Abstract

Global water scarcity at an alarming stage has triggered the interest of many environmentalists and global researchers. Use of freshwater in biomass-based industries would result in depletion of a precious natural resource, which is not sustainable in the long term. Thus, water management technologies are critical to the successful operation of an ethanol plant. Utilization of seawater-based systems and halotolerant enzymes can be a breakthrough in this context. The present study involves marine bacterial strains Bacillus oceanisediminis, Brevibacterium halotolerans, and Psychrobacter celer capable of producing halotolerant cellulases, isolated from Gopalpur, Odisha. The crude enzyme extracts and direct bacterial cultures were independently utilized for saccharification of pretreated rice straw, and the treated rice straw was characterized for the production of reducing sugars using high-performance liquid chromatography (HPLC). The possible bond breakage and formation during saccharification of cellulose was assessed using attenuated total reflectance with Fourier transform infrared (ATR-FTIR) spectroscopy. The relative fraction and size of crystallites in cellulose was evaluated by X-ray diffraction (XRD) study. The biomass saccharified using the crude cellulase from B. oceanisedimins was utilized for the production of bioethanol in freshwater and seawater-based media using Saccharomyces cerevisiae NCIM 3570 and Candida shehatae NCIM 3500. The maximum fermentation efficiency (45.74%) was recorded for saccharified rice straw in freshwater using a consortium of immobilized yeasts. The highest fermentation efficiency (36.69%) was recorded in the seawater system by immobilized S. cerevisiae.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The increasing carbon dioxide emission and growing concern of environment-friendly alternatives for fossil fuels have opened windows for biomass-based products. United Nations in the 2014 World Water Development Report [1] reported consumption of 19–23% of all the available freshwater around the world in the global industrial sector [2]. Water is a significant component of biomass-based industries and with the rapid depletion of freshwater resources; these industries pose more threat to the usage of freshwater. An estimated 3 to 4 gal of freshwater is required to produce 1 gal of ethanol [3]. The current issue warrants designing of sustainable and efficient practices to curb freshwater usage for industrial purposes. Utilization of seawater for biomass-based industries like the biofuel industry can reduce the dependence on freshwater up to a larger extent, and halotolerant enzymes can play a major tool for the same. However, the employment of marine biomass and saline system for saccharification and fermentation insists on halotolerant enzymes. In contrast to normal cellulases, the halotolerant variants are tolerant to high salt concentrations and ionic solvents and utilization of salt tolerant cellulases in the pretreatment of biomass in biofuel industry shall lead to the promotion of utilization of seawater/brackish water. Seawater does not have any substantial negative effect on ionic liquid pretreated biomass or on enzymatic hydrolysis [4].

Halophilic and halotolerant organisms and their enzymes are gaining attention due to their ability to work on marine biomass. Marine hydrolytic enzymes offer salt tolerance, hyperthermostability, cold adaptability, chemoselectivity, barophilicity, regioselectivity, and stereoselectivity [5]. Potential halotolerant enzymes were isolated from hypersaline microbes like halophilic α-amylase from Haloarcula hispanica [6], glucoamylases from marine yeast Aureobasidium pullulans N13d [7], halophilic and thermophilic amyloglucosidase from Halobacterium sodomense that can work between 66 and 76 °C and 8 to 22% of NaCl. A halotolerant cellulase from Bacillus flexus NT was reported to be active at even 15% NaCl concentration [8]. Accellerase-1500 (the cocktail of different glycosidases) was reported to depolymerise cellulose and avicel in reaction media prepared with 1×, 2×, and 4× concentration of seawater [9]. Grande and De Maria [10] assessed the cellulolytic activity of commercially available Accellerase-1500, an enzymatic cocktail of different glycosidases (cellulase, hemicellulase, and a higher level of β-glucosidase, derived from Trichoderma reseii) in different concentrated seawater systems. This was the first report published regarding the enzymatic hydrolysis of cellulose in seawater. Cellulose molecule with varying degrees of crystallinity was assessed for hydrolysis in seawater, and the reports proved that hydrolysis is possible with slight diminishing rates (~ 90%) as compared to that of the reaction carried out in a controlled buffer system. The enzyme effectively hydrolyzed both amorphous and microcrystalline cellulose in seawater. Hydrolysis of amorphous cellulose Sigmacell-101 using Accellerase-1500 remained the same in the buffer and in seawater, which may be due to low crystallinity of the samples. For Sigmacell-20 and Avicel, the hydrolytic activity of the enzyme in seawater was 90% to that of the activity achieved with buffer. A seawater-based approach is essential as a measure to overcome the diminishing freshwater resources and overcoming the dependence of biomass-based industries on these resources. Cellulase is currently being used in a variety of industries including food, textile, and paper industries, which generate a million dollars worth economy. The depletion of fossil fuels and rising demands for biofuels has renewed the interest in cellulases for the utilization of lignocellulose sources, and it is conceived to be the major area for exploitation of cellulases in the future. Hydrolysis of lignocellulose biomass by cellulolytic enzymes plays a potential role in the production of ethanol [11]. The decades of research on cellulases are still unable to resolve the related issues, particularly the cost of production and maintenance of an optimal environment for enzyme action.

Development of a seawater-based biorefinery strategy could make a strong impact in these areas with a holistic utilization of seawater, aiming at more efficient, low-cost, and small water footprint processes. The concept of water footprint emerged in the early 2000s to describe the volume of water used in the entire production process and the overall supply chain [10]. The water footprint of bioethanol production ranges varies between 1300 and 9812 l of water per liter of ethanol, where the major portion of supply is used for cultivation of biomass [12]. The global freshwater resources being limited may trigger a debate on food and land usage with an allocation of such large-scale supply of freshwater for the bioethanol industry [13]. The use of marine biomass and replacement of freshwater with seawater are few approaches to reduce the water footprint of bioethanol production [14, 15]. There are reports for the use of seawater in enzymatic hydrolysis of lignocellulosic biomass [16–18], fermentation process using halotolerant yeasts [19] also, few marine yeasts were isolated and tested for their fermentation capacity in seawater [20]. Utilization of seawater for biofuel production reduces stress on freshwater resources while enabling the cultivation of biomass, saccharification, and processing of biofuel over a common platform [21]. Fermentation of ethanol in seawater using S. cerevisiae has reported the production of 0.5 g ethanol per gram of glucose [21].

