Abstract

Microencapsulation such as ionic gelation is a promising technique to preserve the natural additive in order to develop novel functional food formulations. Hibiscus sabdariffa extract was used as a promising biologically active additive in designing novel functional foods. Active material was trapped in alginate beads by means of ionic gelation. The system was optimized via response surface method (RSM). Independent process factors were chosen as gelling medium (CaCI2) concentration (A), wall material (alginate) concentration (B), and time for the exposure to the gelling medium (C). Encapsulation efficiency (EE) in respect of total phenolic content (TPC) and antioxidant activity of the capsules were dependent factors (YEE and Yantioxidant activity). Based on the Box-Behnken design of RSM, the highest efficiency and antioxidant activity yield were calculated as ~ 90% and 5 mg Trolox equivalent per gram dried capsule under the optimal ionic gelation conditions (6.82% CaCI2, 1.99% alginate, and 16 min of hardening time). In addition, the morphology of the dried microcapsules was analyzed by stereo-microscope and scanning electron microscopy (SEM), respectively. Shape properties of capsules were also defined with sphericity factor (SF) and the roundness (Rn). The results of SF and Rn values were 0.03 ± 0.01 and 1.31 ± 0.08, respectively. Supporting these results, SEM images show that the shapes of the capsules obtained are homogeneous and smooth.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Interest shown in functional foods has been increasing with the increasing importance given to the relationship between the food that consumers consume daily and their health. When the structures of traditionally consumed foods were examined, the beneficial substances contained in these foods were discovered over time. With the enrichment of these beneficial ingredients, novel foods have begun to be produced. Knowing which foods provide what benefits has allowed people to have more control over their health. Therefore, they take this into consideration more when choosing food and beverage. Functional foods, which was first started to be researched in Japan in the 1980s and used as a term, later became widespread in Europe and America over time [1, 2]. The basic method of functional foods is to enrich foods with vitamins, minerals, and phytochemicals with antioxidant activity for special purposes and to strengthen their content [3]. However, the related enrichment process creates high temperature values, light, and oxygen as well as pH alteration of the atmosphere. Therefore, the functional properties of the relevant active components are adversely affected by this situation [4]. Promising alternative methods such as encapsulation of the food additives have been gaining interest in order to develop novel functional foods. In this method, active material with functional property is preserved from external conditions (heat, oxygen, light, acidity, etc.), while its sensory properties are improved by trapping in a wall material [5].

As an effortless, inexpensive, and non-toxic method, ionic gelation creates a polymeric film to cover biologically active compounds This is a very simple technique, non-toxic, and easy to control in terms of production [6]. Owing to its distinctive characteristic such as gel-forming together with Ca++ (multivalent cation), alginate is widely used as wall material. The related polymeric film is formed by crosslinked structure among the G groups of different alginate chains produced from ionic bonds with alginate and the multivalent cation [7]. Encapsulation of hydrophilic bioactive substances such as polyphenols in alginate-based hydrogels was reported in earlier studies. Encapsulation of stevia extract [8], olive leaf extract [9], Moringa oleifera extract [10], Hibiscus extract [11], cactus betalains [12], chokeberry extract [13], betacyanin extract [14], lemon balm extract [15], and butterfly pea flower extract [16] in alginate microbeads were performed with high encapsulation efficiencies. In this study, Hibiscus sabdariffa has been selected as a biologically active substance source depending on the reports demonstrating its various bioactive properties (antioxidant, antitumoral, antihypertensive, and anti-hyperlipemic effects) owing to its phytochemical substances as well as its nutritional value [17,18,19]. Antimicrobial effects have been also demonstrated by in vitro studies [20]. In vivo studies also verified the antioxidant activity of the H. sabdariffa extract [21]. It has been reported to be a promising additive in designing novel functional foods [4]. However, its unstable structure against heat, light, oxygen, and acidity of the medium is the major obstacle preventing its applicability, although it has so many benefits to health verified by several in vivo [18, 21, 22] and in vitro tests [23,24,25].

