Abstract

This research work is devoted to study the effect of ozone degradation and stabilization on the hyperelastic behavior of a natural rubber/butadiene rubber-based rubber blend used in tire sidewalls. Four rubber compounds with different paraffin wax contents were designed and prepared using the conventional machineries. Classical rubber tests including tensile, dynamic mechanical thermal analysis, hardness and fatigue-to-failure were carried out. To evaluate the effect of ozone degradation and wax content on stabilization, two sets of experiments were performed. In the first series, samples were tested without exposure to ozone, while the second series were carried out on samples after exposure to ozone according to a recently developed method. Five hyperelastic models including the neo-Hookean, Yeoh, Ogden, Arruda–Boyce and van der Waals equations were selected. The corresponding parameters of these equations were determined via nonlinear curve fitting on the experimentally obtained uniaxial stress–strain data using the material modeling module implemented in Abaqus code. For the first time in this work, the relationship between the predicted model parameters as well as the initial shear modulus of the above samples with structural changes that take place in rubber during the degradation are presented and discussed. It is also found that the parameters of nonlinear mechanistic models such as Arruda–Boyce and van der Waals can be related to chain scission which takes place during ozone attack on the polymer backbone in rubber compounds.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Tire is one of the most important parts of an automobile so that it plays a vital role in determining the final performance of the vehicle. Therefore, it is necessary to keep its initial physical and mechanical properties during the normal service life. There are several factors such as heat, stress, wear and environmental parameters that affect and reduce tire properties [1]. Nearly 40 % of tire compositions are made of natural rubber (NR) and synthetic rubbers especially, styrene-butadiene rubber (SBR) and butadiene rubber (BR). All these rubbers have double bonds in their backbone which are highly susceptible to ozone degradation.

Ozone is one of the parameters which attack the double bonds of the rubber molecules and break the polymer chains [2]. Deterioration caused by ozone in rubbers is a well-known phenomenon which leads to reduced mechanical and physical properties and efficiency in tires. The ozone level in the normal air can be up to 10 ppm which is quite enough to generate cracks and starts deterioration. Ozone degradation and the protection of rubbers against it has been the subject of research since the 1960s. There are many published works in this area focused on both mechanism and protection methods [3, 4].

Briefly speaking, there are two methods for improving the ozone resistance of rubber compounds especially for tire applications. Traditionally, the first method uses appropriate additives as antiozonant materials such as N-(1,3-dimethyl)-N-phenyl-p-phenylenediamine (6PPD) and paraffin wax. There is a large volume of published studies describing different aspects of this method [5]. The second method involves the blending of base rubber with a highly saturated rubber. The newly added rubber reduces the concentration of the unsaturated double bonds in polymer backbone and thus acts as ozone-resistant rubber. This reduces the ozone effect on the compound. A considerable amount of literature has also been published on this method.

Tse [6] studied the effect of blending of brominated isobutylene/para-methyl styrene copolymer (BIMSM) with an NR/BR compound. This rubber is a terpolymer of isobutylene, para-bromomethylstyrene and para-methylstyrene which acts as an ozone inert phase. The results showed that increasing BIMSM content increased ozone resistance of the compounds. In another study, Sahakaro et al. [7] studied the effect of blending of ethylene propylene diene monomer (M-class) rubber (EPDM) with an NR/BR base compound. Their results also showed that incorporation of 30 phrFootnote 1 EPDM into NR/BR compound improved ozone resistance and there was no need for any extra-chemical as antiozonant. In a recent work carried out by Nabil et al. [8], the blend of NR with virgin and recycled EPDM was thoroughly studied with different blend ratios and a fixed amount of carbon black. It was shown that both virgin and recycled EPDMs could lead to more improved resistance of NR against environmental attacks.

On the other hand, it is generally well known that the rubbery materials are nearly incompressible v ≈ 0.5 and thus their mechanical behavior is described by hyperelastic models. In these models, the strain energy density is correlated to the strain invariants (I 1, I 2, I 3) or principle stretch ratios (λ 1, λ 2, λ 3) using either a phenomenological or mechanistic equation [9]. Advanced finite element analysis of tires under different loading conditions especially for prediction of tire performance in time span requires sophisticated material models. For such cases, the model parameters should be determined not only as a function of stress and strain but also their variation with time needs to be taken into considerations.