The present study was carried out using halotolerant hydrolytic enzymes from halotolerant cellulase producing bacteria from a marine environment capable of saccharifying the alkali pretreated rice straw biomass to reducing sugars in a seawater-based system for production of bioethanol. This research work is the cynosure of the optimization of activity of cellulase (at a particular temperature, pH, and substrate concentration), purification of enzymes produced by potent isolates and their characterization. The change in the composition of biomass was quantitatively and qualitatively investigated using high-performance liquid chromatography (HPLC), whereas attenuated total reflectance with Fourier transform infrared (ATR-FTIR) spectroscopy and X-ray diffraction (XRD) was performed to explore the structural changes in the biomass. Also, the study comprehends the utilization of seawater in the fermentation of saccharified biomass and reducing sugars to ethanol by free and immobilized yeast cells.

2 Materials and methods

2.1 Collection of marine sample

Wood pieces, seawater, algal biomass, and sediment samples were collected from six randomly chosen locations from the Gopalpur sea beach (19.27° N, 84.92° E), Ganjam District (15 km from Berhampur), Odisha, India, in the sterile centrifuge tubes during June 2014 and brought to the lab for further studies. The pH of seawater at the time of collection was recorded to be 7.88 (Sartorius Professional Meter, PP-20) and salinity was found to be 33 ppt (ERMA Hand Refractometer).

2.2 Screening, characterization, and purification of cellulase

All the detailed methods related to isolation, characterization, and purification of cellulase are given as supplementary information (Page 1–4, Section 1.1–1.10).

2.3 Rice straw composition analysis

The composition of rice straw was analyzed by analytical procedure of NREL (National Renewable Laboratory). Biomass was pretreated with 1% NaOH at 121 °C at 15 lbs. pressure for 20 min. Moisture and lignin content was determined by method suggested by Templeton and Ehrman [22].

2.4 Production of cellulase

The marine cellulolytic bacterial strains Bacillus oceanisediminis, Brevibacterium halotolerans, and Psychrobacter celer capable of producing halotolerant cellulases, isolated from Gopalpur, Odisha, were used as potent cellulase producers. The selected isolates were cultured at 37 °C at 150 rpm in 100 mL of enzyme production media composed of 0.1 g NaNO3, 0.1 g KH2PO4, 0.0.1 g KCl, 0.5 MgSO4, 0.5 g yeast extract, 0.1 g glucose, 0.5 g CMC at pH 6.8–7.2. Broth culture after 3 days of incubation period at 32 °C was subjected to centrifugation at 5000 rpm for 15 min at 4 °C. The supernatant was collected and stored as crude enzyme preparation at 4 °C for further enzyme assays [23].

2.5 Saccharification of pretreated biomass with crude enzyme extract

Rice straw was considered as the lignocellulosic biomass feedstock and collected from the agricultural fields located on the outskirts of Rourkela city (22.2492° N, 84.8828° E), Sundergarh, Odisha, India. The selected biomass was pretreated by using 1% NaOH, followed by autoclaving at 121 °C, 15 psi for 20 min. Saccharification of pretreated rice straw was studied in both freshwater and seawater (composition analysis was performed as described by Indira et al. [24] to assess the efficacy of enzymes in both the systems. For saccharification, 100 mg of pretreated rice straw biomass was taken in 50-mL capacity clean and dry test tubes with 5 mL of phosphate buffer, pH 7.4 (freshwater control) and 5 mL of seawater. Crude enzyme extract was added to it in 500 μL volume, and the test tubes were incubated at 50 °C in a water bath for 20 min. The enzymatically treated samples were then harvested, filtered using syringe filters, and stored at 4 °C until further analysis.

2.6 Saccharification of pretreated biomass directly with bacterial culture

Pretreated biomass was used as the carbon source in basal salt media (0.1 g NaNO3, 0.1 g KH2PO4, 0.0.1 g KCl, 0.5 MgSO4, 0.5 g yeast extract, and 0.1 g glucose) prepared both in distilled water (freshwater control) and seawater and autoclaved in 200 mL Erlenmeyer flasks. Overnight grown cultures of potent isolates were added at the 10% as inoculum to the biomass and incubated at 32 °C for 5 days. Saccharification of rice straw was studied in both freshwater and seawater to assess the efficacy of enzymes in both the systems. After incubation, the samples were then harvested, centrifuged at 5000 rpm, and filtered using syringe filters and stored at 4 °C until further analysis.

2.7 Characterization of biomass for enzymatic saccharification using HPLC

Filtered saccharified biomass (20 μL) was injected into the injection loop, and the samples were analyzed for the presence of reducing sugars produced by the saccharification of cellulose by comparing the peaks produced by standards of glucose, mannose, maltotriose, melezitose, stachyose, cellobiose, etc. The samples were analyzed using the Hi-plex H column (Agilent, USA) with sulfuric acid (1 mM) as the mobile phase with 0.7 mL/min as flow rate and column temperature of 60 °C with refractive index (RI) detector (Shimadzu, Japan).

2.8 Characterization of biomass for enzymatic saccharification using ATR-FTIR

The ATR-FTIR spectroscopy analysis was performed to assess the possible bond breakage and formation during saccharification of cellulose. The ATR-FTIR was performed on a Bruker ALPHA spectrophotometer (Ettlinger, Germany) with a resolution of 4 cm−1, a spectral region between 4000 and 800 cm−1, and an average of 25 scans per sample. Sample (10 μL) was kept on the sample holder and scanned; the result obtained was analyzed through OPUS software.

