Abstract

Porphyridium cruentum is a red marine phytoplankton rich in natural bioactive compounds such as phycoerythrin, polyunsaturated fatty acids, proteins, and floridean starch. In addition, it excretes during its growth large amounts of high-value sulfated polysaccharides. In this context, the purpose of this investigation was to systematically study the growth characteristics as well as the accumulation of macromolecules by Porphyridium cruentum growing in different culture media (Pm, F/2, and Hemerick media) under controlled temperature (18 °C), agitation (130 rpm), and irradiance (150 μmol/m2/s) for 52 days. A maximum biomass concentration of 4.65 × 106 cells/mL was achieved with F/2 medium, after 52 days of growth. The highest values of chlorophyll a (1.76 ± 0.007 pg/cell), total carotenoids (0.48 ± 0.0022 pg/cell), phycoerythrin (15.77 ± 0.6 pg/cell), starch (3.97 ± 0.22 g/100 g DW), and proteins (34.36 ± 1.035 pg/cell) concentrations were recorded also with F/2 medium. However, the Pm medium was proven to be the most suitable for lipid production (4.51 ± 0.45% dry weight). Porphyridium cruentum cultured in Hemerick medium showed the highest exopolysaccharides production of 14.19 ± 0.19 pg/cell.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Marine phytoplankton, being autotrophic organisms, use light energy and inorganic nutrients such as carbon dioxide (CO2), phosphorus, and nitrogen to produce high-valuable algal biomass. They have been broadly exploited as potential sources of numerous metabolites including fatty acids [1], proteins [2], carbohydrates [3], and pigments [4]. Microalgae possess significant advantages, including their rapid growth rate as well as their exceptional photosynthetic efficiency under particular settings. They can fix carbon dioxide up to tenfold more efficiently than terrestrial plants, making them highly efficient in CO2 utilization [5]. Additionally, marine microalgae have the benefits of not using up arable land, being unaffected by the season, having a great yield, and not having lignin in their cell walls. Microalgae not only provide good feedstock for the production of bio-petroleum and bio-ethanol, but also could be extensively employed in pharmaceutical, food, and cosmetic fields [6].

The Porphyridium species are spherical single-celled red marine eukaryotic microalgae belonging to the Porphyridiaceae family and the Porphyridiophyceae class with a great biotechnological potential for the production of long-chain polyunsaturated fatty acids, floridean starch, extracellular sulfated polysaccharides, protein, and phycoerythrin [6, 7]. The Porphyridium genus is unique in that its cell walls do not contain the usual rigid cellulose microfibrillar component. Rather, they are encapsulated within a sulfated polysaccharidic matrix. During microalgal growth, the outer layer of this polysaccharide-based mucilage is continuously dissolved into the surrounding medium, resulting in an increase in the viscoelasticity of the medium [8]. These extracellular polysaccharides probably protect microalgal cells during growth from the desiccation phenomenon and multitude extreme environmental circumstances [6, 9]. Porphyridium extracellular polysaccharides showed wide range of potential applications in nutritionals, cosmetics, and pharmaceuticals thanks to their immunomodulatory, antioxidant, antiviral, and antitumor activities [10, 11]. In Porphyridium species, most of the proteins are phycobiliproteins including phycocyanin, phycoerythrin, and allophycocyanin, of which phycoerythrin is the principal phycobiliprotein and also the cause of the fuchsia color of the microalgal cells. The phycobiliprotein can be employed as a natural pigment in cosmetics, dyes, food, and many other industries, and can also be used as a fluorescent labeling reagents for immuno-histochemistry, flow cytometry, fluorescence microscopy, fluorescence immunoassay, and other biomedical investigations [12, 13]. Porphyridium lipids have in common with fish oils the existence of long-chain polyunsaturated fatty acids belonging to the ω-3 family like eicosapentaenoic acid (EPA, C20:5) and docohexaenoic (DHA, C22:6) acids, which have high medical value like reducing the risk of inflammation, diabetes, brain disease, heart disease, arteriosclerosis, and numerous cancers [14, 15]. The lipids in Porphyridium genus are stored predominately in the form of triacylglycerol, which is transesterified to supply energy for metabolic functions and to generate biodiesel [16]. Previous investigations have revealed that microalgae are able to modify their growth as well as their biochemical composition in response to environmental fluctuations such as light intensity, nutrient availability, pH, temperature, and salinity [10]. Investigation on Porphyridium culture conditions has been relatively rare, and most studies concentrated on the impacts of some culture circumstances on one bioactive metabolite accumulation [17,18,19]. In the production of microalgal bioproducts, one of the main goal is to choose the right nutritional medium [20]. The growth medium selection mainly depends on numerous elements that include its chemical composition [21]. Many culture media recipes are available for microalgae cultivation, even if it is essential to know which medium is optimum for the maximum growth of the microalgae and/or metabolites production. In reality, nutrients may be the factors that have the most effect on the quantity as well as the quality of biomass and metabolites in microalgae [22, 23]. Previous research investigated the impact of diverse growth medium compositions on the green microalgae Chlorella vulgaris in an attempt to increase its growth and lipid production employing batch culture conditions [24]. Wang and colleagues [25] carried out an investigation to screen the growth medium suitable for the photoautotrophic cultivation of Chlorella pyrenoidosa under indoor and outdoor conditions, and later optimized the composition of the selected medium.

Our investigation aims to fill the knowledge gap regarding the culture medium screening applied to red microalgae and the generation of metabolites by Porphyridium species. The specific focus is on studying the growth characteristics and the accumulation of polysaccharides, pigments, proteins, and total lipids by Porphyridium cruentum under photoautotrophic conditions in various culture media. By comprehensively understanding the optimal growth conditions and the composition of culture media that promote the accumulation of target metabolites, this study aims to contribute to the development of strategies for enhancing the production of valuable bioactive compounds from microalgae.

2 Materials and methods

2.1 Microalgal strain, growth media, and culture conditions

Porphyridium cruentum strain UTEX 161 was chosen for this investigation, and it was acquired from the UTEX Culture Collection of Algae located at the University of Texas at Austin. Modified Provasoli (Pm) [7], F/2 [26, 27], and Hemerick [28] media were selected for its growth. Table 1 displays the composition of different used media. The experimental cultures were kept in axenic conditions at 18 °C and under a controlled light intensity of 150-μmol photons/m2/s with continuous gentle agitation of 130 rpm to prevent the culture sticking to the bottom of the flask. Microalgal culture in the exponential growth phase with a cell density of 4.05 × 106 cells/mL was used as inoculum at a 10% level (v/v). Porphyridium cruentum was inoculated in 500-mL autoclaved Erlenmeyer glass flask to obtain the final culture volume of 250 mL. All experiments were performed in duplicate. Six-milliliter specimens were collected at 1, 3, 4, 7, 9, 11, 14, 16, 18, 21, 25, 28, 30, 35, 37, 39, 43, 46, 49, and 52 days post-inoculation from each biological duplicate to analyze growth, macromolecules production, and nutrient consumption.

2.2 Growth measurement

Instantaneously after sampling, microalgal growth was assessed spectrophotometrically by measuring the A760 with pure medium set as a reference using V-630 spectrophotometer (Jasco, Bouguenais, France), as described by Dermoun et al. [29], and by cell enumeration using a Malassez’s cell (Supe Rior, U, 200 mm) and an inverted light microscope (Motic microscope AE 2000, Barcelona, Spain). This wavelength is employed for this microalgae strain since it allows the cell growth estimation without interfering with the photosynthetic pigments that are biosynthesized by microalga during cultivation process [3, 30]. Growth rates (μ) were measured during exponential growth period using Eq. (1) [7]. The generation time or doubling time (Gt) was determined using Eq. (2) [10]:

where N0 and Nt correspond to cells concentrations (cells/mL) at time t0 and t, respectively.

2.3 Soluble extracellular polysaccharides concentration determination

Phenol and sulfuric acid assay, as outlined in the previous study conducted by Dubois et al. [31], was used to evaluate the soluble extracellular polysaccharide concentrations. Analytical analyses were conducted on desalted cell-free broths that were obtained by subjecting microalgal suspension to centrifugation (8000 × g for 10 min), followed by treatments of the resulting supernatant by Amicon Ultra-15 centrifugal filter equipped with a 10-kDa molecular weight cutoff membrane. Initially, the supernatant was concentrated by centrifuging (8000 × g for 4 min), and then, it was diluted with MilliQ water to restore its original volume. This concentration and dilution process was repeated five times. For exopolysaccharides concentration assay, 500 μL of sample were introduced at the bottom of glass tube. Then, 500 μL of 5% (m/v) phenol solution was added to 2500 μL of sulfuric acid (> 96%). After incubation period (10 min, ambient temperature), each sample was vortexed for 10 s at 3000 rpm. The tubes were incubated at ambient temperature for 15 min and then additionally transferred to a water bath at 35 °C for half an hour. At last, the optical density was assessed at a wavelength of 483 nm. All samples were analyzed more than three times. The standard calibration curve was prepared using d-glucose in the range 0–100 mg/L.

