Abstract

This paper mainly introduces the potential of methane yield from co-digestion of primary sludge (PS) and the proposed new waste materials of sugarcane leaves (SL) and Corchorus stalks (CS) in Egypt. This paper includes three parts. In the first part, anaerobic co-digestion of PS, SL, and CS at different carbon-to-nitrogen (C/N) ratios was studied to determine the best C/N ratio. The results indicated that the maximum cumulative methane yields (CMYs) were observed at a C/N ratio of 18, which was associated with the highest volatile solid (VS) removal rate (74.41%). In the second part, the effect of using two types of inoculum (fresh cow manure (CM) and rumen content from slaughterhouses (RS)) on increasing the production of methane was investigated. Clearly, using CM as inoculum showed a superiority of the production of methane from co-digestion of PS, SL, and CS. The maximum CMYs were observed using the CM as inoculum from co-digestion of PS, SL, and CS. It was higher about 1.26 times more CMY using RS as inoculum. In the third part, the possibility of enhancing biogas yields from semi-continuous co-digestion of PS, SL, and CS using different organic loading rates (OLR) of 0.5, 1.0, and 2.0 was conducted. The highest biogas production rate was observed at an OLR of 1.0 gVS/(Lreactor.d) that coincided with the optimum VS removal rate. Statistical analysis of the results was conducted using analysis of variance (ANOVA) test, and the C/N ratio of 18 is statistically the best enhanced ratio. Overall, the feasibility of maximizing the methane productivity considering the anaerobic co-digestion of PS, SL, and CS under the optimal operating conditions and configuration was proved.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Most sensitive problems facing the sustainable development of Egyptian society are lack of energy sources and the treatment of their sewage sludge (SS), livestock rumen contents from slaughterhouses, and crop residues in an environmental-friendly manner [1, 2]. Currently, Egypt has 303 wastewater treatment plants that treat 11.85 Mm3 of sewage sludge containing around 2400 t/day of dry solids daily [3]. Each year, great amounts of SS are disposed of in a conventional manner such as landfilling and incineration. In many countries, landfilling and incineration are not a suitable solution due to environmental contamination, land scarcity, and leachate emissions [4].

On the other hand, the amount of agricultural wastes in Egypt is estimated at approximately 35 Mt per year [5]. Agricultural wastes are primarily disposed of through burning, which can have critical environmental repercussions. Sugarcane is one of Egypt’s key strategic agricultural products. It occupies the second important status after wheat and mainly is grown in upper Egypt [6]. Corchorus is also an extremely popular Egyptian green vegetable. Anaerobic digestion (AD) has the ability to reduce the environmental burden and convert crop residues [7], sewage sludge [8], and animal wastes [9] into biogas, which is used for generating electricity.

Carbon-to-nitrogen (C/N) ratio is an important indicator for microbial growth in AD and biological treatment systems. Co-digestion of various plant materials with organic waste enhances the C/N ratio of the feedstock and supplies a wide range of nutrients [10].

Most of the previous studies that investigated anaerobic digestion of various substrates were focused on the effect of the C/N ratio of the used feedstocks on improving biogas production [11, 12] and neglected the effect of the C/N ratio of inoculum. The novelty of this paper is to study the influence of the C/N ratio of the used feedstock, without neglecting the C/N ratio of inoculum on the increase of methane yields.

Elsayed et al. [13] conducted anaerobic co-digestion of sewage sludge and wheat straw in a batch reactor under mesophilic condition, and the results showed that the maximum production of methane was observed at a C/N ratio of 15. Zhang et al.[14] reported that the co-digestion of the goat manure with rice straw or corn stalks greatly increased the production of biogas at C/ N ratios of 35, 21, and 16.

The source of inoculum plays an important role in the AD process [15]. Quintero et al. [16] showed that a higher methane yield was obtained in the reactor inoculated with a mixture of rumen liquid and pig waste sludge. By choosing a suitable inoculum, the production of biogas and the generation of methane from corn stover were improved by 15.5% and 10.8% respectively [17]. Several studies have employed rumen contents as a good inoculum for anaerobic digestion (AD) of a variety of lignocellulosic biomass, including agricultural residues [18], energy crops [16], and aquatic plants [19].

In recent years, Aboudi et al. [20]studied the effect of organic loading rate (OLR) for semi-continuous co-digestion of pig manure with sugar beet by-products, and the results showed that the optimal gas production was recorded at an OLR of 11.2 gVS/(Lreactor.d). Di Maria et al. [21]conducted co-digestion of sewage sludge with fruit wastes, and they observed that at a short hydraulic retention time (10 days), an enhancement in methane yield was occurred.

The novelty of the study aims at studying the possibility of increasing the production of methane from anaerobic co-digestion of PS and the proposed new waste materials of SL and CS in Egypt. The specific aims of this study were as follows: firstly, investigate the effect of the C/N ratios of the used substrates and inoculum on the co-digestion process emphasizing the optimum methane productivity; secondly, study the best type of inoculum (CM and RS) for the optimal gas production; finally, semi-continuous co-digestion of PS, SL, and CS considering the effect of various imposed OLR to highlight the potential methane enhancement was conducted.

2 Methodology

The research methodology of this paper was shown in Fig. 1.

