Abstract

Glycerol, a byproduct from oil-based biodiesel industries, has been used as carbon and energy sources for growing Lactobacillus strains with probiotic characteristics. For such a purpose, crude glycerol (70.6 %) was subjected to a pretreatment with different inorganic acids to remove soap, free fatty acids, and other impurities. The best performance was attained with phosphoric acid at pH 4.0, thus resulting in treated samples containing glycerol whose levels were higher than 96 wt%. The treated glycerol was used to formulate the culture medium and assess the ability of 15 Lactobacillus strains to assimilate it. High cell yields (0.34, 0.28, and 0.25 g cell g−1 glycerol) were achieved by Lactobacillus delbrueckii UFV-H2b20, Lactobacillus acidophilus ATCC 4356, and Lactobacillus plantarum ATCC 8014 strains, respectively. Kinetic profiles in medium containing potassium phosphate buffer solution (pH 6.0) showed similar growth (yields ranging from 0.29–0.31 g g−1) and acetic acid production (yields ranging from 0.33–0.34 g g−1) for the selected lactobacilli bacteria. These results reveal that biodiesel-derived glycerol represents a potential substrate for growing probiotic strains, thence obtaining value-added products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Biodiesel is a renewable fuel produced by the transesterification of vegetable oils or animal fat with alcohol (methanol or ethanol) which has recently aroused substantial interest due to its contribution to petroleum-based diesel global dependence reduction. Nowadays, a large expansion of biodiesel industries has been observed, which is estimated to reach a global production of over 40 billion liters in the next decade [1]. Its process generates approximately 10 wt% of glycerol [2] and its production cost varies inversely and linearly, with fluctuations in the market value of glycerol [3].

The amount of glycerol derived from biodiesel industries shows an exponential growth, and its valorization is critical to increase their economic viability and environmental sustainability [4]. Typically, after an onerous distillation process, glycerol is used as feedstock for producing value-added chemicals to be used as additives by food, pharmaceutical, cosmetic, and paper industries. However, small and medium-size industries cannot afford the highs cost of glycerol purification, and consequently, large amounts of glycerol are being accumulated in the environment [5]. Therefore, it is important to develop new and innovative strategies for using crude glycerol.

Glycerol utilization as raw material for obtaining different molecules has received several research groups’ assiduous attention due to its abundance and low commercial value (lower than US$ 0.20 per lb) [6]. It is a key molecule for biological processes and feasible to be used as carbon and energy source by many microorganisms, including yeast, fungi, and bacteria [7–10]. In this regard, its availability associated with low-cost stimulates its utilization as a potential source of carbon for obtaining a variety of bioproducts through biotechnological processes, such as microbial biomass, organic acid, aldehyde, ethanol, protein, and lipid generation [2, 9–11]. Therefore, the glycerol biorefinery concept should be exploited for obtaining high-quality products of industrial value by biotechnological processes with the aim of improving the feasibility and environmental sustainability of biodiesel industries.

A number of chemical elements are present in biodiesel-derived glycerol, including potassium, nitrogen, and phosphorous which can be used as a nutritional resource for different microorganism species [12, 13]. Nonetheless, crude glycerol could also contain salts, toxic metallic ions that are mainly derived from metal vessel reactors and other impurities associated with the raw material, such as fatty acids, soap, and alcohols that can negatively affect microorganism growth [14–17]. Venkataramanan et al. [18] reported that the growth and metabolism of Clostridium pasteurianum in a medium containing glycerol is slightly inhibited by the presence of oleic acid, and completely inhibited by linoleic acid during anaerobic cultivation. The removal of soap, among other impurities, improves the fermentability of biodiesel-derived glycerol by some microorganisms, whose consumption rate is similar to that observed with pure glycerol [17, 18]. Therefore, it is fundamental to determine the chemical composition of glycerol by considering the effects of some impurities on its applicability and valorization in biotechnological processes.

Studies on many bacterial species glycerol metabolism have shown that glycerol dissimilation can occur through oxidative and reductive pathways [2, 19–21]. Under aerobic conditions, glycerol is converted into dihydroxyacetone or glycerol-3-phosphate by glycerol dehydrogenase (EC 1.1.1.6) and glycerol kinase enzymes (EC 2.7.1.30), respectively [19]. Under anaerobic conditions, glycerol is dehydrated by glycerol dehydratase (EC 4.2.1.30) to 3-hydroxypropionaldehyde, which is subsequently reduced to 1.3-propanediol by the 1.3-propanediol oxidoreductase enzyme (EC 1.1.1.202) [7, 19–21]. Pure glycerol utilization in bacterial strains and yeasts has been reported as a precursor for acrolein, reuterin, 1.3-propanediol, acetate, and other compounds [18–24].

