Abstract

As operating factors play an important role in engine emissions and performance, it is important to explore the simultaneous impact of various operating factors on engine performance and emission responses. Taguchi method was used in order to determine the suitability of using n-pentanol in spark ignition engine and to determine the optimum operating conditions with fewer experiments instead of many experiments. Engine load, n-pentanol percentage and ignition advance were selected as engine operating variables. Three different levels were determined for each of the selected engine variables and an experimental design was created using the Taguchi method. Taguchi method proposed L27 (3 ^ 3) orthogonal array experimental design for three different variables with three different levels. According to the graphs of signal-to-noise ratio obtained with Taguchi design, simultaneous optimum results of all responses were generally determined as high n-pentanol percentage, average ignition advance and average load. According to results, Taguchi design method is an effective method with the aim of defining the impact rates of engine operating parameters and to optimize engine operating variables for best engine performance and emissions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Air pollution is increasing rapidly due to the increasing number of vehicles with the unavoidable population growth worldwide [1,2,3,4,5]. In addition, due to the epidemic that the whole world has faced, especially in recent months, people prefer to use individual vehicles instead of public transportation. In parallel with the increasing number of vehicles, energy consumption is also increasing rapidly [6,7,8,9,10]. For this reason, it has become necessary to use cleaner, renewable fuel to reduce the air pollution caused by internal combustion engine vehicles and to meet the increasing energy demand [11, 12]. Many different alternative fuels have been used in internal combustion engines for years. In spark ignition engines, the use of alcohols as alternative fuel is in a wide range [13,14,15]. While low carbon alcohols such as ethanol and methanol were used in the beginning, today high carbon alcohols are mostly preferred. High carbon alcohols have some advantages over low carbon alcohols, such as better ignition quality, high energy density and the ability to mix easily with conventional fuels [16,17,18]. The use of n-pentanol, which is one of the high carbon alcohols group, as an alternative fuel has become very interesting by researchers in recent years [19,20,21].

In the search for alternative fuel, it is also extremely important to determine the suitability of a fuel for use in internal combustion engines and to determine the optimum operating conditions. Before the development of computer technologies, numerous tests might be needed to determine the suitability of alternative fuels [22]. In particular, it is not efficient to test alternative fuels that are very difficult to obtain or can only be obtained in small quantities. For these reasons, with the developing computer technologies, optimization techniques that can simulate a large number of experiments with less experimentation have started to be used [23,24,25]. Thanks to these techniques, it can be determined with high accuracy whether a fuel can be an alternative to internal combustion engines in less time and with less cost. Taguchi is one of these optimization techniques. Taguchi design, one of the design of experiments-based techniques, is an optimization method that reveals which of the selected input variables is more effective and has the ability to determine the optimum levels of all variables [26, 27].

In the literature, Taguchi has been successfully used to get optimum variables to operate the engine and found convenient for the reduction in time for the process. Ansari et al. [28] used Taguchi design method to examine the effects of selected engine variables on diesel engine performance and exhaust emission responses which is operating with biodiesel fuel blends. In order to determine optimum engine performance and emissions, they determined the biodiesel ratio, injection timing and injection pressure as engine variables. Optimum conditions determined as 30% biodiesel ratio, 15° bTDC injection timing and 200 bar injection pressure. Rai and Sahoo [29] made the designs of their experiments using the Taguchi method in their study, in which they selected compression ratio, engine load and mixing ratio as engine operating parameters. According to their results, they achieved optimum working conditions as 17 compression ratio, 10 kg engine load and 30% biodiesel ratio. Uslu [30] carried out an optimization study using the Taguchi design method in a diesel engine where diethyl ether ratio, palm oil ratio, injection advance and engine load were selected as engine variables. Generally, it achieved optimum performance responses at low levels of diethyl ether, palm oil and spray advance, and high levels of engine load. Optimum emission responses were achieved at low levels of diethyl ether and engine load, and high levels of palm oil ratio and injection advance.

Although there are many studies on the use of n-pentanol in diesel engines, there are limited studies on its use in gasoline engines. In addition, attention has not yet been paid to determine the optimum operating conditions of a spark ignition engine using n-pentanol/gasoline mixtures by optimization techniques. In this study, it is aimed to determine the optimum engine conditions in which the best emission and performance values can be obtained in a gasoline engine using n-pentanol/gasoline fuel blends using Taguchi method.