2.1 Feedstock characteristics

Primary sludge (PS) substrate was obtained from the primary sedimentation tank of the Kima wastewater treatment plant, Aswan, Egypt. The Kima wastewater treatment plant is the activated sludge treatment plant. Sugarcane leaves (SL) and Corchorus stalks (CS) were collected from a local farming area at city of Qift, Egypt, then dried at room temperature. To minimize the size of the SL and CS, they were grinded and brought up to the size of less than 1.0 mm by using a house grinder. The suggested good size for crop residues is ranged from 0.3 to 1.0 mm [22]. Feedstock characteristics that were used in BMP tests were indicated in Table 1. Sugarcane leaves (SL) and Corchorus stalks (CS) were rich in carbon content with proportions of 52.88% and 52.94% relative to their dry weights, while they have a low nitrogen content of 0.89% and 0.91%, respectively. On the other hand, primary sludge (PS) was distinguished by high nitrogen content with a percentage of 6% and with moderate carbon content of 45.72%. SL and CS have greater C/N ratios of 59.62 and 58.18, respectively, while PS has a low C/N ratio of 7.62. Accordingly, anaerobic co-digestion of PS with the agricultural waste of SL and CS will calibrate the C/N ratio of the mixture and improve the gas production[12]. Also, as shown in Table 1, SL and CS substrates have a high VS content of 89% and 86.61%, respectively. Also, PS has a high VS content (71.69%) which can lead to high biodegradability levels [23].

2.2 Inoculum

Two types of inoculum were utilized in this paper to obtain the optimal inoculum for the highest methane production. For the first type of inoculum, samples of fresh cow manure were collected from a small farm located in the city of Qift, Egypt. For the second type of inoculum, a sample of fresh rumen content of cattle from slaughterhouses was collected from the city of Qift central abattoir. Rumen contents were collected from cattle freshly slaughtered. Inoculum was stored in an anaerobic headspace under mesophilic condition (37°C) for over a month to remove the dissolved methane and residual organic matter contained in the inoculum [24].

2.3 Analytical techniques

pH, total solids, and volatile solids were measured according to the standard methods [25]. Total hydrogen, total oxygen, total carbon, and total nitrogen were measured by using a thermal conductivity detector (FLASH EA 1112). Water displacement method was used to measure the daily production of biogas (STP −105 Pa and 273.15 K). Table 1 displays the characteristics of feedstock and inoculum which were used in the biochemical methane potential (BMP) tests.

2.4 Experimental design

In this paper, three sets of experiments were carried out. Two experiment groups of batch tests were conducted in duplicate under mesophilic conditions (37 °C ± 1 °C) according to Mahmoud Elsayed et al.[26]. Batch reactors having a total volume of 500 mL (with a working volume of 400 mL) were used. In the first group of experiments, various mixtures of substrates of PS, SL, and CS with different C/N ratios were prepared to determine the best C/N ratio and are noted R1 to R5 in Table 2. Three extra anaerobic reactors that were referred as C1, C2, and C3 were used as controls for the individual digestion of PS, SL, and CS. The total VS organic load of the feedstock was set to be 7.50 gVS/L in each digester of this group [27]. In the second group of experiments, two various types of inoculums (cow manure and rumen content from slaughterhouses) were used to evaluate the optimal inoculum in anaerobic co-digestion of PS, SL, and CS using the best C/N ratio, which was obtained from the first experiment in anaerobic reactors referred as B1 and B2, respectively, as shown in Table 3.

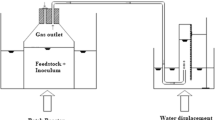

The temperature in all the reactors (37 °C ± 1 °C) was adjusted using a water bath. The value of pH was adjusted to be 7 ± 0.1 in all the reactors before beginning the experiments, by adding six moles of sodium hydroxide (NaOH). Each reactor’s headspace was flushed with nitrogen gas (N2) for 2 min to create an anaerobic condition. Batch reactor setup was illustrated in Fig. 2. At the end of each experiment, all the reactor’s digestion residue was sampled for the calculation of TS and VS. The removal of VS was determined using the following equation:

where VS Removal is the removal of volatile solids for the feedstock utilized, VS Initial (g/L) is the influent volatile solids for the feedstock utilized, and VS Finial (g/L) is the effluent volatile solids for the feedstock utilized.

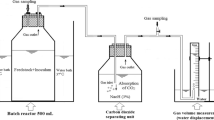

In the third experiment, semi-continuous co-digestion tests of PS, SL, and CS were conducted under mesophilic conditions (37 ± 1 °C). A semi-continuous reactor with working and total volume of 13 L and 20 L, respectively, was used. Figure 3 shows the schematic diagram of the semi-continuous reactor. Three various organic loading rates (OLR) of 0.5, 1.0, and 2.0 gVS/(Lreactor.d) for a constant retention time of 30 days were used. Table 4 shows characteristics of the various tested OLR for semi-continuous co-digestion of PS, SL, and CS. According to the first and second experiments, the mixture of the feedstocks was prepared at optimum C/N ratio and best inoculum. The system was started up as a batch reactor for 10 days to achieve an active acidifying culture by loading the only inoculum to the reactor. Semi-continuous feeding for the reactor started from day 10, where 0.43 L of digested substrates was withdrawn daily from the reactor and replaced with fresh substrates (feedstock + tap water) to maintain the retention time of 30 days.

3 Results and discussion

3.1 Anaerobic co-digestion of PS, SL, and CS at various C/N ratios

3.1.1 Methane production from individual digestion of PS, SL, and CS

Daily production of methane from co-digestion of primary sludge (PS), sugarcane leaves (SL), and Corchorus stalks (CS) at various C/N ratios is presented in Fig. 4. For the PS substrate, the highest values of the daily production of methane were eventuated on the 5th day (8.05 mL/gVSadded) and the 9th day (9.20 mL/gVSadded), whereas for SL, the highest values for the daily production of methane were eventuated on the 2nd day (9.43 mL/gVSadded) and the 5th day (15.33 mL/gVSadded). Finally, the highest daily methane production values of CS occurred on the 2nd day (14.49 mL/gVSadded) and the 3rd day (18.86 mL/gVSadded). For all the mixing ratios, the majority of daily methane production occurred during the first days of the test due to easily degradable organic substances and as a result of the grinding process that occurred for the used feedstock (high solid concentration, carbohydrates, proteins, fats, among others)[28]. The two highest peaks of the daily methane yield of CS and SL are higher than the highest peak of the PS, which could be attributed to the small particle size of CS and SL, which is very simple to digest for micro-organisms [29]. It was noted that methane productions from individual digestion of PS, SL, and CS were reduced daily until there was no methane production. This is expected since the rate of reaction generally decreases with time due to a reduction in the concentration of active substrates [30].