2.9 XRD analysis of rice straw biomass after cellulolysis

The relative fraction and size of crystallites in cellulose can be evaluated by XRD and electron diffraction/microscopic methodologies [25, 26]. The XRD study of treated biomass was obtained using an X-ray diffractometer (Rigaku Ultima IV, Japan) equipped with Ni filter and Cu Kα (l = 1.54056 Å) radiation source. The diffraction angle was varied in the range of 10–80° while the scanning rate was 5°/s. The degree of crystallinity of rice straw biomass was calculated using the equation:

where Icr is the peak intensities from crystalline and Iam is the peak intensities from amorphous regions of cellulose.

2.10 Fermentation of saccharified biomass

Two yeast strains, i.e., S. cerevisiae NCIM 3570 and C. shehatae NCIM 3500 were purchased from the National Collection of Industrial Microorganisms (NCIM), National Chemical Laboratory, Pune, India. These cultures were maintained on MGYP (malt extract 1%, glucose 1%, yeast extract 0.3%, peptone 1%) medium at pH 6.0. Yeast cells were cultured on MGYP broth at pH 6.0, for 48 h at 30 °C and 120 rpm and were immobilized using 3% sodium alginate and 0.05 M calcium chloride solution [27]. Immobilized yeast cells obtained in the form of beads were utilized for the fermentation of sugar solution. Fermentation media was prepared using a 10% initial glucose concentration for S. cerevisiae at pH 6.0–6.5 and 5% glucose to 5% xylose concentration for C. shehatae at pH 5.5. Ten percent of inoculum (immobilized and free cells) was added to fermentation media. The fermentation media was incubated for 120 h at 30 °C and 120 rpm. After incubation, the free and immobilized cells were filtered and the crude broth was analyzed for the ethanol content. Fermentation media was also prepared in distilled water with the same composition at pH 6.0–6.5 and this set up was utilized as control. Saccharified rice straw biomass having a 1.6% concentration of glucose was utilized as biomass for the production of ethanol using freshwater and seawater. A consortium approach was also tried using S. cerevisiae and C. shehatae for the utilization of both six-carbon and five-carbon compounds. Ten percent of inoculum (immobilized and free cells) was added to fermentation media. The fermentation media was incubated for 72 h at 30 °C and 120 rpm. After incubation, the free and immobilized cells were filtered and the crude broth was analyzed for the ethanol content.

2.11 Estimation of ethanol production by HPLC analysis

The amount of ethanol in the crude broth was estimated by HPLC (Shimadzu, Japan) analysis using the Hi-Plex H column (Agilent, USA) having column temperature 60 °C. Sulfuric acid (1 mM) was used as a mobile phase with 0.7 mL/min as a flow rate. RI detector was used for the detection. The concentration of ethanol was determined by using an appropriate standard and using the following formula:

The theoretical yield of ethanol is 0.51 g per 1.0 g of glucose, i.e., 2 mol of ethanol per mole of glucose and 0.51 g of ethanol per 1.0 g of xylose, i.e., 1.67 mol of ethanol per mole of xylose. Ethanol yield (g/g) is defined as the amount of ethanol produced from per gram of sugar. Ethanol yield can be calculated by the following equation [28]:

Fermentation efficiency (FE) was calculated for fermentable sugars and is expressed as the percentage of theoretical yield, using a stoichiometric equation, according to the following formula [28]:

where E is the ethanol concentration (g/L); FS are fermentable sugars; 0.51 is constant which represent a theoretical yield of ethanol from glucose and xylose.

2.12 Salt tolerance of yeast cells

The yeast cells S. cerevisiae and C. shehatae, capable of fermentation in seawater were screened for salt tolerance. The cells were subjected to a varying degree of salt concentration, i.e., [1–9]% of NaCl in standard MGYP broth. The growth of yeast cells was monitored for 48 h by recording absorbance at 600 nm using a spectrophotometer (UV/VIS Spectrophotometer, Lambda 35, PerkinElmer).

2.13 Statistical analysis

Experiments in Sects. 2.2 to 2.11 were conducted in triplicate. Microsoft Excel 2010 was used for the calculation of mean and standard deviation. SPSS (IBM Statistics) software version 19.0 was used for comparing the means through one-way ANOVA, and mean differences were compared using Duncan’s multiple range test.

3 Results and discussion

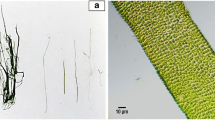

3.1 Isolation and screening of cellulase-producing marine bacteria

Potent cellulase producing bacteria were identified as B. oceanisediminis, B. halotolerans, P. celer, Pseudomonas aeruginosa, and Bacillus subtilis through phenotypic, biochemical, and molecular characterization studies. Detailed results are given as supplementary information (Page 4–8, Section 2.1–2.6).

3.2 Composition of rice straw

The rice straw biomass was composed of 34.5% cellulose, 24% hemicellulose, 11.4% lignin, 3% moisture, and 29.8% of other unidentified constituents, which account for the ash and silica content of the chosen biomass. The holocellulose content was found to be 58.5%, which contributes to the total sugar concentration of the pretreated biomass. Thus, rice straw can be used as a potential substrate for ethanol production with a substantial concentration of carbohydrates similar to the other lignocelluloses (corn stover, 58.29%; sorghum straw, 61%; sugarcane bagasse, 67.15%, and wheat straw, 54%) [29].

