Abstract

Fenton processes are a promising approach toward high-value chemical production from waste lignin. In this study, heterogeneous Fenton oxidation was employed to convert alkaline lignin into vanillin. The effects of Fe0, Fe2+, Fe3+, and H2O2 concentrations, temperature (25–50 °C), and reaction time (15–60 min) on vanillin production from lignin was investigated using response surface methodology under a three-level factorial design. The study reveals that the concentrations of Fe0, Fe2+, Fe3+, and H2O2 had an important effect on vanillin yield, whereas reaction temperature and time had positive effects on the process of vanillin production. Based on the numerical optimization and desirability function, the optimum conditions were 38.05 mg/L Fe0, 49.45 mg/L Fe2+, 71.35 mg/L Fe3+, and 1884.4 ppm H2O2 at 41.404 °C for 60 min at pH 3. Under these conditions, the vanillin yield obtained was 0.690%, which was increased by 2.59-fold from lignin. The experimental results agreed with the predicted values. We show that heterogeneous Fenton oxidation has the potential to convert lignin into high-value aromatic compounds when carried out under optimum conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

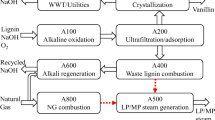

Lignocellulosic biomass typically refers to the dry matter of plants from various sources such as forestry and crops [2]. It is made up largely of secondary cell walls mainly composed of cellulose microfibrils, hemicellulose molecules, and lignin in varying proportions in different species [15, 22, 28]. However, only cellulose and hemicellulose fractions have been successfully exploited, whereas lignin is a waste product and burned as low-value fuel for power generation [11]. For this reason, lignin conversion to valuable chemicals is an approach to improve the economic feasibility of the biorefinery process and has received increased attention in modern biorefinery [1, 23].

Lignin is a complex phenolic polymer composed of three different monomers, p-hydroxyphenyl (H), guaiacyl (G), and syringyl (S) units [16]. Many approaches have been developed for lignin depolymerization. Nevertheless, only aqueous alkaline oxidation has been applied on a commercial scale to convert lignin into chemicals, mainly vanillin (4-hydroxy-3-methoxybenzaldehyde) [9]. Considerably, this process is operated under severe conditions, with high capital and operating costs. To reduce the operational costs, Fenton processes are promising [17]:

For the heterogeneous Fenton system, reactions between H2O2 and iron species generate the reactive oxygen species at ambient temperature and pressure [10]. Following Eqs. (1) to (5), hydroxyl radicals (OH·) are generated at significantly larger amounts than other reactive oxygen species and play a major role in the decomposition of lignin into desired chemicals if the process conditions are well controlled [21]. There are a few previous reports that applied the heterogeneous Fenton processes to oxidize lignin model compounds into aromatic compounds [3, 17]. However, there are almost no studies on the conditions of Fenton oxidation to produce phenolic compounds from lignin. Additionally, it should be noted that the results from model lignin compounds may not be appropriate for real lignin.

In our previous study [24], we presented the optimal concentration of synergistic catalysts (Fe0, Fe2+, and Fe3+) and H2O2 to achieve the highest lignin removal efficiencies of 98.45%. However, lignin-derived products as well as the effect of the process conditions were not investigated. Therefore, this study aimed to optimize the Fenton oxidation process conditions for the conversion of lignin into chemicals with antioxidant properties, using the response surface methodology via a three-level factorial design. Fenton oxidation process conditions included the concentration of synergistic catalysts, temperature at ambient pressure, and reaction time. Mathematical models were built to investigate the effects of various parameters on vanillin formation and antioxidant activities.

2 Material and methods

2.1 Experimental design

A three-level factorial design was used in this study. The main and interaction effects between operational parameters in lignin depolymerization using a synergistic catalyst Fenton reaction were investigated. The parameters coded as A (concentration of synergistic catalysts), B (temperature), and C (reaction time) were designed as indicated by selected factors. Parameters A, B, and C were investigated at three levels: low (− 1), middle (0), and high (+ 1), as shown in Table 1. This factorial design resulted in 32 experimental runs with all possible combinations of A, B, and C. Design and analysis of factorial experiments were carried out using the Design-Expert software (Trial version 11.0.5.0, Stat Ease Inc., Minneapolis, MN, USA). Finally, numerical optimization was carried out to optimize the process conditions and to maximize vanillin yield.