As stated above, ozone degradation changes the structure and backbone of the rubber macromolecules and thus the parameters of material models should be updated during the analysis. Consequently, questions have been raised about the effect of ozone degradation on the hyperelastic behavior and parameters of the associated material model. While many researchers studied the different aspects of the protection against ozone attacks and the description of hyperelastic behaviors of rubbery materials [10], no studies have been found on the effect of ozone degradation on the hyperelastic behavior of rubber compounds. The novel aspect of this study is to investigate the effect of degradation and stabilization using paraffin wax against ozone attacks on the hyperelastic behavior of an NR/BR compound which is formulated to be used in tire sidewalls. Based on our survey, this is the first study to undertake a comprehensive analysis on ozone degradation in long-term behavior of tires. It should be emphasized that although this work is devoted to the mentioned study for an NR/BR blend, the adopted methodology can be used for any rubber compound used in tire or other non-tire applications.

In the remaining part of this paper, we first present the hyperelastic models used in this research and then proceed to the experimental parts in which the selected materials, compound formulations as well as sample preparation methods are given. Next, the results and discussion is presented. Our main focus in this part is to relate the model parameters of the hyperelastic equations to ozone degradation and also stabilization in conjunction with their physical interpretations. Finally, the conclusion gives a brief summary and critique of the findings.

Hyperelastic models

The mathematical description of time-independent mechanical behavior of rubbers is given by hyperelastic models. In these models, strain energy density is correlated to the strain invariants (I 1, I 2, I 3) or principle stretch ratios (λ 1, λ 2, λ 3). There are several hyperelastic models introduced in literature sources with different strategies on their derivation and physical description of their parameters [11, 12]. In this study, it is assumed that interpretation of physical meaning of the parameters in these equations can help us to understand structural changes that take place in rubber compounds under the ozone effect. In this work, we have selected five well-known hyperelastic models to describe the mechanical properties of rubber compounds which are as follows:

Polynomial

This is a phenomenological model which is a general form of early developed well-known Mooney–Rivlin model and given as:

where W is the strain energy density, C ij are parameters of equation and I 1 and I 2 are the first and second invariants of strain tensor, respectively. It is also assumed that due to the incompressibility, I 3 = 0.

In this study, we used a special form of this model given as [13]:

Although the parameter N can take values up to six, when we have both first and second invariants, it rarely has values greater than two. In a polynomial model, regardless of the N values, initial shear modulus is correlated to parameters of N = 1 and is given as [13]:

Yeoh

This model is a special form of polynomial model (Eq. 1) in which it is assumed that the strain energy density is independent of I 2 and also [11]. Therefore, the Yeoh model is expressed by:

In small strains, the initial shear modulus is 2C 10 [9]. The parameters C 20 and C 30 are often smaller than C 10 some order of magnitude and they are only required to create the typical S-shape in stress–strain curve. This model has generally an accurate fit on the stress–strain curves over a wide range of strains, especially when only a simple stress–strain data set in tension mode is available.

Neo-Hookean

This model is the simplest equation for describing the hyperelastic behavior of rubbers. It is a special form of the Yeoh model (Eq. 4) with N = 1, given as:

The initial development of this model was based on the assumption of a Gaussian network for a rubber macromolecule.

Arruda–Boyce

This is a mechanistic model based on eight chains in representative volume element and is given as [14]:

where \( C_{1} = \frac{1}{2},C_{2} = \frac{1}{20},C_{3} = \frac{11}{1050},C_{4} = \frac{19}{7000},C_{5} = \frac{42039}{67375}, \) and, λ m is the locking stretch ratio. At this stretch, the slope of the stress–strain curve rises significantly. The initial shear modulus is given as:

The Arruda–Boyce model is a non-Gaussian model in which for small deformations it is reduced to a Gaussian network based on neo-Hookean solid model.

Ogden

In this model, the strain energy density is correlated to the principal stretch ratios as [12]:

where α i and μ i are model parameters. The initial shear modulus is dependent on all coefficients and is given as:

This model is also a phenomenological model specially developed to describe the nonlinear stress–strain behavior of rubbers.

van der Waals

The van der Waals model [15, 16] which is also known as the Kilian model is given as:

where

where β is linear mixture parameter and when β = 0 only the effect of first invariant is considered. λ m is the locking stretch which means finite extendability of the non-Gaussian chain network. Parameter a is called interaction parameter and takes the interaction between the chains into account. The van der Waals model is a hybrid form of mechanistic and phenomenological models.

