Abstract

The study aimed to treatment of high organic matter concentration in leachate produced by municipal waste in developing countries. The average properties of the raw leachate were investigated, including chemical oxygen demand (COD), biochemical oxygen demand (BOD5), and total suspended solids (TSS), which were found to be 55,058.7, 34,500, and 8080 mg/L, respectively. The study evaluated the performance of integrated systems consisting of modified septic tanks (MST) and horizontal flow subsurface flow constructed wetland (HF-SFCW) to treat this type of leachate. The maximum removal efficiencies for COD, BOD5, and TSS were 61.18%, 55.07%, and 64.6% for MST, and 67.93%, 61.90%, and 71.11% for HF-SFCW. Also, the percentage phosphorus removal was 35.41% for MST and 54.16% for HF-SFCW, while the efficiency of nitrogen compound removal was reported differently for the two methods. MST showed an increase in ammonium concentration due to anaerobic conditions and denitrification, while HF-SFCW showed a significant decrease in ammonium concentration and a slight increase in nitrate and nitrite concentrations. The study concluded that MST and HF-SFCW planted with Phragmites australis exhibited good phytoremediation performance in heavily polluted leachate.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The growing population and an increasingly consumption-oriented lifestyle have caused a considerable increase in the production of municipal solid waste (MSW). Nowadays, although there are many advances in integrated solid waste management (ISWM), such as recycling, composting, and pyrolysis, which have the capacity to recover material and energy, in many countries, especially in developing countries, landfilling is still considered the main method of waste management. On the other hand, the need for landfilling of non-recyclable waste and compost and pyrolysis residues as well as incinerators ash is undeniable. Leachate, which is generated during the disposal of municipal waste in landfills, is a major issue for solid waste facilities. The treatment of landfill leachate is complicated due to its different chemical components, which depend on the age and source of the waste, the atmospheric conditions, and the rate of degradation of the solid waste [1]. Over time, the properties of the leachate switch from a low pH and a high BOD5/COD ratio in the young leachate to a low BOD5/COD ratio and a high ammonium concentration in the old leachate [2].

Currently, the use of conventional leachate treatment systems in landfills is a challenge due to high maintenance costs and high energy consumption as well as lack of access to facilities such as energy sources and qualified personnel [3]. In contrast, nature-based solutions (NBS) have demonstrated their valuable potential in leachate treatment in previous years. Phytoremediation is one of the NBS processes that has been used in various fields either as the main technology or in conjunction with conventional technologies [4, 5]. The fundamental concept of phytoremediation involves the utilization of plants and their accompanying soil microorganisms to decrease the levels or detrimental impact of pollutants present in the surroundings [6, 7]. Compared to the previously used methods, phytoremediation in constructed wastelands (CWs) can be perceived as an alternative “green technology” that provides a more sustainable and environmentally friendly solution for leachate treatment at landfills [8]. Constructed wetlands, in which leachate is treated by physical (e.g., sedimentation, filtration), chemical (e.g., precipitation, adsorption), and biological processes (e.g., microbial degradation, uptake from the water column and root zone), are of particular interest due to their cost efficiency, ease of use and maintenance, and general availability of land around landfills [9]. The diversity of treatment processes in these systems provides multiple and different degradation processes for different classes of compounds and thus higher efficiencies compared to technical systems, which use only one treatment mechanism.

Plants are impressive components of the wastewater treatment system and contribute to improving wetland performance [1]. The selection of plant species to be used is a critical issue in designing CWs. The selected plant must be resistant to harsh environmental conditions, but also be able to tolerate the possible toxic effects of the leachate, e.g., high ammonium concentration. The vegetation in CWs, which in Asian regions is mostly Phragmites australis, plays a vital role in treatment. It releases oxygen and reduces the flow velocity of the water, acts as a filter medium, and improves sedimentation and contact time with the leachate. Its roots and rhizomes provide a suitable substrate for the growth of microbial biofilms, resulting in a higher biological activity per unit area compared to lagoons and ponds. Plants therefore not only play a direct role in the uptake of nutrients and heavy metals but also help to create suitable conditions for the removal of other pollutants [8].