3.3 Characterization of biomass for enzymatic saccharification

3.3.1 Characterization of biomass for enzymatic saccharification using HPLC

HPLC is considered as one of the reliable methods for the analysis of monosaccharides produced by hydrolysis of biomass. The RI detectors are the most common and less expensive detectors available for analysis of products of biomass hydrolysis. The resulting peaks in the chromatogram were compared with the available standards of reducing sugars, and the concentration of sugar present in the pretreated biomass was calculated using the area occupied by the analytes. The concentration of sugars in biomass treated with B. oceanisediminis, B. halotolerans, and P. celer, under different conditions is summarized in Table 1. Alkali pretreated rice straw biomass when treated with crude cellulase from B. oceanisediminis in freshwater, 4.4 g/L of glucose was produced which was increased to almost fourfold, i.e., 16.8 g/L in a seawater-based system. Glucose yield by direct culture treatment in B. oceanisediminis was lower than the activity of crude cellulase, i.e., 4.3 g/L and 13 g/L in freshwater and seawater, respectively. There was an 18.75% decrease in glucose yield in seawater when saccharification was carried out by direct cultures. For B. halotolerans, crude enzyme was 80% more efficient in glucose production in seawater than freshwater, whereas the culture treatment for saccharification was disappointing with only 0.3 g/L glucose yield. This may be due to the consumption of glucose by bacterial culture during their growth. P. celer cellulase was found to be more active in seawater than in freshwater systems. The crude cellulase from P. celer produced 13.4 g/L glucose in seawater which was 82% more than the yield in freshwater, similarly using direct culture treatment process, there was no production of glucose in freshwater but 11.1 g/L glucose production was recorded in seawater. The above-discussed data suggests that seawater is one of the favorable media of action for saccharification of biomass, and the enzymes used here are halotolerant in nature and can withstand the salinity of seawater. Alkali pretreated rice straw biomass yielded 26.30 g/L whereas the acid-treated biomass yielded 10.98 g/L of reducing sugar on saccharification with enzyme cocktail produced by Aspergillus niger MTCC 7956 and Trichoderma reesei RUTC30 cellulase [30]. Alkali pretreatment was found to be more effective than dilute acid pretreatment. Rice straw biomass pretreated with the ammonia fiber explosion (AFEx) method yielded 26 g of glucose per 100 g of biomass using Accellerase 1000 (Genencor, Rochester, NY, USA) [31]. Pretreatment makes the biomass more accessible to enzymes for hydrolysis of cellulose and hemicellulose, thus increasing the saccharification efficiency. Further optimization of saccharification conditions can lead to yields comparable to the fungal strains. Zaky et al. [32] demonstrated the use of Hiplex-H column for deterimination of chlorides and sodium, thus allowing determination of sugars, alcohols, and organic acids in seawater-based samples.

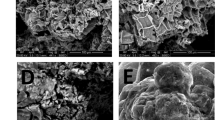

3.3.2 Characterization of biomass for enzymatic saccharification using ATR-FTIR

Previous studies on woody samples suggested a high degree of intercorrelation between the absorption bands [33]. From the analysis of woody biomass, Eucalyptus globulus, it was deduced that the characteristic peaks for cellulose are centered around 1782 cm−1 (C–H stretch first overtone), 2266 cm−1 (O–H, C–O combination bands), and 2332 cm−1 (C–H stretch, C-H deformation) [34]. Based on the above literature, the biomass samples digested with crude enzyme extracts and direct bacterial cultures were analyzed for the presence of cellulose and its conversion product. The characteristic specific maxima of glucose are at 991, 1033, 1078, 1107, and 1149 cm−1, with the highest absorption at 1033 cm−1, which is characteristic of C–O stretch vibration [35]. The IR bands in the region 830, 875, 990, and 1078 cm−1 correspond to glycosidic linkages [36–39]. In the case of direct culture-based saccharification in freshwater in B. oceanisediminis very sharp peak intensity of glucose was evidenced at 1078 cm−1, also there was a substantially noticeable peak at 990 and 850 cm−1, which corresponds to the glycosidic linkages. Similarly, for B. halotolerans and P. celer, the characteristic peak for glucose at 1078 cm−1 was observed but with a lower peak intensity of glucose which may be due to the consumption of glucose by bacterial culture (Fig. 1a). Whereas, in case of treatment with the crude enzyme from B. oceanisediminis in freshwater a reverse trend was observed, i.e., a reduced peak intensity at 1078 cm−1 was observed as compared to that of B. halotolerans and P. celer. The highest peak intensity was observed in the case of P. celer at a slight shift of 1080 cm−1, which includes IR peaks for glucose at 995, 933, 878, and 848 cm−1. In addition, the broad peaks at 3000–2900 cm−1 for lignin, characterized by the aromatic ring [40], C–H and O–H stretching [36] were also present in samples treated with P. celer. For the rice straw biomass treated by direct culture-based saccharification by B. oceanisediminis, B. halotolerans, and P. celer in seawater-based system peaks were evidenced at 1105, 1109, and 1103 cm−1, respectively, which showed a slight shift from 1096 cm−1, characteristic peak of C–H deformation in cellulose (Fig. 1b). Also, for culture-based saccharification by B. oceanisediminis, B. halotolerans, and P. celer in the seawater-based system, strong peaks were evident at 1630, 1643, and 1643 cm−1, characteristic of bending of absorbed residual water [41]. Similar kind of broad peaks at 3000–2900 cm−1 for lignin were also observed in the treated samples (Fig. 1c). In the case of treatment with the crude enzyme in the seawater-based system, similar peaks at 1647, 1645, and 1653 cm−1 were observed. The other infrared (IR) bands for these samples were at 1090 cm−1, which showed a slight shift from 1096 cm−1, characteristic peak of C–H deformation in cellulose (Fig. 1d). Few other peaks involve 613 and 638 cm−1, in samples treated with crude enzymes from B. oceanisediminis and B. halotolerans in the seawater-based system, respectively, which corresponds to the α-D-anomer of glucose.

