Abstract

The traditional soil stabilization techniques, which primarily include calcium-rich additives, are gradually replaced by environmentally friendly techniques as the former increases the carbon footprint emissions. On the other hand, nanomaterials (particles with a size range of less than 100 nm) are gaining acceptance in geotechnical and geoenvironmental engineering due to their non-toxic nature and less energy consumption required for production. These materials have entirely different properties from conventional materials. When mixed with soil particles, their relatively larger specific surface area values trigger an easy and rapid reaction. The paper reviews the applicability of select nanomaterials such as metallic nanoparticles (which include nano-copper oxide (nano-CuO), nano-magnesium oxide (nano-MgO), iron oxide nanoparticles (nano-Fe2O3), nano-alumina (nano-Al2O3), nano-clay, nano-silica (nano-SiO2), colloidal silica, to name a few, in the areas of geotechnical and geoenvironmental engineering by highlighting the associated mechanisms of interaction. The targeted geotechnical properties include plasticity, compressibility, consolidation, permeability, and strength characteristics under different conditions. Further, the effect of the select nanoparticles on microbial activity, their applicability in remediation of organic and inorganic contaminants from different soil–water systems, and their cost-effectiveness are discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The conservation of our ecosystem in its pristine form is paramount. This need has been well recognized and integrated into the 17 Sustainable Development Goals (2030 Agenda) framework, which emerged during the Rio + 20 United Nations Conference on Sustainable Development [1]. A rapid increase in infrastructural development has driven engineers to suitably modify the properties of the undesirable in situ soils using chemical additives such as lime and cement [2,3,4,5,6]. Though the use of such chemical additives has significantly improved the properties of soils, they have also substantially contributed to the increase in carbon footprint emissions released during their production and service life [7, 8]. A gradual transition from carbon-based additives to sustainable materials is witnessed in soil stabilization and remediation. The emergence of nanotechnology in the science and technology world has significantly helped achieve this transition.

Nanotechnology deals with “the understanding, control, and re-engineering of matter in the order of nanometers” (typically less than 100 nm) to produce materials having unique and different properties and functions [9]. These nanoparticles can be synthesized either by a top-down approach (breaking down large sizes into nano-sizes) or a bottom-up approach (atoms are assembled into molecular structures which fall within the nano-range) [10]. Nanotechnology has been applied across many fields such as medicine, engineering, environment, communication, and heavy industry [11,12,13,14,15]. These materials have played a significant role in improving the primary properties of materials in civil engineering and construction by reducing the energy consumption of structures, environmental impact, and cost associated with structures [11, 15,16,17,18]. With the advancement of nanotechnology, these materials paved their way into the field of geotechnical engineering, and a wealth of literature has shown the modification in soil behavior using nano-silica (nano-SiO2), nano-clay, nano-alumina (nano-Al2O3), nano-copper oxide (nano-CuO), to name a few [17, 19,20,21,22,23,24]. The enhancement in soil performance is due to their large specific surface area and high surface reactivity due to the minimal size of nanoparticles and the ease of injection into small pore spaces [14, 15].

However, the mixing methodology adopted for achieving a homogeneous soil–nanoparticle mix plays a significant role in obtaining the desired results [14, 25,26,27,28,29,30,31,32,33,34]. Hence, the non-uniformity in field mixing is one of the primary reasons for the fewer field applications of nanomaterials [14, 15, 35,36,37]. Some of the noteworthy achievements of nanoparticles in soil are (a) reduction in liquefaction potential in sandy soils and silty sands by the use of colloidal silica, nano-silica (nano-SiO2), and laponite [38, 39], (b) reduction in the settlement in soft soils by nano-clay, nano-fly ash, and nano-titanium di-oxide (nano-TiO2) [40, 41], and (c) reduction in plasticity characteristics in soft soils by nano-magnesium oxide (nano-MgO), nano-alumina (nano-Al2O3), nano-sol, and nano-copper oxide (nano-CuO) [18, 27, 42]. Most nanomaterials are developed through labor-intensive physical and chemical processes and require high radiation, temperature, pressure, and analytical grade chemicals as reducing and stabilizing agents. However, with the advent of a non-toxic and environmentally safe production process such as a single-pot green chemistry approach, the chemicals are replaced by plant extracts as reducing and stabilizing agents. The process ultimately results in forming an environment-friendly nanomaterial [43]. Nanomaterials can also act as excellent adsorbents for removing heavy metals from contaminated soils and are widely implemented for decontaminating water [44,45,46,47,48,49].

The present paper summarizes all the outlook of enhancement of soil properties using nanomaterials, such as mixing methodologies for achieving homogeneous soil–nanoparticle mixture, interaction mechanism, improvement in soil properties with the blending of various nanoparticles, and also the application of nanomaterials in the field of geoenvironmental engineering for soil and water decontamination.

1.1 Method of Mixing (Soil–Nano-mixture)

The amount of nanomaterials added to the soil must be measured appropriately to have a considerable effect on soft soils and minimize the agglomeration of nanomaterials. A homogenous mixture is obtained by the uniform mixing of nanoparticles in soil, and it plays a vital role in obtaining the desired results. The required target doses of nano-titanium di-oxide (nano-TiO2) and nano-zinc oxide (nano-ZnO) and soil–water content were achieved by adding the stock dispersion using a pipette into weakly acidic soil with a loam texture. Stock suspensions were continuously stirred to prevent nanoparticle settling during the addition and to maintain homogeneous dispersions [47].

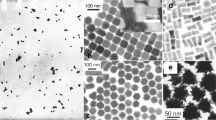

The apex of the pipette is spun around the soil to mix the dispersion and prevent nanoparticles from settling. The most dominating mechanism, i.e., the mixer characteristics proposed by [25], includes mixing action, shear, and convection–diffusion. It is affirmed that in numerical modeling of diffusion equation or Markov chain model, provocation of mixing process satisfies the experiments performed. As a result, the desired output of crystalline composition is achieved on a nanometer scale [19]. Heating suitable materials attains traditional solid-state synthesis with zero or minimum trace of water vapor, and the process is continued until a single solid phase is identified. After identifying the solid phase, the solution is heated at about 1400 °C for about 50 h and then left to cool to room temperature. Before proceeding to the next stage, the weight of the mixture and the amount of weight loss are measured. Afterward, the solution is heated for almost 300 h and left to decompose, resulting in the nanocomposite formation. Three classes of composites are formed by the interaction of layered clay with a polymer [26], which is depicted in Fig. 1.

Phase segregated composites (microcomposites) are produced when polymers cannot inject between the silicate sheets during mixing. Moreover, the phase-separated or microcomposite properties are nearly the same as the traditional composites. Intercalated nanocomposites can be defined as materials in which more than one polymer is injected between the interlayer spaces increasing interlayer space. Structure exfoliated in nature is formed when the silicate layer is thoroughly and uniformly distributed in the constant polymer matrix. Various methods for the preparation of polymer-layered silicate include:

-

Exfoliation–adsorption: Silicate in layered form is flaked into an isolated layer using a solvent in which polymer is dissolvable. Due to the weak forces which hold together the layers of layered silicate, layers can be dispersed in an appropriate solvent. The polymer then adsorbs onto the sheets, and after evaporation of solvents, a multilayered structure is formed by sandwiching the polymer. Nanocomposites are obtained through emulsion polymerization.

-

In situ intercalative polymerization: In this method, within the liquid monomer, the layered silicate expands, resulting in polymer formation within the existing sheets. Before the swelling step by monomer, polymerization can be commenced by heat or radiation.

-

Melt intercalation: Layered silicate is fused with the polymer matrix in the molten state. If the layers are suitable for the selected polymers, the polymers can seep into the interlayer space resulting in the formation of exfoliated or intercalated nanocomposites.

It is not easy to obtain a uniform mixture of soil and nanomaterials in the field, and hence, in place of nano-powders, it is appropriate to mix colloidal nanoparticles. In the field test, the liquefaction risk in the sand is minimized by using colloidal silica grout [14]. Various methods of mixing soil with nanoparticles are listed below.

