Abstract

This study investigated the activity and thermostability of α-amylase in green malt across a diverse panel of 54 barley genotypes, comprising 20 mutants, 19 hulled, 4 hulless, and 11 wild types, using starch as a substrate. The primary objective was to assess the variability in α-amylase activity among these genotypes and identify those with superior enzymatic activity and thermostability. Given that α-amylase is the most thermostable enzyme among the diastatic power enzymes yet exhibits significant activity reduction above 72.5 °C, a threshold frequently exceeded in industrial kilning and mashing. This research is therefore crucial for identifying genotypes that could enhance starch hydrolysis efficiency during mashing, a process critically dependent on sufficient enzymatic activity. We reported α-amylase activity and thermostability across a temperature range of 37 to 85 °C. The findings indicated that optimal temperature for α-amylase activity in barley malting lies between 65 and 75 °C. Interestingly, wild barley genotypes demonstrated the highest mean α-amylase activity, while hulless varieties exhibited the lowest. These results were validated by a significant negative correlation between α-amylase activity and the content of starch. Among the 54 genotypes, 11 displayed high α-amylase activity at 65 °C. Furthermore, one mutant (BL2105) and one wild genotype (WS230) exhibited high activity and thermostability at 75 °C, and another wild genotype (WS236) retained 30% of its original activity after heat treatment at 85 °C. These genotypes with enhanced α-amylase activity and thermostability could be strategically exploited in breeding programs to develop superior malt varieties. Such advancements could significantly enhance both malt quality and efficiency in beer production industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The beer production process involves two steps for producing ethanol from cereal: the enzymatic conversion of starch into sugars during mashing, and subsequently, the transformation of these sugars into ethanol and CO2 during fermentation. An efficient beer brewing process requires high-quality raw material (malt), which provides a rich extract and produces a wort conducive to fermentation by brewing yeasts. The malting process remains somewhat traditional, beginning with steeping, where the raw barley grains are soaked in water. This process activates dormant seeds and prepares grains for germination. By the end of steeping, the moisture content of barley increases from approximately 15% to 45% (Lopez et al. 2007; Fix 1999). After steeping, wet grains are spread out in a germination bed, either in traditional floor maltings or specialized germination vessels. During this phase, hydrolytic enzymes facilitate structural changes within the kernel, leading to the breakdown of large molecules into reducing sugars and free amino acids. The primary goal of germination is to activate enzymes, especially amylases, which play a crucial role in breaking down starches into fermentable sugars during the brewing process. Finally, the germinated grains (green malt) grains are kilned at temperatures ranging from 45–85 °C to halt enzyme activity, producing the malt that contributes color and flavor to beer (Briggs 1998). The finished malt is milled creating grist. The grist, containing endogenous amylases is mixed with water and heated at high temperature (~ 50–70 °C) to convert the residual starch to simple sugars. The step during which gelatinization of the starch granules occur is called mashing, and immediately following it, the liquid, or “wort”, is separated and processed further to make beer (Fox and Bettenhausen 2023). Production of high-quality malt and wort requires efficient activity and thermostability of hydrolytic enzymes (proteolytic, cytosolic, and amylolytic) that are activated or produced during germination. Notably, barley-derived amylases, particularly α and β-amylase, play the most important role in fermentable sugar production (Pares Viader et al. 2021). However, the kilning and mashing stages, which involve elevated temperatures, can significantly influence the stability and activity of these enzymes. Therefore, understanding the thermostability of these enzymes is vital in the brewing industry. Given its contribution to diastatic power (DP) and sensitivity to heat, extensive research has focused on enhancing the thermostability of β-amylase by examining barley cultivar variations (Eglinton et al. 1998; Wang et al. 2003; Gong et al. 2013; Zhang et al. 2014), the exploration of α-amylase variations across barley cultivars remains limited. Despite its lesser contribution to DP than β-amylase, it is the most thermostable of all amylolytic enzymes found in barley malt (Evans and Fox 2017). As a result, with β-amylase becoming denatured in the mashing process, the importance of α-amylase in breaking down starch and maltodextrins into simpler sugars becomes significant. (Henson et al. 2014).

Beer and wine have concealed a fascinating part of history and social life. Over the past half-century, advancements in beer and wine production have been driven by evolving consumer preferences, technological innovations, and a deeper understanding of the brewing sciences. In 2021, global beer production surged to 1.86 billion hectoliters from 1.3 billion in 1998, showcasing the ever-growing demand and love for beer. China, with its vast population, has emerged as the predominant producer and consumer of beer, reflecting the global shift in beer consumption patterns (Statista 2022). The selection of grains during the brewing process is fundamental for defining the taste, texture, and quality of beer. Various cereals, including wheat, barley, sorghum, corn, rice, and oats, are frequently used in multiple forms to obtain different beers (Puligundla et al. 2020). Barley stands out unequivocally as a global favourite. Its unique composition, especially its optimal protein-to-starch ratio, makes it an ideal grain for brewing (Rani and Bhardwaj 2021). Moreover, barley exhibits a wide range of phenotypic and genetic variations due to its extensive history of cultivation and its adaptation across various global environmental and climatic conditions. This diversity is preserved in gene banks, both governmental and international, and in germplasm collections housed in universities, research institutions, breeding firms, and international agricultural agencies (Visioni et al. 2023). Recognizing the unparalleled importance of barley in beer production, there has been a surge in research aimed at improving barley varieties.