2.2 Reagents

Alkaline lignin was purchased from TCI chemicals, Tokyo, Japan. The methoxy group content and ignition residue of alkaline lignin were 10.0–12.0% and 20.0–29.0%, respectively. The 50% hydrogen peroxide (H2O2) was purchased from Thai Peroxide Company Limited (TPL), and sulfuric acid (H2SO4) was purchased from Merck (Darmstadt, Germany). High-purity iron powder, iron (II) sulfate heptahydrate (FeSO4·7H2O), and anhydrous iron (III) chloride (FeCl3) were purchased from Fisher Scientific (Leicestershire, UK). Folin–Ciocalteu’s phenol reagents were purchased from Loba (India), and 2,4,6-tripyridyl-s-triazine, gallic acid, Trolox, vanillin, 2,2-diphenyl-1-picrylhydrazyl, and azinobis-(3-ethylbenozthiazoline-6-sulfonic acid) were purchased from Sigma-Aldrich. All the solutions were prepared by dissolving in deionized water.

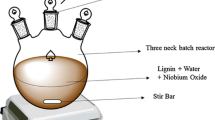

2.3 Reaction’s configurations

A 50-g/L stock solution of lignin was prepared by dissolving in deionized water, and the pH was adjusted from 8.2 ± 0.20 to 7.00 ± 0.05 using 2 M H2SO4. The volume of the reaction mixture in each 250-mL Erlenmeyer flask was 100 mL. First, 50 mL of the lignin stock solution was placed in a flask. Subsequently, FeSO4·7H2O and FeCl3 were weighted and dissolved in an appropriate volume of deionized water to obtain a Fe2+/Fe3+ solution. After this, a Fe2+/Fe3+ solution and an amount of iron powder were added and mixed with the lignin solution in a flask. Afterward, the pH of the mixture was adjusted to 3.00 ± 0.05 using 2 M H2SO4. The mixture was incubated in a shaking incubator at 250 rpm with temperature control for 5 min. Subsequently, a volume of 50% H2O2 was added to initiate the reaction.

The Fenton reactions at the designed reaction time were stopped instantaneously by the addition of 7.5 M NaOH to elevate the pH level to 7.0 [19]. The samples were centrifuged at 10,000 rpm for 10 min to remove the chemical precipitate before analysis.

2.4 Analytical method

2.4.1 Determination of aromatic compounds by UV absorbance spectroscopy

Concentrations of aromatic compounds were estimated by measuring sample absorbance (Genesys 20 UV–Vis spectrophotometer, Thermo Scientific, Waltham, MA, USA) at 280 nm [12]. Briefly, a 50-g/L stock solution of lignin was prepared, and the pH of the solution was adjusted to 7 ± 0.05 using 2 M H2SO4. Subsequently, it was diluted 50-fold with deionized water to obtain a concentration of 0.1 g/L. Absorbance at 280 nm was measured using quartz cuvettes. A calibration curve was obtained by plotting the absorbance values at 280 nm versus the lignin concentration and was linear with respect to concentration in the range 0.005–0.050 g/L (Y = 20.389X, R2 = 0.9993).

The content of aromatic substances in samples could be obtained through a calibration curve equation and was expressed as lignin equivalents (LEs) in grams per gram of initial lignin.

2.4.2 Determination of total phenolic content by Folin–Ciocalteu reagent

The total phenolic content in samples was determined with the Folin–Ciocalteu phenol reagent based on the method described by Dewanto et al. [8]. Briefly, 50 μL of sample was added to 200 μL of distilled water, and the solution was mixed with 50 μL of 2 N Folin–Ciocalteu’s phenol reagent and incubated in the dark for 6 min at 25 °C. Subsequently, 500 μL of a 7% (w/v) sodium carbonate solution and 400 μL of distilled water were added. The mixture was incubated in the dark for 90 min at 25 °C, and absorbance was measured at 760 nm. The total phenolic content was expressed as micrograms gallic acid equivalent per gram of initial lignin.

2.4.3 Determination of the antioxidant capacity

The ferric-reducing antioxidant power (FRAP) of samples was determined using the method proposed by Benzie and Strain [4]. Briefly, FRAP reagent was prepared by mixing 25 mL of 300 mM acetate buffer at pH 3.6, 2.5 ml of 10 mM 2,4,6-tripyridyl-s-triazine (TPTZ) in 40 mM HCl and 2.5 mL of 20 mM Ferric chloride (FeCl3) and incubating this mixture at 37 °C for 30 min before use. Subsequently, 150 μL of the sample were mixed with 1 mL of distilled water and 1 mL of FRAP reagent. The mixture was incubated in the dark for 30 min at 25 °C, and absorbance was measured at 593 nm. A standard curve was prepared using different concentrations of Trolox. The results were reported as milligrams Trolox equivalent (TE) per milligram of initial lignin.