a FTIR spectrum of pretreated rice straw biomass treated with bacterial culture in freshwater. b FTIR spectrum of pretreated rice straw biomass treated with bacterial cellulase in freshwater. c FTIR spectrum of pretreated rice straw biomass treated with bacterial culture in seawater. d FTIR spectrum of pretreated rice straw biomass treated with bacterial cellulase in seawater

3.3.3 XRD analysis of rice straw biomass after cellulolysis

XRD analysis was performed to investigate the change in crystallinity of cellulose present in rice straw after alkaline pretreatment process and saccharification of alkali-pretreated biomass with cellulase. The native XRD profile of alkali-pretreated rice straw biomass is shown in Fig. 2a. Studies suggest that NaOH pretreated biomass to be of easy access to cellulases, which may be due to an increase in the disorderness of crystalline structure or due to an increase in the amorphous fraction of cellulose [42]. The XRD analysis of alkaline-pretreated rice straw biomass shows a crystallinity of 59.073%. On treatment with B. oceanisediminis, B. halotolerans, and P. celer cellulases in freshwater, the percentage of crystallinity decreased to 40.25%, 37.25%, and 36.05%, respectively (Fig. 2a). However, on treatment with cellulase in the seawater-based system, the crystallinity for B. oceanisediminis, B. halotolerans, and P. celer cellulases was found to be 51.58%, 79.34%, and 49.21%, respectively (Fig. 2b). An increase in crystallinity in the case of seawater based pretreatment may be due to the presence of salts, which may contribute to crystallinity percentage during XRD profiling. The XRD analysis of rice straw biomass evidenced the predominant cellulosic peak at 2θ = 22.3°, 22.4°, 22.5°, 22.6°, and 22.3°, 27.4°, 27.4° for unsaccharified rice straw biomass, saccharified biomass by cellulase from B. oceanisediminis, B. halotolerans, and P. celer in the freshwater and the seawater, respectively. The intensity of the major peak of cellulose has decreased in biomass treated with cellulase in freshwater-based system as well as in seawater-based system. The overall increase in crystallinity percentage was observed in seawater-based cellulase systems due to a sharp peak 2θ = 31.9°, which was also reported in the XRD profile of untreated rice straw in seawater (Fig. 2b). A substantial increase in crystallinity of biomass is noticed after pretreatment which is mainly due to the removal of an amorphous hemicellulosic component. However, the crystallinity of cellulose should be mainly taken into account by pretreatment [43]. Increased crystallinity may be due to the hydrolysis of glycosidic linkages in the accessible regions of cellulose. Reports suggest an increase in crystallinity index after dilute acid pretreatment of sugarcane tops and switchgrass [44–46] reported an increase in crystallinity in samples pretreated with ionic liquids, lime, dilute acids, and steam explosion in comparison to untreated biomass. Rice straw treated with diluted acids showed 67.2% crystallinity whereas native rice straw crystallinity of 59.37%, the increase in crystallinity was reported mostly in the amorphous region [47]. Kshirsagar et al. [48] reported similar results where the crystallinity index of untreated biomass increased from 40.84 to 51.49% in dilute acid pretreated rice straw.

3.4 Estimation of ethanol production

Our previously published research reports immobilized S. cerevisiae and C. shehatae producing 10.19 g/L and 13.98 g/L in freshwater and 9.79 g/L and 10.7 g/L ethanol in seawater-based medium [27]. Gonçalves et al. [21] reported 9.65 g/L and 9.68 g/L of ethanol production from freshwater and seawater, respectively, using S. cerevisiae. Production of ethanol by Zymomonas mobilis and Pitchia stipitis were also reported with 9.27 g/L and 9.44 g/L and 8.73 g/L and 7.34 g/L in freshwater and seawater, respectively. The same report accompanied the conversion of substrate into microbial biomass and suggested both ethanol production and biomass conversion to be inversely proportional. All the available literature from the previous studies states that there is no significant difference between the ethanol yields from freshwater or seawater based system, which is possibly due to salt tolerance by S. cerevisiae and capability to metabolize salt [49]. The marine S. cerevisiae AZ65 strain tolerated up to 9% of NaCl and metabolized 25% glucose in seawater-based fermentation medium with a theoretical yield of 83.33% [50]. Keeping the positive outcomes of the two yeast strains, i.e., S. cerevisiae and C. shehatae in mind, saccharified rice straw biomass was fermented using these yeast cells independently and also in the consortium. The initial sugar concentration was maintained at 16 g/L of glucose produced by crude bacterial cellulase from B. oceanisediminis in the seawater-based system. Saccharification of biomass also leads to the production of five carbon residues, which can be fermented using C. shehatae. Consortia were tried to learn the activity of both the yeast cells in the case of co-existence and co-fermentation. Immobilized S. cerevisiae was performing better when saccharified biomass was utilized as a source of sugar for ethanol production in seawater when compared to immobilized C. shehatae cells. In comparison to the freshwater system, an insignificant reduction in ethanol production, 11%, and 19%, was observed for immobilized S. cerevisiae and C. shehatae cells in seawater, respectively. In the case of consortium system, there was a significant reduction (44%) in ethanol production in the seawater system. However, ethanol production in the consortium system which employed both immobilized S. cerevisiae and C. shehatae was highest among the other individual counterparts when freshwater was used as fermenting medium (Table 2). The maximum fermentation efficiency recorded for saccharified rice straw in freshwater is 45.74% using a consortium of immobilized S. cerevisiae and C. shehatae. However, in seawater, the consortium has not shown promising results. The highest fermentation efficiency recorded in the seawater system is by immobilized S. cerevisiae cells (36.69%). Fang et al. [51] reported 89.4 and 85.8% fermentation efficiency from pretreated date palm residues, using S. cerevisiae in freshwater and seawater, respectively. Lau and Dale [52] reported the production of ethanol from unwashed AFEx treated corn stover using Saccharomyces cerevisiae 424A(LNH-ST) using the separate hydrolysis and fermentation (SHF) process. Ethanol yield was found to be 191.5 g/kg untreated corn stover, at an ethanol concentration of 40.0 g/L (5.1 V/V%). Attempts have been made to ferment glucose and xylose in a single process by using two different microorganisms, the feasibility of which depends on the utilization of xylose [53–57]. However, the diauxic behavior xylose fermenters and the competition between the glucose-fermenting and xylose-fermenting yeasts in a co-culture do not always ensure efficient conversion of xylose to ethanol [53, 58].