Despite all the aforementioned advantages of wetlands, due to the characteristics of the leachate, the high concentration of organic compounds, and the presence of hazardous pollutants, pre-treatment is necessary to maintain the population of macrophytes and microorganisms in wetlands. The application of the pre-treatment process prior to wetlands not only reduces the risk of destruction of the system but also increases efficiency, reduces the possibility of clogging the bed, and thus increases the productivity period of the system. Compared to other pre-treatment systems such as aerated lagoons and membrane bioreactors, anaerobic technologies are more attractive. The interest in anaerobic systems is due to the simplicity of the process, low operating costs, and independence from electricity for wetland pre-treatment purposes in leachate treatment in landfills [10]. However, conventional septic tanks have various disadvantages, the most important of which is poor treatment performance [11]. To overcome the issue of low performance and certain other disadvantages, enhancements and modifications to the design of the existing septic tanks or additional after-treatment measures are required [12]. The results of studies on the effectiveness of modified septic tanks compared to conventional septic tanks are valuable and promising. The installation of baffles in these tanks offers the leachate the opportunity to come into contact with the bacteria-rich sludge layer that forms at the bottom of each chamber by creating upward and downward (zig-zag movement) flows [11]. Certainly, the number of baffles has a significant role in the efficiency of the process, and the more upflow chambers (up to 4 chambers) there are, the higher the treatment performance in terms of BOD5, COD, and TSS removal. However, taking into account economic considerations, two to four chambers are advised in septic tanks [12].

Subsurface flow constructed wetlands (SFCWs) are often preferred among the types of CWs because the water flows underground, so insects and vermin do not accumulate in it and there are no unpleasant odors and appearances. SFCWs are operated as vertical or horizontal flow. Although, as mentioned in some previous studies, vertical flow SFCWs (VF-SFCWs) have better efficiency in reducing BOD5 and COD and removing ammonium, sometimes horizontal flow SFCWs (HF-SFCWs) are preferred due to their high efficiency in removing suspended solids and lower risk of clogging [8]. In horizontal flow subsurface flow constructed wetlands (HF-SFCWs), water flows below the ground and comes into contact with a network of aerobic, anoxic, and anaerobic zones. Roots and rhizomes that leak into the aerobic areas in the substrate are very efficient in removing organic matter [13]. In addition, the HF-SFCWs can create the anaerobic conditions for the conversion of nitrate into nitrogen gas (denitrification). In this way, complete nitrogen removal can be achieved [14].

Previous studies have established that CWs are a promising option for the treatment of landfill leachate in tropical regions [15]. In colder regions, the use of subsurface wetlands for treating highly polluted leachate from landfills is not yet widespread. Therefore, investigating the effectiveness of this technology in these regions is a novel topic. In this study, we employed a two-stage system that involved using a modified and unique design of a septic tank specifically for leachate treatment as pre-treatment, followed by a phytoremediation process using subsurface wetlands. Through the optimization of the system’s operating conditions, which included horizontal flow, we were able to improve the treatment process for use in cold regions and meet the effluent standards.

2 Materials and methods

2.1 Site description

The area of the study is located west of Iran about 22 km north of Hamadan. This area is called Hamadan municipal waste landfill (X = 282,363.172 and Y = 3,871,970.395) and covers 230 ha. The average annual temperature was 17 °C and the maximum and minimum annual temperatures were 40 °C and − 11 °C respectively.

2.2 Design integrated system

As shown in Fig. 1, the system included two separate series units (a and b) which respectively offered a volume of 2 m3 for anaerobic treatment and 24 m3 (each pond) for aerobic treatment. Unit b included two sections in parallel, pond b-1 was planted with P. australis, and pond b-2 was left unplanted (control pond). Initially, raw leachate from the storage pond of the landfill was fed into a modified septic tank. After anaerobic treatment in the MST, the effluent was diluted and discharged into the wetland pond. Table 1 shows the dimensions and operating conditions of MST as well as the HF-SFCW unit used in this study.

2.3 Design of the modified septic tank (MST)

The design volume of the septic tank was 2 m3, which was connected to a leachate pipe on one side and to the wetland pond inlet pipe on the other side. The input and output connections were considered via a T-pipe, which allows liquid to enter and exit without turbulence in the flow and interference in sedimentation. The tank consists of two chambers, each with a manhole cover and separated by a partition with openings approximately halfway between the bottom and roof of the tank. Galvanized sheets were used for the construction of a modified septic tank. Although the use of plastic or concrete septic tanks is more common, with the galvanized version it was more feasible to add baffles and inner walls of the tank with a desired angle. To protect the tank walls against the pH change of the leachate and corrosion, the inner walls of the tank were coated with a polymer coating. In the first part, 5 precipitation plates were installed at an angle of 60° and at a distance of 15 cm from each other. These plates are installed to re-settle suspended particles that may be suspended due to gas production in this phase, to prevent them from leaving the flow and entering the second part. In the second part, cross walls and baffles were used to create an upflow and increase the residence time. The dimensions of the design are shown in more detail in Fig. 2.

