Abstract

This paper aims to contribute toward the understanding of the dynamics and control of the biomass gasification process utilizing palm kernel shell (PKS) as the feedstock. In this paper, dynamic modeling of a PKS steam gasification of an integrated biomass pilot plant in Universiti Teknologi PETRONAS (UTP) is developed using Aspen Plus®. A 2 × 2 linear model predictive controller (MPC) scheme is implemented and compared against the conventional Proportional-Integral (PI) controller, where the linear MPC controller is interfaced with the Aspen Plus model of the pilot plant. Pseudorandom binary sequence (PRBS) signals with different signal bandwidths are used to excite the biomass gasification system for the open-loop model identification. The system is investigated with 2.5%, 5%, and 10% step changes in the controlled variables. Quantitative analysis for the performances of the PI and MPC controllers in their ability to track the setpoint of both the controlled variables based on the Integral Absolute Error (IAE) performance index is performed. It can be observed that, for the biomass gasifier studied, both the PI and MPC controllers are relatively comparable in terms of their performances under the step changes introduced.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Higher energy usage, increasing energy prices, and climate change generated by greenhouse gas emissions into the atmosphere are all major concerns and challenges presented by the twenty-first century [1,2,3,4,5]. By promoting the use of renewable energy through successful policymaking and gaining industrial interest, the international community is increasingly ensuring sustainability efforts. As a consequence, the world’s leading main priority is to improve the use of biomass sources or biomass-containing waste materials to produce energy to alleviate and mitigate the problems caused by the rising energy demand [2, 6, 7]. Many environmentally friendly processes have been proposed by researchers all over the world to help the growing initiatives on sustainable development and zero-waste industries [2, 8, 9].

Malaysia is abundant with renewable and non-renewable sources of energy [10] and the increase in environmental problems associated with conventional fossil fuel combustion has increased the development of renewable energy utilization technologies [11]. Malaysian agricultural production has shown consistent growth, leading to an increasing supply of biomass waste, most of which are not being utilized [12]. Coconut shells (CSs) and palm kernel shells (PKSs) [13,14,15] have been regarded as possible biomass sources due to their ease of use and syngas heating properties (HHV) [16,17,18,19,20]. Many factors influence gasification efficiency, including biomass chemical and physical properties [11], gasifier design [12], and operating conditions, such as temperature [15], equivalence ratio [16], and gasifying agent [6, 17].

Control studies are essential in such a system, due to the stronger process interactions and higher complexity compared to conventional processes [21]. One of the most important factors to be considered in retaining a significant advantage in the process industry is the optimal operation of processes. As a result, control strategies are critical in the operational optimization of process setpoint changes and disturbance rejections, as well as the reduction of such systems’ operating costs. Several researchers have reported control studies based on Proportional-Integral (PI)/Proportional-Integral-Derivative (PID) [22, 23] and model predictive controller (MPC) [24, 25] using different feedstocks such as pulverized coal and biomass (coconut shell, wood) for different processes [26] like gasification, methanol synthesis, and boiler combustion system. Fahim Uddin et al. [27] performed a sensitivity analysis of indirect coal gasification in a bayonet-heated gasifier using Aspen Plus®. Robinson and Luyben [22] performed the dynamic process modeling and control of a coal gasification plant at the National Energy Technology Laboratory (NETL) using PI control loops. Daniel and Gandhi [28] developed the mathematical modeling and compared the performance of PI and PID controllers for a coconut shell biomass gasification process. For gasification control purposes, advanced control concepts have been implemented on several small-scale gasifiers. Saade et al. [29] developed a linear model predictive control system for a solar-thermal reactor for carbon-steam gasification. Agustriyanto and Zhang [30] tested several multi-loop control structures for the ALSTOM gasifier benchmark process. Abrol and Hilton [25] developed a linear MPC (4 inputs × 3 outputs) based on a linear process model identified using the data generated from running the first-principle models. Wahid and Taqwallah [31] developed a dynamic model of a steam reformer which is the main process unit for H2 gas production, using the process simulator UniSim® operated in dynamic mode. A first-order plus dead time (FOPDT) model is identified and used to design MPC controllers and compared with the PI controller. V Kalaichelvi et al. [32] developed and implemented a neural network–based predictive controller for biomass boiler drum water level regulation by simulation in MATLAB software. For the boiler drum water level control system, the performance of the neural network controller is compared to that of a traditional PID controller, and it is observed that the neural network–based approach is more effective. Gandhi et al. [33] proposed a fuzzy logic controller for a wood-based biomass gasification plant. The fuzzy logic controller has been implemented for the transfer function model of the gasifier. Mahapatra and Bequette [24] have presented an advanced, centralized, multivariable model predictive control (MPC) technique to address the controllability of an ASU (air separations unit) process from an IGCC Power Plant, and compared the controller performance to decentralized Proportional-Integral (PI) control schemes. Al Seyab et al. [34] developed a simple predictive controller to control an ALSTOM gasifier process using pulverized coal using a linear state-space model.