At the end of 30 days of anaerobic digestion, the cumulative methane yields (CMYs) observed from individual digestion of SL (164.37 mL/gVSadded) were about 1.63 times greater than that from PS (101.13 mL/gVSadded) and about 1.39 times greater than that from CS (118.35 mL/gVSadded). This may be due to the higher TC content of SL (52.88%) than the other used feedstock. Inyang et al.[31] studied anaerobic digestion of sugarcane bagasse, and the results showed 74.67 mL/gVSadded of methane after 40 days. The results of this study indicate that the primary sewage sludge that has been used is poorly anaerobically digestible so it is essential to co-digest with other agricultural wastes[32]. This might be due to a low C/N ratio as its inherent deficiency of carbon [33] that results in an increase in pH values and ammonia accumulation, which is toxic to methanogenic bacteria [34]. Also, PS consists of fiber and different solid particles that settle in the primary sedimentation tank of wastewater treatment plants and are not feasible for biodegradation [35], so it is preferable to co-digest carbon-rich wastes as agriculture residues with nitrogen-rich primary sludge (PS) from primary clarifiers to moderate probable effects of ammonia inhibition and beat nutrient reduction in terms of carbon.

3.1.2 Methane production from co-digestion of PS, SL, and CS

As observed from Fig. 4, the peak values of the daily methane yield from co-digestion of PS, SL, and CS at C/N ratios of 35, 30, 25, 21, and 18 occurred on the 8th day (20 mL/gVSadded), the 22nd day (28 mL/gVSadded), the 13th day (27.6 mL/gVSadded), the 21st day (30.67 mL/gVSadded), and on day 20th (36.8mL/gVSadded), respectively. These maximum peaks are higher than the peak values of the individual digestion of PS, SL, and CS. The highest peaks of methane production were obtained at C/N ratios of 18 and 21. This may be due to the balanced nutrients in the feedstock at these C/N ratios, which improved the methanation process and bacterial growth [36].

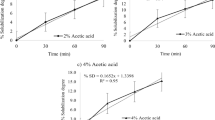

Cumulative methane yields (CMYs) from co-digestion of PS, SL, and CS are shown in Fig. 5. From the figure, CMYs from co-digestion of PS, SL, and CS at C/N ratios of 35, 30, 25, 21, and 18 were 190.13, 233.06, 220.80, 276, and 297.46 mL/gVSadded, respectively, which presented a higher methane production of 1.88, 2.30, 2.18, 2.73, and 2.94 times than digesting PS alone, respectively, and higher methane yield of 1.16, 1.42, 1.34, 1.68, and 1.81 times than digesting SL alone, respectively. Also, it showed a higher methane production of 1.61, 1.97, 1.87, 2.33, and 2.51 times than digesting CS alone, respectively. This may be due to the co-digestion of PS, SL, and CS based on their C/N ratios is an essential way to increase the biodegradability of the feedstock and production of methane [37]. Mixing various feedstocks in anaerobic digestion based on their C/N ratios enhances anaerobic digestion performance and heavily improves biogas production [38]. Also, the methane production was decreased at the highest percentage of C/N ratio, because of the higher rate of consuming the nitrogen from acidogenic bacterium than the consumption of nitrogen from methanogenic bacteria [39]. This result agrees with precedent studies; Wu et al. [40] concluded that at all C/N proportions, all crop residues greatly increased the production of biogas and net volume of methane. Zhang et al.[7] reported that anaerobic co-digestion of goat manure with rice straw or corn stalks at various C/N ratios improved biogas production.

In this study, maximum CMYs were recorded at a C/N ratio of 18 with an improvement of 22%, 12%, 15%, and 4% compared with the other C/N ratios of 35, 30, 25, and 21, respectively. These maximum CMYs were higher than the highest methane yield estimated by Siddiqui et al.[41] who estimated a production of biomethane from industrial food waste (IFW) with sewage sludge of 239 mL/gVSremoved at a C/N ratio of 15. On the other hand, the maximum CMYs were less than the value of CMYs (481.1 mL/gVSadded) obtained from co-digestion of sludge, wheat straw, and buckwheat husk at a C/N ratio of 10.07 [27]. The ideal C/N ratio of 18 (which was obtained from this study) matches with the optimum range (from 9.0 to 30.0) for anaerobic digestion[41]. Previous studies bolster the results obtained in from this work. Yen and Brune [42] proposed for co-digestion of algal sludge with wastepaper an ideal C/N ratio of 18. Elsayed et al.[13] studied co-digestion of wheat straw and primary sludge and reported that the best C/N ratio was 15. Sievers and Brune [43] suggested that a C/N ratio of 16 was the optimal ratio for anaerobic co-digestion of sewage sludge mixtures with paper pulp. The second highest CMYs were detected at a C/N ratio of 21 (276 mL/gVSadded), which matches with Rizk et al. [11] who reported that anaerobic co-digestion of fruit and vegetable wastes with sewage sludge significantly enhanced biogas production at a C/N ratio of 20. Also, the optimal C/N ratio from co-digestion of swine manure with corn stalks was obtained at a C/N ratio of 20 [40]. The highest cumulative methane productions that occurred at C/N ratios of 18 and 21 can be explained by two reasons. Firstly, the C/N ratios of 18 and 21 contain a low percentage of agricultural residues (SL and CS) relative to the other ratios, so lignin is minimum. In anaerobic digestion operation, lignin is regarded as the least degradable substrate of all agricultural residues [40]. Secondly, these C/N ratios contain a higher content of PS substance, which is digested easily [44]. The minimum CMYs were at a C/N ratio of 35 (190.13 mL/gVS). This decrease may be due to the small quantity of PS, which is digested easily.