α-amylase (α-1,4 glucan glucanohydrolase EC. 3.2.1.1), an endohydrolase, is main enzyme in starch hydrolysis during mashing, breaking down amylose and amylopectin into dextrin (Pati and Samantaray 2022). It is synthesized in the aleurone layers of germinating grains in response to gibberellins (Zhang et al. 2019). In barley, there are two α-amylase isozyme families, AMY1 and AMY2. The two families have distinct isoelectric points (pIs) with AMY1 ranging from 4.7–5.2 and AMY2 from 5.9–6.1 (Ajandouz et al. 1992). Notably, AMY2 constitutes 80–98% of the overall α-amylase content in green malt. Unlike AMY1, its levels remain largely consistent during heat treatment in the kilning process (Jones and Jacobsen 1991; Tibbot et al. 2002). Although both isoforms share 80% sequence similarity (Rogers 1985), they exhibit variations in certain physical and chemical characteristics. These differences include the affinity for calcium ions, thermostability and pH fluctuations (Jones and Jacobsen 1991; Rodenburg et al. 1994). In a recent transcriptomic study, malting barley was observed to differentially express 25 of 40 starch hydrolytic enzyme genes, with the maximum number of genes contributing to α-amylase (Vinje et al. 2021). These enzymes exhibit various biochemical properties and thermal responses. Studies indicate that α-amylase starts to lose its activity above 72.5 °C and becomes inactive at 80 °C (de Schepper et al. 2021). Evan et al. (2003) observed that the levels of activity retained after a 10-min exposure to 72.5 °C ranged from 25 to 67%.

Identifying barley genotypes with enhanced α-amylase activity and thermal stability can revolutionize brewing efficiency, and these genotypes can be used to identify novel α-amylase alleles associated with high activity and thermostability. Based upon previous literature on barley malting, there is limited investigation into how the genetic differences among barley cultivars influence α-amylase activity and its thermostability. Published studies have generally involved a narrow selection of genotypes or have examined a limited temperature range for thermostability. In the present study, we investigated the activity and thermal stability of α-amylase across a range of temperatures (37, 55, 65, 75, and 85 °C) in wide barley germplasm, including mutant, hulled, hulless, and wild barley. Further we validated our results by correlating the activity of α-amylase with starch content of green malt. A deeper understanding of the improved α-amylase activity and thermostability in the identified barley varieties can help ensure a consistent and effective conversion of starch to sugars during mashing, even under suboptimal conditions. It may also pave the way for new brewing techniques that exploit the full potential of these enzymes. Consequently, identifying the genotypes with high activity and thermostability can be a game-changer for the beer industry, leading to higher yields, better consistency, and potentially novel beer flavors and profiles.

Materials and method

Plant material and malting procedure

Barley seeds from 54 genotypes (comprising 20 mutants, 19 hulled, 11 wild and 4 hull-less) were cultivated and harvested from the fields of Department of Plant Breeding and Genetics. Before initiating the malting process grains larger than 2.5 mm were selected after removing the thinner ones and seeds were sterilized in a 0.3% sodium hypochlorite solution for 20 min and rinsed with sterile distilled water to prepare for malting. The malting was carried out in a biological oxygen demand (BOD) incubator set at 18 °C and 75–85% humidity. The steeping process was divided into three phases: 8 h wet stage, 17 h air rest, then a 6 h wet stage. The germination was done at 17 °C for 96 h. After this, barley seeds whose plumules had grown to about 75% of the grain’s length were selected.

Extraction and estimation of α amylase

Germinated barley grains (200 mg) were ground with 2 ml of an extraction buffer. The extraction buffer consisted of 50 mM sodium acetate (pH 5), 1 mM calcium chloride, and a small amount of polyvinylpyrrolidone. After thoroughly mixing, the mixture was left at ambient temperature for one hour. The resulting homogenate was then strained through cheesecloth and subsequently centrifuged at 10,000 × g for 10 min at a temperature of 4 °C. To inactivate the β-amylase, the collected supernatant was heated to 70 °C for a duration of 20 min. After cooling, it was centrifuged again at 10,000 × g for 15 min and 4 °C. The resulting clear supernatant was then used to measure the α-amylase activity as described by Devi et al. (2007).

Estimation of α amylase activity and thermostability

To measure the enzyme activity, 450 ul of 50 mM sodium acetate buffer containing 1 mM calcium chloride was added to a mixture containing the enzyme (50 µl) and the substrate (500 µl). The substrate used was 1% starch, prepared in 50 mM sodium acetate buffer with a pH of 5.0. Following one hour incubation in a water bath at temperatures of 37 °C, 55 °C, 65 °C, 75 °C and 85 °C, the reaction was stopped with 1 ml of alkaline copper solution. The Nelson and Somogyi method was employed to determine the reducing sugars produced by α-amylase, using water as a control (Nelson 1944). The test values were calculated by deducting the optical density (OD) of the substrate and enzyme blanks. The α-amylase activity was measured by preparing standard curve of glucose, ranging from 20 to 100 µg. Protein concentration in the enzyme extract was measured following the Lowry method (Lowry et al. 1951), using bovine serum albumin (BSA) as a standard, within a 10–100 µg range. The specific activity of α-amylase was expressed in enzyme activity units per milligram of protein. To investigate the thermostability in more detail, enzyme extracts were incubated for 10 min at temperatures ranging from 55 to 85 °C. Right after the incubation, the tubes were promptly cooled by placing them on ice. The remaining activity of the enzyme was measured using 50 µl samples from these temperature-treated extracts, following the previously described method for samples at 37 °C without treatment. The percentage of relative residual activity was determined by comparing the enzyme activity between treated and untreated conditions.

