Abstract

Microbial treatment of industrial wastewater, following with the production of the valuable products using the biomass of the same cells, enhances the economic benefits of biorefineries. The current study aimed to explore the potential of the oleaginous yeast Yarrowia lipolytica for oily and saline fish canning wastewater biotreatment and to evaluate the features of the yeast biomass for biodiesel and animal feed supplement production. Using Y. lipolytica EBL13 in wastewater reduced chemical oxygen demand by 85% during 7 days. In addition, other parameters, including biological oxygen demand (59%), nitrate (51%), sulfite (50%), total suspended solids (85%), total hardness (15.6%), oil (68.2%), and total phosphorus (91%), were decreased significantly compared to untreated samples. However, pH and ammonia were increased. Amino acid and fatty acid composition analysis of Y. lipolytica biomass showed the presence of essential amino acids and fatty acids in significant quantities, respectively. From 50.2% of protein content derived from the yeast biomass, 16.5% was related to essential amino acids. In addition, linolenic acid (0.15%) and eicosapentaenoic acid (0.21%) as essential omega-3 fatty acids and linoleic acid (22.15%) as essential omega-6 fatty acid were observed in the fatty acid profile. Predicted biodiesel physicochemical parameters such as cetane number (55.7 min), iodine value (76.4 g Iod/100 g oil), and degree of unsaturation (83.54) met the EN 14214 specifications. Y. lipolytica can be introduced as an ideal candidate for fish canning wastewater treatment and production of biodiesel and animal feed supplements.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Voluminous amounts of water consumption and wastewater production in different steps of fish canning industries, including cooking, cleaning, cooling, and sanitization, are considered worldwide environmental challenges [1]. Approximately 10–40 m3 of water is estimated to be required for processing each ton of raw seafood. Eurofish discharges at least 650 m3 effluents/100 tons of tuna daily [2]. Fish canning wastewaters (FCWs) are known for their organic compounds and degradable proteins and lipids [3]. The fish variant, additive type, processing steps, and water source are effective parameters for the characteristics of the produced wastewater [4]. Currently, the wastewater treatment approaches include physicochemical, biological, or combinatory methods [1]. Physicochemical procedures such as sedimentation, acidity adjustment, and dissolved air flotation are mainly used for primary FCW treatment in the refinery systems. The process is followed by aerobic and anaerobic biological techniques to remove organic compounds. FCWs contain large amounts of saline (2–35 g L−1), which cause problems in biological treatment and make desalination necessary [5, 6]. Common desalination methods are expensive and time-consuming techniques and lead researchers to find alternative strategies for removing organic compounds from saline FCWs [7]. Salt-resistant microorganisms have been investigated in a wide range of research. One group of the biotechnologically useful microorganisms with confirmed salinity tolerance behavior are some Yarrowia lipolytica strains. Also, the laboratory adaptation process is one of the strategies to improve the salt resistance phenotype in this yeast [8]. Y. lipolytica, as an oleaginous yeast, can accumulate fats in the form of intracellular lipids by more than 50% of its weight. To date, different strains of Y. lipolytica have been identified in various food matrices and natural environments with a broad spectrum of dry weight during growth on alkanes, lipids, and other fatty substrates [9], and physicochemical conditions (pH, temperature, metal ion concentrations, substrate, and nutrient limitations) [10]. Y. lipolytica has been studied as the cell factory for the synthesis of organic acids, recombinant enzymes, drug components, unsaturated fatty acids, biosurfactants, and polyhydroxyalkanoates. In addition, its bioremediation potentials of hydrocarbons, brominated organic compound pollutants, and heavy metal removal have been reported in many studies [11]. Effluents of olive oil mill, palm oil mill, vegetable oil refinery, waste cooking oil, and soybean oil refinery residue are the examples of matrixes treated by Y. lipolytica in recent studies coupled with the production of biosurfactants, SCO, lipase, citric acid, α-ketoglutaric acid, pyruvic acid, and antioxidant compounds as by-products [10]. Recently, Y. lipolytica has been used to treat crude and diluted tuna wash processing wastewater (TWPW) in Tunisia. After 7 days of incubation, chemical oxygen demand (COD) and total organic carbon levels were reduced by 69.8% in crude wastewater samples, respectively. Also, TWPW showed a reduction of 75% COD and a 74% reduction in total organic carbon [12]. Treatment of olive mill wastewater (DOMW)/TWPW mixture (75:25) by Y. lipolytica resulted in eliminating 97.49% and 98.90% of COD and phosphorus after 7 days, respectively [13]. Dunoyer et al. have also benefited from Y. lipolytica ATCC 9973 enzymatic features to treat dairy waste. Using the yeast enzymatic extract under optimal conditions, fat, BOD, COD, and total solids decreased by 82.88%, 43.32%, 44.3%, and 13.58%, respectively [14]. Data published on the production of ex novo and de novo bio-oil by Y. lipolytica using low-cost substrate have led scientists to study this yeast as a candidate for biodiesel production [15, 16]. Another biotechnologically valuable feature of Y. lipolytica is its capability to produce significant levels of proteins (48–54%) and lipids from low-cost substrates leading it to be introduced as a suitable SCP (single-cell protein) and SCO (single-cell oil) producer yeast [17, 18].