Experimental

Materials

Natural rubber (SMR-20, Standard Malaysian Rubber), butadiene rubber (BR, Arak Petrochemical Co., Iran), aromatic oil (Oil 840, Behran Oil Co., Iran), carbon black and zinc oxide (Pars Oxide Co., Iran), stearic acid, rubber antioxidant 2,2,4-trimethyl-1,2-dihydroquinoline (TMQ), sulfur, N-oxydiethylene-2-benzothiazole sulfonamide (MBS) as a curing accelerator and paraffin wax (Bayer Co., Germany) were the materials used in this study.

Sample preparation and tests

Four rubber compounds based on NR and BR blends containing 0, 1, 2 and 3 phr paraffin wax as ozone degradation controlling factor were designed according to the formulas given in Table 1. To prepare the compounds, NR and BR were first mixed on a two-roll mill (Schwabenthan, Polymix 200L, Germany) for about 6 min at 30–40 °C. Then, ZnO, stearic acid, TMQ and wax were added and mixed for about 4 min. In the third step, the reinforcing filler N330 along with the process oil was added to the mixture and mixed for 8 min. The curing system (sulfur and MBS) was finally added and mixed for 5 min. At the end of mixing, the compound temperature was about 60 °C. To determine the curing properties of the compounds, rheometry tests were carried out according to ASTM D2084 at 160 °C using a Zwick 4308 rheometer (Germany). The prepared compounds were used to mold rubber sheets with 1 and 2 mm thicknesses at 160 °C and 150 bar pressure.

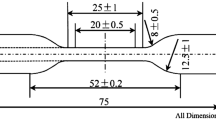

Conventional tensile tests were performed according to ASTM D 412 using a Hiwa tensile test machine (Iran). The hardness of samples was measured by a Zwick hardness test machine according to ASTM D2240. Ozone tests were carried out according to a modified form of ASTM D 1149 in which rubber sample sheets (14.5 × 2.5 cm) were placed in an ozone test cabinet (Hampden test equipment Ltd., England) for 24 h with 50 pphm ozone concentration in environment humidity and temperature. The fatigue properties of compounds were carried out according to ASTM 4482 using a Monsanto fatigue test machine (USA). The dynamic properties of compounds were measured by a Trice 2000 dynamical mechanical test machine according to ASTM E1640. For each separate test, the reported data are the average of the measured values on at least five specimens.

Results and discussion

To examine the effect of ozone degradation and stabilization, two series of identical tests, called as A and B, were performed. In the first series (A), the tests were carried out on all samples without exposing them to ozone, while series (B) were devoted to the test samples after exposing to ozone for studying the effect of ozone degradation and the amounts of paraffin wax on properties and hyperelastic model parameters. Before going through the effect of ozone degradation and wax content on the hyperelastic behavior, the results of classical tests are presented and discussed.

In this section, the first results of mechanical and physical tests such as DMTA (dynamic mechanical thermal analysis), fatigue and hardness are presented to see the ozone degradation controlling effect of paraffin wax and to observe how ozone acts on each sample. Then, the parameters of hyperelastic models are determined using the results of uniaxial tension test by curve fitting method. The effects of ozone degradation on mechanical, physical and structural properties of compounds are discussed with interpretation of the parameters of hyperelastic models.

DMTA

Figure 1 shows the results of storage modulus and tan δ of series A for the samples S 0 to S 3. There are three peaks in the damping curve of all samples. The first peak on the left is the characteristic peak of BR. The second peak is the character peak of SMR (Standard Malaysian Rubber) and the third peak on the right is related to other ingredients probably aromatic oil 840 [17]. It can be seen that there are no significant differences among the obtained results. This is mainly due to the very minor effects of the wax content on the mechanical properties of the unexposed cured compounds. Therefore, the results of sample S 3 from series A were selected and compared with their corresponding results in series B for the samples S 0 to S 3 as presented in Figs. 2 and 3, respectively.

As can be seen in these figures, the loss modulus and tan δ are notably affected by ozone degradation and the dynamical properties are improved with increasing of wax content (from 0 to 3 phr). This is mainly due to the chain scission and the breaking of cross-links which result in smaller polymer chains to be created. Therefore, the mobility of the chain ends which is directly related to the damping in dynamic state is extensively increased due to the formation of smaller polymer chains. These results were consistent with those obtained in a recent study [18] in which the effect of ozone degradation for an epoxy system used in the electrical power systems was investigated.