Extraction and estimation of starch

Starch extraction followed a slightly adjusted method from Yoshida et al. (1976). Barley green malt (200 mg) was treated with 4 ml of 80% ethanol, followed by heating in a boiling water bath for 2 h. The extract was then filtered to separate the sugars. This procedure was repeated using both 80% and 70% ethanol. The remaining residue, which contained starch, was dried at 60 °C. 4 ml of distilled water was added to the dried residue, and the mixture was boiled for half an hour. Subsequently, 9.2 N perchloric acid (HClO4) was added, and the mixture was stirred for 15 min. After centrifuging at 2000 × g, the supernatant was collected. The pellet was treated with 2 ml of 4.6 N HClO4, stirred for another 15 min, and then diluted to 10 ml using distilled water. After another round of centrifugation at 2000 × g, the supernatants were combined and diluted with distilled water to a total volume of 25 ml. The total sugars in the combined supernatants were quantified using the Dubois et al. (1956) method. The standard curve of starch (10–100 µg) was prepared simultaneously.

Statistical analysis

The activity and thermostability measurements were based on the average of three replicates. These averages were then analysed using a analysis of variance, conducted with the GraphPad Prism software (version 9.0.0). Graphical representations were created using Microsoft Excel (Office 365), R (version 4.2.0), GraphPad Prism (version 9.0.0), and NCSS statistical software (2022). To quantify the relative change in enzyme activity, a straightforward percentage change calculation was employed. By subtracting the initial values from the final observed values, and normalizing this difference to the initial value, we obtained a clear metric of change, expressed as a percentage. This method provides a direct and interpretable measure of how enzyme activity varied across different conditions. Furthermore, to facilitate a more structured analysis, the barley genotypes were stratified into three distinct categories based on their enzyme activity and thermostability profiles: low, medium, and high. This categorization was done using equal distribution method by subtracting the lowest value from the highest value. The resulting difference was then divided by three, creating three categories of equal range, as described by Kaur et al. (2019). Such categorization not only aids in the comparative analysis of genotypes but also provides insights into potential genotype clusters that might exhibit similar patterns under varying temperature conditions.

Results and discussion

Examination of variation in α-amylase activity in green malts at different temperatures.

The α-amylase activity is crucial in the malting process as it directly influences the breakdown of starches, thereby affecting the sugar profile and ultimately determining the brewing efficiency and flavor profile of beer. In this study, green malt from various barley genotypes, including hulled, hulless, wild, and mutant types, were analyzed for α-amylase activity and thermostability across a temperature range of 37 to 85 °C. The genotypes, along with their pedigree information, are mentioned in Supplementary Table 1. Among the 54 barley samples examined, the pattern of α-amylase activity showed significant variation, with significant differences at varying temperatures (ANOVA, P < 0.0001, α = 0.05, as depicted in Fig. 1). This variation underscores the substantial impact of genotypic differences on enzyme activity. This finding is consistent with previous research indicating substantial variation in α-amylase activity among different barley cultivars (Acquistucci et al. 2011; Cu et al. 2016; Bera et al. 2018).

Mean α-amylase specific activity (units per milligram of protein) at temperatures of 37, 55, 65, 75, and 85 °C. Each measurement was performed in triplicate. Error bars represent the standard deviation for the average activity at each temperature. Distinct letters signify statistically significant variations with a p value of less than 0.05, as determined by Tukey’s HSD test

At 37 °C, α-amylase activities in the genotypes ranged from 24.4 to 800 U/mg protein (Fig. 2a), with most genotypes (33%) exhibiting activity within the 100–200 U/mg protein range (Fig. 3a). The highest average α-amylase activity was higher in wild genotypes (404.9 U/mg protein), followed by hulled (252.1 U/mg protein), mutant (191 U/mg protein), and hulless varieties (77.4 U/mg protein). Notably, two wild genotypes, WS228 and WS230, showed exceptionally high α-amylase activity in the higher range of 541.4 to 800 U/mg protein, this level of enzymatic activity was not observed in the hulled, mutant, or hulless genotypes at 37 °C. This striking difference in enzyme activity underscores the potential of wild genotypes in enhancing malting quality. When compared to wild types, the α-amylase activity in hulled genotypes was 1.6-fold lower, in mutants 2.12-fold lower, and in hulless genotypes 5.23-fold lower. This trend suggests a significant correlation between genotype and enzyme activity, with wild genotypes emerging as superior in terms of α-amylase production. All hulless genotypes showed activity in the lower range (24.30–108.35 U/mg protein), with KARAN16 recording the lowest activity (88 U/mg protein). This finding supports the hypothesis that α-amylase activity in hulless barley is compromised due to reduced enzyme synthesis during malting, possibly a consequence of acrospire loss and kernel damage owing to the absence of hull protection (Li et al. 2006). Prior research on different hulless varieties has shown that α-amylase in hulless barley malt is more susceptible to inactivation during kilning than in hulled barley malts (Edney and Langrell 2004; Li et al. 2006). The high temperatures used in kilning contribute to the hardening of hulless barley malt, leading to poor malt modification. However, optimizing kilning conditions and modifying the germination process can mitigate damage to acrospires in hulless barley. In a recent study, Izydorczyk et al. (2022) developed hulless barley lines with improved malting potential, marked by significant enhancements in diastatic enzyme levels. The authors suggested that multiple steeping/air-resting cycles and increased water uptake during steeping benefitted the newly developed hulless barley lines. These newly developed lines demonstrated starch contents ranging from 50–70%, aligning with findings from other studies (Asare et al. 2011; Li et al. 2021). In our study, the high starch content in hulless genotypes (67.5–70%) compared to other varieties suggests an insufficient level of α-amylase activity in these lines.