2.4 Design of the horizontal flow subsurface flow constructed wetland (HF-SFCW)

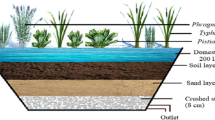

The design of the constructed wetland pond involved determining the dimensions of the reactor, the drainage system (i.e., inlet, outlet pipe), and the placement and mount of each media. As shown in Fig. 3, the wetland pond was made of concrete with a length of 6 m and a width of 4 m. The dimensions of the pond were determined using Eqs. 1–3 according to the average temperature in the cold season [16].

where Ce is the outlet BOD5 (mg.L−1), C0 the inlet BOD5 (mg.L−1), k(T) the reaction rate constant that depends on temperature (°C), and t the hydraulic retention time (day), and Q, d, n, and As are flow rate (m3.day−1), depth (m), number of pond, and surface area (m2), respectively.

In order to create a difference in height between the inlet and outlet and the gravity movement of the flow, the bottom of the pond was built with a slope of 5%. After completion of the preparation, the reed bed of the pond was filled with river pebbles of silica-quartz (Si 30.32%; Al 5.23%; Fe 6.87%; Ca 2.79%; Mg 1.01%) with a size of 25–30 mm in the inlet and outlet zone, respectively, and a size of 12–15 mm in the middle area of the bed [17]. The substrate depth was 0.6 m to allow greater root development and create a larger rhizosphere with a media porosity of 0.5. The flow traversed horizontally through the root site to a depth of 100 mm below the substrate surface. To investigate the role of reeds alone in phytoremediation, a pond with the same dimensions but without plants was constructed as a control pond (Fig. 4) [18, 19].

2.5 Transplanting and planting reeds

So far, numerous studies have been conducted to select suitable plants for the treatment of landfill leachate in Asian regions. In this study, the native plant of the region, P. australis, was selected as the plant component of the wetland. This plant, which is a reed species, is well adapted to the climatic conditions of the region. Also according to the results of previous studies, it has adequate treatment capacity and can tolerate the high ammonium concentration in the leachate of this region. P. australis has a high capacity for the phytoremediation of various nutrients and is superior to other aquatic species in this respect [20]. The plants were gathered from natural wetlands near the pilot at the landfill site. Their roots and rhizomes were washed with tap water to clean out native soil particles and then planted in Unit b-1(constructed wetland) in April 2022 at a density of 5 pieces/m2. The average height of the reed at planting was about 0.1 to 0.3 m. After planting, the reeds were watered for 2 weeks to promote growth and maturation. Plant growth was generally satisfactory. The growth rate was high and the maximum height of the reed was 2.2 m. Four stages of plant growth were observed during the operational period from April 2022 to January 2023: (1) green up and stem elongation, (2) crop development and flowering, (3) from flowering to the beginning of canopy senescence, (4) canopy senescence [17]. After 2 weeks of growth and maturation, the 3-week adaptation period of reed with leachate began. During this phase, the system was exploited with diluted landfill leachate (1:10). After this period and the complete maturation of the reeds, the effectiveness of the wetland was investigated over a period of 9 months, including the cold and warm seasons. In each operating period, 6000 L per week of a mixture of dilution water and landfill leachate was loaded into the HF-SFCWs, with a hydraulic loading rate (HLR) of 0.012 m.day−1 [2].

2.6 Analytical methods

The samples in this study were taken to the laboratory following each stage of the treatment process and underwent various analyses. Initially, they were filtered using 0.45-µm membrane filters to eliminate suspended solids and bacteria. Then, a portable conductivity meter was used to measure electrical conductivity (EC). The physicochemical and microbiological parameters of the samples, such as alkalinity, COD, BOD5, nitrite nitrogen (NO2-N), ammonium nitrogen (NH4-N), nitrate nitrogen (NO3-N), total phosphorus (TP), and total suspended solids (TSS), were analyzed in accordance with standard methods (APHA, 2017). The COD was measured using the open reflux method and a UV–Vis spectrophotometer (model DR 6000 Hach, USA), while the BOD5 was determined through the APHA 5-day BOD test. The TSS was tested at 105 °C [19,20,21,22]. It is important to mention that all of the tests mentioned above were conducted three times to ensure the accuracy of the results.