-

Nano-clay, Nano-alumina (nano-Al2O3), and nano-copper oxide (nano-CuO) were used in organic soil of low plasticity (OL) soil by mixing the beaker containing nanoparticles with water and were kept in an ultrasonic bath for about two hours and then mixed with water. First, nanoparticles are sprayed into soil having ten layers, and then, each layer is mixed individually. After that, the whole mixture is kept in a horizontal cylinder mixture for about three hours [27].

-

Dry and suspension spiking was adopted for applying nano-zinc oxide (nano-ZnO) in loamy sandy soil. For dry spiking, about 20 g of dry soil is mixed uniformly in a jar with nanomaterial and later added to dry soil weighing 180 g. For suspension spiking, soil and water suspension in a ratio of 2:5 by mass is shaken at room temperature. Next, it is filtered in a vacuum condition, and finally, this suspension is added to 200 g of dry soil [28].

-

Colloidal silica was added to the treatment area containing [29] three different soil layers such as silty sand and sand layer (2 m), silt and sandy silt (3 m), sand and silty sand to further depth in such a manner that colloidal silica at the site is diluted with water and stored in a tank. Compared to HCl, NaCl showed better gel control for colloidal silica. Using injection wells, colloidal silica is injected into the field as far as safety is considered for handling acids in the fields. About 90 min is taken to form a firm resonating gel.

-

Modified montmorillonite nano-clay (MMN) in clayey soil sieved by no. 40 sieve is blended with soil, and electric mixture is used for 45 min to achieve uniform mixture. After this, distilled water is added and left for about 16 h in an airtight container [31].

-

Colloidal silica in liquid grout form and silica sand are mixed and accommodated in a cylindrical mold. The liquid grout is then discharged into a mold, and sand is allowed to fall slowly. While pouring the sand, the mold vibrates smoothly to settle the sand inside [32].

-

Mixing CH soil with nano-alumina (nano-Al2O3) & nano-copper oxide (nano-CuO) takes place in dry conditions, and then, water is added to compensate for the needed moisture content. The sample is kept in desiccators afterward for at least 48 h to preserve the moisture in the mixture obtained [33].

-

Nano-clay and nano-alumina (nano-Al2O3) were mixed in three different types of soil CL-ML, CL, SC, by adopting the mixing procedure such that the beaker containing nanoparticles entirely mixed with water is kept in an ultrasonic bath for about two hours and then mixed with distilled water [34].

Generally, the injection method carries out the application of nanomaterials for depths greater than 3 m. In comparison, dry mixing is adopted for shallow depths of treatment. Various methods described above will guide the practicing engineers to adopt a suitable technique specific to the site requirement and soil type.

2 Soil–Nanoparticle Interaction Mechanism

Interaction at the microscopic level controls soil deformation at the macroscopic level [50]. Knowledge of the chemical composition, mineralogical composition, and structural arrangement of the soil are compulsory for understanding the variation in geotechnical properties and changes in environmental conditions [51]. Main iron oxides (haematite and goethite), having a size range of 10–100 nm, form a rigid network in soil which hardens the soil. Iron oxide acts as camouflage in smectite to eliminate swelling characteristics, promoting a firm bond between aggregates [52].

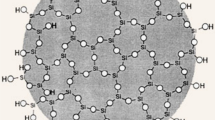

Though the fundamental mechanism of interaction of nanoparticles with soil is not clearly stated, the change in soil properties with the addition of nanoparticles has been explained by various researchers [53, 54]. Figure 2 shows the viscous gel formation due to adsorption through the double layer of water on blending silica nanoparticles in soil. It is observed that the bonding of soil–nano-matrix with viscous gel is more robust than the bonding of clay particles with adsorbed water in untreated soil. Figure 3 depicts the two processes, i.e., ion exchange and organic onium, which explains the chemical reaction behind the formation of nano-clay matrix when the polymer is added to clayey soil. Onium ion structure is also depicted in Fig. 3, where A+ represents N, P, O, S, and X1, X2, X3, X4 denote inert organic epoxide radical. A thorough understanding of the interaction mechanisms between soil particles and nanomaterials will help engineers choose the right material suitable for a soil type and aid in using these materials in combination with other techniques for better improvement in soil properties.

3 Soil Properties

Nowadays, land favorable for construction is minimal. Hence, geotechnical engineers must modify soil characteristics and make it suitable for construction. Researchers have been trying to enhance soil properties by mixing external agents such as nanoparticles in recent years. Nanomaterials are preferred over conventional particles due to their petite size, ease in the injection of nanoparticles into tiny spaces, and remain active for a long time. Different characteristics of soil–nano-mixture improved by the addition of nanoparticles are discussed.

3.1 Plasticity Characteristics

Plasticity is a vital index property of fine-grained soils, predominantly clayey soils. The consistency limit tests by various researchers were done in accordance with BS 1377–2 [55], ASTM D4318-17e1 [56], and IS 2720–5 [57]. When montmorillonite nano-clay or nano-silica (nano-SiO2) is added, the plasticity index (PI) of clayey soil increases [21, 31]. The addition of various nanoparticles such as nano-alumina (nano-Al2O3), nano-copper oxide (nano-CuO), nano-magnesium oxide (MgO), nano-Z also known as organosilane compound, polypropylene nanofiber, a variation in nano-alumina (γ- Al2O3), nano-sol, carbon nanofibers (CNFs), multiwall carbon nanotubes (MWCNTs), nano-fly ash, nano-titanium di-oxide (nano-TiO2), nanoscale hydrated lime (NHL), Nanoscale-Zero Valent Iron (NZVI), and nano-zeolite [11, 31, 40,41,42, 54, 58,59,60], due to their less surface area when compared to silica nanoparticles or nano-clay have shown a decrease in the PI of soil (Table 1).

3.2 Compaction Characteristics

Specific nanoparticles in soil tend to decrease Maximum Dry Density (MDD) due to flocculation and agglomeration of nanoparticles as a result of cation exchange capacity (Cation Exchange Capacity or CEC is the measure of how many particles will remain on the surface of the soil) and low specific gravity of nanoparticles which is generally less than soil. Due to the increase in the volume of soil particles, dry density also increases as the voids occupied by nanoparticles by replacing the air from voids and ultimately increase the unit mass of soil, whereas Optimum Moisture Content (OMC) decreases due to the ion exchange mechanism during the chemical reaction. The compaction characteristics were determined in accordance with BS 1377–2 [55], ASTM D698-12 [61], and IS 2720–7 [53] by various researchers.

Various effects of nanoparticles in different soils are mentioned in Table 2. The effect of nanoparticles resulted in an increment in OMC and a decrement in MDD for clayey soils [27, 60, 62]. For clayey soils with cement content, the size of nanoparticles also played a role in increasing MDD [21].

3.3 Permeability

A critical engineering property that controls the hydraulic stability of soil masses is the soil's permeability. The hydraulic conductivity was determined in various research works in accordance with ASTM D5084-00e1 [63]. The introduction of nanoparticles in the soil can significantly modify this parameter. The primary reason for the decrease in permeability on the addition of nanoparticles is the filling of voids by nanoparticles. As nanoparticles occupy the voids, voids remaining for seepage of water will be minimum and ultimately decrease permeability. Furthermore, agglomeration of particles that occurs after a certain period causes an increase in water movement in soil due to the shearing of nanoparticles by water flow, resulting in increased seepage and hence the permeability. Many researchers conducted several experiments to determine permeability in the soil–nanoparticle mix, and their observations are listed in Table 3.

Colloidal silica proved to be an excellent material in transforming silica sand into a barrier material by considerably reducing permeability [32]. Alsharef et al. [59] performed experiments using nanocarbon on clayey sand. Both MWCNTs and CNFs were used and observed that the hydraulic conductivity seemed to fall in both cases. When the concentration of fly ash increases in clayey soil (CI), the coefficient of permeability shows a decrement. For about 1% nano-calcium silicate (NCS) dosage, hydraulic conductivity is the least, about 4.8 × 10−8 m/s, as shown in Fig. 7. A suitable liner can have the least hydraulic conductivity, and NCS and fly ash behave as one such material due to their very high specific surface area [64].

For soils containing varying contents of bentonite, the effect of nano-alumina (nano-Al2O3), nano-clay, and nano-copper oxide (nano-CuO) had almost no effect on permeability [27, 42]. However, more than a 30% reduction in permeability in clayey soils is achieved by adding nanoparticles [33, 65].