The reducing ability of samples toward the 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical or the free radical-scavenging capacity was measured according to the method described by Williams et al. [5]. Briefly, a 0.15 mM DPPH solution was prepared by dissolving 5.9 mg 2,2-diphenyl-1-picrylhydrazyl in 100 mL methanol and incubated in the dark for 90 min at 25 °C before use; 50 μL of the sample was mixed with 950 μL of DPPH solution. The mixture was incubated in the dark for 30 min at 25 °C, followed by measurement of absorbance at 517 nm using Trolox as the standard. The results were expressed in terms of micrograms Trolox equivalent (TE) per milligram of initial lignin.

The Trolox equivalent antioxidant capacity (TEAC) or the capacity of the antioxidant to scavenge the azinobis-(3-ethylbenzothiazoline-6-sulfonic acid)(ABTS) radical cation was measured following the method described by Re et al. [20]. Briefly, the stock solutions of 7.4 mM ABTS in 20 mM acetate buffer at pH 4.5 and 2.6 mM potassium persulfate were prepared. The ABTS radical solution was prepared by mixing two stock solutions in a volume ratio of 1:1 and incubated at 25 °C for 12 h. Subsequently, the solution was diluted with distilled water to obtain absorbance of 0.700 ± 0.050 at 734 nm before use; 50 μL of the sample was mixed with 950 μL of ABTS radical solution. The mixture was incubated in the dark for 6 min at 25 °C, and absorbance was measured at 734 nm using Trolox as the standard. The activities were expressed in terms of micrograms Trolox equivalent (TE) per milligram of initial lignin.

2.4.4 Simple chemical analysis of lignin-derived products by gas chromatography

After a single extraction of the sample with an equal volume of ethyl acetate, the upper phase of the organic phase was corrected for analysis by gas chromatography with flame ionization detection, following the method described by Wu et al. [25]. Analyses were carried out by GC-FID (Agilent 7890B) and analytical columns of HP-5 (30 m length × 320 μm I.D. × 0.25 μm film thickness). Helium as the carrier gas was set at a rate of 1.2 mL/min. The oven temperature was ramped from 50 to 280 °C at a ramp rate of 10 °C/min and kept at the initial and final temperature for 1 min. The sample (1 μL) was injected in splitless mode, and the injector and detector were set at 250 and 280 °C, respectively. A linear calibration curve of vanillin was obtained by plotting the peak area versus the concentration range of 40–1000 μg/mL of vanillin. Gas chromatography-mass spectrometry (GC-MS) was carried out using the same conditions and applying the database of the National Institute Standard and Technique (NIST). The spectrum of the lignin-derived compounds was compared with the spectra of identified components stored in the NIST mass spectral library.

3 Results and discussion

The results for all responses are summarized in Table 2, and the effects of the three independent variables catalyst concentration, temperature, and time were analyzed by the yield of vanillin and antioxidant activities, using the response surface method of the Design-Expert software (Fig. 1).

Response surface for vanillin production in lignin depolymerization by synergistic catalytic Fenton oxidation, elucidating the effects of synergistic catalysts and temperature at 60 min of reaction time (a), the effects of synergistic catalysts and reaction time at 50 °C (b), the effect of reaction time and temperature at 5 times the synergistic catalysts (c), actual and predicted plots of vanillin yield (%)

3.1 Effects of condition parameters on vanillin production

Regarding the effects of the concentration levels of synergistic catalysts at 50 °C for 15 min, vanillin yields of 0.61, 0.48, and 0.35% were obtained at low, medium, and high concentrations of synergistic catalysts. Vanillin yields of 0.49, 0.56, and 0.61% were obtained when the reaction temperature was 25, 37.5, and 50 °C, respectively. Additionally, vanillin yields of 0.49, 0.62, and 0.73% were obtained at low concentrations of synergistic catalysts at 50 °C for 15, 37.5, and 60 min, respectively. The highest vanillin yield obtained was 0.73% in standard run 25 (38.1 mg/L of Fe0, 49.5 mg/L of Fe2+, 71.4 mg/L of Fe3+, and 1884.4 mg/L of H2O2 at 50 °C for 60 min), and the lowest vanillin yield was 0.33% in standard run 3 (190.3 mg/L of Fe0, 247.3 mg/L of Fe2+, 356.8 mg/L of Fe3+, and 9422.0 mg/L of H2O2 at 25 °C for 15 min). These results show that the three independent parameters governed vanillin production from lignin via heterogeneous Fenton oxidation.