2.4 Starch content determination

After 52 days of cultivation, P. cruentum starch content analysis was carried out using an assay kit (Megazyme, Scotland, UK) according to the manufacturer’s recommendations. One hundred milligrams of the lyophilized biomass were weighed accurately into glass tubes and a gentle tapping of tubes was applied in order to ensure that all samples fell to the bottom of the tube. Two hundred microliteres of 80% ethanol (v/v) were added to moisten the sample and facilitate dispersion, and then incubated immediately with 3 mL of thermostable α-amylase (100 U/mL) in sealed tubes at 100 °C for 6 min, mixing vigorously every two min to gelatinize and hydrolyze starch into maltodextrins. After cooling tubes in a bath at 50 °C, an aliquot (4 mL) of sodium acetate buffer (200 Mm, pH 4.5) containing 5 mM calcium chloride was added followed by amyloglucosidase (100 μL, 3300 U/mL) and the content mixed thoroughly on a vortex mixer and the tube placed in a water bath at 50 °C for half an hour to allow quantitatively hydrolysis of maltodextrins to d-glucose. After incubation, the tubes were removed from the water bath and the mixtures were diluted with sodium acetate buffer (200 Mm, pH 4.5) containing 5 mM calcium chloride to a final volume of 0.1 L, the contents were stirred vigorously and then clarified by centrifugation at 13,000 rpm for 5 min. Immediately after the centrifuge stopped, 100 μL of the supernatant was mixed with 3 mL of the glucose-sensitive and -specific GOPOD reagent and incubated at 50 °C for 20 min. Glucose standards (1 mg/mL in 0.2% (w/v) benzoic acid) were prepared by mixing 100 μL of glucose solution with 3 mL of GOPOD reagent. A510 was measured against the reagent blank.

Starch content was quantified using the following equation (Eq. (3)):

where OD is the optical density of sample solution read against reagent blank, F factor, equal to 101.52, is used to convert optical density values to microgram glucose (100 μg glucose divided by the optical density value obtained for 100 μg of glucose), V is the sample extraction volume (100 mL), and W is the weight of microalgal biomass expressed in milligram.

2.5 Pigments content determination

2.5.1 Phycobiliproteins spectroscopic determination

The extraction process of phycobiliproteins was based on the methodology described by Coward et al. [32] with suitable changes. Concisely, a wet P. cruentum biomass concentrated by centrifugation (8000 × g, 10 min) from 1 mL of the microalgal suspension was used as sample. The wet pellet was twice rinsed with the growth medium by centrifugation and then resuspended in 1 mL of sodium phosphate buffer (100 mM, pH 6.0). To extract phycobiliproteins from microalgal pellets, a sequential process involving freezing, thawing, and ultrasound treatment was employed. The process began with repeated cycles of freezing and thawing until the cell debris no longer exhibited a distinct red color. Each cycle consisted of 3 h of freezing at − 20 °C followed by 1 h of thawing at ambient temperature (20–25 °C). Subsequently, the suspension was subjected to ultrasound treatment using a probe sonicator set at an amplitude of 60% and a cycle of 0.5 for a duration of 10 min [33]. The liquid/solid separation was conducted by centrifugation (8000 × g, 10 min). The supernatant was collected and phycobiliproteins concentrations were spectrophotometrically quantified measuring A565, A620, and A650 using the equations (Eq. (4), Eq. (5), and Eq. (6)) as described by Marcati et al. [34]:

where R-PC, APC, and B-PE are phycocyanin, allophycocyanin, and B-phycoerythrin, respectively. A is the absorbance of the pigment at the particular wavelength.

2.5.2 Chlorophylls and carotenoid determination

To measure the amount of chlorophylls and carotenoids, 1 mL of the microalgal suspension was collected and centrifuged (8000 × g, 10 min). The supernatant was discarded, and the cell pellet was then immersed in 1000 μL ethanol 95% and treated by ultrasounds (amplitude: 60%, cycle: 0.5) using a probe sonicator for 10 min. After sonication, the microalgal residue was removed via centrifugation at 8000 × g for 10 min and the photosynthetic pigments were quantified according to Lichtenthaler [35] using the equations (Eq. (7), Eq. (8), and Eq. (9)):

2.6 Soluble protein concentration determination

The soluble protein content of P. cruentum was determined spectrophotometrically according to the method described previously by Lowry et al. [36]. Microalgal cells harvested by centrifugation (8000 × g; 10 min) were disrupted using ultrasound treatment. In order to determine the soluble protein content, 0.5 mL of the sample was added to 0.7 mL of Lowry reagent. After vortexing the resulting mixture, it was allowed to incubate at room temperature for a period of 20 min. Following incubation, 0.1 mL of Folin–Ciocalteu reagent was introduced to the sample, vortexed, and incubated for half an hour at room temperature and in the dark. A calibration curve was prepared using concentrations of bovine serum albumin (protein standard) ranging from 0 to 0.1 g/L. Finally, the A750 was measured. Each sample was analyzed in triplicate.

2.7 Lipid extraction and fatty acid composition analysis

Porphyridium cruentum total lipid content was determined on day 52 using a chloroform–methanol–water mixture [37]. Concisely, 0.2 g of freeze-dried microalga was precisely weighed and placed in 15-mL centrifuge polypropylene tubes. Subsequently, a mixture of 800 μL MilliQ water, 2 mL chloroform, and 1 mL methanol was added to the tubes, and the contents were vigorously mixed for 2 min. Thereafter, an additional 2 mL MilliQ water and 2 mL of chloroform were added to the content followed by mixing for another 2 min. Then, the solution was centrifuged at 8000 × g for 10 min. The extracted lipids, present in the organic phase (bottom phase), were collected and moved to tubes that had been dried and weighed beforehand. The leftover aqueous phase and biomass residues were then subjected to two additional extractions, each involving 2 mL of chloroform. The organic phases were merged, and a centrifugal evaporator known as Speed-Vac (Savant™ SPD111 SpeedVac™, Thermoscientific) was employed to remove the solvent. The process was carried out at 40 °C under a vacuum pressure of 0.95 bar until a constant weight was reached. The residue was weighted for calculating lipid content and then resuspended in 0.2 mL chloroform to determine the fatty acids composition. The following equation (Eq. (10)) was utilized to determine the percentage of lipid content.

The analysis of fatty acids’ composition was carried out using gas phase chromatography after conversion into methyl esters according to Morrison and Smith’s method [38]. In tubes with screw caps, 0.1 mL of chloroform containing the lipids were mixed with 0.8 mL of a Boron trifluoride-methanol solution 14%. The mixture was boiled for 15 min in a dry-bath and then cooled to ambient temperature. One thousand five hundred microliters of MilliQ water and 750 μL of hexane (comprising heptadecane as an internal standard, with a concentration of 1% (v/v)) were added. After 2 min of vigorous vortexing, the mixture was decanted. The upper phase contained the methylated fatty acids. A gas chromatographer Agilent 6850 Series II system, equipped with an autosampler G4513A, a flame ionization detector (FID), and a polar column HP 88 (112-88A7E) of 100 m × 0.25 mm × 0.2 μm were used. One microliter of sample was injected. The oven was programmed to heat up to 140 °C initially and kept at that temperature for 5 min. After that, the temperature was gradually increased by 4 °C per minute until it reached 240 °C. After reaching 240 °C, the temperature was sustained at that level for 5 min. Nitrogen was employed as the carrier gas, and both the FID and injector temperatures were set at 260 °C. The ChemStation software was utilized for data acquisition and processing. The fatty acids methyl esters were identified and quantified using standards that were also methylated using the same procedure. A total of 25 standard injections were made.

2.8 Nitrate and phosphate quantifications

Nitrate consumption was evaluated on supernatant of culture samples obtained after centrifugation at 8000 × g for 10 min according to the method of Cawse [39] modified by A.P.H.A. [6]. Briefly, 400 μL of sample appropriately diluted was mixed with 3.6 mL of perchloric acid (5%). A210 and A275 were measured. Sodium nitrate solutions, with concentrations ranging from 0 to 0.1 g/L, were analyzed using the same protocol. The spectrophotometer was zeroed at a wavelength of 210 nm for a sample without NaNO3, and a standard curve was established as [NaNO3] = f (A210). To analyze the samples, the absorbance value obtained was corrected using the following equation (Eq. (11)), with reference to the standard curve.

where A275 and A210 are raw values of samples at 275 and 210 nm, respectively, and A275sc is the mean value of absorbance at 275 nm for the sodium nitrate solutions of standard curve.

Inorganic phosphate assay was conducted as described previously by Ames [40]. First, the following solutions were prepared as described below: (1) 0.42% ammonium molybdate tetrahydrate in sulfuric acid (0.5 M), (2) 10% (m/v) ascorbic acid in MilliQ water, and (3) mixture (Mix) including 60 mL of solution 1 and 10 mL of solution 2 prepared just prior to use. Then, 300 μL of supernatant of microalgal suspension were obtained by centrifugation at 8000 × g for 10 min, then suitably diluted, mixed with 700 μL of mix, and the resulting mixture was vortexed and then incubated in a water bath (45 °C; 20 min). To establish a standard curve, monobasic potassium phosphate was used between 0 and 20 mg/L, following the same protocol. The absorbance at a wavelength at 820 nm was then measured.

2.9 Statistical analysis

A statistical analysis was performed to assess significant differences between the tested media using a one-way analysis of variance (ANOVA) and Tukey’s post hoc test. The analysis was conducted at a confidence level of 95%. The statistical package used for the analysis was SPSS 13 (SPSS Ltd., Woking, UK).