3.4 Consolidation Properties

Consolidation parameters explain the consolidation phenomenon characterizing fine-grained soil subjected to a change in effective stress. The consolidation properties were determined in accordance with ASTM D2435/ D2435M-11 [66] and IS 2720–15 [67] by various researchers. In general, nanoparticles such as nano-clay, nano-fly ash, TiO2-nanoparticles, nano-magnesium oxide (nano-MgO), and nano-copper oxide (nano-Cu) reduced the settlement of soft soils. Less water is expelled from the soil during long-term static loading due to the occupancy of nanomaterials in voids. Nanomaterials in the voids cause strenuous water movement, resulting in minor volume change. In addition, water present in the pore spaces will participate in the ion exchange phenomenon. Table 4 highlights the change in consolidation parameters for different soils treated with various nanomaterials.

Collapse potential decreases with a rise in density, moisture content, and vertical stress decrements. In the case of soft soils, the reduction settlement is achieved in the range of 53–67% with the addition of nano-clay, nano-fly ash, nano-magnesium oxide (nano-MgO), and nano-copper oxide (nano-CuO) [40, 41, 44].

3.5 Strength Characteristics

The shear strength of soil can be regarded as its intrinsic capacity to resist failure when forces act on the soil mass and determine the stability of many engineering structures. The addition of organosilane compound in silty soil has shown significant betterment in California Bearing Ratio (CBR) due to the formation of siloxane bond (Si–O–Si), which possesses high bond energy and does not disintegrate at temperatures as high as 2000 °C. The siloxane bond shows high resistance to weathering, chemically stability, and water resistance, resulting in soil densification and increased soil bearing strength. Nano-clay, also known as layered silicate, enhances the thermal, mechanical, and barrier properties by mixing polymers. Nano-clay is classified into several groups, such as montmorillonite, kaolinite, bentonite, halloysite, and hectorite, depending on nanomaterials' morphology and chemical composition. The addition of the improved and modified nano-clay in the asphalt layer in pavement increases toughness [17]. The blending of nano-clay caused a rise in strength compared to conventional materials, in which the stiffening effect can explain the formation of bonds with the binders. With the addition of 4% Nano-clay A and Nano-clay B, the toughness increment was more than the 2% dosage of both materials. The strength characteristics were determined in accordance with ASTM standards [68,69,70,71], BS: 1377–7 [72], IS: 2720–10 [73], and JTG 3430 [74].

In soft soil or peat combination, 1% nano-cement and 1% nano-clay showed maximum shear strength compared to 2% nano-cement and 2% nano-clay [75]. An optimum amount of nano-clay for soil contaminated with 12% kerosene was found to be 2%, while the non-contaminated soil treated with 1% resulted in significant strength attainment [76]. Kaolinite clay blended with 5% nano-silica (nano-SiO2) showed an increment in unconfined strength ratio as large as 1.43 [77]. NCS (0.04%) in combination with (6%) lime and fly ash in the ratio 1:1 has also resulted in significant improvement in UCS due to the formation of C–S–H gel [78]. Changes in various strength properties with the addition of nanoparticles in different soils at different conditions are listed in Table 5. The effect of nanoparticles on Unconfined Compressive Strength (UCS) of soil at 28 days curing time is presented in Fig. 8.

4 Role of Nanomaterials in Geoenvironmental Engineering

Industrialization at a fast pace results in the disposal of chemicals and various by-products into the environment. Various factors which determine the type of technology for remediation depend on soil characteristics, nature and distribution of contaminants, and the toxicity of contaminants, to name a few. Combined expertise from geotechnical and environmental engineering is required to overcome these problems. Thus, in the 1990s, the field of geoenvironmental engineering (or environmental geotechnology) emerged. Technologies such as electrokinetic remediation have been applied for heavy metal decontamination of soils. However, issues such as excessive heat generation while treatment and the presence of metal conduit below the treatment area (for supplying drinking water, natural gas, or sewage movement), corrosion of pipes will be initiated, and hence, researchers have resorted to other sustainable methods [79]. The environmental application of nanomaterials can be categorized under three sections: green chemistry or prevention of pollution, treatment of commodities contaminated with hazardous substances, and sensors for environmental agents [80].

Two different types of treatment that apply to conventional remediation technologies also apply to remediation by nanotechnologies: adsorptive or reactive and in situ or ex situ. Adsorptive remediation technologies are primarily used for metallic contaminants by sequestration. In contrast, reactive technologies affect the degradation of contaminants which are usually harmless. A study was conducted [80] to use nanotechnologies in environmental cleanup. Nanoscale-Zero Valent Iron (NZVI) proved to be the most effective in groundwater decontamination due to its low mobility and high reactivity (high specific surface area) compared to other materials under similar conditions. Various methods involved in environmental cleanup are shown in Fig. 9a. In the figure, the reaction will only occur when contaminants contact iron particles or are dissolved in groundwater. In Fig. 9b, nanoparticles in the porous medium have low mobility, whereas, in Fig. 9c, nanoparticles with more mobility are injected for decontamination of nano-aqueous phase liquid (DNAPL). The addition of nanoparticles to contaminated soil medium also triggered a reaction between nanoparticles and the microorganisms present resulting either in alteration or deterioration.

Three different ways of application of iron particles for groundwater contamination, a traditional method (permeable reactive barrier) consisting of millimeter-sized granular particles of Fe; b zone highly reactive used for treatment made by consecutive injection of nano-Fe particles forming zones that are overlapping of molecules that are attached to molecules of local aquifer material; c decontamination of liquid in nano-aqueous phase by injection of mobile nanoparticles

Red and black cotton soil treated with NCS to retain heavy metals such as Cd2+, Ni2+, and Pb2+ was studied by [81] to understand their leaching behavior. NCS-treated soil showed satisfactory retention levels over a long duration, thereby proving the capability of NCS in encapsulating metal ions in its matrix. Soil collected from different municipal dumpsites was highly spiked with Cd2+ to a concentration of 3,000 mg/l. Sequential extraction in five stages was conducted in these Cd2+ to understand the type of sorption. It was observed that NCS-treated soil showed sorption of about 90%, and leaching was found to be less than 1 cm/year [82].

Soil amended with NCS showed exceptional retention of Ni2+ and was observed that the leaching rate reduced to 0.225 cm/year from 1.14 cm/year [83]. Two semiarid soils were spiked with four heavy metals (As, Cr, Hg, and Pb) and further treated with NCS with 0.5–1.5% concentrations. Extensive desorption was carried out, and it was found that for all mixtures, the removal efficiency was 70%, and about 1 M EDTA (ethylene diamine tetraacetic acid) gives maximum removal efficiency [84].

Various risks and regulations of using engineered nanoparticles in the presence of environmental microorganisms have been discussed in detail by various researchers. For example, it has been observed that the effect of silver nanoparticles (nano-Ag) on E. Coli has been destructive [12, 85, 86]. Table 6 discusses the effect of various engineered nanoparticles on microorganisms in the soil. Nanoparticles synthesized from natural species by single pot green chemistry method can be effectively used in geoenvironmental engineering like bioremediation of aquaphobic contaminants in polluted soil medium [43].

Nanomaterials are ideal adsorbents for hexavalent chromium Cr6+ due to their appropriate particle size, excessive surface area, accessible pores, and high stability. The adsorption of hexavalent chromium from industrial effluents is concluded as the best method for chromium removal in comparison with techniques such as chemical reduction to Cr3+ and solvent extraction, among many others. Nanoscale-Zero Valent Iron (NZVI) is used for geoenvironmental remediation of Cr6+, using which a heavy metal removal efficiency of about 84.4% can be achieved. When NZVI is used in combination with carboxy-methyl cellulose (CMC), an efficiency of about 100% can be achieved in soil containing 10 mg of Cr6+ [13].