3.5 Salt tolerance of yeast cells

Both S. cerevisiae and C. shehatae yielded positive results in the production of ethanol using freshwater and seawater in free and immobilized forms. Also, the total percent of cell viability was more than 70%. Keeping these aspects in mind, the two potent strains were tested for their salt tolerance in varying concentrations of NaCl and results were quite impressive. S. cerevisiae was tolerant of up to 6% NaCl concentration, i.e., 1.026 M, and the growth remained unaffected. Over 7% NaCl concentration the growth was affected and slowed down on the subsequent increase in NaCl concentration (Fig. 3a). The same pattern of growth was also followed by C. shehatae (Fig. 3b). Reduction in growth rate may be due to osmotic stress caused by the bacterial cells due to the presence of high salt concentration. This study was carried out to check the utilization of these yeast strains for fermentation in seawater, ionic solvents, and wastewater from industries that are rich in salts and mineral concentration. The results yielded complied with the high osmolarity glycerol (HOG) signaling system explained by Hohmann et al. [59], which explains the production and accumulation of compatible solute glycerol that acts as a key to osmoregulation in yeast. Salt tolerance studies revealed that yeast cells could be tolerant up to 6% of NaCl concentration, which is much beyond the salt concentration in seawater. In a recent study by Greetham et al. [60], it was evident that marine yeasts are significantly more tolerant to inhibitors than terrestrial yeasts. The marine yeast Wickerhamomyces anomalus M15 was found to be most tolerant with IC50 values of 10.7% (w/w) and 83.9 mM for salt and acetic acid, respectively, as compared to industrial terrestrial yeast Saccharomyces cerevisiae NCYC2592 with 6.0% (w/w) and 75.9 mM, respectively. These properties declare the marine yeasts as clear winner with respect to industrial setup.

4 Conclusion

The performance of B. halotolerans is best among the three isolates chosen for studies, and that of B. oceanisediminis can be further improved by optimization of conditions for saccharification. P. celer is studied for the first time for cellulase activity, and further optimization of the process can lead to a better candidate for industrial scale. The determined molecular weight and secondary structure of purified cellulases are comparable to the results available in the previously reported Bacillus spp., while few outcomes are new and can be verified with further studies over the same. Also, the above studies revealed that seawater could be used as a medium of saccharification of biomass if halotolerant cellulases are used. The three strains (B. oceanisediminis, B. halotolerans, and P. celer) being halotolerant showed best saccharification results with a crude enzyme in seawater. Based on the saccharification of biomass, B. halotolerans was found to exhibit best saccharifying ability, and therefore can be employed as potential cellulase producer in biofuel industries using seawater-based approach. Also, it was evident from the study that it is advantageous to use crude enzymes than the cultures directly for saccharification of biomass. Saccharification of biomass was evident through the physiological characterization methods like FTIR and XRD analysis. FTIR studies showed an extensive bond breakage and formation, and XRD results showed a significant reduction in crystallinity of biomass on hydrolysis with cellulase in freshwater. In seawater, an increase in crystallinity was recorded which may be due to the presence of salts in seawater which contributes to the crystallinity of biomass. Based on the saccharification of biomass, B. oceanisediminis was found to exhibit best saccharifying ability, and therefore, the biomass saccharified with this strain can be used as a substrate for ethanol production. Production of cellulosic ethanol on a commercial scale is in its premature stage of development in many countries, and the global expansion in ethanol yield using freshwater is going to pose a serious threat to the environment. To overcome this, a productive strategy has to be initiated to ease the environmental stress. The present study focused on developing a strategy for fermentation in seawater using S. cerevisiae and C. shehatae both in free and immobilized forms. The growth of cells in seawater is restricted by osmotic pressure due to high salt concentration and keeping that in mind yeast cells were immobilized to reduce the osmotic stress. The performance of S. cerevisiae remains unaffected in seawater and establishes it to be one of the promising organisms for fermentation. Ethanol production in seawater remains unaffected, and therefore, alternative strategies for fermentation in the seawater-based system have to be developed to encourage ethanol production using marine biomass on a marine platform.

References

WWAP (United Nations World Water Assessment Programme) (2014) The United Nations world water development report 2014: water and energy. UNESCO, Paris

Indira D, Das B, Balasubramanian P, Jayabalan R. (2018) Sea water as a reaction medium for bioethanol production. In Patra JK, Das G, Shin HS (Eds.), Microbial Biotechnology: Application in Food and Pharmacology. (pp. 171-192). Singapore: Springer

Keeney D, Muller M (2006) Water use by ethanol plants: potential challenges. Institute for Agriculture and Trade Policy, Minneapolis, MN

Ren H, Zong MH, Wu H, Li N (2016) Utilization of seawater for the biorefinery of lignocellulosic biomass: ionic liquid pretreatment, enzymatic hydrolysis, and microbial lipid production. ACS Sustain Chem Eng 4(10):5659–5666

Lima RN, Porto ALM (2016) Recent advances in marine enzymes for biotechnological processes. In Advances in food and nutrition research (Vol. 78, pp. 153-192). Academic Press

Oren A (2010) Industrial and environmental applications of halophilic microorganisms. Environ Technol 3:825–834

Hutcheon GW, Vasisht N, Bolhuis A (2005) Characterisation of a highly stable a-amylase from the halophilic archaeon Haloarcula hispanica. Extremophiles 9:487–495