These reviews unraveled few vital points. Firstly, from the control system design perspective for biomass-related studies, no dynamic and control studies on the bio-hydrogen gasifier have been reported. All of the works reported so far focused only on other processes such as solar gasification, methanol synthesis, and boiler combustion systems. The bio-hydrogen gasifier is one of the most critical processing units in a biomass gasification process. Many factors influence gasifier efficiency, especially operating conditions such as temperature, equivalence ratio (e.g., steam to biomass or air to biomass), gasifying agent selection, and the chemical and physical properties of the biomass. Secondly, most reported control studies have used pulverized coal and biomass (coconut shells, wood) as feedstocks. No dynamic modeling and control studies have been reported for a steam in situ gasification pilot plant that utilizes palm kernel shells (PKSs) with coal bottom ash as the feedstock. Steady-state analysis alone does not correctly represent neither issues related to daily operations nor the transient behavior of these plants. In addition, very limited studies on the use of coal bottom ash in steam biomass gasification are available. Only Shahbaz et al. [35] experimentally studied the catalytic sorbent–based steam gasification of palm kernel shell in a pilot-scale-integrated fluidized bed gasifier and fixed bed reactor using coal bottom ash as a novel catalyst for cleaner and hydrogen and syngas production. Thirdly, in most of the studies reported, PID or PI controllers were used in the regulation of temperature, flow, pressure, and other process variables. It should be duly noted, however, that several of the papers typically proposed and studied more than one control strategy in their approach. Fourthly, it can be seen that limited studies have shown MPC incorporation, and how it is utilized varied from one paper to the next.

The aim of this work is to contribute toward the understanding of the dynamics and control of bio-hydrogen gasifier process utilizing PKS as the feedstock and coal bottom ash as a catalyst. This study aims to develop and investigate the performance of the decentralized PI-based and the multivariable MPC-based controller strategies for the control of the bio-hydrogen gasifier system described in Part A of this paper [6] using PKS with coal bottom ash, as it is critical to control the gasifier operating conditions adequately under varying plant disturbances to achieve the required product gas composition, particularly for new feedstocks like PKS. Hence, the scope of the present paper is as follows:

-

1.

Development of a linear dynamic model of the pilot plant using a system identification approach.

-

The steady-state simulation model for the gasification system described in Part A of this paper [6] is exported to the ASPEN-DYNAMICS simulation, which is then used to investigate the gasification system’s dynamic behavior. Aspen Plus® is widely used in the simulation of biomass systems [9, 36], and ASPEN-DYNAMICS is available only under Aspen Plus®. The performance of PI controllers is tested using closed-loop system identification.

-

The open-loop response of the dynamic system is investigated, and the system is identified using the first-order process time delay (FOPTD) or second-order process time delay (SOPTD) to represent the pilot-scale plant.

-

2.

Development of a control scheme and comparison of the performance of the PI and MPC controllers for the biomass gasification system.

-

2.

-

For the control study, performances of the basic and advanced process control have been compared using the Proportional-Integral (PI) and model predictive control (MPC) controllers respectively.

-

The MPC implementation protocol can be divided into two stages in practice. The first step is to develop a plant model, and the second is to build a controller. Mostly, system identification techniques are preferred to perform plant modeling. In practice, constructing a plant model solely based on physical laws for control purposes has been unusual. The challenges of designing a plant model using system identification techniques must be discussed for a plant with an interconnected structure. The problems occur during the process of evaluating how the plant should be tested [3, 33] and what type of model structure to use [33,34,35, 37].

-

The linear mathematical model of the MPC controller for biomass gasification has been developed with the Model Predictive Control Toolbox in MATLAB (2018a), which provides a graphical interface to the MPC calculation routines.

-

The controlled and manipulated variables have been identified based on the insights obtained from the process behavior to maintain the desired system constraints.

2 Material and methods

2.1 Steady-state model and experimental setup

The steady-state Aspen Plus® model of the biomass gasification pilot-scale plant has been developed and validated in detail in Part A of this work as reported in [6]. The experimental data used for validation of the steady-state model was obtained from the experimental runs carried out at University Teknologi PETRONAS in a continuous advanced fluidized bed technology pilot-scale gasification pilot-scale facility [35]. The palm kernel shell for the feedstock purchased from Kilang Sawit Nasaruddin Sdn Bhd in Perak, Malaysia, and the coal bottom ash comes from TNB Janamanjung Sdn Bhd in Malaysia. The process flow diagram is as shown in Fig. 1.

2.2 Dynamic simulation of UTP biomass gasification pilot plant

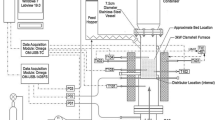

After the steady-state simulation presented in Part A [6] of this paper has converged, equipment sizing is carried out to provide dynamic potentiality of all the equipment installed in the simulation. Valve sizing is an important step in equipment sizing, as the system dynamics are subjected to the flowrates of the streams and volume of the columns. The valve opening percentage and pressure drop are determined and fixed in this step. Valves are designed primarily to be operated at 50% opening at the design condition [38]. Pressure drop plays an important role in valve flexibility, which subsequently affects controllability. The steady-state simulation has been checked for all errors before entering the dynamic simulation. Once the steady-state simulation has been converted to the dynamic environment, it is checked to see if the integrator is running. Pressure-driven simulation has been used in the development of the biomass gasification system since it is a more accurate representation of the real dynamics of the system [39]. The transient responses of the system subjected to step changes in the biomass flowrate, reactor temperature, and steam flowrate are studied. The main purpose of the dynamic simulation is to maintain the reactor temperature and steam to biomass ratio for optimum syngas composition. The insights of the dynamic analysis will help in developing the optimal control strategies of the biomass gasifier system. The flowsheet of the biomass gasification system in the dynamic environment in Aspen Dynamic is represented in Fig. 2. The reactor column data are presented in Table 1.