Many of the previous studies, which investigated anaerobic co-digestion of different substrates on improving biogas production, were focused on the effect of the C/N ratio of the used feedstocks without adding the C/N ratio of the inoculum (Elsayed et al., 2015; Yen and Brune, 2007). In this paper, the effect of the C/N ratio of the used feedstock and inoculum on improving methane yields was studied. The highest cumulative methane yields (CMYs) occurred at a C/N ratio of 18, if we calculated the C/N ratio of the used feedstock and inoculum, while the highest CMYs occurred at a C/N ratio of 10 if we calculated the C/N ratio of the used feedstock without adding the C/N ratio of the inoculum. Finally, it is better to calculate the C/N ratio of the used feedstock and inoculum to be more accurate.

3.1.3 VS removal and pH from co-digestion of PS, SL, and CS

Volatile solid (VS) removal rate and pH from co-digestion of PS, SL, and CS are shown in Table 5. The percentage of VS removal rate from individual digestion of PS, SL, and CS was ranged from 40.52 to 49.32%. The percentages of VS removal rate from individual digestion of SL and CS were greater than the percentage of VS removal rate of digesting PS alone. This can be transferred to easily digest SL and CS in the anaerobic digestion process because of their small particle size. Furthermore, the particular cell structure of PS may also be an explanation for the lower VS removal rate [45]. The maximum removal ratios of VS for the anaerobic co-digestion of PS, SL, and CS were achieved at C/N ratios of 18 and 21 with values of 74.41 and 66.26%, respectively (Table 5). In contrast, the least VS removal rate was exhibited to be 30.52% at a C/N ratio of 35. These results support and confirm the findings of this paper concerning the minimum and maximum values of CMYs that were observed at C/N ratios of 35 and 18, respectively.

pH is a significant parameter affecting anaerobic digestion operation and the growth of microorganisms, so it should be kept at stable rates [46]. Various pH levels are necessary for the two stages of acidification and methanogenesis in an anaerobic digestion process. At a pH value ranging from 6.5 to 8.0, methanogenic microorganisms can markedly generate biogas and methane [47]; however, pH has a harmful impact when it is over 8.5 [48]. In this paper, the value of initial pH was modified for all reactors using six moles of sodium hydroxide solution (NaOH) to a value of 7 ± 0.1. There is a rise in the pH level at the end of the BMP test, and it was noticed in the range of 7.38 to 7.66.

3.1.4 Statistical analysis for CMYs from co-digestion of PS, SL, and CS

This procedure performs a one-way analysis of variance and constructs various tests and graphs to compare the mean values of cumulative methane yields for the five different levels of C/N. Table 6 presents the different C/N ratios and cumulative methane yields obtained during trials 1 and 2 from the co-digestion of PS, SL, and CS. Since the P value of the F-test is less than 0.05, there is a significant difference statistically between the mean cumulative methane yields from one level of C/N ratio to another at the 95.0% confidence level. The C/N ratio of 18 is statistically the best enhanced ratio (Fig. 6).

3.2 Stoichiometric methane (Bo) yield of the samples

3.2.1 Base of empirical formula

The empirical formula was established on the basis of the carbon, hydrogen, oxygen, and nitrogen content of the sample, following the method described by Murphy and Thamsiriroj[49]. The following table presents the stoichiometric description and the maximum methane stoichiometric potential of each sample.

The stoichiometric description of primary sludge (PS), sugarcane leaves (SL), Corchorus stalks (CS), and mixtures of PS, SL, and CS at a ratio of carbon to nitrogen equal to 18 (C/N 18) was C9H12O4N, C69H55O40N, C68H85O42N, and C12H15O6N, respectively (Table 7).

3.2.2 Stoichiometric methane yield and experimental methane potential of each sample

For individual digestion of PS, SL, and CS, Bo yields vary from one sample to another. Low stoichiometric methane (Bo) yield of SL may be correlated with low lipid levels. For the mixture of PS, SL, and CS (at C/N 18), Bo verified the good behavior of the microbial flora in the inoculum used. As shown in Table 8, the Bo value obtained from a C/N ratio of 18 was higher than the experimental CMY value (which were observed from the BMP test at a C/N ratio of 18). The disparity between the theoretical Bo yield and experimental methane yield from the BMP test is attributable to the fact that the estimated theoretical methanogenic potential Bo neglects a number of factors such as non-degradable material and energy demand of the microbes. The practical performance of a biogas reactor would often be lower than the theoretical performance of a biogas reactor [50].

3.3 Anaerobic co-digestion of PS, SL, and CS using different types of inoculum

3.3.1 Methane production from anaerobic co-digestion of PS, SL, and CS utilizing different types of inoculum

Daily production of methane (CH4) from co-digestion of PS, SL, and CS using different types of inoculums (cow manure and rumen content from slaughterhouses) is illustrated in Fig. 7. Maximum daily CH4 yields from individual digestion of cow manure (CM) and rumen content from slaughterhouses (RS) were 23.77 and 12.27 mL/gVS on the 15th and 2nd days, respectively. The highest values of CH4 from mono-digestion of feedstock using RS as inoculum occurred earlier than CM as inoculum. This may be due the growth of microorganisms in rumen content from RS is more than that of cow manure [51].