Oren A (2008) Microbial life at high salt concentrations: phylogenetic and metabolic diversity. Saline Syst 4(1):2

Trivedi N, Gupta V, Kumar M, Kumari P, Reddy CRK, Jha B (2010) An alkali-halotolerant cellulase from Bacillus flexus isolated from green seaweed Ulva lactuca. Carbohydr Polym 83(2):891–897

Grande PM, De Maria PD (2012) Enzymatic hydrolysis of microcrystalline cellulose in concentrated seawater. Bioresour Technol 104:799–802

Singhania RR, Sukumaran RK, Patel AK, Larroche C, Pandey A (2010) Advancement and comparative profiles in the production technologies using solid-state and submerged fermentation for microbial cellulases. Enzym Microb Technol 46(7):541–549

Yang H, Pfister S, Bhaduri A (2013) Accounting for a scarce resource: virtual water and water footprint in the global water system. Curr Opin Environ Sustain 5(6):599–606

Gerbens-Leenes W, Hoekstra AY, van der Meer TH (2009) The water footprint of bioenergy. Proc Natl Acad Sci 106(25):10219–10223

Gerbens-Leenes W, Hoekstra AY (2012) The water footprint of sweeteners and bio-ethanol. Environ Int 40:202–211

Zaky AS, Greetham D, Louis EJ, Tucker G, Du C (2016) A new isolation and evaluation method for marine-derived yeast spp. with potential applications in industrial biotechnology. J Microbiol Biotechnol 26(11):1891–1907

Greetham D, Zaky A, Makanjuola O, Du C (2018) A brief review on bioethanol production using marine biomass, marine microorganism and seawater. Curr Opin Green Sustain Chem 14: 53-59

Klement T, Milker S, Jäger G, Grande PM, de María PD, Büchs J (2012) Biomass pretreatment affects Ustilago maydis in producing itaconic acid. Microb Cell Fact 11(1): 43

Vom Stein T, Grande P, Sibilla F, Commandeur U, Fischer R, Leitner W, de María PD (2010) Salt-assisted organic-acid-catalyzed depolymerization of cellulose. Green Chem 12(10):1844–1849

Senthilraja P, Kathiresan K, Saravanakumar K (2011) Comparative analysis of bioethanol production by different strains of immobilized marine yeast. J Yeast Fungal Res 2(8):113–116

Urano N, Yamazaki M, Ueno R (2001) Distribution of halotolerant and/or fermentative yeasts in aquatic environments. J Tokyo Univ Fish 87:23–30

Gonçalves FA, Santos ESD, de Macedo GR (2015) Alcoholic fermentation of Saccharomyces cerevisiae, Pichia stipitis and Zymomonas mobilis in the presence of inhibitory compounds and seawater. J Basic Microbiol 55(6):695–708

Templeton D, Ehrman T (1995) Chemical analysis and testing task: LAP-003 (Determination of acid-insoluble lignin in Biomass) National Renewable Energy Laboratory. Golden, USA

Tailliez P, Girard H, Millet J, Beguin P (1989) Enhanced cellulose fermentation by an asporogenous and ethanol-tolerant mutant of Clostridium thermocellum. Appl Environ Microbiol 55(1):207–211

Indira D, Sharmila D, Balasubramanian P, Thirugnanam A, Jayabalan R (2016) Utilization of sea water based media for the production and characterization of cellulase by Fusarium subglutinans MTCC 11891. Biocatal Agric Biotechnol 7:187–192

Beecher JF, Hunt CG, Zhu JY (2009) Tools for the characterization of biomass at the nanometer scale, The nanoscience and technology of renewable biomaterials, 1st edn. Blackwell Publishing, Singapore, pp 61–80

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3(1):10

Indira D, Jijnasa B, Arati N, Moumita S, Ajay D, Eldin J, Jayabalan R (2015) Comparative studies of ethanol production and cell viability: free cells versus immobilized cells. Res J Pharm Biol Chem Sci 6(2):1708–1714

Berłowska J, Pielech-Przybylska K, Balcerek M, Dziekońska-Kubczak U, Patelski P, Dziugan P, Kręgiel D (2016) Simultaneous saccharification and fermentation of sugar beet pulp for efficient bioethanol production. BioMed Res Intl 2016, 3154929, 10 pages.

Chandel AK, Chan EC, Rudravaram R, Narasu ML, Rao LV, Ravindra P (2007) Economics and environmental impact of bioethanol production technologies: an appraisal. Biotechnol Mol Biol 2:14–32

Sukumaran RK, Singhania RR, Mathew GM, Pandey A (2009) Cellulase production using biomass feed stock and its application in lignocellulose saccharification for bio-ethanol production. Renew Energy 34(2):421–424

Ko JK, Bak JS, Jung MW, Lee HJ, Choi IG, Kim TH, Kim KH (2009) Ethanol production from rice straw using optimized aqueous-ammonia soaking pretreatment and simultaneous saccharification and fermentation processes. Bioresour Technol 100(19):4374–4380

Zaky AS, Pensupa N, Andrade-Eiroa Á, Tucker GA, Du C (2017) A new HPLC method for simultaneously measuring chloride, sugars, organic acids and alcohols in food samples. J Food Compos Anal 56:25–33

Michell AJ, Schimleck LR (1996) NIR spectroscopy of woods from Eucalyptus globules. Appita J 49(1):23–26

Baillères H, Davrieux F, Ham-Pichavant F (2002) Near infrared analysis as a tool for rapid screening of some major wood characteristics in a eucalyptus breeding program. Ann For Sci 59(5–6):479–490

Adina CHIŞ, Florinela FETEA, Abdelmoumen TAOUTAOU, Carmen S (2010) Application of FTIR spectroscopy for a rapid determination of some hydrolytic enzymes activity on sea buckthorn substrate. Rom Biotechnol Lett 15(6):5738–5744

