Abstract

To mitigate climate relevant air emissions from freight transportation, policy makers stimulate the application of intermodal freight transport chains. The evaluation and selection of intermodal routes based on the key objectives, i.e., greenhouse gas emission, transportation cost and transit time improvements, are the main challenges in the design of intermodal networks. It is the aim of this paper to provide decision support in intermodal freight transportation planning concerning route and carrier choice in transport service design and the assessment of emission abatement potentials. Core of this approach is a capacitated multi-commodity network flow model considering multiple criteria and in-transit inventory. Thereby two processes are modeled, i.e., the transport and transshipment of full truckloads (FTL), to define the material flow of goods through the network. The objective function of the developed network flow model minimizes the number of transported and transshipped FTL assessed by the weighted and normalized criteria (i.e., CO2-equivalents, cost, time) taking into account tied in-transit capital and the distance traveled. Thereby, the model regards carrier and terminal capacities, the option to transfer or either shift the mode and/or change the carrier at predefined terminal transshipment points. The model is incorporated in a decision support system and applied in an example application with industry data from an automotive supplier to demonstrate its application potentials. Within the application among others the potential benefits of the developed optimization model in comparison to a status quo are analyzed. Different criteria weightings and the influence of various levels of in-transit holding costs are investigated. In addition, the introduction of new transportation means such as the Eurocombi is assessed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In 2010, the European freight transportation sector accounted for a total of about 1,216 million tons of CO2-equivalents, which is 25 % of the yearly greenhouse gas (GHG) emissions in the EU-27 (EC 2013, p. 121). These figures represent the most recent data on GHG emissions and at the same time are the highest values ever estimated for the European transport sector. Whereas road transportation, with nearly 72 %, has been by far the largest contributor to rising GHG emissions, sea shipping, with about 14 %, and aviation with approximately 12 % have been clearly less significant. Rail transport in comparison, with less than one percent, is almost non-existent in the statistics. With an average annual growth rate of 1.3 % between 1995 and 2011 the transport sector has an important share in the European’s GDP development (EC 2013, p. 21). Until 2030, a growth of 25 % in the European freight transport performance is projected (Helmreich and Keller 2011, p. 58). The continuous growth of emissions, especially transport emissions, has led to a wide range of effects on the environment and subsequently on society. Whereas environmental effects result in climate change affecting the global socio-economies by increasing inter alia damage costs from natural disasters, actions to mitigate the GHG effect are enacted (EEA 2012, p. 15). As a response to global warming, the awareness of the potential harm to the environment by GHGs is growing, causing policy makers to establish legal frameworks and abate the release of greenhouse gases into the atmosphere. From a company’s perspective, not only do governmental regulations drive the abatement of GHGs from value chain processes, but growing public awareness forces companies towards voluntary commitments and sustainable supply chains with environmentally friendlier products and services. The balancing between sustainability and the continuing transport-intensive international trade is a major challenge of today’s companies. Within this challenge, the review of transport options by distinguishing between transport modes with different effects on emitted GHGs is the central aspect (Christopher 2011, p. 245). To find the best balancing transport decision, companies integrate multiple business objectives into their decision-making process by using service network design models (SND) to help determine the shape of their distribution activities. These models tend to focus on classic business criteria, e.g., cost and service, rather than taking environmental objectives into account (Seiler 2012, p. 67). The multiplicity of objectives often results in conflicts among them leading to the detailed balancing of transportation and inventory costs with service time and quality restrictions but disregard transport emissions. Nevertheless, long-haul freight transportation is responsible for almost 50 % of the total transport emissions in the EU-27 (Helmreich and Keller 2011, p. 129) and forces companies to include environmental concerns into the planning of transportation services. Herein, the incorporation of GHG emissions is inevitable due to the fact that costs and emissions are not necessary linearly dependent as for example in intermodal transportation networks, which include electrical- and fuel-powered transport means. For instance, the energy source for railway operations in Great Britain is mainly fossil fuel, whereas in France it is nuclear energy.

The integrative aspect of multiple conflicting economic and ecologic objectives is an important characteristic in decision-making within tactical freight transportation planning activities. One striking example is the tradeoff assumption between cost, time and emissions such as for air freight transportation. Slower modes in contrast to faster ones provide service at lower costs and emissions but higher transit times. The increased transit time might influence the tied in-transit capital and increase the overall transportation costs affecting the tradeoff assumption. Although the highest cost proportion of freight transportation is associated with the carrier, additional costs for in-transit inventory occur during the distribution process referred to as in-transit holding costs (Kumar 2008, p. 345). The goods are in stock, although not accessible, resulting in imputed inventory costs accordingly. In practice, in-transit holding costs are much lower than the actual transportation costs due to the absence of warehousing costs. However, in-transit inventory consideration in the planning of long-haul freight transportation chains might have significant impacts on the choice of transportation modes and therefore represents one major aspect in this research paper. By combining the transport mode choice with commercial and environmental objectives, the planning process becomes highly complex with a vast variety of transport options requiring decision support (Current and Min 1986, p. 187). This decision support shall focus on the outsourcing of freight distribution activities to logistics service providers and combine the carrier and route selection processes in one mathematical model formulation. Intermodal freight transportation networks are known to exist in various designs consisting of origins, destinations and transshipment nodes, as well as intermodal distribution connecting the nodes. Typical for intermodal transportation networks is its long-haul and full truckload (FTL) characteristics as well as the use of roads, railways or shipping routes to obtain a flow of commodities between production facilities, regional or central warehouses and distant markets. The wide-ranging task is to find the optimal route between the origin and the destination by crossing several transshipment locations with respect to the following transport attributes: e.g., GHG emissions, transport and in-transit holding cost, and transit time. The consideration of these attributes enables the establishment of a multi-stage flow problem for numerous products with limited transport and terminal capacities defining a NP-hard capacitated single-commodity network flow problem (Ghiani et al. 2004, p. 206/217). By integrating shared terminal capacities, the problem becomes a capacitated multi-commodity network flow problem (CMCNF).

The aim of this study is therefore to formulate a capacitated multi-commodity network flow model for the planning of intermodal transportation services while taking multiple criteria and in-transit inventory into account. The planning decision is characterized by the choice of transport mode that is accompanied by the selection of the corresponding carrier, and the determination of the optimal route through a transportation network based on the key criteria, i.e. GHG emission, transportation and in-transit holding cost as well as transit time. Thus, the model shall regard carrier and terminal capacities, the option to either shift the mode and/or change the carrier at predefined terminals, and, next to transportation costs, in-transit (inventory) holding costs. As a result, the integrated processes between the system boundaries are twofold, i.e. the transport (TR) and the transshipment (TS), which includes the modal shift and/or the carrier change at terminals or the simple transfer of the material flow. The material flow of goods through the network is considered as the transport of FTL, which is the most common type in long-haul freight transportation. Thereby FTL refers to a defined capacity unit transported with fixed cost, irrespective of the actual load of the unit (cf. Riekst and Ventura 2008). In order to formulate a mathematical model of the transportation network, specific node definitions are undertaken. Whereas transshipment points represent terminals for the modal and/or carrier shift allowing criteria assessments, transfer points are only geographical locations of different transport routes and account as flow consolidation points without assigned processes. The terminal’s assessment regarding the transport attributes, follows the description of terminals by two nodes, in essence, one node for the input and one dummy node for the output. The connection between those two nodes, which is represented by a dummy arc, is assessed with the transport attributes. Figure 1 illustrates the problem description and shows an exemplary structure allocating three origins (O) with two destinations (D) by linking three transfer points (TP) and six terminals (T) with the corresponding dummy nodes (Td) into a multi-stage transportation network.