In this method, the optimization of the parameters affecting the encapsulation has been carried out by using statistical experimental design method (response surface method). Independent factors affecting the system were selected as film forming material concentrations (sodium alginate and calcium chloride) and hardening time of the microbeads. Physicochemical properties (polyphenolic contents and antioxidant activity) of the produced capsules have been considered as dependent variables. The capsules obtained under optimal conditions were also evaluated in terms of shape properties and morphology (stereo-microscope and SEM).

2 Materials and methods

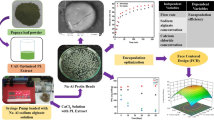

Figure 1 indicates the each step of the experimental work in order to formulate the final product.

2.1 Materials

The dried Hibiscus sabdariffa samples were provided from a local store. The flowers of the plant were used as the active source. The moisture of the samples was calculated according to the mass losses of fresh plants (almost 15%). After the samples were ground by a grinder (Moulinex Super Blender Grinder, LM209041, Paris, France), they were ground and sieved.

Folin-Ciocalteu, DPPH, Trolox, gallic acid, ethanol, methanol, Na2CO3, sodium alginate, and calcium chloride dihydrate were from Sigma-Aldrich (St. Louis, MO, USA).

2.2 Extraction procedure

An automatic solvent extractor (VELP Scientifica, Usmate, Italy) was employed under atmospheric pressure. One gram of plant material was weighed and placed in cellulose thimbles into glass cups by adding 80 mL of aqueous alcohol (80%, v/v). The extraction process continued for almost 1.5 h.

2.3 Microcapsule production

Hibiscus sabdariffa extract was used as the active substance, whereas sodium alginate (1, 1.5, and 2%, w/v) was the coating material. On the other hand, CaCl2 (2, 8.5, and 15%, w/v) was used as gelling medium for the microencapsulation of the active material by means of ionic gelation [9].

The ionic gelation process was applied by adjusting wall material concentration, gelling medium concentration and time for hardening according to Table 1. The ratio of active material to wall material was 1/2 (v/v). The mixture of active material and wall material was dropped to the gelling medium on a magnetic stirrer (Model MSH-20D, DAIHAN Scientific Co. Ltd., Korea) under ambient conditions. After the capsules were formed, it was waited for a while for the capsules to strengthen. Therefore, the time for hardening (15, 30, and 45 min) was also selected as process parameter. Then, the capsules were filtered and washed before drying.

2.4 Particle shape and morphology of microcapsules

Capsule morphology obtained at optimum process conditions was measured by stereo-microscope (Stemi 2000-C, Zeiss, Germany) and AxioCamERc5 camera (Stemi 2000-C, Zeiss, Göttingen, Germany). The measurements of the capsules were carried out using the Zeiss (Carl Zeiss Microscopy GmbH, Germany) program. Determination of shape properties of capsules are defined as how close to sphericity with sphericity factor (SF) and the roundness (Rn). Briefly, capsule diameter was measured and calculated by using following equations [26]:

where dmax is the maximum diameter, dmin is the minimum diameter, P is the perimeter, and A is protection area of the capsules.

Scanning electron microscopy (SEM) analysis was carried out to determine the morphological properties of capsule obtained at optimum process conditions. The samples were visualized on the Zeiss LEO 1430 model SEM (Germany) device after being coated with a 10 nm gold and palladium layer.

2.5 In vitro bioactivity tests

2.5.1 Folin–Ciocalteau method

Approximately 0.1 g of microcapsules were weighed and dissolved in 3 mL of ethanol: acetic acid:water mixture (50:8:42, v/v/v) in order to determine the total phenolic content (TPC) of the capsules. This mixture was mixed in a vortex for 1 min and kept in an ultrasonic bath at 25 °C for 20 min. It was then filtered using 0.45 μm syringe filters. The total phenolic content of the obtained mixture was determined according to the Folin–Ciocalteau method. Based on the assay, 100 µL of the microcapsule mixture was taken into 2000 µL of Folin–Ciocalteau reagent (10%, v/v). After this mixture was kept in the dark for 5 min, 1800 µL of sodium carbonate solution (7.5%, w/v) was added into the mixture and mixed. After the resulting mixture was kept in the dark for 1 h, absorbance values were recorded at 765 nm in a UV spectrophotometer (PG Instruments, T60/Leicestershire and England). For this analysis, a standard gallic acid solution was prepared at different concentrations to create a calibration curve in order to calculate the data in mg gallic acid equivalent (mg-GAE).