The simplified steps to develop the dynamic state simulation for the biomass gasification system are illustrated in Fig. 2.

2.3 Basic control strategies of UTP biomass gasification pilot plant

The development of an efficient base-level regulatory control system for the reactor is an essential goal of the dynamic simulation. A few controls were installed in the dynamic state simulation in this study to maintain the regulated variables such as biomass flowrate, reactor temperature, and steam flowrate in the reactor unit at a setpoint value (SP). The controllers will be tuned based on different gain, integral, and derivative values, with the values defined to observe the controllers’ corrective action. A temperature controller and two flowrate controllers for the steam and biomass feed flowrates are installed on the reactor section in the simulation. Controlling the reactor temperature (PV) is done by adjusting the reactor duty (OP). In this case, a PI (Proportional-Integral) reverse-acting controller is used, which improves the control signal as the control variable decreases. The two flow controllers for biomass and steam flowrates are installed, which are operating in a cascade loop to maintain the steam to biomass ratio. The outer loop is the biomass flowrate loop, which is used to manipulate the flowrate of biomass. The real-time value of the flowrate is sent to a multiplier, which contains the predefined steam to biomass ratio. The ratio, however, can be manipulated in real time by the user. The two values, i.e., the biomass flowrate and the steam to biomass ratio, are multiplied to provide the setpoint to the steam flowrate control loop, which is the inner loop of this cascade. PI reverse-acting controllers are used for both the biomass and steam flowrates, in which the input signal is the flowrate of the feed, while the output OP signal is the percentage valve opening. The tuning specifications of the PI controllers installed in Aspen Plus® are presented in Table 2.

2.4 Development of control strategies based on PI and MPC controllers for the pilot-scale biomass gasification plant.

2.4.1 Methodology for comparison of control strategies for biomass gasification system

The steps followed to perform the control analysis, and the methodology to develop and implement the PI and MPC control strategies to be embedded into the biomass gasification system, are presented graphically in Fig. 3 for clarity and the detail of each step is explained afterward.

2.5 Decentralized Proportional-Integral (PI)–based control

The initial step before control techniques can be applied involves the development of a reliable model of the reactor system. The controlled and manipulated variables have been identified based on the insights obtained from the process behavior to maintain the desired reactor temperature and steam to biomass ratio of the system. The main control objective is to retain the optimal operating temperature and steam to biomass ratio and maximize the product gas composition. PI controllers have been implemented for the reactor system to regulate the important variables, as the PI controller is the most widely adopted controller for industrial application due to its simple structure, ease in design, and low cost.

Aspen Dynamics automatically assigns the control loop for the temperature of the reactor (TIC-100) and the flowrate of the biomass in the reactor (FIC-100) and steam (FIC-101). The flow controller, FIC-100, regulates and maintains the flowrate of steam fed to the reactor by manipulating the opening of V-102. For temperature control, the control loop has been installed to TIC-100 to sustain the temperature of the reactor column by manipulating the heater duty. For the gasification performance, the temperature of the gasifier is a vital parameter to be controlled. The key variables influencing the characteristics of the reactor system are the steam, biomass flow, steam to biomass ratio, and reboiler duty.

The gain and integral values of each controller have been tuned by the trial and error method with internal model control (IMC) [40]. Similarly, Nittaya et al. [41] and Sahraei and Ricardez-Sandoval [42] tuned the controllers in their study using IMC. The trial and error tuning method is an iterative tuning method based on making small changes to the controller setting and monitoring their effect on the loop. Figure 4 shows the flowsheet of the PI control loops installed in the Aspen Dynamics simulation of the reactor system. The steady-state Aspen Plus® model and functions of each unit used in Fig. 4 of the biomass gasification pilot-scale plant have been described in detail in Part A of this work as reported in [6].

2.6 Linear model predictive control

2.6.1 Model identification

The MPC study for biomass gasification system is performed using Model Predictive Control Toolbox in MATLAB, which provides a graphical interface to the MPC calculation routines. Using the available block of Aspen Simulation Modeler (AMS), the Aspen plus Dynamics model is embedded in Simulink. The location of the dynamic Aspen model and input and output signals are specified in the AMS block and the model information is then imported into Simulink. For large models, the importing process may take a long time. The steps of model identification include gathering experimental data, estimating the mathematical model of the system, and validating a mathematical model of the system (Fig. 5).