Several transport lanes characterize the material from the origins to the destinations. The highlighted transport options between the origin 2 (O2) and the destination 1 (D1) serve as an example. Herein, a number of different routes exist to link the two locations, however, depending on the application of transport modes three different routes classify the most emission-, cost- and time-friendly one. For instance, the route \( {\text{O}}_{2} \to {\text{T}}_{2} \to {\text{T}}_{1} \to {\text{TP}}_{2} \to {\text{D}}_{1} \) provides the lowest cost, the route \( {\text{O}}_{2} \to {\text{T}}_{2} \to {\text{T}}_{3} \to {\text{T}}_{5} \to {\text{D}}_{1} \) offers low emissions and the route \( {\text{O}}_{2} \to {\text{TP}}_{3} \to {\text{T}}_{6} \to {\text{T}}_{5} \to {\text{D}}_{1} \) is the fastest. By taking into account the additional transport lanes of the complete network including all origins and destinations and while integrating carrier and shared terminal capacities as well as route restrictions, numerous routing and transshipment options are enabled depending on the decision maker’s ecological and economic preferences.

To enable practical usages of the model it is implemented as a decision support system for intermodal freight transportation planning (DSSIFTP) for the evaluation and selection of intermodal routes in tactical freight transportation planning. By applying the model with actual business data of an automotive supplier on a Western-European logistics network, scenario and sensitivity analyses as well as their validation and demonstration of their suitability and applicability are performed. The database of the case study is based on a case study by Froehling et al. (2013), who analyze a transportation network in terms of ecological benefits on route and haulier choice.

Thus, the contribution of this work is a new model formulation of capacitated multi-commodity network flow model considering carbon emissions, in-transit inventory costs as well as transport and transshipment processes with mode and/or carrier change for intermodal transportation service planning. This model is proposed, implemented and validated with industry data. However, from the application further findings are derived: (1) The interrelations between the decision criteria GHG emissions, cost and time are investigated by the application of the model based on real world industry data. (2) An estimation of potential impacts of Eurocombis, which represent longer heavier vehicles (LHV), on the named criteria is undertaken in scenario analyses.

2 Related literature

International multi-echelon freight networks emerge into intermodal transport when integrating different modes of transport. These networks comprise interconnected logistics chains with different levels, deviating transit times, distances and operation costs as well as transport emissions. One of the main tactical planning problems is the service network design (Crainic and Laporte 1997). Service network design formulations create the transportation strategy to ensure the efficient operation of the logistics chain, to serve demand and to ensure profitability. This is achieved by the network-wide planning of operations to select and schedule transport services, to consolidate terminal activities, and to control the material flow through the logistics system (Crainic and Kim 2007, p. 485). Whereas the network design problem is one of the central problems in combinatorial optimization (Yaghini and Akhavan 2012, p. 728), its difficulty is the distinctive interaction of system components and conflicting criteria. This particularly tactical-based decision problem consists of the distribution network design, the transport mode and capacity choice, the definition of routes and route characteristics to be applied such as the transport frequency and the number of intermediate transshipment points, the assignment of the distribution along the routes and the terminal processes (cf. Caris et al. 2008, p. 287; Goetschalckx et al. 2002, p. 2; Crainic and Dejax 1987, p. 10).

Recent reviews on intermodal freight transportation can be found in (SteadieSeifi et al. 2014; Caris et al. 2013; Bektas and Crainic 2008; Caris et al. 2008; Crainic and Kim 2007; Christiansen et al. 2007; Macharis and Bontekoning 2004). Following these reviews especially service network design (SND) and multi-commodity network flow problems can serve as a basis for this article. Nevertheless, the reviews state that more research on multi-objective planning, especially considering conflicting criteria such as time and cost would merit further research as well as a more elaborate consideration of transshipment operations and their associated costs (SteadieSeifi et al. 2014).

In the abundant number of publications in the field of tactical planning issues such as the named service network design and the more operational multi-mode and multi-commodity network flow problems the incorporation of ecologic concerns and in-transit inventory remain scarcely treated (Macharis and Bontekoning 2004; Crainic and Kim 2007; Meixel and Norbis 2008; Hoff et al. 2010; Caris et al. 2012; Dekker et al. 2012). Relatively little research has been performed on the design of the intermodal service network with regard to the required prerequisites (i.e., transport and in-transit cost as well as time and emission incorporation while integrating transport by road, rail and sea). However, several studies approach the object of this paper and are discussed in the following.

Crainic (2002) defines a modeling framework that considers a multi-modal, multi-commodity network with intermodal transfers and assigns additional arcs for every mode of transport. The framework is embedded into interactive graphic software serving the strategic planning of aggregated large-scale freight flows. The model framework assigns transport flows to different modes and routes with the goal to minimize the total system cost. A detailed research on intermodal transportation and the descriptions of various model application areas is provided by Crainic (2000) and Crainic and Kim (2007). In addition, a multi-modal, multi-commodity, path-flow service network design formulation, which applies product-specific itineraries to define the service path within the transportation network, is described. The objective function minimizes the total cost, comprising operating and transport cost, while satisfying the demand and the service level. The capability of the model to identify tradeoffs between the cost of routing freight on less favorable itineraries and the cost of increasing the service level is noteworthy. While Crainic and Kim (2007) disregard ecologic criteria, Floden (2007) describes a general large-scale model for strategic modeling of intermodal transports solely between road and rail including transport emissions. The author applies heuristics to analyze the competitiveness between all-road and intermodal transport. The developed model determines the most appropriate modal split and defines train timetables, the train type and the number of trains as well as the number of road vehicles, their type and environmental impact. Corbett et al. (2007) developed a freight routing and emissions analysis tool (FREAT), which is a spreadsheet-based decision support tool to evaluate economic and environmental issues related to alternative road and sea freight transport routes. The tool includes a basic network flow model, enables to quantify emissions from intermodal transport alternatives, to evaluate tradeoffs between emissions as well as costs and transit times, and to identify modal combinations with minimum costs, times or emissions by optimization routines. A multi-objective multi-modal multi-commodity flow problem (MMMFP) with time windows, capacities and concave costs to find best routes in international intermodal networks is formulated by Chang (2007). The author considers, apart from multiple objectives, the scheduling of transportation modes and demand delivery times as well as transportation economies of scale. The resulting non-linear model is solved heuristically with relaxation and decomposition techniques. The deducted model is finalized in a large-scale case study application consisting of a global transportation network. Although the formulated model provides some insight into the complexity of network flow problems, the approach by Chang (2007) lacks the demanded in-transit inventory as well as the option to consider comparable criteria, e.g., transport costs, times and emissions. Bauer et al. (2010) propose a capacitated network design formulation based on an integer program with linear costs and multiple products that minimize the amount of GHG emissions of transportation activities. The authors introduce environmental costs, which represent carbon dioxide emissions, into a service network design problem with fleet management. These costs are captured and minimized in order to reduce GHG emissions through appropriate selection of transport services.