Although few reports in literature describe the utilization of glycerol as a sole substrate by Lactobacillus strains, several works have been already published on the feasibility of using it as co-substrate in a medium containing glucose for biphasic growth of Lactobacillus and other species of microorganisms, in which its consumption took place after glucose exhaustion [19, 21]. Such results suggested that the co-fermentation process increases the rate of glycerol assimilation, biomass concentration, and biomolecules production [25, 26]. It seems that the metabolism of sugar co-substrates increases the formation of intermediate metabolites (e.g., pyruvate), which is channeled to NADH production, thus promoting greater glycerol utilization [19, 25, 26]. Therefore, it is worth assessing new potential Lactobacillus strains that are able to metabolize glycerol as carbon and energy source for obtaining biomass and biomolecules.

This study is aimed at characterizing and evaluating different treatments of crude glycerol derived from soybean oil-based biodiesel production, and selecting probiotic Lactobacillus strains with the ability to grow and produce acetic acid in a medium containing glycerol.

2 Material and methods

2.1 Glycerol

Crude glycerol obtained as byproduct derived from soybean oil-based biodiesel production was kindly provided by Bioverde Biocombustíveis S.A industries (Taubaté - São Paulo - Brazil), having in its composition glycerol 70.6 % (w w −1) and impurities 29.4 % (w w −1) mainly soap, salts, water, alkalis, volatile compounds (methanol), and fatty acids, according to the chemical report provided by the company.

2.2 Crude glycerol treatment

The crude glycerol obtained directly from transesterification process (using soybean oil and methanol as feedstock) was denominated glycerol grade G8 considering the original pH 8.0. This glycerol was acidified to neutralize the excess of potassium hydroxide (KOH) used as catalyst and for separating soaps, found mainly under the form of potassium linoleate and potassium oleate. The effectiveness of three different concentrated acids (H2SO4, 90 % (w w −1); H3PO4 85 % (w w −1); and HCl 37 % (w w −1)) to remove impurities contained in the crude glycerol were evaluated independently. A 500-mL Becker flask containing 250-mL of crude glycerol was heated at 75 °C under constant stirring (200 rpm) for 30 min to reduce the viscosity and evaporate methanol residues. At the same time, 0.1 mL concentrated acid was added progressively to the crude glycerol to adjust the pH to 7.0, 6.0, 5.0, 4.0, and 2.0 for obtaining a glycerol denominated grade G7, G6, G5, G4, and G2, respectively. After reducing viscosity and having biphasic formation, the pretreated glycerol was kept overnight in a separating funnel, followed by decantation and separation of the insoluble compounds from the glycerol phase. The treated glycerol was used for the culture media formulation.

2.3 Microorganisms and growth conditions

Fifteen bacterial strains were selected to evaluate their abilities to assimilate glycerol. Lactobacillus LAC01, LAC04, LAC06, LAC07, LAC09, LAC19, LAC23, LAC30, LAC38, LAC40, LAC PCI, and LAC PC2 were previously isolated from human fecal samples at Geraldo Di Biase University Center (Volta Redonda, RJ, Brazil). The Lactobacillus delbrueckii UFV- H2b20 strain was obtained from Department of Food Technology of Federal University of Viçosa (Viçosa, MG, Brazil); Lactobacillus plantarum ATCC 8014 and Lactobacillus acidophilus ATCC 4356 were obtained from the Tropical Culture Collection of Andre Tosselo Foundation (Campinas, SP, Brazil). These strains were maintained at 4 °C in de Man-Rogosa-Sharpe (MRS) slant agar. The Lactobacillus cells were activated by transferring a loopful of the stock culture to a test tube containing 5 mL of sterile and modified MRS broth composed by yeast extract (5 g L−1), peptone (10 g L−1), meat extract (10 g L−1), Tween 80 (0.05 g L−1), magnesium sulfate (0.1 g L−1), and manganese sulfate (0.05 g L−1), in which the glucose was replaced by treated glycerol (10 g L−1). The cultures were inoculated in a 125-mL Erlenmeyer flask containing 50 mL of the same medium composition, followed by incubation at 37 °C to reach the growth exponential phase. The Lactobacillus strains’ ability for using glycerol as carbon source was evaluated in a 125-mL Erlenmeyer flask, containing 50 mL of modified MRS broth with glycerol at 20 g L−1 (pH 6.0, unbuffered media). All the strains were individually inoculated into the media in sufficient amount to achieve an initial cell concentration of 0.05 g L−1. The flasks were incubated under microaerobic condition (without agitation) at 37 °C for 24 h.

A kinetic study was carried out using the selected probiotic strains, which showed the highest cell concentration during the screening tests. The experiments were carried out in unbuffered MRS medium containing treated glycerol 25 g L−1 and in the same medium buffered with potassium phosphate buffer (0.2 M) at pH 6.0. All the experiments were carried out, at least, in duplicate. Replicates differed by less than 5 %.