In this paper, a 2 × 2 system is considered for the MPC development, whereby the controlled variables (or outputs) are the reactor temperature (Y1) and product gas flowrate (Y2), and the corresponding manipulated variables (or inputs) are the heat duty (U1) and steam to biomass ratio (U2). The System Identification Toolbox in MATLAB is used to determine linear transfer functions between each specified input and output data. The information provided by the input-output data will influence the accuracy of the identified model [43]. For the open-loop model identification, pseudorandom binary sequence (PRBS) signals with an amplitude of 5% from the reference line of U1 and U2 with different signal bandwidth were used. The perturbation signals should be designed critically, considering the characteristics of the process, and the model output should enclose all the model information [40, 44].

Originally, the system is excited using PRBS signal from MATLAB, but the model identified is inaccurate and it is assumed to be due to the interface between MATLAB and Aspen Dynamics. The convergence failure of the Aspen Dynamic model occurs mainly due to the stiffness in the system of equations, in particular the reaction rates of fast ionic reactions [45]. The random PRBS signals have been generated directly in Aspen Dynamics, and Fig. 6 shows the input and output responses of the dynamic model.

For the linear MPC model development, the data obtained in Fig. 6 is exported into the MATLAB System Identification Toolbox. Here, the model is generated using the “ident” function. Then, structure selection is done. Four model types are evaluated in the System Identification Toolbox, namely state-space model, ARX model, continuous transfer model, and process model (please see Table 4 in Section 3.2). The performance of the evaluated models is determined by calculating the fit percentage, Fit%, between the model outputs and the process data shown in Fig. 6. Fit% is one of the most widely used metrics for assessing system identification in the time domain. This criterion is calculated by dividing the root mean squared error (RMSE) by the standard deviation of the measured signal. Table 4 in Section 3.2 presented the Fit% for each of the four models evaluated.

The best fit criterion and FPE are used to evaluate the models. Four models that are available in MATLAB System Identification are evaluated: (i) process model, (ii) ARX, (iii) continuous-time identified transfer function, and (iv) state-space models. The following steps are taken to ensure satisfactory controller performance in the model identification and controller tuning:

-

1.

The open-loop model identification is performed and the best fit model is identified.

-

2.

The controllers are tuned in all cases using MATLAB® tuning advisor for better response.

Steady-state values of the inputs and outputs are specified in Table 3.

The steady-state value of the manipulated variables corresponds to a 50% valve opening in control applications. A valve opening range of 25–75% has been specified to the manipulated variables. This range was chosen randomly; however, it is consistent with standard valve opening procedures, which avoid fully opening or closing the valve.

2.6.2 Aspen-MATLAB co-simulation

Once the Aspen Plus® dynamic simulation and controller are ready, the dynamic simulation is then interfaced with the MPC controller using the MATLAB-Simulink model as shown in Fig. 7.

The MPC controller block in Fig. 7 uses the transfer function plant model as given in the system identification stage. The co-simulation starts when the Simulink model is run using the MATLAB code to define the variables in the workspace. The Aspen Plus® model is opened, initialized, and stepped, i.e., run for just one sample time (Ts). The output and disturbance variables are exported to the Simulink environment via the AMSimulation block. These values are then fed to the MPC block (green arrows) along with the setpoints from the workspace. The MPC calculates the inputs which are then sent to the Aspen Plus® model via the AMSimulation block. Once again, the Aspen Plus® model is stepped, i.e., run for just one sample time (Ts), and the co-simulation keeps running to achieve the closed-loop MPC control for a linear dynamic simulation of the gasification system.

2.6.3 Controller tuning

The tuning advisor in the MATLAB MPC Toolbox is used to tune the MPC. The ITAE performance criterion is used to achieve the least sensitive weight matrices of inputs, input rates, and outputs.

The control performance can be measured using different indices such as:

-

Integral Absolute Error (IAE)

-

Integral Square Error (ISE)

-

Integral Time Absolute Error (ITAE)

These indices are calculated using the following equations:

It can be noted that these indices are based on the reference tracking error (E). A higher value of any of these indices corresponds to low control performance; i.e., the controller is poorer at tracking the reference. The absolute or square values of the tracking error are considered, which means that only the magnitudes of the tracking error at each instant are reflected.

3 Result and discussion

3.1 Dynamic responses

In this section, the responses of the selected key gasifier variables to dynamic disturbances are reported. Simulation of transient conditions has been performed in the dynamic state to evaluate the dynamic performance of the model. The design specifications corresponding to the nominal operating conditions have been adapted to perform the following sensitivity analysis:

-

Case 1: Sensitivity analysis of step change in reactor duty (U1)

-

Case 2: Sensitivity analysis of step change in steam to biomass ratio (U2)

The process model is initialized using the base case operating condition from the steady-state simulation to run the dynamic simulation.

3.1.1 Case 1: Sensitivity analysis of step change in reactor duty (U 1)

The temperature is an important parameter in any chemical, biological, or physical reaction. The temperature affects chemical reactions, specifically how different reactants behave at different temperatures. Figure8 shows the graph between reactor duty vs time for ±10% positive and negative step change respectively.

