Abstract

Dextrans are exo-polysaccharides prominently used as biomaterial on the grounds of their biodegradability and biocompatibility characteristics. There is an increasing interest and need to identify alternative cost-effective and renewable carbon source for dextran to reduce the production cost and to improve the overall economy of dextran production. In this work, dextran was produced using Saccharum officinarum juice (SOJ) as a low-carbon source by Leuconostoc mesenteroides MTCC 7337. The suitable condition/parameter for the production of dextran was found to be medium pH, 7; shaking speed, 150 rpm; inoculum size, 5% v/v; and nitrogen source, yeast extract. The different downstream factors including screening of solvent, supernatant to solvent ratio and precipitation time on the recovery of dextran, were studied. The organic solvent, ethanol with volume ratio of 1:4 (supernatant to solvent ratio), and precipitation time of 16 h were selected based on the maximum recovery of dextran from SOJ medium. The purified dextran was characterized by proton nuclear magnetic resonance spectroscopy (1H-NMR), Fourier transform infrared spectroscopy (FTIR), and thermogravimetric analysis (TGA) analysis. The results of rheological studies indicate that dextran solution behaves like a pseudoplastic fluid at higher concentrations of dextran solution. Based on the results, it was found that SOJ could be used as an alternate substrate for the production of dextran.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Microbial exo-polysaccharides (EPS) are synthesized by various microorganisms including fungi, blue-green algae, and bacteria due to various biological functions including self-protection against chemical and environmental stress factors, adherence to surfaces, pathogenesis, and symbiosis [1]. The produced microbial polysaccharides could be loosely attached on the cell surface (or) covalently combined on the cell surface forming a capsule (or) totally secreted into the surrounding broth during the fermentation [2]. Dextran, a microbial homopolysaccharide, is produced by various lactic acid bacterial strains (LABs) such as Lactobacillus, Leuconostoc, Weissella, Streptococcus, Pediococcus, and Acetobacter [3, 4]. The main chain of dextran is made up of d-glucose repeating units connected by α-(1➔6) glycosidic linkages, in which side chains are predominantly attached through α-(1➔3) glycosidic bond. Occasionally, the side branches are linked through α-(1➔2) and α-(1 ➔4) glycosidic linkages [5]. Dextransucrases are glucosyltransferases (E.C.2.4.1.5) which are secreted by Leuconostoc sp., Weissella sp., and other LAB to synthesis dextran from sucrose [5]. Among various bacterial strains such as Weissella confusa, Leuconostoc pseudomesenteroides, Weissella cibaria, Leuconostoc dextranicum, Leuconostoc citreum, and Oenococcus kitaharae, Leuconostoc mesenteroides NRRL B-512(f) is the potential microorganism used for the production of dextran in industrial scale from sucrose as a sole carbon source due to the suitable structural configuration (95% α-(1➔6) glycosidic bonds in backbone with 5% α-(1➔3) glycosidic branched chains).

The molecular mass, thermal stability, and structural behavior are essential characteristics of dextran from an industrial application point of view. The molecular weight and thermal stability of dextran are influenced by process parameters like types of microbial strains, medium condition, medium composition, acceptor concentration, and availability of the enzyme [4, 6]. The molecular mass of commercially available dextran is ranging from 40 to 2000 kDa. Due to the outstanding characteristics of dextran, such as low antigenicity, biodegradability, high water solubility, and high thermal stability with a melting point of 278.36 °C, it is widely used in various industrial applications like blood plasma extender, blood flow improver, petroleum recovery, adjuvants, emulsifiers, stabilizers, thickeners for jam and ice cream, improving moisture retention, food appearance and flavor, cross-linked dextran for protein purification and separation, magnetic resonance imaging enhancer, anticoagulant, preventing sugar crystallization, and as sweeteners [5, 7,8,9,10].

The medium formulation and culturing conditions such as solubility, viscosity, pH, temperature, medium composition such as nitrogen, phosphorous, and ash content along with the type of microbial strains are crucial parameters for the biosynthesis of dextran [11, 12]. In the total cost of production, nearly 50–60% of the cost is attributed to the fermentation step of dextran production [13]. Therefore, researchers had attempted various strategies namely (i) selection of easily available and cost-effective feedstock; (ii) genetically engineered strains; (iii) optimization of medium formulation and culturing condition; (iv) mode of fermentation; and (vi) residue for the improvement of dextran production under economical aspect [12, 14,15,16]. Alternative low-cost substrates namely beet molasses, tomato juice supplemented with sucrose, permeate powder, wheat bran extract, corn steep liquor, rice bran extract, sugarcane bagasse, potato peel extract, palm kernel cake extract, cheese whey, date seeds, rice straw, and wheat straw were tried for the production of microbial dextran [15,16,17,18,19,20]. Maximum production of low molecular weight dextran (42.87 g/L) was obtained with 20% sucrose and 15% permeate powder while 1.3 g/50 mL was obtained with 20% molasses [17, 18]. In the present work, sugarcane (Saccharum officinarum) juice (SOJ) was considered a potential and alternative feedstock for the production of microbial dextran by Leuconostoc mesenteroides subsp. mesenteroides. Owing to the rich composition of feedstock (total sugars 73.1% dry matter (DM); phosphorous and calcium and easy availability), it could be considered a low-cost substrate for the production of industrially important metabolite [21]. In the previous literature, SOJ could be utilized as a cost-effective substrate for the production of value-added industrial products namely polymalic acid (0.41 g/g), pullulan (6.4 g/L), and polyhydroxyalkanoate (0.10 g/g) [22,23,24].

On the basis of novelty, this is the first comprehensive study for production, downstream processing, and characterization of microbial dextran using Saccharum officinarum as a renewable and low-cost carbon source. Different factors namely initial pH, nitrogen source, inoculum size, and shaking speed on the production of dextran followed by solvent precipitation were investigated for maximal dextran production. The rheological behavior, water solubility index (WSI), and water holding capacity (WHC) were examined for the produced dextran. The structural and thermal properties of produced dextran were characterized using FTIR, NMR, and TGA analysis.