Considering the wide biotechnological applications of Y. lipolytica, the current study aimed to evaluate the following three features in a salt-adapted strain: (a) biotreatment efficiency of FCW; (b) biodiesel characteristics which can be produced from the biomass; and (c) capability of biomass for usage as the animal feed supplement. To the best of our knowledge, this is the first report aiming to improve the bio-based circular economy of wastewater treatment through achieving added-value by-products using Y. lipolytica in a cost-effective way.

2 Materials and methods

2.1 Microorganism and wastewater

In this study, Y. lipolytica EBL13 as the recently salt-adapted strain (up to 15% NaCl) developed from Y. lipolytica ATCC 18942 was used for the experiments. Y. lipolytica ATCC 18942 had been cultured under increasing NaCl concentration stress from 0.4 to 2.6 M in a stepwise manner for 200 serial transfers during 7 months and achieved constant growth in 2.6 M NaCl at the endpoint, which was deposited as Y. lipolytica EBL13 (data not shown). To prepare the pre-culture, Y. lipolytica EBL13 was grown in autoclaved wastewater (121 °C, 20 min) at 28 °C and 160 rpm for 72 h.

2.2 FCW biotreatment and quality assessment

The wastewater sample was obtained from a local factory around Tehran in Iran and stored at 4 °C until the experiments. The provided pre-culture sample was amended (%5 v/v) to the biotreatment Erlenmeyer flasks containing 20 mL fresh wastewaters, and the flasks were incubated at 28 °C and 160 rpm for 7 days. To assess the potential of Y. lipolytica EBL13 in the reduction of COD [19], its reduction pattern was monitored at 24-h intervals using the colorimetric standard Hach Method 8000. Uninoculated wastewater samples were considered control flasks and were incubated in the same incubation conditions as test flasks [19]. The experiments were done in three independent experiments inside the lab.

The quality parameters of the wastewater sample including COD; pH; biological oxygen demand (BOD); total dissolved solids (TDS); total suspended solids (TSS); total hardness (TH); salinity; fat, oil, and grease (FOG); phosphate (PO43−); chlorine (Cl); and sulfite (SO32−) were measured by standard methods after 72 h in both test and control Erlenmeyer flasks. BOD (Standard Method 10099), COD (Standard Method 8000), TSS (Standard Method 8006), ammonia (Standard Method 10023), nitrate (Standard Method 8039), total phosphorus (Standard Method 8190), and total nitrogen (Standard Method 10072) were measured using Hach methods [20]. Total hardness (TH), phosphate, chlorine, and sulfite of the wastewater samples were measured using commercial kits.

2.3 Morphological analysis

To study the effect of salt on the yeast morphology using scanning electron microscopy (Tescan Company, Czech Republic), Y. lipolytica EBL13 was cultured in both saline (containing 4% w v−1 NaCl) and non-saline wastewater for 48 h. Harvested cells were washed with dH2O, fixed with glutaraldehyde 2%, and dehydrated by graded series ethanol [21]. Safranin and Sudan black were used to stain the produced lipid bodies.

2.4 Fatty acid profile analysis

To analyze the fatty acid profile, Y. lipolytica EBL13 was inoculated in the Erlenmeyer flask containing autoclaved wastewater and shaken at 28 °C and 160 rpm for 72 h. The cultures were centrifuged at 4000 rpm for 10 min, and the biomass was washed with NaCl solution (%0.9 w/v) and then lyophilized to extract fatty acids. To provide fatty acid methyl esters (FAMEs), the transesterification process was performed by acid catalysis. The yeast cells were sonicated at 90 W for 20 min in an anhydrous condition to lyse the cell wall. FAMEs were extracted using hexane and analyzed by gas chromatography (Agilent Technology 6890, USA) coupled with an FID detector. The retention time values obtained from GC were compared with those of the standard samples [22].

2.5 Prediction of biodiesel characteristics

The characteristics of fatty acid profiles are the factors affecting the quality of the produced biodiesel. In order to investigate the effective parameters in the quality of biodiesel production, the equations listed in Table 1 were used. Accordingly, the studied parameters included soap value (SV), iodine value (IV), cetane number (CN), degree of unsaturation (DU), long-chain saturated fatty acid (LCSF), cold filter plugging point (CFPP), cloud point, drop point, allelic position equilibrium (APE), base-allelic position equilibrium, higher heating value (HHV), kinematic viscosity (υ), and density (ρ) [23, 24].

2.6 Amino acid profile analysis

The extracted protein was hydrolyzed with hydrochloric acid 6 mol L−1 at 110 °C overnight. The sample was filtered using a 0.45-μm filter paper. To achieve the amino acid profile, the filtrate was subjected to high-performance liquid chromatography (HPLC) (YL9100 HPLC system, South Korea) with a binary eluent system and C18 column (5 μm, 4.6 mm × 250 mm). To prepare the elution buffer, 0.5 ml triethylamine was added to 1 L sodium acetate 140 mM pH 6.1 (adjusted by acetic acid and sodium hydroxide). Mobile phases A and B contained 96:4 v/v elution buffer:acetonitrile and 60:40 acetonitrile:dH2O, respectively, and both degassed and filtered. The HPLC was performed at 38 °C with a flow rate of 1 ml min−1, and the response was monitored at 254 nm.