Bar charts depicting the α-amylase specific activity (units per milligram of protein) for each genotype at temperatures of 37, 55, 65, 75, and 85 °C. Different colors of the bars represent different genotype types (mutant, hulled, hulless, and wild barley). Each measurement was performed in triplicate. Error bars represent the standard deviation in the specific activity of each genotype. Statistically significant differences between genotypes at each temperature are indicated by distinct letters, with a significance level of p < 0.05, as determined by Tukey’s HSD test

At 55 °C, notable increase in α-amylase activity was observed across all genotypes compared to their performance at 37 °C. Specifically, the mutant and hulled genotypes demonstrated a significant 40% increase in their average enzyme activity. In contrast, the hulless and wild genotypes exhibited more modest increases of 23% and 8%, respectively. This differential response to temperature among genotypes could be attributed to variations in the amino acid composition and tertiary structure of the α-amylase enzyme, which affect its thermal stability and activity profile. Figure 2b represents the α-amylase activity of individual genotypes at 55 °C. Analyzing the frequency distribution of α-amylase specific activity at this temperature, we found that 50% of the total genotypes fell within the 100 to 300 U/mg protein range, while 18% displayed activity in the 300–400 U/mg protein range (Fig. 3b). Among all, the average activity was highest in wild genotypes (437.5 U/mg protein). Notably, two wild genotypes, WS228 and WS230, stood out with an exceptionally high activity range of 600–860 U/mg protein. Additionally, the hulled genotype BL1714, which exhibited relatively low α-amylase activity (128.4 U/mg protein) at 37 °C, displayed a remarkable increase to 860 U/mg protein at 55 °C. This genotype also demonstrated high thermostability for β-amylase across all the temperatures from 37 to 85 °C, as reported in our previous publication (Rani et al. 2022). The activity of hulled, mutant and hulless genotypes was 1.3, 1.4 and 1.2-fold lower than that of wild genotypes at this temperature.

In our study, all examined genotypes reached their peak α-amylase activity at 65 °C, indicating that the temperature range of 65–75 °C is optimal for α-amylase activity. These findings are in line with previous research suggesting that α-amylase is one of the most thermostable enzymes involved in diastatic power, retaining nearly 100% of its activity after an hour at 65 °C during simulated mashing processes (Evans and Fox 2017; Evans et al. 2003). In contrast, the activity of mutant genotypes almost doubled at 65 °C, while hulled and wild genotypes demonstrated an increase of more than 22%, respectively, compared to their activity levels at 55 °C. Figure 2c represents the α-amylase activity of individual genotypes at 65 °C. Further analysis revealed that 28% of the genotypes had activity levels ranging from 300 to 400 U/mg protein (Fig. 3c). Notably, except for the hulled genotype BL1714, all genotypes which displayed high activity at 55 °C also maintained their performance in the higher range at 65 °C, with activities varying from 197 to 890 U/mg protein. The average α-amylase activity was highest in wild genotypes (536.1 U/mg), with four wild genotypes, WS228 (890 U/mg protein), WS230 (847.5 U/mg protein), WS220 (719 U/mg protein) and WS231 (690 U/mg protein) showing activity in higher range, underscoring their potential for efficient starch conversion in brewing processes. Moreover, two hulled, BL1715 (811 U/mg protein) and PL807 (668 U/mg protein) and five mutant genotypes, including BL2089 (836.5 U/mg protein), BL2091 (711 U/mg protein), BL2098 (707.2 U/mg protein), BL2079 (691 U/mg protein), BL2087 (684.67 U/mg protein) possessed activity in higher range. The average α-amylase activity was observed to be highest in wild genotypes followed by mutants, hulled and hulless.The α-amylase activity is notably impacted by various factors including genetic makeup, germination duration, growth conditions, and the presence of endogenous α-amylase inhibitors and the hormone gibberellin (Cu et al. 2016). In our study, while growth conditions and germination times were uniform across all genotypes, the genetic diversity, levels of α-amylase inhibitors, and the synthesized gibberellic acid (GA) in different genotypes likely contributed to the observed variations in α-amylase activity. Moreover, product inhibition or competition could be another factor influencing enzyme activity in barley. Recent findings by de Schepper et al. (2022) suggest that all products of starch hydrolysis, not just maltose, can diminish α-amylase activity. This is supported by the Baks et al. (2006), who found that increasing concentrations of soluble starch, maltodextrin, and sugars led to decreased amylase activity. Thus, understanding the extent to which product inhibition from starch hydrolysis impacts starch degradation efficiency during mashing is a crucial area for future research.