A wealth of literature on environmental remediation highlighted that this technology mainly depends upon adsorption, absorption, chemical reactions, photocatalysis, and filtration for decontamination of different mediums such as soil, water, and air using either inorganic, carbonaceous, or polymeric nanomaterials [87]. For example, titanium, iron, and binary mixed oxide nanoparticles have been used extensively for water decontamination for organic contaminants such as methylene blue dye, heavy metals, and chlorinated organic solvents [45, 46, 49]. In addition, heavy metals like cadmium (Cd), nickel (Ni), and lead (Pb) can be efficiently immobilized by an environmentally compatible method called Enzyme-Induced Calcite Precipitation (EICP) in soils [88, 89]. A few of the metallic nanoparticles for environmental decontamination by several researchers are discussed in Table 7.

5 Cost-Effectiveness

As we are developing in science and technology, sustainable development emerges as one of the crucial aspects in this field. In the twenty-first century, to improve soil, many unorthodox materials were generally introduced to replace conventional stabilization materials like cement and lime. Some unconventional materials used were microbially induced calcite precipitation (MICP), nanomaterials, environmental fibers, and recycled tires. MICP and nanomaterials significantly affect permeability, mitigate liquefaction, improve strength, and even aid in environmental cleanup. Colloidal silica, bentonite, and laponite show a practical effect on mitigating the liquefaction of sandy foundations. Carbon nanotubes show a satisfactory result in improving Unconfined Compressive Strength (UCS). Recycled tires and environmental fibers are widely used for reinforcing the soil.

The cost comparison of these few unconventional materials in contrast with conventional materials is mentioned below [90]. These conventional materials include:

-

The price per bag of cement added 5% by weight of soil mass varies in the range of 3.28 $–3.93 $. For unit m3, it costs about 9 $.

-

The cost for grouts such as acrylate grout and epoxy grout for unit m3 treatment lies at approximately 298 $ and 459 $, respectively.

-

Sodium silicate is another type of conventional material that, for 1 m3 treatment, requires about 165 $.

Few unconventional materials include:

-

Colloidal silica should be added at about 5% by solution weight and colloidal silica concentration at about 30%. Its price per kg is about 1 $, and treatment per m3 costs about 57 $.

-

Bentonite added about 5% by weight of the solution. For montmorillonite content beyond 95%, its price per kg is about 4 $, and unit m3 treatment amounts to 8 $.

-

Short glass fiber, whose content to be added to the soil is about 2% by weight of soil, charges about 0.5 $ per kg, and treatment per m3 charges about 16 $.

-

Laponite RD is to be added 3% by weight of the solution, and its unit price is approximately 22 $. Therefore, for unit m3 treatment, it amounts to about 277 $.

6 Field Applications

Only limited studies about field-scale testing of soil, especially sandy soils stabilized by nanoparticles, have been conducted. The main reason behind the limited testing is the unavailability of skilled workers and the inefficiency of various mixing procedures in cohesive soil. Few researchers [14, 35, 91, 92] have performed field tests in sand treated with colloidal silica and nano-silica. To imitate the field testing conditions, some small-scale testing like centrifuge tests using colloidal silica has been performed by researchers [14, 36, 78] by adjusting the ionic strength or pH, which controlled the gel time of colloidal silica and made these experiments possible. The colloidal silica is stabilized against gelation (formation of gel with polymer). Hence, the gel formation will require modification of the salt concentration and pH.

The colloidal silica was first introduced in the field by [93]. Applying pressure grouting to apply silica particles with high viscosity in sand deposits makes it quite challenging to apply in the field [14]. The viscosity of colloidal silica can be outstretched in the same range as that of water by just changing the pH or the ionic content, thereby increasing its applicability to any desired location by pressure grouting. As the voids between the sand particles are occupied by colloidal silica, the bond between the sand particles increases significantly, decreasing the permeability. Therefore, colloidal silica is often used by many researchers in field sands as a potential stabilizer due to effective control of the viscosity of colloidal silica. The property of low permeability sand achieved by colloidal silica has been used to prevent water seepage through retaining walls, underground structures, and foundations of dams. This idea of restricting water seepage through a porous medium was first used in industries dealing with petroleum works [15, 94].

One of the most critical applications in the field includes reducing the liquefaction potential by passive remediation at the site [37] due to its little control over viscosity. Figure 10 depicts the passive site stabilization method by [14]. In this field, the top 2-m-thick layer of sand was treated using colloidal silica within a 10-m-thick layer of liquefiable sand. Eight injection wells were installed in a perimeter of a 9 m diameter test area, and slow injection of about 8% by weight of colloidal silica in the top 2 m was initiated. Central extraction well was used to maintain the flow of colloidal silica toward the center when grouting. After initiation of liquefaction by blasting, about 0.3 m settlement occurs in the treated area and about 0.5 m in the nearby untreated area.

In a sanitary landfill, to prevent contamination of groundwater or to prevent movement of water from the polluted zone to the unpolluted zone and to prevent the contamination of the unaffected area of soil beneath the landfill, sand infused with colloidal silica can be used as impermeable cover and bottom liner medium [14]. However, heavy metals like Cd2+, Ni2+, and Pb2+, when disposed of in the soil near an industrial area, leach into groundwater through various means (biotic and abiotic), thus proving fatal. Therefore, the sequential Extraction Process was used by [95] to find heavy metal binding in soil treated with NCS. Five steps of Sequential Extraction were adopted in four different soils collected from different localities of Bangalore. NCS used was in the range of 0.5%–2% by dry weight of soil. It was observed that there was a gradual increase in the binding ability of soil treated with NCS compared to untreated soil.

7 Conclusions

An overview of the application of nanomaterials for different soil types, the mixing methodologies adopted for attaining uniform mixing of nanomaterials, and the interaction mechanism governing the resultant improvement in various soil properties are elaborately discussed in this paper. Blending soil with nanoparticles significantly enhances soil property due to its high specific surface area and charges. Out-turn from various field and laboratory-based experiments show inconsistency, but in general, it has been observed that only a tiny fraction of nanoparticles, due to their high reactivity, show considerable improvement in soil properties. Some noteworthy simplified conclusions which are identified from this review paper are as follows:

-

Nanomaterials are materials with sizes less than 100 nm and are extensively used in geotechnical and geoenvironmental engineering due to their high surface-area-to-volume ratio, which often results in higher reactivity.

-

Using colloidal nanoparticles instead of nanopowders is recommended to achieve a uniform blending of nano-soil mix in the field. The interaction of a polymer with layered clay results in the formation of three types of composites, namely exfoliated nanocomposites, interphase nanocomposites, and phase-separated microcomposites resulting in enhanced geotechnical properties.

-

Ion exchange and organic onium are the two processes responsible for the chemical reaction behind the formation of nano-clay matrix when a polymer is added to clayey soil. The bonding in a soil–nano-matrix with viscous gel is stronger than the bonding of clay particles with adsorbed water in untreated soil.

-

The soil structure gets altered at the atomic or molecular scale by nanoparticles due to their large specific surface area, which results in the enhancement of soil properties.

-

Colloidal silica has been extensively used for cohesionless soils and soils susceptible to liquefaction, whereas nano-copper (nano-Cu), nano-alumina (nano-Al2O3), nano-clay, nano-silica (nano-SiO2) have been used for cohesionless and cohesive soils with varying degrees of success.

-

The reactivity of nanoparticles is heavily dependent on the mineralogical composition and structural arrangement in soils. For example, the plasticity characteristics of Kaolinite were reduced with nano-sol and increased with nano-silica (nano-SiO2).

-

For organic soils, the plasticity characteristics are reduced with nano-copper oxide (nano-CuO), nano-magnesium oxide (nano-MgO), and nano-clay. The plasticity of silty soils was reduced with nano-clay, whereas it increased with an organosilane. Furthermore, the compaction characteristics of clayey soils treated with nano-silica showed an increment in OMC and a decrement in MDD.

-

The permeability of clayey soils decreased with nano-alumina (nano-Al2O3) and at higher concentrations of iron nanoparticles. Therefore, considerable strength improvement in clayey soils can be achieved by blending polypropylene homopolymer with nano-clay.

-

The settlement behavior of soft soil can be controlled with nano-copper oxide (nano-CuO), nano-clay, nano-magnesium oxide (nano-MgO), nano-titanium oxide (TiO2 nanoparticles), and nano-fly ash.

