Abstract

The morphology of photoanode materials strongly affects the photovoltaic performance of dye-sensitized solar cells. TiO2 nanoparticles possess excellent dye adsorption capability. However, they show low electrical conductivity. Moreover, the penetration of electrolyte into pores of mesoporous TiO2 also promotes recombination reaction. In this work, one-dimensional TiO2 nanotubes (TNTs) have been synthesized by the hydrothermal method. The synthesis was carried out at a hydrothermal temperature of 150 °C and then annealed at 600 °C. The TiO2 nanotubes were characterized by scanning electron microscopy and X-ray diffraction analysis. The photoanode was prepared by depositing TNTs on the conductive glass substrates in the paste form and then annealed at 450 °C. Poly(vinylpyrrolidone) acts as a binder and its amount was optimized in the paste for the best Photovoltaics performance of solar cell. The DSSC with TNTs based photoanode showed higher efficiency (7.53%) compared to the TiO2 nanoparticles-based device (5.88%).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The light-harvesting efficiency (LHE) and charge recombination rate affect the photovoltaic performance of DSSCs. The structure and the morphology of photoanode (PE) materials strongly affect these parameters [1]. The performance of DSSCs can be enhanced by tuning the morphology of TiO2. Generally, TiO2 nanoparticles (NPs) thin film is used as a photoanode (PE) because of its high surface area. Thin film with high surface area can absorb more dye molecules and thus gets more sunlight. However, randomly connected TiO2 NPs deflect the smooth flow of electrons and thus leads to enhance the charge recombination and dark current in DSSCs [2]. Moreover, the electron diffusion coefficient of TiO2 NPs is also low owing to the presence of grain boundaries [3]. These grain boundaries trap electrons and consequently reduce the current density of DSSCs [4]. All these defects in TiO2 NPs thin film reduce the efficiency of DSSCs.

To improve the electron transport, different novel structures of TiO2 such as nanofibers (NFs), nanowires (NWs), nanotubes (NTs), hollow spheres, etc. have been developed. However, it has been observed that one-dimensional (1-D) NTs significantly improves the electron transport properties. 1-D NTs provide smooth electronic path for injected electrons and possess lower inter-crystalline contacts compared to TiO2 NPs [5]. These characteristics improve the short-circuit-current density of DSSC [5]. Walid et al. [6] synthesized TNTs by the anodization of titanium foil. They employed TNTs as PE of DSSC and found the efficiency of 3.94%. Poulomi et al. [7] synthesized well-defined and open TNTs by a simple photoresist based method. By utilizing them as a PE material, they got an efficiency of 4.3%. Daibing et al. [8] synthesized vertically oriented TNTs on Ti mesh support by electrochemical anodization. They observed that the tube length also affects the device performance. They attained an efficiency of 2.66% for the tube length of 18 µm. Lee et al. [2] synthesized TNTs by hydrothermal method and got the efficiency of 2.41%. The template method was utilized by Motonari et al. [9] to synthesize TNTs. The efficiency of TNTs cell was 5%.

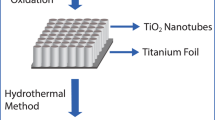

In this work, TNTs have been hydrothermally synthesized using TiO2 NPs. TNTs in the paste form, were deposited on conductive glass substrates by doctor blading technique. The results indicated that the device with TNTs based PE exhibited superior performance in comparison with NPs based DSSC.

2 Experimentation

2.1 Materials

TiO2 NPs, acetyl acetone, Triton X-100, Polyvinylpyrrolidone (PVP), and acetic acid were purchased from Daejung, South Korea. While, N3 photosensitizer, electrolyte, conductive FTO glass substrates, and platinum (Pt) paste were purchased from (SOLARONIX Switzerland).

2.2 Hydrothermal Synthesis of TNTs

10 M solution of NaOH was prepared in 150 ml distilled water followed by normal stirring for 5 min. TiO2 nanoparticles (3 g) were dispersed into NaOH solution, provided with 1 h sonication at room temperature. Sonicated suspension was then vigorously stirred at 30 °C for 1 h. The suspension was autoclaved at a hydrothermal temperature of 150 °C for 24 h. After cooling the precipitates, it was washed with an excess of 0.1 M HCl solution until the pH is reduced to 6.7. The sample was filtered and dried at 80 °C for 24 h. The dried sample was further annealed at 600 °C for 2 h.

2.3 Preparation of Paste

The paste consists of TNTs, PVP, methanol, acetylacetone, Triton X‐100, and acetic acid. The PVP acts as a binder and hold the ingredients of paste together. Similarly, methanol, acetylacetone, Triton X‐100, and acetic acid act as a solvent, a surface modifier, a dispersant, and an acidification agent, respectively. First, PVP (0.1 g) and TNTs (0.4 g) are crushed together in a mortar for 10–15 min to reduce the particles size. Consequently, 3 ml methanol and 0.5 ml acetylacetone were put in the PVP/TNTs mixture and the whole mass was again crushed in a mortar for 15 min to evade cluster formation. After adding acetic acid to the above mixture, the mixture was then sonicated for 15 min. Eventually, 1.5 ml of Triton X‐100 was added followed by 2 ml of methanol. The mixture stirred again for 30 min to gain homogeneity. Finally, the blend was heated in an oven at 50 °C to attain a viscous paste. The paste of TiO2 NPs was prepared in a similar way.