2 Materials and methods

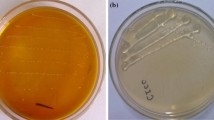

2.1 Microorganism and raw material collection

The microbial strain used in this present study, Leuconostoc mesenteroides subsp. mesenteroides (MTCC 7337), was obtained from Microbial Type Culture Collection (MTCC) and Gene Bank, Chandigarh, India. The strain was maintained using MRS agar plate at 4 °C. It is retrieved and sub-cultured once in 30 days. Two or three loops full of cells were transferred into 100 mL of sterilized MRS broth and incubated in an orbital shaker at 30 °C with an agitation speed of 150 rpm. The sugarcane was obtained from a local village in Thanjavur district, Tamil Nadu, India. The juice extracted from the sugarcane was used as a carbon source. The chemicals and reagents used in this study for the preparation of medium and solvent recovery steps were of analytical grade and purchased from Sigma-Aldrich, India, and Hi Media, India.

2.2 Production, extraction, and purification of dextran

The production medium was prepared using following composition (g/L): carbon source, 50; di-potassium hydrogen phosphate, 20; yeast extract, 20; magnesium sulfate, 0.2; manganese sulfate, 0.01; ferrous sulfate, 0.01; sodium chloride, 0.01; and calcium chloride, 0.02 [25]. In the preparation of SOJ medium with a total sugar content of 50 g/L, the necessary volume of sugarcane juice was added. The initial pH of the production medium was adjusted to pH 7.0 by adding either 1 M sodium hydroxide (NaOH) or 1 M hydrochloric acid (HCl), sterilized at 121 °C for 20 min and cooled to room temperature. The seed culture (5% v/v) with maximum optical density (OD600) between 0.5 and 0.8 was inoculated into the production medium (100 mL) in 250-mL Erlenmeyer conical flask. The fermentation medium was kept in an orbital shaker (Scigenics Biotech, Orbitech) at 30 °C and 150-rpm shaking speed.

The recovery of dextran was carried out by two-stage solvent extraction followed by chemical treatment as per the method described by Du et al. [10]. After fermentation, the broth containing dextran was centrifuged at 8000 rpm (15 min) for the separation of biomass. The supernatant collected was blended with two volumes of ice-cold ethanol for the precipitation which was incubated in the laboratory freezer (4 °C) for 12 h. The precipitated sample was re-suspended and centrifuged at 8000 rpm (15 min). The obtained pellet was resuspended using de-ionized water, till the complete dissolution, and was chemically treated with 10% (v/v) of trichloroacetic acid (TCA) at 4 °C for 12 h. Finally, the sample was centrifuged at 8000 rpm (− 4 °C) for 15 min to the remove the soluble protein from the sample. The supernatant so collected was again mixed with pre-chilled ethanol (1: 2) in the second stage precipitation and the sample was kept at − 4 °C for 12 h. The precipitated sample was centrifuged and the collected pellet was dried in a hot air oven at 80 °C for the removal of moisture. The concentration of dextran was determined by the gravimetric method.

2.3 Different factors affecting dextran production in batch fermentation and downstream processing

The effects of different factors namely initial pH (3–9), inoculum size (1–7% v/v), shaking speed (50–175 rpm), and screening of nitrogen sources (yeast extract, peptone, beef extract, potassium nitrate, urea, sodium nitrate, tryptone, ammonium di-hydrogen phosphate) on the production of dextran were investigated in batch fermentation.

After optimization of fermentation conditions, suitable organic solvent was identified (acetone, ethanol, iso-propanol, and methanol), and the effects of ratio of organic solvent to supernatant (v/v) and precipitation time on recovery of dextran were investigated for the recovery of dextran. All the experiments were performed in triplicate and data were reported as mean ± SD. Tukey’s test (one-way ANOVA) was performed with a 95% confidence level and two-sided confidence interval to compare the means and elucidate the statistical significance of the influencing factors using pairwise comparisons. Minitab 17 (Minitab Inc.) was used for the statistical analysis.

2.4 Evaluation of rheological property

In order to examine the rheology of purified dextran solution, three different compositions of dextran (2, 5, 10% w/v) were prepared using deionized water. The solution was incubated for 6 h [26] with constant stirring. The prepared solution was then subjected to viscosity measurements (Brookefield Viscometer LV DV 2 + pro extra with S18 spindle) in shear rate ranging from 13.2 to 264 s-1. The power law model relating apparent viscosity with shear rate was applied to evaluate the flow behavior and consistency index.

where ηapp is the apparent viscosity (Pa s), k is the consistency index (Pa sn), and n is flow behavior index.

Rao et al. suggested power law model for the determination of flow behavior index and consistency index using different compositions of polymer solution [27].

where ηapp is the apparent viscosity (Pa.s), M and a are the constants, and C is the dextran concentration (% w/v).

2.5 Structural and thermal analysis

The structural properties of produced dextran were characterized using FTIR spectroscopy (PerkinElmer Spectrum, Version 10.03.09, Spectrometer). The transmittance mode was ranging between 4000 and 400 per centimeter with a resolution of 4 per centimeter using the KBr pellet method. Proton nuclear magnetic resonance (1H-NMR) spectroscopy provides accurate structural information of the microbial polymers concerned. The 1H-NMR spectra were recorded at 75 °C and 300 MHz using D2O as the solvent (Bruker 300 MHz).

The thermal stability of dextran was analyzed using TGA (SDT Q600 V20.9 Build 20) in the heating rate of 20 °C per min. The produced dextran was introduced to thermal degradation from 18 to 936 °C under nitrogen condition with a volumetric flow rate of 100 mL/min. Before the analysis, the sample was subjected to drying in a hot air oven to remove the moisture present in it.