2.4 Analytical methods

2.4.1 FTIR-analysis

The removal of soap and free fatty acids from glycerol after treatment with different inorganic acids was determined by Fourier transform infrared spectroscopy (FTIR). FTIR spectra were obtained in a Perkin Elmer Spectrum GX FTIR spectrometer (USA) equipped with a highly attenuated total reflection (HATR) accessory with a resolution of 4 cm−1 and ZnSe crystal. The absorption spectrum was obtained by 50 coaveraged scans and recorded at range of 4000 to 400 cm−1. A thin film of each sample was spread directly on the ZnSe crystal for measurement. The spectral data were analyzed by Von Minelt—KnowItAll® Informatics System—and interpreted by examining the data from literature, taking into consideration the infrared absorptions for pure glycerol, fatty acids, and esters [27, 28].

2.4.2 Elemental composition

The analysis of elements such as Ni, Cu, Fe, Cd, Pb, As, Al, Ca, Mg, Na, and K present in the treated glycerol samples were performed in an atomic absorption spectrometer (AAS) (Perkin Elmer; Model: AAnalyst 800) equipped with modules for atomization by flame and graphite furnace. The values were obtained at the range of 185 and 870 nm with a diffraction grating of 1800 lines mm−1 using a solid state detector and background correction when used in the flame module. The metallic elements were analyzed by flame atomic absorption spectrometry (FAAS), except for As, Cd, and Pb that used electrothermal atomization (ET AAS), according to the Standard Method 3000—Metals [29]. For metals, samples were subjected to digestion using a strong acid mixture composed of HCl and HNO3 (4:1 v v −1). The total phosphorous and organic nitrogen were determined according to the standard methods for water examination [29].

2.4.3 Cell concentration

The cell concentration was determined by optical density (OD) at 600 nm, in spectrophotometer (Beckman DU 640B, Fullerton, U.S.A.). The OD values were correlated to the cell concentration (g L−1) by means of a calibration curve previously established for each bacteria strain. Lactobacillus strains were cultivated in MRS agar by pour plate technique to determinate the total viable cell during cultivation. The media sample was centrifuged at 5000 × g for 15 min and the supernatant was utilized to analyze the substrate consumption.

2.4.4 Glycerol and acetic acid concentration

Glycerol and acetic acid concentration were determined by high performance liquid chromatographic (HPLC) (Waters, Milford, USA) equipped with a refractive index (RI) detector and Bio-Rad HPX-87-H (300 × 7.8 mm) column at 45 °C, using 5 mM H2SO4 as the mobile phase, flow rate of 0.6 mL min−1, and sample volume of 20 μl. All samples were previously filtered through 0.22-μm membrane filters (Millipore) prior to analysis.

2.4.5 Bioprocess parameters

The bioprocess parameters of Y X/S (g g−1, cell-glycerol yield), Q X (g L−1 h−1, cell productivity), cell concentration (g L−1), and glycerol consumption (%) were experimentally determined. The cell (X) yield was calculated by Y X/S = Δ X /Δ S (g g−1) and the volumetric productivity in biomass was expressed by Q X = Δ X/Δt (g L−1 h1), in which: ΔX = X f −X o (X f = final biomass concentration and X o = initial biomass concentration), ΔS = S o−S f (S o = initial glycerol concentration and S f = final glycerol concentration), and Δt = t f−t o (cultivation time). The specific growth rate (μ, h–1) was calculated by linear regression of the ln (A/A 0 ) in function of time on the exponential growth phase, considering A and A 0 as optical density (OD) at time t and initial time of cultivation, respectively [30]. The acetic acid (P) yield was calculated by Y P/S = Δ P /Δ S (g g−1) and the volumetric productivity in acetic acid was Q P = Δ P/Δt (g L−1 h1), in which ΔP = P o−P f (P o = initial acetic acid concentration and P f = final acetic acid concentration).

3 Results and discussion

3.1 Crude glycerol treatment with different inorganic acids

The crude glycerol was submitted to treatment with concentrated inorganic acids so as to eliminate residual methanol, pigments, soaps, as well as free fatty acids. The presence of unsaturated free fatty acids and esters has an inhibitory effect on glycerol diffusion in the membrane cell, thus affecting microbial growth and bioproduct formation [18]. Table 1 shows the total volume of inorganic acid that was added to crude glycerol and its final concentration.