2.7 Removal efficiency

The removal efficiency was estimated using the inlet and outlet concentrations and volumes in Eq. 4:

where Cin is the inlet concentration (mg/L), Vin is the inlet volume (L/day), and Cout and Vout are the outlet concentration and outlet volume, respectively (2).

3 Results and discussion

3.1 Leachate characteristics

A comprehensive program was established to conduct weekly sampling of HF-SFCWs and 2-, 3-, and 7-day periods for MST effluents between April 2022 and January 2023. During each sampling period, eight samples were taken, including influent and effluent from MST, HF-SFCWs, control ponds, and boreholes. Each 500-mL sample was collected and stored in an amber jar that had been soaked in 0.1 mol/L HCl for 24 h and rinsed 5–6 times with deionized water. The pH and temperature were measured immediately on site. The bulk samples were then transferred to the waste laboratory of the Environmental Health Engineering Department at Hamedan University of Medical Sciences in the dark and kept at a temperature of 4 °C. The physicochemical characteristics of the raw leachate, namely COD, BOD5, and TSS, were 50,587.5, 34,500, and 8080 mg/L respectively. Other characteristics of the raw leachate are listed in Table 2.

3.2 Performance of anaerobic leachate treatment in a modified septic tank

After reaching a stable state and undergoing an 8-week maturation process, the performance of the modified septic tank improved. To determine the optimal operating conditions, the modified septic tank (MST) was tested with various hydraulic retention times (HRTs) and corresponding organic loading rates (OLR), as shown in Fig. 5. The range of organic loading was between 3.85 and 7.08 kg/m3. The first day’s results and yield for HRTs of 2, 3, and 7 days were observed during both warm and cold seasons. The hydraulic retention time used in this study was longer than the optimal duration found in comparable research. The reason behind this decision was due to the functioning of the altered septic tank shortly after its initial 8-week start-up, which resulted in a lesser quantity of sludge compared to other similar studies. Therefore, relying on the findings of Fiza Ali Nasra et al.’s research that demonstrated the impact of HRT on the amount of sludge in a septic tank, it was decided to increase the HRT to 7 days to enhance the volume and weight of sludge [10]. The study period showed that temperature had an influence on the anaerobic biodegradation of organic matter. The temperature range observed during the study was − 11 to 40 °C, with seasonal variations. The system was launched in the spring, and its performance decreased as the temperature dropped in the winter. As indicated in Table 3 and Fig. 5, the highest efficiency of the MST in reducing COD and BOD5 occurred after 7 days, with a 61.18% and 55.07% reduction in COD and BOD5, respectively, during the warm season and a 47.06% and 41.02% reduction in COD and BOD5, respectively, during the cold season. The TSS removal percentage was 64.6% when the HRT was set to 7 days, which might be due to sedimentation and the trapping of organic matter in the bottom of the primary chamber, forming aggregated sludge. This study’s findings regarding the increase in removal efficiency of COD, BOD5, and TSS by increasing HRT and seasonal temperature are in line with the studies conducted by Sharma and Nasr [10, 12]. The MST has been found to provide a higher treatment efficiency for effluent with better quality than conventional septic tanks (CSTs). This is due to the MST’s alteration of the flow direction through baffles from horizontal flow to vertical upflow. The new direction improves the contact between the accumulated sludge and incoming leachate, resulting in an increased removal of suspended solids by incorporating dissolved anaerobically biodegradable organic matter [23]. In this anaerobic treatment process, pH is an important and effective parameter. The pH of the raw leachate during the experimental period was observed to be 7.5 ± 0.5, which is the appropriate range for anaerobic metabolism [18]. As the process continued, the pH decreased due to hydrolysis, acidogenesis, and acetogenesis, leading to the accumulation of fatty acids [24]. Alkalinity is another measure of the anaerobic process’s stability. Alkalinity levels were observed to increase by 8–15%, which can be attributed to the formation of carbonates and bicarbonates within the system, indicating proper anaerobic function [12]. As the modified septic tank primarily relied on anaerobic digestion, it was anticipated that there would be a low level of nitrogen removal (28.23% and 21.87% reduction for nitrate and nitrite, respectively) [25]. Slight rises in ammonia concentrations (11.50% and 9.76% in warm and cold seasons, respectively) were detected. The study of Fayza Aly Nasra et al. suggested that the elevation in ammonia concentration could be due to effluent hydrolysis in the tank and high nitrogen-ammonia levels in the leachate [10]. In the warm and cold seasons, the highest phosphorus removal efficiencies were 28.23% and 25%, respectively. The relatively low quantity of biomass in anaerobic systems may account for the lower phosphorus removal. However, precipitation and inclusion in the accumulated sludge may also contribute to phosphorus removal [25]. The findings on phosphorus removal in this study align with the results of Khalid et al. Some of the phosphorus precipitates in the settled solids in the septic tank, while others are absorbed by heterotrophic organisms in the biomass or removed by phosphorus-accumulating organisms (PAOs). Under anaerobic conditions, facultative PAO microorganisms can survive and may be responsible for phosphate degradation in the initial phase. However, most of the phosphorus is chemically removed, such as through the formation of struvite compounds. High loading rates cause excessive growth of heterotrophic microorganisms and reduce the growth of PAOs and nitrifiers (Fig. 5) [26].