2 Materials and Methods

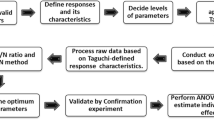

In this study, the experiments were designed with Taguchi method in order to determine the most suitable usage conditions of n-pentanol in gasoline engines. The parameters affecting engine performance and emissions were selected as n-pentanol percentage, ignition advance and engine load. It was found appropriate to use three different levels for the selected parameters, and accordingly, experimental design was carried out with Taguchi method.

The accuracy of the device and the uncertainty analysis of the measured values are essential to ensure the measurement accuracy. In addition, uncertainty analysis is needed as standard conditions in the test environment can be affected by various factors such as environmental factors. The measured values of the uncertainty of the different variables are shown in Table 1. The overall uncertainty was calculated as follows:

Taguchi is a design method used to determine the optimized parameter combinations with a minimum number of experiments, reduce experimental errors and process variety, and determine experimental conditions with orthogonal arrays in order to ensure reproducibility of experiments. In Taguchi method, it is accepted that there are two basic tools for design of experiments (DOE): Orthogonal array (OA) and signal-to-noise (S/N) ratio. OA is a type of generic fractional factorial design that takes into account a selected combination of multiple levels, multiple factors to save time and cost for experimentation. The S/N ratio in Taguchi designs is a robustness measure used to describe control factors that reduce variability in a product or process by minimizing the effects of uncontrollable factors (noise factors). The S/N ratio measures how the response varies with the nominal or target value under different noise conditions. Higher values of the S/N ratio define control factor settings that minimize the effects of noise factors.

Different S/N ratios can be used, such as "smaller is better", "larger is better" and "nominal is best" depending on the purpose of the experiment. In the Taguchi design in this study, "larger is better" is used for brake thermal efficiency (BTHE), while "smaller is better" types are selected for brake specific fuel consumption (BSFC) and all emissions. S/N ratios are given as follows with Eq. (1) and (2), respectively.

Larger is better;

Smaller is better;

where \(n\) is the number of experiments, \(i\) is the number of design factors and \(y_{i}\) is the response factor.

In this study, n-pentanol percentage, engine load and ignition advance were chosen as variables affecting BTHE, BSFC, carbon monoxide (CO), carbon dioxide (CO2), hydrocarbon (HC), oxygen (O2) and nitrogen oxides (NOx) emissions. To examine the effect of each variables on the responses, it is scheduled to test the engine with the three levels shown in Table 2, among the selected factors. Three different levels of selected input variables were determined as 0%, 10% and 20% for n-pentanol percentage, 2.27, 3.78 and 5.30 kW for engine load and finally 10, 14 and 18° bTDC for ignition advance.

The appropriate DOE put forward by Taguchi depending on the three different variables selected as parameters affecting engine performance and emissions and three different levels of these three variables was determined as L27 (3 ^ 3) OA. The DOE created according to the determined L27 OA is shown in Table 3.

Experimental fuels were prepared according to the experimental design determined by Taguchi and experiments were carried out at the specified engine load and ignition advance values. Using the experimental results obtained, a design model was created with Taguchi. S/N ratios from the created model were determined separately for each performance and emission response. In addition, analysis of variance (ANOVA) was applied to determine the proportional effects of the selected variables. ANOVA is a statistically decision-making tool to detect differences in the average performance and helps testing the significance of all main factors [31, 32]. ANOVA evaluates the significance of one or more variables by comparing the response factor tools at various factor levels. ANOVA is also called a linear statistical analysis as the response is a linear function of the factors involved in the experiment [33, 34].

In addition, R2, adjusted R2 (Adj-R2) and predicted R2 (Pred-R2) values, which are important indicators to evaluate the performance of the model created, were calculated with the following equations.

where residuals indicate the quantity of variety not described in the response, model indicates how much variety is described in the model with the general model test for significance, sum of squares (SS) is changes between the overall average and the amount of variety described by the source. \(e_{i}\) is residual for each observation left from the model, \(e - 1\) is a deletion residue that tries to guess ith observation with a model without the ith study and with the resulting model, \(h_{ii}\) is the force of the run in the model.