Vanillin yield was subjected to ANOVA to assess the goodness of fit (Table 3); the p values for the three factors were less than 0.05. Therefore, the concentration of synergistic catalysts and the temperature, as well as the reaction time, significantly influenced vanillin production. However, the interaction between two factor variables was not significant (p > 0.05). For a model equation based on Eq. (1), the high values of R2 of 0.9464—close to 1—together with the predicted R2 of 0.9127 are in reasonable agreement with the adjusted R2 of 0.9335, with a difference of less than 0.2. These fit statistics prove that the model equation in Eq. (1) is suitable to describe the responses of the experiment for vanillin production in lignin depolymerization via synergistic catalytic Fenton oxidation. Moreover, the lack of fit for Eq. (1) was not significant, which suggests that the experimental data of the vanillin yield sufficiently fit the model.

For a model equation based on Eq. (1), the term of concentration of the synergistic catalyst had a negative coefficient in the equation of vanillin yield. This indicates that the vanillin yield obtained was increased with a decrease in the initial concentration of the synergistic catalyst. On other hand, the terms reaction temperature and time showed positive coefficients in the equation, implying that the vanillin yield depends on temperature and reaction time. However, this study did not investigate the rate of vanillin formation from lignin depolymerization. Thus, the relationship between temperature and the rate of vanillin production is not discussed here. Nevertheless, temperature is an important factor in vanillin production. This could be explained based on the collision theory, where increasing the temperature increases the force of molecular collisions until the bonds in lignin are broken, leading to the liberation of lignin-derived molecules which react continuously to form vanillin and other components by multistage reactions. Complex multistage reactions take a long time under mild conditions.

Lignin depolymerization by synergistic catalytic Fenton oxidation is presented in Fig. 2. Hydroxyl radicals have a redox potential of + 2.33 V, which is higher than that of H2O2 (+ 1.36 V). Hydroxyl radicals generated from Fenton reaction can effectively oxidize and cleave carbon–carbon and ether bonds, leading to the depolymerization of lignin. Furthermore, lignin is not only depolymerized, but repolymerization between lignin moieties is also prevented [26]. Therefore, Fenton reactions have proved that the hydroxyl radicals generated have the potential to depolymerize lignin under mild conditions.

Schematic representation of lignin depolymerization by synergistic catalytic Fenton oxidation. The reactions between H2O2 and iron species generate hydroxyl radicals (OH·). Hydroxyl radicals with high oxidation potential can oxidize and depolymerize lignin into low-molecular-weight lignin-derived compounds under optimal conditions

Apart from the depolymerization technique used depending on both the source of lignin and the isolation process, lignin macromolecules contain more guaiacyl than syringyl subunits, which were isolated chemically, leading to higher amounts of more recalcitrant carbon–carbon linkages such as β-5′ and β-β′ linkages [14]. The alkaline lignin (TCI) used in this study contains more guaiacyl than syringyl units, as discussed below. Therefore, the depolymerization of alkaline lignin (TCI) should obtain guaiacyl-derived compounds as the main products [21]. Fortunately, vanillin is a guaiacyl-derived compound and was the desired product in this study; it was the major component in the mixture of ethyl acetate-soluble compounds after reaction.

3.2 Effects of condition parameters on antioxidant activity

The antioxidant activities of lignin-derived substances in the aqueous phase from the 32 experiments are shown in Table 2.

3.2.1 Ferric-reducing antioxidant power

The results show that the highest FRAP of 165.66 g TE/g initial lignin was obtained in the standard run 10 (38.1 mg/L of Fe0, 49.5 mg/L of Fe2+, 71.4 mg/L of Fe3+, and 1884.4 mg/L of H2O2 at 25 °C for 37.5 min). However, high levels of synergistic catalyst concentration (190.3 mg/L of Fe0, 247.3 mg/L of Fe2+, 356.8 mg/L of Fe3+, and 9422.0 mg/L of H2O2) at 37.5 °C for 60 min gave the lowest FRAP at 88.97 ± 0.35 mg TE/g initial lignin in standard run 24. Accordingly, with the result of vanillin obtained, the general trend was that the obtained FRAP was also favored at a low concentration level of synergistic catalysts.

However, temperature and reaction time for the highest FRAP at 25 °C for 37.5 min were lower than those at which the maximum vanillin yield was obtained (50 °C, 60 min). In addition, the effect of the reaction time depends on the temperature. For example, at low levels of synergistic catalysts at 50 °C, the FRAP values of 161.45, 151.16, and 125.48 mg TE/g initial lignin were achieved within 15, 37.5, and 60 min in standard runs 7, 16, and 25, respectively. At the lower temperature of 25 °C, the FRAP values of 160.20, 165.66, and 151.79 mg TE/g initial lignin were achieved within 15, 37.5, and 60 min in standard runs 1, 10, and 19, respectively.