3 Results and discussion

3.1 Screening of appropriate medium for Porphyridium cruentum growth

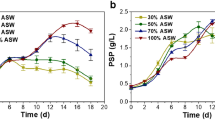

Since the Pm, F/2 and Hemerick media have been commonly employed for Porphyridium genus cultivation [7, 34, 41, 42], the growth and bioactive molecules formation of marine P. cruentum in these three media were compared. The cell density enhanced during the growth time (52 days) for the three tested media, as shown in Fig. 1A. The growth patterns of P. cruentum cultivated in F/2, Pm, and Hemerick media exhibited similarities, and the cell densities at the end of the cultivation period were nearly identical in the F/2 and Pm media. The P. cruentum initial cell density in all media was 3.5 × 105 cells/mL. Porphyridium cruentum achieved its highest cell density on the fifty-second day and was about 4.65 × 106 cells/mL in F/2 medium, 4.5 × 106 cells/mL in Pm medium, and 2.43 × 106 cells/mL in Hemerick one. In all tested media, the growth of P. cruentum had approximately 3 days lag phase and reached the exponential period within 4–7 days. Microalgal cells achieved stationary period within 39 days for all tested media and after that cell growth was very slow (Fig. 1A). This can be explained by the greater nitrogen concentrations in F/2 and Pm media which are beneficial for enhancing biomass output [43] according to other studies revealing final biomass production by Botryococcus braunii [44,45,46,47,48], Isochrysis galbana [49, 50], and Porphyridium sp. [51] depended on nitrogen concentration in culture medium. Furthermore, Guevara and colleagues [52] examined the growth characteristics of two strains of Rhodomonas salina (CS-174 and CS-24) when subjected to various combinations of nutrient concentration, temperature, and light intensity. The optimal growth of both tested strains of Rhodomonas salina was observed when they were exposed to high levels of nitrogen, phosphorus, and irradiance, regardless of the temperature conditions. Here, the lowest concentration of nitrogen (175 mg/L) in Hemerick medium led comparatively to lower cell density as described previously with the green microalga Chlamydomonas reinhardtii [53]. Toumi et al. [54] also found that nitrogen starvation negatively affects the growth of the biomass of Chlorella sorokiniana.

The apparent growth rates (μ) of P. cruentum were determined for the period between the 10th and 37th days and were about 0.050 day−1 (Gt of 13.86 days), 0.049 day−1 (Gt of 14.15 days), and 0.036 day−1 (Gt of 19.25 days) for Pm, F/2, and Hemerick media, respectively. These findings are coherent with those of Huang et al. [55], who observed that the nitrogen supply increased Tetraselmis subcordiformis, Pavlova viridis, and Nannochloropsis oculata growth rates. According to prior research, the growth rates of P. cruentum were between 0.05 and 0.2 days−1 [56] and those of Porphyridium purpureum between 0.14 and 0.22 days−1 depending on culture conditions, while those of Porphyridium marinum were reported between 0.54 and 0.56 days−1 [7]. For Porphyridium sordidum grown in Pm media, Drira and colleagues [57] found an average growth rates and generation times of 0.055 day−1 and 12.6 days, respectively. An investigation recently conducted by Medina-Cabrera et al. [58] on Porphyridium sordidum and comparing it to Porphyridium purpureum indicated apparent μmax at 0.17 and 0.22 day−1, respectively. However, it is extremely difficult to compare the findings from one study to another since these parameters are not typically computed and because they are strongly influenced by culture conditions such salinity and light availability [59]. Figure 1B illustrates the A760 versus the cultivation time (52 days) for the three tested media. The absorbance curves closely mirrored the patterns observed in the cell density profiles for all three media. The absorbance at a wavelength at 760 nm specifically indicated that the F/2 medium provided the optimal conditions for the growth of Porphyridium cruentum. The initial average optical density (OD760) of the culture was measured at 0.092. The absorbance value increased gradually and reached a final average OD760 of 1.10. Thus, by the end of cultivation period, the optical density value had increased by approximately 12-folds. It was observed that there was a significant correlation between cell density and OD760 for different culture media (no specific data were presented). By utilizing absorbance measurements, Medina-Cabrera et al. [58] were able to indirectly compare the growth patterns of Porphyridium sordidum and Porphyridium purpureum. The authors demonstrated that the variation in absorbance observed between the two strains of Rhodophyta was influenced by their distinct cell sizes.

3.2 Culture media screening for exopolysaccharides production

Since the soluble EPS amounts change according to the environmental conditions and microalgal physiological state, EPS production by P. cruentum was also investigated. Findings revealed that EPS concentration enhanced constantly during cultivation process for all tested media as illustrated in Fig. 2A. Maximum EPS production was obtained in Pm medium. After 52 days, EPS concentration rose from 0.43 to 46.46 mg/L. The maximum EPS production was about 14.19 ± 0.19 pg/cell on day fifty-two in Hemerick medium (Fig. 2B; Table 2). The soluble EPS concentrations of Porphyridium genus are in the range of high-yielding microalgae including Botryococcus braunii, Dunaliella salina, Arthrospira platensis, and Rhodella violacea [60]. As already established, F/2 and Pm medium have much nitrate than Hemerick medium; therefore, Hemerick medium’s lower concentration of nitrogen could be directly responsible for P. cruentum’s increased EPS secretion outside the cell. EPS biosynthesis was observed throughout all growth stages; however, it exhibited a notable increase towards the end of the exponential phase and continued during the stationary stage. The stationary phase of growth in multiple microalgae species, including Botryococcus braunii and Chlamydomonas mexicana, has been demonstrated to enhance EPS biosynthesis [61, 62]. This phenomenon is triggered by the scarcity of essential nutrients such as phosphorus and nitrogen. Previous studies conducted on Rhodella violacea [60], Scenedesmus abundans [61], Flintiella sanguinaria [62], and Porphyridium marinum [63] have shown that microalgal cells have the potential to accumulate extracellular polymeric substances under nitrogen-deprived conditions. However, the increase of sodium nitrate concentration in the Chlamydomonas reinhardtii growth medium caused an increase of EPS yield (86.6 mg/L) [63]. The effects of increasing phosphate and nitrogen concentrations in the Chlorella sp. culture medium were investigated by Cheirsilp et al. [64]. Results revealed that the increase in nitrogen and phosphate concentrations resulted in a decrease of exopolymeric substances production. The production of exopolymeric substances by microalgae is influenced not only by the nitrogen concentration in the culture medium but also by other factors. In fact, several studies have indicated that the nitrogen-to-phosphorus (N/P) molar ratio can also affect the EPS production in microalgae [65]. N/P molar ratio for Hemerick medium was 0.22, demonstrating the growth medium’s nitrate depletion situation. The use of growth media with a broad range of N/P molar ratios for P. marinum cultivation was assessed by Soanen and colleagues [66]. Findings demonstrated that the N/P molar ratio of 24.5 resulted in lower specific EPS productivity (0.0503 mg/106 cells) compared to the production obtained with a 3.97 of the N/P molar ratio (0.0622 mg/106 cells). Another research conducted by Razaghi et al. [56] corroborated these findings, demonstrating that high N/P molar ratios of 35 and 50, indicating phosphorous depletion, stimulated biomass production by P. cruentum. Conversely, a low N/P molar ratio of 4.9 promoted the accumulation of carbohydrates. According to Redfield [67], to achieve a balanced culture medium, it is recommended to maintain a N/P molar ratio of 16. This ratio ensures that both nitrogen and phosphorus are depleted simultaneously, leading to optimal conditions for cell growth and significant production of EPS. It should be mentioned that diverse strategies were used to boost EPS biosynthesis and productivity in Porphyridium genus. For instance, an increase of the C/N ratio can promote EPS production by P. purpureum [68]. Light quality was also investigated by You and Barnett [69] as a main parameter to control the growth and polysaccharide production by P. cruentum. According to the researchers, blue light, which has a wavelength between 400 and 500 nm, might be utilized to promote cell growth and increase polysaccharide production to 4.63 g/L. Furthermore, in accordance with Liqin and colleagues study [70], while there was no discernible difference in the growth of cells for different spectra, natural light, green light, and yellow light are better suited for increasing the yield of exopolymeric substances accumulation by P. cruentum compared to blue and red lights. Moreover, P. cruentum cultivated under renewal regime in semi-continuously flat plate photobioreactor was able to produce a maximum output rate of polysaccharide approximately 68.64 mg/L/day. The production of extracellular polymeric substances in Porphyridium sordidum has also been enhanced through the implementation of a two-stage cultivation strategy, as indicated by the findings of Medina-Cabrera et al. [58]. Thus, an increase in light exposure and a drop in temperature induced EPS biosynthesis in the second stage (170 mg/L) compared to that in the first one (50 mg/L).