2.6 Water holding capacity and water solubility index

The water solubility index (WSI) for microbial polysaccharide was evaluated according to the method described by Farinazzo et al. with slight modifications [28]. The lyophilized dextran (0.2 g) was dissolved in ultrapure water (5 mL). In order to achieve the uniform suspension, the dextran solution was agitated for half an hour in a water bath at 40 °C and then subjected to centrifugation at 3000 rpm (− 4 °C) for 15 min. The obtained supernatant was kept in a Petri dish (pre-weighed) and kept in a hot air oven at 105 °C for 4 h to obtain dry solid. The percentage WSI was determined as:

Water holding capacity (WHC) was determined by dissolving the lyophilized dextran sample (0.2 g) in ultrapure water (10 mL). The dextran solution was kept at 40 °C for 10 min for uniform dispersion and then centrifuged at 10,000 rpm for 15 min. The obtained supernatant was carefully removed. The collected pellet was kept in a pre-weighed filter paper. The wet weight of the sample was quantified after draining the excess water. WHC can be determined by the following:

3 Results and discussions

3.1 Different parameters affecting dextran production

3.1.1 Effect of initial pH on the dextran production

During fermentation, the microorganism needs favorable environmental conditions namely medium pH and temperature to carry out their metabolic activities optimally [29]. Generally, medium pH plays a significant role in the activity of dextransucrase influencing the production of microbial dextran [5]. Generally, the optimal pH for dextran production is in the range of 5.0–8.0 [20, 30,31,32]. The effect of initial pH (3–9) on the production of dextran was investigated as shown in Fig. 1a, b. In this study, using the SOJ medium, the production of dextran was so low (1.39 g/L and 2.24 g/L) at a lower pH range (3.0–4.0). Above initial pH 5, the concentration of dextran was greatly increased until pH 7 and then gradually decreased. Similar results were observed for dextran production in the sucrose medium. Tukey’s test has confirmed that the difference in dextran production was statistically significant (P < 0.05) using the SOJ medium. However, there was no statistical difference in dextran concentration observed between initial pH 6 and 8 using the sucrose medium. The possible reason might be that dextransucrase has maximum activity and stability between pH 5.0 and 5.5 [5] but its production is usually favored in pH 6.0–6.9. During the fermentation, the formation of lactic acid as a by-product could alter the medium pH affecting the activity of dextransucrase responsible for dextran production [33]. The suitable medium pH provides the necessary transmembrane proton gradient that regulates the secretion of extra-cellular dextransucrase. Otts and Day had found that secretion of dextransucrase occurs till pH 7.0 and then the production was inhibited at pH 8.0 [34]. This might be a possible reason for the maximum concentration of dextran (12.3 g/L ± 0.014 at 96 h) obtained at initial pH 7 for SOJ medium and initial pH 8 for sucrose medium (10.7 ± 0.01 g/L at 96 h) in this present study. Similarly, the maximum production of dextran (5%) was obtained using the sucrose medium by Leuconostoc mesenteroides CMG713 with initial pH 7 [32]. Santos et al. reported the influence of pH on activity of dextransucrase as well as the production of dextran by L. mesenteroides NRRL B512F and reported the maximum dextran production at pH 5.5 [31]. The production of dextran was negligible in the early stage of fermentation and then significantly improved (7.94 g/L at pH 5.5 and 8th h) in the later stage, at pH 5.0. The optimum pH of 6.88 corresponding to the maximum dextran production of 71.12 ± 3.38 g/L was observed by statistical optimization using the sucrose medium [12]. The maximal dextran production of 9.3 ± 0.2 g/L and 8.7 ± 0.1 g/L was obtained at a controlled pH of 5.5 and uncontrolled pH respectively [12, 35].

In contrast, Karthikeyan et al. illustrated the maximum yield of dextran at optimum pH 8.2–8.5 [36]. Molasses-based production medium resulted in the highest yield of dextran (55 g/L) in the optimal pH ranging from 6.75 to 7.5 [16, 17, 36, 37]. Thus, the optimal pH for dextran production is not a constant factor. It depends on substrates used in the production medium and strains that produce different kinds of glucansucrases and glucans with various structures and properties [8] but it is in the range of pH 6–8.

It was also observed that the concentration of dextran in the SOJ medium was well correlated with cell dry weight during the log phase of the growth (supplementary Fig. 1). This leads to the conclusion that the production of dextran is growth associated. Similar observation had been reported by Lule et al. [30].

3.1.2 Screening of nitrogen sources for dextran production

Microorganism requires a nitrogen source that could support the production of purines, pyrimidines, enzyme cofactors, amino acids, certain carbohydrates, lipids, structural proteins, nucleic acids, and ADP/ATP in the cultivation of biomass and product synthesis [38]. It is also an essential medium factor for the synthesis of extra-cellular dextransucrase necessary for the biosynthesis of dextran [25, 39].

In this present work, both organic and inorganic nitrogen sources namely yeast extract, peptone, beef extract (BE), tryptone, urea, potassium nitrate, ammonium dihydrogen phosphate, and sodium nitrate (SN) were chosen with the same quantity of nitrogen for the formulation of production medium in the biosynthesis of dextran as shown in Fig. 2. It was noted that organic nitrogen sources resulted in significant concentration of dextran than inorganic sources. There was no significant variation observed in the production of dextran between urea controls. The experimental results confirm that the presence of a suitable external nitrogen source was essential for the production of dextran, as the control medium without nitrogen source had shown low concentration of dextran (1.7 ± 0.01 g/L in SOJ medium and 3.4 ± 0.03 g/L in sucrose medium). Yeast extract showed maximum dextran yield of 14.3 ± 0.03 g/L (72 h) and 11.9 ± 0.01 g/L in SOJ medium and sucrose medium respectively among all nitrogen sources used in this study. Beef extract and peptone resulted 0.28 g/L and 0.47 g/L and 0.16 g/L and 0.12 g/L respectively in SOJ and sucrose medium. Tukey’s test has confirmed that the difference in dextran production was statistically significant (P < 0.05). There was no statistical difference in dextran concentration observed using yeast extract, beef extract, and ammonium dihydrogen phosphate as nitrogen sources in the sucrose medium. Srinivas et al. (2014) demonstrated the influence of nitrogen sources on the production of dextran by Plackett-Burman design and also found that casein hydrolysate resulted in the maximum yield of dextran than other nitrogen sources used [39]. Rania et al. reported the maximum concentration of dextran (3.2 g/L) and activity of dextransucrase (3.51 DSU/mL/h) using the combination of yeast extract and peptone in the production medium [40]. The influence of peptone, beef extract, and yeast extract on the production of glucan as well as glucansucrase activity by Weissella confusa was examined and also confirmed that either yeast extract (1.5 %) or peptone (2%) in the production medium is well suitable for dextran fermentation. However, beef extract did not support the production of glucan and glucansucrase [41]. Several authors reported the maximum yield of dextran using yeast extract [42, 43]. The combination of corn steep liquor and casein in the production medium resulted in maximum concentration of dextran (83 g/L) with excellent dextransucrase activity [20, 44]. Even though the various nitrogen sources were suggested for the production of dextran, the suitable nitrogen source was identified by balancing the cost of fermentation as well as the yield of dextran. Since yeast extract is a complex nutrient source containing carbon, nitrogen, vitamins such as pantothenic acid, nicotinic acid, biotin, thiamine, and pyridoxine, it could be acting as a growth stimulator for LAB as well as the production of exo-polysaccharides [30, 33]. A low concentration of yeast extract in the formulation of the production medium could be economically viable for enhancing the production of dextran than other nitrogen sources used. Hence, in this study, yeast extract was selected as a nitrogen source and used in further studies.