Figure 9 a and b demonstrate the reactor temperature and product gas flowrate profiles with a step change of ±10% in reactor temperature, respectively. As the reactor duty increases, the reactor temperature increases. At high temperatures, the biomass to gaseous product conversion is high, and thus increasing the product gas flowrates. At high temperatures, the biomass to gaseous product conversion is high and the product gas flowrates are higher as compared to those at lower temperatures which are due to the water gas shift reaction, which is accelerated by increasing temperatures. The result of the sensitivity analysis suggests that gasification at high temperatures can be optimized to obtain an adequate product gas flowrate.

3.1.2 Case 2: Sensitivity analysis of step change in steam to biomass ratio (U 2)

Figure10 shows the ±10% step changes in the steam to biomass ratio introduced into the Aspen simulation plant model.

The response of steam to biomass ratio change on reactor temperature and product gas flowrate is presented in Fig. 11 a and b respectively. Figure 11 a shows the change in reactor temperature in response to ±10% step change in the steam to biomass ratio. A step increase in steam to biomass ratio increases the reactor temperature from 625 to 637.5°C, which is due to the presence of steam. However, it is important to maintain the proper flow of steam because excessive steam can disturb the reactor temperature equilibrium due to the moisture content present in the steam, resulting in a decreased level of combustion in the gasifier. Similarly, a decrease in temperature of 625 to 612.50°C is observed with a decrease in steam to biomass ratio of +10% respectively.

Figure 11 shows that an increase in steam to biomass ratio results in an increase in reactor temperature and product gas flowrate from the reactor. Temperature is considered an important process variable that influences the conversion of biomass to product gas. The water-gas shift reaction can be accelerated further by increasing the temperature in the presence of steam. At high temperatures, the biomass to gaseous conversion is high, and the product gas flowrates are higher as compared to that at lower temperatures. It is observed that the reactor temperature shows an increase from 625 to 637.50°C with the +10% step increase in steam to biomass ratio. Similarly, the same trend is observed for a negative step change in steam to biomass ratio. It is vital to maintain an optimum value of steam to biomass ratio because an excessive amount of steam tends to lower the gasification temperature which highly affects the product gas quality detrimentally [46].

3.2 System identification

Figures 12 and 13 show the performance of the four identified models, i.e., (i) process model, (ii) ARX, (iii) continuous-time identified transfer function, and (iv) state-space models, in predicting the responses for reactor temperature (Y1) and product gas flowrate (Y2), respectively. It can be observed from both Figs. 12 and 13 as well as Table 4 that the best performance is given by the process model. Hence, a process model is chosen to be the model used in the linear MPC controller development.

The identified process model is a second-order plus time delay model as shown in the equation below:

where

Therefore,

3.3 MPC tuning

As mentioned in Section 2, the 2 × 2 multi-input multi-output MPC controller is tuned using the tuning advisor in the MATLAB MPC Toolbox. The selected configuration of the controller is presented in Table 5.

3.4 System behavior analysis for Proportional-Integral (PI) controller and linear model predictive control (MPC) of the UTP biomass gasification pilot plant

The MPC controller designed is co-simulated or interfaced with the Aspen Plus® dynamic simulation of the pilot plant, to evaluate the effects of setpoint changes on the controller performance system. At every sampling interval, the responses of the key process variables from Aspen Plus® dynamic simulation are sent directly to the MPC controller in MATLAB/SIMULINK platform. Based on the measurements from Aspen Plus®, the MPC controller determines the optimized input sequence for the system. This optimal input sequence is then sent back to the Aspen Plus® dynamic simulation, and the whole sequence is repeated at every sampling interval.

The aim of the control loops of the reactor system is to ensure optimum syngas production in the reactor by maintaining the temperature of the reactor at around 625°C, and the product gas flowrate at 2.92. The performances of the PI and MPC controllers are compared based on the ability to track changes in the output variables from the reference point. The system is investigated with the following step changes in the controlled variables (Table 6).

3.5 Setpoint tracking and disturbance rejection

3.5.1 Reactor temperature Y 1 ±2.5%

To ensure the viability of both the controllers, the system is investigated with 2.5%, 5%, and 10% step changes in the controlled variables. Figure 14 shows the performances of the controlled and manipulated variables for a +2.5% change in the reactor temperature (Y1) (see Fig. 14a). It can be observed that both the PI and MPC controllers can track the reactor temperature with a settling time of 7.2 and 15 min, respectively. However, the MPC controller has an overshoot despite only having a small fluctuation of 0.5°C in the reactor temperature. The change in the reactor temperature significantly disturbed the product gas flowrate (Y2) causing it to deviate away from its desired steady-state value. Even though the MPC controller undergoes an overshoot, it reacts faster than the PI controller in removing the disturbance in the product gas flowrate stream (see Fig. 14b).

The horizontal dash lines in Fig. 14 constitute a tolerance band of ±0.0075% in magnitude. The tolerance range is the difference between the upper and the lower specification limits. The controller is considered to have effectively rejected the disturbance effects on the system if the system returns to the tolerance band within 15 min of the disturbance being introduced. It is observed in Fig. 14b that the MPC controller rejects the disturbance with a maximum deviation of 0.01 and a settling time of 4.8 min. In comparison, a maximum deviation of 0.02 with a settling time of 9 min is observed for the PI controller. The corresponding ITAE values are tabulated in Table 7.