-

Significant improvement in UCS was observed in cohesive soils using nano-silica, nano-clay, and nano-alumina, whereas colloidal silica, nano-zeolite, and organosilane were more effective on cohesionless for strength improvement. The collapse potential of soils can be effectively reduced using nano-silica and nano-clay.

-

Nanoscale-Zero Valent Iron (NZVI) and Nanoscale Hydrated Lime (NHL) in gas oil-contaminated clayey soils resulted in modification of engineering properties and a 50% reduction in gas oil content from the soil.

-

In the case of sandy soils and silty sands, the liquefaction resistance and cyclic stress ratios were improved using colloidal silica, nano-silica, and synthetic nano-clay (laponite). Colloidal silica (as a non-disruptive treatment) has been widely used in sandy soils to minimize the liquefaction potential and is also used as a barrier material in sanitary landfills.

-

Nanoparticles such as NZI, nano-TiO2, binary mixed oxide, and iron can be used as water decontaminants, whereas silver nanoparticles and wet graphene oxide cause the destruction of Escherichia coli in the soil medium.

Though nanotechnology has been used in soil stabilization and soil remediation, there are inherent issues when applying this technology to cohesive soils in general and expansive soils in particular. Life cycle assessment followed by carbon footprint calculations is to be checked before applying this technique for targeted application. Also, the other areas that require attention are nanomaterials' effect on the microbial community and other living beings and their long-term stability. The challenge involved in the management and regeneration of the nanomaterials must be considered for future studies. Research is imperative to examine the effectiveness of nanomaterials in combination with other remediation techniques. The fate of nanomaterials in a contaminated environment followed by the degradation process and the recyclability of these materials are yet to be explored extensively. Before recommending a nano-compound to field applications, it is preferred to have the early involvement of practicing engineers as it assumes importance to identify targeted geotechnical/geoenvironmental applications.

References

Stevens, C.; Kanie, N.: The transformative potential of the sustainable development goals (SDGs). Int. Environ. Agreem. 16, 393–396 (2016). https://doi.org/10.1007/s10784-016-9324-y

Firoozi, A.A.; Guney Olgun, C.; Firoozi, A.A.; Baghini, M.S.: Fundamentals of soil stabilization. Int. J. Geo-Eng. 8, 1–16 (2017). https://doi.org/10.1186/s40703-017-0064-9

Ikeagwuani, C.C.; Obeta, I.N.; Agunwamba, J.C.: Stabilization of black cotton soil subgrade using sawdust ash and lime. Soils and Found. 59, 162–175 (2019). https://doi.org/10.1016/j.sandf.2018.10.004

Pandey, A.; Rabbani, A.: Soil stabilization using cement. Int. J. Civ. Eng. Technol. 8, 316–322 (2017)

Moghal, A.A.B.; Obaid, A.A.K.; Al-Refeai, T.O.: Effect of accelerated loading on the compressibility characteristics of lime-treated semiarid soils. J. Mater. Civ. Eng. 26, 1009–1016 (2014). https://doi.org/10.1061/(asce)mt.1943-5533.0000882

Moghal, A.A.B.; Obaid, A.A.K.; Al-Refeai, T.O.; Al-Shamrani, M.A.: Compressibility and durability characteristics of lime treated expansive semiarid soils. J. Test. Eval. 43, 20140060 (2015). https://doi.org/10.1520/jte20140060

Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O.: Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy. Environ. 26, 303–329 (2001). https://doi.org/10.1146/annurev.energy.26.1.303

Ashfaq, M.; Lal, M.H.; Moghal, A.A.B.; Murthy, V.R.: Carbon footprint analysis of coal gangue in geotechnical engineering applications. Indian. Geotech. J. 50, 646–654 (2020). https://doi.org/10.1007/s40098-019-00389-z

Bayda, S.; Adeel, M.; Tuccinardi, T.; Cordani, M.; Rizzolio, F.: The history of nanoscience and nanotechnology: from chemical-physical applications to nanomedicine. Molecules 25, 112 (2019). https://doi.org/10.3390/molecules25010112 (Basel, Switzerland)

Pal, Singh, J., Kumar, M., Sharma, A., Pandey, G., Chae, K. H., Lee, S.: Bottom-up and top-down approaches for MgO. In: Sonochemical Reactions. IntechOpen (2020). https://doi.org/10.5772/intechopen.91182.

Ugwu, O.O.; Arop, J.B.; Nwoji, C.U.; Osadebe, N.N.: Nanotechnology as a preventive engineering solution to highway infrastructure failures. J. Constr. Eng. Manag. 139, 987–993 (2013). https://doi.org/10.1061/(asce)co.1943-7862.0000670

Hegde, K.; Brar, S.K.; Verma, M.; Surampalli, R.Y.: Current understandings of toxicity, risks and regulations of engineered nanoparticles with respect to environmental microorganisms. Nanotechnol. Environ. Eng. 1, 5 (2016). https://doi.org/10.1007/s41204-016-0005-4

Mitra, S.; Sarkar, A.; Sen, S.: Removal of chromium from industrial effluents using nanotechnology: a review. Nanotechnol. Environ. Eng. 2, 11 (2017). https://doi.org/10.1007/s41204-017-0022-y

Gallagher, P.M.; Conlee, C.T.; Rollins, K.M.: Full-scale field testing of colloidal silica grouting for mitigation of liquefaction risk. J. Geotech. Geoenviron. Eng. 133, 186–196 (2007). https://doi.org/10.1061/(asce)1090-0241(2007)133:2(186)

Persoff, P., Finsterle, S., Moridis, G.J., Apps, J., Pruess, K., Muller, S. J.: Injectable barriers for waste isolation. Office of Scientific and Technical Information (OSTI) (1995). https://doi.org/10.2172/106544

Hossain, K.; Rameeja, S.: Importance of nanotechnology in civil engineering. Eur. J. Sustain. Dev. 4, 161–166 (2015)

You, Z.; Mills-Beale, J.; Foley, J.M.; Roy, S.; Odegard, G.M.; Dai, Q.; Goh, S.W.: Nanoclay-modified asphalt materials: preparation and characterization. Constr. Build. Mater. 25(2), 1072–1078 (2011). https://doi.org/10.1016/j.conbuildmat.2010.06.070

Taha, M.R.: Geotechnical properties of soil-ball milled soil mixtures. In: Nanotechnology in Construction 3, pp. 377–382. Springer Berlin Heidelberg, Berlin (2009). https://doi.org/10.1007/978-3-642-00980-8_51

Imanaka, N.; Köhler, J.; Masui, T.; Adachi, G.Y.; Taguchi, E.; Mori, H.: Inclusions of nanometer-sized Al2O3 particles in a crystalline (Sc, Lu)2(WO4)3 matrix. J. Am. Ceram. Soc. 83, 427–429 (2004). https://doi.org/10.1111/j.1151-2916.2000.tb01211.x

Changizi, F.; Haddad, A.: Effect of nano-SiO2 on the geotechnical properties of cohesive soil. Geotech. Geol. Eng. 34, 725–733 (2016). https://doi.org/10.1007/s10706-015-9962-9

Bahmani, S.H.; Huat, B.B.K.; Asadi, A.; Farzadnia, N.: Stabilization of residual soil using SiO2 nanoparticles and cement. Constr. Build. Mater. 64, 350–359 (2014). https://doi.org/10.1016/j.conbuildmat.2014.04.086

Mohammadi, M.; Niazian, M.: Investigation of nano-clay effect on geotechnical properties of Rasht clay. Int. J. Adv. Sci. Tech. Res. 3, 37–46 (2013)

Bahari, M., Nikookar, M., Arabani, M., Haghi, A.K., Khodabandeh, H.: Stabilization of silt by nano-clay. In: Proceeding of 7th National Congress on Civil Engineering, Zahedan-Iran IR. Vol. 2, pp. 7–8 (2013). https://civilica.com/doc/217047/

Zahedi, M.; Sharifipour, M.; Jahanbakhshi, F.; Bayai, R.: Nanoclay performance on resistance of clay under freezing cycles. J. Appl. Sci. Environ. Manage. 18, 427–434 (2014)