In general, only little research takes in-transit inventories into account. The time and cost criterion in intermodal transport chains, however, might be influenced by the integration of tied capital during the transport as for long distances (Floden 2007). This lack of in-transit inventory consideration in service network design formulations is incorporated by Min (1990). The author develops a stochastic chance-constrained goal programming model, which minimizes cost and risk as well as fulfills service time restrictions. In addition, a tradeoff analysis of the conflicting cost and service is executed. The cost consists of six components including in-transit inventory carrying cost, which are proportional to the speed of the mode and cargo size. In addition to the cost, the transit time, reliability and intermodal compatibility are taken into account as well. The multiplicity of the objective minimizes the distribution costs, the shipment delays, the in-transit inventories at intermediate stops and forbids early shipments. Although intermodal transport services are not taken into account, the incorporation of in-transit inventory costs, which are a key aspect of the research paper, is highlighted. The research on effects of carbon emission regulations on transport mode selection under stochastic demand by Hoen et al. (2011) and (2012) analyze the tradeoff between inventory, transport and emission costs for transport modes. Carbon emission estimates are assigned to transport modes as emission costs and are restricted by different types of regulations. The authors formulate a single product, single location transport mode selection problem with the objective to minimize the total cost. The applied solution method for the selection problem is an order-up-to policy in combination with the results of a single-period Newsboy problem.

Some works on environmentally-orientated routing exist. Laporte (2013) summarizes these under the pollution routing problem. One of the earliest works in this field is the paper by Bektas and Laporte (2013). Further works by Demir et al. (2014) consider potential tradeoffs between costs and time in a bi-objective version of the model which is solved using an adaptive large neigbourhood search combined with a speed optimization procedure. An extension of these models, the time-dependent pollution routing problem, considers also traffic congestion in an mixed integer linear programming model (Franceschetti et al. 2013). Cirovic et al. (2014) consider in their model multiple pollutants and noise next to cost criteria. The model is solved using fuzzy neuronal networks but does not comprise intermodality, transshipments and inventory holding costs since it focuses on the operational routing of delivery operations. Laporte (2013) states that emission minimization is quite straight forward for routing decisions since these are dependent on the energy demand and minimizing energy demand is usually complementary to cost minimization. However, this does not hold necessarily for intermodal transport planning, especially in international freight transportation networks. The choice of the transport mode determines costs, achievable speeds and the needed type of energy. Therefore, tradeoffs between costs, time and emissions can exist. According to the mode different costs for e.g., air, barge, rail or truck transport accrue. This already enables conflicts which are even further supported when the routes are considered. Eurocombis for example are currently only permitted on certain routes in Europe, not all rail tracks are electrified and emission factors vary from country to country, e.g., the generation mix of electricity in Germany differs from the one in France, leading to different emissions for the same train on a German or a French track.

To sum up, transportation planning problems, also on the tactical planning level, are as numerous as the solution approaches. Regarding the specific requirements for sufficient intermodal transportation planning considering comparable economic and ecological objectives as well as in-transit inventory and more elaborate modeling of transshipment operations, remain subject to this research study. As a result, the following transport modeling comprises transshipment operations and integrates transport, transshipment and in-transit holding cost as well as time and carbon dioxide emissions into a capacitated multi-commodity network flow model.

3 Model formulation

Based on the problem description in the introduction, the provided review of related literature in the previous chapter and the “need for solution methods for intermodal routing models taking into account multiple objectives” (Caris et al. 2012, p. 106) a capacitated multi-commodity network flow model is developed. By listing the models specifications and network design characteristics, the model is presented and explained in the following. Thereby the presentation in this section remains mostly generic. A specification of the characteristic attributes with specific data is given within the model application (see Sect. 4).

The network itself is defined as a capacitated and weighted graph \( G = \left( {V,E,\delta ,\lambda ,\kappa ,\vartheta } \right) \) with the set of vertices \( V \) representing the nodes; set of edges \( E \) representing the arcs; edge coefficient \( \delta \) as the product of the weightings \( d \) and \( c \) for the transport attribute assessments; \( \lambda \) and \( \kappa \) as lower and upper edge capacity restrictions for the number of FTLs (e.g., vehicle fleet size limitations) and maximal payload of carriage (e.g., ferry loading limits, weight limits of cranes at terminals or shipping limits on bridges) as well as node coefficient \( \vartheta \) as the upper node capacity representing terminal capacities. The network is described by the physical movement of a product \( p \in P \) with the intermodal carrier \( s \in S \) assessed with the decision criteria \( k \in K \) with \( K = \{ {\text{Time, Cost}},{\text{ CO}}_{2} {\text{e}}\} \) on a link, which is in accordance to the node-to-node demand defined as a doublet \( (i,j) \) with \( i,j \in V \) between origins \( V_{\text{a}} \subset V \backslash (V_{\text{h}} \wedge V_{\text{b}} ) \) and destinations \( V_{\text{b}} \subset V \backslash (V_{\text{h}} \wedge V_{\text{a}} ) \), through intermediate stages \( (h,i),(i,j) \in E. \) The transport flow at capacitated intermediate nodes \( V_{\text{h}} \subset V \backslash (V_{\text{a}} \wedge V_{\text{b}} ) \) is represented by either terminal nodes \( V_{\text{t}} \subset V_{\text{h}} \backslash V_{\text{d}} \) and the corresponding dummy nodes \( V_{\text{d}} \subset V_{\text{h}} \backslash V_{\text{t}} \), or carrier transshipment nodes, which are defined as terminal nodes for carrier transshipments \( V_{{{\text{t}}^{\text{TS}} }} \subset V_{\text{t}} \) and their corresponding carrier transshipment dummy nodes \( V_{{{\text{d}}^{\text{TS}} }} \subset V_{\text{d}} \), or transfer nodes \( V_{\text{h}} \backslash (V_{\text{t}} \wedge V_{\text{d}} ). \) This classification of sets enables the modeling of the CMCNF problem as a transshipment problem in accordance to Domschke (1985, p. 76/77).

In intermodal transportation the objective is characterized by conflicting transport attributes. Potentially conflicting examples are the cost, time and emissions of transports. These attributes are analyzed via multi-criteria decision making (MCDM) approaches to identify synergies between economic and ecological objectives (Dekker et al. 2012, p. 678). The aim of the model is to find a feasible solution of the optimization problem, which at the same time results in an optimal solution for all criteria (Dorfman 1960, p. 607). Optimality is, thereby, defined in accordance to the objectives by prioritized criteria, i.e. minimum GHG emissions, costs or transit times, or a weighted combination of the three. This compromise solution is established by combining individual attributes or rather utility functions into one overall utility function. To guarantee the consideration of individual utility functions, weighting factors are introduced in the overall utility function. The derived aggregated utility function corresponds with the weighted sum of individual utility functions. An additional challenge occurs for attributes, which are either not directly comparable due to rational reasons such as CO2e emissions in gram (gCO2e) and transport costs in monetary units (MU), or are not convertible to one another such as for the minimizing of costs and maximizing of revenue. Consequently, prior to the model application the characteristics of all attributes within the total utility function have to be converted into a uniform scale of measurement with identical scale limits and standardized criterion scores. This normalization process obtains comparable scales by applying the linear scale transformation. This is simply accomplished by dividing the outcome of a certain criterion by its maximum value (Janic et al. 1999, p. 145). The existing relations between the individual values of the attributes remain consistent resulting in comparable normalized assessment factors. By applying the scale transformation and introducing a criteria-dependent weighting factor, an aggregated objective function for the optimization model based on the defined network can be formulated (Geldermann 2006, p. 124/125).

In order to guarantee product-specific criteria weightings, the weighting factor is product-dependent. Thus, for instance, the focus on ecological objectives for one and on service or cost criteria for another product are enabled. The model formulation is completed with the approaching definition of variables and parameters for the GHG emission calculations and the linear scale transformation as well as the statements of the model equations.