However, as can be seen in Fig. 3, for the rubber samples in which the wax was used in conjunction with other stabilizing agents, the samples with lower wax content displayed higher damping values. This may be explained by the fact that the polymer chains in the unaffected samples have a larger capacity of absorption and desorption of energy. In other words, when the polymer chains break under the effect of ozone, their ability to reserve the stored energy decreases due to increase in the mobility of the molecules compared to unbroken chains. In addition, some parts of energy spent for the deformation at fracture point could not be saved. Consequently, the capacity of desorption of energy in the broken chains was smaller and the damping values were greater [19].

Fatigue

As it is expected, the ozone degradation has a severe effect on the fatigue-to-failure properties of rubber compounds. Figure 4 shows number of cycles required before failure for both unexposed and exposed samples S 0 to S 3. No significant differences were found for the unexposed (series A) samples. However, in contrast to the above findings in the DMTA tests, the substantial decline in number of cycles was found in series B even for the samples with 3 phr wax content (S 3).

It is well known that there are two main mechanisms for the failure of samples which are in the initial crack formation and growth steps [20]. With formation of small cracks under ozone attack on polymer chains, the energy required for the growth of cracks is easily provided during the cyclic loadings. Therefore, the cracks grow rapidly and the failure occurs in the samples. It should be noted that in addition to the conventional role of wax in protecting rubber compounds against ozone attack, its molecules also play as internal lubricant and thus facilitate the stress transfer between polymer chains which in turn reduces high stress concentration points and thus increases the fatigue life of the rubber. This finding suggests that the effect of time span on the mechanical properties in dynamic application is very important and thus a proper material model should have the ability to take the drop in mechanical properties into consideration.

Hardness

Figure 5 presents the hardness of samples S 0 to S 3 without exposed (series A) and exposed (series B) to ozone. The graph shows that there is a very slight increase in hardness for the exposed samples while in the unexposed samples no significant change is observed. Hardness of cured rubber compounds is generally a function of many parameters and does not change significantly under the effect of ozone [21, 22].

Hyperelastic

The results of uniaxial tensile tests on the cured samples are presented in Figs. 6 and 7. As it can be expected, all samples without ozone tests (series A) have similar behavior and the mechanical properties of the samples exposed to ozone (series B) are improved with increases in wax content. The parameters of five selected hyperelastic models including neo-Hookean, Yeoh, Ogden, Arruda–Boyce and van der Waals were determined based on the data obtained from uniaxial tests using nonlinear curve fitting module implemented in Abaqus code [13]. The parameters of the above-mentioned models as well as the initial shear modulus computed from each model are presented in Tables 2, 3, 4, 5 and 6. The parameters of neo-Hookean model, i.e., C 10 and the initial shear modulus which is equal to 2C 10, are given in Table 2.

To show the accuracy of the selected models, the predicted and experimentally determined stress–strain curves for the samples B-S 0 (exposed to ozone with 0 phr wax) and B-S 3 (exposed to ozone with 3 phr wax) are shown in Fig. 8a, b, respectively. As it can be seen, for both samples, all five selected models except the neo-Hookean model are quite capable to accurately predict the mechanical behavior of the rubber samples. This means that change in the molecular structure of the rubbers caused by ozone degradation has a very little effect on the hyperelastic behavior. On the other hand, the neo-Hookean model is not as precise as the other models due to its inability to cope with the non-Gaussian behavior of the blended rubber compound with reinforcing filler.

However, owing to its mechanistic nature, the neo-Hookean model parameter is used in our study to interpret the obtained results. The computed errors for these curve fittings are also recorded in Table 7. It should be noted that since similar results were obtained for other samples they are not reported here.

As it can be seen, the model parameter and initial modulus were both changed significantly with wax content in the samples exposed to ozone (B-S 0 to B-S 3) so that they would finally have the values approximately equal to those of the samples without ozone effect (A-S 0 to A-S 3). On the other hand, the neo-Hookean model can be derived from the statistical theory of rubber elasticity for an ideal rubber which is given as [11]:

where W is the strain energy density, N is the number of network chains per unit volume, K is the Boltzmann’s constant, and T is the absolute temperature. Comparison of the above equation with Eq. (5) reveals that:

Therefore, it can be assumed that decrease in C 10 or initial shear modulus (μ 0) is directly related to the number of chains per unit volume (N) which indicates that the chain break due to ozone attack occurs in rubber macromolecules.