Cumulative methane yields (CMYs) from anaerobic co-digestions of PS, SL, and CS using different types of inoculum are represented in Fig. 8. CMYs obtained from individual digestion of CM as inoculum (207 mL/gVSadded) were approximately 2.18 times higher than that from individual digestion of RS as inoculum (95.07 mL/gVSadded). This may be due to CM is rich in organic materials and nutrients [52]. The maximum CMYs from anaerobic co-digestion of PS, SL, and CS were observed using CM as inoculum (297.46 mL/gVSadded). It was higher about 1.26 times CMYs using RS as inoculum (236.13 mL/gVSadded). The rate of methane production was increased by decreasing the C/N from 20.7 to 18. A high C/N ratio leads to deficiency in the AD system, since it indicates rapid consumption of nitrogen by methanogens and leads to lower gas production. This agrees with the results of other authors. Molnar and Bartha[53] showed that manure is a perfect inoculum due to its high buffering capacity and nutrients. Also, El-Mashad and R. Zhang [54] improved biogas production by mixing cow dung with organic wastes.

3.3.2 VS removal rate and pH values

As shown in Table 9, the maximum removal rate of VS from anaerobic co-digestion of PS, SL, and CS using different types of inoculum was observed at cow manure as inoculum. In contrast, the least removal rate of VS was obtained by using rumen content as inoculum.

At the end of the BMP tests, pH values were steady and varied from 7.43 to 7.86. The stable pH range affords a suitable condition for methanogenic microorganisms for producing a high methane yield [47].

Eventually, the results from this work showed that the optimal C/N ratio for anaerobic co-digestion of PS, SL, and CS was 18 that generated highest methane production. On the other hand, the ideal type of inoculum for the optimal production of methane gas was cow manure (as inoculum), which can improve the production of methane and the performance of the reactor.

3.4 Semi-continuous co-digestion of PS, SL, and CS

3.4.1 Effect of OLR on biogas production

The volatile solids that fed into the anaerobic reactor has an extreme effect on biogas and methane production. Daily biogas production from semi-continuous co-digestion of PS, SL, and CS under mesophilic conditions at different OLR is shown in Fig. 9. From the figure, the maximum values of the daily biogas yield from semi-continuous co-digestion of PS, SL, and CS were found to be 5.70, 16.80, and 10.66 L/d at OLRs of 0.5, 1.0, and 2.0, respectively. While, low biogas production was observed at start-up period (Run 0) because the reactor was fed only with inoculum and bacteria take time to adapt to the temperature and environment conditions. Daily biogas yield was improved with the increase in OLR to achieve the optimum value at an OLR of 1 gVS/(Lreactor.d). But the increase of OLR to 2.0 gVS/(Lreactor.d) led to a little detraction in biogas production. It was probably due to high volatile fatty acids (VFA) because of the accumulation of the substrate’s organic content at high OLR so that anaerobic bacteria activity was low and therefore low production of biogas [55]. The highest value of production of biogas was observed at an OLR of 1 gVS/(Lreactor.d), which provides a proper environment for bacteria to increase and transform the carbon content of the feedstock to biogas. This result matches with the previous studies; Edström et al. [51] mentioned that a stable co-digestion process of animal by-products, stomach content, sludge, and food waste was difficult to operate at an OLR above 1 gVS/ (Lreactor.d).

The average production rate of biogas for the different used organic loading rates (OLR) is shown in Fig. 10. From the figure, the highest average production rate of biogas was recorded at an OLR of 1 gVS/(Lreactor.d), while the minimum average production rate of biogas was recorded at an OLR of 0.5 (Run 1) because of using low organic loads. The anaerobic digestion process does not run effectively for the reason that bacteria will exhibit low activity of metabolism, so lower rates of gas will be generated [56]. These results match with the literature review that showed at lower OLR, the AD was inefficient and enhanced with a rise in OLR; while the OLR increased beyond the range, the biogas yield fell dramatically and the system failed [57].

3.4.2 Effect of OLR on the evolution of VS and pH characteristics of the digested feedstock

Removal rates of volatile solids (VS) and pH profiles from semi-continuous co-digestion of PS, SL, and CS at various OLR are shown in Fig. 11. The highest removal rate of VS for the co-digestion of PS, SL, and CS was observed at the OLR of 1.0 (69.93%), while the lowest VS removal rate was recorded at an OLR of 0.5 gVS/(Lreactor.d) with a value of 49.53%. In general, the average removal rates of VS during the three tests of OLR ranged from 56.92 to 69.93%.

The pH of the effluent of a semi-continuous reactor shows the stability of the anaerobic process and its variation based on the buffering capacity of the system [58], so pH should be at a stable range [59]. The average removal of volatile solids rate and pH from semi-continuous co-digestion of PS, SL, and CS at various OLR is shown in Fig. 12. The average pH from semi-continuous co-digestion of PS, SL, and CS at the start of the startup stage (Run 0) was 6.41. After that, the pH increased from 6.41 to 6.65 at Run 1. During the loading rate of 1.0 gVS/(Lreactor.d), the average pH value was increased above 7 to be 7.16. This means that the system was well buffered. The average pH value increased from 7.16 to a value of 7.38 when the loading rate was increased to 2 gVS/(Lreactor.d), which was also above 7 which was in the methanogenic range. Sibiya and Muzenda [47] reported that at a pH value ranged from 6.5 to 8, the methanogenic microorganisms can generate biogas effectively. The stability of pH during the loading rates Run 1, Run 2, and Run 3 indicated that the digester operated under ideal conditions for the production of methane despite increasing OLR [20].