The neutralization of crude glycerol allowed achieving glycerol concentration of 6.2 and 5.8 % higher than glycerol grade G8 by using phosphoric acid (H3PO4) and hydrochloric acid (HCl), respectively. By decreasing pH to 4.0 (G4), it was observed that, in all studied treatments, its final concentration was higher than 900 g L−1, with no significant difference from the treatment using H2SO4 or HCl (Table 1). The utilization of H3PO4 has shown to be at least 6 % more effective than the other acids at removing impurities, due to achieving a final glycerol concentration of 964 ± 3 g L−1. Further addition of acid (G2) has not shown any considerable increase in final glycerol concentration (962 ± 4 g L−1) (no statistical difference between G4 and G2, p > 0.05) (Table 1). This result is similar to those observed at pH 4.0 when the glycerol generated by biodiesel from animal fat was treated with concentrated phosphoric acid [23]. Hájek and Skopal [31] achieved a glycerol concentration which is close to those observed in this study (≈86 %, w/w) by using the same concentrated inorganic acids. Table 1 also shows the amount of acids that were used to decrease pH values during the treatments. At a pH range of 2 to 4 units, more acid was used to decrease its value, though no significant improvement was observed in the pretreated glycerol concentration for each acid in particular.

3.2 Glycerol characterization

Glycerol samples treated with three inorganic acids at pH 4 (G4) was used for further studies because it presented the highest glycerol concentration. Table 2 shows the concentration of various elements detected in crude and processed glycerol treated with inorganic acids.

Glycerol grades G8 and G4 contain a considerable amount of potassium, magnesium, nitrogen, and phosphorous, which can be used as nutrients for Lactobacillus strain growth. As expected, the glycerol treated with phosphoric acid contains a phosphorous concentration which is 11.5 times higher (397 mg L−1) than that with crude glycerol (34.3 mg L−1). Besides the fact that phosphoric acid removes soap, it also contributes to providing a considerable amount of phosphorus for microbial metabolism. Furthermore, the concentration of essential nutrients such as iron (42.2–53.8 mg L−1), copper (1.10–1.88 mg L−1), and nickel (0.40–0.47 mg L−1) was quantified. These elements play an important role as co-factors in metabolic pathways and regulatory systems of bacterial cells [32].

Heavy metals such as arsenic, cadmium, and lead derived from potential metal loss during the biodiesel production process were not detected in the samples. These elements and its ions could exert a negative impact on the growth and viability of microorganisms, which could negatively affect the utilization of glycerol as substrate for medium formulation or food formulation [33]. In addition, sodium was not detected in all analyzed samples, once potassium hydroxide (KOH) was used as catalyst in the biodiesel production process.

Removal of soap and free fatty acid from glycerol G4 was confirmed by Fourier-transformed infrared (FTIR) analysis. FTIR spectroscopy has been reported as an accurate method to identify functional groups by detecting covalent links in high-density liquid samples, such as soybean oil and esters [34]. Figure 1 shows the absorption spectra of crude glycerol and pure substances. The broad absorption band associated with hydroxyl groups of glycerol is at 3356 cm−1 and carbon-oxygen absorptions, which characterize primary and secondary alcohols, were observed at 1044 and 1112 cm−1, respectively.

The peak around 1744 cm−1 wavenumber in pure soybean oil spectra (Fig. 1f) represents the carbonyl group (C = 0), which is characteristic of fatty acid spectra [27, 35]. The peak observed in the range of 1550 cm−1 corresponds to an ionized form of pure potassium oleate and linoleate spectra (Fig. 1c–e), which are the most abundant fatty acids in soybean oil [28, 36]. Similar functional groups observed in samples of crude glycerol show the presence of free fatty acids and soap. The treated glycerol spectrum shows the treatment effectiveness at removing soap with concentrated inorganic acids, which could be concluded due to the absence of ionized ester in the spectrum (Fig. 1b). The presence of free fatty acids, methyl esters and soaps negatively affect the permeability of cell membrane, morphology, and cellular development of many microorganism species, including yeast and bacteria [14, 16–18]. These results showed that the treatment of crude glycerol with phosphoric acid at pH 4 (G4) is effective at removing impurities.

3.3 Screening of probiotic Lactobacillus strains for glycerol assimilation

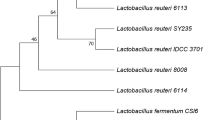

Fifteen potential probiotic Lactobacillus strains that had been previously identified by Sumita [37] were used to assess their ability to metabolize glycerol as main carbon and energy source. Firstly, it was used a modified MRS medium containing crude glycerol (in the range of 5 to 25 g L−1), where the absence of cellular growth was observed in all tested lactobacilli strains, with the exception of L. delbrueckii UFV-H2b20 that provided slight biomass growth (optical density OD600nm was lower than 0.06, data not shown). A different profile was verified by cultivating the lactobacilli strains on modified MRS medium with treated glycerol instead of crude glycerol, as shown by the growth parameters and glycerol consumption. Table 3 displays the values of total lactobacilli viable cells and biochemical parameters, such as Y X/S and Q X , after 24 h of cultivation. Maximal biomass production was used as selection criteria for further experiments.