The result of the ANOVA for the Quadratic Model of FRAP indicates that synergistic catalysts, temperature, and reaction time significantly influence the ferric-reducing antioxidant power. Moreover, the significant term of a two-way interaction between temperature (B) and reaction time (C) confirms that the effect of reaction time depends on the values of temperature: the reaction time adversely affects the FRAP obtained, especially at high temperature. Based on Eq. (2), the high value of R2 of 0.9159, together with the predicted R2 of 0.8647, are in reasonable agreement with the adjusted R2 of 0.8957, indicating the efficacy of the model.

3.2.2 DPPH radical-scavenging activity

The highest DPPH result of 35.47 μg TE/ g initial lignin occurred in standard run 1 (38.1 mg/L of Fe0, 49.5 mg/L of Fe2+, 71.4 mg/L of Fe3+, and 1884.4 mg/L of H2O2 at 25 °C for 37.5 min at 25 °C for 15 min). This concentration level of synergistic catalysts of five times was similar to the FRAP result. However, when the synergistic catalyst concentration, along with the reaction time, was increased, the lowest DPPH result was achieved, in standard run 24 (18.80 μg TE/g initial lignin). In addition, temperature did not obviously influence this response.

The result of the ANOVA of DPPH indicates that only the concentration of synergistic catalyst and the reaction time are statistically significant. The model in Eq. (3) is acceptable (F-value of model < 0.0001, R2 = 0.7795) and significant. There is only a 0.01% chance that the model F-value could occur due to noise. The significant lack of fit for Eq. (3) suggests that the experimental data sufficiently fit the model.

3.2.3 Trolox equivalent antioxidant capacity values

The highest ABTS result of 971.60 μg TE/g initial lignin occurred in standard run 11 (114.2 mg/L of Fe0, 148.4 mg/L of Fe2+, 214.1 mg/L of Fe3+, and 5653.2 mg/L of H2O2 at 25 °C for 37.5 min). With a reaction time of 37.5 min and a temperature of 25 °C, this is similar to the FRAP result. However, a high level of the three factors showed the lowest DPPH result, in standard run 27 (705.60 μg TE/g initial lignin).

The result of the ANOVA of ABTS indicated that the concentration of synergistic catalysts and the reaction time, as well as temperature, significantly influenced the ABTS result. The model in Eq. (4) is acceptable (F-value of model < 0.0001, R2 = 0.7128) and significant. There is only a 0.01% chance that the model F-value could occur due to noise.

Based on the antioxidant activity results, the values obtained from FRAP, ABTS, and DPPH assays, with an identical standard of Trolox, are different. The FRAP values are much higher than those of ABTS and DPPH because FRAP is related to the number of hydroxyl groups on the aromatic rings and the presence of a conjugated system on an aromatic ring, as well as a side chain, on the lignin-derived compounds. In contrast, ABTS and DPPH values are related to the number of hydroxyl groups on the aromatic rings [6]. For this reason, the FRAP values were considerably higher than those of ABTS and DPPH.

Moreover, at the operative condition of maximum FRAP and vanillin, i.e., low levels of catalyst concentration, we found that FRAP was favored at 25 °C for 37.5 min in standard run 10, and vanillin formation was favored at 50 °C for 60 min in standard run 25. This result indicates that lignin depolymerization by synergistic catalytic Fenton oxidation, to generate low-molecular-weight lignin-derived compounds, could be achieved at 25 °C for 37.5 min following vanillin formation by side-chain oxidation or bond cleavage of dimer molecules, which takes a long time and is favored at elevated temperatures.

3.3 Effects of condition parameters on total phenolic and aromatic contents

The result of the ANOVA of TPC shows that only the concentration of synergistic catalysts and the temperature significantly influenced total phenolic content. For a model equation based on Eq. (5), the low values of R2 of 0.5791, together with the predicted R2 of 0.4623 as well as the adjusted R2 of 0.5340, indicate that the model equation in Eq. (5) is poor.

Similarly, the result of the ANOVA of aromatic content shows that the concentration of synergistic catalysts significantly influenced total phenolic content, whereas temperature and time were not significant. For a model equation based on Eq. (6), the low values of R2 of 0.2602, together with the predicted R2 of 0.0332 as well as the adjusted R2 of 0.1809, indicate poor model equation.