Poux, M.; Fayolle, P.; Bertrand, J.; Bridoux, D.; Bousquet, J.: Powder mixing: some practical rules applied to agitated systems. Powder Technol. 68, 213–234 (1991). https://doi.org/10.1016/0032-5910(91)80047-m

Alexandre, M.; Dubois, P.: Polymer-layered silicate nanocomposites: preparation, properties, and uses of a new class of materials. Mater. Sci. Eng. R. Rep. 28, 1–63 (2000). https://doi.org/10.1016/s0927-796x(00)00012-7

Majeed, Z.H.; Taha, M.R.: Effect of nanomaterial treatment on geotechnical properties of a Penang soft soil. J. Asian Sci. Res. 2, 587–592 (2012)

Waalewijn-Kool, P.L.; Diez Ortiz, M.; Van Gestel, C.A.M.: Effect of different spiking procedures on the distribution and toxicity of ZnO nanoparticles in soil. Ecotoxicology 21, 1797–1804 (2012). https://doi.org/10.1007/s10646-012-0914-3

Gallagher, P.M.; Pamuk, A.; Abdoun, T.: Stabilization of liquefiable soils using colloidal silica grout. J. Mater. Civ. Eng. 19, 33–40 (2007). https://doi.org/10.1061/(ASCE)0899-1561(2007)19:1(33)

Van der Ploeg, M.J.C.; Baveco, J.M.; Van der Hout, A.; Bakker, R.; Rietjens, I.M.C.M.; Van den Brink, N.W.: Effects of C 60 nanoparticle exposure on earthworms ( Lumbricus rubellus ) and implications for population dynamics. Environ. Pollut. 159, 198–203 (2011). https://doi.org/10.1016/j.envpol.2010.09.003

Maleki, Y. S., Sharafi, H.: The exploration into the effect of nanoclay additive on soil geotechnical-engineering basic properties. Advances in Environ. Biol. pp. 989–993 (2014). https://link.gale.com/apps/doc/A392176479/AONE?u=anon~a1d0e61&sid=googleScholar&xid=a1feb700. Accessed 13 Apr 2022

Persoff, P.; Apps, J.; Moridis, G.; Whang, J.M.: Effect of dilution and contaminants on sand grouted with colloidal silica. J. Geotech. Geoenviron. Eng. 125, 461–469 (1999). https://doi.org/10.1061/(asce)1090-0241(1999)125:6(461)

Ng, C.W.W.; Coo, J.L.: Hydraulic conductivity of clay mixed with nanomaterials. Can. Geotech. J. 52, 808–811 (2015). https://doi.org/10.1139/cgj-2014-0313

Iranpour, B.; Haddad, A.: The influence of nanomaterials on collapsible soil treatment. Eng. Geol. 205, 40–53 (2016). https://doi.org/10.1016/j.enggeo.2016.02.015

Moridis, G., Apps, J., Persoff, P., et al.: A field test of a waste containment technology using a new generation of injectable barrier liquids (No. LBNL--38817). Lawrence Berkeley National Lab. In: Proceeding, Spectrum 96, Seattle, WA, pp.18–23 (1996). https://inis.iaea.org/search/search.aspx?orig_q=RN:28036379

Conlee, C.T.; Gallagher, P.M.; Boulanger, R.W.; Kamai, R.: Centrifuge modeling for liquefaction mitigation using colloidal silica stabilizer. J. Geotech. Geoenviron. Eng. 138, 1334–1345 (2012). https://doi.org/10.1061/(asce)gt.1943-5606.0000703

Gallagher, P.M.: Passive site remediation for mitigation of liquefaction risk. Doctoral dissertation, Virginia Tech. (2000) http://hdl.handle.net/10919/29610

Ochoa-Cornejo, F., Bobet, A., Santagata, M., et al.: Liquefaction 50 years after anchorage 1964; How nanoparticles could prevent it. Network for earthquake engineering simulation (NEES). In: Proceedings of the 10th national conference in earthquake engineering, Earthquake engineering research institute, Anchorage, AK (2014). https://doi.org/10.4231/D3CC0TT8W.

Huang, Y.; Wang, L.: Laboratory investigation of liquefaction mitigation in silty sand using nanoparticles. Eng. Geol. 204, 23–32 (2016). https://doi.org/10.1016/j.enggeo.2016.01.015

Priyadharshini, R.; Arumairaj, P.D.: Improvement of bearing capacity of soft clay using nanomaterials. Int. J. Sci. Res. 4, 218–221 (2015)

Babu, S.; Joseph, S.: Effect of nano materials on properties of soft soil. Int. J. Sci. Res. 5, 634–637 (2016)

Taha, M.R.; Taha, O.M.E.: Influence of nanomaterial on the expansive and shrinkage soil behavior. J. Nanopart. Res. 14, 1–13 (2012). https://doi.org/10.1007/s11051-012-1190-0-

Ngwenya, C.Z.; Ntwampe, K.S.O.; Silwana, N.: Synthesis of metallic nanoparticles from Beta vulgaris using a single-pot green chemistry approach and their environmental engineering application. Nanotechnol. Environ. Eng. 1, 1–13 (2016). https://doi.org/10.1007/s41204-016-0012-5

Zhang, G.; Germaine, J.; Whittle, A.: Effects of Fe-oxides cementation on the deformation characteristics of a highly weathered old alluvium in San Juan Puerto Rico. Soils Found. 43, 119–130 (2003). https://doi.org/10.3208/sandf.43.4_119

Hooshyar, Z.; Rezanejade Bardajee, G.; Ghayeb, Y.: Sonication enhanced removal of nickel and cobalt ions from polluted water using an iron based sorbent. J. Chem. 2013, 1–5 (2013). https://doi.org/10.1155/2013/786954

Rasalingam, S.; Peng, R.; Koodali, R.T.: Removal of hazardous pollutants from wastewaters: applications of TiO2-SiO2 mixed oxide materials. J. Nanomater. 2014, 1–42 (2014). https://doi.org/10.1155/2014/617405

Ge, Y.; Schimel, J.P.; Holden, P.A.: Evidence for negative effects of TiO2 and ZnO nanoparticles on soil bacterial communities. Environ. Sci. Technol. 45, 1659–1664 (2011). https://doi.org/10.1021/es103040t

Chou, K.S.; Lu, Y.C.; Lee, H.H.: Effect of alkaline ion on the mechanism and kinetics of chemical reduction of silver. Mater. Chem. Phys. 94, 429–433 (2005). https://doi.org/10.1016/j.matchemphys.2005.05.029

Cho, M.; Chung, H.; Choi, W.; Yoon, J.: Different inactivation behaviors of MS-2 phage and Escherichia coli in TiO2 photocatalytic disinfection. Appl. Environ. Microbiol. 71, 270–275 (2005). https://doi.org/10.1128/AEM.71.1.270-275.2005

Lambe, T.W.; Whitman, R.V.: Soil mechanics. John Wiley & Sons, Nashville (1969)

Mitchell, J.K.: Fundamentals of Soil Behavior. 2nd Edition, John Wiley & Sons, Hoboken—references—scientific research publishing. In: Scirp.org (1993). https://www.scirp.org/(S(351jmbntvnsjt1aadkposzje))/reference/ReferencesPapers.aspx?ReferenceID=1832892. Accessed 16 Dec 2021

Shadfan, H.; Dixon, J.B.; Calhoun, F.G.: Iron oxide properties versus strength of ferruginous crust and iron-glaebules in soils. Soil. Sci. 140, 317–325 (1985). https://doi.org/10.1097/00010694-198511000-00001

IS 2720 (Part 7).: Test for determination of water content, dry density relation using light compaction, Bureau of Indian Standards, New Delhi, (2011)

Azzam, W.R.: Behavior of modified clay microstructure using polymer nanocomposites technique. Alex. Eng. J. 53, 143–150 (2014). https://doi.org/10.1016/j.aej.2013.11.010

BS 1377 (Part 2).: Methods of test for soils for civil engineering purposes—Classification tests and determination of geotechnical properties. (2022)

ASTM (American Society for Testing and Materials), D4318-17e1.: Standard Test Methods for Liquid Limit, Plasticity Limit, and Plasticity Index of Soils, “Annual Book of ASTM Standards, Section 4, Vol. 04.08, Soil and Rock; Building Stones,” ASTM, Philadelphia, (2018). https://doi.org/10.1520/D4318-17E01