3.1.3 Effect of inoculum size on dextran production

The microbial polysaccharide production is greatly affected by the volume percentage of inoculum or inoculum size during fermentation [29]. Active seed culture containing young cells with more inoculum size could decrease the lag phase period and also produce maximum biomass concentration in short incubation time enhancing the production of microbial polysaccharides [45]. Figure 3 depicts the influence of inoculum size (1–7%) on the production of dextran. The production of dextran linearly increased with inoculum size till 5% v/v and then decreased in the SOJ medium. Since dextran production is growth-associated, higher concentrations are obtained at higher inoculum size [30]. The result demonstrated that maximum production of dextran (14.3 ± 0.03 g/L) resulted in 5% (v/v) of inoculum size at 72 h in SOJ medium and 7% (v/v) of inoculum size (12.2 ± 0.01 g/L) at 48 h in sucrose medium. Tukey’s test has confirmed that the difference in dextran production was statistically significant (P < 0.05). However, there was no statistical difference in dextran concentration observed between inoculum size 5% and 7% (v/v) using sucrose medium. Therefore, an inoculum size of 5% (v/v) was considered in further studies using the sucrose medium. Above 7% (v/v) of inoculum size, a decrease in dextran concentration was attributed due to the rapid consumption of limiting substrate by larger inoculum size [46]. Low concentration of dextran (below 5% v/v) was achieved by the presence of low inoculum size resulting in low conversion of limiting substrate by microbial fermentation [20]. The maximum production of dextran by Leuconostoc mesenteroides sp. was reported between 4 and 7% inoculum size. The findings were in good agreement with those of existing reports [47].

3.1.4 Effect of shaking speed on dextran production

Shaking condition is necessary to maintain homogeneity and uniform concentration gradient for the continuous transfer of substrate, product, and other components through the cell membranes. However, an increase in shaking speed beyond a certain level developing a high shear force could damage the cell which is essential for microbial polysaccharide production [29]. The effect of shaking speed (0–175 rpm) on the production of dextran was investigated. As shown in Fig. 4, the concentration of dextran increased by increasing the shaking speed till 150 rpm and then decreased. The concentration of dextran which was maximum (13.7 ± 0.03 g/L) in SOJ broth and 14.6 ± 0.02 g/L in sucrose medium) resulted at 150 rpm (48th h). The possible reason might be the maximum growth rate of cells resulting in the significant production of dextran in the exponential growth phase, i.e., in the middle stage of fermentation [18, 48]. Tukey’s test has confirmed that the difference in dextran production was not statistically significant (P < 0.05) at 150 and 175 rpm using SOJ medium and 100, 150, and 175 rpm for sucrose medium. The decrease in dextran concentration at the same shaking speed after 72 h was due to the reduction in microbial growth due to the depletion of limiting substrate in the later stage of fermentation [18, 48]. There was no dextran concentration observed at a static condition in SOJ medium, but around 6 g/L, dextran was observed in the sucrose medium even in static condition. The increase in dextran production and cell growth could be attributed due to the microaerophilic nature of lactic acid bacteria while increasing the shaking speed [42]. It was noted that the low concentration of dextran was obtained below and above 150 rpm. Devi et al. reported that the decline in the synthesis of dextran at high shaking speeds could be attributed to the shear damage of the cells [49]. Vedyashkina et al. studied the effect of stirrer type on the production of dextran and also concluded that maximum yield of dextran by Leuconostoc mesenteroides (24.9 g/L) was achieved in a magnet stirrer than a circular shaker (20.2 g/L) and static condition (21.9 g/L) [37]. In contrast, the maximum production of dextran by Weissella confusa was achieved, when the shaking speed was above 150 rpm [20, 47, 50].

3.2 Cost analysis of medium formulation

The cost of dextran could be minimized by enhancing the productivity of dextran as well as the suitable utilization of cost-effective renewable feedstock in the formulation of medium. Several researches have paid more attention to minimize the cost of medium formulation using tomato juice, molasses, cheese whey, permeate powder for sucrose, yeast extract, and peptone [16,17,18,19]. In this present study, the cost of medium formulation was examined for the production of dextran using sucrose medium and SOJ medium respectively (Table 1). The medium costs of dextran production using sucrose medium and SOJ were estimated to be $146.71 and $108.84 respectively. It was noticed that the cost of the SOJ medium was significantly lowered by 26% than that of the sucrose medium. Hence, SOJ could be considered a potential and cost-effective feedstock compared with sucrose. By performing cost analysis, the SOJ medium was considered for the production of dextran and downstream processing.

3.3 Downstream processing for the recovery of dextran

Downstream processing is an important step in bioprocess engineering that could affect the quality and yield of the final product and also the overall cost of the fermentation.

3.3.1 Effect of volume ratio on the recovery of dextran

For the precipitation of water-soluble polysaccharide, the organic solvent with high molecular weight and lower tendency for hydrophilicity has been suggested [51]. In this present work, the various organic solvents (ethanol, iso-propanol, acetone, and methanol) with different volume ratios, i.e., supernatant to organic solvent volume ratio (1:1–1:6), were considered. According to the maximum recovery of dextran, a suitable organic solvent with an appropriate volume ratio was chosen. The maximum recovery of dextran (12.6 ± 0.01 g/L) was obtained using ethanol in a volume ratio of 1:4 (supernatant to ethanol volume ratio).