Table 3 shows the parameters of the Yeoh model and corresponding initial shear modulus (μ 0) for the prepared samples. The first term in this model, i.e., C 10 (I 1 − 3) can be considered as the part corresponding to ideal behavior of rubber and other terms are representing deviation from the Gaussian theory of rubber elasticity. This gives the Yeoh model ability to more effectively fit the experimental data into the mathematical model compared to the neo-Hookean model. Similar to the neo-Hookean model, the initial shear modulus also was increased with increase of wax content. As it was mentioned earlier, this was also due to the protecting effect of wax which prevented the chain scission and thus maintained the initial modulus against ozone attack.

Table 4 presents the parameters of the Ogden model for the prepared samples and also the initial shear modulus. Similar to the previous models, the data given in this table reveal that there has been a gradual increase in shear modulus with increases in wax content in the exposed ozone samples (B-S 0 to B-S 3). On the other hand, despite its high accuracy in predicting the stress–strain behavior of rubbers, since it is a phenomenological model, the computed parameters can hardly be associated with the molecular structure of the polymer.

Table 5 gives the parameters of the Arruda–Boyce model for the prepared compounds as well as the initial shear modulus. The Arruda–Boyce model is a mechanistic model developed based on statistical mechanics theory. It depends on the first invariant only and thus, it can be a good choice when using uniaxial test data (such as neo-Hookean and Yeoh models) [14]. The variation of initial shear modulus in this model is similar to the previous equations. However, this model has a newly introduced parameter (λ m ) which is termed as “locking stretch”. At this stretch, the slope of stress–strain curve has a sharp rise where the chains are fully extended and the force applied to the chains does not open angular bonds anymore but it spends on overcoming and breaking the internal bonds of the molecules. Therefore, the required force for extra extension will rise significantly. The locking stretch values are higher for longer chains because the final extendability of longer chains is more than that of shorter chains [23].

When ozone attacks the rubber molecules, the double bonds in the chains break and thus become shorter. Consequently, the final extendability and λ m take smaller value. It should be mentioned that as the site of ozone attack on the rubber molecule cannot be exactly found, the final length of the chains after the ozone attack cannot be specified either. In other words, with increasing wax content, there is not always an increase in λ m value. This is due to the possibility of obtaining longer broken chains in the compounds with lower wax content compared to those with higher wax content. However, it can be concluded that the longer exposure to ozone gives rise to obtaining smaller values of λ m in curve fitting procedure.

Finally, the parameters of the van der Waals model for the prepared compounds are presented in Table 6. It should be noted that the initial shear modulus in this model is equal to the model parameter μ as shown in this table. The global interaction parameter (a) refers to the interactive chains. There is no interaction between particles in a Gaussian chain network. Therefore, this parameter can be regarded as an index of deviation from Gaussian chain network. The Gaussian theory of rubber elasticity has a major weakness in the prediction of stress–strain behavior especially at the up-turn point. Hence, Gaussian theories are developed to have better predictions at higher extensions. As it may be seen, the values of global interaction parameter are greater for the samples more degraded by ozone. Breaking of chains under the ozone attack leads to generation of more interactions among polymer chains and thus, the easier chain movement is more dependent on its adjacent chains. The parameter λ m which is the finite extendability of the non-Gaussian chain network has been decreased under the ozone attack as it is discussed above for the Arruda–Boyce model. For a Gaussian chain network, there has been no limitation for λ m . Smaller values of λ m indicate greater deviation from the Gaussian behavior.

The results in Table 6 reveal that λ m decreases under the ozone attack. Interpreting the parameters of van der Waals models showed that it was harder to describe the behavior of more damaged samples—by ozone—according to Gaussian theory.

Conclusion

The effect of ozone degradation and stabilization on the mechanical properties (static and dynamic) and the parameters of some selected hyperelastic models are studied in detail. The parameters of chosen models are determined using nonlinear curve fitting method implemented in Abaqus. It is shown that both ozone attack on the rubber chains and stabilization have great influence on the quantitative values of the model parameters especially the initial shear modulus of the compounds. Having compared the results with different hyperelastic models, it is found that the more damaged samples by ozone attack show more non-Gaussian behavior. Therefore, more complicated models such as van der Waals equations can be more useful when a tire is numerically analyzed for a long-term cyclic loading.