α-amylase activity declined significantly at 75 °C for all the genotypes except BL2105 and WS230 (Fig. 2d). These results were in line with other studies, which suggested that activity for α-amylase decreased once the temperature increased above 72.5 °C (de Schepper et al. 2021; Evans et al. 2003). Decline was more than 50% for all the varieties when the temperature is raised to 75 °C, indicating a quick degradation of the enzyme at 75 °C. The presence of bifunctional amylase subtilisin inhibitor (BASI, an inhibitor of α-Amy II isoform) above 75 °C in these genotypes may be another factor for low activity at higher temperature. However, the decline was highest (82%) in the case of hulless genotype. This supports an idea that enzymes in hulless barley have less activity because of lack of insulation of a hull during kilning. Figure 2d represents the α-amylase activity of individual genotype at 75 °C. The frequency distribution of the means for α-amylase activity at 65 °C indicated that 76% of the genotypes had α-amylase activity up to 200 U/mg protein and few had activity ranging from 200–300 U/mg protein (Fig. 3d). Two genotypes, a mutant BL2105 and a wild genotype WS230 had activity in the higher range (698–1040 U/mg protein). All the remaining genotypes had α-amylase activity in lower range (14–356 U/mg protein). The average α-amylase activity was observed to be less in the case of mutant, hulled and hulless as compared to wild genotypes. All the hulless genotypes possessed activity below 100 U/mg protein with BHS352 possessing the highest activity (83 U/mg protein).

At 85 °C, an analysis of variance revealed a significant decrease in α-amylase activity compared to its activity at 75 °C (P = 0.0012). The total decrease in activity exceeded 60% as compared to 65 °C, with the majority of genotypes exhibiting a decline greater than 80%.The average α-amylase activity in hulless, mutant, hulled, and wild genotypes diminished by 77%, 70%, 53%, and 42%, respectively, relative to their activity at 75 °C. The range of α-amylase activity at 85 °C was between 3.14 and 378 U/mg protein. Figure 2e depicts the α-amylase activity of each genotype at 85 °C. The frequency distribution for α-amylase activity at 85 °C, as shown in Fig. 3e, indicates that most of the genotypes exhibited activity below 100 U/mg protein, while the rest had activity under 200 U/mg protein, except for one wild genotype, WS236, which showed the highest activity of all (238 U/mg protein). It was also observed that the average α-amylase activity in hulless, mutant, and hulled genotypes was significantly lower (12-fold, twofold, and 1.6-fold, respectively) compared to wild genotypes.

Variation among mutants, hulled, hulless, and wild barley genotypes for α-amylase activity at different temperatures

The average α-amylase activity for mutant, hulled, hulless, and wild barley genotypes within the studied temperature range are presented in Fig. 4. Analysis of variance revealed significant variations in α-amylase activity among these genotypes (P < 0.001, α = 0.05), with temperature changes further influencing these differences (P < 0.001, α = 0.05). Principal Component Analysis (PCA) was employed to assess the impact of temperature on the α‐amylase activity of a diverse array of barley genotypes (n = 54). Based on the eigenvalues, two principal components (PCs) were identified: PC1, accounting for 58.45% of the total variance, and PC2, explaining 21.7%. Together, these PCs represented 80.1% of the total variation. The PCA biplot, depicted in Fig. 5, clearly illustrates the distribution of genotypes across various temperature treatments and their interaction with the first two PCs.

Comparison of α-amylase activity in a mutants, b hulled, c hulless, and d wild barley genotypes across various temperature ranges. Each measurement was performed in triplicate. The box plots display the interquartile range (IQR) and whiskers representing 1.5 times the IQR. Black line within each box indicates the mean activity. Outliers are represented by dots outside the whiskers. Each dot within the box plots represents a different genotype, with colors of the boxes corresponding to different temperatures (37 °C, 55 °C, 65 °C, 75 °C, and 85 °C). Distinct letters indicate statistically significant differences in mean activity at each temperature for each genotype type (mutants, hulled, hulless, and wild), as determined by one-way ANOVA followed by Tukey’s HSD test

Biplot of principal components analysis separates the 54 barley genotypes based on the specific activity at five different temperatures. The X axis corresponds to the PC1 values and the Y axis to the PC2 values. Each point shows the sample scores in the two PCs. Black arrows represent the contribution and direction of different temperature treatments contribution on PC1 and PC2. PC, Principle component