In order to evaluate the efficiency of the microcapsules, surface phenolic content (SPC) of the microcapsules was also calculated. One hundred milligrams of beads were dissolved in 3 mL ethanol-methanol solution (1:1, v/v) by keeping in an ultrasonic bath (Protech, Istanbul, Turkey) for 5 min at ambient temperature [27]. After the solutions were filtered using 0.45 μm syringe filters, SPC was calculated as explained above.

2.5.2 DPPH (2,2-diphenyl-1-picryl-hydrazyl-hydrate) free radical method

Fifteen milligrams of microcapsules were dissolved in 3 mL of ethanol:acetic acid:water mixture (50:8:42, v/v). This mixture was vortexed for 1 min and left in a water bath at 40 °C for 20 min. Then, it was passed through 0.45 μm syringe filters. In this method, 3.9 mL of 25 mg L−1 DPPH radical solution was added onto 100 µL of microcapsule mixture. After the obtained mixture was kept in the dark for 1 h, absorbance values were recorded at 517 nm [27]. Antioxidant activity values were calculated by using a standard Trolox solution at different concentrations to create a calibration curve for presentation of the data in mg Trolox equivalent per gram dried matter (mg-TEAC/g-DM).

2.6 Evaluation of encapsulation efficiency

The performance of the capsules is determined by their efficiency values (EE). In order to calculate the EE value, the difference between the TPC and SPC are found. Then, it was divided by TPC value as given in the following:

2.7 Statistical experimental design method

Ionic gelation process for the trapping of the active material of Hibiscus sabdariffa extract into alginate beads was subjected to Box-Behnken design of RSM. This statistical experimental design approach supplies modeling and optimization of the process along with designing the experimental study by establishing the relationship between dependent variable (Y) and independent variables [18]. EE and DPPH free radical scavenging activity of the capsules were dependent variables (responses) of the system, whereas alginate and CaCI2 concentrations and time were independent process parameters. TPC and SPC are important values in order to calculate the efficiency of the capsules based on Eq. 3. It was not possible to evaluate the success of the capsules obtained without finding these values (TPC and SPC). Therefore, these two values are not included in the optimization as they are means rather than goals. Design-Expert software (12.0.1.0 version, StatEase Inc., USA) was used to apply the Box-Behnken design of RSM for the production of alginate beads containing Hibiscus sabdariffa extract.

3 Results and discussions

3.1 Ionic gelation of Hibiscus sabdariffa extract in alginate beads

Table 2 gives the experimental findings depending on the ionic gelation process conditions designed by Box-Behnken. Encapsulation efficiency changed from 59.92 to 89.01%, while antioxidant activity of the capsules varied between 3.81 and 4.98 mg-TEAC per dried base. Quadratic design models proposed by Box-Behnken of RSM for each response (YEE and Yantioxidant activity) are given below:

The proposed models (Eqs. 4 and 5) are given in terms of coded factors to predict the the response for given levels of each factor. On the other hand, the selected models should have insignificant lack of fit. So, the selected systems seem desirable that the models fit according to the calculated insignificant lack of fit (Tables 3 and 4). Additionally, the calculated quadratic equations are found significant (p < 0.0001). Furthermore, coefficient of variation values (< 10%), and high coefficients of determination values (R2, adjusted R2, and predicted R2) verify satisfactory results (R2 > 0.99, adjusted R2 > 0.98, and predicted R2 > 0.91).