It can be noted that almost all tested strains had the ability to grow in a medium containing treated glycerol, except for L. paracasei. It should also be observed that the highest cell concentration was achieved by L. delbrueckii UFV-H2b20 (0.82 g L−1), followed by L. acidophilus ATCC 4356 and L. plantarum ATCC 8014 with 0.73 g L−1 and 0.72 g L−1, respectively (Table 3). Lactic acid bacteria, such as several strains of Lactobacillus, Pediococcus, and Enterococcus, can metabolize glycerol under aerobic and anaerobic conditions [9, 19–22]. Alvarez et al. [19], reported similar biomass concentration for Lactobacillus rhamnosus being grown in 3.9 g L−1 glycerol under microaerobic conditions. These authors also confirmed the ability of Lactobacillus casei ATCC 393, Lactobacillus zeae ATCC 15820, and L. rhamnosus ATCC 15820 to use glycerol as sole carbon source. Pasteris and Strasser de Saad [20] reported that when Pediococcus pentosaceus was cultivated in a medium containing glycerol (4.0 g L−1), the biomass produced (0.56 g L−1) was comparable to that obtained with glucose. Garai-Ibabe et al. [38] reported that Lactobacillus collinoides and Lactobacillus diolivorans isolated from spoiled cider were tested for their capability to grow in a medium containing glycerol. Under microaerobic and anaerobic conditions, these species were able to degrade glycerol in the range of 12 to 90 % of its initial concentration, thus producing biomass and 1,3-propanediol. The Lactobacillus strain behavior studied in this work was also described in a few previously published works.

With regard to the Y X/S parameter, values ranging from 0.08 to 0.34 g g−1 were achieved (Table 3). Based on their highest biomass production in comparison with other lactobacilli strains studied, L. delbrueckii UFV-H2b20, L. acidophilus ATCC 4356 and L. plantarum ATCC 8014 were selected for further experiments.

3.4 Kinetic studies of selected strains

Kinetics of growth, glycerol consumption, pH, and acetic acid production of the lactobacilli grown in an unbuffered medium and in media buffered at pH 6.0 are shown in Fig. 2. During incubation in unbuffered medium containing treated glycerol, L. delbrueckii UFV-H2b20 provided the highest cell concentration (0.88 g L−1) in comparison with L. plantarum ATCC 8014 and L. acidophilus ATCC 4356, with 0.65 g L−1 and 0.78 g L−1, respectively. It is important to note that the growth rate of the lactobacilli in the unbuffered medium decreased when pH dropped from pH 6.0 to pH 5.0, thus affecting microorganism growth and cell viability. It is known that external pH determines the cytoplasmatic pH, thus affecting growth, enzyme activity, and stability of many molecules in bacterial cells [39]. The low glycerol assimilation and growth provided by the strains studied herein could be related to the fact that the lactobacilli species are characterized as neutrophile organisms with optimal pH for growth in the range of 6.0 to 6.5, except for L. delbrueckii that is able to grow at pH 5.5 [40]. Moreover, optimal pH for enzyme activities which are involved in glycerol assimilation by many microorganisms, such as glycerol kinase and glycerol dehydrogenase, ranges from 5.5–7.0 or higher [2, 19, 41]. Pasteris and Strasser de Saad [20] showed that the growth of P. pentosaceus was ceased after 24 h of cultivation, regardless of glycerol consumption. Such limitation was attributed to a low pH which results from acetic acid production. These results are similar to those reported by Alvarez et al. [19] during the cultivation of L. rhamnosus ATTC 7469 in a medium containing pure glycerol as carbon source under aerobic conditions. According to these authors, 0.46 g L−1 of cells were obtained, resulting in a yield of 0.19 g g−1 and substrate consumption of 3.92 g L−1, which corresponds to 60 % of the initial carbon source. The authors also observed a biphasic growth of L. rhamnosus during the co-fermentation of glycerol and glucose. In this condition, glycerol consumption was initiated after glucose exhaustion, thus achieving 0.58 g L−1 biomass. Similar cell density was observed in genetically transformed Lactobacillus panis containing an artificial glycerol oxidative pathway, cultured in modified MRS medium and supplemented with 24 mM glycerol (2.2 g L−1). The engineered strain was able to metabolize almost 50 % of the initial glycerol concentration after 24 h of cultivation, thus resulting in a final cell density (OD600nm) of 0.5 [42].

The buffered medium promoted an increase in the performance of all strains analyzed, due to attaining cell concentration in the range of 1.55 g L−1 and 1.74 g L−1. The highest specific growth rate (μ, h−1) values were in the range of 0.23, 0,24, and 0.25 h−1 for L. delbruecki UFV-H2b20, L. plantarum ATCC 8014, and L. acidophilus ATCC 4356, respectively (Table 4). These values are 50 % higher than those observed in an unbuffered medium (Table 4). The cell volumetric productivity (Q X ) was similar for all studied strains during 24 h of cultivation. Regarding substrate concentration, glycerol was not consumed completely by all studied bacteria, whose consumption was in a range of 10 to 12 % and 21 to 24 % of the glycerol that had been initially supplied to the unbuffered and buffered media, respectively (Table 4). Cultures conducted with pure glycerol (25 g L−1) at same conditions showed slightly lower values of cell concentration (1.45–1.68 g L−1) and glycerol utilization (18–21 %) in comparison with that observed with the buffered medium containing treated glycerol (data not shown).