In line with the transport and transshipment processes, two decision variables are defined representing the number of FTLs transported (\( x_{psij}^{\text{TR}} \)) or transshipped (\( x_{psij}^{\text{TS}} \)) carrying one product p by carrier s between two locations i and j. Whereas the transshipment process leads to the introduction of an additional variable \( v_{psij}^{\text{TS}} \) for the implementation of carrier replacements, the transport process is restricted by capacities leading to the introduction of the binary variable \( y_{psij} \) as shown in Table 1.

k for the assessment of transport and transshipment options, evaluates the time criterion in [(h ⋅ t)/km], the costs in [MU/km], and the emissions in [gCO2e/km]. As shown in Table 2, the transport and transshipment emissions are represented by emission factors per watt-hour and energy demand figures per ton-kilometer, and evaluated with respect to the payload in tons [t].

By applying the criteria assessments in the linear scale transformation, the assessment factors and their maxima result in comparable normalized assessment factors for the two processes (cf. Table 3).

Table 4 lists all the applied model parameters, followed by the illustration of the model equations.

The objective function (1) summarizes the challenge of finding the optimal route by minimizing the number of transported and transshipped FTL according to the assessment factors for transports and transshipments and the normalized assessment factors of the linear scale transformation including in-transit holding costs and the distance traveled, and weighted along with the decision maker’s requirements. While the first term of the equation evaluates and weights the number of transported and transshipped FTL for the GHG emission and time criterion, the second term adds in-transit holding to the general transportation and transshipment costs.

The linear scale transformation in (2) determines the standardized values of the assessments for transshipments and transports based on the proportion of the linear scale transformation value and its maxima for every decision criterion. In contrast to the carrier transshipment process (TS), the transportation process (TR) includes additional tied capital in form of time dependent in-transit holding costs.

Whereas for the cost and time criterion the values are obtained by simple calculations, the transport emissions are computed based on the GHG emission calculation methods depicted in the following Eq. (3). Based on the emission factor and the energy demand, the GHG calculation methodology defines the assessment factor in accordance to the released GHG emissions of the transport (TR) and transshipment (TS) process. The applied GHG emission calculation methods are arbitrary and formulated with respect to the equality of units to allow accurate assessment factor evaluation. In order to obtain the GHG emissions of the transport and transshipment processes, the emission factors, the energy demand and the carrier-specific payloads need to be known. While the payload is order-specific, the emission factor depends on the chosen type of energy source (e.g., fuel type), though the energy demand is the result of the mode and several other transport-characterizing aspects such as product category and route topography.

The model is described by the distribution of complete transport units (FTL) carrying one category of product, starting from origins, crossing several transfer and/or terminal nodes and ending at destinations. The origins provide a certain amount of product supply (A pi ), whereas, destinations demand the equivalent (B pj ) as shown in (4) and (5). The supply provision constraint (4) prohibits, excluding the transferred amount of truckloads, the maximum output of payload per product by origins. The demand satisfaction (5) defines, excluding the transferred amount of truckloads, the maximum number of payload to be transshipped for demand coverage per product to destinations. Due to the input–output equilibrium, origins and destinations can be handled as transshipment nodes as well. The model Eqs. (4) and (5), moreover, enable the design of transport loops (milk runs) by allowing input as well as output of the transportation flow at origins and destinations.

The transportation flow through transfer points and terminals, respectively, the number of FTLs entering and leaving, are to be identical. Since terminals are assessed with GHG emissions, costs and times, the input and output flow of the created dummy terminal corresponds to the input and output of the terminal. The terminal flow constraint (6) causes all the input of FTL transports to terminals of a product-carrier combination to be equal to the transports shipped to the related dummy terminal. This constraint is required to model the FTL transports between terminals and dummy terminals for terminal criteria valuation.

The transshipment flow constraint (7) allows the transshipment of transports on different carriers and ensures that transshipped input and output are in balance as well.

The transfer flow constraint (8) guarantees the equilibrium between the input and the output of FTL transportation at each transfer point per product-carrier combination.

The constraint carrier replacement (9) enables the transshipment of truckloads at defined terminals to new carriers. FTLs at transfer points only cross the location as in (5), while FTLs at terminals can either change the mode of transport and/or might be replaced by another carrier at transshipment terminals as in (9). Thereby, is \( x_{psij}^{\text{TR}} \) the substantial decision variable representing the number of FTLs of a product p, with carrier s transported from location i to j. In addition, the number of FTLs of product p transshipped on the new carrier s at transshipment terminal j is expressed by the decision variable \( x_{psij}^{\text{TS}} \). In contrast, variable \( v_{psij}^{\text{TS}} \) expresses the former and replaced carrier s.

To ensure the accurate replacement of the former carrier to the new one, the carrier’s capacities have to match in accordance to the payload flow constraint (10). Similar to the transfer flow constraint (5), the payload flow constraint guarantees the equilibrium between ingoing and outgoing truckloads at each transshipment point per product-carrier combination. This constraint becomes valid when carriers transship during the transport and ensures that the transported truckload is permitted to be transshipped by the new carrier.

In case of the requirement to follow carrier-specific constraints such as contractual restrictions of the minimal permitted number of FTLs per carrier between network locations, the minimal flow of FTLs per product, carrier and link can be defined by taking the binary flow variable \( y_{psij} \) into account. The minimal flow restriction (11) ensures that a specific minimal flow of products with assigned carriers between locations is fulfilled. The minimal flow \( (F_{psij} ) \) bounds the decision variable \( x_{psij}^{\text{TR}} \) to the lowest number of FTLs and therefore enables the consideration of quantity discounts on number of transports for instance. The reason behind this restriction is the integration of contractually established regulations with carriers to at least operate a minimal number of transports for either grant quantity discount or due to general terms and conditions (Goetschalckx 2011, p. 130).

The payload capacity constraint (12) restricts the transported truckload up to a certain weight limit \( ({{LC}}_{psij} ) \) per product, carrier and node pair such as for weight limitations on ferries, bridges or cargo cranes at terminal for instance. To incorporate weight limits on the route, the vehicle’s weight plus the payload have to be taken into account.

The bundle constraint (13) states the binary transportation flow of product-carrier combinations between start and end locations. The binary transport flow is required to allow a minimal transport flow between locations as in Eq. (11) and to limit the payload capacity of transshipments as in Eq. (12). Using the big number M (i.e. applying the so called Big M-method) ensures that as soon as there is at least one FTL represented by \( x_{psij}^{\text{TR}} \) the binary variable takes the value of one (cf. also Kallrath and Wilson 1997).

Also, the proportion of applied carriers (CP) can be specified in percentage to restrict the use of carriers for business dependence reasons in accordance to the carrier proportion constraint (14).

Furthermore, carriers might be capacitated \( ({{CC}}_{psij} ) \) by the number of transports between two locations for a product with a specific carrier such as in the vehicle fleet size. Hence, the maximum number of FTLs per planning period can be set conclusively by the carrier capacity constraint (15).

Important for the realistic implementation of the model is also the consideration of capacity at terminals (U ij ) of processed FTLs per planning period. The terminal capacity constraint (16) restricts the product independent number of FTL to be processed at terminals in the considered time frame and incorporates the product-network with shared terminals into one integrated transportation network. Thus, since commodity networks share terminals, the terminal capacity is the critical parameter that transforms multiple single-commodity network flow problems into one capacitated multi-commodity network flow problem.

While, the FTL transport unit can be distributed on numerous routes by several carriers on various transport channels, using different types of fuel and with respect to the predefined capacities and criteria such as transit time constraints, the decision about the optimal route is a challenge. The criteria satisfaction constraint (17) enables to define limits on the values of the criteria \( (R_{pki} ) \) such as the maximum transit time per FTL transport. Moreover, it guarantees that specific criteria settings, for instance the transport budget (cost), the CO2e emissions and/or average transit times per FTL, must be satisfied while the intermodal transportation units are distributed between origins and destinations. These restrictions enable the strict obedience of lead times or statutory emission requirements. The knowledge about the limits of these restrictions is mandatory to set feasible model outcomes.