Considering the effects of process variables depending on p values, all the parameters, their interactions and second powers were found significant. The interaction between alginate concentration and time was the most significant followed by C, AB, and B2 at p < 0.0001 (Table 3). The remaining terms were also significant at p < 0.05. When the other response (antioxidant activity) is considered, similar observations were also recorded (Table 4). Similarly, selected process variables were all found as significant for the current ionic gelation system. Hardening time was followed by BC, A2, B, AB, and C2 as the significant parameters (p < 0.0001). Similarly, the remaining terms were also significant at p < 0.05 as seen in Table 4.

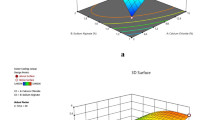

Three-dimensional (3D) plots produced by Design-Expert software also enable to observed the effects of the process parameters as seen in Figs. 2–4. When the concentration of the gelling medium increased, the efficiency of the beads increased at first. After 12.5% of CaCI2, the yields fixed as seen in Fig. 2a. Multivalent calcium ions are required to create the microcapsules. Therefore, the first increase is expectable at first. Later, the active calcium linking sites on the chain can be saturated after the optimal CaCI2 concentration [28]. The same tendency was also observed in the change of alginate concentration. The yield of the encapsulation rises until the concentration of wall material was 1.8%. Similar effect of sodium alginate concentration was also observed by Guerra-Valle et al. [29]. Sucrose/gallic acid solutions were trapped into alginate beads with ionic gelation. After 2% (w/w) of alginate, the EE of the capsules kept stable. However, the conditions less than this concentration of cover material caused the active ingredient inside to leak out. Similarly, Toprakçı and Şahin (2022) observed similar alginate effect on the EE of the alginate beads with respect to TPC of olive leaf extract [9]. On the other hand, Fig. 2b shows the effects of gelling medium and wall material concentrations on the antioxidant activity of the capsules. Expectedly, increasing the concentration of sodium alginate favored the antioxidant activity of the microcapsules. As the surrounding of the capsule becomes thicker, the transmission of the biologically active material to the external environment is prevented. So, the antioxidant activity of the capsule becomes higher [30].

We can see the hardening time effect in Fig. 3. Encapsulation efficiency was enhanced by exposure to CaCI2 as seen in Fig. 3a. EE in terms of major phenolic compound of olive leaf extract was also enhanced regularly by hardening time during the ionic gelation of olive leaf extract in alginate beads [9]. This might the fact that Ca+2 stay in contact with alginate for a longer time and strengthen the membrane around the capsule [31]. Conversely, antioxidant activity values of the capsules decreased by exposure time when the calcium chloride concentration is 1.5% (Fig. 3b). This can be explained by the release of bioactive extracts from the capsules or the exchange of calcium bound in the alginate structure [10]. However, Fig. 4 shows that time increases the antioxidant activity of the beads when the calcium chloride concentration is 8.5%. So, this is the result of interaction effect between the variables (time and gelling medium). If the concentration of the gelling medium is higher, the time affects the antioxidant activity positively.

3.2 Validation of the optimum conditions of Box-Behnken design

Optimization study was also performed by Design-Expert software. Confidence interval was stated at the 95% confidence level. The criteria for the optimization of the selected system were to maximize EE and antioxidant activity while keeping the levels of the calcium chloride, alginate, and time in range. Table 5 gives the optimum conditions for the present ionic gelation system with the highest EE and antioxidant activity yields, respectively. The acceptability value (composite desirability) found while determining the optimum condition was 1. Verification tests were also conducted as seen in Table 5 with satisfactory error values (< 2%).

3.3 Particle shape and morphology of microcapsules

Figure 5 shows that the images of microcapsules produced using alginate bead with ionic gelation. When the microcapsule images were analyzed, the SF value was measured as 0.039 ± 0.018 and the Rn value as 1.310 ± 0.086. The Rn value, which shows how close the obtained capsules are to sphericity, indicates that the closer to 1, the more perfectly spherical the capsules. In the case of tail formation in capsules, the Rn value approaches to zero. The Rn value is generally used to define spherical and elliptical particles. On the other hand, SF value accepts the ratio of the maximum and minimum diameters of a sphere and the value of a perfect sphere as zero. SF value is commonly used for tear drop and pear-shaped particles, but also capsules with SF < 0.05 could be considered to be spherical shape [26, 32]. The results show that the sphericity of the obtained microcapsules is acceptable. In a study, which alginate beads were obtained by electrostatic extrusion method of d-limone, the SF value was determined between 0.003 and 0.210 [33]. It has been reported that high viscosity polymer solutions and the alginate solution flow rate gives deformed particles having shape of eggs or drops [33].