For a −2.5% change in the setpoint of Y1, the responses of the controlled variables in Fig. 15 show similar behavior as previously observed. It can be noted that even though a comparable performance is observed for both controllers for the −2.5% change in temperature, MPC settles relatively faster than the PI controller for both Y1 and Y2.

3.5.2 Reactor temperature Y 1 ±5%

The performance of PI and MPC controllers has been investigated with the higher value of ±5% step change in the reactor temperature. Figure 16 shows the performance of the MPC and PI controllers with a step change of +5% in the reactor temperature. The MPC initially caused an overshoot of 0.39% as shown in Fig. 16a; however, the MPC settled faster (9 min) than the PI controller (15 min). The disturbance rejection in Y2 in response to the +5% change in reactor temperature Y1 is as shown in Fig. 16b. It is observed that there is fluctuation in the MPC controller response; however, the settling time is similar to the PI controller.

For a −5% change in the setpoint of Y1, the responses of the controlled variables for both controllers are comparable as shown in Fig. 17. The quantitative analysis for the performances of PI and MPC controllers based on the ITAE performance index is presented in Table 8. For the overall performances in the ability to track the setpoint of both controlled variables for ±5% step changes, the MPC controller has 11.9% and 20.7% lower error in the ITAE index in comparison to the PI controller. The ITAE values obtained for the +5% step change for the MPC and PI controllers are 83.3 and 94.6 respectively, while for the −5% step change the ITAE values are 67.0 and 84.6 respectively. А lower ITAE index value indicates а better performance of the controller. As the setpoint tracking target moves further away from the steady-state value, the PI controller is shown to have a slower response. Hence, it can be concluded that the MPC controller is relatively better, due to its lower settling time and its capabilities in handling interactions between the variables of the reactor, in contrast to the PI controller.

3.5.3 Product gas flowrate Y 2 ±5%

The performances of the reactor system for ±5% and ±10% setpoint tracking of the product gas flowrate are investigated. Figure 18 a shows the performances of the controlled and manipulated variables for a +5% change in the product gas flowrate (Y2). In Fig. 18a, it can be seen that both controllers can track the product gas flowrate with a settling time of 7 min for the MPC and 15 min for PI controller, respectively, in the product gas flowrate. However, the MPC controller has an overshoot of 0.5% but settled faster than the PI. Figure 18 b shows the corresponding effect observed in the reactor temperature (Y1) for the setpoint change in Y2. An observation of the change in the reactor temperature from 625.4 to 626.2°C is shown in Fig. 18b. The ITAE values obtained for +5% step changes for MPC and PI are 0.44 and 0.65 respectively, as shown in Table 9.

Similar behavior can be observed in Fig. 19 for a −5% change in Y2. The MPC controller is more aggressive than the PI, but it settled faster than the PI controller does. The ITAE values obtained for the −5% step changes (Fig. 19) for MPC and PI controllers are 0.43685 and 0.497845 respectively. А lower ITAE index value indicates а slightly better performance of the controller. Similarly, the IAE and ISE for MPC and PI are also reported in Table 9.

3.5.4 Product gas flowrate Y 2 ±10%

Figure 20 a depicts the performance of MPC and PI controllers with the higher step change of +10% in the product gas flowrate (Y2). It can be seen in Fig. 20a that for this large step change, both controllers are relatively sluggish in their responses. The MPC controller suffers an overshoot of 0.97% and settled after 12 min, whereas the PI controller settled in 15 min. It can be observed that both the controllers have performed well and comparable performances of MPC and PI controllers are observed.

Similarly, for a −10% change in the setpoint of Y2, the response of the controlled variables is in the opposite direction with comparable settling time and behavior as shown in Fig. 21. It is observed that the MPC controller settled in 10.8 min in comparison to PI which settled in 15 min. Moreover, the MPC controller rejects the disturbance with a maximum deviation of 0.03 and a settling time of 4.5 min. The performances of PI and MPC controllers based on the ITAE performance index are performed and reported in Table 10. The MPC controller has 8.9% and 8.7% lower error in the ITAE index in comparison to the PI controller for the ±10% step changes. The PI controller tends to have a slower response when the setpoint moves away from the steady-state value.

4 Conclusion

This paper aims to contribute to a better understanding of the dynamics and control of biomass gasification using PKS as a feedstock and coal bottom ash as a catalyst. In this paper, a dynamic model has been developed to replicate the biomass gasification performance of the actual plant using Aspen Plus® software. The pilot-scale gasification plant is used to perform a process optimization analysis for the gasification of PKS using coal bottom ash as a catalyst to assess the optimum conditions for producing the most H2 and syngas composition.

The aim of the control loops of the biomass gasification system is to maintain optimum operating conditions in the reactor system. The controlled and manipulated variables have been identified based on the insights obtained from the dynamic process behavior to maintain the desired optimum operating conditions of the system. A 2 × 2 linear MPC scheme is implemented, where the model identified using the Model Predictive Control Toolbox in MATLAB is a second-order plus time delay model. Pseudorandom binary sequence (PRBS) signals with different signal bandwidths are used to excite the biomass gasification system for the open-loop model identification.