3 Results and Discussion

In present study, ANOVA was employed to identify the influence ratios of selected engine variables on engine emission and performance responses. The ANOVA results for BTHE, BSFC, CO, CO2, HC, O2 and NOx are shown in Table 4. S/N ratio graphs showing graphical representation of variation response characteristics related to various control parameter levels are also given below for performance and emission responses.

In accordance with Taguchi method, the S/N ratio is the measure of the impact of noise fraction on performance. Both average and variation in S/N ratio have been considered, and a larger S/N ratio indicates better performance of the system.

3.1 Effect of Process Variables on Performance

S/N ratio graphs for BTHE and BSFC, which are considered as performance responses, are shown in Figs. 1 and 3, respectively. When S/N ratio graphs are examined, it is seen that the optimum engine variable levels for BTHE are 20% n-pentanol percentage, 5.30 kW engine load and 18 ° bTDC ignition advance. On the other hand, optimum values for BSFC were found 0% n-pentanol ratio, 3.78 kW load and 18 °bTDC ignition advance. While the maximum level of n-pentanol percentage is optimum for BTHE, the minimum percentage of n-pentanol is optimum for BSFC. Increasing the BSFC due to the smaller lower calorific value of n-pentanol compared to gasoline caused the percentage of 0% to be optimum. On the other hand, 20% n-pentanol percentage has emerged as optimum for BTHE, as it improves combustion thanks to the oxygen content it contains will increase BTHE. The increase in the ignition advance had a positive effect for both performance variables. BTHE increased and BSFC decreased as the maximum pressure approached closer to the upper dead point with increasing ignition advance. Also, getting more air/fuel mixture into the engine with increased engine load will increase not only BTHE but also BSFC. Thus, the lowest level of engine load is optimum for the BSFC, while the highest level for BTHE is optimum.

In addition to the optimum variable levels, the representation of the degree of influence of the variables is given in Figs. 2 and 4 for BTHE and BSFC, respectively. Engine load was the most effective variable for BTHE with a ratio of 50.14%, while the percentage of n-pentanol was for BSFC with 38.7% according to the distribution of effect degrees (Figs. 1, 2, 3, 4).

3.2 Effect of Process Variables on Exhaust Emissions

S/N ratio graphs for CO, CO2, HC, O2 and NOx evaluated as emission responses are shown in Figs. 5, 7, 9, 11 and 13, respectively. Optimum n-pentanol percentage was obtained as 20% for CO, HC and O2, 10% for NOx and 0% for CO2. As the ratio of n-pentanol, which contains oxygen, in the mixture increases, the rate of complete combustion increases, so an increase in O2, a decrease in CO and HC is expected. S/N ratio graphs also gave results that support this expectation. As the complete combustion rate increases, the conversion ratio of carbon atoms to CO2 increases, so the lowest n-pentanol level has been optimum for CO2. The optimum n-pentanol level of NOx was found to be 10% since the amount of oxygen in the mixture higher than the optimum level with a n-pentanol ratio of more than 10% will cause the NOx to increase again.

Optimum engine load levels were found to be 5.30 kW, which is the maximum engine load level for CO, HC and O2, while the minimum level for CO2 and NOx was 2.27 kW. When examined in terms of ignition advance, optimum results were obtained as 14 ° bTDC for CO and HC, 10 ° bTDC as the lowest level for CO2 and NOx and 18 ° bTDC as the highest level for O2. As the ignition advance increases, the temperature inside the cylinder will increase as higher-pressure levels will be reached. Therefore, low ignition advance for NOx, which is a function of temperature, will be the optimum level. On the other hand, if the ignition is delayed too much, the average ignition advance level was obtained optimally for CO and HC, as the risk of incomplete combustion at the end of the expansion stroke would increase. Also, although the possibility of incomplete combustion began to emerge at the maximum ignition advance level, the best results for O2 emission were obtained at the maximum ignition advance level, thanks to the oxygen content of n-pentanol.