3.3 Performance of horizontal flow subsurface flow wetland

As shown in Table 2, in the tests conducted, the BOD5/COD ratio of the landfill leachate was in the range of 0.56 to 0.68. The ratio of BOD5/COD is an important parameter to assess the biodegradability of organic matter, and it determines the efficiency of organic removal in biological processes, which depends on the leachate’s biodegradability ratio [2]. A ratio higher than 0.5 indicates that the organic matter in the leachate can be easily degraded, whereas a ratio less than 0.3 suggests that the organic matter is not easily degraded during the treatment process [2]. Despite the adequate biodegradability ratio of usage leachate for natural treatment systems, in order for the inflow to be tolerable to the plant, the leachate was diluted with certain ratios and discharged into the wetland and control pond. The water for diluting the raw leachate was taken with a pump from a drainage collection channel near the landfill. The performance was evaluated as a function of 3 different hydraulic retention times (7, 14, and 21 days) for the warm season and 5 hydraulic retention times (7, 14, 21, 28, and 35 days) for the cold season. With the exception of pH, all parameters showed signed differences between the initial and final values. The results of Fig. 3 show well that process efficiency improves with increasing HRT and temperature and decreasing OLR. In the last months of the project, higher organic loads were introduced into the system to determine the tolerance limit of plants and the efficiency of the system, so during this phase, the simultaneous increase in OLR and decrease in temperature led to a decrease in process efficiency. The most effective reduction of COD was 67.93% in September with an HRT of 21 days and an average daily temperature of 35 °C. Since biological processes and bioremediation are strongly influenced by the ambient temperature, a higher degradation of organic matter was achieved in summer due to the increased microbial activity [27]. Based on Yalcuk and Ugurlu, the low COD removal in the first months of the experiment can be attributed to the presence of weakly active microorganisms in the media of the HF-SFCWs at the beginning of the operation. In addition, at the beginning of the use of the system, the plants were not fully developed and had a weak biofilm association in the roots. These findings are consistent with our results [28]. The HF-SFCW exhibited a higher BOD5 removal (61.90%) in the warm season than in the cold season (44.34%). Organic compounds (BOD5) are biodegraded both aerobically and anaerobically by bacteria attached to the roots and rhizomes of the plant [25]. Multiple factors, such as the organic degradation rate in the pre-treatment process, the OLR, long HRT, and larger surface area, may have improved the digestion of degradable and recalcitrant organic matter and reduction of BOD5 in the wetlands [29]. The water depth of HF wetlands is a critical parameter affecting organic matter removal. Choosing an appropriate depth shows better performance in organic matter removal as it increases the diffusion rate of atmospheric oxygen in the wetland bed and supports the associated degradation pathways [21]. In this study, using the results of previous studies, the bed depth was designed to be 0.6 m, so that the roots of the P. australis could penetrate the entire bed and provide an oxygen supply to the entire bed.

The highest efficiency of TSS removal was 71.11% (Fig. 6). The suspended solids that remained from the pre-treatment were successfully removed by filtration and settled in the first meters after the inlet area [21]. During the operation period of this horizontal subsurface SCW system, in addition to reasonable efficiency in reducing TSS, no problems such as bed clogging and sludge accumulation were observed.