Notes

Parts per hundred rubber.

References

Gent AN (2006) In: Gent A, Walter JD (eds) Mechanical properties of rubber, the pneumatic tire. The National Highway Traffic Safety Administration, USA

Cataldo F (2001) The action of ozone on polymers having unconjugated and cross- or linearly conjugated unsaturation: chemistry and technological aspects. Polym Degrad Stab 73:511–520

Andrews EH (1966) Resistance to ozone cracking in elastomer blends. J Appl Polym Sci 10:47–64

Rakovskii SK, Podmaster’yev VV, Razumovskii SD, Zaikov GE (1991) The mechanism of crack formation in rubbers under the effect of ozone. Int J Polym Mater 15:123–133

Cataldo F (2001) On the ozone protection of polymers having non-conjugated unsaturation. Polym Degrad Stab 72:287–296

Tse MF (2007) Ozone cracking and flex cracking of cross-linked polymer blend compounds. J Appl Polym Sci 103:2183–2196

Sahakaro K, Datta RN, Baaij J, Noordermeer JWM (2007) Blending of NR/BR/EPDM by reactive processing for tire sidewall applications. III. Assessment of the blend ozone- and fatigue-resistance in comparison with a conventional NR/BR compound. J Appl Polym Sci 103:2555–2563

Nabil H, Ismail H, Azura AR (2013) Compounding, mechanical and morphological properties of carbon black filled natural rubber/recycled ethylene-propylene-diene-monomer (R-EPDM) blends. Polym Test 32:385–393

Ali A, Hosseini M, Sahari BB (2010) A review of constitutive models for rubber-like materials. Am J Eng Appl Sci 3:232–239

Ghoreishy MHR, Alimardani M, Mehrabian RZ, Ganjali ST (2013) Modeling the hyperviscoelastic behavior of a tire tread compound reinforced by silica and carbon black. J Appl Polym Sci 128:1725–1731

Yeoh OH (1993) Some forms of the strain energy function for rubber. Rubber Chem Technol 66:754–771

Ogden RW (1986) Recent advances in the phenomenological theory of rubber elasticity. Rubber Chem Technol 59:361–383

Abaqus (2014) Theory guide, Version 6.14

Arruda EM, Boyce MC (1993) A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J Mech Phys Solids 41:389–412

Kilian HG, Vilgis Th (1984) Fundamental aspects of rubber–elasticity in real networks. Colloid Polym Sci 262:15–21

Kilian HG, Enderle HF, Unseld K (1986) The use of the van der Waals model to elucidate universal aspects of structure-property relationships in simply extended dry and swollen rubbers. Colloid Polym Sci 264:866–876

Chiu HT, Li WC, Tsai PA (2006) A study of rheological behavior and compatibility of NR/BR blends. Polym Plast Techol 45:845–855

Middleton J, Burks B, Wells T, Setters AM, Jasiuk I, Predecki P, Hoffman J, Kumosa M (2013) The effect of ozone on polymer degradation in polymer core composite conductors. Polym Degrad Stab 98:436–445

Scanlan J (1960) The effect of network flaws on the elastic properties of vulcanizates. J Polym Sci 43:501–508

Braden M, Gent AN (1962) The attack of ozone on stretched rubber vulcanizates. III. Action of antiozonants. J Appl Polym Sci 6:449–455

Findik F, Yilmaz R, Koksal T (2004) Investigation of mechanical and physical properties of several industrial rubbers. Mater Des 25:269–276

Li ZH, Zhang J, Chen SJ (2008) Effects of carbon blacks with various structures on vulcanization and reinforcement of filled ethylene-propylene-diene rubber. eXPRESS Polym Lett 2:695–704

Andrady AL, Llorente MA, Mark JE (1980) Model networks of end-linked polydimethylsiloxane chains.VII. Networks designed to demonstrate non-gaussian effects related to limited chain extensibility. J Chem Phys 72:2282–2290

Acknowledgments

The authors would like to express their gratitude to Iran Polymer and Petrochemical Institute for the permission to publish this work and also financial support to do this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghoreishy, M.H.R., Naderi, G. & Roohandeh, B. An experimental investigation on the degradation effect of ozone on hyperelastic behavior of an NR/BR blend. Iran Polym J 24, 1015–1024 (2015). https://doi.org/10.1007/s13726-015-0389-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-015-0389-1