Figure 6 shows scanning electron microscopy images of the microcapsules containing active substances from Hibiscus sabdariffa. Similar to SF and Rn results, SEM images also show that the microcapsules are spherical and homogeneous. Also microcapsules are more regular and homogeneous surface with a smooth shape. In the capsules obtained with alginate bead with ionic gelation, there was no shrinkage or cracks were observed. Volic et al. reported that the surface of the capsules were obtained by alginate bead encapsulation method, as a wrinkle free surface [34].

4 Conclusions

The outcome of the current study has indicated that alginate-based hydrogels for trapping the polyphenols of Hibiscus sabdariffa can be produced with the proposed ionic gelation method successfully (almost 90% encapsulation efficiency). Statistical experimental design approach has pointed out that all selected process parameters, their interactions, and second powers influenced the microencapsulation system significantly at p < 0.05. Depending on the statistical indicators such as F and p values, coefficient of variation (1.34% and 0.60%), lack of fit (p > 0.05), and coefficients of determinations (R2 = 0.9933 and 0.9968, adjusted R2 = 0.9847 and 0.9928, predicted R2 = 0.9183 and 0.9891), the data produced from the quadratic model equations obtained using response surface method were compatible with the experimental results. Furthermore, validation study has supported the optimum conditions with satisfactory error values (< 2%). Particle shape and morphology results showed that the homogeneous and smooth structure were defined for microcapsules, as well as the closeness to the perfect sphericity. The alginate beads scavenged the free radical depending on in vitro antioxidant activity test (DPPH) results, indicating that the current microcapsules containing Hibiscus sabdariffa extract might be natural alternative additive for the development of functional food formulations. Considering the safety issues, further studies must be done to scale and commercialize the applications of natural substances in food formulations.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Arai S, Osawa T, Ohigashi H et al (2001) A mainstay of functional food science in Japan—history, present status, and future outlook. Biosci Biotechnol Biochem 65:1–13. https://doi.org/10.1271/BBB.65.1

Iwatani S, Yamamoto N (2019) Functional food products in Japan: a review. Food Sci Hum Wellness 8:96–101. https://doi.org/10.1016/J.FSHW.2019.03.011

Smith J, Charter E, Shahidi F (2010) Functional food product development. Funct Food Prod Dev. https://doi.org/10.1002/9781444323351

Marques Mandaji C, da Silva PR, Campos Chisté R (2022) Encapsulation of bioactive compounds extracted from plants of genus Hibiscus: a review of selected techniques and applications. Food Res Int 151:110820. https://doi.org/10.1016/J.FOODRES.2021.110820

Quirós-Sauceda AE, Ayala-Zavala JF, Olivas GI, González-Aguilar GA (2014) Edible coatings as encapsulating matrices for bioactive compounds: a review. J Food Sci Technol 51:1674–1685

Wissam Z, Samer H (2019) Encapsulation of flaxseed oil extract in alginate-salep system by ionic gelation. Brazilian J Pharm Sci 55:261. https://doi.org/10.1590/S2175-97902019000200261

Benavides S, Cortés P, Parada J, Franco W (2016) Development of alginate microspheres containing thyme essential oil using ionic gelation. Food Chem 204:77–83. https://doi.org/10.1016/j.foodchem.2016.02.104

Arriola NDA, Chater PI, Wilcox M et al (2019) Encapsulation of stevia rebaudiana Bertoni aqueous crude extracts by ionic gelation – effects of alginate blends and gelling solutions on the polyphenolic profile. Food Chem 275:123–134. https://doi.org/10.1016/j.foodchem.2018.09.086