The observed average α-amylase activity was notably lowest in hulless genotypes and highest in wild genotypes across all tested temperatures. Of all the genotypes studied, eleven demonstrated notably high α-amylase activity (ranging from 659 to 890 U/mg protein) at a temperature of 65 °C. Interestingly, two genotypes, one wild (WS230) and one mutant (BL2105), exhibited significantly higher α-amylase activities at 75 °C. At this temperature, WS230 maintained an α-amylase activity similar to that at 65 °C, while BL2105 showed a threefold increase in activity compared to its performance at 65 °C. However, a sharp decline in activity was noted at 85 °C. Yet, WS236, another wild genotype, showed a marked increase in activity at 85 °C. These three genotypes, WS236, WS230, and BL2105, demonstrated distinct responses to temperature variations, as indicated by their PC1 scores. Contrarily, none of the hulled or hulless genotypes showed higher range activities at 75 °C and 85 °C. Within the hulled category, BL1714 showed the highest activity at 55 °C, while BL1715 and PL807 showed highest activity at 65 °C, demonstrating their high activity. This increased activity may be due to the presence of diverse α-amylase isozymes or unique α-amylase alleles in these barley lines, possibly offering more stable enzyme structures at elevated temperatures. Variations in α-amylase isozymes might arise from post-translational modifications, such as protease cleavage at the C or N termini (Koehler and Ho 1990; Jones and Jacobsen 1991; Søgaard et al. 1991). Unlike enzyme activity, thermostability is less impacted by germination time and is more closely linked to protein structure (Kadziola et al. 1994) and the heat shock response generated during heat stress. Previous research on β-amylase has delved into various factors influencing its activity and thermostability, including site‐directed mutagenesis, random mutation, and substrate docking. However, detailed information on factors enhancing α-amylase’s thermostability remains scarce. Cu et al. (2016) identified three single nucleotide polymorphisms in the amy1 gene sequence of a wild barley accession (Tel-Shoket CPI77146-32), potentially contributing to the enhanced activity and thermostability of α-amylase in this variety. Further investigations, particularly in mapping populations derived from these identified lines, are expected to shed more light on the underlying reasons for the heightened α-amylase activity.

Residual α-amylase activity of barley genotypes after incubation at different temperatures

To study the thermal stability of α-amylase from various barley genotypes, the residual α-amylase activity was measured following a 10-min exposure to temperatures between 55 and 85 °C. There was no significant difference in mean residual activities at 55 °C versus untreated samples and 65 °C versus untreated samples except in case of hulless, as shown in the Fig. 6. Notably, there was a significant reduction of 70–90% in residual α-amylase activity after a 10-min exposure at 75 °C, with a further pronounced decrease observed at 85 °C. These findings are in line with the earlier observations that α-amylase activity diminishes significantly at elevated temperatures of 75 and 85 °C. Interestingly, the mutant genotype BL2105, known for its high α-amylase activity at 75 °C, showed non-significant change for residual activity after a 10-min heat treatment at 75 °C as observed in the untreated sample. This suggests that BL2105 possesses a unique thermal stability or a heat-resistant variant of α-amylase. WS230, also characterized by high enzyme activity at 75 °C, demonstrated 40% reduction in activity after the same heat treatment. This indicates that while WS230 has robust α-amylase activity and is thermally stable but its enzyme is not as thermally stable as that of BL2105. Furthermore, % decrease in residual activity after heat treatment at 75 °C was substantially highest in hulless barley genotypes followed by hulled, mutant and wild genotypes. At 85 °C, almost all genotypes exhibited negligible residual activity, except for WS236, which retained 30% of its activity.

Scatter plot representing the residual α-amylase activity after a 10-min heat treatment at various temperatures (55 °C, 65 °C, 75 °C, and 85 °C). The reference activity, recorded at 37 °C, corresponds to the untreated control samples. Each point represents average residual activity for studied genotypes, with shapes and colors differentiating the genotype types. Mean activity for each genotype type is represented by lines connecting the mean values across temperatures. Different letters indicate statistically significant differences in average residual activity between genotype types and temperatures, as determined by Tukey’s HSD test. Each measurement was performed in triplicate

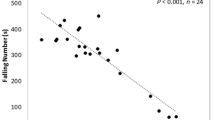

Correlation of α-amylase activity with starch content in different barley genotypes

The correlation of starch content with α-amylase activity at 37 °C is presented for each genotype in Fig. 7. There was a significant variation in the total starch concentration among the 54 genotypes, ranging from 50–70% (p < 0.0001, α = 0.005). The results confirmed the anticipated inverse relationship between total α-amylase activity and starch content. In summary, there was a strong negative correlation between starch content and α-amylase activity (r = -0.87, p < 0.001), highlighting the critical role of α-amylase in converting starch into sugars.

Conclusion

This study highlights significant variability in α-amylase activity among different barley genotypes, underscoring the crucial role of temperature on enzyme performance. The data indicate that α-amylase activity peaks at 65 °C and significantly declines at 75 °C, suggesting an optimal activity range between 65 and 75 °C. Eleven genotypes exhibited exceptionally high activity at 65 °C, with one mutant genotype (BL2105) and one wild genotype (WS230) demonstrating both high activity and remarkable thermostability at 75 °C. These genotypes could be targeted for enhancing malting efficiency. Furthermore, wild varieties demonstrated higher average activity and residual activity percentages compared to hulled, hulless, and mutant types, underscoring their value as resources for breeding programs aimed at improving thermal stability in cultivated barley. Identifying the isoforms related to high activity and thermostability in these genotypes in future studies could lead to advancements in enzyme engineering, optimizing α-amylases for different temperatures, and enhancing malting processes. Additionally, genotypes with lower thermostability identified in our study could be further tested for desirable malt qualities and might be useful in producing low-alcohol beers.