Iso-propanol has shown a maximum precipitation capability of dextran (5 g/L) in a volume ratio of 1:2 (supernatant to iso-propanol volume ratio). It was also noted that the maximum recovery of dextran by ethanol was approximately twofold higher than iso-propanol. Tukey’s test has confirmed that the difference in dextran recovery was not statistically significant (P < 0.05) between acetone and methanol. There was no significant difference in the percentage recovery of dextran observed between the methanol and acetone. Based on the maximum recovery and cost, a supernatant to ethanol volume ratio of 1:4 was selected for the recovery of dextran by solvent extraction technique. Numerous researchers demonstrated reported the maximum recovery of dextran using ethanol [10, 30, 52]. In contrast, few researchers had reported other solvent systems namely methanol, acetone, and iso-propanol for the recovery of dextran [3, 36, 53]. Youssef et al. demonstrated the possibility of recovering maximum quantity of water-soluble polysaccharide in the solvent extraction techniques with two (or) three volumes of organic solvent per one volume of the supernatant [54]. The different volume ratios of supernatant to ethanol (ice-cooled) (1:1–1:3) were preferred by various researchers for the recovery of water-soluble polysaccharides from fermentation [16, 55, 56].

3.3.2 Effect of precipitation time on dextran extraction

Figure 5b explains the effect of precipitation time on the recovery of dextran from SOJ medium using a volume ratio of 1:4 at − 4 °C. It was noted that the maximum dextran recovery of 14.35 ± 0.01 g/L was observed at 20th h followed by at 16th h (14.01 ± 0.01 g/L). However, Tukey’s test has confirmed that there was no significant difference in dextran recovery at different precipitation times. Generally, dextran precipitation from the supernatant was observed immediately after solvent addition and sometimes after 12–16 h of ice-chilled solvent addition [18, 44, 57].

3.4 Rheological properties of dextran

Rheological property of dextran solutions is generally influenced by the composition of dextran in the solution, molecular mass, system temperature, and presence of acceptor molecules [58].

In Table 2, it could be seen that an increase in the composition of dextran increases consistency index and the solution became more viscous. While increasing the concentration of dextran, the solution behavior had shifted to non-Newtonian indicated by flow behavior index (n) lower than unity [59]. Landon et al. have shown that dextran at low concentrations behaves as Newtonian and as concentration increases, pseudoplasticity of the dextran solution increases [58].

It was noticed that in the high concentration range of dextran solution, the solution viscosity decreased while increasing the shear rate, indicating the pseudoplastic nature of fluid. Above 66 s-1, the solution viscosity became independent of the shear rate. Due to its pseudoplasticity, dextran could be employed in the food formulations as table syrups, dairy products, and salad dressings to improve texture and palatability [60]. The low viscosity observed could be attributed to low molecular of dextran produced by Leuconostoc mesenteroides MTCC 7337 in the sugarcane juice medium. The presence of sugars like fructose and glucose in the medium influences the molecular mass of microbial dextran [61].

The relation between apparent viscosity and dextran concentration was calculated from the power law equation and was found at some fixed shear rates (Fig. 6). The viscosity increased with concentration reaching a plateau and at higher shear rates, the slope (a) slightly increases while the intercept (M) decreases slightly. The findings were consistent with previous report [62, 63].

3.5 Water holding capacity and water solubility index

The water solubility of the microbial polymer is usually affected by the length of the main and branched chains, secondary and tertiary structures, and arrangement of glycosidic linkages [64]. Higher degree of WHC indicates greater porous structure of the produced dextran that could retain significant water content by the formation of hydrogen bonds [65]. The microbial polysaccharide with a high degree of WSI and WHC could be used as water-binding agents and stabilizers in food industries [66]. The WHI and WSI of produced dextran by Leuconostoc mesenteroides MTCC 7337 using SOJ medium were found to be 250.14 ± 0.88% and 91.65 ± 2.52% respectively. The findings were comparable with existing reports [10, 28, 52].

3.6 FTIR and 1H-NMR analysis

Figure 7a explains the FTIR spectra for produced dextran using SOJ medium by Leuconostoc mesenteroides. The broad absorption bands at 3352.13 and 2922.21 cm-1 illustrated the hydroxyl vibrations and –CH stretching of the aliphatic groups in the sample [52, 67]. The functional groups namely C=O and C–O stretching vibrations were due to the peaks at 1640.50 and 1457.70 cm-1 respectively [10, 52, 67]. A small hump in the absorption peak appeared nearly at 1415 cm-1 characterized crystallinity of produced dextran. This peak is generally described as crystallinity band [68]. The characteristic absorption peaks at 1074.19 cm-1 and 761 cm-1 were due to the presence of α-(1,6) glycosidic linkage and α-(1, 4) glycosidic linkage respectively [69]. The weak transmittance peaks appeared at 760 and 550 cm-1 were due to the indication of glycosidic linkages in the microbial polysaccharide [28, 70]. There was no significant peak that appeared at 890 cm-1, indicating the absence of β-configuration in the polysaccharide The results obtained were comparable with those of existing reports [15, 52, 67].

1H-NMR spectra for produced dextran using SCB are shown in Fig. 7b. In the spectra, the intensive peak at 4.7 ppm was to the solvent (D2O) peak. Two slight peaks at 4.98 and 5.16 ppm confirmed to anomeric proton assigned to H-1 of α (1,6) and α(1,2) glycosyl residues respectively [52]. The characteristic peaks observed at 3.5–4.0 ppm illustrating the presence of C2–C6 linked protons (1H) in the dextran. Alkyl region in the sample was characterized by the peak appeared at 1.0–2.0 ppm [28, 66].