Furthermore, all strains assessed herein showed the ability to produce acetate at a concentration of up to 2.00 g L−1 in the buffered medium. The acetate synthesis in Lactobacillus strains could be associated with the activation of pyruvate dehydrogenase complex (PDH) under microaerobic condition and acetate kinase (ACK) pathways [43]. Acetic acid yield values ranged from 0.33 to 0.43 g g−1 and the volumetric productivity (Q P) was similar after 24 hours of cultivation in the unbuffered and buffered medium (Table 4).

In a previous work, acetic acid production (≈1.78 g L−1) was reported with the recombinant bacteria L. panis, which was cultured in modified MRS medium containing 160 mM glycerol (14.7 g L−1) for 24 hours under uncontrolled pH conditions [42]. Alvarez et al. [19], while culturing the probiotic strain L. rhamnosus in pure glycerol, reported acetate concentration (0.66 g L−1) which is 25 % lower than those observed in the present work (unbuffered medium), yielding 0.16 g g−1 acetic acid. The authors also reported the production of 1.27 g L−1 of acetic acid during the co-fermentation of glycerol and glucose by L. rhamnosus. Similar results were found through the present work by using glycerol as the main substrate. Pasteris and Strasser de Saad [21] have produced 0.24 g L−1 of acetic acid with 12.5 % glycerol consumption by L. hilgardii in the co-fermentation of glycerol and glucose. When glycerol was used as carbon source at different concentrations, L. pentosaceus produced acetic acid at a concentration of 0.86 g L−1 [20]. Nonetheless, the amount of biomass and acetic acid produced in the present work is still lower in comparison with those produced by some yeast strains in glycerol. For example, the yeast Yarrowia lipolytica while it was being grown with glycerol (30 g L−1) under nitrogen-limited conditions, secreted 9.2 g L−1 acetic acid and produced 7.1 g L−1 of biomass [24].

Pflügl et al. [25] reported the production of acetic acid in a range of 5.3 to 19.5 g L−1 by co-fermenting glycerol (10 to 70 g L−1) and glucose (30 g L−1). Such results demonstrate that glycerol-sugar co-fermentation enhances the assimilation rate of glycerol and acetic acid production. In a more recent work, these authors conducted cultures of L. diolivorans in a bioreactor by using neutralized raw glycerol (10 g L−1) and glucose (20 g L−1) as substrates, thus achieving 6.7 g L−1 concentration of acetic acid [26]. In a glycerol-glucose co-fermentation by L. reuteri DSM 20016 for 1,3-propanediol production, 2.9 g L−1 biomass and 12.9 g L−1 acetic acid was reported [44]. According to literature, co-fermentation could be a strategy to increase glycerol assimilation by the strains studied herein.

In this work, it was demonstrated that L. delbruecki UFV-H2b20, L. plantarum ATCC 8014, and L. acidophilus ATCC 4356 are able to grow with glycerol being used as sole substrate.

4 Conclusion

Results of glycerol treatments have revealed that all analyzed inorganic acids allowed obtaining a glycerol concentration that was higher than 900 g L−1 after decantation. Besides soap removal from crude glycerol, phosphoric acid treatment provides phosphorous in the culture medium for cell growth. L. delbrueckii UFV-H2b20, L. plantarum ATCC 8014, and L. acidophilus ATCC 4356 yielded the highest biomass production. Regarding the kinetic analysis, the batch culture data of L. delbrueckii UFV-H2b20 and L. acidophilus ATCC 4356 showed a similar performance for biomass and acetic acid production in media containing glycerol and phosphate buffer. These results will contribute to promoting the potential use of glycerol derived from biodiesel production as substrate for lactobacilli growth.