Figures 6, 8, 10, 12 and 14 show which engine variables are more effective for CO, CO2, HC, O2 and NOx, respectively. While the ignition advance was the most effective for CO and HC, the n-pentanol percentage was found to be the most effective variable for CO2 and CO2. For NOx, the engine load was determined to be the most effective variable (Figs. 5, 6, 7, 8, 9, 10, 11, 12, 13, 14).

4 Conclusions

In this study, it is aimed to optimize engine operating parameters and determine the effect degree of parameters in order to obtain optimum performance and emissions in spark ignition engine using n-pentanol/gasoline fuel mixtures. The results obtained are listed below:

-

For the n-pentanol percentage, the optimum level was obtained as 20% for BTHE and 0% for BSFC, which are considered as performance responses. In terms of emissions, it was found to be the highest level of 20% for CO, HC and O2, 0% for CO2 and 10% for NOx.

-

In the evaluation made in terms of engine load, the highest engine load level of 5.30 kW was obtained as the optimum value for BTHE, CO, HC and O2. On the other hand, the lowest level of 2.27 kW for BSFC, CO2 and NOx has been determined as optimum.

-

Optimum levels of ignition advance were obtained as 18 ° bTDC for both performance responses. In addition, it was found to be 14 ° bTDC for CO and HC, 10 ° bTDC for CO2 and NOx, and 18 ° bTDC for O2.

-

In evaluating the most effective engine variables on performance and emission responses, the most effective variable on BTHE and NOx was determined as engine load. For BSFC, CO2 and O2, the n-pentanol percentage was determined to be the most effective, while the ignition advance for CO and HC was found to be the most effective variable.

Based on the results obtained from the study, it was concluded that pentanol can be used successfully as an alternative fuel or fuel additive for the gasoline engine. In addition, in this study, it is thought that determining the n-pentanol ratio and engine variables levels that should be used for high performance and low emission when n-pentanol is used in spark ignition engine will shed light on future studies.

Data Availability

The data used and/or analyzed throughout the present study are available from the authors on reasonable request.

Abbreviations

- Adj-R 2 :

-

Adjusted R2 value

- ANOVA:

-

Analysis of variance

- BSFC:

-

Brake specific fuel consumption

- bTDC:

-

Before top dead center

- BTHE :

-

Brake thermal efficiency

- CO:

-

Carbon monoxide

- CO2 :

-

Carbon dioxide

- DOE:

-

Design of experiment

- F-value:

-

Value of F-test

- HC:

-

Hydrocarbon

- NOx :

-

Nitrogen oxides

- P-value:

-

Probability value

- Pred-R 2 :

-

Predicted R2 value

- R 2 :

-

Correlation coefficient

- S/N:

-

Signal to noise

- SS:

-

Sum of squares

- OA:

-

Orthogonal array

- O2 :

-

Oxygen

References

Sun, S.; Jin, J.; Xia, M.; Liu, Y.; Gao, M.; Zou, C.; Wang, T.; Lin, Y.; Wu, L.; Mao, H.; Wang, P.: Vehicle emissions in a middle-sized city of China: current status and future trends. Environ. Int. 137, 105514 (2020)

Anenberg, S.C.; Miller, J.; Minjares, R.; Du, L.; Henze, D.K.; Lacey, F.; Malley, C.S.; Emberson, L.; Franco, V.; Klimont, Z.; Heyes, C.: Impacts and mitigation of excess diesel-related NOx emissions in 11 major vehicle markets. Nature 545, 467–471 (2017)

Passaponti, M.; Rosi, L.; Savastano, M.; Giurlani, W.; Miller, H.A.; Lavacchi, A.; Filippi, J.; Zangari, G.; Vizza, F.; Innocenti, M.: Recycling of waste automobile tires: Transforming char in oxygen reduction reaction catalysts for alkaline fuel cells. J. Power Sour. 427, 85–90 (2019)

Sun, C.S.; Liu, Y.; Qiao, X.; Ju, D.; Tang, Q.; Fang, X.; Zhou, F.: Experimental study of effects of exhaust gas recirculation on combustion, performance, and emissions of DME-biodiesel fueled engine. Energy 197, 1172333 (2020)