3.7 Thermal gravimetric analysis

The thermal stability of produced dextran was evaluated using TGA and DSC for the determination of melting point, decomposition point, and glass transition temperature. Generally, medium parameters namely carbon source, nitrogen source, types of microorganisms, and other micronutrients could affect the thermal degradation pattern for microbial polysaccharides [10, 71]. Thermal gravimetric analysis (TGA curve) for the produced dextran using the SOJ medium has shown the occurrence of thermal degradation by three stages. In the first stage, an initial weight loss of 7% was observed in the temperature range of 20–110 °C. This weight loss was attributed due to the removal of moisture content and volatile components associated with microbial dextran [72]. The weight of dextran was then thermally stable between 120 and 218 °C. In the second stage of thermal degradation, a huge quantity of weight loss (~ 30%) appeared between 220 and 345 °C due to the depolymerization of dextran including the decomposition of polymeric chains, rupture of C–C and glycosidic bonds [73, 74]. The final stage for weight loss (approximately 10%) was occurred in the third stage between 350 and 916 °C illustrated the carbonation reactions resulting in the formation of char residues [75]. The greater weight percentage of char at the end of thermal degradation illustrated the crystallinity behavior of dextran which was very difficult to thermally degrade due to the presence of strong intermolecular H-bonding between the chains [76]. The thermal degradation temperature for produced dextran by L. mesenteroides MTCC 7337 in SOJ medium was found to be 231.2 °C as shown in DTG (thermogravimetrically-derived) curve. The thermal decomposition point for the produced dextran using L. pseudomesenteroides and L. pseudomesenteroides JF7was found to be 298.81 °C and 320.8 °C respectively. [28].

Thermal behavior of produced dextran in terms of enthalpy change was described by DSC curve as shown in Fig. 8. The first endothermic peak was observed at ~ 68 °C which was associated with moisture content associated with microbial dextran. The melting temperature (Tm) of the produced dextran using SOJ medium was found to be 240.46 °C. The findings were promising to the existing literature [10, 28]. Due to the high degradation temperature and decomposition point of dextran, it could be applied to food industry to improve thermo-tolerance of the product [10].

4 Conclusion

In this study, the dextran production by Leuconostoc mesenteroides MTCC 7337 was investigated using sucrose and SOJ medium. The production of dextran was compared by one variable at a time using sucrose and SOJ medium. The suitable condition/variable for the production of dextran was found to be nitrogen source, yeast extract; inoculum size, 5% (v/v); and shaking speed, 150 rpm. At the industrial scale, the market price of carbon source has directly influenced the production of polysaccharide. This present study implies to be a breakthrough in the production of microbial dextran using SOJ as a potential feedstock compared with sucrose medium. In the downstream processing step, dextran recovery was maximized at 16th h with 1:4 supernatant to ethanol volume ratio. From the rheology study, it was observed that the produced dextran showed pseudoplastic behavior at high concentrations of dextran solution. The purified dextran was characterized by FTIR, NMR, and TGA. On the basis of TG analysis, the produced dextran has shown high decomposition temperature (231.2 °C). The α-(1,6) linkages (main chain) with α-(1,2) glycosidic linkages (branched chains) of produced dextran were confirmed using NMR and FTIR analysis. The high water solubility and retention of dextran signifies it use as a water-binding agent and can also be used in food and cosmetic industries.

References

Ponnusami V, Gunasekar V (2015) Production of pullulan by microbial fermentation. In: Polysaccharides: Bioactivity and Biotechnology, pp 1–2241

Li RH, Bin ZH, Hu XQ et al (2016) An efficiently sustainable dextran-based flocculant: synthesis, characterization and flocculation. Chemosphere 159:342–350

Capek P, Hlavoňová E, Matulová M et al (2011) Isolation and characterization of an extracellular glucan produced by Leuconostoc garlicum PR. Carbohydr Polym 83:88–93

Falconer DJ, Mukerjea R, Robyt JF (2011) Biosynthesis of dextrans with different molecular weights by selecting the concentration of B-512FMC dextransucrase, the sucrose concentration, and the temperature. Carbohydr Res 346:280–284

Naessens M, Cerdobbel A, Soetaert W, Vandamme EJ (2005) Leuconostoc dextransucrase and dextran: Production, properties and applications. J Chem Technol Biotechnol 80:845–860

Zhang Z, Liu Z, Tao X, Wei H (2016) Characterization and sulfated modification of an exopolysaccharide from Lactobacillus plantarum ZDY2013 and its biological activities. Carbohydr Polym 153:25–33

Purama RK, Goyal A (2008) Identification , effective purification and functional characterization of dextransucrase from Leuconostoc mesenteroides NRRL B-640. Bioresour Technol 99:3635–3642

Vettori MHPB, Blanco KC, Cortezi M et al (2012) Dextran: effect of process parameters on production, purification and molecular weight and recent applications. Diálogos & Ciência 2012:171–186

Qader SAU, Iqbal L, Aman A et al (2005) Production of dextran by newly isolated strains of Leuconostoc mesenteroides PCSIR-4 and PCSIR-9. Turkish J Biochem 31:21–26

Du R, Qiao X, Zhao F et al (2018) Purification, characterization and antioxidant activity of dextran produced by Leuconostoc pseudomesenteroides from homemade wine. Carbohydr Polym 198:529–536

Liu J, Wang X, Pu H et al (2017) Recent advances in endophytic exopolysaccharides: production, structural characterization, physiological role and biological activity. Carbohydr Polym 157:1113–1124

Du R, Xing H, Yang Y et al (2017) Optimization, purification and structural characterization of a dextran produced by L. mesenteroides isolated from Chinese sauerkraut. Carbohydr Polym 174:409–416

Brigham CJ, Kurosawa K, Rha C, Sinskey AJ (2011) Bacterial carbon storage to value added products. J Microb Biochem Technol:s3

Agrawal M, Shukla R, Goyal A (2011) UV mutagenesis of Leuconostoc mesenteroides NRRL B-640 for generation of a mutant (B-640 M) with hyper-producing dextransucrase activity. Curr Trends Biotechnol Pharm 5:1445–1453

Moussa TAA, Khalil NM (2012) Solid-state fermentation for the production of dextran from Saccharomyces cerevisiae and its cytotoxic effects. Life Sci J 9:2210–2218

Moosavi-nasab M, Gavahian M, Yousefi AR et al (2010) Fermentative production of dextran using food industry wastes. World Acad Sci Eng Technol 44:1043–1045

Behravan J, Fazly Bazzaz BS, Salimi Z (2003) Optimization of dextran production by Leuconostoc mesenteroides NRRL B-512 using cheap and local sources of carbohydrate and nitrogen. Biotechnol Appl Biochem 38:267