References

OECD-FAO. Agricultural Outlook 2014 -2023: Biofuel – OECD – FAO – Agricultural Outlook 2014 – 2023 < http://stats.oecd.org/Index.aspx?QueryId=36348> (Acessed 18.09.2015)

Wong MS, Li M, Black RW, Le TQ, Puthli S, Campbell P, Monticello DJ (2014) Microaerobic conversion of glycerol to ethanol in Escherichia coli. Appl Environ Microbiol 80–10:3276–3282

Haas MJ, McAloon HJ, Yee WC, Foglia TA (2006) A process model to estimate biodiesel production costs. Biores Technol 97:671–678

Yazdani SS, Gonzalez R (2007) Anaerobic fermentation of glycerol: a path to economic viability for the biofuels industry. Curr Opin Biotech 18:213–219

Pachauri N, He B (2006) Value-added utilization of crude glycerol from biodiesel production: a survey of current research activities. In Proceedings of the ASABE Annual International Meeting 9:1–16

Clomburg JM, Gonzalez R (2013) Anaerobic fermentation of glycerol: a platform for renewable fuels and chemicals. Trends Biotech 31:20–28

Luyten K, Albertyn J, Skibbe WF, Prior BA, Ramos J, Thevelein JM, Hohmann S (1995) Fps1, a yeast member of the MIP family of channel proteins, is a facilitator for glycerol uptake and efflux and is inactive under osmotic stress. EMBO J 14:1360–1371

Lages F, Silva-Graça M, Lucas C (1999) Active glycerol uptake is a mechanism underlying halotolerance in yeasts: a study of 42 species. Microbiol SGM 145:2577–2586

Doi Y (2015) L-Lactate production from biodiesel-derived crude glycerol by metabolically engineered Enterococcus faecalis: Cytotoxic evaluation of biodiesel waste and development of glycerol-inducible gene expression system. Appl Environ Microbiol. doi:10.1128/AEM.03418-14

Tchakouteu SS, Kalantzi O, Chr G, Koutinas AA, Aggelis G, Papanikolaou S (2015) Lipid production by yeast growing on biodiesel-derived crude glycerol: strain selection and impact of substrate concentration on the fermentation efficiency. J Appl Microbiol 118–4:911–927

André A, Diamantopoulou P, Philippoussis A, Sarris D, Komaitis M, Papanikolaou S (2010) Biotechnological conversion of bio-diesel derived waste glycerol into added-value compounds by higher fungi: production of biomass, single-cell oil and oxalic acid. Ind Crops Prod 31:407–416

Papanikolaou S, Fakas S, Fick M, Chevalot I, Galiotou-Panayotou M, Komatis M (2008) Biotechnological valorisation of raw glycerol discharged after bio-diesel (fatty acid methyl esters) manufacturing process: Production of 1,3-propanediol, citric acid and single cell oil. Biomass Bioenerg 32:60–71

Thompson JC, He B (2006) Characterization of crude glycerol from biodiesel production from multiple feedstocks. Appl Eng Agric 22:261–265

Jenkins JK, Courtney PD (2003) Lactobacillus growth and membrane composition in the presence of linoleic or conjugated linoleic acid. Can J Microbiol 49:51–57

Pyle DJ, Garcia RA, Wen Z (2008) Producing docosahexaenoic acid (DHA)-rich algae from biodiesel-derived crude glycerol: effects of impurities on DHA production and algal biomass composition. J Agric Food Chem 56:3933–3939

Chatzifragkou A, Papanikolaou S (2012) Effect of impurities in biodiesel-derived waste glycerol on the performance and feasibility of biotechnological procecess. Appl Microbiol Biotechnol 95:13–27

Samul D, Leja K, Grajek W (2014) Impurities of crude glycerol and their effect on metabolite production. Ann Microbiol 64–3:891–898

Venkataramanan KP, Boatman J, Kurniawan Y, Taconi KA, Bothun GD, Scholz C (2012) Impact of impurities in biodiesel-derived crude glycerol on the fermentation by Clostridium pasteurianum ATCC 6013. Appl Microbiol Biotechnol 93:1325–1335

Alvarez MF, Medina R, Pasteris S, Strasser de Saad AM, Sesma F (2004) Glycerol Metabolism of Lactobacillus rhamnosus ATCC 7469: Cloning and expression of two glycerol kinase genes. J Mol Microbiol Biotechnol 7:170–181

Pasteris SE, Strasser de Saad AM (2005) Aerobic glycerol catabolism by Pediococcus pentosaceus isolated from wine. Food Microbiol 22:399–407

Pasteris SE, Strasser de Saad AM (2009) Sugar-glycerol co-fermentations by Lactobacillus hilgardii isolated from wine. J Agric Food Chem 57:2853–3858

Claisse O, Lonvaud-Funel A (2000) Assimilation of glycerol by a strain of Lactobacillus collinoides isolated from cider. Food Microbiol 17:512–519

Barbosa C, Fernandes A, Berbert-Molina M, Boniolo F, Rossi A, Prata AMR (2009) Growth of Bacillus thuringiensis var. israelensis in glycerol derived from biodiesel industry aiming the production of bioinsecticide. In: European Congress on Biotechnology - 14, 2009, Barcelona. Proceedings 1: S227–S227

Chatzifragkou A, Petrou I, Gardeli C, Komaitis M, Papanikolaou S (2012) Effect of Origanum vulgare L. essential oil on growth and lipid profile of Yarrowia lipolytica cultivated on glycerol-based media. J Am Oil Chem Soc 88:1955–1964