Ammonium concentration decreased by 67.45% in HF-SFCWs and 42.61% in the control pond. NH4 are essential nutrients for proper plant growth, playing an effective role in the biochemical and physiological functions of plants and significantly raising and improving their performance and quality. The results reported by Dan A et al. confirm these findings [30].

As predicted, a 14.28% and 15% increase in nitrate and nitrite in the HF-SFCW effluent was obtained due to the nitrification process. NO2− and NO3− concentration increment signifies that adsorbed ammonium was subjected to nitrification by nitrifier population attached to the media or rhizosphere. On the other hand, according to Li et al., the development of the root system influences ammonium degradation, so ammonium degradation may increase as the system matures since O2 availability is higher in a mature system [31]. Nitrogen in CWs is either volatilized as NH3, taken up by microorganisms and plants, or transferred from one form to another in a cycle through the mechanisms of ammonification, nitrification, and denitrification as well as nitrogen fixation [32]. NO3− and NH4+ are essential nutrients for proper plant growth, playing an effective role in the biochemical and physiological functions of plants and significantly raising and improving their performance and quality [31]. In leachate with very high pollutant concentration, other pollutant removal routes have also been identified. As Bakhshudeh et al. and Ho et al. reported, the nitrification process in the presence of high concentrations of BOD5 is not limited to the aerobic zones on the roots and BOD5 removal changes from aerobic to the anaerobic mechanism [1, 33]. In this regard, Silvestrini et al. noted that ammonium degradation under anaerobic conditions is probably due to nitrifying bacteria. So, complete nitrogen removal can be achieved in horizontal subsurface wetlands, as the anaerobic conditions for conversion of nitrate to nitrogen gas (denitrification) are present [2].

A 54.16% decrease in phosphorus concentration in the effluent showed that phosphorus removal is possible through plant absorption and environmental absorption in subsurface flow wetlands. Phosphorus removal in subsurface flow wetlands is usually attained by media adsorption; in the achievement of the adsorption-based removal route, special materials are required that were composed of calcium, aluminum, and iron components. The HF wetland also showed considerable phosphorus removal percentages, which could be related to the adsorption capacities of the sand media used [21]. Only limited information is available in this context so further investigations and evidence as well as molecular analyses are suggested for future studies.

As shown in Table 3, considerable differences were found between the performance of the wetland and the control pond. The greater efficiency of the planted wetland compared to the control pond in reducing all parameters indicates the role of P. australis in absorbing pollutants, aerating the root zone, facilitating water movement, and preventing clogging of the system [34]. Reed roots and rhizomes are hollow and contain air-filled channels that transport oxygen from the atmosphere into the substrate [25]. Many scientists believe that microorganisms in the rhizosphere significantly improve the ability of P. australis to eliminate organic compounds. Microorganisms also vary depending on the type of chemicals produced by reeds. Informed by the studies of Justyna Milke et al. and the study of Toscano et al., P. australis demonstrates a higher removal capacity compared to other species studied. Moreover, it is confirmed that this plant is a superior plant species that can be used for treatment in constructed wetlands, particularly in cold regions. Importantly, it has a positive effect on reducing NH4 concentration [20].

It is important to mention that, the increase in the surface temperature of the sand layer on some hot days in August or around midday up to 42 °C caused an increase in evaporation and transpiration at the water’s surface. This may therefore lead to an increase in the concentration at the outlet and a reduction in the measured efficiency compared to the actual value of the system efficiency. C. H. Sim et al. also mentioned this in their study [35]. Finally, the findings of this research demonstrate that Phragmites australis planted in HF-SFCW systems can efficiently eliminate contaminants from highly polluted leachates in cold regions by creating suitable operational conditions.

4 Conclusion

The result obtained from this study was as follows:

-

The modified septic tank was a highly efficient alternative to the conventional septic tank. However, further treatment by an after-treatment system is required to meet effluent standards.

-

The quality of the HF-SFCWs’ effluent was enhanced by the appropriate design of an efficient primary treatment system.

-

The use of horizontal subsurface SCW, in addition to being reasonably efficient in leachate treatment, does not cause problems such as clogging of the bed by insects and vermin and odor generation that occur with other types of surface and vertical wetlands.

-

The use of CW in the environment, in addition to protecting the environment from leachate, plays an important role in restoring biodiversity and creating a green and beautiful environment and clean air for landfill.