Esmaeilnejad-Moghadam B, Mokarram RR, Hejazi MA et al (2019) Low molecular weight dextran production by Leuconostoc mesenteroides strains: optimization of a new culture medium and the rheological assessments. Bioact Carbohydrates Diet Fibre 18:100181

Han J, Hang F, Guo B et al (2014) Dextran synthesized by Leuconostoc mesenteroides BD1710 in tomato juice supplemented with sucrose. Carbohydr Polym 112:556–562

Onilude AA, Olaoye O, Fadahunsi IF et al (2013) Effects of cultural conditions on dextran production by Leuconostoc spp. Int Food Res J 20:1645–1651

Srichayet P, Limsangouan N, Puntapurt K (2000) The composition of sugarcane juice and production of granulated sugar. 2000

Wei P, Cheng C, Lin M et al (2017) Production of poly (malic acid) from sugarcane juice in fermentation by Aureobasidium pullulans: kinetics and process economics. Bioresour Technol 224:581–589

Kayalvizhi V, Antony U (2011) Microbial a nd physico-chemical changes in tomato juice subjected to pulsed electric field treatment. African J Agric Res 6:6348–6353

Singh R, Gaur R, K. Pandey P, et al (2018) A novel media optimized for production of pullulan in flask type fermentation system. Int J Curr Microbiol Appl Sci 7:53–61.

Tsuchiya H, Koepsell H, Corman J et al (1952) The effect of certain cultural factors on production of dextransucrase by Leuconostoc mesenteroides. North Reg Res Lab 64:521–526

Zarour K, Goretti M, Prieto A et al (2017) Rheology and bioactivity of high molecular weight dextrans synthesised by lactic acid bacteria. Carbohydr Polym 174:646–657

Rao MA, Cooley HJ, Vitali AA (1984) Flow properties of concentrated juices at low temperatures. Food Technol

Farinazzo FS, Valente LJ, Almeida MB et al (2020) Characterization and antioxidant activity of an exopolysaccharide produced by Leuconostoc pseudomesenteroides JF17 from juçara fruits (Euterpe edulis Martius). Process Biochem 91:141–148

Choudhury AR, Sharma N, Prasad GS (2012) Deoiledjatropha seed cake is a useful nutrient for pullulan production. Microb Cell Fact 11:3–11

Lule VK, Singh R, Pophaly SD et al (2016) Production and structural characterisation of dextran from an indigenous strain of Leuconostoc mesenteroides BA08 in Whey. Int J Dairy Technol 69:520–531

Santos M, Teixeira J, Rodrigues A (2000) Production of dextransucrase, dextran and fructose from sucrose using Leuconostoc mesenteroides NRRL B512 ( f ). Biochem Eng J 4:177–188

Sarwat F, Qader SAU, Aman A, Ahmed N (2008) Production & characterization of a unique dextran from an indigenous Leuconostoc mesenteroides CMG713. Int J Biol Sci 4:379–386

Kanimozhi J, Moorthy IG, Sivashankar R, Sivasubramanian V (2017) Optimization of dextran production by Weissella cibaria NITCSK4 using response surface methodology-genetic algorithm based technology. Carbohydr Polym 174:103–110

Otts DR, Day DF (1988) Dextransucrase secretion in Leuconostoc mesenteroides depends on the presence of a transmembrane proton gradient. J Bacteriol 170:5006–5011

Lazić ML, Veljković VB, Vučetić JI, Vrvić MM (1993) Effect of pH and aeration on dextran production by Leuconostoc mesenteroides. Enzyme Microb Technol 15:334–338

Karthikeyan RS, Rakshit SK, Baradarajan A (1996) Optimization of batch fermentation conditions for dextran production. Bioprocess Eng 15:247–251

Vedyashkina TA, Revin VV, Gogotov IN (2005) Optimizing the conditions of dextran synthesis by the bacterium Leuconostoc mesenteroides grown in a molasses-containing medium. Appl Biochem Microbiol 41:409–413

Zhang ZY, Jin B, Kelly JM (2007) Production of lactic acid from renewable materials by Rhizopus fungi. Biochem Eng J 35:251–263

Srinivas B, Padma PN (2014) Screening Of Diverse Organic, Inorganic And Natural Nitrogen Sources For Dextran Production By Weissella Sps Using Plackett-Burman Design. 3:234–237

Abedin RM, El-Borai AM, Shall MA, El-Assar SA (2013) Optimization and statistical evaluation of medium components affecting dextran and dextransucrase production by Lactobacillus acidophilus ST76480.01. Life Sci J 10:1746–1753

Shukla S, Goyal A (2011) Optimization of fermentation medium for enhanced glucansucrase and glucan production from Weissella confusa. Brazilian Arch Biol Technol 54:1117–1124

Baruah R, Deka B, Kashyap N, Goyal A (2018) Dextran utilization during its synthesis by Weissella cibaria RBA12 can be overcome by fed-batch fermentation in a bioreactor. Appl Biochem Biotechnol 184

Majumder A, Bhandari S, Purama RK et al (2009) Enhanced production of a novel dextran from Leuconostoc mesenteroides NRRL B-640 by Response Surface Methodology. 59:309–315

Fattah AFA, Hashem AM, El-refai MA, Gebreel HM (2012) Production and properties of dextransucrase by free and immobilized cells of Leuconostoc paramesenteroides. Egypt Pharm J:42–48

Wang X, Xu P, Yuan Y et al (2006) Modeling for gellan gum production by. Microbiology 72:3367–3374

Hamieh A, Olama Z, Holail H (2013) Microbial production of polyhydroxybutyrate , a biodegradable plastic using agro-industrial waste. Glob Adv Res J Microbiol 2:54–64

Srinivas B, Padma PN (2015) Effect of process parameters on dextran production by Weissella Confusa. Int J Res Appl Sci Eng 3:373–377

Qader SAU, Aman A (2012) Low molecular weight dextran: Immobilization of cells of Leuconostoc mesenteroides KIBGE HA1 on calcium alginate beads. Carbohydr Polym 87:2589–2592

Devi N, Singh AK, Azmi W (2018) Analysis of the combined effects of aeration and agitation rate on dextransucrase production by Leuconostoc lactis KU665298 in a Laboratory Fermenter using Response Surface Methodology. J Microbiol Biotechnol 7:41–52