3.3 Culture media screening for starch production

At the end of the cultivation process, the concentration of microalgal starch was assessed on day fifty-two. The experimental findings obtained by the cultivation of P. cruentum under various nutritional growth medium compositions are illustrated in Fig. 3. Porphyridium cruentum was able to accumulate starch in all studied circumstances. However, the amount of starch produced depended on the medium used. The highest starch content of 3.97 ± 0.22 % was obtained for P. cruentum cultivated with F/2 medium (Table 2). For P. cruentum grown in Hemerick medium, the starch production was about 1.77 ± 0.06%. The microalgal starch concentration obtained in the present investigation was the lowest in comparison with the starch contents reported in previous studies resulting from cultivation of other green microalgae under photoautotrophic conditions, including Scenedesmus acuminatus, Chlorella sp., Chlorococcum sp., Chlamydomonas sp., Scenedesmus sp., and Nannochlorum sp. [71, 72]. Contrary to the results of Ramus and Robins [73] and Ramus [74], who showed that Porphyridium aerugineum begun active starch production midway through the exponential stage, Sheath and colleagues [75] found that a starch accumulation during the declining growth period of Porphyridium purpureum. The discrepancy observed could be attributed to the use of different species or potentially variations in the environmental conditions of the cultures employed in each experiment. Additionally, the amounts of cellular starch in these two species varied significantly. Porphyridium purpureum and Porphyridium aerugineum had maximal starch amounts of about 4 pg starch/cell [75] and 0.6 pg starch/cell [73], respectively. Polysaccharide biosynthesis in microalgae tends to be enhanced by high light intensities. Porphyridium purpureum grown under high irradiance of 4300 lx was shown to accumulate starch substantially more than under low light intensity (430 lx) [76]. According to Friedman et al. [77], Porphyridium aerugineum and Porphyridium sp. demonstrated also 3- and 0.6-fold increases in polysaccharide amounts, respectively, when the growth irradiance was enhanced from 75 to 300 μmol photons/m2/s. Consistent findings from other microalgae species indicated an increase in starch content with moderate levels of irradiance [78]. For example, Spirulina platensis cultivated outdoors produced considerably less carbohydrates on gloomy days than on bright days [79]. In a recent study conducted by Ben Hlima and colleagues [7], the influence of sodium chloride concentration on starch accumulation was examined. The results revealed that as the salinity of the culture medium decreased, there was a corresponding increase in the production of starch by Porphyridium marinum. It is noteworthy that inducing stress through nutrient deficiency is currently the most frequently employed strategy to enhance starch accumulation in certain strains of microalgae. The effect of nitrate concentrations increase from 0.3 to 1.7 g/L on starch production in Porphyridium marinum cells was also assessed [7] and findings obtained through response surface methodology modeling showed that the concentration of nitrogen had noticeable impact on starch accumulation. However, it has been shown that restricting nitrogen can ameliorate the production of starch by Tetraselmis subcordiformis during the early stage of culture [80]. Nitrogen depletion was also employed as a mean to induce starch accumulation in various other microalgae species, like Chlorella sp., Chlamydomonas reinhardtii, and Chlamydomonas sp. [78, 81].

Comparison between Hemerick, F/2, and Pm media in the production of starch by P. cruentum on day 52. Data are expressed as mean value ± standard deviation. Different low case letters (a, b, and c) present statistically significant differences (p < 0.05), according to one-way analysis of variance and Tukey’s post hoc test

3.4 Culture media screening for pigments production

To explore the impact of the culture medium on pigments production by microalgae, kinetics of phycobiliproteins (APC, R-PC and B-PE) as well as liposoluble pigments (Chlorophyll a, Chlorophyll b and carotenoids) accumulations with Pm, F/2, and Hemerick media are illustrated in Figs. 4 and 5, respectively. The chlorophyll a, carotenoids, B-PE, APC, and R-PC contents of P. cruentum cells in the F/2 medium were higher than that in the Pm and Hemerick media. During the cultivation under photoautotrophic mode, amounts of chlorophyll a and PE in P. cruentum cells grown in Pm and F/2 media started to increase from approximately the 7th day until the end of the cultivation period. It is important to highlight that the B-PE contents in microalgal cells grown in F/2 and Pm media by the end of the cultivation process were respectively about 6- and 4-fold higher than in the Hemerick medium (Fig. 4), validating the visual discrepancies noticed in the coloration of microalgal cultures. In the present investigation, the highest chlorophyll a and phycoerythrin amounts were 6.47 ± 0.38 μg/mL and 0.045 ± 0.0015 mg/mL, respectively. Porphyridium cruentum cells grown in Hemerick medium demonstrated the highest chlorophyll a content of 0.46 ± 0.045 μg/mL on day 39, and then, chlorophyll a concentration decreased and reached 0.33 ± 0.034 μg/mL at the end of the experiment (Fig. 5C). Porphyridium cruentum cultivated in Hemerick medium reached the highest B-PE concentration of 0.0076 ± 0.0002 mg/mL at the end of the cultivation period (Fig. 4C). Carotenoid amounts enhanced slowly in all tested media during the cultivation time leading to a final carotenoids concentrations of 2.03 ± 0.024 μg/mL, 0.86 ± 0.024 μg/mL, and 0.322 ± 0.007 μg/mL in F/2, Pm, and Hemerick medium, respectively. On the other hand, APC, R-PC, and chlorophyll b amounts did not show any clear changes throughout the growing period. B-PE was found to be the predominant pigment in P. cruentum cultures cultivated using Pm, F/2, and Hemerick media. To account for potential variations in biomass, e.g., the number of cells, pigment content per cell was further assessed. In line with the earlier findings, the highest P. cruentum cells content of B-PE (15.77 ± 0.6 pg/cell, day 16), chlorophyll a (1.76 ± 0.007 pg/cell, day 18), and total carotenoids (0.48 ± 0.0022 pg/cell, day 18) were also found in F/2 medium, as shown in Fig. 6 and Table 2. At the end of the cultivation period, the B-PE to R-PC ratio was 5.65, 6.94, and 5.11 for P. cruentum grown with Pm, F/2, and Hemerick media, respectively, with a starting value of 5.42 for all tested media. The rapid reduction in the B-PE to R-PC ratio suggests that B-PE is more sensitive to variations in the medium conditions compared to R-PC [82, 83]. Various factors can influence the phycobiliproteins ratios, with irradiance and mineral components in the culture medium being among the most significant ones [82, 83]. For instance, it was shown previously by Li et al. [82] that the B-PE to R-PC ratio for Porphyridium purpureum SCS-02 grown under low nitrogen concentrations decreased faster than that in case of medium and high nitrogen concentrations. In the experiment conducted in this study, the B-PE to protein ratio was initially increased until day 16 for P. cruentum in all tested media, and after that, the ratio remained stable for microalgal cells grown in Pm and F/2 media and decrease for microalga cultivated in Hemerick medium. The total carotenoids to chlorophyll ratio was employed as a means to evaluate the correlation between the overall carotenoid content and chlorophyll levels. Total carotenoids/chlorophyll ratio is a sensitive marker to identify the environmental stress conditions as well as photooxidative damage in microalgal culture [84]. Carotenoid concentration will enhance and result a high total carotenoids/chlorophyll ratio if the culture displays poor cell development or is under oxidative stress (e.g., illumination, nutrient limitation). The highest total carotenoids/chlorophyll ratio of 0.97 was observed at the end of the cultivation process for microalgal cells cultivated in Hemerick medium. The increase of total carotenoids/chlorophyll ratio could be attributed to nitrogen depletion in the growth medium, resulting in a decline in the photosynthetic rate.

In microalgae, photosynthetic pigments serve the purpose of capturing photons and subsequently transferring the absorbed light to the reaction centers [85]. The abundance of pigments within microalgal cells is directly correlated with their photosynthetic efficiency [86]. Mineral element concentrations in the culture medium and the conditions of irradiance have a notable impact on the content of phycobiliproteins in microalgal cells. Depending on used strains, it is very important to provide an appropriate culture medium and operating conditions that favor microalgal cell growth and effective pigment accumulation. Under enhanced illumination or mineral component depletions, the growth rate of microalgae undoubtedly changes, and microalgae cells’ photosynthetic apparatus goes through a substantial modification: the phycobiliprotein amounts, including R-PC and B-PE, are decreased. Moreover, as reported in previous reports [82, 87,88,89], their ratios are modified. It was shown previously by da Silva et al. [89] and Algarra and Rudiger [90] that phycoerythrin has the most noticeable modifications. Numerous studies have observed the drop in B-PE in Porphyridium purpureum cells during batch cultivation, which is explained by the fact that its concentration is directly correlated with the amount of nitrogen present in the growing medium [82, 91,92,93]. Consuming nitrogen enables the microalgae to produce two molecules of glutamate, one of which, after being exported to the cytoplasm, enters the biosynthetic route for phycobiliproteins production. Zhao et al. [94], Levy and Gantt [95], and Chaloub et al. [96] revealed that nitrogen starvation during the cultivation process conducted to a reduction in photosynthetic pigment concentrations, including chlorophylls and phycobiliproteins. In Rhodomonas genus, the response to nitrogen deprivation takes place gradually [97]. In fact, during the first days of cultivation, the pigment content does not change, and the concentrations of chlorophylls and phycoerythrin were reduced by 50% and 90%, respectively, after 6 days of nitrogen depletion. In contrast, Gargouch and colleagues [41] revealed that the B-PE accumulation (a maximum of 40 mg PE/g DW) by Porphyridium marinum CCAP 1380/10 was stimulated by the raising in nitrogen amount (sodium nitrate concentration = 3.4 g/L). It has been also reported in the same report that this microalga produced more B-PE when phosphorus was absent from its growth medium (0 g/L K2HPO4) [41]. The findings aligned with the study of Kathiresan et al. [95], which demonstrated that Porphyridium purpureum exhibited the highest accumulation of B-PE at low phosphorus levels, highlighting the essential role of phosphorus in the biosynthesis of proteins such as phycobiliproteins. As previously mentioned, these phycobiliproteins are used by microalgal cells as a source of nitrogen, and some elements depletion, such as phosphorus, can encourage their formation if nitrogen is accessible. This conclusion was supported by a comparison of the culture media compositions employed in the present investigation. Porphyridium cruentum cultivated in F/2 medium accumulated better amount of phycobiliproteins than when the same microalga was grown in Hemerick and Pm media, as microalgal cells were putted under stressful conditions due to the presence of high nitrogen (nitrate) concentration associated to phosphorus (phosphate) deficiency in F/2 medium.