2.7 Statistical analysis

SPSS statistic software version 24 was used for statistical analysis of the obtained data. The results were analyzed by one-way ANOVA followed by the Tukey test. The values with p < 0.05 were considered a significant response.

3 Results and discussion

3.1 Wastewater treatment analysis

COD analysis results of the wastewaters samples treated with Y. lipolytica EBL13 indicated that the yeast was able to reduce about 85% of COD after 4 days compared to the control sample (Fig. 1). Lim et al. reported the reduction of soluble COD from 800 to 300 mg L−1 in FCW treated with Candida rugopelliculosa for 20 h [25]. Another study using Oocystis sp. (microalgae isolated from the lagoon) led to 70% COD decrease in FCW after 10 days [26]. Grgas et al. studied the effect of NaCl concentration on FCW treatment efficiency by activated sludge. Results showed that the presence of 2% salt in FCW caused 60%, 70%, and 100% decrease in COD, NH4+, and PO43−, respectively [27]. Here, the COD/BOD ratio in FCW was 2.35, which indicated the high biodegradable fraction, while the values of more than 3.5 show predomination of an inert fraction [28].

The growth of Y. lipolytica EBL13 and consumption of fatty acids and protein compounds in the effluent, which led to ammonia production, can be a possible reason for increasing wastewater pH after yeast treatment (Table 2). Mansour et al. have shown that growing a strain of Y. lipolytica isolated from cheese in the lactate-containing medium with high concentrations of amino acid resulted in a dramatic pH increase due to amino acid degradation and ammonia production [29]. Also, the ammonia concentration in the media increases by a functional nitrate reductase in Y. lipolytica, which converts the absorbed nitrate to nitrite as the intermediate metabolite. Finally, ammonia is synthesized by nitrite reductase. Therefore, the nitrate reductase function results in decreasing nitrate concentration and increasing ammonia levels [30]. The reduction of total nitrogen is associated with microbial growth and biomass production and also BOD and COD levels. Phosphorous is one of the essential elements for the synthesis of yeast cellular components, including phospholipids, proteins, and nucleic acids. Phosphorous uptake is known as a limiting growth factor and is regulated by the phosphate signal transduction pathway (PHO pathway) in Saccharomyces cerevisiae through sensing phosphorous concentration signals [31]. One of the key enzymes in sulfur metabolism is sulfite reductase in Y. lipolytica, which catalyzes the reduction of sulfite to sulfide, which then converts to cysteine in combination with O-acetyl-l-serine by cysteine synthase [32]. BOD analysis of FCW showed that after treatment, wastewater BOD decreased by about 60%. In addition, reduction in other wastewater quality indexes, including FOG, nitrate, total nitrogen, total phosphor, sulfite, TH, and TSS, confirmed the efficiency of biological treatment with Y. lipolytica EBL13. Various hydrolytic enzymes of Y. lipolytica, such as lipase, protease, and esterase, are responsible for the organic matter degradation [33] and a significant reduction in the BOD, COD, and FOG levels. Also, it should be considered that the low total nitrogen amount indicated the high levels of carbon/nitrogen (C/N) ratio in the studied FCW. Lopes et al. showed induction of lipase production by Y. lipolytica W29 and IMUFRJ 50682 in the high C/N ratios [34]. In addition, this condition is in favor of citric acid and intracellular lipid accumulation, and de novo lipid biosynthesis [33]. The significant capacity of Y. lipolytica in biosurfactant production from the various oily substrates such as glycerol, cottonseed oil, soapstock, corn oil, ground-nut oil refinery residual waste, crude glycerin, and canola oil has been confirmed by several studies [35]. The high adsorption propensity of biosurfactants to suspended solids leads to an increase in their biodegradability and, hence, a decrease in TSS amounts [36].

Even though the COD, BOD, oil, and phosphate have decreased by 59.06%, 59.04%, 68.2%, and 91.34, respectively, they have not met the 1989 standards of Law 93/1962 for the specifications of liquid wastes to be disposed of in public sewerage [37]. Therefore, further treatments are necessary to achieve the standard levels. The quality parameters of some FCWs published in the literature are summarized in Table 3.

3.2 Morphological assessment

Y. lipolytica is a biotechnologically beneficial yeast strain with multiple valuable physiological and metabolic properties [9]. Various changes in environmental factors such as pH, nutrient starvation, temperature, oxygen availability, heavy metal concentration, and mechanical parameters, including pressure and mixing, can lead to stressful conditions for the cells. In addition, carbon and nitrogen source types can be considered determining parameters for yeast morphology [38, 39]. Braga et al. had observed that Y. lipolytica W29 and MTLY40-2P showed mycelium form in the presence of olive oil, while they showed yeast form when castor oil was used as the carbon source [40]. Published literature has proven the influence of environmental factors on the morphologic alterations in Y. lipolytica cells from yeast to mycelium form. To evaluate the role of salt in morphologic features of Yarrowia, saline (containing 4% NaCl) and non-saline FCW were used. Here, Y. lipolytica EBL13 morphology has changed from cocci shape in non-saline conditions to elongated shape in saline conditions (Fig. 2). In parallel, Andreishcheva et al. adapted Y. lipolytica to 9% salt in a basal medium enriched with yeast extract, glycerol, and vitamins. The adapted cells were observed in a more round shape with decreased size compared to the control strain [8]. Figure 2(B) shows the lipid content in Y. lipolytica in FCW.