Toprakçı İ, Şahin S (2022) Encapsulation of olive leaf antioxidants in microbeads: application of alginate and chitosan as wall materials. Sustain Chem Pharm 27:100707. https://doi.org/10.1016/J.SCP.2022.100707

Kaltsa O, Alibade A, Bozinou E, et al (2021) Encapsulation of Moringa oleifera extract in Ca-alginate chocolate beads: physical and antioxidant properties. J Food Qual 2021:.https://doi.org/10.1155/2021/5549873

de Moura SCSR, Berling CL, Germer SPM et al (2018) Encapsulating anthocyanins from Hibiscus sabdariffa L. calyces by ionic gelation: pigment stability during storage of microparticles. Food Chem 241:317–327. https://doi.org/10.1016/j.foodchem.2017.08.095

Otálora MC, Carriazo JG, Iturriaga L et al (2016) Encapsulating betalains from Opuntia ficus-indica fruits by ionic gelation: Pigment chemical stability during storage of beads. Food Chem 202:373–382. https://doi.org/10.1016/J.FOODCHEM.2016.01.115

Tzatsi P, Goula AM (2021) Encapsulation of extract from unused chokeberries by spray drying, co-crystallization, and ıonic gelation. Waste Biomass Valorization 12:4567–4585. https://doi.org/10.1007/S12649-020-01316-7/FIGURES/8

Fathordoobady F, Jarzębski M, Pratap-Singh A, et al (2021) Encapsulation of betacyanins from the peel of red dragon fruit (Hylocereus polyrhizus L.) in alginate microbeads. Food Hydrocoll 113:106535. https://doi.org/10.1016/J.FOODHYD.2020.106535

Najafi-Soulari S, Shekarchizadeh H, Kadivar M (2016) Encapsulation optimization of lemon balm antioxidants in calcium alginate hydrogels. 27:1631–1644.https://doi.org/10.1080/09205063.2016.1226042

Pasukamonset P, Kwon O, Adisakwattana S (2016) Alginate-based encapsulation of polyphenols from Clitoria ternatea petal flower extract enhances stability and biological activity under simulated gastrointestinal conditions. Food Hydrocoll 61:772–779. https://doi.org/10.1016/J.FOODHYD.2016.06.039

Zannou O, Koca I, Aldawoud TMS, Galanakis CM (2020) Recovery and stabilization of anthocyanins and phenolic antioxidants of roselle (Hibiscus sabdariffa L.) with Hydrophilic Deep Eutectic Solvents. Molecules 25:. https://doi.org/10.3390/MOLECULES25163715

Fernández-Arroyo S, Rodríguez-Medina IC, Beltrán-Debón R et al (2011) Quantification of the polyphenolic fraction and in vitro antioxidant and in vivo anti-hyperlipemic activities of Hibiscus sabdariffa aqueous extract. Food Res Int 44:1490–1495. https://doi.org/10.1016/J.FOODRES.2011.03.040

Di̇nçer C, Üniversitesi A, Güvenliği ve Tarımsal Araştırmalar Merkezi G, et al (2021) Termal ve ultrases proseslerinin adaçayı ve hibiskus ekstraktlarının bazı kalite özellikleri üzerine etkisi. Mediterr Agric Sci 34:33–39. https://doi.org/10.29136/MEDITERRANEAN.786890

Ali BH, Al Wabel N, Blunden G (2005) Phytochemical, pharmacological and toxicological aspects of Hibiscus sabdariffa L.: a review. Phyther Res 19:369–375. https://doi.org/10.1002/PTR.1628

Ajiboye TO, Salawu NA, Yakubu MT et al (2011) Antioxidant and drug detoxification potentials of Hibiscus sabdariffa anthocyanin extract. Drug Chem Toxicol 34:109–115. https://doi.org/10.3109/01480545.2010.536767

Hirunpanich V, Utaipat A, Morales NP et al (2006) Hypocholesterolemic and antioxidant effects of aqueous extracts from the dried calyx of Hibiscus sabdariffa L. in hypercholesterolemic rats. J Ethnopharmacol 103:252–260. https://doi.org/10.1016/J.JEP.2005.08.033