Abbreviations

- BOD:

-

Biological oxygen demand

- BSA:

-

Bovine serum albumin

- DP:

-

Diastatic power

- GA:

-

Gibberellic acid

- OD:

-

Optical density

- PC:

-

Principal component

- PCA:

-

Principal component analysis

- U/mg:

-

Units per milligram

References

Acquistucci R, Turfani V, Aureli G (2011) Amylase modification induced by the germination process in organic barley. Eur Food Res Technol 232(4):583–590. https://doi.org/10.1007/s00217-011-1423-y

Ajandouz EH, Abe J, Svensson B, Marchis-Mouren G (1992) Barley malt-α-amylase. Purification, action pattern, and subsite mapping of isozyme 1 and two members of the isozyme 2 subfamily using p-nitrophenylated maltooligosaccharide substrates. Biochim Biophys Acta Gen Subj 1159:193–202

Asare EK, Jaiswal S, Maley J, Baga M, Sammynaiken R, Rossnagel BG, Chibbar RN (2011) Barley grain constituents, starch composition, and structure affect starch in vitro enzymatic hydrolysis. J Agric Food Chem 59(9):4743–4754. https://doi.org/10.1021/jf200054e

Baks T, Janssen AE, Boom RM (2006) The effect of carbohydrates on α-amylase activity measurements. Enzyme Microb Technol 39(1):114–119. https://doi.org/10.1016/j.enzmictec.2005.10.005

Bera S, Sabikhi L, Singh AK (2018) Assessment of malting characteristics of different Indian barley cultivars. J Food Sci Technol 55(2):704–711. https://doi.org/10.1007/s13197-017-2981-1

Briggs DE (1998) Malts and malting. Springer Science & Business Media, Berlin

Cu ST, March TJ, Degner S, Eglinton JK (2016) Identification of novel alleles from wild barley for the improvement of α-amylase and related malt quality traits. Plant Breed 135(6):663–670. https://doi.org/10.1111/pbr.12417

De Schepper CF, Michiels P, Buvé C, Van Loey AM, Courtin CM (2021) Starch hydrolysis during mashing: a study of the activity and thermal inactivation kinetics of barley malt α-amylase and β-amylase. Carbohydr Polym 255:117494. https://doi.org/10.1016/J.CARBPOL.2020.117494

Devi R, Munjral N, Gupta AK, Kaur N (2007) Cadmium induced changes in carbohydrate status and enzymes of carbohydrate metabolism, glycolysis and pentose phosphate pathway in pea. Environ Exp Bot 61(2):167–174. https://doi.org/10.1016/j.envexpbot.2007.05.006

Dubois M, Gilles KA, Hamilton JK, Rebers PT, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28(3):350–356

Edney MJ, Langrell DE (2004) Evaluating the malting quality of hulless CDC Dawn, acid-dehusked Harrington, and Harrington barley. J Am Soc Brew Chem 62:18–22. https://doi.org/10.1094/ASBCJ-62-0018

Eglinton JK, Langridge P, Evans DE (1998) Thermostability variation in alleles of barley beta-amylase. J Cereal Sci 28:301–309. https://doi.org/10.1016/S0733-5210(98)90010-8

Evans DE, Fox GP (2017) Comparison of diastatic power enzyme release and persistence during modified Institute of Brewing 65 C and Congress programmed mashes. J Am Soc Brew Chem 75(4):302–311. https://doi.org/10.1094/ASBCJ-2017-4707-01

Evans E, Van Wegen B, Ma Y, Eglinton J (2003) The impact of the thermostability of α-amylase, β-amylase, and limit dextrinase on potential wort fermentability. J Am Soc Brew Chem 61(4):210–218. https://doi.org/10.1094/ASBCJ-61-0210

Fix G (1999) Principles of brewing science: a study of serious brewing issues. Brewers Publications, Boulder

Fox GP, Bettenhausen HM (2023) Variation in quality of grains used in malting and brewing. Front Plant Sci 14:1172028. https://doi.org/10.3389/fpls.2023.1172028

Gong X, Westcott S, Zhang XQ, Yan G, Lance R, Zhang G, Sun D, Li C (2013) Discovery of novel Bmy1 alleles increasing β-amylase activity in Chinese landraces and Tibetan wild barley for improvement of malting quality via MAS. PLoS ONE 8(9):e72875. https://doi.org/10.1371/journal.pone.0072875

Henson CA, Duke SH, Vinje MA (2014) A comparison of barley malt amylolytic enzyme thermostabilities and wort sugars produced during mashing. J Am Soc Brew Chem 72(1):51–65. https://doi.org/10.1094/ASBCJ-2014-0130-01

Izydorczyk MS, Badea A, Beattie AD (2022) Physicochemical properties and malting potential of new Canadian hulless barley genotypes. J Am Soc Brew Chem 81(2):299–307. https://doi.org/10.1080/03610470.2022.2065453

Jones RL, Jacobsen JV (1991) Regulation of synthesis and transport of secreted proteins in cereal aleurone. Int Rev Cytol 126:49–88. https://doi.org/10.1016/S0074-7696(08)60682-8

Kadziola A, Ji A, Svensson B, Haser R (1994) Crystal and molecular structure of barley α-amylase. J Mol Biol 239:104–121. https://doi.org/10.1006/jmbi.1994

Kaur S, Bhardwaj RD, Kapoor R, Grewal SK (2019) Biochemical characterization of oat (Avena sativa L.) genotypes with high nutritional potential. LWT - Food Sci 110:32–39. https://doi.org/10.1016/j.lwt.2019.04.063

Koehler SM, Ho TH (1990) Hormonal regulation, processing, and secretion of cysteine proteinases in barley aleurone layers. Plant Cell 2(8):769–783. https://doi.org/10.1105/tpc.2.8.769