3.3 Amino acid and fatty acid profile

Amino acid profile analysis showed that 50.2% w/w of the produced biomass in FCW contained proteins (Table 4). The most presented amino acids were Ala (77 mg/g biomass, 153.39 mg/g protein), Glu (70 mg/g biomass, 139.44 mg/g protein), Asp (65 mg/g biomass, 129.48 mg/g protein), Gly (58 mg/g biomass, 115.54 mg/g protein), and Ser (50 mg/g biomass, 99.6 mg/g protein). In addition, all essential amino acids were presented in amino acid composition, which comprised 32.9% of the profile.

Amino acid composition is affected by several parameters such as physical culture conditions, substrate type, and substrate concentration [41]. Figure 3 shows a comparison of some amino acid content in total cell proteins in Y. lipolytica EBL13 and other strains. As represented in Fig. 3, Y. lipolytica EBL13 showed higher levels of Trp and sulfur-containing amino acids (Met and Cys) when growing on FCW as the substrate compared with other strains cultured on glycerol or glucose-containing substrates.

Currently, about 97% of the soybean meal produced in the world is used as animal feed. In contrast, plant-based protein sources need to be supplemented with essential amino acids to achieve optimal performance. Since Lys content is low in cereals (for example, 2.8 mg g−1 in wheat), the current yeast-based SCP with 22 mg/g biomass can be a suitable food supplement alternate for poultry. In addition, Lys, Met, and Thr are the first three limiting amino acids for broilers, respectively [42,43,44]. Lys content of Y. lipolytica has been reported to be as much as its content in a whole egg [10]. Synthesis pathways of the essential amino acids in Y. lipolytica extracted from the KEGG database are presented in Fig. 4.

Gly and Ser are not generally considered essential in the diet of poultry. However, they are necessary for young birds’ growth [45]. Cys and Tyr that are synthesized from Met and Phe, respectively, are classified as semi-essential amino acids [46].

Currently, various companies use yeast biomass to produce SCP, including Unilever, Tangshan Top Bio-technology Co. (Saccharomyces sp.), Skotan S.A. (Y. lipolytica), Shanghai Tramy Green Food Co. (S. cerevisiae and Trichoderma sp.), Phillips Petroleum Company USA (Pichia sp. and Torula sp.), Nucelis (Y. lipolytica), Mondelez (yeast), Liquichemica (Candida maltosa), LeSaffre (yeast), Lallemand Inc. (Yeast), IFP (Candida tropicalis), Flint Hills Resources (S. cerevisiae), Cangzhou Tianyu Feed Additive Co. (yeast powder), Belly Yeast (Kluyveromyces), Bega Cheese (Saccharomyces), and Amoco (Candida utilis). In the industrial production processes of SCP, companies have tried to use the cheapest substrates such as carbon dioxide, alkanes, methanol, natural gas, and industrial effluents [18]. In the list published by the International Dairy Federation (IDF), the European Food and Feed Cultures Association (EFFCA), and the American Food and Drug Administration (FDA), Y. lipolytica is seen as Generally Regarded As Safe (GRAS) for food applications [10, 17]. Safety of Y. lipolytica yeast biomass as a novel food pursuant to Regulation (EU) 2015/2283 was declared by the European Food Safety Authority (EFSA) in 2019 [47]. A comparison of essential amino acid percentages in Y. lipolytica EBL13 and S. cerevisiae strains showed more agreement with FAO/WHO/UNU recommendations in Y. lipolytica EBL13 (Table 5).

In addition to essential amino acids, the presence of essential fatty acids (EFAs) in food is of special importance. For example, EFA deficiency in cystic fibrosis patients has been observed. Furthermore, EFA shortage can cause liver and kidney disorders which lead to growth defects, impaired immune system function, and skin dryness, particularly in children. EFAs are classified into two groups, omega-3 and omega-6, which cannot be biosynthesized by a human. According to dietary guidelines for poultry, 4–5% of daily food content should be fat, from which 1% should be omega-6. Y. lipolytica is an oleaginous microorganism and is used as a model for the production of bio-oils. Regarding the importance of essential fatty acids in oils, the fatty acid profile of Y. lipolytica EBL13 was analyzed to find essential fatty acid content (Table 6). Linolenic acid (0.15%) and eicosapentaenoic acid (0.21%) as essential omega-3 fatty acids and linoleic acid (22.15%) as essential omega-6 fatty acid were observed in the fatty acid profile.

Y. lipolytica biomass has previously been used as a substitute for eicosapentaenoic acid supplied by cornmeal, fish meal, and rapeseed oil during salmon farming. Feeding salmon fish using biomass containing 6% eicosapentaenoic acid and 2% oil increased the weight of fish from 180 to 400 g in 95 days. These results showed a significant increase in growth compared to control samples fed rapeseed oil and a mixture of rapeseed and fish oil [48]. The fatty acid composition in Y. lipolytica EBL13 biomass is compared with some widely used plant oils in Table 7.