Baruah R, Deka B, Kashyap N (2017) Dextran utilization during its synthesis by Weissella cibaria RBA12 can be overcome by fed-batch fermentation in a bioreactor. Appl Biochem Biotechnol 184:1–11

Heilig ML (1994) United States Patent Office. ACM SIGGRAPH Comput Graph 28:131–134

Feng F, Zhou Q, Yang Y et al (2018) Characterization of highly branched dextran produced by Leuconostoc citreum B-2 from pineapple fermented product. Int J Biol Macromol 113:45–50

Robyt JF, Kimble BK, Walseth TF (1974) The mechanism of dextransucrase action. Direction of dextran biosynthesis. Arch Biochem Biophys 165:634–640

Youssef F, Roukas T, Biliaderis CG (1999) Pullulan production by a non-pigmented strain of Aureobasidium pullulans using batch and fed-batch culture. Process Biochem 34:355–366

Sugumaran KR, Ponnusami V (2017) Conventional optimization of aqueous extraction of pullulan in solid-state fermentation of Cassava bagasse and Asian palm kernel. Biocatal Agric Biotechnol 10:204–208

Huang J, Zhu S, Li C, et al (2019) Cost-effective optimization of gellan gum production by Sphingomonas paucimobilis using corn steep liquor. Prep Biochem Biotechnol 0:1–7.

Prechtl RM, Wefers D, Jakob F, Vogel RF (2018) Cold and salt stress modulate amount, molecular and macromolecular structure of a Lactobacillus sakei dextran. Food Hydrocoll 82:73–81

Landon RS, Law RCS, Webb C (1993) Fermentation broth rheology during dextran production by Leuconostoc mesenteroides B512 ( F ) as a possible tool for control. Appl Microbiol Biotechnol 40:251–257

Tirtaatmadja V, Dunstan DE, Boger DV (2001) Rheology of dextran solutions. J Nonnewton Fluid Mech 97:295–301

Prasanna PHP, Bell A, Grandison AS, Charalampopoulos D (2012) Emulsifying, rheological and physicochemical properties of exopolysaccharide produced by Bifidobacterium longum subsp. infantis CCUG 52486 and Bifidobacterium infantis NCIMB 702205. Carbohydr Polym 90:533–540

Santos M, Rodrigues A, Teixeira JA (2005) Production of dextran and fructose from carob pod extract and cheese whey by Leuconostoc mesenteroides NRRL B512 ( f ). Biochem Eng J 25:1–6

Moosavi-nasab M, Alahdad Z, Nazemi S (2009) Characterization of the dextran produced by Leuconostoc mesenteroides from date fruit extract. Iran Agric Res 27:79–88

Mothé CG, Rao MA (1999) Rheological behavior of aqueous dispersions of cashew gum and gum arabic: effect of concentration and blending. Food Hydrocoll 13:501–506

Wang ZM, Cheung YC, Leung PH, Wu JY (2010) Ultrasonic treatment for improved solution properties of a high-molecular weight exopolysaccharide produced by a medicinal fungus. Bioresour Technol 101:5517–5522

Zhu KX, Huang S, Peng W et al (2010) Effect of ultrafine grinding on hydration and antioxidant properties of wheat bran dietary fiber. Food Res Int 43:943–948

Kavitake D, Devi PB, Singh SP, Shetty PH (2016) Characterization of a novel galactan produced by Weissella confusa KR780676 from an acidic fermented food. Int J Biol Macromol 86:681–689

Zhou Q, Feng F, Yang Y et al (2017) Characterization of a dextran produced by Leuconostoc pseudomesenteroides XG5 from homemade wine. Int J Biol Macromol:1–8

Bertocchi C, Delneri D, Signore S et al (1997) Characterization of microbial cellulose from a high-producing mutagenized Acetobacter pasteurianus strain. Biochim Biophys Acta - Gen Subj 1336:211–217

Purama RK, Goswami P, Khan AT, Goyal A (2009) Structural analysis and properties of dextran produced by Leuconostoc mesenteroides NRRL B-640. Carbohydr Polym 76:30–35

Yang Y, Peng Q, Guo Y et al (2015) Isolation and characterization of dextran produced by Leuconostoc citreum NM105 from manchurian sauerkraut. Carbohydr Polym 133:365–372

Rosca I, Roxana A, Peptanariu D et al (2017) Biosynthesis of dextran by Weissella confusa and its In vitro functional characteristics. Int J Biol Macromol.

Zamora F, González MC, Dueñas MT et al (2002) Thermodegradation and thermal transitions of an exopolysaccharide produced by Pediococcus damnosus 2.6. J Macromol Sci - Phys 41 B:473–486

Kenari HS, Imani M, Nodehi A (2013) Full factorial design-of-experiments for preparation of crosslinked dextran microspheres. J Appl Polym Sci 127:3712–3724

Miao M, Huang C, Jia X et al (2015) Physicochemical characteristics of a high molecular weight bioengineered α-D-glucan from Leuconostoc citreum SK24.002. Food Hydrocoll 50:37–43

Llamas-arriba MG, Puertas AI, Prieto A et al (2019) Characterization of dextrans produced by Lactobacillus mali CUPV271 and Leuconostoc carnosum CUPV411 María. Food Hydrocoll 89:613–622

Sun YX, Liu JC, Yang XD, Kennedy JF (2010) Purification, structural analysis and hydroxyl radical-scavenging capacity of a polysaccharide from the fruiting bodies of Russula virescens. Process Biochem 45:874–879

Acknowledgments

All authors are thankful to the Management SASTRA Deemed to be University, Thanjavur, Tamil Nadu, India, for providing the necessary facilities. Ms. Sameeha Syed Abdul Rahman, who is a research scholar, is a recipient of the DST – INSPIRE fellowship (IF180367) from the Department of Science and Technology, Government of India, and the support is duly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 33 kb)

Rights and permissions

About this article

Cite this article

Rahman, S.S.A., Venkatachalam, P. & Karuppiah, S. Cost-effective production of dextran using Saccharum officinarum juice (SOJ) as a potential feedstock: downstream processing and characterization. Biomass Conv. Bioref. 12, 4863–4875 (2022). https://doi.org/10.1007/s13399-020-00926-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00926-4