3.5 Culture media screening for soluble protein production

Regarding protein production, the soluble protein accumulation by P. cruentum was also studied in the present investigation under standard culture conditions. As the culture progressed, the protein content revealed a gradually increasing trend in all three media as shown in Fig. 7A. The soluble protein levels of P. cruentum were found to rise by a factor of 9.4 and 10 when grown in Pm and F/2 media, respectively, after a 52-day cultivation period. For Hemerick medium, there was a 2.88-folds increase in soluble protein in microalgal cells over cultivation period. The maximum protein content was observed in F/2 medium was 0.108 ± 0.013 g/L, whereas the lowest protein concentration was obtained in Hemerick medium (0.067 ± 0.0041 g/L). When the soluble proteins concentration was computed on a per cell basis (Table 2), the maximum protein content was detected in F/2 medium after 18 days of culture reaching 43.36 ± 1.035 pg/cell (Fig. 7B). It was previously shown that the total protein content of Porphyridium purpureum in the dried algal biomass ranges from 28 to 41%. Protein content is primarily influenced by light intensity, the amount of nitrogen in culture medium, and the length of the cultivation process [89, 98]. When the culture medium’s nitrogen concentration was moderate (1.2 g/L), salinity was high (40 g/L), and light intensity was close to 190 mol photons/m2/s, Ben Hlima et al. [7] found that Porphyridium marinum could produce the maximal protein under these conditions. Several studies have demonstrated that nitrogen deficiency may provoke oxidative stress in plants, which may contribute to the production of stress-responsive proteins. Based on the findings of Hockin et al. [99], a deficiency in nitrogen can lead to a reduction in protein content. This, in turn, can impede electron transfer across the photosynthetic complex in diatoms, resulting in an elevated generation of reactive oxygen species and subsequent oxidative stress. In addition, green microalgae such as Chlamydomonas reinhardtii, Chlorella minutissima, and Chlorella zofingiensis exhibit a general drop in both protein and chlorophylls content when subjected to nitrogen deficiency [100,101,102,103]. When nitrogen is lacking in the growth medium, nitrogen-rich molecules are broken down and used as nitrogen cell reservoirs to facilitate time-restricted growth processes [103, 104]. Many microalgae switch their metabolism towards hyper-accumulation of extracellular polysaccharides or intracellular lipids and carbohydrates when they are exposed to unfavorable environmental circumstances or nutrients’ restriction throughout their growth [105].

3.6 Culture media screening for lipid production

Three culture media were tested in order to know how P. cruentum responded to changes in growth medium composition in terms of lipid biosynthesis. Results showed that the highest lipid concentration on day 52 was obtained with Pm medium (4.51 ± 0.45 % dry weight) (Table 2). There was no significant difference observed in the lipid content between Hemerick medium (1.96 ± 0.37% dry weight) and F/2 medium (1.87 ± 0.27% dry weight). Lipid concentrations were reported between 9 and 14% in the previous study by Becker [14] on P. cruentum. The lipid levels of the same microalgal cells were, however, significantly lower (0.5–1.6%) in the investigation of Asgharpour and colleagues [106]. This may be a result of different strains or growing media components. In response to stressful growth conditions, numerous microalgae alter their metabolic pathways to prioritize the accumulation of lipids, intracellular carbohydrates, or extracellular polymeric substances, while simultaneously suppressing protein synthesis [105]. According to Wong et al. [24], it was demonstrated that when Chlorella vulgaris cells were subjected to nitrogen starvation in bold basal medium, there is an enhancement in the production of lipid. This observation aligns with previous findings in Chlamydomonas reinhardtii, where a nitrogen-deprived environment led to a notable increase in lipid production [107]. In fact, under nitrogen deficiency conditions, microalgal growth decelerates, and since the biosynthesis of new cell membrane components is no longer necessary, the cells redirect their resources towards accumulating fatty acids into triacyl glycerol [108, 109]. However, it was shown by Mata et al. [110] that enhancing the nitrogen concentration in the growth medium by a factor of ten resulted in elevated lipid productivity and content in Dunaliella tertiolecta. Porphyridium purpureum SCS-02 was cultivated in an ASW medium with varying levels of nitrogen supply: low (3.5 mM KNO3), medium (5.9 mM KNO3), and high (17.6 mM KNO3), and the findings revealed that the overall lipid content remained relatively unchanged across different nitrogen concentrations [82]. In the current investigation, P. cruentum grown in Hemerick medium displayed a relatively lower lipid content when compared to the Pm medium. The main contributing factor for this difference was probably the presence of an excessive concentration of phosphorus in Hemerick medium. It has been previously documented in the literature that an excess of phosphorus promotes the growth of microalgae rather than the accumulation of lipids [24].

Microalgae possess a diverse range of fatty acids, and their composition can vary depending on the species and the specific growth conditions they are exposed to. Cohen et al. [111] proposed a correlation between the environmental conditions and the fatty acid composition in P. cruentum. In the current study, the fatty acid composition in the three tested media was investigated. As shown in Table 3, the major fatty acids from P. cruentum on day 52 were palmitic (C16:0; 60.79–63.14%), stearic (C18:0; 4.24–7.93%), linoleic (C18:2; 12.39–18.10%), and arachidonic (C20:4; 10.81–20%) acids. It contained also low amounts of cis-22:2n-6 (13,16-docosadienoic acid; 0–0.26%) and C18:1-Cis-9 (oleic acid; 0–1.54%). As reported by Shanab et al. [112], the primary fatty acids identified in most Porphyridium species consist of palmitoleic, palmitic, stearic, linoleic, oleic, arachidonic (ARA, C20:4, ω-6), and eicosapentaenoic (EPA, C20:5, ω-3) acids. These fatty acids have been recognized for their immune-suppressant and antifreeze properties [112]. The lipid content as well as the fatty acid composition of Porphyridium, a genus of Rhodophyta, exhibit variability influenced by a range of factors. The most effective strategy for increasing the amount of neutral lipids in microalgae, which are primarily made up of triglycerides with a high saturation degree, is nitrogen depletion [113, 114]. According to Kavitha et al. [115], a moderate rise in the quantities of nitrate, phosphate, chloride, and sulfate encouraged P. purpureum’s best biomass production, total lipid accumulation (17.9% w/w), and EPA amount (34.6% w/w).

3.7 Nitrate and phosphate consumption by P. cruentum

For a thorough analysis of the microalgal growth features, the nutrients uptake was examined. Nitrate was measured as it serves as an essential nutrient for microalgae, facilitating protein production and promoting cellular growth [116]. It is generally known that low nitrate levels favor the shift to the stationary phase, inducing the biosynthesis of extracellular polysaccharides as a response to nutrient deprivation [117, 118]. Figure 8A, B, and C demonstrated that none of the tested media was fully utilized at the end of the experiment. On the day fifty-two, the average nitrate uptake by P. cruentum in culture with Hemerick medium was 1.4 ± 0.022 mM. For cultures with Pm and F/2 media, the average uptake were 6 ± 0.4 mM and 3.64 ± 0.0083 mM, respectively. For Pm, F/2, and Hemerick media, the nitrate uptakes were 0.115 ± 0.008, 0.07 ± 0.0002, and 0.027 ± 0.0004 mM per day, respectively. In a recent study conducted by Medina-Cabrera et al. [58], it was discovered that the rate of nitrate uptake was 0.06 mM/day for P. sordidum and 0.22 mM/day for P. purpureum. After 52 days of the cultivation process, P. cruentum cultivated in Pm and F/2 metabolized 29.31 ± 0.37% and 33.33 ± 0.2% of the total nitrate, respectively. In the previous study, P. sordidum and P. purpureum metabolized respectively, 17% and 68% of the total nitrate after a month of the cultivation process [58]. Thus, since P. purpureum absorbs more nitrate than P. sordidum, the scientists concluded that P. purpureum is affected by nitrate consumption significantly more than P. sordidum.

Phosphorus is a crucial component for microalgal growth and the primary factor restricting their cultivation, despite constituting only 1% of the total biomass of microalgae [119]. Indeed, it participates in a variety of biological functions, encompassing the biosynthesis of proteins, phospholipids, pigments, and nucleic acids. Thus, as phosphate shortage is directly related to a decline in the production of microalgal cells, phosphate consumption was also evaluated. In this respect, it was observed that at the end of the cultivation process phosphate was consumed by P. cruentum cultivated in Pm medium, reaching a final concentration of 0.83 ± 0.037 mM. On day 52 of the cultivation process, 90.78 ± 0.23% of phosphate was consumed as illustrated at Fig. 8D. Porphyridium cruentum consumed 0.0067 ± 0.0007 mM/day of phosphate available in F/2 (Fig. 8E). For microalgal cells cultivated in Hemerick medium, phosphate consumption was observed till the end of the cultivation process (58.14 ± 1%) (Fig. 8F). It was revealed by Medina-Cabrera et al. [58] that in the first 10 days of microalgal cultivation, phosphate was consumed by P. sordidum and P. purpureum reaching 0.02 mM/day and 0.04 mM/day, respectively. After that, until the end of the cultivation process, no substantial phosphate use was found.

4 Conclusion

The present investigation aimed to examine the influence of three distinct mineral culture media, namely Pm, F/2, and Hemerick medium, on both the growth and metabolite production of P. cruentum UTEX 161. Microalgal cells exhibited notable variations in growth and the accumulation of bioactive compounds across the three culture media that were tested. Specifically, F/2 medium demonstrated favorable conditions for the growth of P. cruentum and the accumulation of chlorophylls, carotenoids, PE, proteins, and starch. On the other hand, Pm medium supported lipid production, while Hemerick medium exhibited the highest production of soluble EPS in P. cruentum culture. Overall, P. cruentum showcased its importance as a producer of valuable metabolites such as carotenoids, proteins, chlorophylls, phycoerythrin, and carbohydrate polymers. To enhance metabolite productivity, further optimization of cultivation conditions is recommended. This can be achieved by exploring the optimization of media composition and scaling up the cultivation system. Additionally, focusing on improving the production of EPS holds potential for further exploration of its biotechnological applications.

Data availability

Not applicable.