-

In conclusion, the results of this study indicated that the integration of MST and HF-SFCW planted with Phragmites australis could be efficient to an acceptable extent with the phytoremediation process in the treatment of highly polluted leachate in the municipal solid waste landfills of western Iran.

Data availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Bakhshoodeh R, Alavi N, Oldham C, Santos RM, Babaei AA, Vymazal J et al (2020) Constructed wetlands for landfill leachate treatment: a review. Ecol Eng 146:105725

Silvestrini NEC, Hadad HR, Maine MA, Sánchez GC, del Carmen PM, Caffaratti SE (2019) Vertical flow wetlands and hybrid systems for the treatment of landfill leachate. Environ Sci Pollut Res 26:8019–8027

Stefanakis A, Akratos CS, Tsihrintzis VA (2014) Vertical flow constructed wetlands: eco-engineering systems for wastewater and sludge treatment. Newnes

Cross K, Tondera K, Rizzo A, Andrews L, Pucher B, Istenič D, Mcdonald R (2021) Nature-Based Solutions for Wastewater Treatment. IWA Publishing

Rizzo A, Tondera K, Pálfy T, Dittmer U, Meyer D, Schreiber C et al (2020) Constructed wetlands for combined sewer overflow treatment: a state-of-the-art review. Sci Total Environ 727:138618

Kavusi E, Ansar BSK, Ebrahimi S, Sharma R, Ghoreishi SS, Nobaharan K, Astatkie T (2022) Critical review on phytoremediation of polyfluoroalkyl substances from environmental matrices: Need for global concern. Environmental Research 217:114844

Dolatabadi N, Mohammadi Alagoz S, Asgari Lajayer B, van Hullebusch ED (2021) Phytoremediation of polycyclic aromatic hydrocarbons-contaminated soils. Climate Change and the Microbiome: Sustenance of the Ecosphere, pp 419–445

Masoud AM, Alfarra A, Sorlini S (2020) Constructed wetlands as a solution for sustainable sanitation: a comprehensive review on integrating climate change resilience and circular economy. Water 14(20):3232

Midhun G, Divya L, George J, Jayakumar P, Suriyanarayanan S (2016) Wastewater treatment studies on free water surface constructed wetland system. Integrated Waste Management in India: Status and Future Prospects for Environmental Sustainability, pp 97–109

Nasr FA, Mikhaeil B (2016) Treatment of domestic wastewater using modified septic tank. Desalin Water Treat 56(8):2073–2081

Nasr FA, Mikhaeil B (2013) Treatment of domestic wastewater using conventional and baffled septic tanks. Environ Technol 34(16):2337–2343

Sharma MK, Khursheed A, Kazmi AA (2014) Modified septic tank-anaerobic filter unit as a two-stage onsite domestic wastewater treatment system. Environ Technol 35(17):2183–2193

Parde D, Patwa A, Shukla A, Vijay R, Killedar DJ, Kumar R (2021) A review of constructed wetland on type, treatment and technology of wastewater. Environ Technol Innov 21:101261

Shahi Khalaf Ansar B, Kavusi E, Dehghanian Z, Pandey J, Asgari Lajayer B, Price GW, Astatkie T (2022) Removal of organic and inorganic contaminants from the air, soil, and water by algae. Environ Sci Pollut Res 1–29

Ogata Y, Ishigaki T, Ebie Y, Sutthasil N, Witthayaphirom C, Chiemchaisri C et al (2018) Design considerations of constructed wetlands to reduce landfill leachate contamination in tropical regions. J Mater Cycles Waste Manage 20:1961–1968

Crites RW, Middlebrooks EJ, Bastian RK (2014) Natural wastewater treatment systems. CRC press

Tuttolomondo T, Leto C, La Bella S, Leone R, Virga G, Licata M (2014) Water balance and pollutant removal efficiency when considering evapotranspiration in a pilot-scale horizontal subsurface flow constructed wetland in Western Sicily (Italy). Ecol Eng 87:295–304

Kamil IM, Muntalif BS, Putri AR (2015) Incorporating constructed wetland in septic tank system to protect groundwater quality. J Acad Res 7(3):456

Sepehri S, Kanani E, Abdoli S, Rajput VD, Minkina T, Asgari LB (2023) Pb (II) Removal from aqueous solutions by adsorption on stabilized zero-valent iron nanoparticles—a green approach. Water 15(2):222