Li Y, McCaig R, Egi A, Edney M, Rossnagel B, Sawatzky K, Izydorczyk M (2006) Malting characteristics of three Canadian hulless barley varieties, CDC freedom, CDC mcgwire, and CDC gainer. J Am Soc Brew Chem 64(2):111–117. https://doi.org/10.1094/ASBCJ-64-0111

Li M, Geng L, Xie S, Wu D, Ye L, Zhang G (2021) Genome-wide association study on total starch, amylose, and amylopectin in barley grain reveals novel putative alleles. Int J Mol Sci 22(2):553. https://doi.org/10.3390/ijms22020553

Lopez PP, Prieto FG, Gaytan MM, Roman AD (2007) Chemical and physical characterization of different barley varieties produced in the center region of Mexico. Rev Chil Nutr 34:1–12. https://doi.org/10.4067/S0717-75182007000100008

Lowry O, Rosebrough N, Farr A, Randall R (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193(1):265–275

Nelson N (1944) A photometric adaptation of the Somogyi method for the determination of glucose. J Biol Chem 153(2):375–380

Pares Viader R, Yde MSH, Hartvig JW, Pagenstecher M, Carlsen JB, Christensen TB, Andersen ML (2021) Optimization of beer brewing by Monitoring α-amylase and β-amylase activities during mashing. Beverages 7(1):13. https://doi.org/10.3390/BEVERAGES7010013

Pati S, Samantaray DP (2022) Enzymes in brewing and wine industries. Novel food grade enzymes: applications in food processing and preservation industries. Springer, Singapore, pp 165–181

Puligundla P, Obulam VSR, Lim S (2020) Recent developments in high gravity beer-brewing. Innov Food Sci Emerg Technol 64:102399. https://doi.org/10.1016/j.ifset.2020.102399

Rani H, Bhardwaj RD (2021) Quality attributes for barley malt: “The backbone of beer.” J Food Sci 86(8):3322–3340. https://doi.org/10.1111/1750-3841.15858

Rani H, Bhardwaj RD, Kaur S, Grewal SK (2022) Investigating diverse barley (Hordeum vulgare L.) germplasm for thermostability of β‐amylase: a key player of diastatic power. Cereal Chem 99(6):1339–1348. https://doi.org/10.1002/cche.10596

Rodenburg KW, Juge N, Guo XJ, Sogaard M, Chaix JC, Svensson B (1994) Domain B protruding at the third beta strand of the alpha/beta barrel in barley alpha-amylase confers distinct isozyme-specific properties. Eur J Biochem 221(1):277–284. https://doi.org/10.1111/j.1432-1033.1994.tb18739.x

Rogers JC (1985) Two barley α-amylase gene families are regulated differently in aleurone cells. J Biol Chem 260(6):3731–3738. https://doi.org/10.1016/S0021-9258(19)83685-2

Søgaard M, Olsen FL, Svensson B (1991) C-terminal processing of barley α-amylase 1 in malt, aleurone protoplasts, and yeast. Proc Natl Acad Sci 88:8140–8144. https://doi.org/10.1073/pnas.88.18.8140

Statista (2022) Worldwide beer production. https://www.statista.com/statistics/270275/worldwide-beer-production

Tibbot BK, Wong DWS, Robertson GH (2002) Studies on the C-terminal region of barley α-amylase 1 with emphasis on raw starch-binding. Biologia 57(11):229–238

Vinje MA, Henson CA, Duke SH, Simmons CH, Le K, Hall E, Hirsch CD (2021) Description and functional analysis of the transcriptome from malting barley. Genomics 113(5):3310–3324. https://doi.org/10.1016/j.ygeno.2021.07.011

Visioni A, Basile B, Amri A, Sanchez-Garcia M, Corrado G (2023) Advancing the conservation and utilization of barley genetic resources: insights into germplasm management and breeding for sustainable agriculture. Plants 12(18):3186. https://doi.org/10.3390/plants12183186

Wang J, Zhang G, Chen J, Shen Q, Wu F (2003) Genotypic and environmental variation in barley beta-amylase activity and its relation to protein content. Food Chem 83(2):163–165. https://doi.org/10.1016/S0308-8146(03)00058-X

Yoshida S (1976) Determination of sugar and starch in plant tissue. Laboratory manual for physiological studies of rice.

Zhang HT, Chen TL, Zhang BL, Wu DZ, Huang YC, Wu FB, Zhang GP (2014) Variation in β-amylase activity and thermostability in Tibetan annual wild and cultivated barley genotypes. J Zhejiang Univ Sci B 15(9):801. https://doi.org/10.1631/jzus.B1400026

Zhang L, Li CQ, Jiang W, Wu M, Rao SQ, Qian JY (2019) Pulsed electric field as a means to elevate activity and expression of α-amylase in barley (Hordeum vulgare L.) malting. Food Bioprocess Technol 12(6):1010–1020. https://doi.org/10.1007/s11947-019-02274-2

Author information

Authors and Affiliations

Contributions

RDB designed the experiment. HR conducted the experiments and wrote the manuscript. SK provided the research material. RDB, SKG and SK revised the manuscript. All authors read and approved the final version of the manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rani, H., Bhardwaj, R.D., Grewal, S.K. et al. Exploring the variation in α-amylase activity and thermostability in green malt of diverse barley (Hordeum vulgare L.) germplasm. J. Plant Biochem. Biotechnol. 33, 400–412 (2024). https://doi.org/10.1007/s13562-024-00902-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13562-024-00902-3