References

Dammak M, Ben Hlima H, Elleuch F et al (2021) Photoautotrophic two stage process for lipids production in oleaginous microalgae Tetraselmis sp. Renew Energy 177:280–289. https://doi.org/10.1016/j.renene.2021.05.126

Derbel H, Elleuch J, Mahfoudh W et al (2023) In vitro antioxidant and anti-inflammatory activities of bioactive proteins and peptides from Rhodomonas sp. Appl Sci 13(5):3202. https://doi.org/10.3390/app13053202

Hachicha R, Elleuch f, Ben Hlima H et al (2022) Biomolecules from microalgae and cyanobacteria: applications and market survey. Appl Sci 12:1924. https://doi.org/10.3390/app12041924

Elleuch F, Ben Hlima H, Barkallah M et al (2019) Carotenoids overproduction in Dunaliella sp.: transcriptional changes and new insights through lycopene cyclase regulation. Applied Sciences - Switzerland 9(24):5389. https://doi.org/10.3390/app9245389

Lu X, Nan F, Feng J et al (2020) Effects of different environmental factors on the growth and bioactive substance accumulation of Porphyridium purpureum. IJERPH 17:2221. https://doi.org/10.3390/ijerph17072221

Tounsi L, Hentati F, Ben Hlima H et al (2022) Microalgae as feedstock for bioactive polysaccharides. Int J Biol Macromol 221:1238–1250. https://doi.org/10.1016/j.ijbiomac.2022.08.206

Ben Hlima H, Dammak M, Karkouch N et al (2019) Optimal cultivation towards enhanced biomass and floridean starch production by Porphyridium marinum. Int J Biol Macromol 129:152–161. https://doi.org/10.1016/j.ijbiomac.2019.01.207

Arad S (Malis), Levy-Ontman O (2010) Red microalgal cell-wall polysaccharides: biotechnological aspects. Curr Opin Biotechnol 21:358–364. https://doi.org/10.1016/j.copbio.2010.02.008

Agathokleous E, Kitao M, Komatsu M et al (2023) Single and combined effects of fertilization, ectomycorrhizal inoculation, and drought on container-grown Japanese larch seedlings. J For Res 34:1077–1094. https://doi.org/10.1007/s11676-022-01565-3

Ferreira AS, Mendonça I, Póvoa I et al (2021) Impact of growth medium salinity on galactoxylan exopolysaccharides of Porphyridium purpureum. Algal Res 59:102439. https://doi.org/10.1016/j.algal.2021.102439

Peña-Medina RL, Fimbres-Olivarría D, Enríquez-Ocaña LF et al (2023) Erythroprotective potential of phycobiliproteins extracted from Porphyridium cruentum. Metabolites 13:366. https://doi.org/10.3390/metabo13030366

Trinquet E, Maurin F, Préaudat M, Mathis G (2001) Allophycocyanin 1 as a near-infrared fluorescent tracer: isolation, characterization, chemical modification, and use in a homogeneous fluorescence resonance energy transfer system. Anal Biochem 296:232–244. https://doi.org/10.1006/abio.2001.5298

Waggoner A (2006) Fluorescent labels for proteomics and genomics. Curr Opin Chem Biol 10:62–66. https://doi.org/10.1016/j.cbpa.2006.01.005

Ben Hlima H, Farhat A, Akermi S et al (2022) In silico evidence of antiviral activity against SARS-CoV-2 main protease of oligosaccharides from Porphyridium sp. Sci Total Environ 836:155588. https://doi.org/10.1016/j.scitotenv.2022.155580

Hu H, Wang H-F, Ma L-L et al (2018) Effects of nitrogen and phosphorous stress on the formation of high value LC-PUFAs in Porphyridium cruentum. Appl Microbiol Biotechnol 102:5763–5773. https://doi.org/10.1007/s00253-018-8943-3

Paliwal C, Mitra M, Bhayani K et al (2017) Abiotic stresses as tools for metabolites in microalgae. Bioresour Technol 244:1216–1226. https://doi.org/10.1016/j.biortech.2017.05.058

Hasanah H, Setyaningsih I, Uju U (2016) Harvesting and separation technique of Porphyridium cruentum polysaccharide using ultrafiltration membrane. Jurnal Pengolahan Hasil Perikanan Indonesia 119:110–120. https://doi.org/10.17844/jphpi.v19i2.13454

Gilles R, Pequeux A (1977) Effect of salinity on the free amino acids pool of the red alga Porphyridium purpureum (=Porphyridium cruentum). Comp Biochem Physiol A: Physiol 57:183–185. https://doi.org/10.1016/0300-9629(77)90371-1

Lee Y-K, Tan H-M, Low C-S (1989) Effect of salinity of medium on cellular fatty acid composition of marine alga Porphyridium cruentum (Rhodophyceae). J Appl Phycol 1:19–23. https://doi.org/10.1007/BF00003531

Ben Hlima H, Smaoui S, Barkallah M et al (2021) Sulfated exopolysaccharides from Porphyridium cruentum: a useful strategy to extend the shelf life of minced beef meat. Int J Biol Macromol 193:1215–1225. https://doi.org/10.1016/j.ijbiomac.2021.10.161

Drira M, Elleuch J, Hadjkacem F et al (2022) Influence of the sulfate content of the exopolysaccharides from Porphyridium sordidum on their elicitor activities on date palm vitroplants. Plant Physiol Biochem 186:99–106. https://doi.org/10.1016/j.plaphy.2022.06.012

Dammak M, Ben Hlima H, Tounsi L et al (2022) Effect of heavy metals mixture on the growth and physiology of Tetraselmis sp.: Applications to lipid production and bioremediation. Bioresour Technol 360:127584. https://doi.org/10.1016/j.biortech.2022.127584

Liang Y, Sarkany N, Cui Y (2009) Biomass and lipid productivities of Chlorella vulgaris under autotrophic, heterotrophic and mixotrophic growth conditions. Biotechnol Lett 31:1043–1049. https://doi.org/10.1007/s10529-009-9975-7

Wong Y, Ho YH, Ho KC et al (2017) Growth medium screening for Chlorella vulgaris growth and lipid production. J Aquac Mar Biol 6:00143

Wang W, Han F, Li Y et al (2014) Medium screening and optimization for photoautotrophic culture of Chlorella pyrenoidosa with high lipid productivity indoors and outdoors. Bioresour Technol 170:395–403

Guillard RRL (1975) Culture of phytoplankton for feeding marine invertebrates. In: Smith WL, Chanley MH (eds) Culture of marine invertebrate animals. Springer, US, Boston, MA, pp 29–60

Guillard RRL, Ryther JH (1962) Studies of marine planktonic diatoms: I. Cyclotella nana Hustedt, and Detonula confervacea (CLEVE) Gran. Can J Microbiol 8:229–239. https://doi.org/10.1139/m62-029

Handbook of phycological methods | Plant science. In: Cambridge University Press. https://www.cambridge.org/af/academic/subjects/life-sciences/plant-science/handbook-phycological-methods-culture-methods-and-growth-measurements, https://www.cambridge.org/af/academic/subjects/life-sciences/plant-science. Accessed 2 September 2022

Dermoun D, Chaumont D, Thebault J-M, Dauta A (1992) Modelling of growth of Porphyridium cruentum in connection with two interdependent factors: light and temperature. Bioresour Technol 42:113–117. https://doi.org/10.1016/0960-8524(92)90069-A

Griffiths MJ, Garcin C, van Hille RP, Harrison STL (2011) Interference by pigment in the estimation of microalgal biomass concentration by optical density. J Microbiol Methods 85:119–123. https://doi.org/10.1016/j.mimet.2011.02.005

Dubois M, Gilles KA, Hamilton JK et al (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

Coward T, Fuentes-Grünewald C, Silkina A et al (2016) Utilising light-emitting diodes of specific narrow wavelengths for the optimization and co-production of multiple high-value compounds in Porphyridium purpureum. Bioresour Technol 221:607–615. https://doi.org/10.1016/j.biortech.2016.09.093

Derbel H, Elleuch J, Tounsi L et al (2022) Improvement of biomass and phycoerythrin production by a strain of Rhodomonas sp. isolated from the Tunisian Coast of Sidi Mansour. Biomolecules 12:885. https://doi.org/10.3390/biom12070885

Marcati A, Ursu AV, Laroche C et al (2014) Extraction and fractionation of polysaccharides and B-phycoerythrin from the microalga Porphyridium cruentum by membrane technology. Algal Res 5:258–263. https://doi.org/10.1016/j.algal.2014.03.006

Lichtenthaler HK (1987) [34] Chlorophylls and carotenoids: pigments of photosynthetic biomembranes. In: Methods in Enzymology. Elsevier, pp 350–382. https://doi.org/10.1016/0076-6879(87)48036-1

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275. https://doi.org/10.1016/S0021-9258(19)52451-6

Abdelkafi S, Fouquet B, Barouh N (2009) In vitro comparisons between Carica papaya and pancreatic lipases during test meal lipolysis: Potential use of CPL in enzyme replacement therapy. Food Chem 115:488–494. https://doi.org/10.1016/j.foodchem.2008.12.043

Morrison WR, Smith LM (1964) Preparation of fatty acid methyl esters and dimethylacetals from lipids with boron fluoride–methanol. J Lipid Res 5:600–608

Cawse PA (1967) The determination of nitrate in soil solutions by ultraviolet spectrophotometry. Analyst 92:311. https://doi.org/10.1039/an9679200311

Ames BN (1966) [10] Assay of inorganic phosphate, total phosphate and phosphatases. In: Methods in Enzymology. Elsevier, pp 115–118