IS 2720 (Part 5).: Test for determination of Liquid Limit, Plastic Limit, and Plasticity Index of soil, Indian Standards Institution, New Delhi, (2006)

Khalid, N.; Arshad, M.F.; Mukri, M.; Mohamad, K.; Kamarudin, F.: Influence of nano-soil particles in soft soil stabilization. Electro. J. Geotech. Eng. 20, 731–738 (2015). https://doi.org/10.1200/JCO.1983.1.2.138

Alsharef, J.M.A.; Taha, M.R.; Firoozi, A.A.; Govindasamy, P.: Potential of using nanocarbons to stabilize weak soils. Appl. Environ. Soil. Sci. 2016, 1–9 (2016). https://doi.org/10.1155/2016/5060531

Nasehi, S.A.; Uromeihy, A.; Nikudel, M.R.; Morsali, A.: Use of nanoscale zero-valent iron and nanoscale hydrated lime to improve geotechnical properties of gas oil contaminated clay: a comparative study. Environ. Earth. Sci. 75, 1–20 (2016). https://doi.org/10.1007/s12665-016-5443-6

ASTM (American Society for Testing and Materials), D698-12.: Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)), “Annual Book of ASTM Standards, Vol. 04.08, Soil and Rock; Building Stones,” ASTM, Philadelphia, (2021). https://doi.org/10.1520/D0698-12R21

Nohani, E.; Alimakan, E.: The effect of nanoparticles on geotechnical properties of clay. Int. J. Life Sci. 9, 25–27 (2015). https://doi.org/10.3126/ijls.v9i4.12670

ASTM (American Society for Testing and Materials), D5084-00e1.: Standard Test Methods for measurement of hydraulic conductivity of saturated porous materials using a flexible wall Permeameter, “Annual Book of ASTM Standards, Vol. 04.08, Soil and Rock; Building Stones,” ASTM, Philadelphia, (2017). https://doi.org/10.1520/D5084-00E01.

Bhadra, S.M.; Leander, T.: Effect of fly ash and nano calcium silicate in clayey soil used as clay liner. Int. Res. J. Eng. Technol. 7, 2451–2455 (2020)

Reginatto, C., Cecchin, I., Carvalho, R.L.R., et al.: Influence of iron nanoparticle concentration on the hydraulic conductivity of a residual clayey soil. In: Geo-Chicago 2016. American Society of Civil Engineers, Reston, VA pp. 458–466 (2016). https://doi.org/10.1061/9780784480120.047

ASTM (American Society for Testing and Materials), D2435/ D2435M-11.: Standard Test Methods for one dimensional consolidation properties of soil using incremental loading, “Annual Book of ASTM Standards, Vol. 04.08, Soil and Rock; Building Stones,” ASTM, Philadelphia, (2020). https://doi.org/10.1520/D2435_D2435M-11

IS: 2720 (Part 15).: Method of test for soil for determination of consolidation properties, Bureau of Indian Standards, New Delhi, (2002)

ASTM (American Society for Testing and Materials), D1833-21.: Standard Test Methods for California Bearing Ratio (CBR) of Laboratory Compacted Soil, “Annual Book of ASTM Standards, Vol. 04.08, Soil and Rock; Building Stones,” ASTM, Philadelphia, (2021). https://doi.org/10.1520/D1883-21

ASTM (American Society for Testing and Materials), D3080-04.: Standard Test Methods for Direct Shear Test of Soil Under Consolidated Drained Conditions. “Annual Book of ASTM Standards, Vol. 04.08, Soil and Rock; Building Stones,” ASTM, Philadelphia, (2012). https://doi.org/10.1520/D3080-04

ASTM (American Society for Testing and Materials), D2166-06.: Standard Test Methods for Unconfined Compressive Strength of Cohesive Soil. “Annual Book of ASTM Standards, Vol. 04.08, Soil and Rock; Building Stones,” ASTM, Philadelphia, (2016). https://doi.org/10.1520/D2166-06

ASTM (American Society for Testing and Materials), D5333-92.: Standard Test Methods For Measurement of Collapse Potential of Soil. “Annual Book of ASTM Standards, Vol. 04.08, Soil and Rock; Building Stones,” ASTM, Philadelphia, (2017). https://doi.org/10.1520/D5333-92R96

BS 1377 (Part 7).: Methods of test for soils for civil engineering purposes Part 7: shear strength tests (Total stress), (2015)

IS 2720 (Part 10).: Method of test for soil for determination of unconfined compressive strength of soil, Bureau of Indian Standards, New Delhi, (2006)

JTG 3430–2020.: Test Methods of Soil for Highway Engineering, Institute of Highway Research, Ministry of Transport, (2021)

Subramani, V.; Sridevi, S.: Soil stabilization using nano materials. Int. J. Res. Appl. Sci. Eng. Technol. 4, 641–645 (2016)

Mohammad Ali, Z.S.; Shabnam, M.; Armina, S.: The potential use of nanoclay to increase strength of contaminated soil. MATEC Web Conf 67, 02010 (2016). https://doi.org/10.1051/matecconf/20166702010

Moayed, R.Z.; Rahmani, H.: Effect of Nano-SiO2 solution on the strength characteristics of Kaolinite. J. Geotech. Geoenviron. Eng. 11, 83–87 (2017). https://doi.org/10.5281/zenodo.1131922

Mohammed, S.A.S.; Moghal, A.A.B.; Lateef, M.A.: Strength characteristics of nano calcium silicate, fly ash and lime blended tropical soils. In IFCEE 2018, 105–114 (2018). https://doi.org/10.1061/9780784481592.011

Mohammad, N.; Moghal, A.A.B.; Rasheed, R.M.; Almajed, A.: Critical review on the efficacy of electrokinetic techniques in geotechnical and geoenvironmental applications. Arab. J. Geosci. 15, 781 (2022). https://doi.org/10.1007/s12517-022-10037-1

Tratnyek, P.G.; Johnson, R.L.: Nanotechnologies for environmental cleanup. Nano Today 1, 44–48 (2006). https://doi.org/10.1016/s1748-0132(06)70048-2

Mohammed, S.A.S.; Moghal, A.A.B.: Efficacy of nano calcium silicate (NCS) treatment on tropical soils in encapsulating heavy metal ions: leaching studies validation. Innov. Infrastruct. Solut. 1, 21 (2016). https://doi.org/10.1007/s41062-016-0024-9

Mohammed, S.A.S.; Moghal, A.A.B.; Sanaulla, P.F.; Kotresha, K.; Reddy, H.P.: Cadmium fixation studies on contaminated soils using nano calcium silicate—treatment strategy. Geotech. Front. 2017, 434–442 (2017a). https://doi.org/10.1061/9780784480434.047

Mohammed, S.A.S.; Sanaulla, P.F.; Kotresha, K.; Moghal, A.A.B.: Sustainable use of contaminated soils amended with nano calcium silicate mixture for nickel encapsulation in an aqueous medium. Mater. Today Proc. 4, 12271–12277 (2017b). https://doi.org/10.1016/j.matpr.2017.09.159

Mohammed, S.A.S.; Moghal, A.A.B.: Nanomaterials-based solidification/stabilization of metal-contaminated soils. In: Nanomaterials for soil remediation, pp. 385–407. Elsevier, Amsterdam (2021). https://doi.org/10.1016/B978-0-12-822891-3.00018-9

Beddow, J.; Stolpe, B.; Cole, P., et al.: Effects of engineered silver nanoparticles on the growth and activity of ecologically important microbes: Impact of silver nanoparticles on environmental microbes. Environ. Microbiol. Rep. 6, 448–458 (2014). https://doi.org/10.1111/1758-2229.12147

Tegou, E.; Magana, M.; Katsogridaki, A.E., et al.: Terms of endearment: Bacteria meet graphene nanosurfaces. Biomaterials 89, 38–55 (2016). https://doi.org/10.1016/j.biomaterials.2016.02.030

Guerra, F.D.; Attia, M.F.; Whitehead, D.C.; Alexis, F.: Nanotechnology for environmental remediation: materials and applications. Molecules 23, 1760 (2018). https://doi.org/10.3390/molecules23071760