The weighting factor constraint (18) limits the sum of weights of the decision criteria per product to be 1. With respect to the decision makers preference a variety of combinations enables the prioritization of product-dependent decision criteria, e.g., the focus on ecology while keeping the classic business criteria may result in the scenario \( ({\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 2}}\right.\kern-0pt} \!\lower0.7ex\hbox{$2$}}|{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 4}}\right.\kern-0pt} \!\lower0.7ex\hbox{$4$}}|{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 4}}\right.\kern-0pt} \!\lower0.7ex\hbox{$4$}}) \). In contrast, the balancing of objectives would share the weightings according to \( ({\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 3}}\right.\kern-0pt} \!\lower0.7ex\hbox{$3$}}|{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 3}}\right.\kern-0pt} \!\lower0.7ex\hbox{$3$}}|{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 3}}\right.\kern-0pt} \!\lower0.7ex\hbox{$3$}}) \). In addition, by highlighting solely one criterion the weighting is fully set to 1 as for the most ecologic assessment with (1|0|0), or the most economic assessment with (0|1|0) as well as the most service-oriented assessment with (0|0|1).

In summary, whereas the decision variables are assumed integers to fulfill the claim of FTL transports, the model finds its optimal number with the according route. The FTL between locations i and j is hereby achieved by assigned carriers s, which are defined by the modes of transport used, the carrying product p and payload l s , and assessed with individual emission, costs and time attributes k of the transportation and transshipment processes.

4 Example application

The formulated mathematical model is implemented in GAMS framing a decision support system for intermodal freight transportation planning (DSSIFTP) consisting of a MS Excel-based database and user interface. The DSSIFTP is applied on a real life case study to find, test and confirm intermodal transport potentials through practically orientated descriptive research. The practitioner in our case is the logistics purchasing department of the company referred to as the decision maker, whose responsibility is the planning of intermodal transportation chains. Beyond the pure transport planning, the further focus is to decrease negative effects of freight transport on the environment by considering ecological measures such as GHG emissions. Other than the mentioned ecologic goal, the general objective is the presentation of potential application areas of the model.

4.1 Description of the application setting

The transport network structure of the multinational supplier for the automotive industry is represented by two transport lanes which are defined by two products consisting of 57 nodes linked with 90 edges in accordance to Froehling et al. (2013). The authors analyzed the considered transportation network in terms of ecological benefits on route and haulier choice using a basic transshipment model. The reader is referred to this publication as its input data is applied in the following example application.

Depending on the product or rather the transport lane, two origins are defined and one destination. Hence, each product starts at one origin, a production facility, and ends at the same destination, a warehouse. Various terminals which act as transshipment points between the production facility and the warehouse enable the modal shift. In this case, the transportation network is classified as a multi-stage network with transshipment points and no transfer points. The 27 terminals are distributed along the 25,473-km long transport network, which is located in Western Europe encompassing Great Britain, the Netherlands, Belgium and France. Terminals are freight stations that might be classified as container, ferry, shipping or freight terminals and enable the transshipment of truckloads on either different carriers and/or transport modes. Since terminals are modeled as a pair of nodes, the corresponding terminal-dummy nodes amount to 27, resulting in 54 terminal-related nodes in total. The distance between the terminal and the dummy node is set to 10 km to assess the transshipment process. As a consequence, the values of the assessment factors for the transshipment are adapted to the appropriate unit by dividing them by the distance to guarantee accurate value comparison. The network data, in particular the distances, are based on a survey of carriers, current logistics service providers, shipping and railroad companies as well as the reference companies’ in-house employees. In order to enable a sufficient database, additional distance data for transport by road were obtained from www.viamichelin.fr, by rail from www.ecotransit.org and by sea from www.freietonne.de. The ensuing transport lanes overlap each other and define the network structure as shown in Fig. 2 for the lane A (Dundee–Rouvignies) and in Fig. 3 for the lane B (Ballymena–Rouvignies).

In summary, the network design involves, starting from the origins, the in-haulage to the transshipment points by road, the subsequent main run by road, rail and/or sea transport, the out-haulage to the final destination via truck. Within the spanning network the carriers compete with each other in terms of costs, times and GHG emissions. The decision by which carrier and consequently by which mode of transport what share of freight should be distributed under predefined requirements of the reference company is the key objective of this example application.

4.2 Experimental design

The application of the model has the further aim to investigate measurements of GHG reduction in freight transportation as well as the analysis of conflicting criteria in intermodal transportation planning. Therefore, the following first scenario analysis focuses on the optimization of the transport network. In practical manner, the final results of the optimization approach can immediately be implemented by the reference company. Apart from the carrier variation of every scenario, different weighting combinations of the criteria in the objective function are included. In essence, every scenario is assessed sevenfold resulting in seven additional weighting sub-scenarios. These seven sub-scenarios reflect three assessment variants (Full, Semi and Shared) of the criteria weighting (w pk ) as shown in Table 5. The aim of the weighting diversity is the analysis on how the criteria influence the planning of intermodal transports and especially the choice of transport mode. As a remark to presentation purposes, the results of either the weighting scenario (1|1|1) or \( ({\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 3}}\right.\kern-0pt} \!\lower0.7ex\hbox{$3$}}|{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 3}}\right.\kern-0pt} \!\lower0.7ex\hbox{$3$}}|{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 3}}\right.\kern-0pt} \!\lower0.7ex\hbox{$3$}}|) \), as in accordance to model constraint (12), are consistent. The same note accounts for the semi assessed scenarios. Due to the lead time restriction of the reference company to set the maximum travel time for transport lane A to 55 h and transport lane B to 102 h, the service time scenarios are of minor importance leading to the emphasis on the ecological, economic and the multi-criteria assessment scenario.

The initial analysis evaluates different scenarios regarding the current and the additional carrier base as well as the theoretical implementation of Eurocombis and compares the results to the reference scenario (Scenarios 1–3). This reference scenario serves as the numerical foundation for the identification of influences in consequence of the model’s application. The estimated transport volume per transport lane of the year 2011 by the reference company formulates the reference scenario with deriving total GHG emissions, the transport costs in monetary units (MU) and average transit as shown in Fig. 4. The forthcoming sensitivity analysis introduces varying in-transit holding costs and observes its impact on the model results as well as the route, carrier and mode choice (Scenario 4). The concluding results provide practical insights on the planning of intermodal transportation chains with respect to in-transit inventory. Figure 4 provides an overview of the overall scenarios and defines the experimental design for the approaching investigation.

The status quo scenario includes the defined data and the current carriers operating at the reference company (Scenario 1, S1). All the defined model parameters are applied to optimize the status quo of the reference company in planning intermodal transports with respect to the weighted criteria as well as the defined constraints and capacities. On the contrary, the extended scenarios comprise additional carriers in the form of new transport means (Scenario 2, S2) and the prospective application of Eurocombis (Scenario 3, S3). S2 is similar to S1 apart from the consideration of additional routes and transport modes. The goal is the detection of potential improvements for immediate realization. S3 extends the parameter selection by Eurocombis, which provide a high payload capacity per vehicle leading to positive effects on transport sustainability in contrast to trucks. By comparing the reference scenario and the individual weighting scenarios, the optimization approach covers the investigation of 22 scenarios. The analysis in the base scenarios (S1–S3) is extended by the in-transit holding costs to S2 for the evaluation of effects on the model results (Scenario 4, S4) 22 scenarios are observed as well. First, a range of holding costs is set to specify a realistic value base. Second, theoretical in-transit holding costs are determined for each product. With product-specific in-transit holding costs included, the model outcomes are compared to S2 regarding the modal choice and the percentage criteria deviation.