4 Conclusions

This study investigated the capability of enhancing production of methane from anaerobic co-digestion of primary sludge (PS), sugarcane leaves (SL), and Corchorus stalks (CS). Three experiment groups were conducted in this study; in the first experiment, various mixtures of PS, SL, and CS depending on their C/N ratios were prepared to obtain the best C/N ratio and study the effect of adding the C/N ratio of inoculum to the used feedstock for the optimal methane production. The maximum cumulative methane yield (CMY) and maximum removal rate of VS were observed at a C/N ratio of 18, which was greater than the other C/N ratios. This may be due to the C/N ratio of 18 including a low percentage of agricultural residues (contain lignin), which are considered as the least degradable substrate. In contrast, the least CMYs and minimum removal rate of VS were noticed at a C/N ratio of 35. In the second part, the effect of inoculum type (fresh cow manure and rumen content from slaughterhouses) on improving methane production was conducted to determine the ideal inoculum. The maximum CMYs and removal rate of VS from anaerobic co-digestions of PS, SL, and CS (utilizing two different types of inoculum) were obtained using the cow manure as inoculum because cow manure could provide buffering capacity and a wide range of nutrients. In the third experiment, semi-continuous co-digestion of PS, SL, and CS using different organic loading rates (OLR) was conducted. The greatest biogas production was obtained at an OLR of 1.0 gVS/(Lreactor.d), which provides a proper environment for bacteria to increase and transform the carbon content of the feedstock to biogas. The highest biogas production rate was associated with the highest volatile solids (VS) removal rate. Finally, co-digestion of PS, SL, and CS based on their C/N proportion can appreciably enhance the biodegradability of the feedstock and hence methane yields.

Abbreviations

- AD:

-

Anaerobic co-digestion

- BMP:

-

Biochemical methane potential

- C/N:

-

Carbon-to-nitrogen ratio

- CM:

-

Cow manure

- CMYs:

-

Cumulative methane yields

- CS:

-

Corchorus stalks

- OLR:

-

Organic loading rate

- PS:

-

Primary sludge

- RS:

-

Rumen content from slaughterhouses

- SL:

-

Sugarcane leaves

- SS:

-

Sewage sludge

- TS:

-

Total solids

- TC:

-

Total carbon

- TN:

-

Total nitrogen

- TO:

-

Total oxygen

- VS:

-

Volatile solids

References

Rizzardini CB, Goi D (2014) Sustainability of domestic sewage sludge disposal. Sustain. 6(5):2424–2434. https://doi.org/10.3390/su6052424

Abou Hussein SD, Sawan OM (2010) The utilization of agricultural waste as one of the environmental issues in Egypt (a case study). J Appl Sci Res 6(8):1116–1124

Ghazy M, Dockhorn T, Dichtl N (2009) Sewage sludge management in Egypt: current status and perspectives towards a sustainable agricultural use. World Acad Sci Eng Technol 57:492–500

Elsayed M, Pena J, Villot A, Gerente C, Andres Y (2017) Energy potential from buckwheat husks through a thermochem-ical and biochemical approaches, European biomass conference and exhibition proceedings, (25thEUBCE), pp. 1403–1405

Hassan HBA, el Gebaly MR, Ghani SSA, Hussein YMM (2014) An economic study of recycling agricultural wastes in Egypt. Middle East J Agric Res 3(3):592–608

Abdel-Maksoud BM (2012) “Sugarcane production in Egypt: synthesis of salient research findings,” in International Conference on:“New role for the world sugar economy in a changed political and economic environment.” Aswan, Egypt (pp. 10–13)

Zhang T, Liu L, Song Z, Ren G, Feng Y, Han X, Yang G (2013) Biogas production by co-digestion of goat manure with three crop residues. PLoS One 8(6):1–7. https://doi.org/10.1371/journal.pone.0066845

Zhang W, Wei Q, Wu S, Qi D, Li W, Zuo Z, Dong R (2014) Batch anaerobic co-digestion of pig manure with dewatered sewage sludge under mesophilic conditions. Appl Energy 128:175–183. https://doi.org/10.1016/j.apenergy.2014.04.071

Møller HB, Sommer SG, Ahring BK (2004) Methane productivity of manure, straw and solid fractions of manure. Biomass Bioenergy 26(5):485–495. https://doi.org/10.1016/j.biombioe.2003.08.008

Sosnowski P, Wieczorek A, Ledakowicz S (2003) Anaerobic co-digestion of sewage sludge and organic fraction of municipal solid wastes. Adv Environ Res 7(3):609–616. https://doi.org/10.1016/S1093-0191(02)00049-7

Rizk MC, Bergamasco R, Tavares CRG (2007) Anaerobic co-digestion of fruit and vegetable waste and sewage sludge. Int J Chem React Eng 5(1):1–10. https://doi.org/10.2202/1542-6580.1439

Elsayed M, Blel W, Soliman M, Andres Y, and Hassan R (2021) Semi-continuous co-digestion of sludge, fallen leaves, and grass performance. Energy 221:119888. https://doi.org/10.1016/j.energy.2021.119888

Elsayed M, Andres Y, Blel W, Gad A (2015) Methane production by anaerobic co-digestion of sewage sludge and wheat straw under mesophilic conditions. Int J Sci Technol Res 4(6):1–6

Zhang G, Liu L, Song Z, Ren G, Feng Y, Han X, Yang (2013) Biogas production by co-digestion of goat manure with three crop residues. PLoS One 8(6):1–7. https://doi.org/10.1371/journal.pone.0066845