3.4 Prediction of biodiesel characteristics

Several physical and chemical parameters determine the quality of produced biodiesel from various feedstocks. Prediction of these properties using fatty acid profiles may lead to selecting an appropriate and cost-effective oily source candidate for large-scale applications [49]. Viscosity is considered an index of fuel resistance against shear and tensile forces and shows an inverse relationship with biodiesel fluidity. Therefore, in the case of high-density fuels, injectors do not exhibit accurate performance, especially in cold starting engine conditions [50]. The high degree of unsaturation in the oily feedstocks leads to the production of low viscosity biodiesel. Here, the calculated value of viscosity according to Table 1 was 1.33 mm2/s. According to biodiesel specifications established by ASTM D6751 and EN 14214, kinematic viscosity should be 1.9–6.0 mm2/s and 3.5–5.0 mm2/s, respectively.

The fuel fluidity is also affected directly by DU as another key fuel feature. While increasing DU levels improves fluidity, more unsaturated fuels suffer from more NOx emissions. The maximum DU in Europe and Spain are met at 137 and 160, respectively [23]. The calculated DU for the predicted biodiesel from Y. lipolytica EBL13 was 83.54.

The IV provides a direct indication of unsaturation degree and is described as the mass of iodine (I2) in grams that is necessary to completely saturate the molecules of 100 g of oil. Here, the IV was measured as 76.4 g Iod/100 g, which is in accordance with EN 14214 specifications that require the maximum value of biodiesel IV as 120 g Iod/100 g. In addition, the SFA to USFA ratio in the fatty acid profile was 0.65. Darvishi et al. have reported the SFA to USFA ratio of 0.56 in Y. lipolytica–treated vegetable oil refinery wastewater [51].

CN is one of the biodiesel quality determining parameters that result in long combustion delay in high values. However, decreased levels of CN cause more noise radiation during fuel ignition. The predicted CN in the current study was 55.7 min which satisfied the minimum CN of ASTM D6751 and EN 14214 standards which are 47 min and 51 min, respectively.

The calculated cold flow parameters, CP and CFPP, were 8.96 °C and 9.22 °C, respectively. Since CP and CFPP values of diesel depend on the climate, they are not considered in ASTM D6751 and EN 14214 standards.

In Fig. 5, the predicted biodiesel from Y. lipolytica EBL13 and plant and yeast oils in published literature are grouped in each area of the triangular graph. According to this graph, a comparison of fatty acid profiles in plant and yeast species demonstrated a significant compositional difference. However, yeast oils of various genera showed more similar properties to each other when compared to plant ones. To achieve biodiesel which satisfies the EN 14214 specifications completely, the fatty acid composition must fit part A in the triangular graph (Fig. 5). Table 8 indicates a comparison of the different parameters in biodiesel produced from different oleaginous yeasts.

Comparison of the different parameters in biodiesel produced from yeast and plant oils in different studies [55] and this study. (A) Biodiesel that satisfied EN 14214. (B) Appropriate CFPP. (C) Appropriate CN, and IV

Considering the importance of biological fuels and animal food supplements, developing a microbial strain with multiple biotechnological applications may be of interest. Investigation of Y. lipolytica EBL13 fatty acid and amino acid composition indicates the high potential of this yeast strain in food and environmental biotechnology. In addition, the by-products in the wastewater treatment process lead to cost reduction of the treatment process. Eurofish uses 1300 m3 of wastewater produced during fish processing to produce 1300 m3 of biogas per day [52].

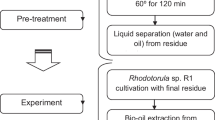

Nowadays, sustainable management of waste streams through secondary material recovery from fully treated and semi-treated wastewaters is an eco-friendly strategy that maintains the circular flow of water, waste, material, and energy [53, 54]. Here, producing biodiesel from the remaining biomass of Y. lipolytica following the biotreatment of FCW can lead to a decrease in the demand for fossil fuel and also minimize the CO2 emission into the environment. In addition, SCP production as the animal food supplement from the biomass can reduce agricultural demand to supply animal feed and also reduce the water and energy consumption. Figure 6 shows a circular economy flow in FCW management using Y. lipolytica EBL13. Accordingly, followed by FCW treatment by Y. lipolytica EBL13 in a fish canning operational unit, the extracted SCP from the yeast biomass can be consumed by fish as a food supplement, and the extracted SCO can be used for biodiesel production to provide the required fuel in the same unit.

4 Conclusion

Freshwater scarcity and the growing world population have highlighted the need to access low-cost food and water through wastewater recycling and microbial SCP production. In the current study using FCW as the carbon source, Y. lipolytica EBL13 showed an 85% decrease in COD levels. It should be noted that autoclaving the FCW sample may lead to evaporating volatile compounds and therefore result in fewer levels of COD compared with actual values, which is a limitation in the accurate evaluation of treatment efficiency. In addition, the yeast produced 50.2% protein as the by-product, from which 16.5% was composed of essential amino acids. Also, essential omega-3 fatty acids and omega-6 fatty acids composed 25.15% and 22.15% of the fatty acid profile, respectively. According to our obtained results, Y. lipolytica EBL13 may be a potent SCP and SCO producer strain for animal feed applications. Furthermore, predicted parameters of the biodiesel produced from Y. lipolytica EBL13 fatty acids such as cetane number, iodine value, and unsaturation degree met the EN 14214 specifications. However, it is helpful to produce biodiesel from yeast lipids and then measure its parameters to obtain a more precise understanding of biodiesel quality. Finally, it should be noted that applying fatty acids of Y. lipolytica EBL13 can be used as biofuel, and other yeast components such as its amino acids may be useful in animal feed supplement production. Nevertheless, it is suggested to test the produced SCP as the animal feed supplement in laboratory animal models in further experiments.