Jagtap, S.P.; Pawar, A.N.; Lahane, S.: Improving the usability of biodiesel blend in low heat rejection diesel engine through combustion, performance and emission analysis. Renew. Energy 155, 628–644 (2020)

Yesilyurt, M.K.: The examination of a compression-ignition engine powered by peanut oil biodiesel and diesel fuel in terms of energetic and exergetic performance parameters. Fuel 278, 118319 (2020)

Sakthivel, R.; Ramesh, K.; Purnachandran, R.; Shameer, P.M.: A review on the properties, performance and emission aspects of the third generation biodiesels. Renew. Sustain. Energy Rev. 82(3), 2970–2992 (2018)

Doğan, B.; Erol, D.; Yaman, H.; Kodanli, E.: The effect of ethanol-gasoline blends on performance and exhaust emissions of a spark ignition engine through exergy analysis. Appl. Therm. Eng. 120, 433–443 (2017)

Yesilyurt, M.K.; Aydin, M.: Experimental investigation on the performance, combustion and exhaust emission characteristics of a compression-ignition engine fueled with cottonseed oil biodiesel/diethyl ether/diesel fuel blends. Energy Conv. Manag. 205, 112355 (2020)

Canan, A.; Calhan, R.; Ozkaymak, M.: Investigation of the effects of different slags as accelerant on anaerobic digestion and methane yield. Biomass Conv. Biorefinery (2021)

Wu, Q.; Xie, X.; Wang, Y.; Roskilly, T.: Effect of carbon coated aluminum nanoparticles as additive to biodiesel-diesel blends on performance and emission characteristics of diesel engine. Appl. Energy 221, 597–604 (2018)

Gülüm, M.; Onay, F.K.; Bilgin, A.: Comparison of viscosity prediction capabilities of regression models and artificial neural networks. Energy 161, 361–369 (2018)

Kalwar, A.; Singh, A.P.; Agarwal, A.K.: Utilization of primary alcohols in dual-fuel injection mode in a gasoline direct injection engine. Fuel 276, 118068 (2020)

Liu, W.; Shadloo, M.S.; Tlili, I.; Maleki, A.; Bach, Q.: The effect of alcohol–gasoline fuel blends on the engines’ performances and emissions. Fuel 276, 117977 (2020)

Turkcan, A.; Altinkurt, M.D.; Coskun, G.; Canakci, M.: Numerical and experimental investigations of the effects of the second injection timing and alcohol-gasoline fuel blends on combustion and emissions of an HCCI-DI engine. Fuel 219, 50–61 (2018)

Uslu, S.; Celik, M.B.: Combustion and emission characteristics of isoamyl alcohol-gasoline blends in spark ignition engine. Fuel 262 (2020).

Yilmaz, N.; Atmanli, A.; Vigil, F.M.: Quaternary blends of diesel, biodiesel, higher alcohols and vegetable oil in a compression ignition engine. Fuel 212, 462–469 (2018)

Nour, M.; Attia, A.; Nada, S.: Combustion, performance and emission analysis of diesel engine fuelled by higher alcohols (butanol, octanol and heptanol)/diesel blends. Energy Conv. Manag. 185, 313–329 (2019)

Wang, Q.; Yin, S.; Ni, J.: The effects of n-pentanol, di-n-butyl ether (DBE) and exhaust gas recirculation on performance and emissions in a compression ignition engine. Fuel 184, 118961 (2021)

Yesilyurt, M.K.; Eryilmaz, T.; Arslan, M.: A comparative analysis of the engine performance, exhaust emissions and combustion behaviors of a compression ignition engine fuelled with biodiesel/diesel/1-butanol (C4 alcohol) and biodiesel/diesel/n-pentanol (C5 alcohol) fuel blends. Energy 165, 1332–1351 (2018)

Pan, M.; Huang, R.; Liao, J.; Ouyang, T.; Zheng, Z.; Lv, D.; Huang, H.: Effect of EGR dilution on combustion, performance and emission characteristics of a diesel engine fueled with n-pentanol and 2-ethylhexyl nitrate additive. Energy Conv. Manag. 176, 246–255 (2018)

Mehra, R.K.; Duan, H.; Luo, S.; Rao, A.; Ma, F.: Experimental and artificial neural network (ANN) study of hydrogen enriched compressed natural gas (HCNG) engine under various ignition timings and excess air ratios. Appl. Energy 228, 736–754 (2018)

Ramesh, R.; Vivekanandan, S.; Sivaramakrishman, Prakash, D.: Performance optimization of an engine for canola oil blended diesel with Al2O3 nanoparticles through single and multi-objective optimization techniques. Fuel 119617 (2020).