Xu F, Yu J, Tesso T, Dowell F, Wang D (2013) Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: a mini-review. Appl Energy 104:801–809

Schwanninger M, Rodrigues J, Pereira H, Hinterstoisser B (2004) Effects of short time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib Spectrosc 36:23–40

Kubo S, Kadla JF (2005) Hydrogen bonding in lignin: a Fourier transform infrared model compound study. Biomacromolecules 6:2815–2821

Sills DL, Gossett JM (2012) Using FTIR to predict saccharification from enzymatic hydrolysis of alkali pretreated biomasses. Biotechnol Bioeng 109:353–362

Binod P, Satyanagalakshmi K, Sindhu R, Janu KU, Sukumaran RK, Pandey A (2012) Short duration microwave assisted pretreatment enhances the enzymatic saccharification and fermentable sugar yield from sugarcane bagasse. Renew Energy 37(1):109–116

Karthika K, Arun AB, Rekha PD (2012) Enzymatic hydrolysis and characterization of lignocellulosic biomass exposed to electron beam irradiation. Carbohydr Polym 90(2):1038–1045

Mittal A, Katahira R, Himmel ME, Johnson DK (2011) Effects of alkaline or liquidammonia treatment on crystalline cellulose: changes in crystalline structure and effects on enzymatic digestibility. Biotechnol Biofuels 4:41

Singh J, Suhag M, Dhaka A (2015) Augmented digestion of lignocellulose by steam explosion, acid and alkaline pretreatment methods: a review. Carbohydr Polym 117:624–631

Sindhu R, Kuttiraja M, Binod P, Janu KU, Sukumaran RK, Pandey A (2011) Dilute acid pretreatment and enzymatic saccharification of sugarcane tops for bioethanol production. Bioresour Technol 102(23):10915–10921

Samuel R, Pu Y, Foston M, Ragauskas AJ (2010) Solid-state NMR characterization of switchgrass cellulose after dilute acid pretreatment. Biofuels 1(1):85–90

Zhang T, Datta S, Eichler J, Ivanova N, Axen SD (2011) Identification of a haloalkaliphilic and thermostable cellulase with improved ionic liquid tolerance. Green Chem 13:2083–2090

Cao Y, Tan HJ (2004) Structural characterization of cellulose with enzymatic treatment. J Mol Struct 705:189–193

Kshirsagar SD, Waghmare PR, Loni PC, Patil SA, Govindwar SP (2015) Dilute acid pretreatment of rice straw, structural characterization and optimization of enzymatic hydrolysis conditions by response surface methodology. RSC Adv 5(58):46525–46533

Hohmann S (2002) Osmotic stress signaling and osmoadaptation in yeasts. Microbiol Molbiol Rev 66(2):300–372

Zaky AS, Greetham D, Tucker GA, Du C (2018) The establishment of a marine focused biorefinery for bioethanol production using seawater and a novel marine yeast strain. Sci Rep 8(1):12127

Fang C, Thomsen MH, Brudecki GP, Cybulska I, Frankaer CG, Oyanedel JRB, Schmidt JE (2015) Seawater as an alternative to fresh water in the pretreatment of date palm residues for bioethanol production in coastal and/or arid areas. ChemSusChem 8(22):3823–3831

Lau MW, Dale BE (2009) Cellulosic ethanol production from AFEX-treated corn stover using Saccharomyces cerevisiae 424A (LNH-ST). Proc Nat Acad Sci 106(5):1368–1373

Fu N, Peiris P (2008) Co-fermentation of a mixture of glucose and xylose to ethanol by Zymomonas mobilis and Pachysolen tannophilus. World J Microbiol Biotechnol 24:1091–1097

Qian M, Tian S, Li X, Zhang J, Pan Y, Yang X (2006) Ethanol production from dilute acid softwood hydrolysate by co-culture. Appl Biochem Biotechnol 134:273–283

Lebeau T, Jouenne T, Junter GA (1997) Simultaneous fermentation of glucose and xylose by pure and mixed cultures of Saccharomyces cerevisiae and Candida shehatae immobilized in a two-chambered bioreactor. Enzym Microb Technol 21:265–272

Grootjen DRJ, Jansen ML, van der Lans RGJM, Luyben KCAM (1991) Reactors in series for the complete conversion of glucose/xylose mixtures by Pichia stipitis and Saccharomyces cerevisiae. Enzym Microb Technol 13:828–833

Laplace JM, Delgenes JP, Moletta R, Navarro JM (1993) Cofermentation of glucose and xylose to ethanol by a respiratory-deficient mutant of Saccharomyces cerevisiae co-cultivated with a xylose-fermenting yeast. J Ferment Bioeng 75:207–212

De Bari I, Cuna D, Nanna F, Braccio G (2004) Ethanol production in immobilized-cell bioreactors from mixed sugar syrups and enzymatic hydrolysates of steam-exploded biomass. Appl Biochem Biotechnol 114:539–557

Hohmann S, Krantz M, Nordlander B (2007) Yeast osmoregulation. Methods Enzymol 428:29–45

Greetham D, Zaky AS, Du C (2019) Exploring the tolerance of marine yeast to inhibitory compounds for improving bioethanol production. Sustain Energy Fuels 3(6):1545–1553

Acknowledgments

The authors gratefully acknowledge the financial support and laboratory facilities from the Department of Life Science, National Institute of Technology, Rourkela, Odisha.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 5675 kb)

Rights and permissions

About this article

Cite this article

Indira, D., Jayabalan, R. Saccharification of lignocellulosic biomass using seawater and halotolerant cellulase with potential application in second-generation bioethanol production. Biomass Conv. Bioref. 10, 639–650 (2020). https://doi.org/10.1007/s13399-019-00468-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00468-4