2.4 Fabrication and Characterization of DSSCs

PEs were made by depositing photoactive nanomaterial paste on FTO (7Ω/sq) glass substrates by means of doctor blading. The wet films were annealed at 450 °C for 30 min to get dry films. The average thickness of photoanode film was ~ 10 µm (measured by profilometer). In the same way, counter electrodes (CEs) were made by coating the Pt paste on FTO glass followed by annealing at the same conditions. The photoanodes were then dipped into 0.05 mM solution of N3 dye for 24 h. The dye solution was prepared in methanol solvent. The electrolyte was the then poured between the PE and the CE after joining them with super glue. The active area of each cell was 0.20 cm2. The current–voltage (I-V) characteristics of fabricated devices were measured using IV-5 solar simulator (PVmeasurement, Inc, class AAA) under the light intensity of 100 mWcm− 2. The incident photons to current efficiency (ICPE) spectra were obtained by QEX10 (PVmeasurement, Inc).

3 Results and Discussion

3.1 SEM Analysis

The growth of nanotubes is observed via SEM analysis. Figure 1a and b show the random distribution of TiO2 NPs. The SEM images show that these particles are spherical in nature. It has also been observed that these particles are well connected with each other through interface boundary and form agglomerates (Fig. 1a and b). Figure 1c shows the cluster of TNTs. The tubular structure of TNTs has been observed at a hydrothermal temperature of 150 °C (Fig. 1d, e, and f). These Fig. 1d, e, and f show that hydrothermally synthesized each tube carries a specific length, diameter, and well-oriented structure compared to TiO2 NPs.

The hydrothermal method is mainly a crystallization process that involves crystal nucleation and consequently growth. The growth and specific structure of TNTs (shown in Fig. 1c-f) depend on the energy supply from the external source. The hydrothermal temperature affects the nucleation growth of TiO2 nanoparticles. Higher the nucleation rate more will be the growth of TNTs and vice versa. Thus, the hydrothermal temperature is a critical parameter to control the growth of TNTs [10, 11].

3.2 XRD Analysis

The XRD patterns shown in Fig. 2 demonstrates the crystallite size, specific crystal structure, and phase composition of TNTs and TiO2 NPs. Six discrete peaks are identified for TiO2 nanostructures. All the peaks are indexed and matched with the hexagonal anatase structures of TiO2 [12]. The results reflect the high purity crystallite morphology and ions regularity thorough out the lattice. No impurity peak and additional peak is seen in the XRD pattern of each sample. The peaks at (004) of TNTs and TNPs show the preferential direction of growth. The strong peaks are observed at (101) for TNTs samples indicate high value of aspect ratio [13].

3.3 Photovoltaic (PV) Performance of DSSCs

The I-V characteristics and calculated PV parameters e.g., open-circuit voltage (Voc), short circuit current density (JSC), Fill Factor (FF), and efficiency (η) of DSSCs are shown in Fig. 3 and Table 1, respectively. These values were measured under irradiation at 100Wcm−2. The results in Table 1 show that the DSSCs constructed with TNTs achieved PCE of 7.53% which is higher than DSSC with TiO2 NPs (5.88%). The increment in efficiency value can be attributed to enhanced Jsc owing to smooth and fast flow of electrons in TNTs. The SEM analysis (Fig. 1d, e, and f) shows that TNTs have a more regular and well-oriented structure compared to TiO2 NPs. Therefore, they provide a fast electron transport. Unlike, TNTs, TiO2 NPs possess compact structure (Fig. 1a and b). These particles are well connected with each other and provide more interface resistance compared to TNTs. Therefore, TNTs based DSSC shows higher Jsc in comparison with device constructed with TiO2 NPs. Figure 3b illustrates that the shifting of the IPCE extrema is coherent with the value of Jsc recorded in the Table 1. Moreover, TNTs based DSSC also provides higher FF as compared TiO2 NPs based DSSC. It is because TNTs provide more active sites for dye adsorption and less grain boundaries for recombination reactions. However, no significance difference can be observed in Voc, as shown in Table 1.

4 Conclusion

In this work, TiO2 NTs were successfully synthesized by the hydrothermal method. The synthesis was carried out at 150 °C and then annealed at 600 °C. It was observed that TNTs have a more regular and well-oriented structure compared to TiO2 NPs, hence provide a fast electron transport. Thus, the hydrothermal method is a simple and economical way to prepare TNTs for the PE of DSSCs. PEs were fabricated by depositing TNTs paste on conductive substrates. The DSSCs fabricated using TNTs paste showed improved values of Jsc (17.753 mA/cm2) and Voc (738.492 mV) as compared to nanoparticles. The efficiency of DSSC fabricated with TNTs paste was 7.53%, 28% higher than the device constructed with TiO2 NPs (5.88%). Consequently, 1-D TNTs are effective semiconductor material for the PE of DSSCs.