Kurtulbaş E, Pekel AG, Bilgin M et al (2020) Citric acid-based deep eutectic solvent for the anthocyanin recovery from Hibiscus sabdariffa through microwave-assisted extraction. Biomass Convers Biorefinery 12:351–360. https://doi.org/10.1007/S13399-020-00606-3/FIGURES/8

Şahin S, Kurtulbaş E, Pekel AG et al (2021) Enhanced extraction of high added-value products from Hibiscus sabdariffa using automatic solvent extractor: kinetics and modeling. Sustain Chem Pharm 19:100356. https://doi.org/10.1016/j.scp.2020.100356

Şahin S, Pekel AG, Toprakçı İ (2020) Sonication-assisted extraction of Hibiscus sabdariffa for the polyphenols recovery: application of a specially designed deep eutectic solvent. Biomass Convers Biorefinery 1–11.https://doi.org/10.1007/s13399-020-00837-4

Lee BB, Ravindra P, Chan ES (2013) Size and shape of calcium alginate beads produced by extrusion dripping. Chem Eng Technol 36:1627–1642. https://doi.org/10.1002/CEAT.201300230

Tolun A, Altintas Z, Artik N (2016) Microencapsulation of grape polyphenols using maltodextrin and gum arabic as two alternative coating materials: Development and characterization. J Biotechnol 239:23–33. https://doi.org/10.1016/J.JBIOTEC.2016.10.001

Zam W, Bashour G, Abdelwahed W, Khayata W (2014) Alginate-pomegranate peels’ polyphenols beads: effects of formulation parameters on loading efficiency. Brazilian J Pharm Sci 50:741–748. https://doi.org/10.1590/S1984-82502014000400009

Guerra-Valle M, Petzold G, Orellana-Palma P (2022) Optimization of encapsulation by ıonic gelation technique of cryoconcentrated solution: a response surface methodology and evaluation of physicochemical characteristics study. Polym 2022, Vol 14, Page 1031 14:1031.https://doi.org/10.3390/POLYM14051031

Blandino A, Macías M, Cantero D (1999) Formation of calcium alginate gel capsules: Influence of sodium alginate and CaCl2 concentration on gelation kinetics. J Biosci Bioeng 88:686–689. https://doi.org/10.1016/S1389-1723(00)87103-0

Gholamian S, Nourani M, Bakhshi N (2021) Formation and characterization of calcium alginate hydrogel beads filled with cumin seeds essential oil. Food Chem 338:128143. https://doi.org/10.1016/J.FOODCHEM.2020.128143

Ergin F, Atamer Z, Comak Göcer EM et al (2021) Optimization of Salmonella bacteriophage microencapsulation in alginate-caseinate formulation using vibrational nozzle technique. Food Hydrocoll 113:106456. https://doi.org/10.1016/J.FOODHYD.2020.106456

Lević S, Pajić Lijaković I, Dorević V et al (2015) Characterization of sodium alginate/d-limonene emulsions and respective calcium alginate/d-limonene beads produced by electrostatic extrusion. Food Hydrocoll 45:111–123. https://doi.org/10.1016/J.FOODHYD.2014.10.001

Volić M, Pajić-Lijaković I, Djordjević V et al (2018) Alginate/soy protein system for essential oil encapsulation with intestinal delivery. Carbohydr Polym 200:15–24. https://doi.org/10.1016/J.CARBPOL.2018.07.033

Funding

The authors would like to thank Istanbul University-Cerrahpaşa for their support of this Project (Project No: FDK-2021–36079).

Author information

Authors and Affiliations

Contributions

İrem Toprakçı: Software, validation, formal analysis. Mehmet Torun: Validation, formal analysis. Selin Şahin: Conceptualization, methodology, writing—reviewing and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Toprakçı, İ., Torun, M., Torun, F.B. et al. Alginate-based hydrogels for trapping the polyphenols of Hibiscus sabdariffa: use of a statistical experimental design approach. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-03421-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-03421-0