Gargouch N, Karkouch I, Elleuch J et al (2018) Enhanced B-phycoerythrin production by the red microalga Porphyridium marinum: a powerful agent in industrial applications. Int J Biol Macromol 120:2106–2114. https://doi.org/10.1016/j.ijbiomac.2018.09.037

Ulusoy Erol HB, Menegazzo ML, Sandefur H et al (2020) Porphyridium cruentum grown in ultra-filtered swine wastewater and its effects on microalgae growth productivity and fatty acid composition. Energies 13:3194. https://doi.org/10.3390/en13123194

Li Z, Ma X, Li A, Zhang C (2012) A novel potential source of β-carotene: Eustigmatos cf. polyphem (Eustigmatophyceae) and pilot β-carotene production in bubble column and flat panel photobioreactors. Bioresour Technol 117:257–263. https://doi.org/10.1016/j.biortech.2012.04.069

Banerjee A, Sharma R, Chisti Y, Banerjee UC (2002) Botryococcus braunii: a renewable source of hydrocarbons and other chemicals. Crit Rev Biotechnol 22:245–279. https://doi.org/10.1080/07388550290789513

Dayananda C, Sarada R, Bhattacharya S, Ravishankar GA (2005) Effect of media and culture conditions on growth and hydrocarbon production by Botryococcus braunii. Process Biochem 40:3125–3131. https://doi.org/10.1016/j.procbio.2005.03.006

Lupi FM, Fernandes HML, Tomé MM et al (1994) Influence of nitrogen source and photoperiod on exopolysaccharide synthesis by the microalga Botryococcus braunii UC 58. Enzyme Microb Technol 16:546–550. https://doi.org/10.1016/0141-0229(94)90116-3

Yang S, Wang J, Cong W et al (2004) Utilization of nitrite as a nitrogen source by Botryococcus braunii. Biotechnol Lett 26:239–243. https://doi.org/10.1023/B:BILE.0000013722.45527.18

Ashokkumar V, Rengasamy R (2012) Mass culture of Botryococcus braunii Kutz. under open raceway pond for biofuel production. Bioresour Technol 104:394–399. https://doi.org/10.1016/j.biortech.2011.10.093

Martel CM (2009) Nitrogen-deficient microalgae are rich in cell-surface mannose: potential implications for prey biorecognition by phagotrophic protozoa. Braz J Microbiol 40:86–89. https://doi.org/10.1590/S1517-83822009000100014

Zarrinmehr MJ, Farhadian O, Heyrati FP et al (2020) Effect of nitrogen concentration on the growth rate and biochemical composition of the microalga, Isochrysis galbana. Egypt J Aquat Res 46:153–158

Arad S, Friedman O, Rotem A (1988) Effect of nitrogen on polysaccharide production in a Porphyridium sp. Appl Environ Microbiol 54:2411–2414. https://doi.org/10.1128/aem.54.10.2411-2414.1988

Guevara M, Arredondo-Vega BO, Palacios Y et al (2016) Comparison of growth and biochemical parameters of two strains of Rhodomonas salina (Cryptophyceae) cultivated under different combinations of irradiance, temperature, and nutrients. J Appl Phycol 28:2651–2660. https://doi.org/10.1007/s10811-016-0835-2

Yang L, Chen J, Qin S et al (2018) Growth and lipid accumulation by different nutrients in the microalga Chlamydomonas reinhardtii. Biotechnol Biofuels 11:1–12. https://doi.org/10.1186/s13068-018-1041-z

Toumi A, Politaeva NA (2021) Impact of the nitrate concentration on the biomass growth and the fatty acid profiles of microalgae Chlorella sorokiniana. IOP Conf Ser: Earth Environ Sci 689:012026. https://doi.org/10.1088/1755-1315/689/1/012026

Huang X, Huang Z, Wen W, Yan J (2013) Effects of nitrogen supplementation of the culture medium on the growth, total lipid content and fatty acid profiles of three microalgae (Tetraselmis subcordiformis, Nannochloropsis oculata and Pavlova viridis). J Appl Phycol 25:129–137. https://doi.org/10.1007/s10811-012-9846-9

Razaghi A, Godhe A, Albers E (2014) Effects of nitrogen on growth and carbohydrate formation in Porphyridium cruentum. Open Life Sci 9:156–162. https://doi.org/10.2478/s11535-013-0248-z

Drira M, Elleuch J, Ben Hlima H et al (2021) Optimization of exopolysaccharides production by Porphyridium sordidum and their potential to induce defense responses in Arabidopsis thaliana against Fusarium oxysporum. Biomolecules 11:282. https://doi.org/10.3390/biom11020282

Medina-Cabrera EV, Rühmann B, Schmid J, Sieber V (2020) Characterization and comparison of Porphyridium sordidum and Porphyridium purpureum concerning growth characteristics and polysaccharide production. Algal Res 49:101931. https://doi.org/10.1016/j.algal.2020.101931

Borjas Esqueda A, Gardarin C, Laroche C (2022) Exploring the diversity of red microalgae for exopolysaccharide production. Mar Drugs 20:246. https://doi.org/10.3390/md20040246

Balti R, Le Balc’h R, Brodu N et al (2018) Concentration and purification of Porphyridium cruentum exopolysaccharides by membrane filtration at various cross-flow velocities. Process Biochem 74:175–184. https://doi.org/10.1016/j.procbio.2018.06.021

Kroen WK, Rayburn WR (1984) Influence of growth status and nutrients on extracellular polysaccharide synthesis by the soil alga Chlamydomonas mexicana (Chlorophyceae)1. J Phycol 20:253–257. https://doi.org/10.1111/j.0022-3646.1984.00253.x

Díaz Bayona KC, Garcés LA (2014) Effect of different media on exopolysaccharide and biomass production by the green microalga Botryococcus braunii. J Appl Phycol 26:2087–2095. https://doi.org/10.1007/s10811-014-0242-5

Bafana A (2013) Characterization and optimization of production of exopolysaccharide from Chlamydomonas reinhardtii. Carbohydr Polym 95:746–752. https://doi.org/10.1016/j.carbpol.2013.02.016

Cheirsilp B, Mandik YI, Prasertsan P (2016) Evaluation of optimal conditions for cultivation of marine Chlorella sp. as potential sources of lipids, exopolymeric substances and pigments. Aquacult Int 24:313–326. https://doi.org/10.1007/s10499-015-9927-2

Delattre C, Pierre G, Laroche C, Michaud P (2016) Production, extraction and characterization of microalgal and cyanobacterial exopolysaccharides. Biotechnol Adv 34:1159–1179

Soanen N, Da Silva E, Gardarin C et al (2016) Improvement of exopolysaccharide production by Porphyridium marinum. Bioresour Technol 213:231–238. https://doi.org/10.1016/j.biortech.2016.02.075

Redfield AC (1958) The biological control of chemical factors in the environment. Am Sci 46:230A-221

Li S, Ji L, Chen C et al (2020) Efficient accumulation of high-value bioactive substances by carbon to nitrogen ratio regulation in marine microalgae Porphyridium purpureum. Bioresour Technol 309:123362. https://doi.org/10.1016/j.biortech.2020.123362

You T, Barnett SM (2004) Effect of light quality on production of extracellular polysaccharides and growth rate of Porphyridium cruentum. Biochem Eng J 19:251–258. https://doi.org/10.1016/j.bej.2004.02.004

Liqin S, Wang C, Lei S (2008) Effects of light regime on extracellular polysaccharide production by Porphyridium cruentum cultured in flat plate photobioreactors. In: 2008 2nd International Conference on Bioinformatics and Biomedical Engineering. pp 1488–1491. https://doi.org/10.1109/ICBBE.2008.701

Choi SP, Nguyen MT, Sim SJ (2010) Enzymatic pretreatment of Chlamydomonas reinhardtii biomass for ethanol production. Bioresour Technol 101:5330–5336. https://doi.org/10.1016/j.biortech.2010.02.026

Rodjaroen S, Juntawong N, Mahakhant A, Miyamoto K (2007) High biomass production and starch accumulation in native green algal strains and cyanobacterial strains of Thailand. Kasetsart J – Nat Sci 41:570–575

Ramus J, Robins DM (1975) The correlation of golgi activity and polysaccharide secretion in Porphyridium 1 2. J Phycol 11:70–74. https://doi.org/10.1111/j.1529-8817.1975.tb02750.x

Ramus J (1972) The production of extracellular polysaccharide by the unicellular red alga Porphyridium aerugineum 1, 2. J Phycol 8:97–111. https://doi.org/10.1111/j.1529-8817.1972.tb04007.x

Sheath RG, Hellebust JA, Sawa T (1979) Floridean starch metabolism of Porphyridium purpureum (Rhodophyta): I. Changes during ageing of batch culture. Phycologia 18:149–163. https://doi.org/10.2216/i0031-8884-18-2-149.1

Viola R, Nyvall P, Pedersén M (2001) The unique features of starch metabolism in red algae. Proc R Soc Lond B 268:1417–1422. https://doi.org/10.1098/rspb.2001.1644

Friedman O, Dubinsky Z, Arad SM (1991) Effect of light intensity on growth and polysaccharide production in red and blue-green Rhodophyta unicells. Bioresour Technol 38:105–110

Eriksen NT, Riisgård FK, Gunther WS, Lønsmann Iversen JJ (2007) On-line estimation of O2 production, CO2 uptake, and growth kinetics of microalgal cultures in a gas-tight photobioreactor. J Appl Phycol 19:161–174. https://doi.org/10.1007/s10811-006-9122-y

Tredici MR, Carlozzi P, Chini Zittelli G, Materassi R (1991) A vertical alveolar panel (VAP) for outdoor mass cultivation of microalgae and cyanobacteria. Bioresour Technol 38:153–159. https://doi.org/10.1016/0960-8524(91)90147-C