Forster-Carneiro T, Pérez M, Romero LI (2007) Composting potential of different inoculum sources in the modified SEBAC system treatment of municipal solid wastes. Bioresour Technol 98(17):3354–3366. https://doi.org/10.1016/j.biortech.2006.10.024

Quintero M, Castro L, Ortiz C, Guzmán C, Escalante H (2012) Enhancement of starting up anaerobic digestion of lignocellulosic substrate: Fique’s bagasse as an example. Bioresour Technol 108:8–13. https://doi.org/10.1016/j.biortech.2011.12.052

Li L, Yang X, Li X, Zheng M, Chen J, Zhang Z (2011) The influence of inoculum sources on anaerobic biogasification of NaOH-treated corn stover. Energy Sources, Part A Recover Util Environ Eff 33(2):138–144. https://doi.org/10.1080/15567030902937192

Okeh OC, Onwosi CO, Odibo FJC (2014) Biogas production from rice husks generated from various rice mills in Ebonyi State, Nigeria. Renew Energy 62:204–208. https://doi.org/10.1016/j.renene.2013.07.006

Yue ZB, Wang J, Liu XM, Yu HQ (2012) Comparison of rumen microorganism and digester sludge dominated anaerobic digestion processes for aquatic plants. Renew Energy 46:255–258. https://doi.org/10.1016/j.renene.2012.03.030

Aboudi K, Álvarez-Gallego CJ, Romero-García LI (2015) Semi-continuous anaerobic co-digestion of sugar beet byproduct and pig manure: effect of the organic loading rate (OLR) on process performance. Bioresour Technol 194:283–290. https://doi.org/10.1016/j.biortech.2015.07.031

Di Maria F, Sordi A, Cirulli G, Gigliotti G, Massaccesi L, Cucina M (2014) Co-treatment of fruit and vegetable waste in sludge digesters. An analysis of the relationship among bio-methane generation, process stability and digestate phytotoxicity. Waste Manag 34(9):1603–1608. https://doi.org/10.1016/j.wasman.2014.05.017

Yong Z, Dong Y, Zhang X, Tan T (2015) Anaerobic co-digestion of food waste and straw for biogas production. Renew Energy 78:527–530. https://doi.org/10.1016/j.renene.2015.01.033

Elango D, Pulikesi M, Baskaralingam P, Ramamurthi V, Sivanesan S (2007) Production of biogas from municipal solid waste with domestic sewage. J Hazard Mater 141(1):301–304. https://doi.org/10.1016/j.jhazmat.2006.07.003

Hansen TL et al (2004) Method for determination of methane potentials of solid organic waste. Waste Manag. https://doi.org/10.1016/j.wasman.2003.09.009

McCrady MH (1966) Standard methods for the examination of water and waste-water (12th ed.). Am J Public Heal Nations Heal 56(4):684–684. https://doi.org/10.2105/ajph.56.4.684-a

Elsayed M, Andres Y, Blel W, Hassan R, Ahmed A (2019) Effect of inoculum VS, organic loads and I/S on the biochemical methane potential of sludge, buckwheat husk and straw. Desalin Water Treat 157:69–78. https://doi.org/10.5004/dwt.2019.24121

Elsayed M, Andres Y, Blel W, Gad A, Ahmed A (2016) Effect of VS organic loads and buckwheat husk on methane production by anaerobic co-digestion of primary sludge and wheat straw. Energy Convers Manag 117:538–547. https://doi.org/10.1016/j.enconman.2016.03.064

Wei L et al (2019) Optimization of the co-digestion of sewage sludge, maize straw and cow manure: microbial responses and effect of fractional organic characteristics. Sci Rep 9(1):1–10

Mshandete A, Björnsson L, Kivaisi AK, Rubindamayugi MST, Mattiasson B (2006) Effect of particle size on biogas yield from sisal fibre waste. Renew Energy 31(14):2385–2392. https://doi.org/10.1016/j.renene.2005.10.015

Mokobia K, Ikhuoria EU, Olugbemide D, Omorogbe SO (2012) Production and characterization of biogas obtained from sugarcane leaves production and characterization of biogas obtained from sugarcane leaves (Saccharum species). Int J Basic Appl Sci Omorogbe etal Int J Basic Appl Sci 11(33):258–262

Inyang M, Gao B, Pullammanappallil P, Ding W, Zimmerman AR (2010) Biochar from anaerobically digested sugarcane bagasse. Bioresour Technol 101(22):8868–8872. https://doi.org/10.1016/j.biortech.2010.06.088

Elsayed M, Diab A, Soliman M (2020) Methane production from anaerobic co-digestion of sludge with fruit and vegetable wastes: effect of mixing ratio and inoculum type. Biomass Convers Biorefine. https://doi.org/10.1007/s13399-020-00785-z

McLeod JD, Othman MZ, Beale DJ, Joshi D (2015) The use of laboratory scale reactors to predict sensitivity to changes in operating conditions for full-scale anaerobic digestion treating municipal sewage sludge. Bioresour Technol 189:384–390. https://doi.org/10.1016/j.biortech.2015.04.049

Heaven S, Milledge J, Zhang Y (2011) Comments on ‘Anaerobic digestion of microalgae as a necessary step to make microalgal biodiesel sustainable. Biotechnol Adv 29(1):164–167. https://doi.org/10.1016/j.biotechadv.2010.10.005

Hobson PN, Wheatley AD (1993) Anaerobic digestion; modern theory and practice. Elsevier Applied Science, London

Lastella G, Testa C, Cornacchia G, Notornicola M, Voltasio F, Sharma VK (2002) Anaerobic digestion of semi-solid organic waste: biogas production and its purification. Energy Convers Manag 43(1):63–75. https://doi.org/10.1016/S0196-8904(01)00011-5