Therefore, Eqs. (5) and (6) are not suitable to describe the responses of the experiment for total phenolic content and aromatic content, respectively. This result could be explained by the hydroxyl radicals from the Fenton reaction, which react with phenolic moieties via electrophilic attack to generate aromatic intermediates; however, the ring-opening reaction of aromatic intermediates by hydroxyl radicals is relatively low when the temperature of the Fenton reaction is below 140 °C [7]. For this reason, reaction temperature and time within the range of the experiment had no effects on aromatic content in lignin oxidation via the Fenton process.

3.4 Optimization and validation of the experimental model of vanillin yield

Numerical optimization was used to determine the optimal conditions of the operating parameters in the Fenton process for the conversion of lignin into vanillin. The goal for each parameter and a response were selected from the menu. The three independent parameters catalyst concentration, temperature, and time were maintained within the design range, and the maximum was selected for the response variable vanillin yield. The optimal process conditions for vanillin production from lignin through the heterogeneous Fenton oxidation were predicted by the regression model.

Based on the response surface and desirability by the Design-Expert software, three solutions were selected, and the confirmation experiment was conducted at selected solutions to compare the actual responses with the optimal predicted values. Table 4 shows the comparison between the predicted and actual values. Under these conditions, the maximum vanillin yield obtained was 0.713% at 38.05 mg/L Fe0, 49.45 mg/L Fe2+, 71.35 mg/L Fe3+, and 1884.4 ppm H2O2 at 41.404 °C for 60 min at pH 3. Differences between predicted and experimental values were less than 5%. The optimum vanillin yield obtained was 0.690% at 38.05 mg/L Fe0, 49.45 mg/L Fe2+, 71.35 mg/L Fe3+, and 1884.4 ppm H2O2 at 41.404 °C for 60 min at pH 3. This indicates the suitability and applicability of the designed models.

3.5 Low-molecular-weight lignin-derived products

The low-molecular-weight lignin-derived compounds from alkaline lignin depolymerization via synergistic catalytic Fenton oxidation are shown in Fig. 3 and Table 5; 2.5% alkaline lignin was depolymerized by synergistic catalytic Fenton oxidation with optimized conditions, including 38.05 mg/L Fe0, 49.45 mg/L Fe2+, 71.35 mg/L Fe3+, and 1884.4 ppm H2O2 at 41.404 °C for 60 min at pH 3. The reaction was terminated by adjusting the pH to 7 prior to the extraction with ethyl acetate for GC-MS analysis [25]. A mixture of aromatic aldehydes, ketones, and esters in ethyl acetate was identified; for example, peaks at retention times of 12.16 and 13.12 min were identified as vanillin and acetovanillone, respectively. Fortunately, vanillin, which is aldehydic, showed the largest area (71.40%) of the chromatogram peaks. In addition, vanillin-derived esters, such as ethyl vanillate (retention time of 14.24 min) and methyl homovanillate (retention time of 15.02 min), were also identified. These aromatic compounds are derived from the guaiacyl subunit of lignin. On the other hand, syringyl-derived compounds represented peaks with a small area in the chromatogram and included aldehyde types (syringaldehyde, retention time of 15.13 min) and ketone types (acetosyringone, retention time of 15.96 min).

This implies that the alkaline lignin used as a raw material in this study might contain more guaiacyl than syringyl units [21]. As a result of GC-MS analysis, the existence of the aromatic compounds in the aqueous phase indicated that synergistic catalytic Fenton oxidation under optimized conditions is a potential approach toward lignin valorization to produce mainly vanillin, using technical lignin as raw material.

Comparing with other studies, both homogeneous and heterogeneous catalytic Fenton oxidations were applied for the depolymerization of lignin to generate chemicals. However, it has been reported that dicarboxylic acids are the main components of lignin-derived compounds after lignin depolymerization by Fenton oxidation with ferrous iron [13, 27] and chalcopyrite [18] as catalysts. These dicarboxylic acids are byproducts of aromatic ring cleavage of lignin monomers.

In the present study, optimized synergistic catalyst concentration, temperature, and reaction time achieved lignin depolymerization. Furthermore, with mild conditions at temperatures lower than 60 °C, at ambient pressure, and within 60 min, vanillin is the main component of the lignin-derived products, not dicarboxylic acid. This indicates that the technique described in the present study could control the oxidation process in lignin depolymerization to minimize aromatic ring cleavage, avoiding dicarboxylic acid formation and achieving a high aromatic aldehyde content in the product mixture.

