisitsak P, Pechyen C (2019) Core shell microcapsules of neem seed oil extract containing azadirachtin and biodegradable polymers and their release characteristics. Polym Bull 76:3803–3817

Sharma R, Goel A (2018) Development of insect repellent finish by a simple coacervation microencapsulation technique. Internat J Cloth Sci Tech 30:152–158

Cheng SY, Yuen CWM, Kan CW, Cheuk KKL (2008) Development of cosmetic textiles using microencapsulation technology. RJTA 12:41–51

Peniche C, Arguelles-Monal W, Peniche H, Acosta N (2003) Chitosan: an attractive biocompatible polymer for microencapsulation. Macromol Biosci 3:511–520

Ghosh SK (2006) Functional coatings and microencapsulation: a general perspective. In: Ghosh SK (ed) Functional coatings: by polymer microencapsulation. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. https://doi.org/10.1002/3527608478.ch1

Türkoğlu GC (2013) Production and characterization of various capsules which are gained functional properties to textile materials. MSc Thesis, DokuzEylul University, The Graduate School of Natural and Applied Sciences 2013.

Türkoğlu GC, Sarıışık AM, Erkan G, Deveci Ö, Yıkılmaz MS, Kontart O, Öztuna S (2013) Durable insect repellent behaviour of cotton fabric by permethrin capsules. In: 1st International Conference On Natural Fibers, Portugal

Türkoğlu GC, Sarıışık AM, Erkan G, Deveci Ö, Yıkılmaz MS, Kontart O, Öztuna S (2013) Microencapsulated limonene loaded textile and its insect repellent behavior. In: 14th National & 1st International recent developments, textile technology and chemistry symposium, Turkey

World Health Organization (2005) Guidelines for laboratory and field testing of long-lasting insecticidal mosquito nets WHO/CDS/WHOPES/GCDPP/ 2005.11

Abbott WS (1925) A method of computing of the effectiveness of an insecticide. J Econ Entomol 8:265–267

Anoopkumar AN, Puthur S, Rebello S, Aneesh EM (2017) Screening of a few traditionally used medicinal plants for their larvicidal efficacy against aedesaegyptilinn (diptera: culicidae), a dengue fever vector. SOJ Microbiol Infect Dis 5:1–5

Sharma S, Srivastava AK (2005) Free radical copolymerization of limonene with butyl methacrylate: synthesis and characterizaton. Indian J Chem Tech 12:62–67

Minkwan K, Seung HS, Han DG (2014) Nonvolatile insect repelling agent prepared by grafting of permethrin on polybutadiene. Macromol Res 22:1348–1351

Shahba AF, Halawa O, Ragaei M, Hashem M (2011) Development of longer-lasting insect repellence cellulosic based curtain fabrics. Mater Sci Appl 2:200–208

Acknowledgements

This study (00783.STZ.2011-1) was funded by Ministry of Science, Industry and Technology, Republic of Turkey. We also would like to thank Organik Kimya for partial financial support and acknowledge engineer Selda ÖZTUNA for utilizing the facility of the laboratories. We would also like to thank and commemorate Prof. Dr. Önder DEVECİ for his support and suggestions in mosquito bioassays. Preliminary studies about limonene and permethrin capsules were presented on 1st International Recent Developments, Textile Technology and Chemistry Symposium, Turkey and 1st International Conference on Natural Fibers, Portugal.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Türkoğlu, G.C., Sarıışık, A.M., Erkan, G. et al. Micro- and nano-encapsulation of limonene and permethrin for mosquito repellent finishing of cotton textiles. Iran Polym J 29, 321–329 (2020). https://doi.org/10.1007/s13726-020-00799-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-020-00799-4