4.3 Data determination

Apart from the model parameters (i.e. number of nodes, products and carriers) and restrictive constraints (terminal, carrier and payload capacities) the input data for the model application covers detailed figures on the calculation of transport emissions. Due to the amount of data required, the reader is referred to Froehling et al. (2013) for a detailed overview on input figures. These comprise the determination of CO2e based on the well-to-wheel emission factors and coefficients per product category (e.g., bulk, average or volume goods) from the aligned sources Kranke et al. (2011), the DIN EN 16258 standard and the application EcoTransIT (2011) for different transport modes as well as classes of transport means (e.g., Eurocombi) and the country-specific electricity mix (eTraction) for electric means of transport. Additional data is briefly provided in this section.

The input data covers carrier- and criteria-specific figures. Within the described transport lanes the distribution of FTLs is done by carriers. For each transport lane particular carriers are assigned with certain characteristics such as the maximal payload in metric tons or the price per kilometer. Depending on the transport lane, either Dundee–Rouvignies (A) or Ballymena–Rouvignies (B), and the option to involve additional transport modes, current and potential carriers are defined. The carriers per transport lane are shown in Table 6 including relevant average figures per carrier as well as the share of transport for road, rail and sea shipping with the current situation at the reference company. The difference in the additional number of carriers between both transport lanes is due to specific requirements of the reference company.

In order to assess every edge of the transport network with the criteria GHG emissions and the transport cost as well as the transit time, their composition have to be identified for every defined carrier. In fact, the distance between every location is known as well as the price per kilometer for every carrier, the determination of the transport cost criteria is consequently evident. In almost the same manner, for the determination of the transit times between two locations the particular speed of the intermodal transport unit is required. This ranges from 50/60/80 km/h for road and 21–45 km/h for sea, and is 21 km/h for rail transport. The terminal operation time ranges between 9 and 50 h.

Another important restriction regarding the terminals is the capacity to process the number of FTL transports within the planning period. As the basis of the planning period for the applied case study is set to one year, the terminal capacity is expressed as the maximal number of transports transshipped at a certain terminal per year. It is assumed in consequence, that the capacity for every terminal is to process 2,500 transports per year. The terminal capacity (U ij ) is a very crucial restriction for the model, due to its impact on the transport network by combining the two sub-networks, one for each transport lane, into one parent network with limited node capacities at terminals. In other words, by assuming the terminal capacity is not restricted, each transport lane can be represented as an individual network and therefore be modeled separately. Further input parameters for the modeling of the described transport network are presented in Table 7 and comprise carrier-specific limitations, supply and demand figures as well as route restrictions. These restrictions might influence the model’s outcome fundamentally. One of those crucial parameters are in-transit holding cost (\( f_{p}^{\text{INV}} \)), which are assigned to every product. The in-transit costs are defined by the ratio of the product’s value and the inventory costs for the planning period and will be explained in more detail later. Nevertheless, the in-transit holding costs are not considered in the base scenarios (S1–S3) and are set to zero. Aside from the actual optimization of the applied intermodal transportation model, the effects of introducing in-transit holding cost is one of the key aspects in this paper and therefore analyzed in detail in scenario S4. To define the assignment of the 90 edges of the network, every product is assigned to corresponding carriers and transport modes with either the calculated travel time or the set terminal time at transshipment points. The final allocation of the parameters results in 262 rows of linear scale transformation assessment for transports (\( f_{skij}^{\text{TR}} \)) and 15 rows for transshipments (\( f_{psk}^{\text{TS}} \)), each per carrier, with respect to the GHG emissions in gCO2e per kilometer, the load time in h · t per kilometer and the cost in accordance to the monetary unit per kilometer.

4.4 Results of the base scenarios

The goal of the model application in the base scenarios (S1–S3) is to compare the effects of a model application in comparison to the reference scenario and investigate the effects of the different criteria on the model results. The results of the three scenarios in combination with the seven weighted sub-scenarios are presented in percentage deviation of total CO2e emissions, transport costs and average transit time to the defined reference scenario in Fig. 5.

For the status quo situation (S1) the most ecological result, by solely weighting the GHG criterion, reduces the total CO2e emissions by 9.7 % and in addition limits the transit time by an average of 22 %, but raises the costs by 12.4 %. The lower emissions are mainly caused by a terminal switch and an increased share of ferry shipping. In this case, road and rail transportation are constrained by physical barriers requiring a detour while ferry shipping enables a time benefit. Considering the cost criteria only, the most economical scenario lowers the total costs by 3 %, while keeping the CO2e emissions in average 1 % higher. The cost savings are mainly caused by a higher share of the railway carrier B_CARRIER_4, which is responsible for almost 50 % of the transports. In line with this figures is the scenario considering multiple criteria with the shared assessment, which improves the status quo situation through decision support with a total cost reduction of 3 % and almost constant GHG emissions (0.6 %). For transport lane A two-thirds of the FTLs are transported by road and one-third by ferry. At transport lane B three-fourths are distributed by ferry shipping and the rest by road. The combination of road and ferry shipping benefits the reduction of the decision criteria and underlines the synergy effects of intermodal transportation chains.

The inclusion of additional carriers and transport modes (S2) has a significant impact on the output. At best for the ecology the CO2e emissions can be reduced by 38.8 %, mainly because of the use of a new railway carrier (A_CARRIER_A2). Especially for product 1 with a carrier share of 58 % the railway seems to be a preferable alternative. For product 2 the railway is ecologically beneficial as well accounting for approximately 18 % of the share due to the intermodal carrier B_CARRIER_A3. Nevertheless, this CO2e reduction is at the expense of comparable high transport costs (+42.3 %). The mentioned carriers, with low average CO2e figures but the highest price rates, are the main cause of the vast total cost upsurge. When emphasizing the economical criterion only, the total cost are reduced by 5.1 % while emitting 2.9 % more of GHG emissions. In that case, the transport by rail is due to the higher transport price less attractive and therefore neither included in the transports of product 1 nor of product 2. Instead, the most inexpensive carriers are applied up to the specified limit of 66 %. Those carriers combine road and water transport, and are mostly ‘fishyback’ operations (RoRo) for transport lane A and container transports (LoLo) for transport lane B, with a predominant proportion of sea shipping. Obviously, the best scenario for a practical implementation is a compromise of all criteria as achieved by the shared assessment. The CO2e emissions decrease by approximately 1.9 %, the cost by 3.2 % and the average transit time remains at 51.8 h for transport lane A and 102 h for transport lane B. In total numbers, the outcome would lead to a saving of approximately 144 kMU, consisting of 75 kMU for transport lane A and 69 kMU for transport lane B, and the reduction of 165.32 tons of CO2e emissions. In evidence, the application of additional carriers is illustrated by the share of transports. Although transport by rail is not included in the solution, the additional carriers A_CARRIER_A1 with 61 % and B_CARRIER_A1 and B_CARRIER_A2, both with about 30 %, are recommended by the decision support system for future implementation. Interesting is the investigation of the critical price of the offered logistics service where railway transportation is an alternative to road and sea. The considered prices per kilometer for the two road-rail carriers are currently 1.214 MU/km for A_CARRIER_A2 and 1.365 MU/km for B_CARRIER_A3. By reducing the price, insights on the attractiveness of the railway in comparison to other transport modes can be provided formulating the subject for further investigations.