References

Cristóvão RO et al (2015) Fish canning industry wastewater treatment for water reuse–a case study. J Clean Prod 87:603–612. https://doi.org/10.1016/j.jclepro.2014.10.076

Venugopal V (2021) Valorization of seafood processing discards: bioconversion and bio-refinery approaches. Front Sustain Food Syst 5:611835. https://doi.org/10.3389/fsufs.2021.611835

Chowdhury P, Viraraghavan T, Srinivasan A (2010) Biological treatment processes for fish processing wastewater–a review. Bioresour Technol 101(2):439–449

Cristóvão RO et al (2016) Assessing the influence of oil and grease and salt content on fish canning wastewater biodegradation through respirometric tests. J Clean Prod 127:343–351. https://doi.org/10.1016/j.jclepro.2016.04.057

del Rio AV et al (2018) Performance and microbial features of the partial nitritation-anammox process treating fish canning wastewater with variable salt concentrations. J Environ Manag 208:112–121. https://doi.org/10.1016/j.jenvman.2017.12.007

Correa-Galeote D et al (2021) Salinity is the major driver of the global eukaryotic community structure in fish-canning wastewater treatment plants. J Environ Manag 290:112623. https://doi.org/10.1016/j.jenvman.2021.112623

Karagiannis IC, Soldatos PG (2008) Water desalination cost literature: review and assessment. Desalination 223(1–3):448–456. https://doi.org/10.1016/j.desal.2007.02.071

Andreishcheva E et al (1999) Adaptation to salt stress in a salt-tolerant strain of the yeast Yarrowia lipolytica. Biochemistry (Mosc) 64:1061–1067

Darvishi F (2014) Biotechnological applications of the yeast Yarrowia lipolytica, Vol. 74. Springer, New York, NY, USA. https://doi.org/10.1007/978-3-319-06437-6

Gottardi D et al (2021) Recovery and valorization of agri-food wastes and by-products using the non-conventional yeast Yarrowia lipolytica. Trends Food Sci Technol 115:74–86. https://doi.org/10.1016/j.tifs.2021.06.025

Liu H-H, Ji X-J, Huang H (2015) Biotechnological applications of Yarrowia lipolytica: past, present and future. Biotechnol Adv 33(8):1522–1546. https://doi.org/10.1016/j.biotechadv.2015.07.010

Hamimed S et al (2021) High-performance biological treatment of tuna wash processing wastewater using Yarrowia lipolytica. Environ Sci Pollut Res 28(2):1545–1554. https://doi.org/10.1007/s11356-020-10586-6

Hamimed S et al (2022) Bio-nanocrystallization of NaCl using saline wastewaters through biological treatment by Yarrowia lipolytica. Environ Technol Innov 26:102338. https://doi.org/10.1016/j.eti.2022.102338

Dunoyer AT, Cuello REG, Salinas RP (2020) Biodegradation of dairy wastes using crude enzymatic extract of Yarrowia lipolytica ATCC 9773. Rev Ambiente Agua 15. https://doi.org/10.4136/ambi-agua.2448

Radha P et al (2020) Synthesis of single-cell oil by Yarrowia lipolytica MTCC 9520 utilizing slaughterhouse lipid waste for biodiesel production. Biomass Convers Biorefin:1-12. https://doi.org/10.1007/s13399-020-01132-y

Poli JS et al (2014) Microbial lipid produced by Yarrowia lipolytica QU21 using industrial waste: a potential feedstock for biodiesel production. Bioresour Technol 161:320–326. https://doi.org/10.1016/j.biortech.2014.03.083

Bourdichon F et al (2012) Food fermentations: microorganisms with technological beneficial use. Int J Food Microbiol 154(3):87–97. https://doi.org/10.1016/j.ijfoodmicro.2011.12.030

Ritala A et al (2017) Single cell protein—state-of-the-art, industrial landscape and patents 2001–2016. Front Microbiol 8:2009. https://doi.org/10.3389/fmicb.2017.02009

Galluzzi L et al (2017) Molecular definitions of autophagy and related processes. EMBO J 36(13):1811–1836. https://doi.org/10.15252/embj.201796697

Manual HP (1998) DR/2010 Spectrophotometer Handbook. HACH Company, Loveland

Masoudi R et al (2018) Adsorption of cadmium from aqueous solutions by novel Fe3O4-newly isolated Actinomucor sp. bio-nanoadsorbent: functional group study. Artif Cells Nanomed Biotechnol 46(sup3):S1092–S1101. https://doi.org/10.1080/21691401.2018.1533841

Nouri H et al (2019) Enhanced growth and lipid production in oleaginous fungus, Sarocladium kiliense ADH17: study on fatty acid profiling and prediction of biodiesel properties. Renew Energy 135:10–20. https://doi.org/10.1016/j.renene.2018.11.104