References

Ahmad, W.; Mehmood, U.; Al-Ahmed, A.; Al-Sulaiman, F.A.; Aslam, M.Z.; Kamal, M.S.; Shawabkeh, R.A.: Synthesis of zinc oxide/titanium dioxide (ZnO/TiO2) nanocomposites by wet incipient wetness impregnation method and preparation of ZnO/TiO2 paste using poly(vinylpyrrolidone) for efficient dye-sensitized solar cells. Electrochim. Acta. 222, 473–480 (2016). https://doi.org/10.1016/J.ELECTACTA.2016.10.200

Lee, C.H.; Kim, K.H.; Jang, K.U.; Park, S.J.; Choi, H.W.: Synthesis of TiO 2 nanotube by hydrothermal method and application for dye-sensitized solar cell. Mol. Cryst. Liq. Cryst. (2011). https://doi.org/10.1080/15421406.2011.566078

Kambe, S.; Nakade, S.; Kitamura, T.; Wada, Y.; Yanagida, S.: Influence of the electrolytes on electron transport in mesoporous TiO2-electrolyte systems. J. Phys. Chem. B. 106, 2967–2972 (2002). https://doi.org/10.1021/jp013397h

Sun, K.C.; Qadir, M.B.; Jeong, S.H.: Hydrothermal synthesis of TiO2 nanotubes and their application as an over-layer for dye-sensitized solar cells. RSC Adv. 4, 23223–23230 (2014). https://doi.org/10.1039/c4ra03266g

Karim, N.A.; Mehmood, U.; Zahid, H.F.; Asif, T.: Nanostructured photoanode and counter electrode materials for efficient dye-sensitized solar cells (DSSCs). Sol. Energy. 185, 165–188 (2019). https://doi.org/10.1016/J.SOLENER.2019.04.057

Sharmoukh, W.; Allam, N.K.: TiO 2 nanotube-based dye-sensitized solar cell using new photosensitizer with enhanced open-circuit voltage and fill factor. ACS Appl. Mater. Interfaces. 4, 4413–4418 (2012). https://doi.org/10.1021/am301089t

Roy, P.; Albu, S.P.; Schmuki, P.: TiO2 nanotubes in dye-sensitized solar cells: Higher efficiencies by well-defined tube tops. Electrochem. commun. 12, 949–951 (2010). https://doi.org/10.1016/j.elecom.2010.04.029

Luo, D.; Liu, B.; Fujishima, A.; Nakata, K.: TiO2 nanotube arrays formed on Ti meshes with periodically arranged holes for flexible dye-sensitized solar cells. ACS Appl. Nano Mater. 2, 3943–3950 (2019). https://doi.org/10.1021/acsanm.9b00849

Adachi, M.; Murata, Y.; Okada, I.; Yoshikawa, S.: Formation of titania nanotubes and applications for dye-sensitized solar cells. J. Electrochem. Soc. 150, G488 (2003). https://doi.org/10.1149/1.1589763

Lee, T.H.; Ryu, H.; Lee, W.J.: Fast vertical growth of ZnO nanorods using a modified chemical bath deposition. J. Alloys Compd. 597, 85–90 (2014). https://doi.org/10.1016/j.jallcom.2014.02.003

Meng, Y.; Lin, Y.; Yang, J.: Synthesis of rod-cluster ZnO nanostructures and their application to dye-sensitized solar cells. Appl. Surf. Sci. 268, 561–565 (2013). https://doi.org/10.1016/j.apsusc.2012.12.171

Shah, L.A.; Malik, T.; Siddiq, M.; Haleem, A.; Sayed, M.; Naeem, A.: TiO2 nanotubes doped poly(vinylidene fluoride) polymer membranes (PVDF/TNT) for efficient photocatalytic degradation of brilliant green dye. J. Environ. Chem. Eng. 7, 103291 (2019). https://doi.org/10.1016/j.jece.2019.103291

Lim, Y.C.; Zainal, Z.; Hussein, M.Z.; Tan, W.T.: the effect of heat treatment on phase transformation, morphology and photoelectrochemical response of short Tio 2 nanotubes. Dig. J. Nanomater. Biostruct. 8(1), 167–176 (2013)

Acknowledgements

The authors acknowledge the support provided by PPE department, UET Lahore.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Babar, F., Mehmood, U., Nazar, R. et al. Hydrothermal Synthesis of TiO2 Nanotubes and Preparation of Paste Using Polyvinylpyrrolidone (PVP) as a Binder for The Photoanode of Dye-Sensitized Solar Cells (DSSCs). Arab J Sci Eng 47, 6379–6383 (2022). https://doi.org/10.1007/s13369-021-06362-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06362-4