Pflügl S, Marx H, Mattanovich D, Sauer M (2012) 1, 3-Propanediol production from glycerol with Lactobacillus diolivorans. Bioresour Technol 119:133–140

Pflügl S, Marx H, Mattanovich D, Sauer M (2014) Heading for an economic industrial upgrading of crude glycerol from biodiesel production to 1,3-propanediol by Lactobacillus diolivorans. Bioresour Technol 152:499–504

Keller RJ (1986) The Sigma Library of FT-IR Spectra. Sigma Chemical Company Inc, St. Louis

Pachler KGR, Matlok F, Gremlich HU (1988) The Merck-FT-IR Atlas. VCH, Verlagsgesellschaft mbH, Weinheim

American Public Health Association (APHA) (1998) Standard methods for the examination of water and wastewater, 20 thth edn. American Public Health Association, American Water Works Association, and Water Pollution Control Federation, Washington, D.C

Carvalheiro F, Moniz P, Duarte LC, Esteves MP, Gírio FM (2011) Mannitol production by lactic acid bacteria grown in supplemented carob syrup. J Ind Microbiol Biotechnol 38:221–227

Hájek M, Skopal F (2010) Treatment of glycerol phase formed by biodiesel production. Bioresource Technol 101:3242–3245

Outten FW, Outten CE, Hale J, O’Halloran TV (2000) Transcriptional activation of an Escherichia coli copper efflux regulon by the chromosomal MerR homologue, CueR. J Biol Chem 275:31024–31029

FAO/WHO, 2003. Legal Notice N. 66/2003. Heavy metals regulations. Available in: http://faolex.fao.org/docs/pdf/eri42405.pdf

Zagonel GF, Peralta-Zamora P, Ramos LP (2004) Multivariate Monitoring of soybean oil ethanolysis by FTIR. Talanta 63:021–1025

Hazimah AH, Ooi TL, Salmiah A (2003) Recovery of glycerol and diglycerol from glycerol pitch. J Oil Palm Res 15:1–5

Myint LL, El-Halwagi MM (2009) Process analysis and optimization of biodiesel production from soybean oil. Clean Technol Environ Policy 11:263–276

Sumita TC (2007) Characterization of Lactobacillus strains isolated from human feces, concerning to their probiotic properties. 91pages. Dissertation (Master of Science in Industrial Biotechnology). Escola de Engenharia de Lorena, Universidade de São Paulo, Lorena, São Paulo, Brazil

Garai-Ibabe G, Ibarburu I, Berregi I, Claisse O, Lonvaud-Funel A, Irastorza A, Dueñas MT (2008) Glycerol metabolism and bitterness producing lactic acid bacteria in cider making. Int J Food Microbiol 121:253–261

Slonczweski JL, Fujisawa M, Dopson M, Krulwich TA (2009) Cytoplasmic pH measurement and homeostasis in bacteria and archaea. Adv Microb Physiol 55:1–79

Hutkins RW, Nannen NL (1993) pH homeostasis in lactic acid bacteria. J Dairy Sc 76:2354–2365

Pettigrew DW, D-P MA, Conrad CA, Johnson JR (1988) Escherichia coli glycerol kinase: cloning and sequencing of the glpK gene and the primary structure of the enzyme. J Biol Chem 263:135–13941

Kang TS, Korber DR, Tanaka T (2014) Metabolic engineering of glycerol-oxidative pathway in Lactobacillus panis PM1 for utilization of bioethanol thin stillage: potential to produce platform chemicals from glycerol. Appl Environ Microbiol 80:7631–7639

Lorquet F, Goffin P, Muscariello L, Baudry JB, Ladero V, Sacco M, Kleerebezem M, Hols P (2004) Characterization and functional analysis of the poxB gene, which encodes pyruvate oxidase in Lactobacillus plantarum. J Bacteriol 186:3749–3759

Ricci MA, Russo A, Pisano I, Palmieri L, De Angelis M, Agrimi G (2015) Improved 1, 3-propanediol synthesis from glycerol by the robust Lactobacillus reuteri strain DSM 20016. J Microbiol Biotechnol 25:893–902

Acknowledgments

The authors gratefully acknowledge the financial support of São Paulo State Research Foundation—FAPESP (Process No. 2008/57447-9). The authors also thank Ms. Cibele Rosa de Oliveira and Mr. Adilson Nicanor de Assis for the technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rivaldi, J.D., Duarte, L.C., Rodrigues, R.d.C.L. et al. Valorization of glycerol from biodiesel industries as a renewable substrate for co-producing probiotic bacteria biomass and acetic acid. Biomass Conv. Bioref. 7, 81–90 (2017). https://doi.org/10.1007/s13399-016-0216-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-016-0216-8