4 Conclusions

In the current study, the three independent variables of the heterogeneous Fenton oxidation of lignin, including Fe0, Fe2+, Fe3+, and H2O2 concentration, temperature (25–50 °C), and reaction time (15–60 min), were investigated to optimize the process condition of the Fenton oxidation for the conversion of technical lignin into vanillin. Response surface methodology using a three-level factorial design was employed to evaluate the effects of factors on the response and to provide a regression model for the prediction of the response. The result shows that the concentration of the synergistic catalyst had a negative effect on vanillin yield, whereas reaction temperature and time had positive effects. However, the three factors had effects on antioxidant activities, although they did not differ from that on vanillin yield. Numerical optimization and desirability function were carried out using the Design-Expert software. The optimum conditions for the conversion of lignin into vanillin through Fenton oxidation were 38.05 ppm Fe0, 49.45 ppm Fe2+, and 71.35 ppm Fe3+, incorporating 1884.4 ppm H2O2 at 41.80 °C for 60 min and pH 3 at a stirring speed of 250 rpm. Under optimum conditions, vanillin yield was 0.690%, which was increased by 259.38% from the starting material. The GC-MS result of the ethyl acetate fraction from treated lignin under optimum conditions confirmed that the major component is vanillin, followed by acetovanillone and small quantities of methyl homovanillate and ethyl vanillate. We show that the heterogeneous Fenton oxidation is an effective approach to convert lignin into vanillin. However, vanillin yield needs to be improved. Further studies are therefore needed to investigate the effects of process parameters, such as ratio of lignin and hydrogen peroxide and sequential addition of hydrogen peroxide, to overcome the negative effects of high reactant concentrations on the formation of products.

References

Amore A, Ciesielski PN, Lin CY, Salvachua D, i Nogué VS (2016) Development of lignocellulosic biorefinery technologies: recent advances and current challenges. Aust J Chem 69:1201–1218. https://doi.org/10.1071/CH16022

Auxenfans T, Terryn C, Paës G (2017) Seeing biomass recalcitrance through fluorescence. Sci Rep 7:8838–8846. https://doi.org/10.1038/s41598-017-08740-1

Behling R, Chatel G, Valange S (2017) Sonochemical oxidation of vanillyl alcohol to vanillin in the presence of a cobalt oxide catalyst under mild conditions. Ultrason Sonochem 36:27–35. https://doi.org/10.1016/j.ultsonch.2016.11.015

Benzie IF, Strain JJ (1996) The ferric reducing ability of plasma (FRAP) as a measure of "antioxidant power": the FRAP assay. Anal Biochem 239:70–76. https://doi.org/10.1006/abio.1996.0292

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol 28:25–30. https://doi.org/10.1016/S0023-6438(95)80008-5

Cerretani L, Bendini A (2010) Rapid assays to evaluate the antioxidant capacity of phenols in virgin olive oil. In: Preedy VR, Watson RR (eds) Olives and olive oil in health and disease prevention. Academic Press, San Diego, pp 625–635. https://doi.org/10.1016/B978-0-12-374420-3.00067-X

Comninellis C (1994) Electrochemical oxidation of organic pollutants for wastewater treatment. In: CAC S (ed) Studies in environmental science, vol 59. Elsevier, Amsterdam, pp 77–102. https://doi.org/10.1016/S0166-1116(08)70548-X

Dewanto V, Wu X, Adom KK, Liu RH (2002) Thermal processing enhances the nutritional value of tomatoes by increasing total antioxidant activity. J Agric Food Chem 50:3010–3014. https://doi.org/10.1021/jf0115589

Fache M, Boutevin B, Caillol S (2016) Vanillin production from lignin and its use as a renewable chemical. ACS Sustain Chem Eng 4:35–46. https://doi.org/10.1021/acssuschemeng.5b01344

García Einschlag FS, Braun AM, Oliveros E (2015) Fundamentals and applications of the photo-Fenton process to water treatment. In: Bahnemann DW, Robertson PKJ (eds) Environmental photochemistry part III. Springer, Berlin, pp 301–342. https://doi.org/10.1007/698_2013_247

Guadix-Montero S, Sankar M (2018) Review on catalytic cleavage of C–C inter-unit linkages in lignin model compounds: towards lignin depolymerisation. Top Catal 61:183–198. https://doi.org/10.1007/s11244-018-0909-2

Janshekar H, Brown C, Fiechter A (1981) Determination of biodegraded lignin by ultraviolet spectrophotometry. Anal Chim Acta 130:81–91. https://doi.org/10.1016/S0003-2670(01)84153-2

Kang J, Irmak S, Wilkins M (2019) Conversion of lignin into renewable carboxylic acid compounds by advanced oxidation processes. Renew Energy 135:951–962. https://doi.org/10.1016/j.renene.2018.12.076

Kishimoto T, Chiba W, Saito K, Fukushima K, Uraki Y, Ubukata M (2010) Influence of syringyl to guaiacyl ratio on the structure of natural and synthetic lignins. J Agric Food Chem 58:895–901. https://doi.org/10.1021/jf9035172