Milke J, Gałczyńska M, Wróbel J (2020) The importance of biological and ecological properties of Phragmites australis (Cav.) Trin. Ex. Steud., in phytoremediation of aquatic ecosystems—the review. Water 12(6):1770

Saeed T, Haque I, Khan T (2019) Organic matter and nutrients removal in hybrid constructed wetlands: influence of saturation. Chem Eng J 371:154–165

AsgariLajayer B, Najafi N, Moghiseh E, Mosaferi M, Hadian J (2020) Effects of gamma irradiation on physicochemical and biological characteristics of wastewater effluent and sludge. Int J Environ Sci Technol 17:1021–1034

Van Lier JB (2008) High-rate anaerobic wastewater treatment: diversifying from end-of-the-pipe treatment to resource-oriented conversion techniques. Water Sci Technol 57(8):1137–1148

Anil R, Neera AL (2016) Modified septic tank treatment system. Procedia Technol 24:240–247

I. Abdel-Shafy H, A. El-Khateeb M (2013) Integration of septic tank and constructed wetland for the treatment of wastewater in Egypt. Desalination Water Treat 51(16–18):3539–46

Khalid M, Hashmi I, Khan SJ (2017) Performance evaluation of membrane-based septic tank and its reuse potential for irrigating crops. Water Environ Res 89(8):744–751

Saeed T, Miah MJ, Majed N, Hasan M, Khan T (2020) Pollutant removal from landfill leachate employing two-stage constructed wetland mesocosms: co-treatment with municipal sewage. Environ Sci Pollut Res 27:28316–28332

Yalcuk A, Ugurlu A (2009) Comparison of horizontal and vertical constructed wetland systems for landfill leachate treatment. Bioresource technology 100(9):2521–2526

Saeed T, Majed N, Miah MJ, Yadav AK (2022) A comparative landfill leachate treatment performance in normal and electrodes integrated hybrid constructed wetlands under unstable pollutant loadings. Sci Total Environ 838:155942

Dan A, Oka M, Fujii Y, Soda S, Ishigaki T, Machimura T et al (2017) Removal of heavy metals from synthetic landfill leachate in lab-scale vertical flow constructed wetlands. Sci Total Environ 584:742–750

Li YC, Zhang DQ, Wang M (2017) Performance evaluation of a full-scale constructed wetland for treating stormwater runoff. Clean-Soil Air Water 45(11):1600740

Soares E, Hamid A, Mangkoedihardjo S (2021) Phytoremediation of zinc polluted soil using sunflower (Helianthus annuus L.). J Phytology 13:9–12

Hu Y, He F, Ma L, Zhang Y, Wu Z (2016) Microbial nitrogen removal pathways in integrated vertical-flow constructed wetland systems. Biores Technol 207:339–345

Stefanakis AI, Tsihrintzis VA (2012) Effects of loading, resting period, temperature, porous media, vegetation and aeration on performance of pilot-scale vertical flow constructed wetlands. Chem Eng J 181:416–430

Sim C, Quek B, Shutes R, Goh K (2013) Management and treatment of landfill leachate by a system of constructed wetlands and ponds in Singapore. Water Sci Technol 68(5):1114–1122

Acknowledgements

This article was adapted from part of the results of dissertation project number 140004293724. The authors would like to thank the Department of Environmental Health Engineering, Faculty of Health, Hamadan University of Medical Sciences and Iran National Science Foundation (INSF), for financial support for providing facilities and resources to conduct this research study.

Funding

The research leading to these results received funding from funding and facilities provided by Hamadan University of Medical Sciences under Grant Agreement No: 140004293724 and Iran National Science Foundation (INSF) under Grant Agreement No: 4000708.

Author information

Authors and Affiliations

Contributions

The authors confirm their contribution to the paper as follows:

• Study conception and design: Mohammad Taghi Samadi, Ghorban Asgari, Mostafa Leili, Sonia Chavoshi;

• Data collection: Sonia Chavoshi;

• Analysis and interpretation of results: Mohammad Taghi Samadi, Ghorban Asgari, Mostafa Leili, Sonia Chavoshi;

• Draft manuscript preparation: Mohammad Taghi Samadi, Sonia Chavoshi.

All authors reviewed the results and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Samadi, M.T., Asgari, G., Leili, M. et al. Integrated modified septic tank and constructed wetland: an alternative green technology for phytoremediation of highly polluted leachate. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04333-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04333-3