Moghal, A.A.B.; Lateef, M.A.; Mohammed, S.A.S.; Lemboye, K.K.; Chittoori, B.C.S.; Almajed, A.: Efficacy of enzymatically induced calcium carbonate precipitation in the retention of heavy metal ions. Sustainability. 12, 7019 (2020). https://doi.org/10.3390/su12177019

Moghal, A.A.B.; Lateef, M.A.; Abu Sayeed Mohammed, S., et al.: Heavy metal immobilization studies and enhancement in geotechnical properties of cohesive soils by EICP technique. Appl. Sci. 10, 756 (2020). https://doi.org/10.3390/app10217568 (Basel)

Liu, G.; Zhang, C.; Zhao, M., et al.: Comparison of nanomaterials with other unconventional materials used as additives for soil improvement in the context of sustainable development: a review. Nanomaterials 11(1), 15 (2020). https://doi.org/10.3390/nano11010015 (Basel)

Ciardi, G.; Vannucchi, G.; Madiai, C.: Effect of colloidal silica grouting on geotechnical properties of liquefiable soils: a review. Geotechnics 1, 460–491 (2021). https://doi.org/10.3390/geotechnics1020022

Jurinak, J.J.; Summers, L.E.: Oilfield applications of colloidal silica gel. SPE Prod. Eng. 6, 406–412 (1991). https://doi.org/10.2118/18505-pa

Yonekura, R., Kaga, M.: Current chemical grout engineering in Japan. In: grouting, soil improvement and geosynthetics. ASCE, pp. 725–736 (1992). https://cedb.asce.org/CEDBsearch/record.jsp?dockey=0075095

Bennett, K.E., Fitzjohn, J.L., Harmon, R.A., Yates, P.C. Jr.: Colloidal silica-based fluid diversion. European Patent (1988). https://patents.google.com/patent/EP0260888A2/en

Kotresha, K.; Mohammed, S.A.S.; Sanaulla, P.F., et al.: Evaluation of sequential extraction procedure (SEP) to validate binding mechanisms in soils and soil-nano-calcium silicate (SNCS) mixtures. Indian. Geotech. J. 51, 1069–1077 (2021). https://doi.org/10.1007/s40098-020-00464-w

Hareesh, P., Vinoth Kumar, R.: Assessment of nano materials on geotechnical properties of clayey soils. In: Docplayer.net (2016). http://docplayer.net/33577666-Assessment-of-nano-materials-on-geotechnical-properties-of-clayey-soils.html Accessed 16 Dec 2021

Thomas, G.; Rangaswamy, K.: Strengthening of cement blended soft clay with nano-silica particles. Geomech. Eng. 20, 505–516 (2020)

Alireza, T.: Effect of adding nanoclay on the geotechnical behavior of fine-grained soft soils. J. Eng. Geo. 11, 225–246 (2017)

George, A.; Kannan, K.: Potential impact of nanoclay on the Atterberg limits of clayey soil. Int. Res. J. Eng. Technol. 7, 2316–2318 (2020)

Karimiazar, J.; Teshnizi, E.S.; Mirzababaei, M.; Mahdad, M.; Arjmandzadeh, R.: California bearing ratio of a reactive clay treated with nano-additives and cement. J. Mater. Civ. Eng. 34, 1–11 (2022). https://doi.org/10.1061/(ASCE)MT.1943-5533.0004028

Alireza, S.G.S., Mohammad, M.S., Hasan, B.M.: Application of Nanomaterial to Stabilize a Weak Soil. In: International conference on case histories in geotechnical engineering. Vol. 5 (2013). https://scholarsmine.mst.edu/icchge/7icchge/session_06/5

Samala, H.R.; Mir, B.A.: Some studies on microstructural behaviour and unconfned compressive strength of soft soil treated with SiO2 nanoparticles. Innov. Infrastruct. Sol. 5, 1–12 (2020). https://doi.org/10.1007/s41062-020-0283-3

Cheng, G.; Zhu, H.H.; Wen, Y.N.; Shi, B.: Gao, L: Experimental investigation of consolidation properties of nano-bentonite mixed clayey soil. Sustainability. 12, 459 (2020). https://doi.org/10.3390/su12020459

Gallagher, P.M.; Mitchell, J.K.: Influence of colloidal silica grout on liquefaction potential and cyclic undrained behavior of loose sand. Soil. Dyn. Earthq. Eng. 22, 1017–1026 (2002). https://doi.org/10.1016/s0267-7261(02)00126-4

Díaz-Rodríguez, J.A., Antonio–izarraras, V.M.: Mitigation of liquefaction risk using colloidal silica stabilizer. In: Proceedings of the 13th world conference on earthquake engineering, Vancouver, BC, Canada. pp. 1–6 (2004). https://www.iitk.ac.in/nicee/wcee/article/13_509.pdf. Accessed 13 Apr 2022

Díaz-Rodríguez, J.A.; Antonio-Izarraras, V.M.; Bandini, P.; López-Molina, J.A.: Cyclic strength of a natural liquefiable sand stabilized with colloidal silica grout. Can. Geotech. J. 45, 1345–1355 (2008). https://doi.org/10.1139/t08-072

Kodaka, T., Oka, F., Ohno, Y., Takyu, T., Yamasaki, N.: Modeling of cyclic deformation and strength characteristics of silica treated sand. In: Geomechanics. American Society of Civil Engineers, Reston, VA. pp. 205–216 (2005). https://doi.org/10.1061/40797(172)11

Ghasabkolaei, N.; Janalizadeh, A.; Jahanshahi, M.; Roshan, N.; Ghasemi, S.E.: Physical and geotechnical properties of cement-treated clayey soil using silica nanoparticles: an experimental study. Eur. Phys. J. Plus. 131, 1–11 (2016). https://doi.org/10.1140/epjp/i2016-16134-3

Tomar, A.; Sharma, T.; Singh, S.: Strength properties and durability of clay soil treated with mixture of nano silica and polypropylene fiber. Mater. Today 26, 3449–3557 (2020). https://doi.org/10.1016/j.matpr.2019.12.239

Sharo, A.A., Alawneh, A.S.: Enhancement of the strength and swelling characteristics of expansive clayey soil using nano-clay material. In: Geo-Chicago 2016. American Society of Civil Engineers, Reston, VA. pp. 451–457 (2016). https://doi.org/10.1061/9780784480120.046

Jiang, P.; Zhou, L.; Zhang, W.; Wang, W.; Li, N.: Unconfined compressive strength and splitting tensile strength of lime soil modified by nano clay and polypropylene fiber. Crystals 12, 285 (2022). https://doi.org/10.3390/cryst12020285

Babaei, A.; Ghazavi, M.; Ganjian, N.: Shear strength parameters of clayey sand treated with cement and nano titanium dioxide. Geotech. Geol. Eng. 40, 133–151 (2022). https://doi.org/10.1007/s10706-021-01881-1

Rajkishore, S.K.: Nanotoxicity at various trophic levels: a review. Biosafety of nanoparticles. Bioscan 8, 975–982 (2013)

Chen, X.; Cen, C.; Tang, Z., et al.: The key role of pH value in the synthesis of titanate nanotubes-loaded manganese oxides as a superior catalyst for the selective catalytic reduction of NO with NH3. J. Nanomater. 2013, 1–7 (2013). https://doi.org/10.1155/2013/871528

Lu, H.; Wang, J.; Stoller, M., et al.: An overview of nanomaterials for water and wastewater treatment. Adv. Mater. Sci. Eng. 2016, 1–10 (2016). https://doi.org/10.1155/2016/4964828

Acknowledgements

This project was financially supported by the Researchers Supporting Project number (RSP-2021/279), King Saud University, Riyadh, Saudi Arabia. The authors thank the reviewers for their constructive comments, which helped the cause of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Harsh, H., Moghal, A.A.B., Rasheed, R.M. et al. State-of-the-Art Review on the Role and Applicability of Select Nano-Compounds in Geotechnical and Geoenvironmental Applications. Arab J Sci Eng 48, 4149–4173 (2023). https://doi.org/10.1007/s13369-022-07036-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07036-5