The analysis on introducing LHVs reveals the high potential of the Eurocombi (S3). The GHG emissions can be reduced by 45.7 % at the expense of a transport cost increase by 31.6 % mainly due to the similar share of rail transport and the Eurocombi for both products. In contrast, when considering economic objectives, the total costs can be dropped by 21.5 % while increasing the GHG emissions by merely 2.1 %. Those results are primarily caused by a very high proportion of the Eurocombi on the route. In detail, while for transport lane A the Eurocombi claims 96 % of the transport and around 75 % of those are caused by a combination of road and ferry shipping, for transport lane B 72 % are assigned to the Eurocombi carrier B_CARRIER_EU2 and, hence, the combination of container shipping (LoLo) via road and sea. When applying equally shared criteria weightings, the CO2e emissions decrease by 16.3 %, the transportation costs by 15.2 % and the average transit time by 28.4 %. As a result, the potential introduction of LHVs seems to have an enormous impact on emission, cost and time savings representing a valuable, but due to its currently limited area of operation in Europe, unverified form of prospective freight transportation.

By comparing S1, S2 and S3 with each other, the most compromising scenarios are delivered by the shared assessments of the decision criteria. The aggregated perspective emphasizes the consideration of multiple criteria for the planning of intermodal transport chains. Prioritizing a single criterion according to the full assessment scenarios, results in a negative impact on at least one of the other criteria. The focus on minimizing CO2e emissions for instance affects the cost negatively and vice versa. To increase the value of one objective, one may need to reduce the value obtained for other objectives requiring a tradeoff (correlation) analysis for future research.

4.5 Results of the inventory holding cost scenario with sensitivity analysis

While the previous section gained insights with regard to the planning of intermodal transports at the reference company the subsequent numerical investigation focuses on the so far excluded in-transit holding costs (\( f_{p}^{\text{INV}} \)). At first, all weighting assessment scenarios will be investigated and compared to S2 with regard to the introduction of fixed product-specific in-transit holding costs defining scenario 4 (S4). Second, solely the multi-criteria assessment (1|1|1) is analyzed in accordance to varying in-transit holding costs. The calculation of those costs is based on the assumption that product 1 has a value of 60 MU per unit and product 2 has a value of 160 MU per unit. With respect to Arnold et al. (2008, p. 259/626), who estimate inventory cost around 15–20 %, an average inventory holding cost proportion of 20 % results in 12 MU and 36 MU of inventory holding cost per year. This value is divided by the planning period of 1 year leading to the assumed in-transit holding costs of 0.001 and 0.004 MU/h:

4.5.1 Effect of introdution of in-transit holding costs

By applying these holding costs on the transportation process of the model, the accruing effects are illustrated in Fig. 6. The first observation is the expected overall increase of total costs. As the results of the reference scenario were lacking holding costs during the shipping, their consideration leads to additional cost risings. From the ecological point of view, the scenario (1|0|0) shows little consequences on the output while keeping the carrier share constant. By reason of no changes in the objective function, this observation leads to anticipated results. In contrast, the economic scenario (0|1|0) results in a decrease of GHG emissions and reduces the transit time by more than 11 % in comparison to excluding holding costs. Those results are almost merely reasoned by the route modifications of transport lane B. The cost minimization scenario reveals that transport by rail is ignored. Moreover, transport by sea tends to be substituted by road transport when introducing carrying inventory while prioritizing costs. This is the case for transport lane B especially, where B_CARRIER_4 is replaced by B_CARRIER_2, although the former offers a substantially low price per kilometer, but the later has a higher payload capacity (cf. Table 6). This observation is unexpected, since the carrier B_CARRIER_4 is included in every other optimized cost minimization scenario, but highlights the tradeoff between costs and payload capacities. A first statement can be formulated that the introduction of in-transit holding costs effects the intermodal transportation planning to consider carrier payload specifications instead of the offered price only. The results of the multi-criteria scenario (1|1|1) taking inventory in-transit into account are in line with this first statement. First, the reduction of GHG emissions is increased by 7 %. Second, the average transit time is reduced by 13 % mainly due to the reduction of the average time for transport lane B. While the carrier shares of the transport lane A remain, carrier B_CARRIER_4 is replaced by B_CARRIER_2, that primarily applies road transport and leads with a higher payload capacity per FTL to a lower number of transports (60 FTLs less) dropping the total emissions. This effect of applying faster modes of transports but simultaneously mitigating total GHG emissions reveals, that the payload of carriers is another crucial parameter within cost, time and emission tradeoff. Furthermore in scenario (1|1|1), the use of B_CARRIER_A1 is increased by 10 % to favor road transport. The final total costs increase by 8.1 % in comparison to the reference scenario. The complete view on the costs per transport, as shown in Table 8, presents the proportion of the in-transit holding costs. By comparing the reference scenario to S2, the decrease of the average cost per transport is in line with the aggregated view on the total costs. On the contrary, when including in-transit inventory and the resulting costs into the model, as done in S4, both transport lanes show the expected cost growth. With an average transit time (A: 52.5 h; B: 70 h) as well as the number of products per FTL (A: 1,500; B: 262), the average in-transit holding cost per unit can be estimated as shown in Table 8. These figures represent the average costs of storing one FTL during the transportation process and are in line with estimates provided by Gudehus (2011, p. 656) with the ratio between transport and inventory cost being around 10 %. Conclusively, the obtained average in-transit holding cost might be useful to carry forward discussions and future analysis on in-transit inventory considerations in freight transportation. Because of the option to introduce in-transit inventory into the model, the field of application as well as the system boundaries can be enlarged covering inventory theory as a future prospect.

Overviewing the scenario considering multiple criteria and the ecologic scenario, it is detected that the economic scenario benefits the GHG emissions when including in-transit holding into the model. This statement might lead to the conclusion that by including inventory in-transit, the classic business criteria may contribute to the environment, although ecological aspects are not taken into account explicitly. One explanation is the selection of carriers with a higher payload capacity, which results in a lower number of transports (i.e. FTLs) and consequently in fewer emitted CO2e totals.

4.5.2 Varying product-specific in-transit holding costs

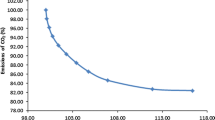

Thus far, a fixed proportion of 20 % of the product values of 60 and 180 MU was assumed as inventory holding cost. However, this proportion is within business practice depending on the product’s category and characteristics, as well as the type of industry. With respect to the obtained information about the product’s value as an additional parameter affecting the average inventory holding cost, the following analysis emphasizes product value variations. Different percentages for average inventory holding cost of product value variations are applied resulting in several product-specific in-transit holding cost scenarios. The remaining parameters are kept constant in accordance to scenarios S2 and S4. In the same manner, the outcomes of the weighting scenarios S2 and S4 are listed to enable a correct comparison of effects. While the product value of 180 MU as well as the inventory holding cost proportion of 20 % remain constant for product 2, these parameters are varied for product 1. The reason behind is the investigation of consequences on the shared terminal capacities of the two transport lanes and the overall influence on the criteria outcomes as well as the route, carrier and modal choice. The product value is increased from 60 to 180 MU, 300, 600 and 1,200 MU, and the inventory holding cost proportion from 5 to 10, 20 and 30 %. The combined parameter variations result in different theoretical in-transit holding cost as shown in Table 9. By applying the presented in-transit holding cost figures on the model, various model output results are obtained. Table 9 highlights different model outputs by the cell color specifying four scenario cases. Whereas cells with no color refer to the same model result as of the multi-criteria scenario S4-(1|1|1), cells in shades of gray refer to changed model results; same-colored cells refer to same outputs. In consequence, three different shades of gray, i.e. light-gray, gray and dark-gray, are distinguishable, indicating three distinctive model outputs as shown in Table 10 of total emissions and costs. With higher in-transit holding costs, the total cost increase as expected, but the total emissions decline. This decline is mainly the cause of carriers with higher payload capacities as investigated in the following.