To ensure the achievability of both the PI and MPC controllers, the system is investigated with 2.5%, 5%, and 10% step changes in the controlled variables. Quantitative analysis for the performances of the PI and MPC controllers in their ability to track the setpoint of both the controlled variables based on the Integral Absolute Error (IAE) performance index is performed. It can be observed that, for the biomass gasifier studied, both the PI and MPC controllers are relatively comparable in terms of their performances under the step changes introduced.

References

Kwon EE, Kim S, Lee J (2019) Pyrolysis of waste feedstocks in CO2 for effective energy recovery and waste treatment. J CO2 utilization 31:173–180

Verma OP, Manik G, Sethi SK (2019) A comprehensive review of renewable energy source on energy optimization of black liquor in MSE using steady and dynamic state modeling, simulation and control. Renew Sust Energ Rev 100:90–109

Bílková T, Fridrichová D, Pacultová K, Karásková K, Obalová L, Haneda M (2021) Reaction mechanism of NO direct decomposition over K-promoted Co-Mn-Al mixed oxides–DRIFTS, TPD and transient state studies. J Taiwan Inst Chem Eng 120:257–266

Chen H, Lu X, Wang H, Sui D, Meng F, Qi W (2020) Controllable fabrication of nitrogen-doped porous nanocarbons for high-performance supercapacitors via supramolecular modulation strategy. J Energy Chem 49:348–357

Naradasu D, Long X, Okamoto A, Miran W (2020) Bioelectrochemical systems: principles and applications. In: Bioelectrochemical Systems. Springer, pp 1–33

M. Hussain, H. Zabiri, F. Uddin, S. Yusup, and L. D. Tufa, Pilot-scale biomass gasification system for hydrogen production from palm kernel shell (part A): steady-state simulation, Biomass Conversion and Biorefinery, 2021/04/02 2021, doi: https://doi.org/10.1007/s13399-021-01474-1.

Hussain M, Dendena Tufa L, Yusup S, Zabiri H (2019) Thermochemical behavior and characterization of palm kernel shell via TGA/DTG technique. Materials Today: Proceedings 16:1901–1908, 2019/01/01/. https://doi.org/10.1016/j.matpr.2019.06.067

Mohammadidoust A, Omidvar MR (2020) Simulation and modeling of hydrogen production and power from wheat straw biomass at supercritical condition through Aspen Plus and ANN approaches. Biomass Conversion and Biorefinery:1–17

Li B et al (2020) Simulation of sorption enhanced staged gasification of biomass for hydrogen production in the presence of calcium oxide. Int J Hydrog Energy 45(51):26855–26864

E. M. B. Aske, Design of plantwide control systems with focus on maximizing throughput, 2009

A. Faanes, Controllability analysis for process and control system design, 2003

J. Morud, Studies on the dynamics and operation of integrated plants, Dr. Ing. Thesis, Norwegian Univ. of Science and Technology, Trondheim, 1995

Hussain M, Tufa LD, Azlan RNABR, Yusup S, Zabiri H (2016) Steady state simulation studies of gasification system using palm kernel shell. Procedia engineering 148:1015–1021

Hussain M, Tufa LD, Yusup S, Zabiri H (2018) A kinetic-based simulation model of palm kernel shell steam gasification in a circulating fluidized bed using Aspen Plus®: a case study. Biofuels 9(5):635–646. https://doi.org/10.1080/17597269.2018.1461510

Inayat A, Inayat M, Shahbaz M, Sulaiman SA, Raza M, Yusup S (2020) Parametric analysis and optimization for the catalytic air gasification of palm kernel shell using coal bottom ash as catalyst. Renew Energy 145:671–681

Xu G, Murakami T, Suda T, Kusama S, Fujimori T (2005) Distinctive effects of CaO additive on atmospheric gasification of biomass at different temperatures. Ind Eng Chem Res 44(15):5864–5868

Florin NH, Harris AT (2007) Hydrogen production from biomass coupled with carbon dioxide capture: the implications of thermodynamic equilibrium. Int J Hydrog Energy 32(17):4119–4134

Kong M, Fei J, Wang S, Lu W, Zheng X (2011) Influence of supports on catalytic behavior of nickel catalysts in carbon dioxide reforming of toluene as a model compound of tar from biomass gasification. Bioresour Technol 102(2):2004–2008

Khan Z, Yusup S, Ahmad MM, Rashidi NA (2014) Integrated catalytic adsorption (ICA) steam gasification system for enhanced hydrogen production using palm kernel shell. Int J Hydrog Energy 39(7):3286–3293

Herguido J, Corella J, Gonzalez-Saiz J (1992) Steam gasification of lignocellulosic residues in a fluidized bed at a small pilot scale. Effect of the type of feedstock. Ind Eng Chem Res 31(5):1274–1282

Roh K, Lee JH (2014) Control structure selection for the elevated-pressure air separation unit in an IGCC power plant: self-optimizing control structure for economical operation. Ind Eng Chem Res 53(18):7479–7488

Robinson PJ, Luyben WL (2008) Simple dynamic gasifier model that runs in Aspen Dynamics. Ind Eng Chem Res 47(20):7784–7792