Shirneshan, A.; Bagherzadeh, S. A.; Najafi, G.; Mamat, R.; Mazlan, M.: Optimization and investigation the effects of using biodiesel-ethanol blends on the performance and emission characteristics of a diesel engine by genetic algorithm. Fuel 119753 (2020).

Ganji, P.R.; Raju, V.R.K.; Rao, S.S.: Computational optimization of biodiesel combustion using response surface methodology. Therm. Sci. 21(1), 465–473 (2017)

Zhang, M.; Hong, W.; Fangxi, X.; Su, Y.; Liu, H.; Zhou, S.: Combustion, performance and particulate matter emissions analysis of operating parameters on a GDI engine by traditional experimental investigation and Taguchi method. Energy Conv. Manag. 164, 344–352 (2018)

Uslu, S.; Aydın, M.: Effect of operating parameters on performance and emissions of a diesel engine fueled with ternary blends of palm oil biodiesel/diethyl ether/diesel by Taguchi method. Fuel 275, 117978 (2020)

Ansari, N.A.; Sharma, A.; Singh, Y.: Performance and emission analysis of a diesel engine implementing polanga biodiesel and optimization using Taguchi method. Process Safety Environ. Protect. 120, 146–154 (2018)

Rai, R.K.; Sahoo, R.R.: Taguchi-Grey method optimization of VCR engine performance and heat losses by using Shorea robusta biodiesel fuel. Fuel 281, 118399 (2020)

Uslu, S.: Optimization of diesel engine operating parameters fueled with palm oil-diesel blend: comparative evaluation between response surface methodology (RSM) and artificial neural network (ANN). Fuel 276, 117990 (2020)

Asghar, A.; Raman, A.A.A.; Daud, W.M.A.W.: A comparison of central composite design and Taguchi method for optimizing Fenton process. Sci. World J. (2014)

Wahyudin, K.A.; Murphiyanto, R.D.J.; Perdana, M.K.; Kasih, T.P.: Application of Taguchi method and ANOVA in the optimization of dyeing process on cotton knit fabric to reduce re-dyeing process. The International Conference On Eco Engineering Development 2017 (ICEED 2017), (2017).

Sharma, A.; Maurya, N.K.; Singh, Y.; Singh, N.K.; Gupta, S.K.: Effect of design parameters on performance and emissions of DI diesel engine running on biodiesel-diesel blends: Taguchi and utility theory. Fuel 281, 118765 (2020)

Govindasamy, R.; Subramani, S.: Numerical optimization of design and fuel factors and development of a statistical model for the emission control of DI CI engine. Fuel 281, 118656 (2020)

Acknowledgements

The authors are indebted to the Editor and reviewers of this paper for their invaluable suggestions.

Funding

This work was supported by Scientific Research Projects Coordination Unit of Kırıkkale University. Project number: 2018/067.

Author information

Authors and Affiliations

Contributions

Samet Uslu, Hayri Yaman and Murat Kadir Yesilyurt were responsible for methodology and writing—review & editing. Samet Uslu was responsible for software and writing—original draft. Hayri Yaman and Murat Kadir Yesilyurt performed conceptualization and investigation.

Corresponding author

Ethics declarations

Conflict of interest

The authors pointed out that there is no potential conflict of interest.

Ethical approval

The authors declared that no animal and human studies are presented in this manuscript and no potentially identifiable human images or data are given in this research.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Rights and permissions

About this article

Cite this article

Uslu, S., Yaman, H. & Yesilyurt, M.K. Optimization of Parameters Affecting the Performance and Emissions of a Spark Ignition Engine Fueled with n-Pentanol/Gasoline Blends Using Taguchi Method. Arab J Sci Eng 46, 11711–11724 (2021). https://doi.org/10.1007/s13369-021-05675-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05675-8