Brányiková I, Maršálková B, Doucha J et al (2011) Microalgae—novel highly efficient starch producers. Biotechnol Bioeng 108:766–776. https://doi.org/10.1002/bit.23016

Maeda I, Seto Y, Ueda S et al (2006) Simultaneous control of turbidity and dilution rate through adjustment of medium composition in semi-continuous Chlamydomonas cultures. Biotechnol Bioeng 94:722–729. https://doi.org/10.1002/bit.20884

Li T, Xu J, Wu H et al (2019) Growth and biochemical composition of Porphyridium purpureum SCS-02 under different nitrogen concentrations. Mar Drugs 17:124. https://doi.org/10.3390/md17020124

Borovkov AB, Gudvilovich IN, Maltseva IA et al (2022) Growth and B-phycoerythrin production of red microalga Porphyridium purpureum (Porphyridiales, Rhodophyta) under different carbon supply. Microorganisms 10:2124. https://doi.org/10.3390/microorganisms10112124

Netto AT, Campostrini E, Oliveira JG de, Bressan-Smith RE (2005) Photosynthetic pigments, nitrogen, chlorophyll a fluorescence and SPAD-502 readings in coffee leaves. Sci Hortic 104:199–209. https://doi.org/10.1016/j.scienta.2004.08.013

Kursar TA, Alberte RS (1983) Photosynthetic unit organization in a red alga: relationships between light-harvesting pigments and reaction centers. Plant Physiol 72:409–414. https://doi.org/10.1104/pp.72.2.409

Yokoya NS, Necchi O, Martins AP et al (2007) Growth responses and photosynthetic characteristics of wild and phycoerythrin-deficient strains of Hypnea musciformis (Rhodophyta). J Appl Phycol 19:197–205. https://doi.org/10.1007/s10811-006-9124-9

Sosa-Hernández JE, Rodas-Zuluaga LI, Castillo-Zacarías C et al (2019) Light intensity and nitrogen concentration impact on the biomass and phycoerythrin production by Porphyridium purpureum. Mar Drugs 17:460. https://doi.org/10.3390/md17080460

Velea S, Ilie L, Filipescu L (2011) Optimization of Porphyridium purpureum culture growth using two variables experimental design: light and sodium bicarbonate. UPB Sci Bull Series B 73:81–94

da Silva AF, Lourenço SO, Chaloub RM (2009) Effects of nitrogen starvation on the photosynthetic physiology of a tropical marine microalga Rhodomonas sp. (Cryptophyceae). Aquat Bot 91:291–297. https://doi.org/10.1016/j.aquabot.2009.08.001

Algarra P, Rudiger W (1993) Acclimation processes in the light harvesting complex of the red alga Porphyridium purpureum (Bory) Drew et Ross, according to irradiance and nutrient availability. Plant Cell Environ 16:149–159. https://doi.org/10.1111/j.1365-3040.1993.tb00856.x

Fuentes-Grünewald C, Bayliss C, Zanain M et al (2015) Evaluation of batch and semi-continuous culture of Porphyridium purpureum in a photobioreactor in high latitudes using Fourier transform infrared spectroscopy for monitoring biomass composition and metabolites production. Bioresour Technol 189:357–363. https://doi.org/10.1016/j.biortech.2015.04.042

Gudvilovich IN, Borovkov AV (2014) Production characteristics of the microalga Porphyridium purpureum (Bory) Drew Ross (Rhodophyta) in batch and quasi-continuous culture. Int J Algae 16:271–283. https://doi.org/10.1615/InterJAlgae.v16.i3.70

Fábregas J, García D, Morales E et al (1998) Renewal rate of semicontinuous cultures of the microalga Porphyridium cruentum modifies phycoerythrin, exopolysaccharide and fatty acid productivity. J Ferment Bioeng 86:477–481. https://doi.org/10.1016/S0922-338X(98)80155-4

Zhao L-S, Su H-N, Li K et al (2016) Supramolecular architecture of photosynthetic membrane in red algae in response to nitrogen starvation. Biochimica et Biophysica Acta (BBA) - Bioenergetics 1857:1751–1758. https://doi.org/10.1016/j.bbabio.2016.08.005

Levy I, Gantt E (1990) Development of photosynthetic activity in Porphyridium purpureum (Rhodophyta) following nitrogen starvation1,2. J Phycol 26:62–68. https://doi.org/10.1111/j.0022-3646.1990.00062.x

Chaloub RM, Motta NMS, de Araujo SP et al (2015) Combined effects of irradiance, temperature and nitrate concentration on phycoerythrin content in the microalga Rhodomonas sp. (Cryptophyceae). Algal Resh 8:89–94. https://doi.org/10.1016/j.algal.2015.01.008

Dupre C, Guary J-C, Grizeau D (1994) Effect of photon fluence rate, nitrogen limitation and nitrogen recovery on the level of phycoerythrin in the unicellular alga, Rhodosorus marinus (Rhodophyceae). Physiol Plant 92:521–527. https://doi.org/10.1111/j.1399-3054.1994.tb08846.x

Rebolloso Fuentes M (2000) Biomass nutrient profiles of the microalga Porphyridium cruentum. Food Chem 70:345–353. https://doi.org/10.1016/S0308-8146(00)00101-1

Hockin NL, Mock T, Mulholland F et al (2012) The response of diatom central carbon metabolism to nitrogen starvation is different from that of green algae and higher plants. Plant Physiol 158:299–312. https://doi.org/10.1104/pp.111.184333

Zhu S, Huang W, Xu J et al (2014) Metabolic changes of starch and lipid triggered by nitrogen starvation in the microalga Chlorella zofingiensis. Bioresour Technol 152:292–298. https://doi.org/10.1016/j.biortech.2013.10.092

Siaut M, Cuiné S, Cagnon C et al (2011) Oil accumulation in the model green alga Chlamydomonas reinhardtii: characterization, variability between common laboratory strains and relationship with starch reserves. BMC Biotechnol 11:7. https://doi.org/10.1186/1472-6750-11-7

Msanne J, Xu D, Konda AR et al (2012) Metabolic and gene expression changes triggered by nitrogen deprivation in the photoautotrophically grown microalgae Chlamydomonas reinhardtii and Coccomyxa sp. C-169. Phytochemistry 75:50–59. https://doi.org/10.1016/j.phytochem.2011.12.007

Ördög V, Stirk WA, Bálint P et al (2012) Changes in lipid, protein and pigment concentrations in nitrogen-stressed Chlorella minutissima cultures. J Appl Phycol 24:907–914. https://doi.org/10.1007/s10811-011-9711-2

Lv J-M, Cheng L-H, Xu X-H et al (2010) Enhanced lipid production of Chlorella vulgaris by adjustment of cultivation conditions. Bioresour Technol 101:6797–6804. https://doi.org/10.1016/j.biortech.2010.03.120

Zachleder V, Brányiková I (2014) Starch overproduction by means of algae. In: Bajpai R, Prokop A, Zappi M (eds) Algal biorefineries. Springer, Netherlands, Dordrecht, pp 217–240

Asgharpour M, Rodgers B, Hestekin JA (2015) Eicosapentaenoic acid from Porphyridium cruentum: increasing growth and productivity of microalgae for pharmaceutical products. Energies 8:10487–10503. https://doi.org/10.3390/en80910487

James GO, Hocart CH, Hillier W et al (2011) Fatty acid profiling of Chlamydomonas reinhardtii under nitrogen deprivation. Bioresour Technol 102:3343–3351. https://doi.org/10.1016/j.biortech.2010.11.051

Sharma KK, Schuhmann H, Schenk PM (2012) High lipid induction in microalgae for biodiesel production. Energies 5:1532–1553. https://doi.org/10.3390/en5051532

Widjaja A, Chien C-C, Ju Y-H (2009) Study of increasing lipid production from fresh water microalgae Chlorella vulgaris. J Taiwan Inst Chem Eng 40:13–20. https://doi.org/10.1016/j.jtice.2008.07.007

Mata TM, Almeidab R, Caetanoa NS (2013) Effect of the culture nutrients on the biomass and lipid productivities of microalgae Dunaliella tertiolecta. Chem Eng 32:973

Cohen Z, Vonshak A, Richmond A (1988) Effect of environmental conditions on fatty acid composition of the red alga Porphyridium cruentum: correlation to growth rate1. J Phycol 24:328–332. https://doi.org/10.1111/j.1529-8817.1988.tb04474.x

Shanab SMM, Hafez RM, Fouad AS (2018) A review on algae and plants as potential source of arachidonic acid. J Adv Res 11:3–13. https://doi.org/10.1016/j.jare.2018.03.004

Liu H, Fang HHP (2002) Extraction of extracellular polymeric substances (EPS) of sludges. J Biotechnol 95:249–256. https://doi.org/10.1016/S0168-1656(02)00025-1

Ye Y, Clech PL, Chen V, Fane AG (2005) Evolution of fouling during crossflow filtration of model EPS solutions. J Membr Sci 264:190–199. https://doi.org/10.1016/j.memsci.2005.04.040

Kavitha MD, Kathiresan S, Bhattacharya S, Sarada R (2016) Culture media optimization of Porphyridium purpureum: production potential of biomass, total lipids, arachidonic and eicosapentaenoic acid. J Food Sci Technol 53:2270–2278. https://doi.org/10.1007/s13197-016-2185-0

Mostert ES, Grobbelaar JU (1987) The influence of nitrogen and phosphorus on algal growth and quality in outdoor mass algal cultures. Biomass 13:219–233. https://doi.org/10.1016/0144-4565(87)90061-8