Romano RT, Zhang R (2008) Co-digestion of onion juice and wastewater sludge using an anaerobic mixed biofilm reactor. Bioresour Technol 99(3):631–637. https://doi.org/10.1016/j.biortech.2006.12.043

Wang X, Yang G, Feng Y, Ren G, Han X (2012) Optimizing feeding composition and carbon-nitrogen ratios for improved methane yield during anaerobic co-digestion of dairy, chicken manure and wheat straw. Bioresour Technol. https://doi.org/10.1016/j.biortech.2012.06.058

Choi Y, Ryu J, Lee SR (2020) Influence of carbon type and carbon to nitrogen ratio on the biochemical methane potential, pH, and ammonia nitrogen in anaerobic digestion. J Anim Sci Technol 62(1):74–83. https://doi.org/10.5187/jast.2020.62.1.74

Wu X, Yao W, Zhu J, Miller C (2010) Biogas and CH4 productivity by co-digesting swine manure with three crop residues as an external carbon source. Bioresour Technol 101:4042–4047. https://doi.org/10.1016/j.biortech.2010.01.052

Siddiqui Z, Horan NJ, Anaman K (2011) Optimisation of C:N ratio for co-digested processed industrial food waste and sewage sludge using the BMP test. Int J Chem React Eng 9:1. https://doi.org/10.1515/1542-6580.2327

Yen HW, Brune DE (2007) Anaerobic co-digestion of algal sludge and waste paper to produce methane. Bioresour Technol 98(1):130–134. https://doi.org/10.1016/j.biortech.2005.11.010

Sievers DM, Brune DE (1978) Carbon/nitrogen ratio and anaerobic digestion of swine waste. Trans ASAE 21(3):537–541

Levlin E (2010) Maximazing sludge and biogas production for counteracting global warming. Research and application of new technologies in wastewater treatment and municipal solid waste disposal in Ukraine, Sweden and Poland: Proceedings of a Polish-Swedish-Ukrainian Seminar, pp. 95–104. Retrieved from http://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-81528

Nges IA, Liu J (2009) Effects of anaerobic pre-treatment on the degradation of dewatered-sewage sludge. Renew Energy 34(7):1795–1800. https://doi.org/10.1016/j.renene.2008.12.001

Krishania M, Kumar V, Vijay VK, Malik A (2013) Analysis of different techniques used for improvement of biomethanation process: a review. Fuel 106:1–9. https://doi.org/10.1016/j.fuel.2012.12.007

Sibiya NT, Muzenda E (2014) “A review of biogas production optimization from grass silage,” in International Conference on Chemical Engineering and Advanced Computational Technologies, pp. 24–25

Chandra R, Takeuchi H, Hasegawa T (2012) Methane production from lignocellulosic agricultural crop wastes: a review in context to second generation of biofuel production. Renew Sust Energ Rev. https://doi.org/10.1016/j.rser.2011.11.035

Murphy JD, Thamsiriroj T (2013) “Fundamental science and engineering of the anaerobic digestion process for biogas production,” in The biogas handbook, Elsevier, pp. 104–130

Angelidaki I, Sanders W (2004) Assessment of the anaerobic biodegradability of macropollutants. Rev Environ Sci Biotechnol 3(2):117–129. https://doi.org/10.1007/s11157-004-2502-3

Edström M, Nordberg Å, Thyselius L (2003) Anaerobic treatment of animal byproducts from slaughterhouses at laboratory and pilot scale. Appl Biochem Biotechnol 109(1–3):127–138

Hamilton DW (2014) Anaerobic digestion of animal manures: understanding the basic processes. Id: BAE-1747 https://extension.okstate.edu/fact-sheets/anaerobic-digestion-of-animal-manures-understanding-the-basic-processes.html

Molnar L, Bartha I (1988) High solids anaerobic fermentation for biogas and compost production. Biomass 16(33):173–182. https://doi.org/10.1016/0144-4565(88)90090-X

El-Mashad HM, Zhang R (2010) Biogas production from co-digestion of dairy manure and food waste. Bioresour Technol 101(11):4021–4028. https://doi.org/10.1016/j.biortech.2010.01.027

Agyeman FO, Tao W (2014) Anaerobic co-digestion of food waste and dairy manure: effects of food waste particle size and organic loading rate. J Environ Manag 133:268–274

Raposo F, De la Rubia MA, Fernández-Cegrí V, Borja R (2012) Anaerobic digestion of solid organic substrates in batch mode: an overview relating to methane yields and experimental procedures. Renew Sust Energ Rev 16(1):861–877

Rincón B, Borja R, González JM, Portillo MC, Sáiz-Jiménez C (2008) Influence of organic loading rate and hydraulic retention time on the performance, stability and microbial communities of one-stage anaerobic digestion of two-phase olive mill solid residue. Biochem Eng J 40(2):253–261

Mata-Alvarez J, Macé S, Llabrés P (2000) Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour Technol 74(1):3–16. https://doi.org/10.1016/S0960-8524(00)00023-7

Ward AJ, Hobbs PJ, Holliman PJ, Jones DL (2008) Optimisation of the anaerobic digestion of agricultural resources. Bioresour Technol 99(17):7928–7940. https://doi.org/10.1016/j.biortech.2008.02.044

Funding

The authors acknowledge with thanks the Ministry of Higher Education and Aswan University, Faculty of Engineering, Civil Engineering Department (Egypt) that funded this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Elsayed, M., Hassany, R. & Soliman, M. Anaerobic co-digestion of sludge, sugarcane leaves, and Corchorus stalks in Egypt. Biomass Conv. Bioref. 13, 2177–2191 (2023). https://doi.org/10.1007/s13399-021-01577-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01577-9