Ramos MJ et al (2009) Influence of fatty acid composition of raw materials on biodiesel properties. Bioresour Technol 100(1):261–268. https://doi.org/10.1016/j.biortech.2008.06.039

Talebi AF, Tabatabaei M, Chisti Y (2014) BiodieselAnalyzer: a user-friendly software for predicting the properties of prospective biodiesel. Biofuel Res J 1(2):55–57. https://doi.org/10.18331/BRJ2015.1.2.4

Lim J, Kim T, Hwang S (2003) Treatment of fish-processing wastewater by co-culture of Candida rugopelliculosa and Brachionus plicatilis. Water Res 37(9):2228–2232. https://doi.org/10.1016/S0043-1354(02)00586-9

Riaño B, Molinuevo B, García-González M (2011) Treatment of fish processing wastewater with microalgae-containing microbiota. Bioresour Technol 102(23):10829–10833. https://doi.org/10.1016/j.biortech.2011.09.022

Grgas D et al (2020) Fish canning wastewater treatment in sequencing batch reactor with activated sludge. Holist Approach Environ 10(2):29–34. https://doi.org/10.33765/thate.10.2.1

Coldebella A et al (2017) Effluents from fish farming ponds: a view from the perspective of its main components. Sustainability 10(1):3

Mansour S, Beckerich J, Bonnarme P (2008) Lactate and amino acid catabolism in the cheese-ripening yeast Yarrowia lipolytica. Appl Environ Microbiol 74(21):6505–6512. https://doi.org/10.1128/AEM.01519-08

Perli T, Borodina I, Daran J-M (2021) Engineering of molybdenum-cofactor-dependent nitrate assimilation in Yarrowia lipolytica. FEMS Yeast Res 21(6):foab050. https://doi.org/10.1093/femsyr/foab050

Watanabe T et al (2008) Breeding of wastewater treatment yeasts that accumulate high concentrations of phosphorus. Appl Microbiol Biotechnol 80(2):331–338. https://doi.org/10.1007/s00253-008-1529-8

Hébert A et al (2013) New insights into sulfur metabolism in yeasts as revealed by studies of Yarrowia lipolytica. Appl Environ Microbiol 79(4):1200–1211. https://doi.org/10.1128/AEM.03259-12

Lopes M et al (2022) Yarrowia lipolytica as a biorefinery platform for effluents and solid wastes valorization–challenges and opportunities. Crit Rev Biotechnol 42(2):163–183. https://doi.org/10.1080/07388551.2021.1931016

Lopes M et al (2009) The use of olive mill wastewater by wild type Yarrowia lipolytica strains: medium supplementation and surfactant presence effect. J Chem Technol Biotechnol 84(4):533–537. https://doi.org/10.1002/jctb.2075

Fontes G et al (2012) Renewable resources for biosurfactant production by Yarrowia lipolytica. Braz J Chem Eng 29(3):483–494

Al-Ani RR, Hassan FM, Al-Obaidy AHMJ (2020) Environmental evaluation of surfactant: case study in sediment of Tigris River, Iraq, in River Deltas-Recent Advances IntechOpen. https://doi.org/10.5772/intechopen.94324

Fahim FA et al (2001) Evaluation of some methods for fish canning wastewater treatment. Water Air Soil Pollut 127(1):205–226. https://doi.org/10.1023/A:1005292204184

Bellou S et al (2014) Morphological and metabolic shifts of Yarrowia lipolytica induced by alteration of the dissolved oxygen concentration in the growth environment. Microbiology 160(4):807–817. https://doi.org/10.1099/mic.0.074302-0

Magdouli S, Brar SK, Blais JF (2018) Morphology and rheological behaviour of Yarrowia lipolytica: impact of dissolved oxygen level on cell growth and lipid composition. Process Biochem 65:1–10. https://doi.org/10.1016/j.procbio.2017.10.021

Braga A et al (2016) Quantitative image analysis as a tool for Yarrowia lipolytica dimorphic growth evaluation in different culture media. J Biotechnol 217:22–30. https://doi.org/10.1016/j.jbiotec.2015.10.023

Timoumi A et al (2018) Impacts of environmental conditions on product formation and morphology of Yarrowia lipolytica. Appl Microbiol Biotechnol 102:3831–3848. https://doi.org/10.1007/s00253-018-8870-3

Corzo A et al (2007) Marginality and needs of dietary valine for broilers fed certain all-vegetable diets. J Appl Poult Res 16(4):546–554. https://doi.org/10.3382/japr.2007-00025

Rehman AU et al (2019) Growth performance of broilers as influenced by different levels and sources of methionine plus cysteine. Animals 9(12):1056. https://doi.org/10.3390/ani9121056

Kidd M (2004) Nutritional modulation of immune function in broilers. Poult Sci 83(4):650–657. https://doi.org/10.1093/ps/83.4.650

Siegert W, Rodehutscord M (2019) The relevance of glycine and serine in poultry nutrition: a review. Br Poult Sci 60(5):579–588. https://doi.org/10.1080/00071668.2019.1622081

Ravindran V (2010) Poultry feed availability and nutrition in developing countries. Poult Dev Rev 60–63