Garelli F, Mantz R, De Battista H (2006) Limiting interactions in decentralized control of MIMO systems. J Process Control 16(5):473–483

Mahapatra P, Bequette BW (2012) Design and control of an elevated-pressure air separations unit for IGCC power plants in a process simulator environment. Ind Eng Chem Res 52(9):3178–3191

Abrol S, Hilton CM (2012) Modeling, simulation and advanced control of methanol production from variable synthesis gas feed. Comput Chem Eng 40:117–131

S. Farhana, M. Elsaadany, and H.-u. Rehman, An optimal stand-alone solar streetlight system design and cost estimation, in 2021 6th International Conference on Renewable Energy: Generation and Applications (ICREGA), 2021: IEEE, pp. 248-252

F. Uddin, S. A. Taqvi, and I. Memon, Process simulation and sensitivity analysis of indirect coal gasification using Aspen Plus® model, 2006

V. D. P1 and S. G. A. Design for modeling and control of temperature process in downdraft gasifier system: simulation studies, International Journal of Pure and Applied Mathematics. vol. Volume 117 No. 10 2017, 13-17, no. ISSN: 1311-8080 (printed version); ISSN: 1314-3395 (on-line version) url: http://www.ijpam.eu doi: 10.12732/ijpam.v117i10.3 Special Issue 2017.

Saade E, Clough DE, Weimer AW (2014) Model predictive control of a solar-thermal reactor. Sol Energy 102:31–44

R. Agustriyanto and J. Zhang, Control structure selection for the ALSTOM gasifier benchmark process using GRDG analysis, 2006

Wahid A, Taqwallah H (2018) Model predictive control based on system re-identification (MPC-SRI) to control bio-H2 production from biomass. In: IOP Conference Series: Materials Science and Engineering, vol 316, no. 1. IOP Publishing, p 012061

V. Kalaichelvi, R. Ganesh Ram, and R. Karthikeyan, Biomass boiler drum water level control system using neural networks, in Applied Mechanics and Materials, 2014, vol. 541: Trans Tech Publ, pp. 1260-1265

Gandhi AS, Kannadasan T, Suresh R (2012) Biomass downdraft gasifier controller using intelligent techniques. Gasification for Practical Applications:107–128

Al Seyab R, Cao Y, Yang S-H (2006) Predictive control for the ALSTOM gasifier problem. IEE Proceedings-Control Theory and Applications 153(3):293–301

Shahbaz M, Yusup S, Inayat A, Patrick DO, Ammar M, Pratama A (2017) Cleaner production of hydrogen and syngas from catalytic steam palm kernel shell gasification using CaO sorbent and coal bottom ash as a catalyst. Energy Fuel 31(12):13824–13833

Liu R, Graebner M, Tsiava R, Zhang T, Xu S (2021) Simulation analysis of the system integrating oxy-fuel combustion and char gasification. J Energy Res Technol 143(3):032304

Darman NH, Harun A (2006) Technical challenges and solutions on natural gas development in Malaysia, In The petroleum policy and management project, 4th Workshop of the China-Sichuan Basin Study. Beijing, China

N. H. Darman and A. R. B. Harun, Technical challenges and solutions on natural gas development in Malaysia, In The petroleum policy and management project, 4th Workshop of the China-Sichuan Basin Study, Beijing, China, 2006

Luyben WL (2006) Control of a multiunit heterogeneous azeotropic distillation process. AICHE J 52(2):623–637

Uddin F, Tufa LD, Shah Maulud A, Taqvi SA (2018) System behavior and predictive controller performance near the azeotropic region. Chem Eng Technol 41(4):806–818

Nittaya T, Douglas PL, Croiset E, Ricardez-Sandoval LA (2014) Dynamic modelling and control of MEA absorption processes for CO2 capture from power plants. Fuel 116:672–691

Sahraei MH, Ricardez-Sandoval L (2014) Controllability and optimal scheduling of a CO2 capture plant using model predictive control. Intern J Greenhouse Gas Cont 30:58–71

Liao P et al (2018) Application of piece-wise linear system identification to solvent-based post-combustion carbon capture. Fuel 234:526–537

B. Dai, X. Wu, X. Liang, and J. Shen, Model predictive control of post-combustion CO 2 capture system for coal-fired power plants, In 2017 36th Chinese Control Conference (CCC), 2017: IEEE, pp. 9315-9320.

Zhang Q, Turton R, Bhattacharyya D (2016) Development of model and model-predictive control of an MEA-based postcombustion CO2 capture process. Ind Eng Chem Res 55(5):1292–1308

Moghadam RA, Yusup S, Azlina W, Nehzati S, Tavasoli A (2014) Investigation on syngas production via biomass conversion through the integration of pyrolysis and air–steam gasification processes. Energy Convers Manag 87:670–675

Acknowledgements

The authors gratefully acknowledge the financial grant from Universiti Teknologi PETRONAS.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hussain, M., Zabiri, H., Uddin, F. et al. Pilot-scale biomass gasification system for hydrogen production from palm kernel shell (part B): dynamic and control studies. Biomass Conv. Bioref. 13, 8173–8195 (2023). https://doi.org/10.1007/s13399-021-01733-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01733-1