The first observation defines a critical range of in-transit holding cost that leads to diverse model results. In the observed case the range is between \( f_{1}^{\text{INV}} = 0.01 \) and \( f_{1}^{\text{INV}} = 0.027 \) clarifying the distinguished cases to be analyzed. The detailed model results of the four scenario cases are shown in Table 11. By comparing the carriers and the carrier share of transport lane A, the central aspect is the introduction of the road carrier A_CARRIER_2. The higher the in-transit holding cost are, the higher is the carrier’s share by rising from 0 to 3, 20 and 28 %. Thus, the predominant sea shipping carrier A_CARRIER_1 is less often applied with increasing in-transit holding cost. Although A_CARRIER_1 has a cost advantage of 0.028 MU/km in comparison to A_CARRIER_2, the longer average transit time of 8 h due to slower shipping by sea seems to be the crucial factor for the carrier choice. This aspect is confirmed by the average transit time development of transport lane A, which decreases slightly from 52.5 to 52.4, 52.1 and 51.4 h. With the increasing in-transit holding costs of product 1, the average holding cost per FTL transport rise as well. From the perspective of transport lane B a slight increase of average in-transit holding costs in the colored scenario cases is observable. This increase is mainly due to very little changes in the carrier shares of transport lane B by influencing the average transit time to grow from 70 to 70.1 and 70.5 h. It is worth to emphasize the adjustment of the in bold highlighted carrier route of B_CARRIER_A1 in the dark-gray case. For some FTL transports a longer route by ferry is assigned. This observation is due to the impact of the increased share of road carrier A_CARRIER_2, who consumes the terminal’s capacity and forces FTLs of transport lane B to select other carrier routes. The data are presented in Table 12).

Whereas in S2 in-transit inventory is not taken into account, in the further scenario cases in-transit inventory holding costs are introduced with ascending values. The impact on the total CO2e emissions is a constant decrease up to almost −4 %. The total transportation cost increase with the step-wise rise of product-specific in-transit holding costs to almost 25 %. The decline of the average transit time is the result of the model to priorities the time criterion with growing in-transit holding cost and highlights the payload capacities of the carriers as an additional important parameter. Transport lane B shows no significant effects on the criteria. In fact, because no parameter variation is applied on product 2, the only impact of varying in-transit holding cost of product 1 is the shared terminal capacity of both transport lanes. With high in-transit holding cost of product 1, the terminal capacity is assigned to transport lane A accordingly, rather than being divided among the lanes.

4.6 Considering carrier transshipments

The following excursus on carrier transshipments highlights the importance of carrier replacements on the route and the consideration of transfer points, payload and carrier limitations as well as additional criteria restrictions for a more realistic application approach. To enable carrier transshipments and the resulting modal shifts, certain predefined parameters have to be adapted such as the alignment of the carrier payloads. The previously defined payload capacity is individual and prohibits the replacement of carriers during the distribution process due to the inconsistent carrier payloads. In practice, carriers might interchange on the route due to logistic reasons. Those might be caused by carrier restrictions such as limited scope of operation or transport mode for instance. The payload of every carrier is aligned in accordance to its capacity. By continuing the payload adjustment for each carrier, the model equation for the carrier replacement (9) and the transshipment flow Eq. (5) enable the substitution of carriers by one another. This substitution allows the use of carriers with different transport modes and thus affects the model results. In case of different transport units, such as the trailer type container or semi-trailer truck, the defined payload capacity restricts inappropriate solutions. The transshipment points, which permit the substitution of the carrier, have to be specified as well. Thus, four terminals with high turnover rates are due to its inclusion in both transport lanes set as carrier transshipment terminals (\( V_{{{\text{t}}^{\text{TS}} }} \)). It is the increased problem complexity due to the carrier transshipment terminals that limits the introduction of further ones. Basically, at every additional terminal that permits the substitution of carriers, the model evaluates each carrier with identical payload capacities leading to a larger amount of variables to be considered in the model calculations. Furthermore, transfer points are introduced, which can either be junctions or branches of the transportation flow. Terminal (51|52) is redefined as a transfer point without any terminal operations and criteria weighting assessments. Further input parameters which were not included in the base scenario analysis due to missing data are presented in Table 12. To enable feasible results of the model, the restrictions must be valid. Thus, some experimental model runs were executed and one, which is based on the situation of the scenario S2, is presented in the following.

The effects of the consideration of carrier transshipments via the additional constraints and model features are illustrated in Table 13. The option to transship carriers at terminals comes at the expense of supplementary emissions, costs and operation times for the carrier transshipment process, which is weighted with 1 % of the maximal criteria assessment per carrier for the replacement on new ones. Nonetheless, 3,507 FTLs in total are transshipped on other carriers. As highlighted in bold in Table 13; 1,685 FTLs are transshipped at terminal (45|46) on A_CARRIER_A1; 702 FTLs are transshipped at terminal (43|44) on A_CARRIER_1, and further 1,120 FTLs are transshipped at the same terminal on B_CARRIER_2. All the FTLs are reloaded between heavy trucks, hence, a modal shift is not performed. Another effect highlights the usage of the introduced transfer point (51|52) by the rail carrier A_CARRIER_A2, assuming that in the current case a railway connection to the warehouse in Rouvignies exists, although this route is not taken into account in any observed scenarios (cf. Table 11), but seems to be attractive due to the lack of assessment factors.

The modifications of the model influence the results according to the restrictions and model adjustments. Another observation with respect to the transport capacity of carrier A_CARRIER_A1 reveals the required reduction of the limited amount of transports per year on 1010 FTLs (702 + 308). Moreover, regarding the payload flow constraint, important impacts on the routes of transport lane B occur. Whereas the routes of carrier B_CARRIER_A1 included terminal (15|16), the new route covers terminal (11|12). Further remarks prove the obedience of the carrier satisfaction restrictions and in combination with the other model adjustments lead to a reduction of total GHG emissions and an increase of total costs mainly due to the consideration of in-transit holding cost. In conclusion, the consideration of specific model parameters allows adjustments to achieve the most realistic view on the individual transportation chain to obtain the best possible decision support for the final planning tasks.

5 Discussions

The model development focused on the determination of the most appropriate transport decision for a multinational enterprise and highlights that the balanced realization of the transport modes road and sea is competitive to pure distribution by truck or ship. More precisely because of the flexibility offered by shipping either the vehicle via ferry or the container via maritime vessel, the objectives set by the decision maker are fulfilled. Although container shipping is more environmentally friendly, set lead or transit time constraints limit their usage. By defining hard restrictions on transit times, as applied by the reference companies lead time limit, a shared and synergistic utilization of road and sea as well as container and trailer shipping can be achieved. An additional remark for further research is the restriction of GHG emissions according to the criteria satisfaction constraint while solely prioritizing the economic weighting scenario, which after Hoen et al. (2012, p.18) may lead to emission reductions at smaller cost increases. Taking into account the current discussions on introducing longer heavier vehicles (e.g., Eurocombi) in long-haul freight transportation, its application, especially in combination with sea shipping as demonstrated, might lead to various advantages in terms of emission, cost and time savings. However, trucking processes in general are limited to compulsory rest periods and need to be integrated in future research allowing a more realistic modeling approach.