Kumar M, Campbell L, Turner S (2016) Secondary cell walls: biosynthesis and manipulation. J Exp Bot 67:515–531. https://doi.org/10.1093/jxb/erv533

Li M, Pu Y, Ragauskas AJ (2016) Current understanding of the correlation of lignin structure with biomass recalcitrance. Front Chem 4:45. https://doi.org/10.3389/fchem.2016.00045

Lin YY, Lu SY (2019) Selective and efficient cleavage of lignin model compound into value-added aromatic chemicals with CuFe2O4 nanoparticles decorated on partially reduced graphene oxides via sunlight-assisted heterogeneous Fenton processes. J Taiwan Inst Chem Eng 97:264–271. https://doi.org/10.1016/j.jtice.2019.02.007

Ma R, Guo M, Zhang X (2014) Selective conversion of biorefinery lignin into dicarboxylic acids. ChemSusChem 7:412–415. https://doi.org/10.1002/cssc.201300964

Pesakhov S, Benisty R, Sikron N, Cohen Z, Gomelsky P, Khozin-Goldberg I, Dagan R, Porat N (2007) Effect of hydrogen peroxide production and the Fenton reaction on membrane composition of Streptococcus pneumoniae. Biochim Biophys Acta 1768:590–597. https://doi.org/10.1016/j.bbamem.2006.12.016

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26:1231–1237. https://doi.org/10.1016/S0891-5849(98)00315-3

Ren T, Qi W, Su R, He Z (2019) Promising techniques for depolymerization of lignin into value-added chemicals. ChemCatChem 11:639–654. https://doi.org/10.1002/cctc.201801428

Rennie EA, Scheller HV (2014) Xylan biosynthesis. Curr Opin Biotechnol 26:100–107. https://doi.org/10.1016/j.copbio.2013.11.013

Rinaldi R, Jastrzebski R, Clough MT, Ralph J, Kennema M, Bruijnincx PCA, Weckhuysen BM (2016) Paving the way for lignin valorisation: recent advances in bioengineering, biorefining and catalysis. Angew Chem Int Ed 55:8164–8215. https://doi.org/10.1002/anie.201510351

Seesuriyachan P, Kuntiya A, Kawee-ai A, Techapun C, Chaiyaso T, Leksawasdi N (2015) Improvement in efficiency of lignin degradation by Fenton reaction using synergistic catalytic action. Ecol Eng 85:283–287. https://doi.org/10.1016/j.ecoleng.2015.10.013

Wu W, Dutta T, Varman AM, Eudes A, Manalansan B, Loqué D, Singh S (2017) Lignin valorization: two hybrid biochemical routes for the conversion of polymeric lignin into value-added chemicals. Sci Rep 7:8420. https://doi.org/10.1038/s41598-017-07895-1

Wu K, Ying W, Shi Z, Yang H, Zheng Z, Zhang J, Yang J (2018) Fenton reaction-oxidized bamboo lignin surface and structural modification to reduce nonproductive cellulase binding and improve enzyme digestion of cellulose. ACS Sustain Chem Eng 6:3853–3861. https://doi.org/10.1021/acssuschemeng.7b04191

Zeng J, Yoo CG, Wang F, Pan X, Vermerris W, Tong Z (2015) Biomimetic Fenton-catalyzed lignin depolymerization to high-value aromatics and dicarboxylic acids. ChemSusChem 8:861–871. https://doi.org/10.1002/cssc.201403128

Zeng Y, Himmel ME, Ding SY (2017) Visualizing chemical functionality in plant cell walls. Biotechnol Biofuels 10:263–278. https://doi.org/10.1186/s13068-017-0953-3

Funding

Financial support was received from National Research Council of Thailand (NRCT) via the Royal Golden Jubilee PhD Program, Thailand (Grant No. PHD/0162/2559) to Mr. Apisit Manassa and Dr. Phisit Seesuriyachan. In addition, this work was also partially financially supported and/or in-kind supported by Biotechnology Program, Graduate School of Chiang Mai University, Cluster of Agro Bio-Circular-Green Industry (Agro BCG): CMU-8392(10)/W. 152-12032020, Faculty of Agro-Industry, and Chiang Mai University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 32 kb)

Rights and permissions

About this article

Cite this article

Manassa, A., Seesuriyachan, P. Valorization of alkaline lignin and optimization of vanillin production by heterogeneous Fenton-type catalysts. Biomass Conv. Bioref. 11, 1029–1039 (2021). https://doi.org/10.1007/s13399-020-00902-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00902-y