EFSA Panel on Nutrition NF et al (2019) Safety of Yarrowia lipolytica yeast biomass as a novel food pursuant to Regulation (EU) 2015/2283. EFSA J 17(2):e05594. https://doi.org/10.2903/j.efsa.2019.5594

Hatlen B et al (2012) Growth performance, feed utilisation and fatty acid deposition in Atlantic salmon, Salmo salar L., fed graded levels of high-lipid/high-EPA Yarrowia lipolytica biomass. Aquaculture 364:39–47. https://doi.org/10.1016/j.aquaculture.2012.07.005

Brahma S et al (2022) Biodiesel production from mixed oils: a sustainable approach towards industrial biofuel production. Chem Eng J Adv:100284. https://doi.org/10.1016/j.ceja.2022.100284

Giakoumis EG (2013) A statistical investigation of biodiesel physical and chemical properties, and their correlation with the degree of unsaturation. Renew Energy 50:858–878. https://doi.org/10.1016/j.renene.2012.07.040

Darvishi F, Salmani N, Hosseini B (2019) Biovalorization of vegetable oil refinery wastewater into value-added compounds by Yarrowia lipolytica. J Chem Technol Biotechnol 94(9):2961–2968. https://doi.org/10.1002/jctb.6102

Simal-Gandara J et al (2021) Re-valorization of food losses and food co-products. Front Media SA. https://doi.org/10.3389/fsufs.2021.779734

Neczaj E, Grosser A (2018) Circular economy in wastewater treatment plant–challenges and barriers. Proceedings 11:614. https://doi.org/10.3390/proceedings2110614

Silveira CF et al (2021) Valorization of swine wastewater in a circular economy approach: effects of hydraulic retention time on microalgae cultivation. Sci Total Environ 789:147861. https://doi.org/10.1016/j.scitotenv.2021.147861

Chatzifragkou A et al (2011) Biotechnological conversions of biodiesel derived waste glycerol by yeast and fungal species. Energy 36(2):1097–1108. https://doi.org/10.1016/j.energy.2010.11.040

Najafpour G, Zinatizadeh A, Lee L (2006) Performance of a three-stage aerobic RBC reactor in food canning wastewater treatment. Biochem Eng J 30(3):297–302. https://doi.org/10.1016/j.bej.2006.05.013

Artiga P et al (2008) Use of a hybrid membrane bioreactor for the treatment of saline wastewater from a fish canning factory. Desalination 221(1–3):518–525. https://doi.org/10.1016/j.desal.2007.01.112

Zufia J, Aurrekoetxea G (2002) Integrated processing of fish canning industry wastewater: the EFLUCON project. J Aquat Food Prod Technol 11(3–4):303–315. https://doi.org/10.1300/J030v11n03_22

Iwuagwu JO, Ugwuanyi JO (2014) Treatment and valorization of palm oil mill effluent through production of food grade yeast biomass. J Waste Manag 2014. https://doi.org/10.1155/2014/439071

Izah SC, Bassey SE, Ohimain EI (2017) Amino acid and proximate composition of Saccharomyces cerevisiae biomass cultivated in Cassava mill effluents. Mol Microbiol Res 7. https://doi.org/10.5376/mmr.2017.07.0003

Goodrum JW, Geller DP (2005) Influence of fatty acid methyl esters from hydroxylated vegetable oils on diesel fuel lubricity. Bioresour Technol 96(7):851–855. https://doi.org/10.1016/j.biortech.2004.07.006

Kumar R et al (2020) Multi-fold enhancement in sustainable production of biomass, lipids and biodiesel from oleaginous yeast: an artificial neural network-genetic algorithm approach. Energy Fuels 4(12):6075–6084. https://doi.org/10.1039/D0SE00922A

Guerfali M et al (2018) Single cell oil production by Trichosporon cutaneum and lignocellulosic residues bioconversion for biodiesel synthesis. Process Saf Environ Prot 113:292–304. https://doi.org/10.1016/j.psep.2017.11.002

Khot M, Ghosh D (2017) Lipids of Rhodotorula mucilaginosa IIPL32 with biodiesel potential: oil yield, fatty acid profile, fuel properties. J Basic Microbiol 57(4):345–352. https://doi.org/10.1002/jobm.201600618

Bhatia SK et al (2017) Microbial biodiesel production from oil palm biomass hydrolysate using marine Rhodococcus sp. YHY01. Bioresour Technol 233:99–109. https://doi.org/10.1016/j.biortech.2017.02.061

Nair AS et al (2020) Production of microbial lipids from optimized waste office paper hydrolysate, lipid profiling and prediction of biodiesel properties. Renew Energy 148:124–134. https://doi.org/10.1016/j.renene.2019.12.008

Ananthi V et al (2019) Enhanced microbial biodiesel production from lignocellulosic hydrolysates using yeast isolates. Fuel 256:115932. https://doi.org/10.1016/j.fuel.2019.115932

Funding

This work is based upon research funded by the Iran National Science Foundation (INSF) under project no. 4002334.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Azin, E., Moghimi, H., Dastgheib, S.M.M. et al. Biovalorization of wastewater of fish canning process by Yarrowia lipolytica for biodiesel and animal feed supplement production. Biomass Conv. Bioref. 14, 7981–7994 (2024). https://doi.org/10.1007/s13399-022-03025-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03025-8